FM Broadband Multistation

Broadcast Antenna

Model 6017

Instruction Manual

Installation, Operation, &

Maintenance

Congratulations!

Thank you for purchasing one of the finest FM broadcast antennas on

the market today. The Shively Labs 6017 antenna is widely recognized

as the top-of-the-line in its class for its superior performance and dura

bility.

Your purchase is backed by the best technical support in the industry.

Shively is a leading manufacturer in the broadcast industry, providing

an extensive range of antennas, transmission line and components.

Our technical staff has a wealth of experience in the broadcast indus

try and is standing by to serve you in any way.

This manual is intended to give you a good basic understanding of your

antenna: its proper and safe installation, startup, and operation, and

troubleshooting and maintenance information to keep it working satis

factorily for years to come.

Please have everyone involved with the

antenna read this manual carefully, and keep it handy for future refer

-

-

-

ence.

Meanwhile, please feel free to contact your sales representative at

Shively Labs at any time if you need information or help. Call or write:

-

Publication No. IM017 (100201)

2

IMPORTANT

Please read this manual in its entirety before beginning

installation of your antenna!

Failure to follow the installation and operation

instructions in this manual could lead to failure of your

equipment and might even void your warranty!

Table of Contents

Chapter 1 Preparing for Installation..................................................1

Receiving ............................................................................................. 1

Unpacking............................................................................................ 1

Check the System ................................................................................. 2

Chapter 2 Installing the Mounts .................................................. ...... 3

Before Beginning Mount Installation :......................................................3

Mark Mount Locations on the Mounting Pole ...........................................3

Installing the Radiator Mounts on the Pole.............................................. 3

Installing the 4-Way Power Divider Mounts on the Pole ........................... 4

Installing the Main Power Divider Mounts

(if applicable) .................................................................... 6

Chapter 3 Installing the Radiators and Power Dividers.....................8

Before Beginning Radiator and Power Divider Installation: ....................... 8

Installing Radiators ............................................................................... 8

Installing Power Dividers ....................................................................... 9

Chapter 4 Installing the Coaxial Feed System.................................10

Before Beginning Feed System Installation : .......................... ................ 10

Installing the Power-Divider-to-Radiator Cables..................................... 11

Installing the Main Power Divider (if applicable) .................................... 12

Installing the Main Feed Cables............................................................ 12

Chapter 5 Pressurization and Startup..............................................14

Before Beginning Pressurization:............................ .... .. .. .... .. ... .. .... .. .. .. . 14

Pressurization Procedure ..................................................................... 14

Step 1. Leak Testing....................................................................... 14

Step 2. Purging the System............................................................. 16

Step 3. Leaving the System Pressurized ........................................... 17

Before Beginning Intial Characterization: .............................................. 17

Initial Characterization (recommended) ................................................ 18

Step 1. Transmission Line VSWR Reading ........ ................................ 18

Step 2. Transmission Line TDR Reading........................................... 19

Step 3. System VSWR Reading...................................... .................. 19

Step 4. Checking Radiator Function ................................................. 19

Checkout............................................................................................ 19

Chapter 6 Operation.........................................................................21

Precautions ........................................................................................ 21

The Antenna.......... .. .. ... .... .. .. .. .. .. ..... .. .. .. .. .. .... .. ... .. .. .. .... .. .. .. ... .... .. .. .. .. . 21

Chapter 7 Troubleshooting .............................................................. 22

Precautions ........................................................................................ 22

Internal Arcing....................................................................... ............. 22

Broad Spectrum RF Noise.................................................................... 23

High VSWR at Startup or during Operation............................................ 23

Erratic VSWR...................................................................................... 24

Change in Coverage............................................................................ 24

Pressure Loss or Excessive Gas Usage .................................................. 24

i

Table of Contents

(continued)

Chapter 8 Maintenance ........................................... .........................26

Precautions.........................................................................................26

Maintenance Log............................................ ..................................... 26

Physical Inspection.................... ..........................................................26

Paint..................................................................................................27

Troubleshooting.................................................................................. 27

Return Policy ......................................................................................27

Sample Maintenance Log.............................. .. .. ... .... .. .. .. .. .... ... .. .. .. .... .. . 2 8

List of Illustrations

List of Tables

Figure 1 Typical Mount Installation on Pole, top view.........................3

Figure 2 4-Way Power Divider Installation, top and side views............5

Figure 3 Main Power Divider Mount Styles.........................................6

Figure 4 Radiator Installation, top view.............................................9

