Circularly Polarized FM

Broadcast Antenna

Model 6822

Instruction Manual

Installation, Operation, &

Maintenance

Congratulations!

Thank you for purchasing one of the finest FM broadcast antennas on the

market today. The Shively Labs 6822 is the top-of-the-line in its class for its

simplicity, superior performance and durability.

Your purchase is backed by the best tec

is a leading manufacturer in the broadcast industry, providing an extensive

range of antennas, transmission line and components. Our technical staff has

a wealth of experience in the broadcast industry and is standing by to serve

you in any way.

This manual is intended to give you a good basic

antenna: its proper and safe installation, startup, and operation, and troubleshooting and maintenance information to keep

years to come.

Please have everyone involved with the antenna read this

hnical support in the industry. Shively

understanding of your

it working satisfactorily for

manual carefully, and keep it handy for future reference.

Meanwhile, please feel free to contact your sales representative at Shively

Labs at any time if you need information or help. Call or write:

Publication No. im-6822 (180507)

IMPORTANT

Please read this manual in its entirety before beginning

installation of your antenna!

Failure to follow the instal

instructions in this manual could lead to failure of your

equipment and might even void your warranty!

lation and operation

Table of Contents

Chapter 1 Preparation........................................................................ 1

Check the shipment...............................................

Torque specifications............................................

................................1

................................. 1

Table 1 Torque specifications ..................................................... 1

Check the parts..................................................................................... 1

Set up the mounting location. .....

Tower-leg mount.................................................

Support-pipe mount...............................................

Top-mounted support pipe.........................................

Preparing the tower leg or mounting pipe .........................

........................................................... 1

............................. 2

........................... 2

....................... 2

................. 2

Figure 1 Mounting options.......................................................... 3

Figure 2 Tower layout, single antenna bay .................................. 4

Figure 3 Tower layout, two-bay antenna ..................................... 5

Figure 4 Tower layout, three-bay antenna ................................... 6

Figure 5 Tower layout, four-bay antenna..................................... 7

Figure 6 Tower layout, five-bay antenna ..................................... 8

Figure 7 Tower layout, six-bay antenna ....................................... 9

Figure 8 Tower layout, eight-bay antenna ................................. 10

Figure 9 Top mounted installation............................................. 11

Figure 10 Proper (and improper) securing of bay cables ............. 12

Chapter 2 Bay Assembly................................................................... 13

Attach the mount to the bay weldment............................

Mounting pipe size to 3-1/2 inches outside diameter: .............

Mounting pipe size 3-1/2 inches to

six inches outside diameter:......... 13

..................... 13

........... 13

Figure 11 Mount attachment, pipe size up to 3-1/2 inches .......... 14

Table 2 Mounting U-bolt usage ................................................ 14

Figure 12 Mount attachment, pipe size 3-1/2" to 6".................... 15

Attach the bay arms. ........................................................................... 15

Figure 13 Bay arm attachment.................................................. 16

Attach the bay cable (single-bay antenna only) ..................................... 16

Attach the feedstraps to the endseal. ............................

....................... 16

Figure 14 Bay cable & feedstrap attachment (bay cable for single-bay

antenna only) ................................................................. 17

Chapter 3 Mounting the Antenna Bay(s) ......................................... 19

Tower leg or mounting pipe up to 3-1/

2 inches outside diameter:........... 19

Figure 15 Bay mounting on pipe up to 3-1/2 inches OD .............. 19

Tower leg or mounting pipe 3-1/2 to 6 inches outside diameter: ............ 20

Figure 16 Bay mounting on pipe 3-1/2" - 6" OD........................ 20

Chapter 4 Connecting the Antenna (single-bay).............................. 21

Connect the antenna bay..........................................

........................... 21

Figure 17 Single bay antenna connection .................................. 21

Chapter 5 Connecting the Antenna (2- to 6-bay) ............................ 23

Mount the power divider..........................................

............................ 23

Figure 18 Power divider mounting............................................. 23

i

Table of Contents

Install the slugged line section (if applicable). ....................................... 24

Figure 19 Slugged line section installation (if applicable)............. 25

Install the optional fine-matching transformer (if applicable) .................. 26

Figure 20 Fine-matching transformer installation........................ 27

Connect the antenna bay cables........................................................... 28

Figure 21 Antenna bay cable connection ................................... 28

Connect the tower transmission line. .................................................... 29

Figure 22 Tower transmission line connection............................ 29

Chapter 6 Connecting the Antenna (8-bay) ..................................... 31

Mount the power dividers. ........................................

Install the slugged line section (if appl

icable). ....................................... 31

........................... 31

Figure 23 Power divider mounting for 8-bay antenna ................. 32

Figure 24 Slugged line section installation (if applicable)............. 33

Install the optional fine-matching transformer (if applicable) .................. 34

Figure 25 Fine-matching transformer installation........................ 35

Connect the antenna bay cables........................................................... 36

Figure 26 Antenna bay cable connection ................................... 36

Connect the tower transmission line. .................................................... 37

Figure 27 Tower transmission line connection............................ 38

Chapter 7 Installing the De-icer System (if applicable)................... 39

Precautions.....................................................

De-icer system description .......................................

Dual-setting thermostat .........................................

Electric power ...................................................

.................................... 39

............................ 39

......................... 39

............................. 39

Table 3 De-icer specifications .................................................. 39

De-icer installation .............................................................................. 40

Installing the de-icer junction bo

xes. ............................................... 40

Figure 28 De-icer junction box installation ................................. 40

Figure 29 Junction box installed on antenna bay ........................ 41

Installing the interbay cables.......................................................... 41

Figure 30 Interbay cable section, bottom end ............................ 41

Figure 31 Sheath cut back........................................................ 42

Figure 32 Sheath bent back over the grommet .......................... 42

Figure 33 Final assembly, top of second junction box ................. 42

Figure 34 De-icer electrical schematic diagram........................... 43

Installing the tower junction box ..................................................... 44

Installing the thermostat (if applicab

le)............................................ 44

Table 4 Thermostat readings .................................................... 44

Chapter 8 Retuning .......................................................................... 45

Before beginning retuning: .......................................

Setup ...........................................................

Tuning ...........................................................

...................................... 45

........................... 45

.................................... 46

Figure 35 Arm length vs. frequency .......................................... 46

Figure 36 Feed strap angle vs. frequency .................................. 46

Figure 37 Optimal VSWR at 108 MHz, narrow feedstrap ............. 47

ii

Table of Contents

Figure 38 Optimal VSWR at 108 MHz, wide feedstrap................. 48

Figure 39 Optimal VSWR at 88 MHz, wide feedstrap................... 49

Chapter 9 Startup............................................................................. 51

Initial characterization ..........................................

Before beginning initial characterization: .......................

Read transmission line VSWR. ....................................

Read transmission line TDR......................................

Read system VSWR. ................................................

Impedance trimming. ..............................................

............................... 51

................... 51

..................... 51

....................... 51

....................... 51

............................ 52

Figure 40 Impedance-matching transformer .............................. 52

Checkout. ........................................................................................... 53

Operation. ......................................................

.................................... 53

Figure 41 Apply the signal. ....................................................... 54

Chapter 10 Maintenance .................................................................. 55

Log ..............................................................

Inspection ......................................................

Paint ............................................................

Return policy ....................................................

Troubleshooting ...................................................

Broad spectrum RF noise. ........................................

High VSWR ........................................................

Change in coverage ...............................................

Chapter 11 Parts ......................................................

Bay components

(without de-icers) ................................................

...................................... 55

.................................... 55

...................................... 55

.................................. 55

............................... 55

....................... 55

............................ 55

......................... 55

........................ 57

............ 57

Table 5 Components, antenna bay without de-icer (per bay) .....57

Figure 42 Components, 6822 bay (without de-icers)................... 58

De-Icer Components ........................................................................... 59

Table 6 Components, de-icer (per bay) ..................................... 59

Figure 43 Components, 6822 de-icer......................................... 59

Mounting system components .............................................................. 60

Up to 3-1/2" mounting pipe OD:...................................

