SICC-A Series

Air-cooled Central Water Chiller

Date: Apr, 2013

Version: Ver.B (English)

Contents

1. General Description..................................................................................9

1.1 Coding Principle.................................................................................10

1.2 Feature...............................................................................................10

1.3 Technical Specifications.....................................................................12

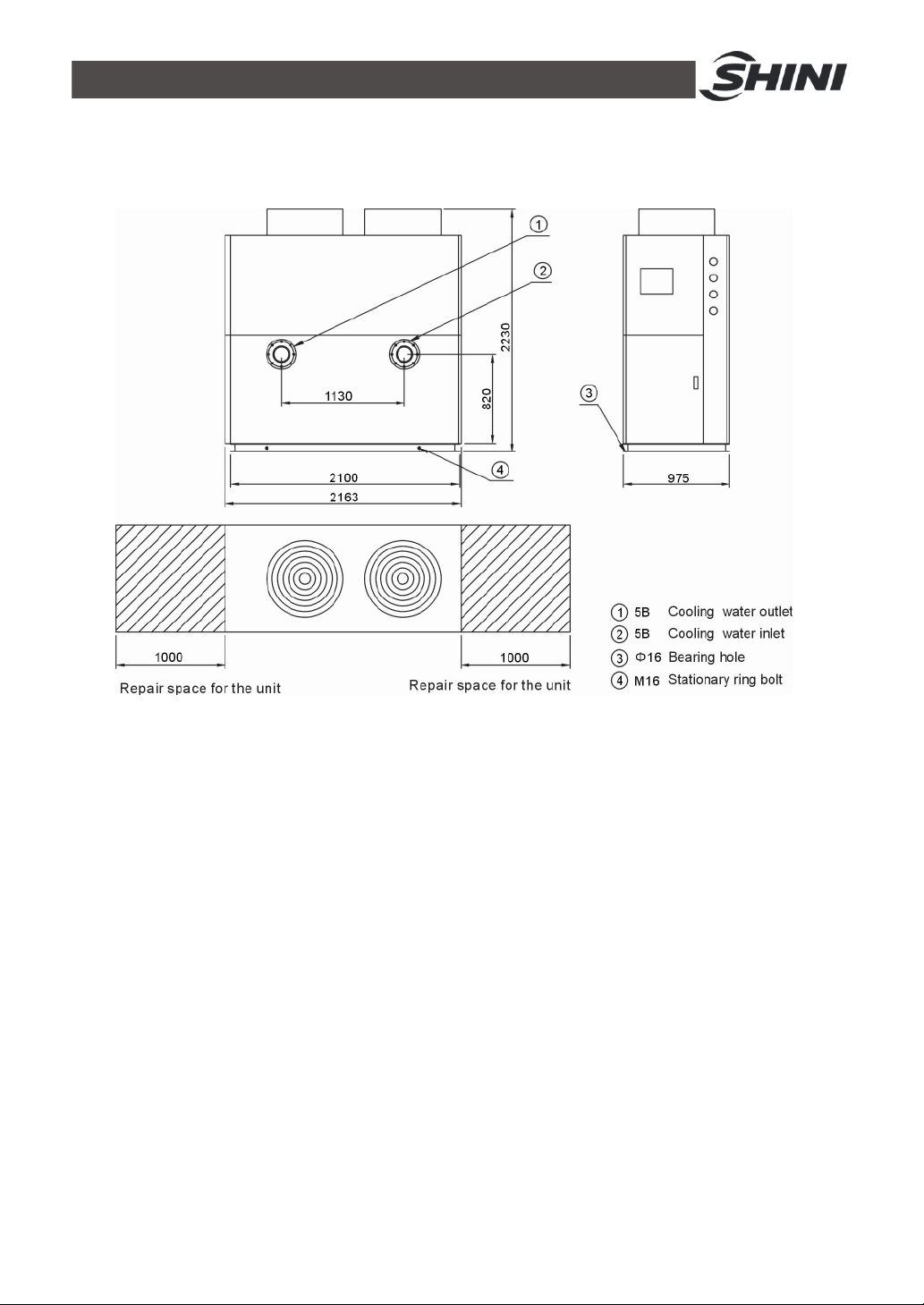

1.3.1 SICC-A Series Outline Dimensions.........................................12

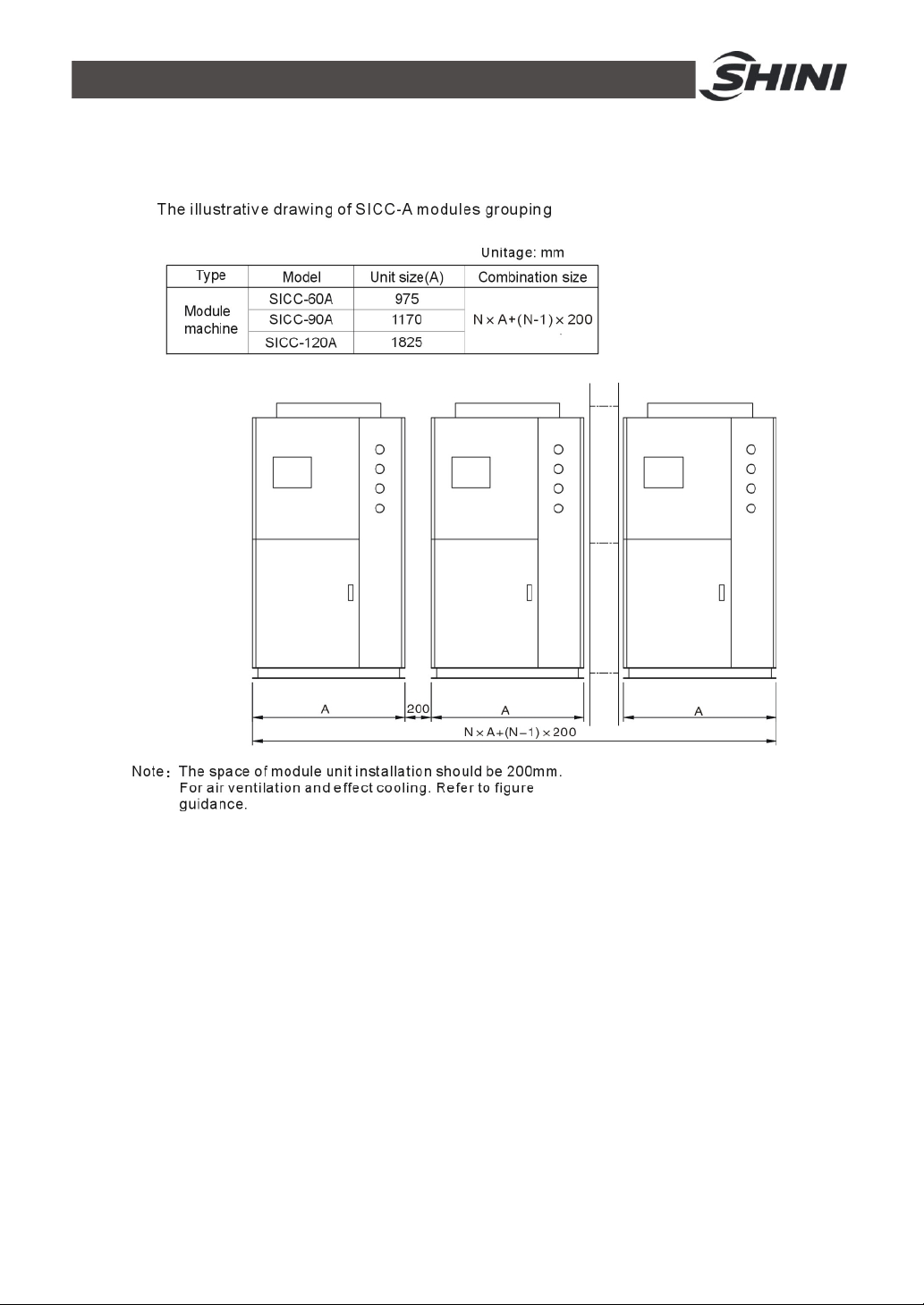

1.3.2 The Illustrative Drawing of SICC-A Modules Grouping............15

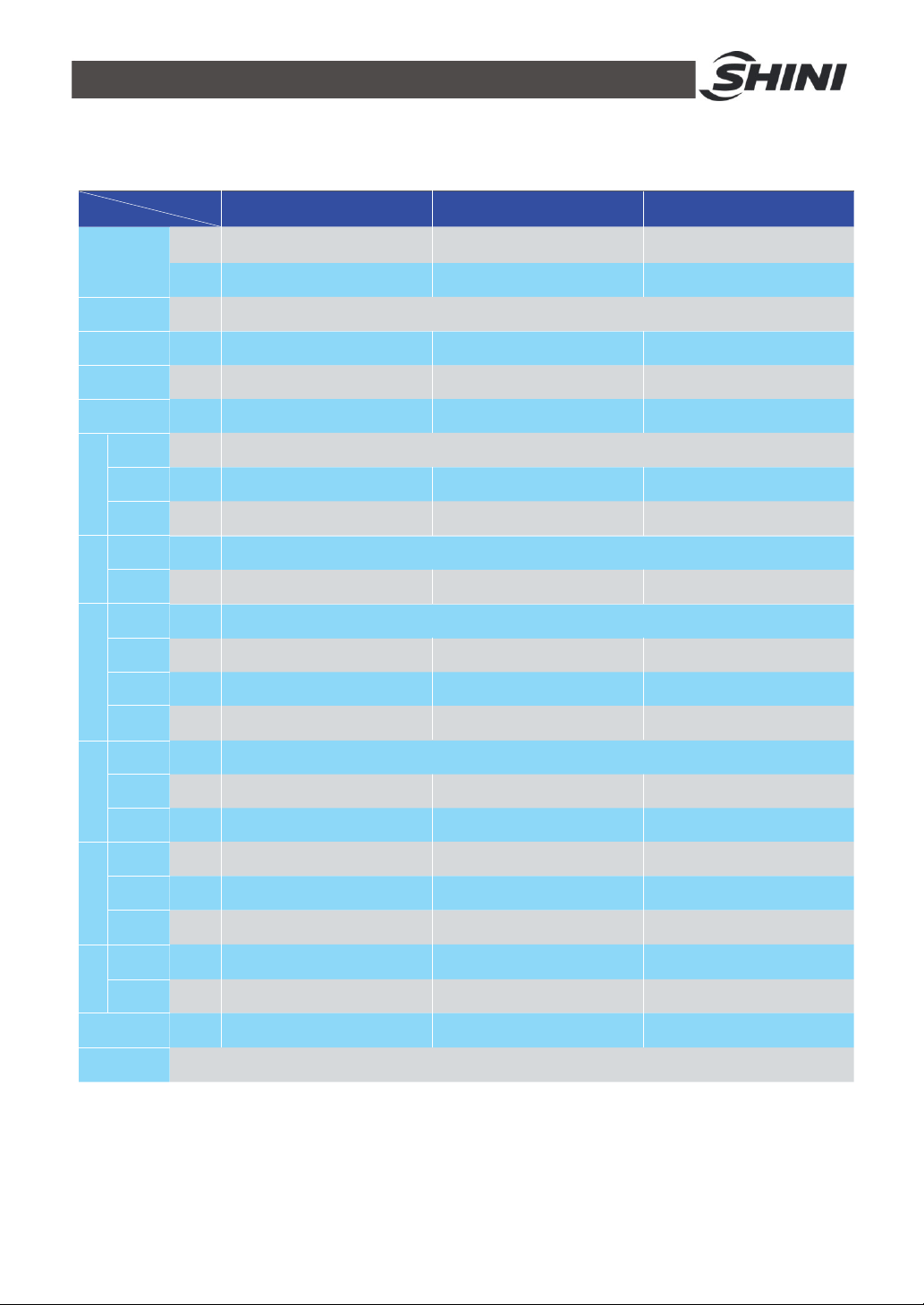

1.3.3 Specification............................................................................19

1.4 Safety Regulations.............................................................................20

1.4.1 Notice Items for Safe Operation..............................................20

1.4.2 Safety Signs and Labels..........................................................21

1.4.3 Signs and Labels.....................................................................21

1.5 Exemption Clause..............................................................................22

2. Structure Characteristics and Working Principle.................................23

2.1.1 Working Principle.....................................................................23

2.1.2 Working Flow Instruction.........................................................23