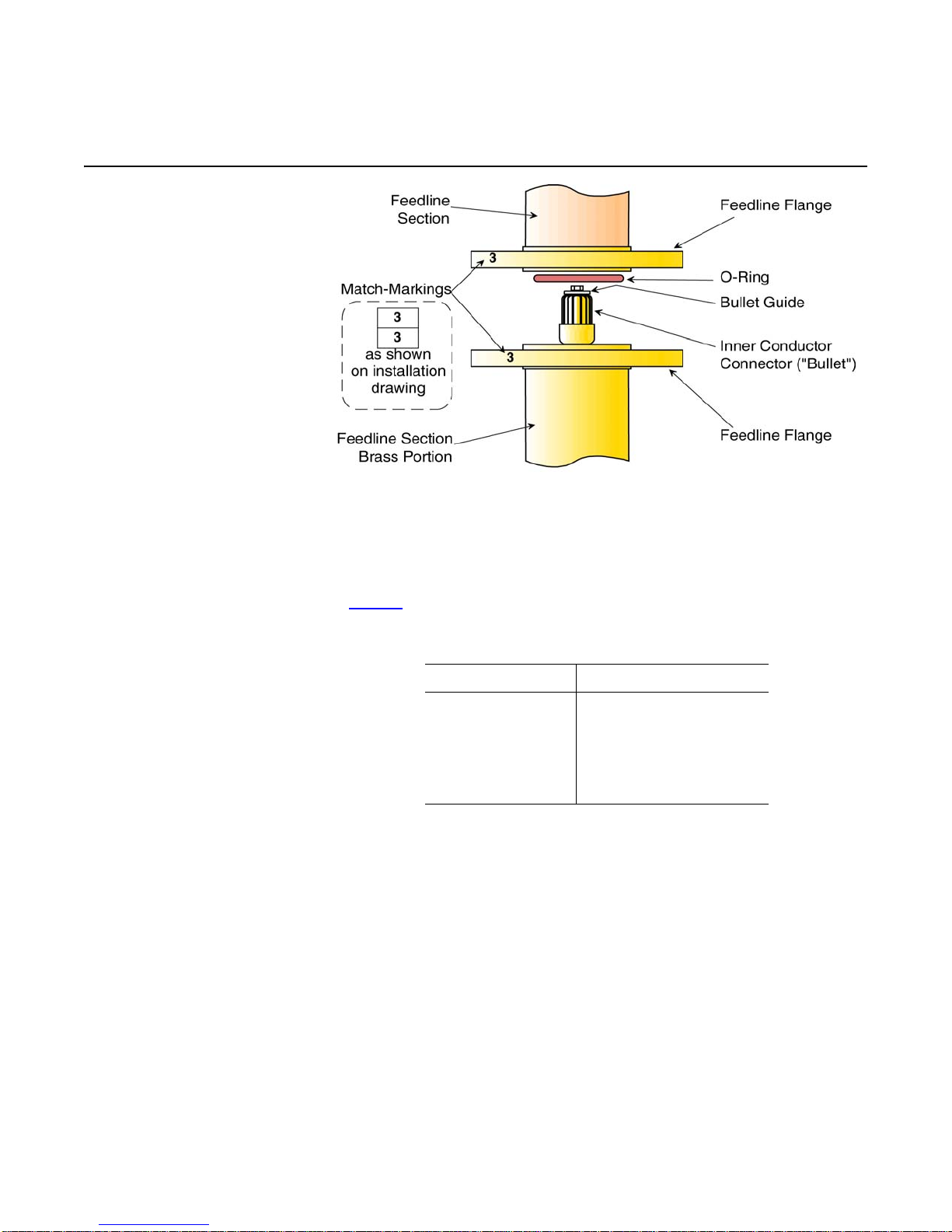

Figure 5 Feedline Flange Detail ......................................................10

Figure 6 Flange Bolt Tightening Sequences..................................... 12

Figure 7 Pressurized Gas Schematic..... ........................................... 15

Table 1 Minimum Bending Radii, Semiflex Coax..............................10

Table 2 Torque Specifications, Flange Bolts....................................11

Table 3 Volume of Coax per 1000 Feet of Length...........................17

Table 4 Troubleshooting Internal Arcing ....................................... 22

Table 5 Troubleshooting High VSWR ............................................23

Table 6 Troubleshooting Pressure Loss or Excessive Gas Usage.......24

ii

Preparing for Installation

1 Preparing for Installation

Receiving

Unpacking

As soon as you receive your antenna, BEFORE signing for the shipment:

a. Check to be sure all the material has arrived.

NOTE

The box number and the total number of boxes are marked on

each box; for example, “Box 2 of 5” means “box number 2 of a

total of five boxes.”

b. Check for evident damage to any of the boxes.

c. If any boxes are missing, or if any are obviously damaged, describe

the problem in a WRITTEN note on the shipping papers BEFORE

signing them. Then call Shively right away, and we’ll do everything

we can to correct the situation.

Important!

Never store the antenna system outdoors, boxed or otherwise.

Take pains to keep the antenna components dry. You will need to

purge moisture from the interior of the antenna components

before applying transmitter power, and purging will be much more

time-consuming if the components get wet.

a. Find Box 1; it is marked “Open This Box First.” It contains the trans-

former and two copies of the installation drawing. The parts list on

one sheet of the installation drawing shows what box each item is in.

b. Then open the boxes and examine for shipping damages. File any

necessary claims with the carrier immediately.

c. If all the boxes are present and in good condition but material seems

to be missing, please contact Shively Labs immediately, using the

telephone or Fax number on the inside cover of this manual. For the

best service, have our shop order number (S/O) handy; it's in the

block at the bottom right corner of the installation drawing.

d. Along with your antenna you will get a spare parts kit. Place this in a

safe place until it is needed.

