Page 1

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

T242 TRIMMER

X7502800900

07/10

WARNING!

Minimize the risk of injury to yourself and

others! Read this manual and familiarize yourself with

the contents. Always wear eye and hearing protection

when operating this unit.

Page 2

Introduction

50FEET

(15m)

The Shindaiwa 242 Series hand

held power equipment has been

designed and built to deliver superior

performance and reliability without

compromise to quality, comfort, safety

or durability.

Shindaiwa engines represent the leading

edge of high-performance engine

technology, delivering exceptionally

high power with remarkably low

displacement and weight. As an owner/

operator, you’ll soon discover for

yourself why Shindaiwa is simply in a

class by itself!

IMPORTANT!

The information contained in this

owner’s/operator’s manual describes

units available at the time of publication.

Echo, Inc. reserves the right to

make changes to products without prior

notice, and without obligation to make

alterations to units previously

manufactured.

WARNING!

The engine exhaust from

this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm.

Contents

Attention Statements ........................... 2

Safety Instructions ............................... 2

Safety Labels ......................................... 4

Product Description ............................. 5

Specifications ........................................ 6

Emission Control ................................. 6

PAGE

Assembly and Adjustments ................. 7

Mixing Fuel .......................................... 9

Filling the Fuel Tank ......................... 11

Starting the Engine ............................ 12

Stopping the Engine .......................... 12

Checking Unit Condition................... 12

PAGE

Cutting Grass with a Trimmer Head . 13

Maintenance ....................................... 13

Long Term Storage ............................ 17

Troubleshooting Guide ..................... 18

Warranty Statement ........................... 21

Attention Statements

Throughout this manual are special

“attention statements”.

DANGER!

A statement preceded by

the triangular attention symbol and

the word “DANGER” contains information that should be acted upon to

prevent serious injury or death.

the triangular attention symbol and

the word “WARNING” contains information that should be acted upon to

prevent serious bodily injury.

A statement preceded by the word

WARNING!

A statement preceded by

IMPORTANT!

“IMPORTANT” is one that possesses

special significance.

IMPORTANT!

The operational procedures described in this manual are intended to help you get the most from this unit as well as to protect

you and others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended to

replace any safety rules and/or laws that may be in force in your area. If you have questions regarding your 242 series hand

held power equipment, or if you do not understand something in this manual, your Shindaiwa dealer will be glad to assist you.

You may also contact Shindaiwa at the address printed on the back of this Manual.

CAUTION!

A statement preceded by the

word “CAUTION” contains information that should be acted upon

to prevent mechanical damage.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