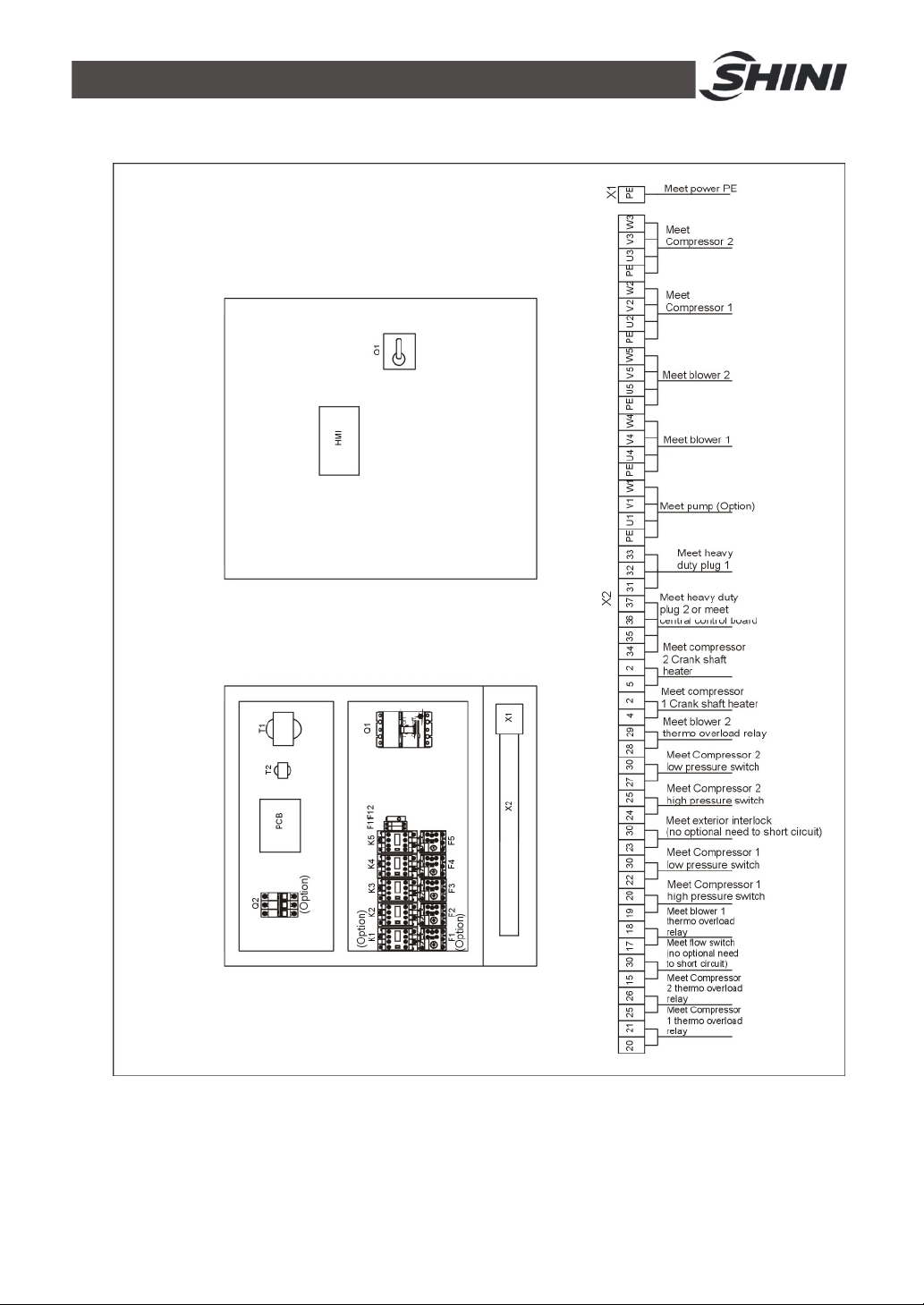

2.2 Electrical Diagram..............................................................................24

2.2.1 Main Circuit (SICC-60A)..........................................................24

2.2.2 Control Circuit (SICC-60A)......................................................25

2.2.3 Electrical Components Layout (SICC-60A)..............................26

2.2.4 Electrical Components List (SICC-60A)...................................27

2.2.5 Main Circuit (SICC-90A)..........................................................28

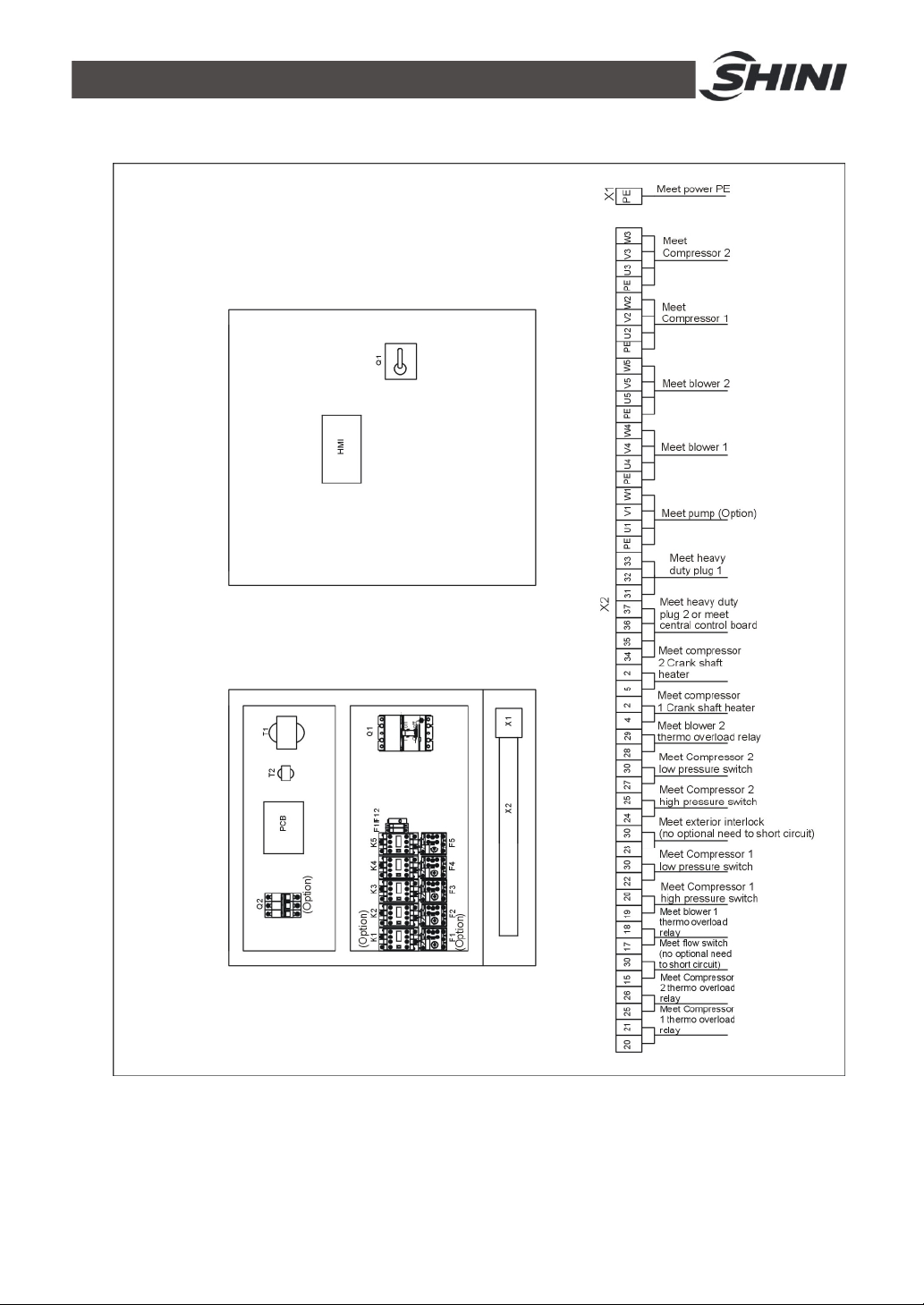

2.2.6 Control Circuit (SICC-90A)......................................................29

2.2.7 Electrical Components Layout (SICC-90A)..............................30

2.2.8 Electrical Components List (SICC-90A)...................................31

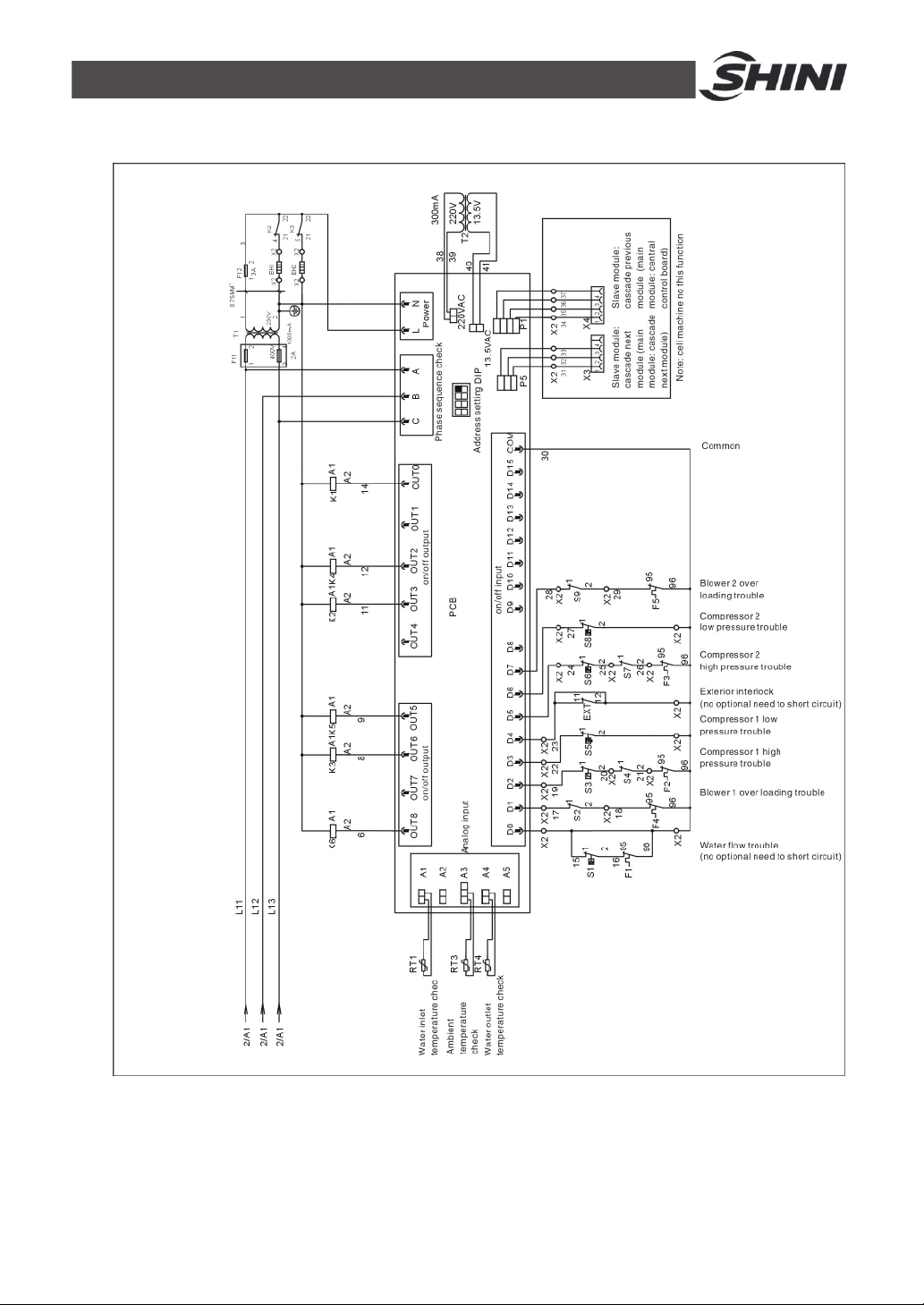

2.2.9 Main Circuit (SICC-120A)........................................................32

2.2.10 Control Circuit (SICC-120A)....................................................34

2.2.11 Electrical Components Layout (SICC-120A)............................35

2.2.12 Electrical Components List (SICC-120A).................................36

3. Installation and Debugging.....................................................................37

3.1 Installation Notice Items.....................................................................37

3.2 Select Installation Site........................................................................38

3(61)