CAUTION

All contact surfaces and openings to the interior of the components are protected from contamination and from physical damage by caps and plastic bags. Do not remove this protection until

ready to connect the components.

1

Preparing for Installation

Check the System

Remember!

It is YOUR responsibility to ensure that your installation meets all

applicable codes and the centerline-of-radiation requirements of

your FCC construction permit.

Shively's factory designer has planned the installation of the antenna

based upon information provided by you. If this information contained

errors, the parts and mounting hardware will have been designed

incorrectly and will cause expensive delays in installation.

Therefore,

we recommend that you recheck the installation parameters during this

planning stage.

Check all the parts to be sure that they will fit the tower and each

other. Study the installation drawings carefully to confirm that the infor

mation used in designing the antenna and mounts was, in fact, accurate.

Have a reliable tower person, familiar with antennas and coaxial line,

inspect the tower and review the installation drawings before the full

rigging crew arrives.

If design problems are found, contact Shively Labs immediately. Pay

particular attention to:

• Frequency of the antenna.

-

• Fit of the mounts to the tower members.

• Freedom from interference by gussets, leg flanges, guys and their

attachment points, tower face members, obstruction lights, and

other components.

• Compatibility of transmission line and antenna input terminals.

• Location of the transmission line run relative to the antenna input

terminal.

• Use of non-metallic guy sections on the tower in the region to be

occupied by the FM antenna. Ensure that there are no metal guys

within ten feet (three meters) of any radiator.

• Availability of proper electrical service for deicers, if applicable.

• The adequacy of the tower structure and guys to carry the windload

placed upon them by the antenna.

You gave Shively this information at the time of purchase, but a last

check at this time can catch an error, which will be easier to correct

before installation begins.

2

Installing the Mounts

2 Installing the Mounts

Before Beginning

Mount Installation:

Mark Mount

Locations on the

Mounting Pole

Installing the

Radiator Mounts on

the Pole

CAUTION

Before you begin, study the installation drawing carefully. The

illustrations in this manual show typical details, but antennas vary

due to pattern requirements and tower designs, so you must go

by the installation drawing for the actual configuration of your

antenna.

a. Starting at the top of the antenna, use a steel measuring tape to find

the location of each mount in accordance with the installation draw

ing. Mark the mount locations on the pole.

b. Also mark the location on the pole of any accessory mounts, such as

for the power dividers or special coax line sections, to make sure

they will fit as planned.

c. If any problems appear during this process, please call Shively Labs

and discuss them with the installation designer.

-

(not to scale)

Figure 1. Typical Mount Installation on Pole, top view

3

Installing the Mounts

Figure 1 is a top view showing how the radiator mount pieces fit

together. Assemble and install the radiator mounts according to Figure

1, your installation drawing, and the following guidelines:

a. Find the marked locations on the mounting pole where the radiator

mounts will be located.

b. To ensure good electrical contact between the mounts and the sup-

port pole, scrape the pole paint away at the mount locations.

c. Install the mounts as shown in Figure 1 and your installation draw-

ing.

d. When all mounts are in place, sight along them vertically to make

sure they are aligned before tightening them.

e. Repaint the pole where you remo ved the paint in step b.

Installing the 4- Way

Power Divider

Mounts on the Pole

Assemble and install the 4-way power divider mounts according to Fig-

ure 2 on page 5, your installation drawing, and the following guide-

lines:

a. Find the marked locations on the mounting pole where the power

divider mounts will be located.

b. Referring to the installation drawing, mark the locations of the power

divider mounts (generally there will be either two or four mounts per

power divider).

CAUTION

If you don't get good electrical contact between the mounts and

the pole, the antenna may not perform as designed, and may pro

duce stray signals that will interfere with other services on the

tower.

c. To ensure good electrical contact between the mounts and the sup-

port pole, scrape the pole paint away at the power divider mount

locations.

d. Use band clamps to attach the power divider mounts loosely to the

pole.

e. When all mounts are in place, sight along them vertically to make

sure they are aligned before tightening them.

-

f. Repaint the pole where you removed the paint in step c.

4

Installing the Mounts

(not to scale)

Figure 2. 4-Way Power Divider Installation, top and side views

5

Installing the Mounts

Installing the Main

Power Divider

Mounts

(if applicable)

If your antenna has more than one level, a main power divider will distribute the signal among the 4-way power dividers at each antenna

level. Assemble and install the main power divider mounts according to

Figure 3, your installation drawing, and the following guidelines:

(not to scale)

Figure 3. Main Power Divider Mount Styles

6

Installing the Mounts

a. Find the marked location on the mounting pole where the power

divider mounts will be located.

b. Referring to the installation drawing, mark the locations of the power

divider mounts (generally there will be two mounts).

CAUTION

If you don't get good electrical contact between the mounts and

the pole, the antenna may not perform as designed, and may pro

duce stray signals that will interfere with other services on the

tower.

c. To ensure good electrical contact between the mounts and the sup-

port pole, scrape the pole paint away at the power divider mount

locations.

d. Use band clamps to attach the power divider mounts loosely to the

pole.

e. Repaint the pole where you removed the paint in step c.

