Einstart®-C User Manual

Add: NO.1398 XIANGBIN RD. WENYAN XIAOSHAN, HANGZHOU, 311258, CHINA Website:www.shining3d.com

www.3dker.cn

Einstart

®

-C

USER MANUAL

HANGZHOU SHINING3D TECH CO., LTD.

STOCK CODE:830978

Einstart®-C User Manual

CATALOG

1 Summary ................................................................................................................................................. 1

1.1 How to use the User Manual ......................................................................................................... 1

1.2 Attention ........................................................................................................................................ 1

1.3 Product Model ............................................................................................................................... 1

2 Product Introduction ................................................................................................................................ 2

2.1 Product Appearance ..................................................................................................................... 2

2.2 Device parameters and accessories ............................................................................................. 2

2.3 Sound illustration .......................................................................................................................... 2

3 Preparation .............................................................................................................................................. 3

3.1 Hardware Installation .................................................................................................................... 3

3.2 Software Installation and Serial Number Registration ................................................................... 3

4 Using the Printer ..................................................................................................................................... 6

4.1 Slicing ........................................................................................................................................... 6

4.2 Print .............................................................................................................................................. 8

5 Software .................................................................................................................................................. 9

5.1 A detailed look at the software interface ........................................................................................ 9

5.2 Software functions ...................................................................................................................... 10

5.3 Advanced Parameters ................................................................................................................ 12

5.4 Introduction of LED Screen Button and Its Logic ........................................................................ 13

6 3Dker Platform(Website address:http://www.3dker.com/) .............................................................. 22

6.1 Model Downloading .................................................................................................................... 22

6.2 Software and Firmware Down loading. ....................................................................................... 22

7 Maintenance ......................................................................................................................................... 23

7.1 Printer Working Environment ...................................................................................................... 23

7.2 Clean Up the Printing Environment ............................................................................................. 23

7.3 Changing the Filament ................................................................................................................ 23

7.4 Loading Filament ........................................................................................................................ 23

7.5 STL File ....................................................................................................................................... 23

Einstart®-C User Manual

7.6 Set the Print Bed ......................................................................................................................... 23

7.7 Sliding Rail .................................................................................................................................. 23

7.8 Consumable Parts List ................................................................................................................ 23

8 FAQ ....................................................................................................................................................... 24

8.1. The filament is blocked .............................................................................................................. 24

8.2. Extruder height adjustment ........................................................................................................ 24

8.3. Model won’t stick to the platform. ............................................................................................... 24

8.4. Nozzle is surrounded by filament ............................................................................................... 24

8.5. 3dStar software cannot connect to the 3D printer. ..................................................................... 25

8.6. Cannot read files on USB drive .................................................................................................. 25

8.7. The extruder is blocked, forming thin strands during printing or the model is dislocated. .......... 25

8.8. Limit switch malfunction ............................................................................................................. 25

8.9 USB drive cannot be detected。 ................................................................................................. 25

Appendix: .............................................................................................................................................. 26

Einstart®-C User Manual

1

Einstart®-C User Manual

1 Summary

1.1 How to use the User Manual

This User Manual is set out to explain the following; Product Introduction, Preparation, How to Use the

Printer, Software Operation & Help, 3Dker Platform, Maintenance and FAQ. Please read the manual carefully

before use and follow instructions when using the Einstart-C.

1.2 Attention

Please consider the following information before using the printer.

1.2.1 Safety

The printer is only compatible with the power supply offered by Hangzhou Shining 3D Tech Co., Ltd.

Using an alternative power supply may lead to safety risks and/or damage to the printer

The print head reaches temperatures of over 200°C. To minimize potential risk, keep the printer door

closed during operation of the printer. It is also advisable to keep the printer door closed to reduce any outside

airflow, which can affect print quality.

DO NOT touch the model, print nozzle, print bed and any other part inside the printer until fully cooled to

room temperature. Care must be taken during the removal of 3D printed parts.