3.3 Bearing Platform................................................................................39

3.4 Hanging and Transporting of the Unit................................................40

3.5 Water System Tubing.........................................................................41

3.6 Combined Installation of Modules......................................................43

3.7 Essentials for Electric Wiring..............................................................43

3.8 Power Connection..............................................................................44

4. Operation Guide......................................................................................45

4.1 Control Panel.....................................................................................45

4.2 The Make Up and Layers of the Display Interface.............................45

4.2.1 The Make up of the Display Interface......................................45

4.2.2 Interfaces Show.......................................................................45

4.3 Main Working Interface......................................................................46

4.3.1 Interface Demonstration..........................................................46

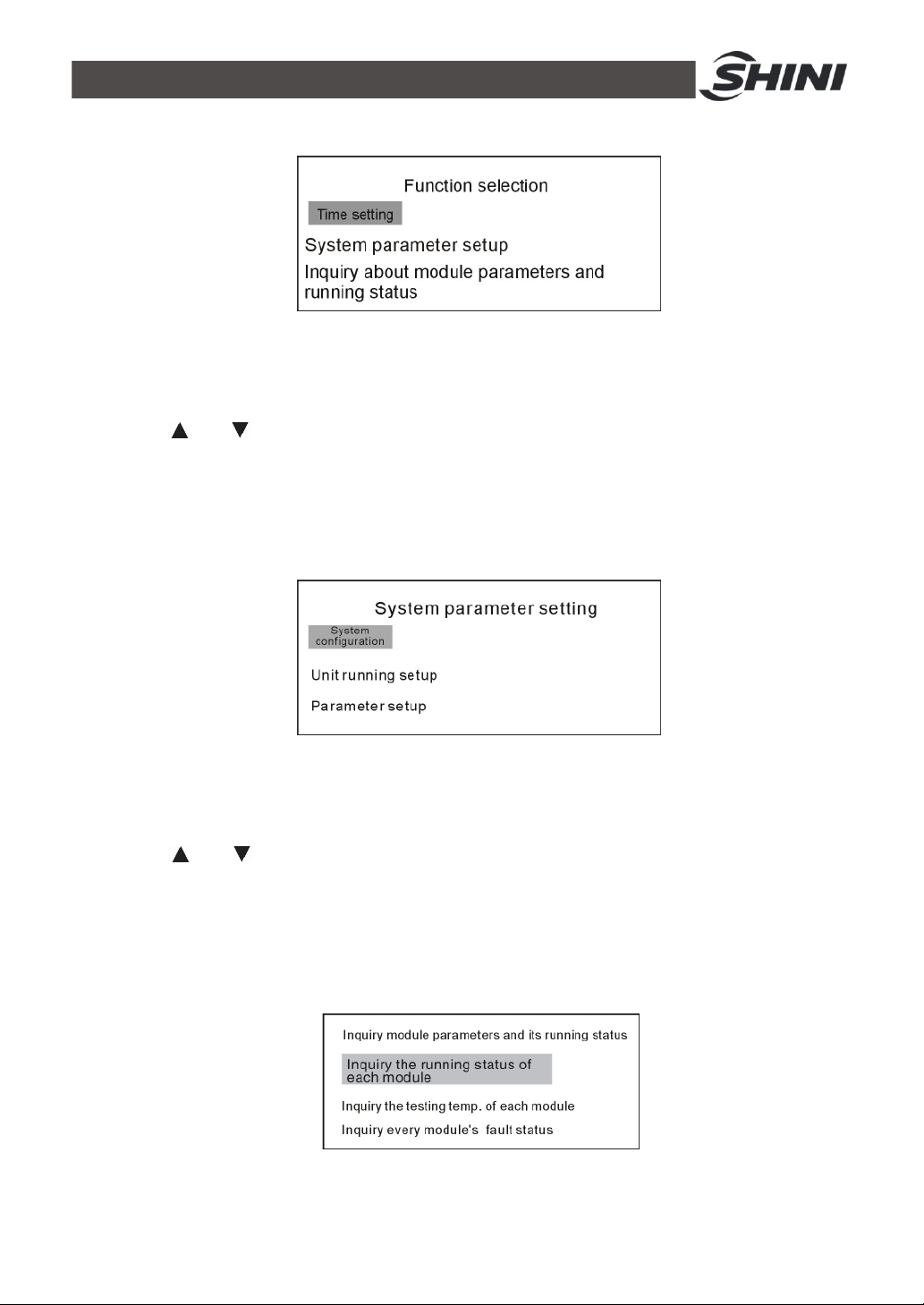

4.4 Selecting Interface of System Function..............................................46

4.4.1 Interface Demonstration..........................................................47

4.4.2 Interface Operation..................................................................47

4.5 System Parameter Setup Interface....................................................47

4.5.1 Interface Demonstration..........................................................47

4.5.2 Interface Operation..................................................................47

4.6 Inquiry Parameters of the Module......................................................47

4.6.1 Interface Demonstration..........................................................47

4.6.2 Interface Operation..................................................................48

4.7 System Time Setup............................................................................48

4.7.1 Interface Demonstration..........................................................48

4.7.2 Interface Operation..................................................................48

4.8 System Configuration.........................................................................48

4.8.1 Interface Demonstration..........................................................48

4.8.2 Interface Instruction.................................................................48

4.8.3 Interface Operation..................................................................49

4.9 Unit Running Settings........................................................................50

4.9.1 Interface Demonstration..........................................................50

4.9.2 Interface Operation..................................................................50

4.10 Parameter Setting..............................................................................50

4.10.1 Interface Demonstration..........................................................50

4(61)

4.10.2 Interface Operation..................................................................50

4.11 Unit Running Setup............................................................................51

4.11.1 Interface Demonstration 1.......................................................51

4.11.2 Interface Demonstration 2.......................................................51

4.11.3 Interface Instruction.................................................................51

4.11.4 Interface Operation..................................................................51

4.12 Inquiry Module Temperature..............................................................52

4.12.1 Interface Demonstration..........................................................52

4.12.2 Interface Instruction.................................................................52

4.12.3 Interface Operation..................................................................52

4.13 Inquiry Faults......................................................................................52

4.13.1 Interface Demonstration..........................................................52

4.13.2 Interface Instruction.................................................................53

4.14 The Configuration of Module Unit.......................................................53

5. Trouble-shooting.....................................................................................57

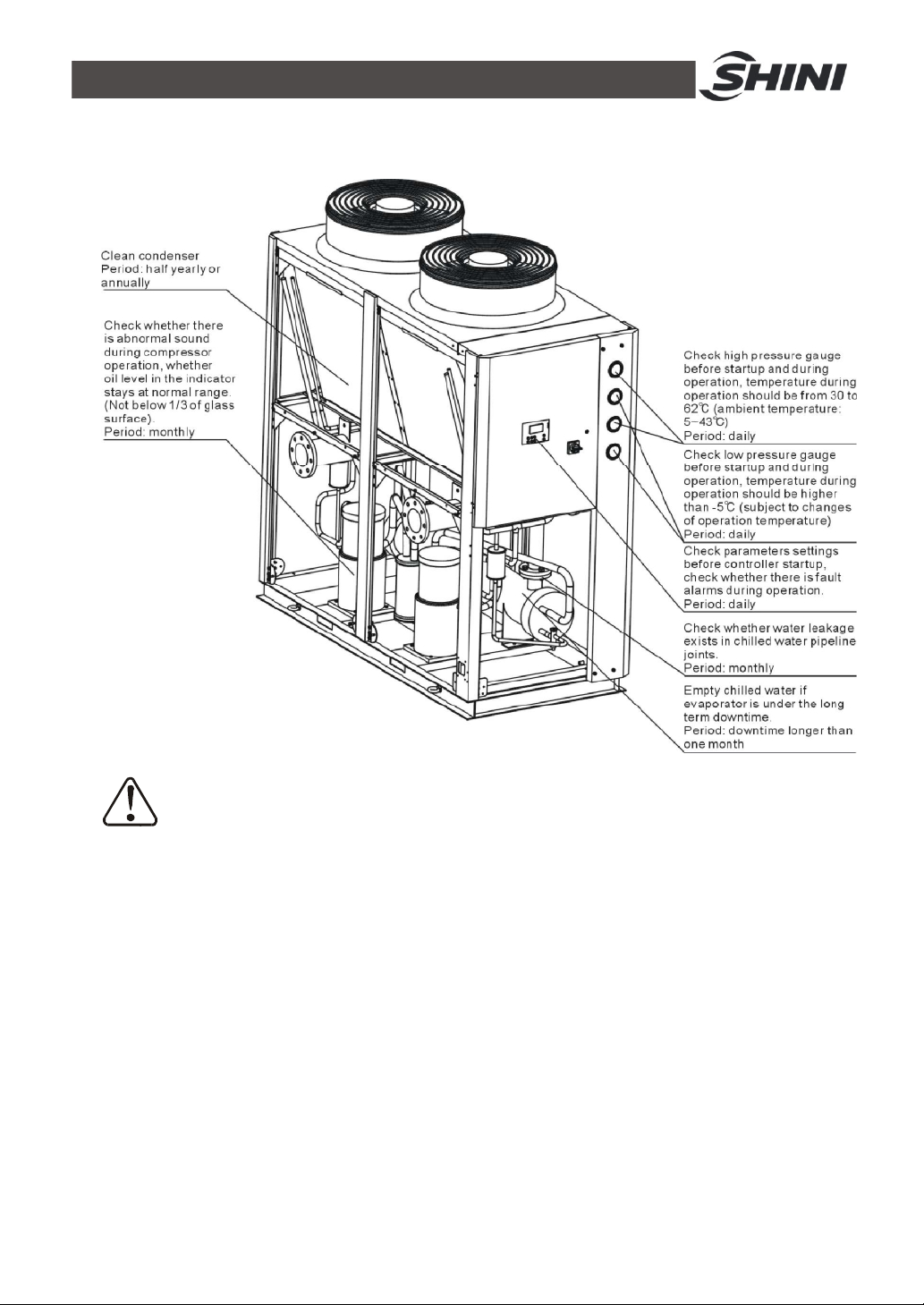

6. Maintenance and Repair.........................................................................58

6.1 Daily Repair and Check Items............................................................59

6.2 Monthly Periodical Checking Items....................................................59

6.3 Monthly Periodical Checking..............................................................59

6.4 Maintenance Schedule.......................................................................60

6.4.1 About the Machine...................................................................60

6.4.2 Installation & Inspection...........................................................60

6.4.3 Daily Checking.........................................................................60

6.4.4 Weekly Check..........................................................................60

6.4.5 Monthly Check.........................................................................60

6.4.6 Trimonthly Checking................................................................60

6.4.7 Check Half-yearly....................................................................61

6.4.8 Yearly Checking.......................................................................61

6.4.9 3 year Checking.......................................................................61