................... 60

Table 7 Components, mounts for up to 3-1/2" mounting pipe

(per antenna bay) .......................................................... 60

Figure 44 Components, mounts for up to 3-1/2" mounting pipe .. 60

3-1/2" - 6" mounting pipe OD: ........................................................ 61

Table 8 Components, mounts for 3-1/2" to 6" mounting pipe

(per antenna bay) .......................................................... 61

Figure 45 Components, mounts for 3-1/2" to 6" mounting pipe... 62

Feed system components .................................................................... 63

Table 9 Components, feed system for single-bay antenna ....... 63

Table 10 Components, feed system for 2-bay antenna

(per array) .................................................................. 63

Table 11 Components, feed system for 3-bay antenna

(per array) .................................................................. 63

Figure 46 Feed system components for 2- to 6-bay antennas......64

iii

Table of Contents

Table 12 Components, feed system for 4-bay antenna

(per array) .................................................................. 65

Table 13 Components, feed system for 5-bay antenna

(per array) .................................................................. 65

Table 14 Components, feed system for 6-bay antenna

(per array) .................................................................... 65

Table 15 Components, feed system for 8-bay antenna

(per array) .................................................................. 66

Figure 47 Feed system components, 8-bay antenna ................... 67

Accessories and optional items ............................................................. 68

Table 16 Accessories and optional items ................................... 68

Figure 48 Slugged line section (if applicable) components .......... 69

Figure 49 Fine-matching transformer (optional) components ......70

iv

Preparation

1Preparation

Check the shipment.

Torque specifications.

As soon as you receive your antenna, BEFORE signing for the shipment:

a. Check to be sure all the material has arrived.

Check for evident damage to any of the boxes.

b.

c. If any boxes are missing, or if any are obviously damaged, describe the

problem in a WRITTEN note on the shipping papers BEFORE signing them.

Then call Shively right away, and we’ll do everything we can to correct the

situation.

Important!

Never store the antenna system outdoors, boxed or otherwise. Take

pains to keep the antenna components dry. You will need to purge moisture from the interior of the ant

enna components if they get wet.

NOTE

Use an anti-seize compound to minimize galling on stainless steel

threads.

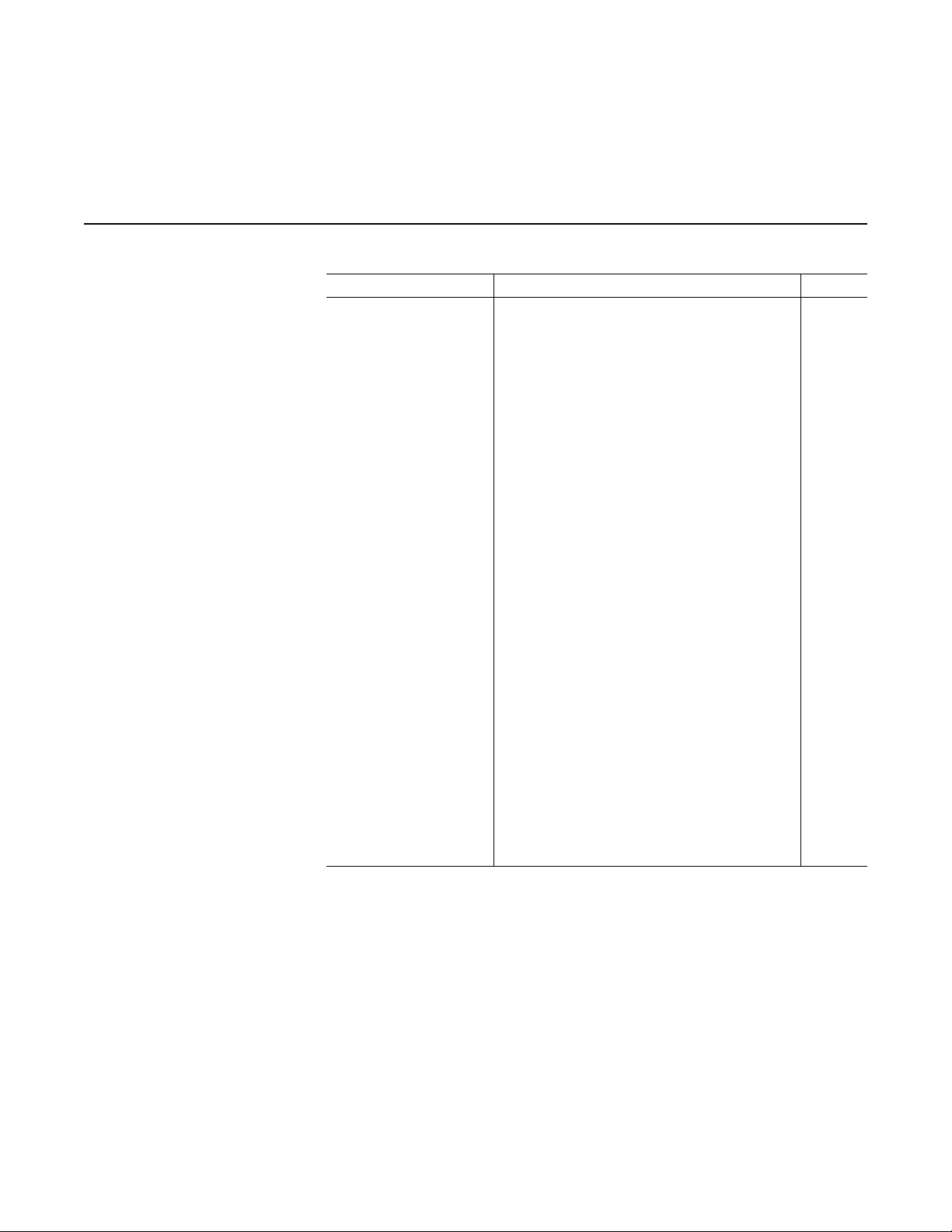

Table 1. Torque specifications

Hardware size Torque (dry) Torque (lubricated)

5/16-18 (1-5/8" EIA flanges) 132 in-lbf (14.9 N-m) 112 in-lbf (12.7 N-m)

3/8-16 (2-1/8", 3-1/8" EIA

flanges)

7/16 DIN (antenna input fit-

ting)

236 in-lbf (26.7 N-m) 201 in-lbf (22.7 N-m)

18 - 22 lb-in (21 - 25

cm-kg)

n/a

Check the parts.

Set up the mounting location.

Important

Improper antenna mounting is a leading cause of

poor performance in 6822

antennas. It is very

important to install the

antenna as indicated and

to position it away from

other metallic structures.

Check to be sure all the parts listed in Chapter 11, as applicable, have arrived

in good condition.

NOTE

Item callouts are consistent across all the illustrations in this manual.

Remember!

It is YOUR responsibility to ensure that your installation meets all applicable codes and the centerline-of-radiation requirements of your

construction permit.

FCC

CAUTION

Before attaching the pipe mounts to the tower, scrape away tower paint

to ensure good electrical contact. If you don’t, the antenna may generate unwanted electrical signals, and per

formance may be degraded.

CAUTION

Watch for tower components that might interfere with your installation.

Mounting is a little different for tower-leg mounting, support-p

top-mounted poles.

ipe mount, and

1

Preparation

Tower-leg mount

Support-pipe mount

Top-mounted support pipe

The 6822 antenna may be mounted on a tower leg if the tower has at least

18" face width. The width is necessary to allow separation between the

antenna and the power divider, as shown in

The tower leg must extend at least five feet

and five feet below the bottom bay.

Figure 2 shows the mounting, cable run of a typical side-mounted single-bay

antenna.

An alternative is to mount to a customer-supplied vertical pipe (Figure 1b),

which in turn is mounted on the tower. The pipe must be between 2-3/8” and

2” (60 and 89 mm) nominal outside diameter and mounted at least 16" off

3-1/

the tower.

The mounting pipe must extend at

bay and five feet below the bottom bay.

Figure 3 through Figure 8 show support-pipe mounting for two- through eight-

bay antennas.

least five feet (1500 mm) above the top

Figure 1a.

(1500 mm) above the top bay

NOTE

Shively can accommodate other pipe sizes if necessary by special order.

NOTE

This mounting method can only be used for a single-bay antenna,

because it allows no location to mount a power divider.

If your support pipe is mounted on top of a tower or bui

locate the antenna with

the bottom antenna bay and the top of the tower or building. Then mount the

pipe in accordance with the guidelines above.

at least ten feet (3.1 m) of vertical clearance between

lding (Figure 9),

Preparing the tower leg or mounting pipe

CAUTION

If you don't get good electrical contact between the

mounts, the support pipe,

and the tower, the

antenna may not perform

as designed and may produce stray signals that will

interfere with other ser-

vices on the tower.