Although considered safe, the printer sends out small concentrations of vapor during printing therefore

good ventilation is recommended.

1.2.2 Protection

Keep the printer away from water as this may damage the printer.

DO NOT cut off power supply or unplug the USB cable during printing as it may cause print failure.

The printer operates at a room temperature of 5℃ to 30 ℃. Print quality may be affected if the

temperature is not in this range.

Shining 3D has no responsibility for any damage caused to the printer through using print material or a

power supply not offered by Shining 3D.

1.3 Product Model

Einstart®-C Wifi International

Einstart®-C2 Wifi Domestic

Within this Manual, the model is noted as the Einstart®-C when describing common functions. Any notes

applying to the Einstart®-C2 will be made apparent.

Einstart®-C User Manual

2

2 Product Introduction

The Einstart®-C 3D printer is easy to operate and maintain. Its basic principle is that, upon digital input,

plastic is heated, melted and deposited to form the desired 3D model. The design is built up layer upon layer

with each successful layer turning solid to give a finished printed model that is sturdy and durable.

2.1 Product Appearance

Einstart®-C

2.2 Device parameters and accessories

See Appendix.

2.3 Sound illustration

The printer uses sound effects to give the user an indication of processes that are occurring e.g. Printer

start-up, filament loading etc.

Einstart®-C User Manual

3

3 Preparation

3.1 Hardware Installation

3.1.1 Remove the package

Unpack the inner and outer packaging and remove the cushioning foam. Use this manual and technical

drawings above to learn about accessories and set-up.

3.1.2 Print bed installation

Remove the print bed, open the printer door and fit it to the platform holder. Allow the magnet and

positioning block to cooperate and align with one another.

3.1.3 Install the Bowden Tube

Locate the transparent Bowden tube inside the printer and feed it through the central hole at the back of

the printer. Then insert it in to the extruder through the blue quick connector. The Bowden tube is easily

removed by pressing down on the quick connector and pulling the tube out.

3.1.4 Power Supply Connection

Start by connecting the adaptor to the cable plug. Once completed, insert the cable plug in to the mains

socket and connect the adaptor to the jack in the back right of the printer.

3.1.5 Turn On the Printer

Once the power supply is connected, press the switch on the right side of the printer to turn on. The LCD

screen display will indicate that the printer is turned on.

3.1.6 Filament Load

Remove the filament packaging and cut the end of the filament at an angle with pliers or scissors to create

a pointed tip. Place the filament reel on the filament holder located inside the printer on the right hand side.

Then feed the filament through the hole inside the printer and into the Bowden tube until it reaches the extruder.

Please refer to charter 5.4(11, 24, 25) for detailed operation.

Note: For better adhesion of the 3D print to the bed, we recommend a layer of masking tape or glue

stick on the print bed prior to print.

3.2 Software Installation and Serial Number Registration

The slicing software, 3dStar, supports several OS including WIN7 32bit/64bit, WIN8, WIN10 and Mac OS x.

The slicing software, serial port driver, serial number and selected model data can be found on the USB drive

provided. Please read the “Read Me” file and software user manual carefully before installing the software.

Einstart®-C User Manual

4

3.2.1 Software Installation and Registration for Windows OS.

3.2.1.1 Steps:

Open the file folder in the USB drive or download the installation software from our website. Find the

Setup.exe and run it. Click “Next” to enter the below interface and click “I Agree” after reading and accepting

the 3DPRINT END USER LICENSE AGREEMENT.

Choose the installation path you want by clicking “Browse” and click “Install”.

Upon Agreeing the license clause, click “Install” in the popup window. Complete the installation process by

Clicking “Finish”.

Einstart®-C User Manual

5

Note: If you’ve installed “Microsoft Visual C++ 2013”, just click “Repair” as below picture shows.

Install the FTDI CDM Drivers. Click “Extract” and operate according to the guidance given until installation

is complete.

Einstart®-C User Manual

6

4 Using the Printer

To obtain model data, please refer to charter 5.1 . There are also some 3D files available on the USB

drive provided.