-

7

Installing the Radiators and Power Dividers

3 Installing the Radiators and Power Dividers

Before Beginning

Radiator and Power

Divider Installation:

Installing Radiators

CAUTION

All electrical contact surfaces and openings to the interior of the

components are protected from contamination and from physical

damage by plastic protectors. Do not remove the protectors until

ready to connect the components.

CAUTION

The interiors of the components must be kept dry during installation. Avoid assembly during wet weather.

NOTE

Keep the plastic protectors in case you ever need to return components for repair.

CAUTION

Do not use silicone grease on an O-ring, as this will soften the silicone O-ring. Use only a light lubricating coat of petroleum jelly

(provided); too much may hamper electrical contact and contami

nate the interior of the system.

Be sure the O-ring is properly seated in its groove and not

pinched between the flange contact surfaces.

Attach the radiators to their mounts according to Figure 4 on page 9

and your installation drawing.

-

a. Fit the holes in the radiator backpalte over the studs on the mount.

b. Attach the radiator to the mount, using the 3/8” hardware provided.

8

Installing the Radiators and Power Dividers

Installing Power

Dividers

(not to scale)

Figure 4. Radiator Installation, top view

Assemble and install the power dividers and their mounts according to

your installation drawing and the following guidelines:

a. Check the mount locations against your installation drawing.

b. Attach the power dividers to the mounts as shown in Figure 2 on

page 5.

c. Double-check the tightness of all components.

9

4 Installing the Coaxial Feed System

Before Beginning

Feed System

Installation:

Installing the Coaxial Feed System

Figure 5. Feedline Flange Detail

CAUTION

Semiflex cable has a minimum bending radius, specified by the

manufacturer. Bending it too sharply will damage the cable. See

Table 1 for the various sizes.

Table 1. Minimum Bending Radii, Semiflex Coax

Cable Size Radius

1/2” 5” (127 mm)

5/8” 5” (127 mm)

7/8” 10” (254 mm)

1-5/8” 20” (510 mm)

CAUTION

Stressing a coax connection after assembly can detune the system. Therefore, never make a connection and then bend or twist

the cable.

Likewise, do not use the connector and flange to force the coax

into shape. Form the coax to the desired shape before attaching it

and align the connection properly, then make the connection.

10

Installing the Coaxial Feed System

CAUTION

Do not use silicone grease on the O-rings, as this tends to dissolve the silicone O-ring. Use only a light lubricating coat of petroleum jelly; too much may hamper electrical contact and

contaminate the interior of the system.

Be very careful that each O-ring is seated in its groove and not

pinched between flange contact surfaces, as this will cause a leak

in the system and will be expensive to find and repair.

NOTE

Keep the hardware securing the plastic protectors. It will be used

for the final connections.

Installing the

Power-Divider-toRadiator Cables

The semiflex cables have been pre-formed at the factory and marked

for their respective locations. Use the markings to determine which

cables go where. Install the power-divider-to-radiator flex coaxial

cables as shown on the installation drawing. Follow these guidelines:

CAUTION

Be very careful to connect each power divider port to the correct

radiator.

CAUTION

The specific lengths of your flex cables are required to maintain

proper system phasing. Often cables will be longer than needed

merely to reach the antenna inputs. This is normal and necessary.

a. Remove the plastic protector from the coax flange. Don’t lose the

hardware or the O-ring.

b. Lubricate the O-ring lightly and insert it into the groove in the coax

flange.

CAUTION

Be sure each component’s inner conductor fits cleanly over the

mating component’s inner conductor connector. If any of the fin

gers of the connector are forced outside the inner conductor (a

"split bullet"), this will cause arcing and damage to the antenna.

-

c. Use the hardware from the protective covers to attach the compo-

nents. Table 2 shows torque specifications for the v arious siz e flange

bolts. Figure 6 shows the flange bolt tightening sequence for each

coax size.

Table 2. Torque Specifications, Flange Bolts

Line Size Bolt Size Torque

1/2” 1/4-20 7 ft-lb 9 N-m

5/8” 1/4-20 7 ft-lb 9 N-m

7/8" 1/4-20 7 ft-lb 9 N-m

1-5/8" 5/16-18 12 ft-lb 16 N-m

11

Installing the Coaxial Feed System

Figure 6. Flange Bolt Tightening Sequences

d. After all RF components (ie: power dividers, radiators, rigid coax)

have been connected to each other, tighten the mounting bolts

securing the RF feed system to the pole.

Installing the Main

Power Divider (if

applicable)

Installing the Main

Feed Cables

If your antenna has more than one level, a main power divider will

feed it, with a cable to the four-way power divider at each level. Install

the power divider in accordance with

installation drawing.

a. Secure the power divider to the mount saddles using the band

clamps provided (generally, two clamps on a 6"-long saddle and four

clamps on a 12"-long saddle).

b. Connect the flex coax from the main power divider to the four-way

power dividers at the antenna levels.