Table Index

Table 1-1:Specification...................................................................................19

Table 2-1:Electrical Components List (SICC-60A).........................................27

5(61)

Table 2-2:Electrical Components List (SICC-90A).........................................31

Table 2-3:Electrical Components List (SICC-120A).......................................36

Picture Index

Picture 1-1:Series Outline Dimensions (SICC-60A).......................................12

Picture 1-2:Series Outline Dimensions (SICC-90A).......................................13

Picture 1-3:Series Outline Dimensions (SICC-120A).....................................14

Picture 1-4:The Illustrative Drawing of SICC-A Modules Grouping................15

Picture 1-5:SICC-60A Refrigerating Performance Curves.............................16

Picture 1-6:SICC-90A Refrigerating Performance Curves.............................17

Picture 1-7:SICC-120A Refrigerating Performance Curves...........................18

Picture 2-1:Working Principle.........................................................................23

Picture 2-2:Main Circuit (SICC-60A)..............................................................24

Picture 2-3:Control Circuit (SICC-60A)...........................................................25

Picture 2-4:Electrical Components Layout (SICC-60A)..................................26

Picture 2-5:Main Circuit (SICC-90A)..............................................................28

Picture 2-6:Control Circuit (SICC-90A)...........................................................29

Picture 2-7:Electrical Components Layout (SICC-90A)..................................30

Picture 2-8:Main Circuit 1 (SICC-120A).........................................................32

Picture 2-9:Main Circuit 2 (SICC-120A).........................................................33

Picture 2-10:Control Circuit (SICC-120A).......................................................34

Picture 2-11:Electrical Components Layout (SICC-120A)..............................35

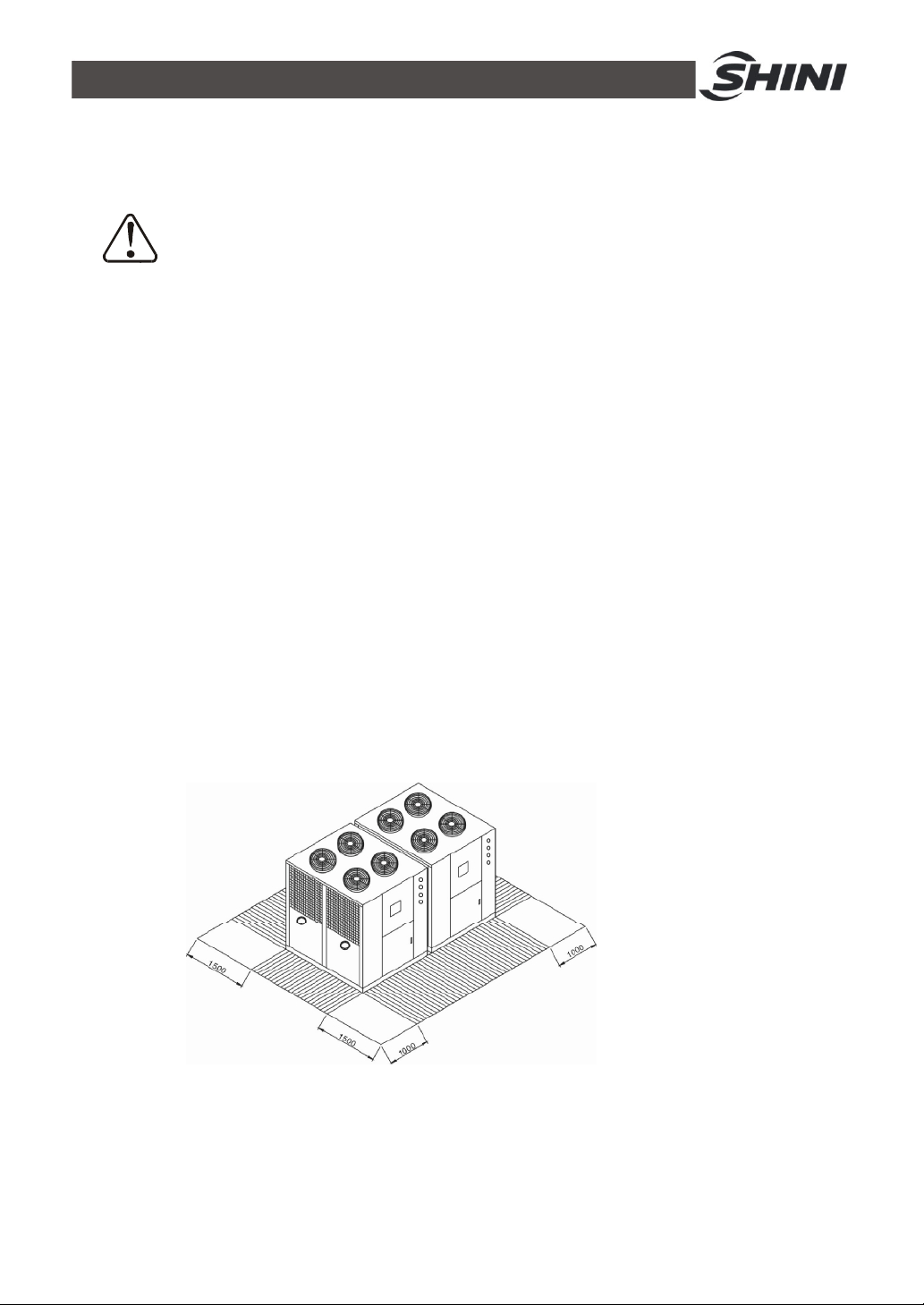

Picture 3-1:Installation Space........................................................................38

Picture 3-2:Platform Installation.....................................................................39

Picture 3-3:Hanging and Transporting of the Unit..........................................40

Picture 3-4:Same Direction Way 1.................................................................42

Picture 3-5:Same Direction Way 2.................................................................42

Picture 3-6:Combined Installation of Modules................................................43

Picture 3-7:Essentials for Electric Wiring.......................................................44

Picture 4-1:Control Panel...............................................................................45

Picture 4-2:Interfaces Show...........................................................................46

Picture 4-3:Main Working Interface................................................................46

Picture 4-4:Selecting Interface of System Function........................................47

6(61)

Picture 4-5:System Parameter Setup Interface..............................................47

Picture 4-6:Interface Demonstration...............................................................47

Picture 4-7:Interface Demonstration...............................................................48

Picture 4-8:System Configuration...................................................................48

Picture 4-9:Unit Running Settings..................................................................50

Picture 4-10:Parameter Setting......................................................................50

Picture 4-11:Unit Running Setup 1.................................................................51

Picture 4-12:Unit Running Setup 2.................................................................51

Picture 4-13:Inquiry Module Temperature......................................................52

Picture 4-14:Sub-interface 1..........................................................................52

Picture 4-15:Sub-interface 2..........................................................................53

Picture 4-16:Sub-interface 3..........................................................................53

7(61)

8(61)

1. General Description

Read this manual carefully before operation to prevent damage of the

machine or personal injuries.

SICC-A series are applicable for cooling moulds to reduce products molding cycle,

also they are available in the cooling of equipments in order to maintain a normal

temperature. Besides, they are suitable for other industries with the need of

cooling.

Model: SICC-90A

9(61)

1.1 Coding Principle

SICC-xxxA

-

xx

First Three Codes: Refrigerating Capacity (kW)

Note:

Refrigerant:

No code=R22 R1=R407C R2=R410A

A=Air Cooled

Shini Central Water Chillers

CE=CE Conformity

1.2 Feature

1) Standard configuration

● Modularized design makes it easier to combine module units 1 to 15.

Cooling capacity can be enlarged by increasing the number of modules or

choose appropriate modules to connect to existing system.

● The water route of the modules can be linked via linking one module to the

inlet/outlet water tube. No need to install the inlet/outlet water tube for each

module alone. The soft rubber tube is used to connect the modules, thus it is

very convenient to construct.

● Adopts imported components like scroll compressor, expansion valve which

ensure stable performance. The whole unit will not stop due to one module

failure.

● When the whole unit is running, the microcomputer will auto adjust the

performance of each module or open / shut respective module unit

according to system load. The module unit adopts double compressors and

its power adjustable range is enlarged after combination to save up power

whenever possible.

● Wired control system enables the main unit and its controller to be separated

from each other.

2) Accessory option

● Optional RS485 communication realizes the remote monitoring and network

function.

10(61)

All service work should be carried out by a person with technical training or

corresponding professional experience. The manual contains instructions for both

handling and servicing. Chapter 6, which contains service instructions intended for

service engineers. Other chapters contain instructions for the daily operator.

Any modifications of the machine must be approved by SHINI in order to avoid

personal injury and damage to machine. We shall not be liable for any damage

caused by unauthorized change of the machine.

Our company provides excellent after-sales service. Should you have any problem

during using the machine, please contact the company or the local vendor.

Headquarter and Taipei factory:

Tel: (886) 2 2680 9119

Shini Plastics Technologies (Dongguan), Inc:

Tel: (86) 769 8111 6600

Shini Plastics Technologies India Pvt.Ltd.:

Tel: (91) 250 3021 166

11(61)

1.3 Technical Specifications

1.3.1 SICC-A Series Outline Dimensions

Picture 1-1:Series Outline Dimensions (SICC-60A)

12(61)

Picture 1-2:Series Outline Dimensions (SICC-90A)

13(61)

Picture 1-3:Series Outline Dimensions (SICC-120A)

14(61)

1.3.2 The Illustrative Drawing of SICC-A Modules Grouping

Picture 1-4:The Illustrative Drawing of SICC-A Modules Grouping

15(61)

Picture 1-5:SICC-60A Refrigerating Performance Curves

16(61)

Picture 1-6:SICC-90A Refrigerating Performance Curves

17(61)

Picture 1-7:SICC-120A Refrigerating Performance Curves

18(61)

1.3.3 Specification

Table 1-1:Specification

Items

Refrigeration

Capacity

Power

Total Power

Running

Current

Startup Current

Type

Power

Crank Case

CompressorRefrigerantEvaporatorCondenser

Heater

Type

Filling

Quantity

Type

Cooling

Flow

Pressure

Loss

Water

Coupler

Type

Blower

Power

Air

Quantity

Width (W)

Model

kW

kcal/hr

---

kW

A

A

---

kW

kW

---

kg

---

m3/hr

kPa

inch

---

kW

m3/hr

mm

SICC-60A

60

51,600

19

33

140

8.5 × 2

0.07 × 2

15

10.3

27

5

1.68

26,000

2163

SICC-90A

90

77,400

3Φ, 400 / 460VAC, 50 / 60Hz

28

48

175

Hermetic Scroll

13.6 × 2

0.07 × 2

R22 ( R407C Optionaly Available )

18

Closed Shell and Tube Evaporator

15.5

39.2

5

Tube-fin Air-cooled Condenser

1.68

39,000

2163

SICC-120A

120

103,200

37

61

230

18.8 × 2

0.09 × 2

36

20.6

49

5

3.72

52,000

2163

Depth (D)

Machine

Dimensions

Height (H)

Before

Packing

After

Weight

Packed

Noise Level

dB(A)

Measures

Exchange

mm

mm

kg

kg

dB(A)

975

2230

720

760

71

1 kW = 860 kcal/hr 1 RT = 3,024 kcal/hr 10,000 Btu/hr = 2,520 kcal/hr

1170

2230

820

870

72

1825

2230

1300

1350

74

Note: 1) The cooling power refers to the following conditions: We reserve the right to change

outdoor dry bulb temperature 35℃, temperature at specifications without prior notice.

cooling water inlet is 12℃ and 7℃ at its outlet.