4.1 Slicing

4.1.1 For slicing, open the 3dStar software and choose corresponding device model in “setting”,

“Application”. For this printer, you should choose E-c.

4.1.2 Choose the corresponding machine type. For this printer, you should choose E-C.Click the folder

icon to open and load an .stl file as the below picture demonstrates.

Einstart®-C User Manual

7

4.1.3 The 3dStar software allows users to view, move, rotate and scale their 3D model according to

requirements. To zoom in and out, use the scroll wheel on the mouse. To rotate around your model, left-click

and drag. To pan across your model, right-click and drag.

4.1.4 Click the settings icon on the top right of the screen to make any necessary adjustments to your 3D

model. See charter 5.1, 5.2 and 5.3 for detailed information on software and print settings. Click the generator

icon to generate path in .gsd format once you have confirmed your settings.

Einstart®-C User Manual

8

4.1.5 The sliced file is stored in the same folder as the original STL file. Copy the GSD file on to USB flash

drive.

Note: When saving your file, the file name should avoid special characters and contain English

characters and numbers only.

4.2 Print

4.2.1 For set-up, refer to section 3.1.

4.2.2 Refer to the below steps for print operation. For further detail on the LCD touch screen, please refer

to section 5.4

Einstart®-C User Manual

9

5 Software

5.1 A detailed look at the software interface

Model saving path: After 3dStar loads the model, you can see the model stored location in this area.

Additionally, the sliced data path for printing will be stored in the same location.

Menu:The menu of 3dStar contains File, Edit, View, Print, Tools and Help.

Model preview area:Check the model in this area after loading successfully.

Model edit area:View, move, rotate and scale up/down the model.

Fast print setting:In 3dStar, users can conveniently load file, generate path (parameters will be the same

as your previous print) and print after generating (only when printer is online).

Print parameter information: Check and edit the slicing parameters in detail.

Model advanced edit switch:Allows the user to switch display once the model is loaded successfully. Click

to switch to the advanced edit interface.

Model/Path viewer switch: Click the arrow on the right to open and check model and path information.

Einstart®-C User Manual

10

5.2 Software functions

N

o.

Positio

n in

Software

Legend

Submenu

Description

1

Menu-

File

New

Clear current model

Open…

Open local STL file

Add…

Add new model to current

Recent Files

Link to recently opened files

Save

Save current model

Save As

Save current model as other

position

Exit

Exit 3dStar

2

Menu-

Edit

Select All

Select all models

Copy

Copy selected model

Paste

Paste copied model

Delete

Delete selected model

Layout

Optimal layout for current

model

View

View model from different

Move

Move model from X,Y, or Z

direction

Rotate

Rotate model around X,Y, or

Z axis

Scale

Up/Down

Scale up or down the model

3

Menu-

Print

Start/Stop

Print

Start/Stop print. Print cannot

resume if stop

Pause/Resu

me Print

Pause or resume printing

Einstart®-C User Manual

11

Building

Status

Check the status of current

print

Generate

Path

Slice current model and

generate path

4

Menu-

Tool

Select

Select online machine

Machine

Calibration

Calibrate the machine

Firmware

Detect firmware update

Manager for

STL File

Manage local STL file

Manager for

Machine

Manage machine

Manager for

Material

Manage material

Path Viewer

View the generated path

Setting

Settings for generator and

machine

Language

Select language

5

Menu-

Help

Version

Check current software

About

More information

Einstart®-C User Manual

12

5.3 Advanced Parameters

5.3.1 Path Generator

The use of “basic setting” is normally sufficient. We suggest you generate path with our default parameters

since improper changes could lead to print failure or extruder blockage.

5.3.1.1 Print Mode

Simple: 0.4mm layer thickness;

Fast: 0.3mm layer thickness;

Standard: 0.3mm layer thickness;

Quality: 0.15mm layer thickness;

Extreme: 0.1mm layer thickness;

5.3.1.2 Support

Null Support: No support when generating path.