Prepare the mounting location as follows (see Figure 10):

a. Starting at the top of the support pipe, mark the location of each bay in

accordance with the installation drawing.

b. Also, mark the specified location of any accessory mounts (eg: de-icer box

mounts), to make sure they will fit as planned.

c. To ensure good electrical contact between the support pipe and the tower,

remove the tower paint and any rust at the support pipe mount locations

before installing the mounts. After installing the mounts, be sure to touch up

the paint where you removed it.

2

Figure 1. Mounting options

Preparation

3

Figure 2. Tower layout, single antenna bay

Preparation

4

Preparation

Figure 3. Tower layout

antenna

, two-bay

IMPORTANT!

If you ordered a custom-

spaced antenna, please

refer to your antenna

test data sheet for bay-

to-bay spacing.

5

Figure 4. Tower layout, threebay antenna

IMPORTANT!

If you ordered a custom-

spaced antenna, please

refer to your antenna

test data sheet for bay-

to-bay spacing.

Preparation

6

Figure 5. Tower layout, four-bay antenna

IMPORTANT!

If you ordered a custom-

spaced antenna, please

refer to your antenna

test data sheet for bay-

to-bay spacing.

Preparation

7

Figure 6. Tower layout, five-bay antenna

IMPORTANT!

If you ordered a custom-

spaced antenna, please

refer to your antenna

test data sheet for bay-

to-bay spacing.

Preparation

8

Figure 7. Tower layout, six-bay antenna

IMPORTANT!

If you ordered a custom-

spaced antenna, please

refer to your antenna

test data sheet for bay-

to-bay spacing.

Preparation

9

Figure 8. Tower layout, eightbay antenna

IMPORTANT!

If you ordered a custom-

spaced antenna, please

refer to your antenna

test data sheet for bay-

to-bay spacing.

Preparation

10

Figure 9. Top mounted

ation

install

Preparation

11

Figure 10. Proper (and

improp

er) securing of bay cables

Preparation

12

Bay Assembly

2 Bay Assembly

Attach the mount to the bay weldment

Mounting pipe size to 3-1/2 inches outside diameter:

Mounting pipe size 3-1/2 inches to six inches outside diameter:

NOTE

For mounting pipes between 3-1/2" and 6" diameter, see the next section.

NOTE

The mount is reversible and can be attached to either side of the bay

weldment.

a. Using two screws (Figure 12, 1) with hardware (2, 3, and 4), at t ac h th e ba lun

mount (29

Table 1

b. Using the two 1"-pipe U-bolts (30

balun mount to the bay weldment. Tighten in accordance with Table 1

c. With reference to Table 2

using.

d. Insert two mounting U-bolts (31

mount. Install the hardware (33

Discard the unused U-bolts.

) to the bay weldment (5) as shown. Tighten in accordance with

on page 1.

) with hardware (2, 3, and 4), secure the

.

, determine which size mount U-bolts you will be

or 32 - but not both!) into the slots in the

, 34, and 35) loosely onto the U-bolts.

NOTE

For mounting pipes up to 3-1/2" diameter, see the previous section.

NOTE

The mount is reversible and can be attached to either side of the bay

weldment.

a. Using two screws (Figure 12, 1) with hardware (2, 3, and 4), at t ac h th e ba lun

mount (36

Table 1

b. Using the two 1"-pipe U-bolts (30

balun mount to the bay weldment. Tighten in accordance with Table 1

) to the bay weldment (5) as shown. Tighten in accordance with

on page 1.

) with hardware (2, 3, and 4), secure the

.

c. Using the galvanized 5/8" hardware (Figure 12

threaded rods (40

) to the balun mount.

, 37, 38, and 39), attach the

NOTE

Mount antenna bays with feed straps up, clear of all guylines and other

obstructions.

d. Using the galvanized 5/8" hardware, attach the support clamps (41) loosely

to the threaded rods (40

13

).

Figure 11. Mount attachment,

pipe size up to 3-1/2 inch

es

Bay Assembly

Table 2. Mounting U-bolt usage

Mounting pipe size U-bolt size

Up to 2 inches (5.1 cm)

outside diameter

2 to 4 in (5 to 10.2 cm) 4 in (10.2 cm)

4 to 6 in (10 to 15.2 cm) See

14

2 in (6.35 cm)

Figure 12

Figure 12. Mount attachment, pipe size 3-1/2" to 6"

Bay Assembly

Attach the bay arms.

CAUTION

Do not loosen the hose clamps or move the sliding V-arms. This will spoil

the performance of your antenna.

a. Locate the inner and outer dipole arms (Figure 13, 7). The sliding V-arms

) on each dipole arm are factory-assembled and adjusted for proper

(18

performance (all the same), and secured with hose clamps (19

b. Using upper arm clamps (6

the two dipole arms (7

Tighten in accordance with Table 1

15

) and 5/16-18 hardware (1, 2, 3, and 4), attach

) to the saddles on the bay weldment (5) as shown.

.

).

Figure 13. Bay arm attachment

Bay Assembly

Attach the bay cable (single-bay antenna only)

Attach the feedstraps to the endseal.

NOTE

If your antenna has more than one bay, skip this section and go on to

Attach the feedstraps to the endseal.

a. Attach the angled connector of the bay cable section (Figure 14 on page 17,

) to the base of the endseal (9).

8

b. Pass the cable under the arm saddle to the mount end of the weldment.

Secure it firmly to the weldment, using tie-wraps (44

).

NOTE

The feedstraps are shipped in place on the dipole arms.

a. Remove the wingnut and washers from the endseal (Figure 14, 9) (the white

plastic dome on the antenna weldment).

CAUTION

Do NOT move the feedstrap clips on the sliding V-arms. The antenna

was tuned with the clips in place. If you move them, the antenna will not

work as expected.

b. L o osen the fee d strap clip h a rdware (10)

) into place over the endseal.

(11

c. Place the slots in the feedstraps over the endseal stud and reinstall the

endseal washers and the wingnut. Be sure to reinstall the brass washer (12

as shown. Tighten the wingnut.

just enough

to swing the feedstraps

)

16

Figure 14. Bay cable & feedstrap

attachment (bay cable for

single-bay ant

enna only)

Bay Assembly

d. Tighten the feedstrap clip hardware, only unt

not overtighten.

17

il the lock washer flattens. Do

Mounting the Antenna Bay(s)

3 Mounting the Antenna Bay(s)

WARNING

Whenever a rigger is on the tower in the area of the antenna, shut off

the signal and lock it off so that it cannot be turned on accidentally. RF

emissions at close range are hazardous.

CAUTION

Do not attach the bays together with the RF cable before mounting

them. NEVER try to support the bays from the cable.

Tower leg or mounting pipe up to 3-1/2 inches outside diameter:

Fi gure 15. Bay mo unting on pipe up to 3-1/2 inches OD

a. At the locations you marked on the mounting pipe (Set up the mounting

location. on page 1 ) , scrape awa y any paint or other coating to achieve good

electrical contact.

NOTE

Mount antenna bays with feed straps up, clear of all guylines and other

obstructions.

b. Using the U-bolts (Figure 15, 31 or 32), attach the antenna bays at the

marked locations.

c. Repeat for the other antenna bay(s) as applicable.

d. Align the bays to the correct azimuth and align them vertically with each

other, then tighten the mounting hardware in accordance with Table 1

page 1.

e. Repaint the pipe as needed around the antenna bay mount.

on

19

Mounting the Antenna Bay(s)

Tower leg or mounting pipe 3-1/2 to 6 inches outside diameter:

Figure 16. Bay mounting on pipe 3-1/2" - 6" OD

a. At the locations you marked on the mounting pipe (Set up the mounting

location. on page 1 ) , scrape awa y any paint or other coating to achieve good

electrical contact.

NOTE

Mount antenna bays with feed straps up, clear of all guylines and other

obstructions.

b. Using the threaded rods (40), support clamps (41), and 5/8-11 galvanized

hardware (Figure 16

locations. Tighten in accordance with Table 1

c. Repeat for the other antenna bay(s) as applicable.

d. Align the bays to the correct azimuth and align them vertically with each

other, then tighten the mounting hardware in accordance with Table 1

page 1.

e. Repaint the pipe as needed around the antenna bay mount.