2) Change to use R407C environment friendly refrigerant

is available as option, but the refrigeration capacity can

be decreased by 5%.

19(61)

1.4 Safety Regulations

Strictly abide by the following safety regulations to prevent damage of the

machine or personal injuries.

1.4.1 Notice Items for Safe Operation

Read the following regulations before installation or using under the

consideration of safety.

1) Do not drop water in the electrical part to avoid insulation damage.

2) Put device connect to ground according to electrician operating regulation to

avoid creepage.

3) Any tubes or electrical device mount on air conditioner must be installed by

professional technicians.

4) Please install units in flat and ventilative place and keep suitable distances.

5) Keep away from fire source,such as water heater.gas and electric stove.

6) Avoid being exposed to weather.

7) Construct according to installation instructions and notice.

8) This type of air-conditioner is designed for adults. Keep children away from it.

9) Any deeds trying to change its specification are dangerous.

10) Don't use evaporable solvents, oil or toluene to avoid accidents.

11) Ensure this machine not to press on the electrical wires to avoid creepage

and burning.

12) Do not touch the machine with wet hands in case of accident.

13) Under no circumstances should you try to repair the water chiller. Because

the untrained may cause greater damages or failures. Please inquire local

service agents.

14) Do not pour water or detergent on the surface of machine when cleaning it.

Please wipe it with cloth or neutral detergent.

15) Do not place things on the upper surface of the water chiller inorder to avoid

danger during running.

16) Connect the water chiller to special electricity supply. It is forbidden to share

circuit with other devices.

17) Do not change or repair the electrical wires without authority.

18) Do not insert anything into air outlet of the water chiller to avoid damage or

danger.

20(61)

1.4.2 Safety Signs and Labels

The installation of electrical devices should be conducted by professional

electricians.

During repairing and maintenance, must turn off the main switch and

control switch.

Warning!

High Voltage danger!

Put up this symbol in the shell of the electric cabinet.

Warning!

Be careful! this symbol stands that take careful hereby!

Attention!

No need for regular inspection because all the electrical parts in the

control unit are fixed tightly!

1.4.3 Signs and Labels

This is for indicating motor rotating

direction.

When phase reversal happens, the alarm

sounds and indicator on control panel will

indicate. Please exchange the place of

the two electrical wires to solve this

problem.

Water outlet: drainage outlet/ cooling

water outlet.

Water inlet: replenish water for machine/

cooling water inlet.

21(61)

Drainage port: water outlet of water

system.

1.5 Exemption Clause

The following statements clarify the responsibilities and regulations born by any

buyer or user who purchases products and accessories from Shini (including

employees and agents).

Shini is exempted from liability for any costs, fees, claims and losses caused by

reasons below:

1. Any careless or man-made installations, operation and maintenances upon

machines without referring to the Manual prior to machine using.

2. Any incidents beyond human reasonable controls, which include man-made

vicious or deliberate damages or abnormal power, and machine faults caused

by irresistible natural disasters including fire, flood, storm and earthquake.

3. Any operational actions that are not authorized by Shini upon machine,

including adding or replacing accessories, dismantling, delivering or repairing.

4. Employing consumables or oil media that are not appointed by Shini.

22(61)

2. Structure Characteristics and Working Principle

2.1.1 Working Principle

Picture 2-1:Working Principle

2.1.2 Working Flow Instruction

Cooling circulation:The high temp. high pressure air from compressor's high

pressure spraying outlet comes into fin type air side heat exchanger, which as a

condenser to cool down the air into liquid. Then it comes into expansion valve

after filtration. There, after a pressure downfall, comes into shell and tube type

evaporator. The low temp.low pressure and satuated refrigerant absorbs the

heat from cooling water so to low down its temp.. The state of the shell and tube

type evaporator's refrigerant outlet are low temp.. Low pressure air, which then

comes to air and liquid separator to separate air and liquid. Thereafter, the air

comes to compressor's low pressure air suction inlet to get compressed. The

high pressure spraying outlet(compressor)→condenser(air side heat

exchanger)→filter→expansion valve→evaporator (water side heat exchanger)

→air and liquid separator→the low pressure air suction inlet.

23(61)

2.2 Electrical Diagram

2.2.1 Main Circuit (SICC-60A)

Picture 2-2:Main Circuit (SICC-60A)

24(61)

2.2.2 Control Circuit (SICC-60A)

Picture 2-3:Control Circuit (SICC-60A)

25(61)

2.2.3 Electrical Components Layout (SICC-60A)

Picture 2-4:Electrical Components Layout (SICC-60A)

26(61)

2.2.4 Electrical Components List (SICC-60A)

Table 2-1:Electrical Components List (SICC-60A)

NO. Symbol Name Specification Part NO.

1 Q1

2 Q2 Circuit breaker

3 K1 Contactor

4 K2 K3 Contactor 230VAC 50Hz YE00331100000

5 K4 K5 Contactor 230VAC 50Hz YE00300000000

6 T1 Transformer IN=400V OUT=230V 1000mA YE70402300000

7 T2 Transformer IN=230V OUT=12V 3VA YE70015300000

8 F1 Overload relay

9 F2 F3 Overload relay 12.5~20A YE01125200100

10 F4 F5 Overload relay 1.25~2A YE01125200000

11 F11 Fuse box 500V 32A 2P YE41032200000

12 - Fuse 2A 18×30 500V YE46002000100

13 F12 Fuse 2A YE41001000000

14 PCB Control board 230VAC 50/60Hz M-02

15 HMI Hmi 230VAC 50/60Hz M-02

16 X1 Terminal board 660V 112A YE61103500000

17 X2 Terminal board 660V 41A YE61040000000

18 - Terminal board - YE61043500000

19 - Terminal board 660V 24A YE61250000000

20 - Terminal board - YE61253500000

21 - Terminal board 660V 24A YE61250000000

22 - Terminal board - YE61253500000

23 X3 X4

24 -

25 M1 Pump motor 400V 50Hz -

26 M2 M3 Compressor 400V 50/60Hz 8.5kW -

27 M4 M5 Fan motor 400V 50/60Hz 0.7kW -

28 EH1 EH2

Circuit breaker 90A YE41109000000

Heavy duty plug

Heavy duty plug

Compressor crankcase

heater

(Optional ) model selection with

pump power

(Optional ) model selection with

pump power

(optional ) model selection with

pump power

4P YE68041000100

Accessories: shipment with

- -

YE68041000000

-

-

-

* means possible broken parts.

** means easy broken part. and spare backup is suggested.

Please confirm the version of manual before placing the purchase order to guarantee that

the item number of the spare part is in accordance with the real object.

27(61)

2.2.5 Main Circuit (SICC-90A)

Picture 2-5:Main Circuit (SICC-90A)

28(61)

2.2.6 Control Circuit (SICC-90A)

Picture 2-6:Control Circuit (SICC-90A)

29(61)

2.2.7 Electrical Components Layout (SICC-90A)

Picture 2-7:Electrical Components Layout (SICC-90A)

30(61)

2.2.8 Electrical Components List (SICC-90A)

Table 2-2:Electrical Components List (SICC-90A)

NO. Symbol Name Specification Part NO.

1 Q1

2 Q2 Circuit breaker

3 K1 Contactor

4 K2 K3 Contactor 230VAC 50Hz YE00331100000

5 K4 K5 Contactor 230VAC 50Hz YE00300000000

6 T1 Transformer IN=400V OUT=230V 1000mA YE70402300000

7 T2 Transformer IN=230V OUT=12V 3VA YE70015300000

8 F1 Overload relay

9 F2 F3 Overload relay 25~36A YE01253600200

10 F4 F5 Overload relay 2~3.2A YE01023200000

11 F11 Fuse box 500V 32A 2P YE41032200000

12 - Fuse 2A 18×30 500V YE46002000100

13 F12 Fuse 2A YE41001000000

14 PCB Control board 230VAC 50/60Hz M-02

15 HMI Hmi 230VAC 50/60Hz M-02

16 X1 Terminal board 660V 112A YE61163500000

17 X2 Terminal board 660V 41A YE61060000000

18 - Terminal board - YE61063500000

19 - Terminal board 660V 24A YE61250000000

20 - Terminal board - YE61253500000

21 - Terminal board 660V 24A YE61250000000

22 - Terminal board - YE61253500000

23 X3 X4

24 -

25 M1 Pump motor 400V 50Hz -

26 M2 M3 Compressor 400V 50/60Hz 13.4kW -

27 M4 M5 Fan motor 400V 50/60Hz 1.04kW -

28 EH1 EH2

Circuit breaker 90A YE41109000000

Heavy duty plug

Heavy duty plug

Compressor crankcase

heater

(optional) model selection with

pump power

(optional) model selection with

pump power

(optional) model selection with

pump power

4P YE68041000100

Accessories: shipment with

- -

YE68041000000

-

-

-

* means possible broken parts.

** means easy broken part. and spare backup is suggested.

Please confirm the version of manual before placing the purchase order to guarantee that

the item number of the spare part is in accordance with the real object.

31(61)

2.2.9 Main Circuit (SICC-120A)

Picture 2-8:Main Circuit 1 (SICC-120A)

32(61)

Picture 2-9:Main Circuit 2 (SICC-120A)

33(61)

2.2.10 Control Circuit (SICC-120A)

Picture 2-10:Control Circuit (SICC-120A)

34(61)

2.2.11 Electrical Components Layout (SICC-120A)

Picture 2-11:Electrical Components Layout (SICC-120A)

35(61)

2.2.12 Electrical Components List (SICC-120A)

Table 2-3:Electrical Components List (SICC-120A)

NO. Symbol Name Specification Part NO.

1 Q1

2 Q2 Circuit breaker

3 K1 Contactor

4 K2 K3 Contactor 230VAC 50Hz YE00331100000

5 K4 K5 Contactor 230VAC 50Hz YE00300000000

6 T1 Transformer IN=400V OUT=230V 1000mA YE70402300000

7 T2 Transformer IN=230V OUT=12V 3VA YE70015300000

8 F1 Overload relay

9 F2 F3 Overload relay 32~40A YE01125200100

10 F4 F5 Overload relay 1.25~2A YE01125200000

11 F11 Fuse box 500V 32A 2P YE41032200000

12 - Fuse 2A 18×30 500V YE46002000100

13 F12 Fuse 2A YE41001000000

14 PCB Control board 230VAC 50/60Hz M-02

15 HMI Hmi 230VAC 50/60Hz M-02

16 X1 Terminal board 660V 41A YE61163500000

17 X2 Terminal board 660V 41A YE61100000000

18 - Terminal board - YE61103500000

19 - Terminal board 660V 24A YE61250000000

20 - Terminal board - YE61253500000

21 X3 X4

22 - Heavy duty plug

Circuit breaker 120A YE41161600000

Heavy duty plug

(optional ) model selection with

pump power

(optional ) model selection with

pump power

(optional ) model selection with

pump power

4P YE68041000100

Accessories: shipment with

manual

YE68041000000

-

-

-

23 M1 Pump motor 400V 50Hz -

24 M2 M3 Compressor 400V 50/60Hz 18.78kW -

25 M4 M5 Fan motor 400V 50/60Hz 0.7kW -

26 EH1 EH2

Compressor

Crankcase Heater

- -

* means possible broken parts.

** means easy broken part. and spare backup is suggested.

Please confirm the version of manual before placing the purchase order to guarantee that

the item number of the spare part is in accordance with the real object.