Outer Support: “Outer Support” creates support where the support structure is printed directly on the raft

or platform (when printing without raft).

Einstart®-C User Manual

13

Full Support:Both outer and inner support when generating path. “Inner Support” means support is

created on the model surface.

Add Raft: When generating path, the software will generate a raft for your model, which can secure the

model effectively and compensate height variance.

Thin-wall: When generating path, the software will create a shell structure rather than infill. It will also close

the bottom of the model but not the top.

Peel off Factor: Users can adjust the distance between model and raft by changing this factor. It is a ratio

related to layer thickness. For example, if layer thickness is 0.2 mm and peel off factor is 2, the distance

between the model and raft is 0.4 mm.

Extruder Temperature: Temperature the nozzle will reach when printing. We suggest you set this value

based on the requirement of the material used.

Print once generated: Once the path is generated and the machine is ready, the printer will automatically

begin printing.

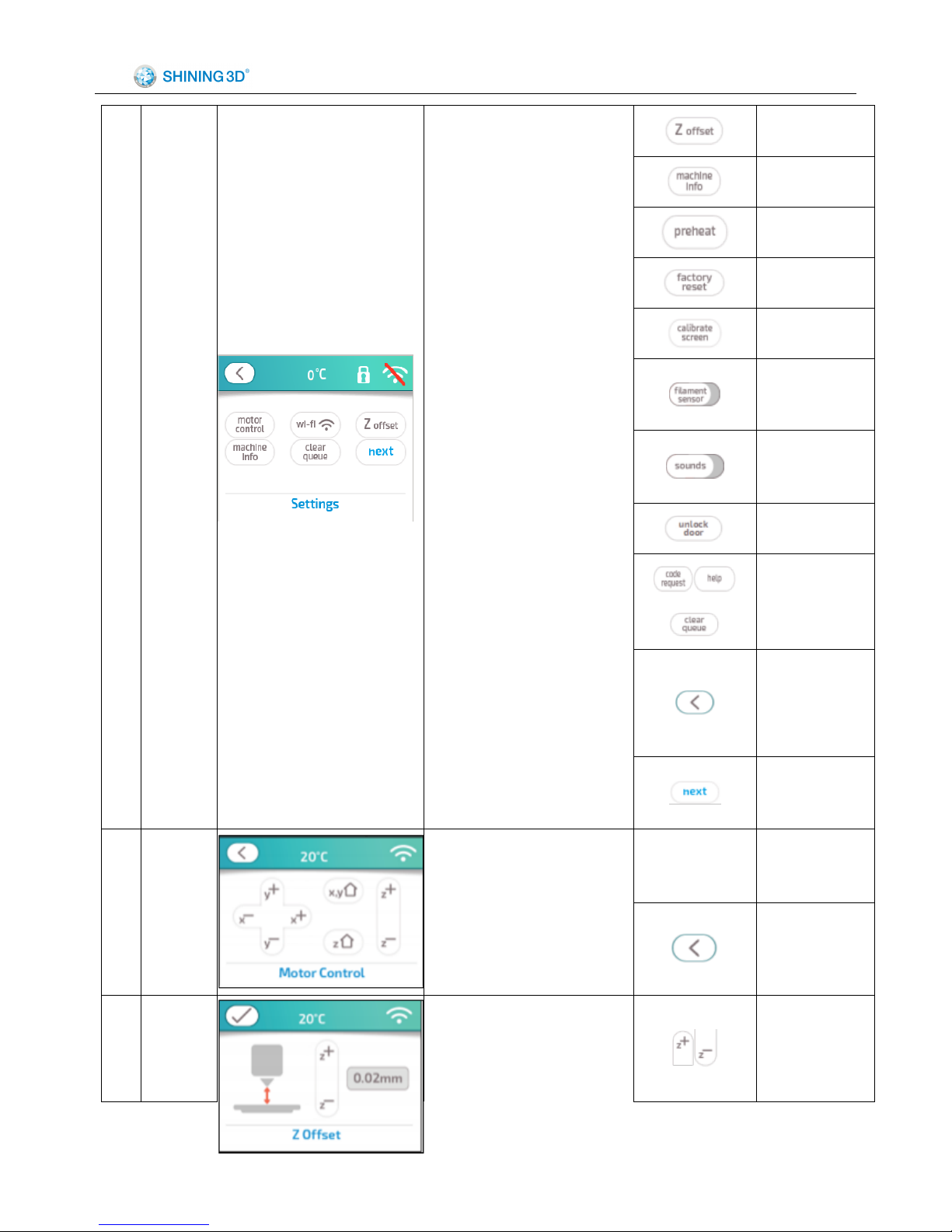

5.4 Introduction of LED Screen Button and Its Logic

No.

Interface

Pic.

Function

Button function

Logic

1

Choose

Language

language selection is

required during initial set up.

Language

Choosing

Skip to 2

2

WIFI

Connectio

n

Connect to WIFI or not.

Skip to 3

Skip to 11

Einstart®-C User Manual

14

3

WIFI

Checking

Searching for available

WIFI or trying to connect to the

WIFI used previously.

Skip

automatically

Skip to 4

4

WIFI List

A list of available WIFI is

generated. Scroll using the

arrows“

∧

” and “

∨

”.

Refresh the list

Skip to 11

5

Input WIFI

Password

Enter the password using

the keyboard.

Skip to 6 or 7

Skip to 4

6

WIFI

Connectio

n

succeeds

WIFI is connected

successfully.

Skip to 8

7

WIFI

Connectio

n fails

WIFI connection has

failed.

Skip to 5

Einstart®-C User Manual

15

8

Firmware

updates

The printer is checking

that the firmware is up to date.

Skip

automatically

Skip to 9

9

Updating

page