, 37, 38, and 39), attach the antenna bays at the marked

on page 1.

on

NOTE

The Model 6822 does not require pressurization or purging. The feed

system up to the bay may be pressurized.

Proceed to

Antenna (2- to 6-bay) on page 23 as applicable.

Connecting the Antenna (single-bay) on page 21 or Connecting the

20

Connecting the Antenna (single-bay)

4 Connecting the Antenna (single-bay)

Connect the antenna bay.

Figure 17. Single bay antenna connection

The antenna bay is not pressurized. The feed system up to the bay may be

pressurized.

a. Provide a gas stop between the tower transmission line and the antenna

input if necessary.

b. Connect the tower DIN transmission cable to the input of the antenna bay

cable (Figure 17

, 8). Tighten in accordance with Table 1 on page 1.

c. Loop or drape any excess cable and secure it to the pipe, using tie-wraps

) or customer-supplied clamps, to p re v en t wi n d d ama ge t o th e c a bles and

(44

to ensure the weight of the cable is not carried by the antenna input.

NOTE

The Model 6822 bay does not require pressurization or purging.

Installation of your Model 6822 single-bay is now complete. Please proceed to

Startup on page 51.

21

Connecting the Antenna (2- to 6-bay)

5 Connecting the Antenna (2- to 6-bay)

Mount the power divider.

Figure 18. Power divider mounting

NOTE

Two-way and 4-way feed

systems shown. Three,

five, and six-way feed systems are similar.

Using a power divider mounting kit (Figure 18, 45), mount the power divider

46, 49, 52, 55, or 58) to the mounting structure with its outlet ports roughly

(

halfway along the antenna array. Locate the mounts as close to th

the power divider as you can.

e ends of

NOTE

You may need to provide a coax adapter between your transmission line

and the power divider.

23

Connecting the Antenna (2- to 6-bay)

Install the slugged line section (if applicable).

In the event your antenna has non-standard bay spacing or other special features, we may have provided you

perfect the tuning of the antenna. This piece is to be installed between the

output of the transformer (if applicable) and the input of the power divider.

with a line section containing a "slug" to

CAUTION

Do not remove or modify the slug from the slugged line section. This will

ruin your antenna’s performance.

NOTE

Line section mounts are generally similar to feedline mounts and should

be installed in the same manner.

NOTE

You may need to provide a coax adapter between your transmission line

and the slugged line section.

Install the slugged line section (

your power divider (

a. Ensure there is an inner conductor connector in the slugged line section

outlet flange.

b. Attach the mounts (45

c. Coat the O-ring (43

the antenna), then install it in the O-ring groove in the outlet flange.

d. Mate the flanges and secure the slugged line section to the mounting pipe.

Do not fully tighten the mounts until the flange hardware is in place.

e. Install the flange hardware kit (42

the flange. Tighten in accordance with Table 1

Figure 20, 46, 49, 52, 55, or 58) as follows:

or 54, as applicable) lightly with O-Lube (supplied with

70 or 71, as applicable) at the input flange of

) to the slugged line section, close to the ends.

or 53, as applicable) hardware and secure

on page 1.

f. Tighten the mount hardware in accordance with Table 1

.

24

Figure 19. Slugged line section

ation (if applicable)

install

Connecting the Antenna (2- to 6-bay)

25

Connecting the Antenna (2- to 6-bay)

Install the optional fine-matching transformer (if applicable)

One of the unique features of Shively Labs antenna systems is the adjustable

impedance-matching transformer (

ally available with the antenna. It allows the installer to c

changes in the input impedance caused by the installation (tower, conduit,

ladder, etc.).

Figure 20, 72 or 73, as applicable) option-

ompensate for

NOTE

The transformer may be oriented in whichever direction you wish (see

Figure 20). Make it easy to reach for adjustment at startup.

NOTE

Transformer mounts are generally similar to feedline mounts and should

be installed in the same manner.

NOTE

You may need to provide a coax adapter between your transmission line

and the fine-matching transformer.

Install the transformer at the input

46, 49, 52, 55, or 58, as applicable), or slugged line section (70 or 71, as

applicable), as follows:

a. Ensure there is an inner conductor connector in the transformer outlet

flange.

b. Attach the transformer mounts (45

c. Coat the O-ring (43

the antenna), then install it in the O-ring groove in the transformer outlet

flange.

d. Mate the flanges and secure the transformer to the mounting pipe. Do not

fully tighten the mounts until the flange hardware is in place.

e. Install the flange hardware kit (42

the flange. Tighten in accordance with Table 1

or 54, as applicable) lightly with O-Lube (supplied with

flange of your power divider (Figure 20,

) to the transformer, close to the ends.

or 53, as applicable) hardware and secure

on page 1.

f. Tighten the mount hardware in accordance with Table 1

26

.

Figure 20. Fine-matching

ransformer installation

t

Connecting the Antenna (2- to 6-bay)

27

Connecting the Antenna (2- to 6-bay)

Connect the antenna bay cables.

Figure 21. Antenna bay cable connection

CAUTION

Stressing a coax connection after assembly can detune the system.

Therefore, never make a connection and then bend or twist the cable, or

use the connector to force the coax into shape. Form the cable first,

then attach it to the connector.

CAUTION

The minimum single bending radius for HCA78-50J coax is 4" (100 mm).

The repeated bending radius is 10" (250 mm). Do not bend it too tightly;

you may damage it.

CAUTION

The minimum bending radius for 1/2" coax is 3" (8 cm). Do not bend it

too tightly; you may damage it.

CAUTION

Do not overtighten the connectors. Overtightening may damage them.

a. Connect the output end (90° connectors) of the antenna bay cable (47, 50,

, or 59) to the DIN connector at the bottom of the endseal.

56

b. Run the cable along the antenna weldment and secure it, using tie-wraps

), so as to prevent it moving and chafing against the U-bolt or other

(44

surfaces.

c. Connect the input end of the antenna bay cable to the power divider DIN

outputs.

d. Secure the cable to the mounting pipe or tower leg, using tie-wraps or

customer-supplied cable clamps.

e. Repeat for the other antenna bay(s).

28

Connecting the Antenna (2- to 6-bay)

Connect the tower transmission line.

Figure 22. Tower transmission line connection

a. The antenna system is not pressurized, but the tower transmission line may

be. If neces s a ry, provide a g a s stop betwe e n t he tower tran s m ission line and

the system input (power divider input, or transformer input if applicable).

b. Coat the O-ring (54

install it in the O-ring groove in the flange.

c. Using the 1-5/8" EIA flange hardware kit (Figure 22

transmission cable to the power divider (or transformer) input. Tighten in

accordance with Table 1

d. Sec ure t he to wer t ran s mis s ion c abl e to t h e mo u nti ng pi pe or tower leg, using

tie-wraps or customer-supplied cable clamps.

) lightly with O-Lube (supplied with the antenna), then

, 45), attach the tower

on page 1.

29

e. Loop or drape any excess cable and tie-wrap it to the pipe, to prevent wind

damage to the cables and to ensure the weight of the cable is not carried by

the antenna input.

NOTE

The Model 6822 antenna does not require pressurization or purging. The

feed system up to the power divider may be pressurized.

Installation of your Model 6822 2- to 8-bay antenna is now c

proceed to

Startup on page 51.

omplete. Please

Connecting the Antenna (8-bay)

6 Connecting the Antenna (8-bay)

Mount the power dividers.

Install the slugged line section (if applicable).

a. Using two mount bases (Figure 23, 63), two saddles (64), and two hose

clamps (65), mount the 1-5/8" 2-way power divider (62) onto the mounting

structure with its outlet end roughly halfway between bays 4 and 5. Locate

the mounts as close to the ends of the power divider as you can.

NOTE

You may have to provide short threaded rod sections to fit the 7/8" 7/8" power dividers to the mounting structure.

b. Using lightly lubricated O-rings (

the 7/8" transmission line sections (66 or 67, as applicable) to the outlet

flanges of the 2-way power divider (62). Secure them to the mounting pole,

using power divider mounting kits (45).

c. Using lightly lubricated O-rings (43) and flange hardware kits (42), attach the

7/8" to 7/8" power dividers (46, 49, 52, 55, or 58) to the outlet flanges of

the transmission line sections. Secure them to the mounting pole, using

power divider mounting kits (45).