36(61)

3. Installation and Debugging

Please read this chapter carefully before installation, and you must

install the machine according to the following procedures!

Before installation, please read this chapter carefully and install according to the

procedures as follows!

Install the water chiller near windows or places with good air flowing because

air-cooled central water chiller needs a good heat-releasing condition. If the

water chiller is installed inside the factory, then the surrounding temperature

should not be higher than 35 centigrade and there must have fans to make

air-flow flow fluently or air tube piping the hot air produced by water chiller

outside. If the water chiller is installed outdoor, a veil is needed to cover the top

of the chiller.

3.1 Installation Notice Items

1) Make sure that voltage of electricity matches with the nameplate.

2) Connect the electricity wire and earth wire according to local regulations.

3) Use independent electricity wire and power switch .The diameter of the wire

should not be less than that of electric cabinet’s wire.

4) The end of the electricity wire should be safe and firm.

5) There-phase electricity and five wires are utilized. Connect the power to live

wire, (N) to zero wire and (G) to ground wire.

6) Electric Power distribution demand .Main power voltage: ±10% Main power

frequency: ±2%.

7) Install pipe work system according to scheme of wiring. Protect water chilling

pipes with hear-insulating materials.

8) Make sure that the diameter of the recycling pump pipeline not less than that

of condenser’s connection tube. (Install the inlet or outlet pipeline system

according to the drawing of the assembly line)Large-diameter tube should be

used to connect to cooling water for long-range transmission.

9) The very top of the cooling water recycling loop system must be configured

with self-discharging valve, the lowest with drain valve.

10) Install filter in the cooling water recycing loop due to bad water quality in the

water source and wash the filter at certain times.

37(61)

11) Test if the pipeline leaks after installation. Wrap insulating layer onto the

cooling water recycling pipe to aviod loss of refrigeration capacity and

pipeline leakage.

Power connection must be conducted by professional electricians!

Do not change the circuit of the water chiller without our company's

authority. If the machine is damaged by unauthorized change we are not

responsible for this.

3.2 Select Installation Site

1) No heat source existence nearby to acoid efficiency reduction due to

absorbing hot air.

2) No impact imposed by high temperature, vapor or oil stain.

3) Avoid being spattered by water vapor when choosing installation site near

cooling water tower, so to avoid any short ciruit or creepage.

4) Proper ventilation without hindrance for air inhaled exhaled.

5) No existence of inflammable substance.

6) When using concrete bearing platform,the platform must be firm and flat.

Install shockprooof mat in the bolt of bearing platform if necessary.

7) Set apart some service space.Space ranges are recommended as shown in

figure 3-1.

Length unit: mm

Picture 3-1:Installation Space

38(61)

3.3 Bearing Platform

1) The unit should be installed on concrete or steel structure bearing platform

that is firm and the surface of the baring platform should be smooth and flat.

The in tensity of the platform should hold the whole unit, if the inten sity is not

strong enough, it is easy to cause vibration and noise.

2) The surface of the concrete base platform normally has compo as horizontal

ornament and with waterproof treatment,the surrounding of it should have

drainage sink placed, and the slope angle should be no less than 0.5%,and

the slope should lead to drainage outlet.

3) Inorder to maintain quiet operation and prevent the vibration and noise

transmission from interfering the under floors,the absorber should be laid

between the unit base and base platform. Please maintain horizontal when

install the unit and mount anti vibration pad when it is necessary.

4) Inorder to keep connection pipe from being twisted to crack by earthquake,

typhoon, or by long time running caused movement. The fixation method

should be taken into consideration, refers to following examples for platform

installation and fixation:

Picture 3-2:Platform Installation

1. Photo 3-2 the platform size is for module unit, pay special attention to

the real location and size of installation holes.

2. When adopts photo 3-3 showed fixation way, keep bearing bolt holes

for platform and its absorber as photo 3-2 showed installation hole

location.

39(61)

3.4 Hanging and Transporting of the Unit

1) Propose plans of hanging and transporting before practise, including entering

date for each unit. Dimensions of appearance. Weight, path, reserved holes,

hanging and transporting device as well. Figure 3-1 shows the details.

Items Check points

Path

Unload

Transporting

Transporting

Path adjustment Adjust with the wall,floor to facilitate transporting.

Others

1. Check aisle, stair gate and transporting path.

2. Check roof,base room and hanging path.

1. Check the weight of the unit.

2. Prepare unload devices.

3. Check the temporary laying place and keep the unit clean.

1. If the large-scale machine can be decomposed, then decompose

it and transport each part respectively and then combine them

finally.

2. If the large-scale machine cannot be decomposed, then dig hole

in the wall or earth to transport it.

Arrangenent of Labor and hanging device; problems of woker and

unit safety.

2) According to safety command, when hanging and transporting units, assign

special person to direct and there must be warning and precaution measures

to ensure safety of people and machines.

3) Consider the weight of the unit. Take woven belt as hanging device and add

bearing articles to avoid damage to metal board.Keep horizontal or vertical

state. It is forbidden the unit inclined by over 30 degrees.

4) Protect the unit from being cut or deformation.Place protective mat or wood

poles in the contact places between woven belt and the unit.

Picture 3-3:Hanging and Transporting of the Unit

40(61)

3.5 Water System Tubing

1) The inlet /outlet pipes and valves of the unit should have itselves insulated.

The outside parts should have protective veil to prevent the thermo lost and

dewfall happen and this brings no impact on building structure and

anti-freezing when it is in winter.

2) To ensure that there is enough water in the water-side exchanger and

pipeline system so to avoid its internal icy water comes to freeze up, over low

pressure and bad oil return rate within system when refrigerating, there after

lead to the failure of the compressor and burn down to the worse. So water

flow switch should be mounted at the water outlet side and was controlled

chainly with compressor.

3) If closed circuit type water distribution pipelines are used, an inflated water

tank should be placed higher by at least 1m than top of the whole set of water

distribution pipelines to buffer the water volume's expansion or contraction

and the isolated backup water pressure to water distribution pipelines'

influence. Check valve should not be mounted at the outlet of inflated water

tank so to avoid pipe leakage or crack.

4) The pump of the unit should be mounted at the water inlet of the main module

machine.

5) Avoid air left in the water system, Install automatic exhaust steam

dischanging valve in the highest position of all the water distribution pipes.

The horizontal pipe of the water distribution system must be laid with an

inclination of 1/250.

6) There should have flexible joint, flange joint and break valve for later

maintenance.

7) There mameter and pressure meter should be set in the inlet and outlet of the

unit to facilitate daily check.

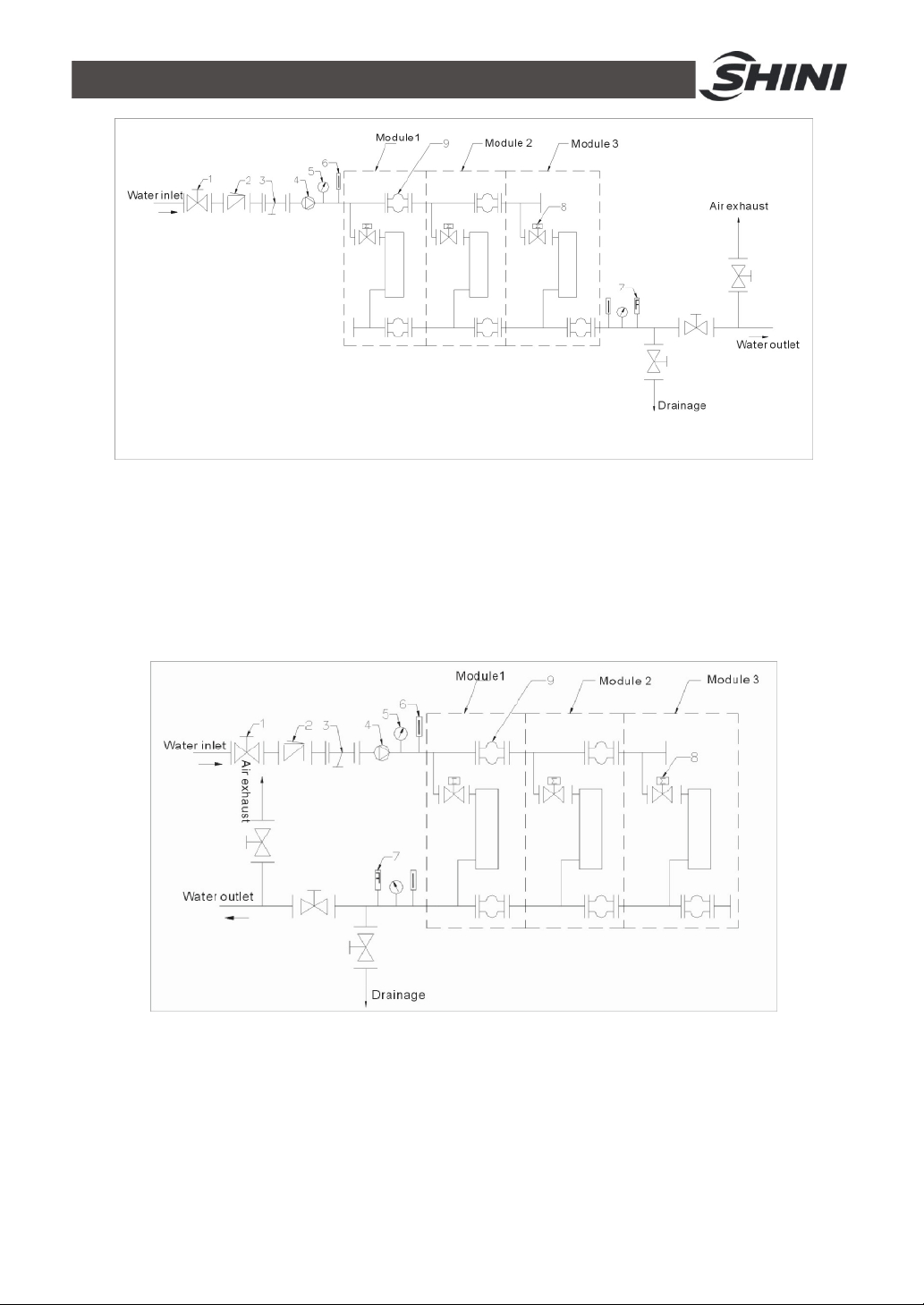

8) There are same directions way and opposite direction way to install the water

pipe of the module unit.