Figure 3 on page 6 and your

CAUTION

To prevent damage to power dividers, position the hose clamp

screw housings over the saddles, not against the power dividers.

c. As each feedline section is lifted into place, remove the plastic bags

and protective covers from the flanges and install an O-ring, lubricat

ing it with a light coat of petroleum jelly (provided with the antenna).

d. Secure each feedline section to its mount before installing the next

section.

A main feed cable brings power from the main power divider to the

four-way power divider at each level of the antenna.

CAUTION

Components are usually interchangeable and are therefore not

normally match-marked in any way. Assemble any bay to any feed

cable, with any mount, etc. If any matching is necessary with your

system, it will be indicated on the installation drawing.

-

CAUTION

Be very careful to connect each power divider port to the correct

radiator.

Install these cables in the same manner as the power-divider-to-radiator cables. Their mounts are similar to the four-way power divider

mounts, but slightly larger to accommodate the corrugated cable outer

conductor.

12

Pressurization and Startup

5 Pressurization and Startup

Before Beginning

Pressurization:

Important

Shively Labs will not accept responsibility for antenna failure after

operation without proper purging or positive pressure of dry air or

dry nitrogen.

CAUTION

When pressurizing the system, never use a "garage" air compressor, as it will not clean the air and will blow both moisture and

contaminants such as oil and graphite into the coaxial system.

Be sure to use a good quality pressure gauge which will read

accurately in the 10 - 20 psig range; don't depend on the cylinder

gauge, which will not be accurate at a low pressure.

Do not over-pressurize the system; it takes time for the entire system to fill with the new pressure and the pressure gauge to stabilize.

CAUTION

If all moisture is not removed from the interior of the system, it

will condense when the weather cools. The condensed moisture

(water) will cause arcing and permanent physical destruction of

the coaxial system, including the transmitter outp ut network.

CAUTION

You must blow dry gas

pressure. The gas

volume

through

accomplishes the purge.

the system, not just maintain a

Pressurization

Procedure

Step 1. Leak Testing

CAUTION

Never operate the antenna system without proper purging and

constant positive dry gas pressure.

CAUTION

Although initial characterization is at your discretion, we strongly

recommend it as the best way to identify both initial problems and

possible future system damage.

After the antenna is installed and all lines are connected, it is necessary to check the system for leaks, purge with dry gas to remove all

moisture, and leave the system pressurized with dry gas to av oid f uture

infiltration of moisture. These steps must be taken before RF power is

applied to the system.

a. Connect a source of dry gas (cylinder nitrogen or air from a compres-

sor-dehydrator) to the system as shown in Figure 7 on page 15.

b. Be sure to include a good quality gauge which reads accurately in the

5 - 20 psig (35 - 135 kPa) range; don't depend on the cylinder

gauge, which will not be accurate enough in this pressure range.

14

Pressurization and Startup

Pressure Correction:

where PC = corrected

final pressure, psig

P

= final pressure as

R

read, psig

T

= beginning temper-

1

ature, degrees F.

= final temperature,

T

2

degrees F.

Figure 7. Pressurized Gas Schematic

c. Pressurize the system to eight (8) psig, then close the shutoff valve.

Give the system one half hour to stabilize, then record the pressure

and the temperature.

d. W ait twenty -f our hours, then read the pressure and the temperature

again and use the formula in the sidebar to obtain a corrected pres

sure for comparison.

e. If the system loses pressure at an unacceptably high rate, re-pres-

surize it, leaving the gas supply on. A rule of thumb is that the final

pressure should not be less than half the initial pressure after

twenty-four hours.

15

-

Pressurization and Startup

f. Find the leak(s), using a leak detector or soap bubbles. (The most

common cause of leakage is an O-ring pinched in a flange.)

g. Correct any leaks that are found. Then repeat the leak test until the

results are satisfactory.

Step 2. Purging the

System

When the system is new, and any time that it has been opened, it must

be purged with dry gas before operation to eliminate moisture.

The dry gas used may be dry cylinder nitrogen or air from a compressor-dehydrator. Shively Labs suggests three volume changes of dry gas

for an "average" system.

There is a pressure relief valve at the top of each four-way power

divider. This valve is set to open at about 10 psig. So, to purge the sys

tem, it is not necessary to send a worker to the top of the antenna to

open a valve or loosen a flange. Simply raise the internal pressure

enough to open the relief valve. When the purge is complete, lower the

pressure and the valve will close.

Purge your system as follows:

a. Determine how wet the system is. If a system of rigid line carefully

protected from weather and assembled in dry weather is average, a

system exposed to moisture during storage or installation will be rel

atively wet. New semi-flex transmission line, delivered pressurized

with dry gas, will be relatively dry; used semi-flex will be extremely

wet.

Important

Never apply transmitter power while the antenna is under vacuum.