The printer updates

firmware automatically if it

detects updates are available.

DO NOT turn off the printer

during updating! restart will

occur automatically if updates

are successful.

Skip

automatically

Skip to 10

10

Welcome

Page

This is displayed once the

printer is prepared and ready

for use. Click any area on the

screen to skip to the home

page.

Any area

Skip to 11

11

HOME

Page

Home Page. You can

select any function button to

enter its interface.

Skip to 12

Skip to 24

Skip to 29

12

Printing

Selection

Select model source for

printing.

Skip to 13

Skip to 14 or 15

Einstart®-C User Manual

16

Local default

model

Skip to 11

13

Printing

Confirma--

tion

Select a model file for

printing.

Skip to 17 or 18

Skip to 24

Skip to 12

14

USB drive

file list

When the USB drive is

plugged in, this interface will

allow you to select a model

from the USB drive to print.

Select any model

in the list

Skip to 16

Skip to 12

15

USB

undetecte

d

If the USB drive is not

plugged in or cannot be

detected, this will be

displayed.

Skip to 12

16

Copying

File

Copying model file to the

device.

Finish copying

Skip to 13

Skip to 14

17

Leveling

print bed

After printing has begun,

this display can be seen

Skip

automatically

Skip to 18 or 19

Einstart®-C User Manual

17

during bed level checking.

Skip to 14

18

Printer

Heating

Up

Displayed during the print

head heating process.

Skip

automatically

Skip to 20

Skip to 14

19

Bed Error

If an error occurs during

bed auto leveling , this display

will be seen.

Skip to 17

22

Printing

Printing in process.

Pause current

printing

Skip to 23

Stop current

printing

Skip to 23

23

Stop current printing

confirmation.

Skip to 11

Skip to 22

24

Printing

Paused

Printing Paused display.

Various printing processes

can be managed at this stage.

Skip to 25

Skip to 12

Skip to 22

Einstart®-C User Manual

18

25

Filament

Managem

ent

Manage filament, you can

select to load or unload

filament here.

Skip to 26

Skip to 26

Skip to 11

26

Printer

Heating

Up

This display can be seen

during the print head heating

process.