In the event your antenna has non-standard bay spacing or other special features, we may have provided you

perfect the tuning of the antenna. This is to be installed between the output

of the transformer (if applicable) and the input of the power divider.

43) and flange hardware kits (42), attach

with a line section containing a "slug" to

CAUTION

Do not remove or modify the slug from the slugged line section. This will

ruin your antenna’s performance.

NOTE

Line section mounts are generally similar to feedline mounts and should

be installed in the same manner.

Install the slugged line section (

power divider (62) as follows:

a. Ensure there is an inner conductor connector in the slugged line section

outlet flange.

b. Attach the mounts (45) to the slugged line section, close to the ends.

c. Coat the O-ring (54) lightly with O-Lube (supplied with the antenna), then

install it in the O-ring groove in the outlet flange.

d. Mate the flanges and secure the slugged line section to the mounting pipe.

Do not fully tighten the mounts until the flange hardware is in place.

e. Install the flange hardware kit (53) hardware and secure the flange. Tighten

in accordance with Table 1

f. Tighten the mount hardware in accordance with Table 1

Figure 23, 71) at the input flange of your

on page 1.

.

31

Figure 23. Power divider

mounting for

8-bay antenna

Connecting the Antenna (8-bay)

32

Figure 24. Slugged line section

ation (if applicable)

install

Connecting the Antenna (8-bay)

33

Connecting the Antenna (8-bay)

Install the optional fine-matching transformer (if applicable)

One of the unique features of Shively Labs antenna systems is the adjustable

impedance-matching transformer (

antenna. It allows the installer to compensa

ance caused by the installation (to

Figure 25, 73) optionally available with the

te for changes in the input imped-

wer, conduit, ladder, etc.).

NOTE

The transformer may be oriented in whichever direction you wish (see

Figure 25). Make it easy for yourself to reach for adjustment at startup.

NOTE

Transformer mounts are generally similar to feedline mounts and should

be installed in the same manner.

NOTE

You may need to provide a coax adapter between your transmission line

and the fine-matching transformer.

Install the transformer at the input

slugged line section (71) if applicable, as follows:

a. Ensure there is an inner conductor connector in the transformer outlet

flange.

b. Attach the transformer mounts (45) to the transformer, close to the ends.

c. Coat the O-ring (54) lightly with O-Lube (supplied with the antenna), then

install it in the O-ring groove in the transformer outlet flange.

d. Mate the flanges and secure the transformer to the mounting pipe. Do not

fully tighten the mounts until the flange hardware is in place.

e. Install the flange hardware kit (53) hardware and secure the flange. Tighten

in accordance with Table 1

flange of your power divider (62) or

on page 1.

f. Tighten the mount hardware in accordance with Table 1

.

34

Figure 25. Fine-matching

ransformer installation

t

Connecting the Antenna (8-bay)

35

Connecting the Antenna (8-bay)

Connect the antenna bay cables.

Figure 26. Antenna bay cable

connec

tion

CAUTION

Stressing a coax connection after assembly can detune the system.

Therefore, never make a connection and then bend or twist the cable, or

use the connector to force the coax into shape. Form the cable first,

then attach it to the connector.

CAUTION

The minimum single bending radius for HCA78-50J coax is 4" (100 mm).

The repeated bending radius is 10" (250 mm). Do not bend it too tightly;

you may damage it.

CAUTION

The minimum bending radius for 1/2" coax is 3" (8 cm). Do not bend it

too tightly; you may damage it.

CAUTION

Do not overtighten the connectors. Overtightening may damage them.

a. Connect the output end (90° connectors)

56, or 59) to the DIN connector at the bottom of the endseal.

of the antenna bay cable (47, 50,

b. Run the cable along the antenna wel

(44), so as to prevent it moving and chafing against the U-bolt or other

surfaces.

c. Connect the input end of the antenna bay cable to the power divider DIN

outputs.

d. Secure the cable to the mounting pipe or tower leg, using tie-wraps or

customer-supplied cable clamps.

e. Repeat for the other antenna bay(s).

36

dment and secure it, using tie-wraps

Connecting the Antenna (8-bay)

Connect the tower transmission line.

NOTE

You may need to provide a coax adapter between your transmission line

and the antenna components.

a. The antenna system is not pressurized, but the tower transmission line may

be. If neces s a ry, provide a g a s stop betwe e n t he tower tran s m ission line and

the system input (power divider input, or transformer input if applicable).

b. Coat the O-ring (43 or 54, as applicable) lightly with O-Lube (supplied with

the antenna), then install it in the O-ring groove in the flange.

c. Using the flange hardware kit (42 or 53, as applicable), attach the tower

transmission cable to the power divider (or transformer) input. Tighten in

accordance with Table 1

d. Sec ure t he to wer t ran s mis s ion c abl e to t h e mo u nti ng pi pe or tower leg, using

tie-wraps or customer-supplied cable clamps.

e. Loop or drape any excess cable and tie-wrap it to the pipe, to prevent wind

damage to the cables and to ensure the weight of the cable is not carried by

the antenna input.

on page 1.

NOTE

The Model 6822 antenna does not require pressurization or purging. The

feed system up to the power divider may be pressurized.

Installation of your Model 6822 2- to 8-bay is now complete. Please

Startup on page 51.

to

proceed

37

Figure 27. Tower transmission line connection

Connecting the Antenna (8-bay)

38

Installing the De-icer System (if applicable)

7 Installing the De-icer System (if applicable)

Precautions

WARNING

Installation should be performed only by personnel

experienced in RF systems, qualified in electrical work, and familiar

with this equipment.

De-icer system description

WARNING

Don't expose personnel to the medical hazards of intense radio frequency (RF) radiation. Whenever working on the tower in the area

the antenna, turn off all transmitters and lock them out so that they cannot be turned on accidentally.

of

CAUTION

All parts of the de-icer system within approximately 20 feet (6 meters) of

any radiator must be shielded from RF energy, and the entire outdoor

portion of the system must be made waterproof.

CAUTION

An improperly installed de-icer can overheat and damage your antenna.

The de-icer system consists of the heating elements in the bays, their branch

cables, a bay junction box for each antenna bay, interbay cables, and a "pigtail" of wires about 10 feet (3 meters) long which you

tower junction box you are to provide. The following will help in installation:

• System electrical schematic:

• Electrical specifications: Table

• Thermostat readings: Table

Your system may also include specially-ordered

mounted main control box, a power cable extending up the tower, or a towermounted dual-setting thermostat.

Figure 34 on page 43.

3 on page 39.

4 on page 44.

items, such as a ground-

will connect to the

Dual-setting thermostat

Electric power

CAUTION

Remember that conditions may be favorable for icing on the tower, even

if they are not on the ground.

Shively Labs deicers are designed to prevent ice from forming on antenna elements and are not designed to melt ice that has already formed. For this reason, Shively Labs recommends that the system be installed

mounted dual-setting thermostat assembly (Shively Labs Model 55522-G502)

and de-icer control box (Shively Labs Model 94068) that ensure the deicers

are operated in the temperature range ice is most likely to form.

The de-icer system requires 240 VAC, 50 - 60 Hz., single-phase. Table 3 shows

approximate heater leg resistances and current draw, respectively.

Table 3. De-icer specifications

Heater leg

resistance,

1-Bay 288 0.42

2-Bay 144 0.84

3-Bay 96 1.3

4-Bay 72 1.7

5-Bay 57 2.1

6-Bay 48 2.5

with a tower-

Heater leg (T1 or T2)

current draw, amps

39

Installing the De-icer System (if applicable)

Table 3. De-icer specifications (continued)

De-icer installation

Installing the de-icer junction boxes.

Figure 28. De-icer junction box installation

ater leg

He

resistance,

8-Bay, single circuit 36 3.3

a. Insert the electrical leads (Figure 28, 23) from the antenna mast through the

side port of the junction box.

Heater leg (T1 or T2)

current draw, amps

b. Screw the junction box onto the threaded end of the antenna mast as shown

(Figure 29

). Tighten the jam nut against the junction box.