41(61)

Names of Parts:

1. Stop valve 2. One way valve 3. Y type filtration valve

4. Pump 5. Pressure meter 6. Thermometer

7. Flowmeter 8. Solenoid valve 9. Rubber soft pipe

Picture 3-4:Same Direction Way 1

Names of Parts:

1. Stop valve 2. One Way valve 3. Y type Filtration valve

4. Pump 5. Pressure meter 6. Thermometer

7. Flowmeter 8. Solenoid valve 9. Rubber soft pipe

Picture 3-5:Same Direction Way 2

42(61)

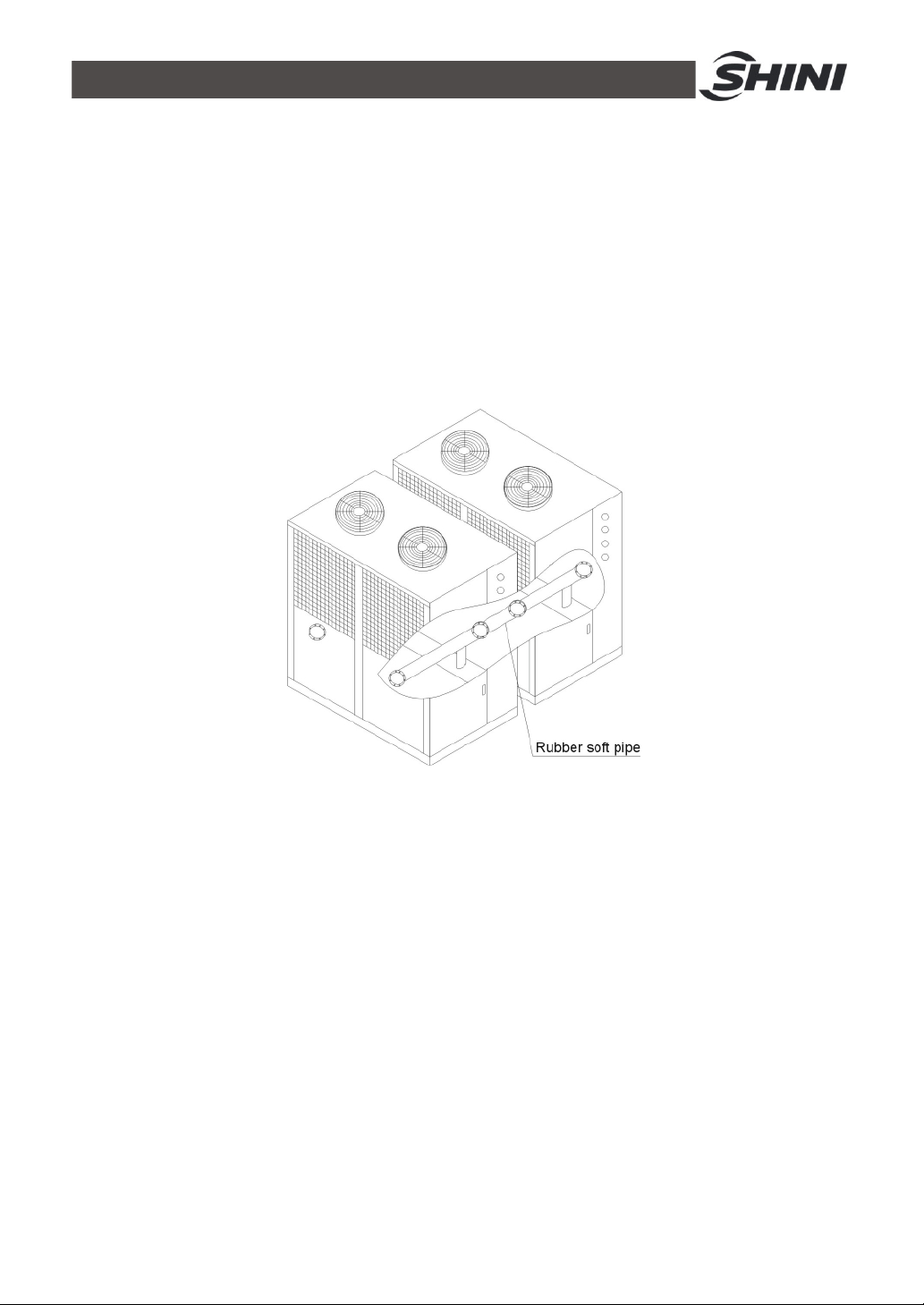

3.6 Combined Installation of Modules

1) Disassembly the sideplates around the machine, calibrate the cooling water

inlet to combine the modules. Use rubber soft pipe to connect the module's

chilling water pipe.

2) The non-exist end of the cooling water pipe should be fixed by flange.

3) Refers to wiring diagram to tandem the communication line to next

submodule, the communication line of which tandems to next submodule

thereby.

Picture 3-6:Combined Installation of Modules

3.7 Essentials for Electric Wiring

1) The electricity supply should use special branch circuit.

2) Wiring work should be conducted according to relevant national electric

standards and grounding.

3) Refer to wiring diagram to conduct wiring work. Lock up every contact screws,

do not let them loosen.

4) The voltage has to be stable when in operation, take all the voltage down fall

into consideration, the unit working voltage should maintain at±10% within

rated voltage. Over high or over low voltage will bring bad effect to the unit.

5) The length of the power cable must ensure the voltage gap value between

the head and tail of cable be less than ±2% within rated voltage, if the length

can not be shorter. Then enlarge the diameter of the cable.

43(61)

6) The wiring connection between power and unit should be conducted

according to electrical regulations with good insulation, after the unit being

connected to the power; the terminals of the electrical components resistance

should be at least more than 3MΩ.

7) Inorder to avoid the damage to those electrical devices such as transformer

or wiring due to short circuit, and helps to separately control the start/stop of

every compressor, every incoming cable needs to equip proper amount of

non-fuse breaker. Showed in the following photo:

8) Inorder to ensure personal safety, to avoid electric shock due to creepage the

housing of the unit needs to have a good grounding protective device to avoid

electric shock, all the work should be carried out by strictly follow the

electrical regulations.

Picture 3-7:Essentials for Electric Wiring

3.8 Power Connection

Check the specification of the electricity supply to see if it matches with that of

the demand. For SICC-A series, the specification of power is AC3Φ400V type.

We can also manufacture according to client’s special demand. The ground wire

must be connected to when connect to the power.

Ensure the power switch's shut-off condition befor being connected to

power wire.

44(61)

4. Operation Guide

4.1 Control Panel

Picture 4-1:Control Panel

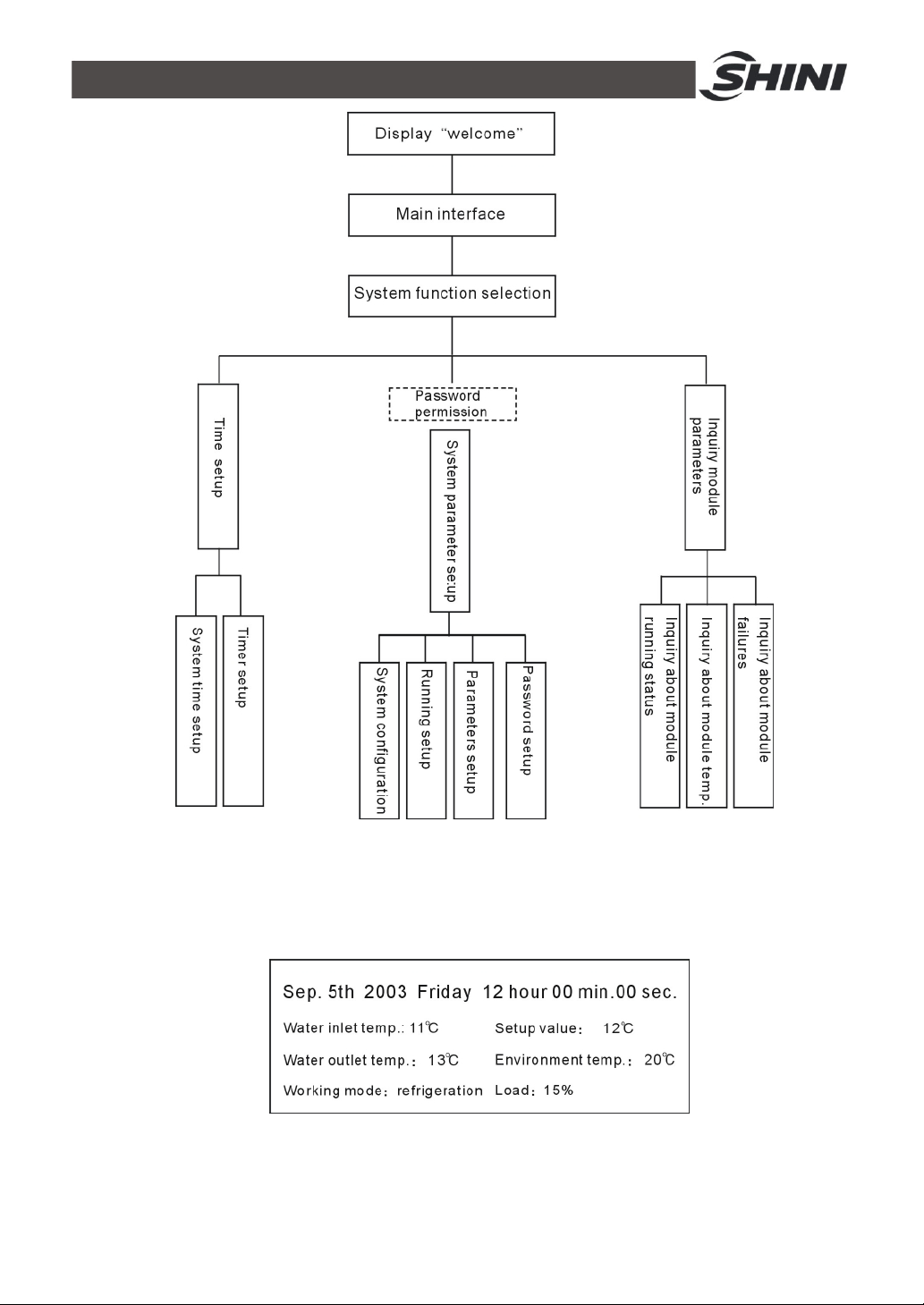

4.2 The Make Up and Layers of the Display Interface

4.2.1 The Make up of the Display Interface

a Startup display “welcome”

b Main working interface

c System function selecting interface

d 1 Time setup interface

1) Set system time

2) Set auto start/stop time

e System parameters setup interface

1) System configuration

2) Tthe setup for unit running

3) The setup of system parameters

f Iinquiry module parameter selecting interface

1) Inquiry every module's running condition interface

2) Inquiry every module's detecting temp. interface

3) Inquiry every module's faults status interface

4.2.2 Interfaces Show

45(61)

Picture 4-2:Interfaces Show

4.3 Main Working Interface

4.3.1 Interface Demonstration

Picture 4-3:Main Working Interface

4.4 Selecting Interface of System Function

46(61)

4.4.1 Interface Demonstration

Picture 4-4:Selecting Interface of System Function

4.4.2 Interface Operation

Press “ ” or “ ” to select different functions, press “menu” key to enter selected

functions, press“return”key to back to main working interface.

4.5 System Parameter Setup Interface

4.5.1 Interface Demonstration

Picture 4-5:System Parameter Setup Interface

4.5.2 Interface Operation

Press " " or " " key to select different functions, press "menu" key to enter into

selected function, press "return" key to back to main working interface.

4.6 Inquiry Parameters of the Module

4.6.1 Interface Demonstration

Picture 4-6:Interface Demonstration

47(61)

4.6.2 Interface Operation

Press " " or " " key to select different functions, press "menu" key to enter

selected function, press "return" key to back to main working interface.

4.7 System Time Setup

4.7.1 Interface Demonstration

Picture 4-7:Interface Demonstration

4.7.2 Interface Operation

Press " " or " " key to select "year" "month" "day" "date" "hour" and "min"

settings, press">"or"<"key to change the value of selected items, press"eturn"

key to back to time setting interface.

4.8 System Configuration

4.8.1 Interface Demonstration

Picture 4-8:System Configuration

4.8.2 Interface Instruction

To set up the parameters for system configuration

1) Module quantity: set up the number of component module, setup range: 1-15.

2) Pump: configured with build-in pump or outfitted pump. When displays

"available", it indicates build-in pump and when displays "not available", it

indicates outfitted pump.

3) Hot pump: configured modules are single cooling unit and hot pump unit.

When displays “available”it indicates hot pump unit and when displays "not

available" it indicates single cooling unit.

48(61)

4) Auxiliary heat 1: check if there is auxiliary heat in module configuration 1#.

When displays “available”it indicates module 1# has been connected to

auxiliary heat and when displays "not available" it indicates module 1# has no

auxiliary heat connection.

5) Auxiliary heat 2: check if there is auxiliary heat in module configuration 2#.