Skip

automatically

Skip to 27 or 28

Skip to 25

27

Filament

loading

When the print head

reaches loading temperature,

this display indicates that you

can insert filament.

Skip to 25

28

Filament

Unloading

When the print head

reaches unloading

temperature, this display

indicates that the Printer is

reversing filament.

Skip

automatically

Skip to 29

29

Ready to

unload

Follow screen prompts for

loading of filament.

Skip to 25

30

Skip to 31

Skip to 14

Einstart®-C User Manual

19

Settings

Select Settings on the

HOME page to change

various parameters.

Skip to 32

Skip to 33

Skip to 34

Skip to 36

Skip to 37

Currently

Nonfictional

Mute or not

Unlock door

Currently

Nonfictional

Skip to last page

or 11

To next page

31

Motor

Control

Control the axial motor.

XYZ motor

control buttons

Control motor

Skip to 30

32

Print head

Offset

Change the print head

offset.

Increase or

decrease offset

Einstart®-C User Manual

20

Skip to 30

33

About

Printer

Firmware/software

version and total printing time.

Skip to 8

Skip to 30

34

Preheat A

Allows user to preheat.

Skip to 35

Skip to 30

35

Preheat B

Preheat temperature

setting.

Change target

temp

Save target

temp

Stop preheat

Skip to 34

36

Factory

Reset

Allows user to reset the

printer to default settings.

Reset to factory

setting

Skip to 30

Einstart®-C User Manual

21

37

Touch

screen

locate

Relocate touch screen

area.