-

-

b. If you have any liquid w ater in your tr ansformer or your tr ansmission

line, use a vacuum pump to dry the transmission line and trans

former. Apply as much vacuum as you can to the system and hold

the vacuum for 8 hours. This should remove an y liquid w ater. [A vac

uum pump can be rented or borrowed from a refrigeration contractor.]

c. Determine the volume of dry gas to use for the purge.

d. Table 3 shows approximate volumes inside various coax sizes. Add

the length of the antenna to the length of the transmission line to

determine the overall length of the system. You may ignore the vol

-

ume inside the radiators.

16

-

Pressurization and Startup

Table 3. Volume of Coax per 1000 Feet of Length

Coax Size Volume

1/2" 2 cu. ft. (0.06 m3)

5/8" 3 cu. ft. (0.08 m3)

7/8" 4 cu. ft. (0.11 m3)

1-5/8" 13 cu ft. (0.37 m3)

NOTE

A standard nitrogen cylinder (9 inch diameter by 55 inches tall)

contains about 200 cubic feet (2.6 m

els 1235 and 2577 compressor-dehydrators will provide about 12

cubic feet (0.34 m

3

m

) per hour.

e. Connect a source of dry gas (cylinder nitrogen or air from a compres-

sor-dehydrator) to the system as shown in Figure 7.

f. Raise the gas pressure to 12 or 13 psig (83 - 90 kPa).

3

) per hour; the Model 1234 about 78 cu ft (2.2

3

) of gas. Shively Labs Mod-

Step 3. Leaving the

System Pressurized

Before Beginning

Intial

Characterization:

g. If the relief valve has opened, the nitrogen cylinder will slowly drain

or the compressor-dehydrator will not shut down.

Remember

It is critical to blow dry gas

merely maintain a pressure; the gas volume accomplishes the

purge.

After completion of the purge, reduce the supply pressure to about 5 to

7 psig, allowing the pressure relief valve to close and seal the system.

After the pressure has stabilized, keep careful note of cylinder pressure or compressor-dehydrator running time, to be sure that no large

leaks have been overlooked. This is especially important immediately

after installation or any subsequent opening and reassembly.

Although initial characterization is at your discretion, we strongly recommend it as the best way to identify both initial problems and possible future system damage.

through

the system, rather than

17

Pressurization and Startup

Important

In the days before the hazards of intense RF power were realized,

it was common practice to have a technician climb the tower and

adjust the impedance match using the transmitter as a signal

source and reading the VSWR or return power on the transmitter.

This practice MUST NOT be used, as few transmitters can be

operated at a low enough power level to av oid exposing the rigger

to an unsafe RF level. For ref erence, see 29 CFR, Section 1910.97,

the OSHA standard for exposure to non-ionizing radiation.

To test and adjust VSWR safely, use low-power test equipment,

such as a network analyzer or an impedance bridge. If you don't

have access to low-power test equipment, please call Shive ly Labs

before proceeding.

WARNING

Whenever a rigger is on the tower in the area of the antenna,

shut off the transmitter signal and lock it off so that it cannot be

turned on accidentally.

Low-power test equipment should be used to prevent excessive radiation exposure to the person doing the adjusting.

Initial

Characterization

(recommended)

Step 1. Transmission

Line VSWR Reading

CAUTION

A high transmission line VSWR may indicate damaged transmission line and is likely to cause problems in the future, including

serious damage to your equipment.

Should any problems arise later with your antenna, it will be extremely

helpful to know what the system’s characteristics were when it was

new. We recommend you perform the tests in this section after installa

tion.

The first step is to characterize the transmission line by itself

a. Briefly disconnect the transmission line from the antenna system

input. Seal the antenna system input to prevent the entry of mois

ture.

b. Terminate the coax transmission line in an instrument-quality 50-

ohm load.

c. Measure and record the voltage standing wave ratio (VSWR). File

this information with this manual for future reference.

d. The VSWR of the transmission line should be within the man ufac-

turer's specifications. If it is, proceed. If not, you should call the

manufacturer before connecting the antenna. Problems must be

worked out with the design engineer on a case-by-case basis.

-

-

18

Pressurization and Startup

Step 2. Transmission

Line TDR Reading

Step 3. System VSWR

Reading

Step 4. Checking

Radiator Function

With the transmission line still terminated in 50 ohms, make a time

domain reflectometer (TDR) plot. Label and file the plot with this man

ual.

You tested the VSWR of the transmission line alone. Now test the

VSWR of the system as a whole.

a. Remove the load and connect the transmission line to the trans-

former input, with an O-ring to seal the connection.

b. Repeat the purge process after sealing the line, in accordance with

Purging the System on page 16.

c. Measure VSWR. VSWR at this point should be below 1.2 : 1.

d. Record the reading and file it with this manual.

If VSWR is not satisfactory, check to be sure all the radiators are func-

tioning (see below). If they are, call Shively Labs to help identify the

problem.

Again using the low-power test equipment to provide a signal to the

antenna and read VSWR, have the rigger detune each radiator in turn.

The simplest way to detune a radiator is to short across the "wings" or

dipole arms, for instance with a screwdriver or wrench.

-

Checkout

Each time, a deflection in VSWR should be apparent. The deflection for

various bays should be similar, but not necessarily identical.