40

Figure 29. Junction box installed

enna bay

on ant

Installing the De-icer System (if applicable)

NOTE

The access cover of the junction box may be positioned on the left or

right side.

c. (Top bay only) Using PTFE tape to seal the opening, install the pipe plug

(Figure 28

, 26) in the top port of the junction box.

Installing the interbay cables.

Figure 30. Interbay cable section, bottom end

a. Examine an interbay cable section (Figure 28, 23). It consists of a liquid-tight

connector (28

end of a length of cable.

b. Identify the top end an d t h e b o t to m e n d o f t h e c a b l e s e c t i o n . At the top end,

the components are pre-assembled and tightened.

c. At the bottom end (Figure 30

and the outer cable insulation and the braided sheath have been cut back to

the proper length at the factory.

d. Install the top end of the cable section:

(1) Apply PTFE tape to the body threads on the top end.

(2) Turning the entire cable section, screw the top end into the bottom port

of the topmost junction box. Tighten.

e. Install the bottom end of the cable section:

(1) Remove the body from the cable assembly. Using PTFE tape, install the

body into the port at the top of the second junction box. Tighten.

(2) Using scissors, slit the braided sheath (Figure 31

insulation.

): a gland, a retainer, a bushing, and a body, all strung on

), the components are only loosely assembled

) to the end of the

each

41

Figure 31. Sheath cut back

Figure 32. Sheath bent back over the grommet

Installing the De-icer System (if applicable)

(3) Slide the grommet to the end of the insulation. Unravel the sheath as

necessary and bend it back over the grommet (Figure 32

).

Figure 33. Final assembly, top of second junction box

(4) Insert the leads through the body and the top port of the second

junction box.

(5) Press the bushing (unraveled sheath and all) into the body (Figure 33

Then screw the cable gland over the retainer and onto the bushing and

tighten.

42

).

Figure 34. De-icer electrical

schema

tic diagram

NOTE

Customer-supplied items

are shown in broken lines.

Installing the De-icer System (if applicable)

NOTE

Wire nuts, cover with

screws, and gaskets, and

tie-wraps are provided

with the de-icer cable sections.

CAUTION

Shively Labs's de-icer

control box, Model 94068,

is designed for interior

installation only.

43

Installing the De-icer System (if applicable)

Installing the tower junction box

Installing the thermostat (if applicable)

f. Inside each junction box, connect the leads as shown in Figure 28

nuts (7) to secure the connections.

g. Repeat for the remaining bays, junction boxes, and interbay cables.

h. Secure the interbay cables to the mounting pipe or tower leg, using tie-

wraps.

i. Connect the 10-foot pigtail at the bottom of the bottommost junction box.

, using wire

CAUTION

It is important to ground both the tower junction box and the control

box, as shown in the schematic diagrams.

a. Furnish a tower junction box as shown schematically in Figure 34 to connect

the antenna’s de-icer harness to the main power.

b. Run the ten-foot de-icer pigtail to the tower junction box and secure it to the

mounting pipe and/or the tower.

If you are using a thermostat, you may locate and mount it at your discretion.

We recommend mounting it as close as practical to the antenna.

CAUTION

When testing the thermostat, be sure to have one or both thermostat

leads disconnected before taking resistance readings. Otherwise, readings may be affected by other co

a. Before you connect the thermostat, measure the resistance across the

thermostat circuit and from it to ground to ensure that there are no shortcircuits. Thermostat readings should be as shown in Table 4

b. Mount the thermostat near the antenna and connect the thermostat leads to

points S1 and S2 in the control box as shown in the schematic diagram,

Figure 34

.

mponents.

on page 44.

Table 4. Thermostat readings

Reading

ation

Loc

Leg-toGround

Leg-to-Leg Above about 38° F

Ambient

Temperature

Any Defective thermo-

(3.3° C)

Between about 10°

about 38° F

and

(-6.7° to 3.3° C)

Below about 10° F

-6.7° C)

(

Resistance =

0 ohms

(short circuit)

stat or shorted

ads

le

Defective thermo-

stat or shorted

ads

le

OK Defective thermo-

Defective thermo-

stat or shorted

ads

le

Resistance =

infinite ohms

(open circuit)

OK

OK

stat or broken leads

OK

44

Retuning

8 Retuning

If you are re-using an existing antenna at a different frequency, or setting up

a used antenna at your site, you will need to retune the antenna to your

needs.

Before beginning retuning:

Setup

Important

In the days before the hazards of intense RF power were realized, it was

common practice to have a technician climb the tower and adjust the

impedance match using the transmitter as a signal source and reading

the VSWR or return power on the transmitter. This practice MUST NOT

be used, as few transmitters can be operated at a low enough power

level to avoid exposing the rigger to an unsafe RF level. For reference,

see 29 CFR, Section 1910.97, the OSHA standard for exposure to nonionizing radiation.

To test and adjust VSWR safely, use low-power test equipment, suc

a network analyzer. If you don't have access to low-power test equipment, please call Shively Labs before proceeding.

h as

WARNING

Whenever a rigger is on the tower in the area of the antenna, shut off

the transmitter signal and lock and tag it out so that it cannot be turned

on accidentally.

Low-power test equipment should b

tion exposure to the person d

A high transmission line VSWR may indicat

likely to cause problems in the future, including serious damage to your equipment.

a. A dju st t he a rm l en g th s an d fe e d s t ra p s t o th e se t tin gs i n Figure 35 an d Figure

36. This is a good starting point.

b. Install the radiators on the tower leg or mounting pipe at the specified bay-

to-bay spacing (full-wave 118", half-wave 60". Special spacing in accordance

with specification - contact the factory if necessary).

oing the adjusting.

e used to prevent excessive radia-

e damaged transmission line and is

c. Attach the feed cables to each bay in turn and dress cables along the tower

leg or mounting pipe (do not leave them hanging loosely in the RF field).

Attach the power divider near the bottom bay of the array using the saddle

"C" clamps and hose clamps. Coil the excess feed cables at the power divider

to the smallest diameter allowable w i th the minimu m r epeatable bend radius

for the cable being used.

NOTE

If the array is half-wave or special spaced the power divider input may

need to be slugged - contact the factory.

45

Tuning

Figure 35. Arm length vs. frequency

Figure 36. Feed strap angle vs. frequency

Retuning

a. Tweak for minimum VSWR from there (see Chapter 9). The specification is

less than 1.2:1 (Figure 37

46

, Figure 38, and Figure 39).

Figure 37. Optimal VSWR at 108 MHz, narrow feedstrap

Retuning

47

Figure 38. Optimal VSWR at 108

MHz,

wide feedstrap

Retuning

48

Figure 39. Optimal VSWR at 88

wide feedstrap

MHz,

Retuning

49

Startup

9Startup

We strongly recommend initial characterization as the best way to identify

both initial problems and possible future system damage.

Initial characterization

Before beginning initial characterization:

Read transmission line VSWR.

Important

In the days before the hazards of intense RF power were realized, it was

common practice to have a technician climb the tower and adjust the

impedance match using the transmitter as a signal source and reading

the VSWR or return power on the transmitter. This practice MUST NOT

be used, as few transmitters can be operated at a low enough power

level to avoid exposing the rigger to an unsafe RF level. For reference,

see 29 CFR, Section 1910.97, the OSHA standard for exposure to nonionizing radiation.

To test and adjust VSWR safely, use low-power test equipment, suc

a network analyzer. If you don't have access to low-power test equipment, please call Shively Labs before proceeding.

h as

WARNING

Whenever a rigger is on the tower in the area of the antenna, shut off

the transmitter signal and lock and tag it out so that it cannot be turned

on accidentally.

Low-power test equipment should b

tion exposure to the person d

A high transmission line VSWR may indicat

likely to cause problems in the future, including serious damage to your equipment.

The first step is to characterize the transmission line by itself.

a. Briefly disconnect the transmission

the antenna system input to prevent the entry of moisture.

oing the adjusting.

e used to prevent excessive radia-

e damaged transmission line and is

line from the antenna system input. Seal

Read transmission line TDR.

Read system VSWR.

b. Terminate the coax transmission line in an instrument-quality 50-ohm load.

c. Measure and record the voltage standing wave ratio (VSWR) across the

operating band. File this information with this manual for future reference.

d. The VSWR of the transmission line should be within the manufacturer's

specifications. If it is, proceed. If not, you should call the manufacturer

before connecting the antenna. Problems must be worked out with the

design engineer on a case-by-case basis.