Skip

automatically

Skip to 10

Einstart®-C User Manual

22

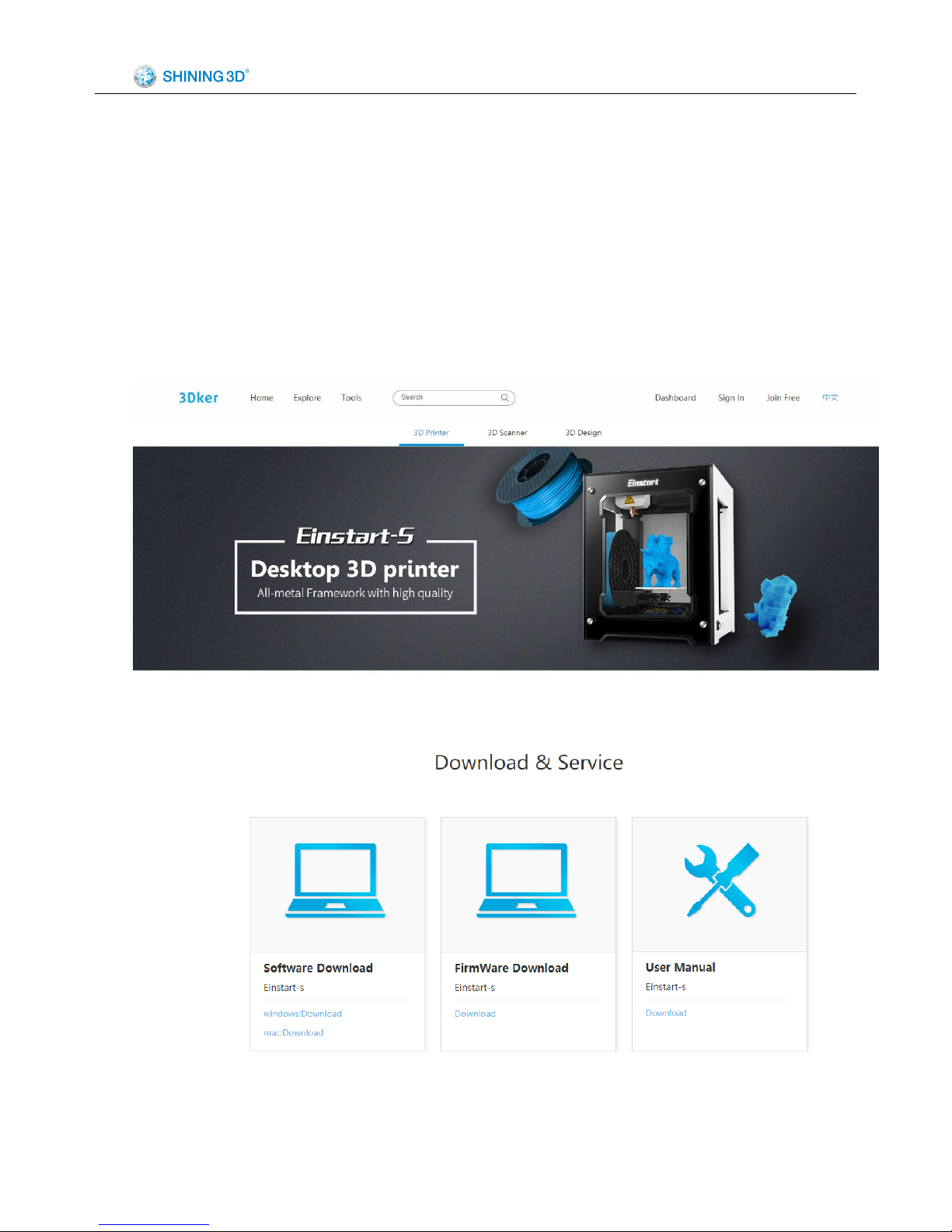

6 3Dker Platform(Website address:http://www.3dker.com/)

6.1 Model Downloading

Visit the 3Dker platform where you can find and download 3D model data designed by other users or

designers.

6.2 Software and Firmware Down loading.

Click “Tools” in the top menu to enter downloading page and select “3D printer”.

Scroll down the page and download the newest software, firmware and user manual on the below page.

Einstart®-C User Manual

23

7 Maintenance

7.1 Printer Working Environment

Make sure the printer is set on a stable flat surface. Do not interfere with moving parts during the printing

process.

Please hold the print bed securely when turning the printer off in the occurrence the bed drops with loss of

power.

7.2 Clean Up the Printing Environment

Dust may cause jamming on the sliding rail,which in turn may lead to poorer quality printing. We

recommend cleaning the Nozzle weekly. Follow instructions on our 3DKer website under “Maintenance”.

7.3 Changing the Filament

Filament should be changed when there is around 20 cm filament left or before using the unload

command.

7.4 Loading Filament

Make sure the print head reaches loading temperature before inserting filament. The tip of the filament

should be straight and sharp.

7.5 STL File

“3Dstar” slicing software supports STL format only.

7.6 Set the Print Bed

The print bed should be orientated and set correctly.

Make sure the print bed surface is flat and clean.

We recommend carrying out the auto levelling process regularly, particularly when printing often.

7.7 Sliding Rail

Lubricating grease should be add to the sliding rail annually.

7.8 Consumable Parts List

#

Parts photo

Parts name

Normal life cycle

1 Tube

3 months

2 Nozzle

3 months

3

Heat block

3 months

Einstart®-C User Manual

24

4 Heat rod

3 months

5 Thermistor

3 months

8 FAQ

8.1. The filament is blocked

Problem: A skipping sound is heard during printing or the loading of filament.

Solution: First, unload the filament and ensure the tip is even before reloading. If this does not solve the

problem, please take apart the extruder and clean.

8.2. Extruder height adjustment

Problem: During printing, either the first layer is not flat and wide but appears as a thin spiraled line or the

extruder touches the print bed.

Solution: If the distance between the print bed and head is more than 2mm, the extruder height needs to

be adjusted. (Refer to section 5.3.4).

8.3. Model won’t stick to the platform.

Problem: The edges of the model are warped or are becoming unstuck when printing.

Solution: Apply a thin layer of glue stick evenly on the platform. It is also worth considering a reduction in

strip rate or an increase in nozzle temperature (+-5~10℃).

Strip rate ranges from 1.8 to 2.6, a lower strip rate generally results in better adhesion.