If the VSWR of the array does not change when a radiator is detuned,

that bay is not functioning. Check to be sure the radiator was installed

properly, including the inner conductor connector.

If you cannot find the problem, please call Shively Labs before proceeding.

Before beginning checkout of the antenna system, be sure the following items have been done:

• The antenna system has been installed in accordance with this manual and the installation drawing.

• All radiators are operating and VSWR is within specification.

• The initial characterization data have been recorded.

• The system is gas-tight and purged.

Check the system out as follows:

a. Bring up RF power slowly and observe transmitter readings, stability,

and general operation.

b. Run at about half power for at least an hour, reading forward and

reflected power, stability, etc.

19

Pressurization and Startup

c. If the system is stable and seems to be operating properly, bring it

up to full power. Take initial readings, and repeat the readings peri

-

odically.

Performance readings should not change, and there should be no evidence of heating in the antenna system.

If any problem is found, fix it now. Call Shively Labs if you need help or

advice.

20

Operation

6 Operation

Precautions

The Antenna

The broadcast industry has recently recognized the potential medical

hazards of intense radio frequency radiation. Don't expose personnel to

personal harm. For reference, see CFR 29, Section 1910.97, the OSHA

standard for exposure to non-ionizing radiation.

WARNING

Whenever a rigger is on the tower in the area of the antenna,

shut off the transmitter and lock it off so that it cannot be turned

on accidentally.

CAUTION

Never operate the antenna system without proper purging and

constant positive dry gas pressure. Shively Labs will not accept

responsibility for antenna failure after operation without proper

purging or positive pressure of dry air or dry nitrogen.

Once the antenna has been installed and tested according to this manual, simply apply the transmitter signal. Don't exceed the rated power

capacity of the antenna.

To obtain the best performance and dependability from your Shively

Labs antenna, read and follow the "maintenance" section of this man

ual.

-

21

Troubleshooting

7 Troubleshooting

Precautions

WARNING

Troubleshooting should be performed only by personnel experienced in RF systems and familiar with this equipment.

WARNING

The broadcast industry has recently recognized the potential medical hazards of intense radio frequency radiation. Don't expose

personnel to personal harm. For reference, see CFR 29, Section

1910.97, the OSHA standard for exposure to non-ionizing radia

tion. Whenever a rigger is on the tower in the area of the

antenna, shut off the transmitter and lock it off so that it cannot

be turned on accidentally.

-

CAUTION

Whenever you have the system o pen for repair, you must purge it

again as described in

begin operating the system under power until you are sure all the

moisture has been purged from it. You can do permanent damage

to the entire system, including the transmitter.

Purging the System on page 16. Never

CAUTION

VSWR does not change of its own accord. If you find you must

repeatedly readjust the transformer to correct the VSWR, find and

correct the problem quickly. Otherwise, you will almost certainly

burn up your antenna and damage your transmitter. Look for the

cause in the following table.

Internal Arcing

Look for the cause of internal arcing in Table 4.

Table 4. Troubleshooting Internal Arcing

Possible Causes: Cures:

Physical damage to transmission

line, feedline, or radiators.Dam

age may have been caused by

ice, lightning, tower work, or

many other factors.

Damage may cause arcing

directly or by allowing water

inside the system.

Missing or misaligned O-ring, if

the system has been opened re

cently.

Loss of pressurization. Locate the leak. Re-purge in accor-

22

Locate the damage. Replace dam-

-

aged components.

Purge the system after repair, in

accordance with

tem on page 16.

Locate the O-ring leak, using soap

-

solution. Replace the O-ring if

damaged.

dance with Purging the System on

page 16 and restore pressurization.

Purging the Sys-

Troubleshooting

Broad Spectrum RF

Noise

High VSWR at

Startup or during

Operation

(may interfere with other

services on the tower)

This indicates that some metal components are not in good electrical

contact with the tower. First, check your antenna mounts, then other

tower components, to be sure that the tower paint has been scraped

away and that all mounting hardware is tight.

Any metal part in poor contact with the tower will constitute a non-linear junction and cast a broad-spectrum signal. This includes antennas,

transmission line, mounts, ladders, and other electrical components.

High VSWR (Voltage Standing Wave Ratio) is caused by any factor

which changes the impedance match between the transmitter and the

antenna system.

Look for the cause in Table 5.

Table 5. Troubleshooting High VSWR

Possible Causes: Cures:

Wrong antenna for the application

and frequency. Occasionally a cus

tomer provides wrong data to Shively

or buys a used antenna designed for

another application.

Contact your sales representa-

-

tive at Shively Labs.

Split bullet in the transmission line or

in the baymount (see

page 10). A split bullet is an inner

conductor connector misaligned such

that one or more of its contact arms

is stuck outside the conductor in

stead of inside. (A missing bullet will

cause infinite VSWR.)

Mismatched assembly of the antenna. The assembly must be exactly as

shown in the installation drawing.

Radiators out of sequence (especially

on a null-filled or half-wave-spaced

system).

Components of other services have

entered the RF field (later installa

tions or broken components).

Physical damage to the cables, power dividers, or radiators. This may be

from ice, lightning, tower work, or

any other source.