With the transmission line still terminated in 50 ohms, make a time domain

reflectometer (TDR) plot. Label and file the plot with this manual.

You tested the VSWR of the transmission line alone. Now test the VSWR of the

system as a whole.

a. Remove the load and connect the transmission line to the antenna system

input.

b. Measure VSWR. VSWR at this point should be around 1.2 : 1 or better. If it

is not, check to be sure all the radiators are functioning (below).

c. Record the reading and file it with this manual.

51

Startup

Impedance trimming.

Figure 40. Impedance-matching

ransformer

t

If your antenna is equipped with the optional Shively fine-matching transformer, adjust the transformer (

a. Loosen the hose clamps on the t

move.

b. Grasp one of the tuning stubs and slide it in or out about 1/4 inch or 6

millimeters. It will move stiffly because of O-ring friction.

Figure 40) as follows:

uning stubs enough to allow the stubs to

c. Read the V S W R. If the rea d i ng went down , m ove the cont r o l rod a

same direction. If the VSWR went up, move the same rod in the opposite

direction. Repeat until no further improvement is seen.

d. Adjust the second and third tuning stubs in the same manner.

gain in the

NOTE

If you get "lost," return all three tuning stubs to the factory setting (all

the way out) and start over.

e. Return to the first tuning stub, and so forth, until you have the l

possible VSWR or return power reading. This is the optimal transformer

setting at this frequency.

f. VSWR for each frequency at this point should be below 1.2 : 1. If it is not,

call Shively Labs to help identify the problem.

g. When you have set the transformer, use a sharp point to scribe the shaft of

each control rod where it leaves the flange collar. Record the settings of the

control rods and file this information with this manual for future reference.

h. Tighten the hose clamps. If the clamps are left loose, vibration may change

the adjustments.

owest

52

Startup

Checkout.

Operation.

a. Before beginning checkout of the antenna system, be sure the following

items have been done:

• The antenna system has been installed in

manual and the installation drawing.

• All radiators are operating and VSWR

• The initial characterization data have

• The system is gas-tight, purged, and pressurized.

b. Check the system out as follows:

1) Bring up RF power slowly and observe transmitter readings, stability,

(

and general operation.

(2) Run at about half power for at least an hour, reading forward and

reflected power, stability, etc.

(3) If the system is stable and seems to be operating properly, bring it up

to full power. Take initial readings, and repeat the readings periodically.

c. Performance readings should not change, and there should be no evidence

of abnormal heating in the antenna system.

d. If any problem is found, fix it now. Call Shively Labs if you need help or

advice.

Once the antenna has been installed and VSWR has been optimized, simply

apply the transmitter signal. Don’t exceed the rated power of the antenna.

accordance with this

is within specification.

been recorded.

53

Figure 41. Apply the signal.

Startup

54

Maintenance

10 Maintenance

WARNING

Whenever a rigger is on the tower in the area of the antenna, shut off

the signal and lock it off so that it cannot be turned on accidentally. RF

emissions at close range are hazardous.

Log

Inspection

Paint

Return policy

Troubleshooting

Broad spectrum RF noise.

High VSWR

We recommend that you keep a log of VSWR readings and any other performance notes and maintenance history for your ant

invaluable for troubleshooting.

Whenever a rigger is on the tower for any reason, it is a good idea to have

him check your antenna for general condition, looseness of connectors and

mounts, and electrical damage.

The radiator should never be painted; this will affect the VSWR.

When returning any material to the factory, be sure to call your salesperson

and obtain an returned materials authorization (RMA) number first. Material

may be refused and sent back to you at your expense if you don’t do this.

This indicates that some component is not in good electrical contact with the

tower. Make sure mounts are tight, that tower paint has been removed from

under the mounts, and that components of other systems are likewise in good

contact with the tower.

This is caused by any factor that changes the impedance match between the

antenna and the transmitter. Look for:

• Defective RF connector. Make sure connect

and that center pins are not bent over.

enna. Such a record can be

ors are in good shape,

Change in coverage

• Damage to any antenna components.

• Paint on radiators.

• Ice buildup on radiators.

• Interference from other tower components, especially com

broken by wind or ice.

This may be caused by the same factors that can cause high VSWR. Look for

VSWR changes as well.

Do recognize, however, that appar

jective factors or faults of the receiving equipment. Before doing more than

ng the VSWR, be sure that an actual coverage change has occurred.

checki

55

ent changes in coverage may be due to sub-

ponents

Parts

11 Parts

NOTE

Item numbers are consistent across all the illustrations in this technical

manual, with the exception of the assembly drawings in Appendix A.

Bay components

(without de-icers)

Table 5. Components, antenna bay without de-icer (per bay)

Part Number Description Qty.

1. 5/16-18SS036HM Screw, hex head 5/16-18 x 2-1/4" SS 4

2. 5/16-18SS Nut, hex 5/16-18 SS 4

3. 5/16SSF Washer, flat 5/16" SS 8

4. 5/16SSS Washer, split lock 5/16" SS 4

5. 97353-G502 Bay weldment 1

6. 97353-09 Clamp, upper arm 4

7. 97353-01 Arm, dipole 2

8. 97353-G505-

036.00

9. 99786-G502 Endseal assembly 1

10. 97353-07 Clip, feedstrap 2

11. 97353-10 Feedstrap 2

12. 96384-11 Washer, #10 endseal brass Bokers 2

13. 01/4-20SS016HM Screw, hex head 1/4-20 x 1-1/4" SS 2

14. 01/4-20SS Nut, hex 1/4-20 SS 2

15. 01/4SSF Washer, flat 1/4" SS 4

16. 01/4SSS Washer, split lock 1/4" SS 2

17. 96384-12 Washer, 1/4" brass Bokers 4

18. 99014-07 V-arm, sliding 4

19. 52750-M10H-1.13 ODClamp, hose 4

(single-bay antenna only) Cable assembly,

16 DIN female to 90° 7/16 DIN male,

7/

36" long

1

20. 0006-32SS Nut, hex 6-32 SS 4

21. 0006SSS Washer, split lock #6 SS 4

22. 0006SSFN Washer, flat #6 narrow 4

57

Figure 42. Components, 6822 bay (without de-icers)

Parts

58

Parts

De-Icer Components

Figure 43. Components, 6822 de-icer

Table 6. Components, de-icer (per bay)

Part Number Description Qty.

23. 51299-G5XXX.XX LGDe-icer bay-to-bay box cable assembly,

ductor with shield

3-con

24. 97353-12 Box, aluminum conduit tee 1

25. 2426-141 Locknut, 1/2" pipe 1

26. 52762-CUP-1 Plug, pipe, 1/2" NPT (end bay only) 1

27. 2426-RC55 Nut, wire, crimp-on 2

28. 2426-2521 Connector, liquid-tight, 1/2" 2

1

59

Mounting system components

Parts

Up to 3-1/2" mounting pipe OD:

Figure 44. Components, mounts

for up t

o 3-1/2" mounting pipe

NOTE

For mounting pipes between 3-1/2" and 6" diameter, see the next section.

Table 7. Components, mounts for up t

(per antenna bay)

Part Number Description Qty.

29. 98141-07 Mount, balun for 1.50" - 3.50" OD pipe 1

30. 6384-16 U-bolt, 1" pipe 2

31. 55020-48 U-bolt, stainless 4.00" 2

32. 55020-49 U-bolt, stainless 2.50" 2

33. 03/8-16SS Nut, hex 3/8-16 SS 8

34. 03/8SSF Washer, flat 3/8" SS 8

35. 03/8SSS Washer, split lock 3/8" SS 8

1. 5/16-18SS036HM Screw, hex head 5/16-18 x 2-1/4" SS 2

2. 5/16-18SS Nut, hex 5/16-18 SS 2

3. 5/16SSF Washer, flat 5/16" SS 4

4. 5/16SSS Washer, split lock 5/16" SS 2

o 3-1/2" mounting pipe

60

Parts

3-1/2" - 6" mounting pipe OD:

NOTE

For mounting pipes up to 4" diameter, see the previous section.

Table 8. Components, mounts for 3-1/

(per antenna bay)

Part Number Description Qty.