When displays "available" it indicates module 2# has been connected to

auxiliary heat and when displays "not available" it indicates module 2# has no

auxiliary heat connection.

Note!

There is no heating function for this machine.

6) Module number: select the module that needs online function.

7) Setup online function: check to see if it needs to be online. When displays

"start" , it indicates this module is online, and works effectively within the unit

and when displays "forbidden", it indicates that this module is offline and

works invalid within the unit ( if some module has faults or due to some other

reason, it can not be put into the unit to work, its online function can be

forbidden.

Note!

The online function of module 1# can not be“forbidden”

4.8.3 Interface Operation

Press " " or " " key to select different functions, press ">" or "<" return key to

back to time setting interface.

49(61)

4.9 Unit Running Settings

4.9.1 Interface Demonstration

Picture 4-9:Unit Running Settings

4.9.2 Interface Operation

Press " " or " " key to select different function, press ">" or "<" key to change

the value of selected items, press "return" key to back to the time setting

interface.

4.10 Parameter Setting

4.10.1 Interface Demonstration

Picture 4-10:Parameter Setting

4.10.2 Interface Operation

Press" " or " " key to select different functions, press ">" or "<" key to change

the value of selected items. Press “return”key to back to time setting interface.

Press " " or " " key to select the setup items and it supports screen scrolling.

Press“menu”key to resume the above parameters back to default values.

50(61)

4.11 Unit Running Setup

4.11.1 Interface Demonstration 1

Picture 4-11:Unit Running Setup 1

4.11.2 Interface Demonstration 2

Picture 4-12:Unit Running Setup 2

4.11.3 Interface Instruction

Inquiry each module's running status

1) There are 3 status namely open, close and no connection for each module,

the no connection status is not displayed.

2) Inquiry each module's detailed running parameters by pressing " " " " key

to select module firstly, then press "menu" key to access into every module's

running status parameters. As enterring into interface demonstration 2.

3) It displays the inquired module number firstly, then folllowing below displays

its module running status.

4) When the screen pops up "waiting for defrosting "or" defrosting", thetop right

corner of the first line displays its status and there is no display when in other

condition.

4.11.4 Interface Operation

Press " " " " key to select different module(interface demonstration 1), press "

return" key to back to inquiry module parameter interface. Press "menu" key to

enter into running status nquiry interface.

51(61)

4.12 Inquiry Module Temperature

4.12.1 Interface Demonstration

Picture 4-13:Inquiry Module Temperature

4.12.2 Interface Instruction

The first line displays the inquiry module number, the rest displays the elated

temp. Value from module testing.

4.12.3 Interface Operation

Press ">" or "<" key to select different module(module number is in the range of

network module number), press “return” key to back toinquiry module parameter

interface.

4.13 Inquiry Faults

4.13.1 Interface Demonstration

4.13.1.1 Sub-interface 1

Picture 4-14:Sub-interface 1

4.13.1.2 Sub-interface 2

52(61)

4.13.1.3 Sub-interface 3

Picture 4-15:Sub-interface 2

Picture 4-16:Sub-interface 3

4.13.2 Interface Instruction

1) For every module fault inquiry,it consists of 3 sub-interfaces.

2) The first line displays the module number and the faults number.

3) Support page up/down to inquiry fault.

4) Communication: indicate the status between the module and central control

board, when it displays "fault", it means communication failure.

5) For other faults' instruction, please refer to function instruction book.

4.14 The Configuration of Module Unit

Shini SICC-A series adopt modular design with three unit modules including

SICC-60A, SICC-90A and SICC-120A, each of them can be used as a unit

independently or combine together to meet system load based on actual

operations. SICC-A series modular device is capable of automatically switching

on or off unit modules to save energy as system load varies. Shini is able to fare

15 unit modules combination to reach the maximum cooling capacity of 1800kW.

Users can follow steps below to combine these unit modules:

1) Pipeline Connection of Chilled Water

53(61)

In modularized configuration for chilled water circuit, there are two methods of

connection: reversed return and direct return. In reversed return connection

chilled water flow distance through every unit module is the same while in direct

return the flow distance is not equal. Flow distance in reversed return has the

same resistance and water flow while flow distance in direct return has the

different resistance and water flow. Generally, chilled water pipeline connection

adopts reversed return type.

Chilled water inlet and outlet in SICC-A unit module adopt 5 inch flange as joint

face. Use 5 inch rubber connecting flange can complete the combination of two

unit modules of pipeline. Both flange and rubber connecting flange are national

standard parts and they are conveniently to purchase.

2) Control Line Connection of Host/Sub Modules

Complete control line connection following chilled water pipeline connection.

No.1 terminal in host PCB connects display control panel. No.2 terminal

connects No.1 terminal of sub 1# module and No.2 terminal of sub 1#module

connects No.1 terminal of sub 2# module. Complete connection in sequence as

number of unit module increases. (Note: four lines in No.1 terminal and three in

No.2. When connecting No.1 and No.2, the black line in No.1 terminal is free of

connection).

3) Control Setting

Complete control setting following control line connection. Firstly is the setting of

each unit module address, which can be finished by controlling DIP switches on

PCB. Address range is from 1 to 15. On the using of module combination,

display control panel connects 1# module to centrally control all unit modules in

the system. Refer picture below for DIP switch setting (Black area indicates

54(61)

switching DIP to “ON”, as shown in number “4”).

address

Module

DIP1 DIP2 DIP3 DIP4

number

OFF OFF OFF OFF Keep as spare

Must have module 1# which the

OFF OFF OFF ON 1

OFF OFF ON OFF 2

OFF OFF ON ON 3

OFF

OFF

OFF

OFF

ON OFF OFF OFF 8

ON OFF OFF ON 9

ON OFF ON OFF 10

ON OFF ON ON 11

ON ON OFF OFF 12

ON ON OFF ON 13

ON ON ON OFF 14

ON ON ON ON 15

ON OFF OFF 4

ON OFF ON 5

ON ON OFF 6

ON ON ON 7

shared water pipe detecting and

devices has all been connected to

Remark

55(61)

Next comes the setting on the control panel. Select and press buttons in

sequence: Function selection—System param. Setting—Password

(input)—System configuration:

1. Network module number: setting the number of modules composing system.

2. Water pump: equipped with the built-in pump or external pump. ON means

built-in pump and OFF means external pump.

3. Heat pump: units include single cool and heat pump models. ON means it is

heat pump and OFF single cool.

4. Auxiliary heat 1: indicate whether 1# module is equipped with auxiliary heat.

ON means connecting one and OFF no connecting.

5. Auxiliary heat 2: indicate whether 2# module is equipped with auxiliary heat.

ON means connecting one and OFF no connecting.

6. Module number for modularized configuration: module selected to be

ONLINE or not (set the module to be ONLINE running).

7. ONLINE setting: set the module to be ONLINE running. ON means module

online and it is activated in the unit while OFF means module offline and it is

idle in the unit (module is not applied to the unit for any fault, set it offline). 1#

module can not be OFFLINE.

56(61)

5. Trouble-shooting

Failures Possible reasons Solutions

1. NO power

Fan, pump and

compressor can

not start up

Pump runs but

compressor can

not start.

Compressor

stops immediately

after it starts.

Big lnlet/outlet

water

temperature

difference and

over low

low-pressure

(when cooling

flow runs).

2. Power switch jumps

3. Power fuse is burnt.

4. Pump overloads.

1. The setup value for temperature

switch is too high.

2. Failure in temperature switch.

3. Compressor overloads.

4. The setup temperature for

compressor is too low (for heat flow)

5. No restore after the protective switch

jumps.

1. Air inlet or outlet gets hindered.

2. Condenser is dirty.

3. Bad ventilation due to bad landform.

4. Fan fails.

5. The cooling water valve has not been

opened.

6. Overlow cooling water auantity.

7. Cooling medium leaks.

8. Compressor overloads.

1. Pipeline blocks due to wrong pipeline

switching

2. Too much gas in the pipeline.

1. Wait for power recovery

2. Check the power and make it ormal

3. Change power fuse

4. Check and reset or repair the

failure.

1. Edit the value.

2. Check or change.

3. Check and reset.

4. Edit the value (for heat flow)

5. Check and reset.

1. Remove the hindering articles.

2. Wash and clean.

3. Improve gy client.

4. Check and repair.

5. Open the valve.

6. Check the pump to remove the tube

air.

7. Repair the leak spot.

8. Edit setup value.

1. Check the valve of the pipeline and

attachments.

2. Exhaust the air in the pipeline.

57(61)

6. Maintenance and Repair

Note!

All repairing work must be conducted by professional person to avoid

personal injury and damage of machine.

Matters require attention when do machine maintenance are as follows:

1) Do not stop the machine via cut the power supply unless emergncyoccurs.

2) When failure occurs and machine stops, press the main power switch (alarm

light will go out). Check the failure and do not start the machine before

trouble-shooting.

3) Check the system periodically to expand the system's lifespan and avoid

safety accident.

4) Dispose the water because water with high PH will accelerate the rust to the

copper tube and decrease the heat exchanger's lifespan. Keep the water PH

in the scale of 7.0~8.5.

58(61)

5) Keep the unit dry, clean and ventilative.

6) The daily operation, unit management, maintenance and repair must be

conducted by professional technicians. (Danger exists when dissembling and

checking the unit, please take care!)

6.1 Daily Repair and Check Items

1) Operation, startup, stop, maintenance and repair works must be conducted by

professional technicians to expand the unit's lifespan.

2) Daily check includes recording indoor/outdoor temperature, cooled water

temperature, voltage, current for further reference, such as adjustment and

maintenance.

3) Clean the appearance of the unit.

6.2 Monthly Periodical Checking Items

1) Check if the screws loosen.

2) Clean indoor air conditioner box or filter of cool air blower.

3) Check if the joint of the pipelines leaks.

4) Check the wire to see if there is any damage, the connection is firm and

whether contact points are burnt.

5) Check the compressor oil level (notice there is no-oil-indicating window).

6) Check the cooling water system to see if it is air proof. If there is air, please

exhaust it.

7) Check the cooling medium pressure.

8) Clean the dirt of the condenser.

9) Check the inflated tank to see if the supplementary feed water is normal.

6.3 Monthly Periodical Checking

1) Check according to monthly check items.

2) Check the insulation resistance of the compressor to see if it is above 10MΩ.

3) Check high voltage switch and low voltage switch to see if their trip off values

are normal.

59(61)

6.4 Maintenance Schedule

6.4.1 About the Machine

Model SN Manufacture date

Voltage Ф V Frequency Hz Power kW

6.4.2 Installation & Inspection

Check if the pipe are connected correctly

Check if the pipe has any leakage

Check if the sealed joint has any crack

Electrical component installation

Voltage: V Hz

Fuse melting current: 1 Phase A 3 Phase A

Power phase sequence check

6.4.3 Daily Checking

Check the function of switches.

Check all wires of the machine.

Check whether pressure gauges are accurate.

Check whether compressor temperature is normal.

Check whether cooling water circulation is normal.

6.4.4 Weekly Check

Check if the joint point is loose.

Check chiller's protective alarming function.

Check whether set point of hi-low pressure switch is normal.

6.4.5 Monthly Check

Check the circulated pipe to seeif there is any leakage.

Check whether there are bubbles in liquid indicator.

Check whether there is abnormal sound in pump.

Check whether there is scale formation in tank.

6.4.6 Trimonthly Checking

Check whether condenser is under blockage.

60(61)

6.4.7 Check Half-yearly

Check and clean filter and expansion valve.

Check the whole machine condition.

Clean condenser.

6.4.8 Yearly Checking

Check whether the contactor is normal.

6.4.9 3 year Checking

PC board renewal.

No fuse breaker renewal.

61(61)

Loading...

Loading...