Figure 5 on

-

-

Replace the inner conductor

connector. It may also be nec

essary to replace the inner conductor section if it has been

damaged.

Reassemble according to the installation drawing.

Assemble the antenna exactly

as shown in the installation

drawing and as marked.

Remove broken components.

Rearrange tower components

as necessary to correct the

VSWR problem.

Replace damaged components.

-

23

Troubleshooting

Table 5. Troubleshooting High VSWR (continued)

Possible Causes: Cures:

Erratic VSWR

Change in Coverage

Paint has been applied to the radiators, possibly during a recent tower

painting.

If VSWR readings flucutate, then either there is residual water in the

system, or system components are damaged.

Follow this sequence of actions:

a. Repeat the purging process as described in Purging the System on

page 16.

b. Test impedance again.

c. If pu rging does not correct the si tuation, you may have liquid water

in your transmission line. Use a vacuum pump to dry the transmis

sion line. [A vacuum pump can be rented or borrowed from a refrigeration contractor.]

d. Hold as much vacuum as you can for 24 hours, then check VSWR

again.

e. If VSWR is still erratic, contact Shively Labs.

Changes in broadcast coverage may be caused by the same factors

that produce VSWR changes. If coverage seems to have changed, look

for VSWR changes and troubleshoot in accordance with

Startup or during Operation on page 23.

Remove the paint from the radiators.

-

High VSWR at

Pressure Loss or

Excessive Gas

Usage

It is important to recognize, however, that apparent changes in coverage may be due to subjective factors or faults of the receiving equipment. Before doing more than checking the VSWR, be sure that an

actual coverage change has occurred.

If your system will not hold pressure as described in Leak Testing on

page 14, look for the cause in Table 6.

Table 6. Troubleshooting Pressur e Loss or Excessive Gas Usage

Possible Causes: Cures:

O-ring missing or poorly installed

in transmission line, feedline, or

baymount flange.

Loose connecting hardware between components.

24

Find the leaky O-ring using soap

solution. Replace the O-ring.

Tighten loose connections when

found.

Troubleshooting

Table 6. Troubleshooting Pressure Loss or Excessive Gas Usage

Possible Causes: Cures:

Mechanical damage to cables,

power dividers, or radiators.

Check for leaks using soap solu

tion.

Replace damaged components.

-

25

Maintenance

8 Maintenance

Precautions

WARNING

Maintenance should be performed only by personnel experienced

in RF systems and familiar with this equipment.

WARNING

The broadcast industry has recently recognized the potential medical hazards of intense radio frequency radiation. Don't expose

personnel to personal harm. For reference, see CFR 29, Section

1910.97, the OSHA standard for exposure to non-ionizing radia

tion. Whenever a rigger is on the tower in the area of the

antenna, shut off the transmitter and lock it off so that it cannot

be turned on accidentally.

-

CAUTION

When you have had the system open for repair, you must purge it

again as described in

begin operating the system under power until you are sure all the

moisture has been purged from it. You can do permanent damage

to the entire system, including the transmitter.

Purging the System on page 16. Never

CAUTION

When removing or replacing radiators on the tower, never let the

weight of the radiator hang on the cable. This will damage the

connector and possibly the inner conductor. Support the weight of

the radiator until the mount bolts are tightened.

Maintenance Log

Physical Inspection

CAUTION

Do not use silicone grease on an O-ring, as this will soften the silicone O-ring. Use only a light lubricating coat of petroleum jelly

(provided); too much may hamper electrical contact and contami

nate the interior of the system.

Be sure the O-ring is properly seated in its groove and not

pinched between the flange contact surfaces.

Shively recommends that you keep a maintenance log; in it record performance parameters such as readings of VSWR.

Such a log can be invaluable in spotting and identifying problems. Sam-

ple Maintenance Log on page 28 shows a suggested log form you may

use if you like.

The antenna system should operate for years with no problem. However, any time you have a rigger up on the tower, it's a good idea to

have him check for general condition, looseness of components, and

electrical damage. During this inspection, all mounting, flange-connec

tion, and electrical hardware should be tightened.

-

-

26

Maintenance

Keep an eye on dry gas usage. A sudden increase in usage indicates a

leak in the system. Troubleshoot per

Chapter 7.

Paint

Troubleshooting

Return Po licy

The radiators should never be painted (a coating of paint affects

VSWR), and they need no surface protection, since they are made of

stainless. This includes Teflon or other "ice-prevention" coatings.

It is not necessary to paint the coax and power dividers, although no

harm will result from doing so.

Troubleshoot the antenna system as described in Chapter 7.

When returning any material to the factory, be sure to call your salesman and obtain an authorized return (AR) number first. Use this number in all correspondence. This number helps us to track your returned

item. It will expedite repair or replacement and prevent loss of your

material.

27

Maintenance

Sample

Maintenance Log

DATE VSWR GAS PRESS OBSERVATIONS

Visual Inspection of Antenna, Obstruction Lighting; Hard

ware Checked; Tower Repairs Accomplished; etc.

-

28

Loading...

Loading...