Nozzle temperature ranges from 195℃ to 230℃ , a higher temperature generally results in better

adhesion.

8.4. Nozzle is surrounded by filament

Problem: The filament has gathered around the nozzle.

Solution: Remove the extruder cover and press the load button to heat the printer head. Remove the

cooling protective cover once the filament has softened. Finally, remove the filament using tweezers (Please

Einstart®-C User Manual

25

refer to the video or document instruction named “Clean nozzle”.).

Reason: The filament has failed to stick to the model or platform and as such has gathered round the

nozzle.

8.5. 3dStar software cannot connect to the 3D printer.

Problem: Error message indicating lack of connection to the printer or printer not registered.

Solution: Refer to section 6.1.2 and if the problem still exists, please contact support.

8.6. Cannot read files on USB drive

Problem: error message indicating no file in drive or no USB drive found.

Solution: The Einstart®-C is capable of reading .gsd files only,Make sure you have the right file format.

8.7. The extruder is blocked, forming thin strands during printing or the model is

dislocated.

Solution:

(1) Clean the filament and check whether the nozzle is blocked.

(2) Load filament again.

(3) Shut down the printer and check whether the X axis and Y axis move normally.

(4) Attempt to print the model again to determine if there are further problems.

Reason: (1) Poor quality filament may cause the extruder to become blocked.

(2)The nozzle is knocking in to the model causing dislocation

(3)The nozzle is blocked.

(4) The temperature sensor is broken.

(5)The cooling fan is not working.

8.8. Limit switch malfunction

Problem: A loud knocking noise may indicate the limit switch is broken.

Solution: Change limit switch (Refer to the video and document).

Reason: The limit switch may have been broken when cleaning residual filament or during transportation

of the printer

8.9 USB drive cannot be detected。

Problem: USB drive is not detected once plugged in to the printer

Solution: Restart the device or re-insert the USB drive. Make sure you are using a USB drive instead of

USB reader + SD card.

Einstart®-C User Manual

26

Appendix:

1. List of Product and Accessories

Einstart®-C

Einstart®-C 3d Printer

1 unit

Power Supply(Output 19V/4.95A)

1 PCS

USB cable

1 PCS

Bowden tube

1 PCS

3D printing Material

2 reels

Print bed

1 PCS

USB flash drive (4G)

1 PCS

Einstart®-C User Manual

27

Scraper

1 PCS

User manual

1 PCS

Handy tool

1 PCS

Einstart®-C User Manual

28

2. Parameter of the Printer

Einstart®-C User Manual

29

FCC Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

FCC Radiation Exposure Statement

This equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled environment. This

equipment should be installed and operated with a minimum distance of 20 centimeters between the radiator

and your body.

Einstart®-C User Manual

30

More information please join our WeChat by scanning below QR code

Company Desktop 3D printer department 3Dker

Hangzhou Shining3D Tech Co., Ltd.

Add: NO.1398 XIANGBIN RD. WENYAN

XIAOSHAN, HANGZHOU , 311258, P.R. CHINA

Zip code: 311258

Working time:8:30-17:30

Tel:0571-83821911

Tax:0571-82999510

Technical support:

QQ:1984522360

Skype: shining_support

e-mail:aftersales@shining3d.com

Website:http://www.shining3d.com

Einstart®-C User Manual

31

Copyright

This document is copyrighted and contains proprietary information that is the property of Hangzhou

Shining 3D Tech Co., Ltd. The user does not have the right to copy, reproduce, or translate this document in

any way or to any media without the prior written consent of Hangzhou Shining 3D Tech Co., Ltd.

Disclaimer

This user manual is an instruction for installation, operation, and maintenance, but not product warranty.

All efforts have been made to ensure the accuracy and completeness of the information in this manual.

However, Shining 3D Tech Co., Ltd accepts no responsibility for any errors or omissions contained in the

documentation and reserves the right to explain and revise the publishing and fault of this manual. The

information in this manual is subject to change without notice.

Loading...

Loading...