36. 98141-06 Mount, balun for 3-1/2" - 6-5/8" OD 1

1. 5/16-18SS036HM Screw, hex head 5/16-18 x 2-1/4" SS 2

2. 5/16-18SS Nut, hex 5/16-18 SS 2

3. 5/16SSF Washer, flat 5/16" SS 4

4. 5/16SSS Washer, split lock 5/16" SS 2

30. 6384-16 U-bolt, 1" pipe 2

37. G58NUT Nut, hex 5/8-11 heavy galvanized 12

38. G58FW Washer, flat 5/8 heavy galvanized 12

39. G58LW Washer, split lock 5/8" galvanized 8

40. G58R-12 Rod, full threaded 5/8-11 galvanized 4

41. 98141-04 Clamp, support for 3-1/2" - 6-5/8" OD 2

2" to 6" mounting pipe

61

Figure 45. Components, mounts

for 3-1/

2" to 6" mounting pipe

Parts

62

Parts

Feed system components

Table 9. Components, feed system for single-bay antenna

Part Number Description Qty.

42. 82912-G506 Kit, flange hardware, 7/8" flange 1

43. 9068-215 O-ring, silicone, 7/8" EIA flange 1

44. TY529MX Tie-wrap 6

Table 10. Components, feed system for 2-bay ant

(per array)

Part Number Description Qty.

45. 98162-G501 Kit, power divider mount, 7/8" 1

46. 078F-716X2 Power divider, 2-way 7/8" EIA flange to

7/16 DIN male

42. 82912-G506 • Kit, flange hardware, 7/8" flange 1

43. 9068-215 • O-ring, silicone, 7/8" EIA flange 1

47. 97353-G505-

120.00

48. 97353-G505-

96.00

44. TY529MX Tie-wrap 12

(Full-wave-spaced) Coax cab

ft (3 .0 m) long , 7/1 6 DI N mal e on i n put e nd

and 90° 7/16 DIN male on output end

(Half-wave-spaced) Coax

(2.44 m) long, 7/16 DIN male on input end

and 90° 7/16 DIN male on output end

le section, 10

cable section, 8 ft

enna

1

2

2

Table 11. Components, feed system for 3-bay ant

(per array)

Part Number Description Qty.

45. 98162-G501 Kit, power divider mount, 7/8" & 1-5/8" 1

49. 078F-716X3 Power divider, 3-way 7/8" EIA flange to

7/16 DIN male

42. 82912-G506 • Kit, flange hardware, 7/8" flange 1

43. 9068-215 • O-ring, silicone, 7/8" EIA flange 1

50. 97353-G505-

192.00

51. 97353-G505-

156.00

44. TY529MX Tie-wrap 25

(Full-wave-spaced) Coax cab

ft (4.88 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

(Half-wave-spaced) Coax

ft (3.96 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

le section, 16

cable section, 13

enna

1

3

3

63

Figure 46. Feed system components for 2- to 6-bay antennas

Parts

64

Parts

Table 12. Components, feed system for 4-bay ant

(per array)

Part Number Description Qty.

45. 98162-G501 Kit, power divider mount, 7/8" & 1-5/8" 1

52. 158F-716X4 Power divider, 4-way 1-5/8" EIA flange to

16 DIN male

7/

53. 82912-G501 • Kit, flange hardware, 1-5/8" flange 1

54. 9068-328 • O-ring, silicone, 1-5/8" EIA flange 1

50. 97353-G505-

240.00

47. 97353-G505-

120.00

44. TY529MX Tie-wrap 35

Table 13. Components, feed system for 5-bay ant

Part Number Description Qty.

45. 98162-G501 Kit, power divider mount, 7/8" & 1-5/8" 1

55. 158F-716X5 Power divider, 5-way 1-5/8" EIA flange to

54. 82912-G501 • Kit, flange hardware, 1-5/8" flange 1

55. 9068-328 • O-ring, silicone, 1-5/8" EIA flange 1

56. 97353-G505-

336.00

57. 97353-G505-

168.00

44. TY529MX Tie-wrap 50

(Full-wave-spaced) Coax cab

ft (6 .1 m) long , 7/1 6 DI N mal e on i n put e nd

and 90° 7/16 DIN male on output end

(Half-wave-spaced) Coax

ft (3 .0 m) long , 7/1 6 DI N mal e on i n put e nd

and 90° 7/16 DIN male on output end

(per array)

16 DIN male

7/

(Full-wave-spaced) Coax cab

ft (8.54 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

(Half-wave-spaced) Coax

ft (4.27 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

le section, 20

cable section, 10

le section, 28

cable section, 14

enna

1

4

4

enna

1

5

5

Table 14. Components, feed system for 6-bay ant

(per array)

Part Number Description Qty.

45. 98162-G501 Kit, power divider mount, 7/8" & 1-5/8" 1

58. 158F-716X6 Power divider, 6-way 1-5/8" EIA flange to

16 DIN male

7/

54. 82912-G501 • Kit, flange hardware, 1-5/8" flange 1

55. 9068-328 • O-ring, silicone, 1-5/8" EIA flange 1

59. 97353-G505-

384.00

(Full-wave-spaced) Coax cab

ft (9.78 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

65

le section, 32

enna

1

6

Parts

Table 14. Components, feed system for 6-bay ant

(per array) (continued)

Part Number Description Qty.

60. 97353-G505-

216.00

44. TY529MX Tie-wrap 70

Table 15. Components, feed system for 8-bay ant

Part Number Description Qty.

45. 98162-G501 Kit, power divider mount, 7/8" & 1-5/8" 4

61. 158F-716X4 Power divider, 4-way 1-5/8" EIA flange to

42. 82912-G506 • Kit, flange hardware, 7/8" flange 2

43. 9068-215 • O-ring, silicone, 7/8" EIA flange 2

62. 100456-501 Power divider, 2-way 1-5/8" EIA flange to

54. 82912-G501 • Kit, flange hardware, 1-5/8" flange 1

55. 9068-328 • O-ring, silicone, 1-5/8" EIA flange 1

63. 98361-G501 Mount base assembly 2

64. 98359-G503 Saddle assembly, 1-5/8" 2

65. 6114-*** Clamp, hose 4

66. 99459-G501-

168.00

67. 99459-G501-

054.00

68. 97353-G505-240 (Full-wave-spaced) Coax cab

69. 97353-G505-156 (Half-wave-spaced) Coax

44. TY529MX Tie-wrap 70

(Half-wave-spaced) Coax

ft (5.49 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

(per array)

7/16 DIN male

1-5/8" EIA flange

(Full-wave-spaced) Air-flex high-power line

ion, flanged, ***" long with 1-5/8" ter-

sect

minals

(Half-wave-spaced) Air-flex high-power

section, flanged, ***" long with 1-5/8"

line

terminals

ft (6.10 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

ft (3.96 m) long, 7/16 DIN male on input

end and 90° 7/16 DIN male on output end

cable section, 18

le section, 20

cable section, 13

enna

6

enna

2

1

2

2

8

8

66

Figure 47. Feed system

compon

ents, 8-bay antenna

Parts

67

Parts

Accessories and optional items

Table 16. Accessories and optional items

Part Number Description Qty.

70. Various Line section, slugged, 7/8" 1

42. 82912-G506 • Kit, flange hardware, 7/8" flange 1

43. 9068-215 • O-ring, silicone, 7/8" EIA flange 1

71. Various Line section, slugged, 1-5/8" 1

54. 82912-G501 • Kit, flange hardware, 1-5/8" flange 1

55. 9068-328 • O-ring, silicone, 1-5/8" EIA flange 1

72. 99952-G502 Transformer, fine matching, 7/8" EIA 1

42. 82912-G506 • Kit, flange hardware, 7/8" flange 1

43. 9068-215 • O-ring, silicone, 7/8" EIA flange 1

73. 99952-G502 Transformer, fine matching, 1-5/8" EIA 1

54. 82912-G501 • Kit, flange hardware, 1-5/8" flange 1

55. 9068-328 • O-ring, silicone, 1-5/8" EIA flange 1

45. 98162-G501 Kit, power divider mount, 7/8" & 1-5/8" 4

68

Figure 48. Slugged line section

licable) components

(if app

Parts

69

Figure 49. Fine-matching

t

ransformer (optional)

components

Parts

70

Loading...

Loading...