PAGE

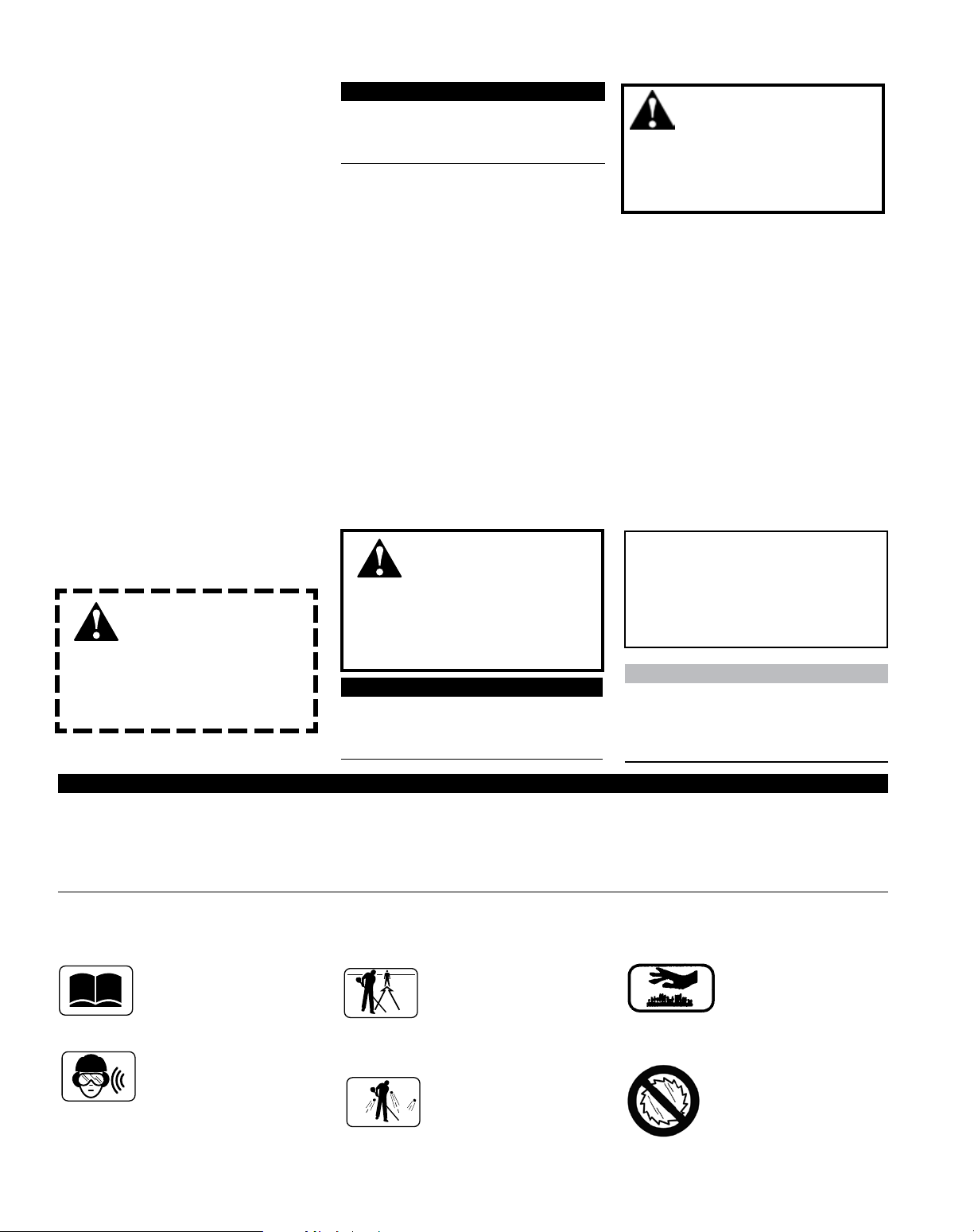

Warning and Operational Labels

Read and follow this operator's

manual. Failure to do so could

result in serious injury..

Wear eye and hearing protection

at all times during operation of

this unit. Wear head protection

where there is a risk of falling

objects.

2

Make sure no one is

within 15 M / 50 feet of an

operating machine.

Beware of thrown or

richocheted objects

WARNING: Surface can

be hot. Always wear

gloves when handling

this unit.

Do not use blades.

String line only

Page 3

DO NOT OPERATE THIS UNIT�

IF YOU ARE TIRED, ILL OR�

UNDER THE INFLUENCE OF�

ALCOHOL, DRUGS, OR�

MEDICATION.�

�

Safety Instructions

Work Safely

Shindaiwa trimmers operate at very

high speeds and can do serious damage

or injury if they are misused or abused.

Never allow a person without training or

instruction to operate this unit!

WARNING!

Minimize the Risk of Fire

WARNING!

Never make unauthorized

attachment installations. Do

not use attachments not approved

by Shindaiwa for use on this unit.

Stay Alert

You must be physically and mentally fit

to operate this unit safely.

WARNING!

Never operate

power equipment of any

kind if you are tired or if you are

under the inuence of alcohol,

drugs, medication or any other

substance that could affect your

ability or judgement.

NEVER smoke or light res near

the engine.

ALWAYS stop the engine and allow

it to cool before refueling. Avoid

overlling and wipe off any fuel that

may have spilled.

ALWAYS inspect the unit for fuel

leaks before each use. During each

rell, check that no fuel leaks from

around the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using

the unit immediately. Fuel leaks must

be repaired before using the unit.

Safety Instructions

WARNING!

Use Good Judgment

ALWAYS wear eye protection to

shield against thrown objects.

NEVER run the engine when

transporting the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

ALWAYS move the unit to a place

well away from a fuel storage area

or other readily ammable materials

before starting the engine.

NEVER place ammable material

close to the engine mufer.

NEVER operate the engine without

the spark arrester screen in place.

ALWAYS use the proper cutting tool

for the job.

ALWAYS stop the engine

immediately if it suddenly begins to

vibrate or shake. Inspect for broken,

missing or improperly installed parts

or attachments.

NEVER extend trimming line beyond

the length specied for your unit.

ALWAYS keep the unit as clean

as practical. Keep it free of loose

vegetation, mud, etc.

ALWAYS hold the unit rmly

with both hands when cutting or

trimming, and maintain control at all

times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any

maintenance work.

ALWAYS, if a saw blade should

bind fast in a cut, shut off the engine

immediately. Push the branch or

tree to ease the bind and free the

blade.

3

Page 4

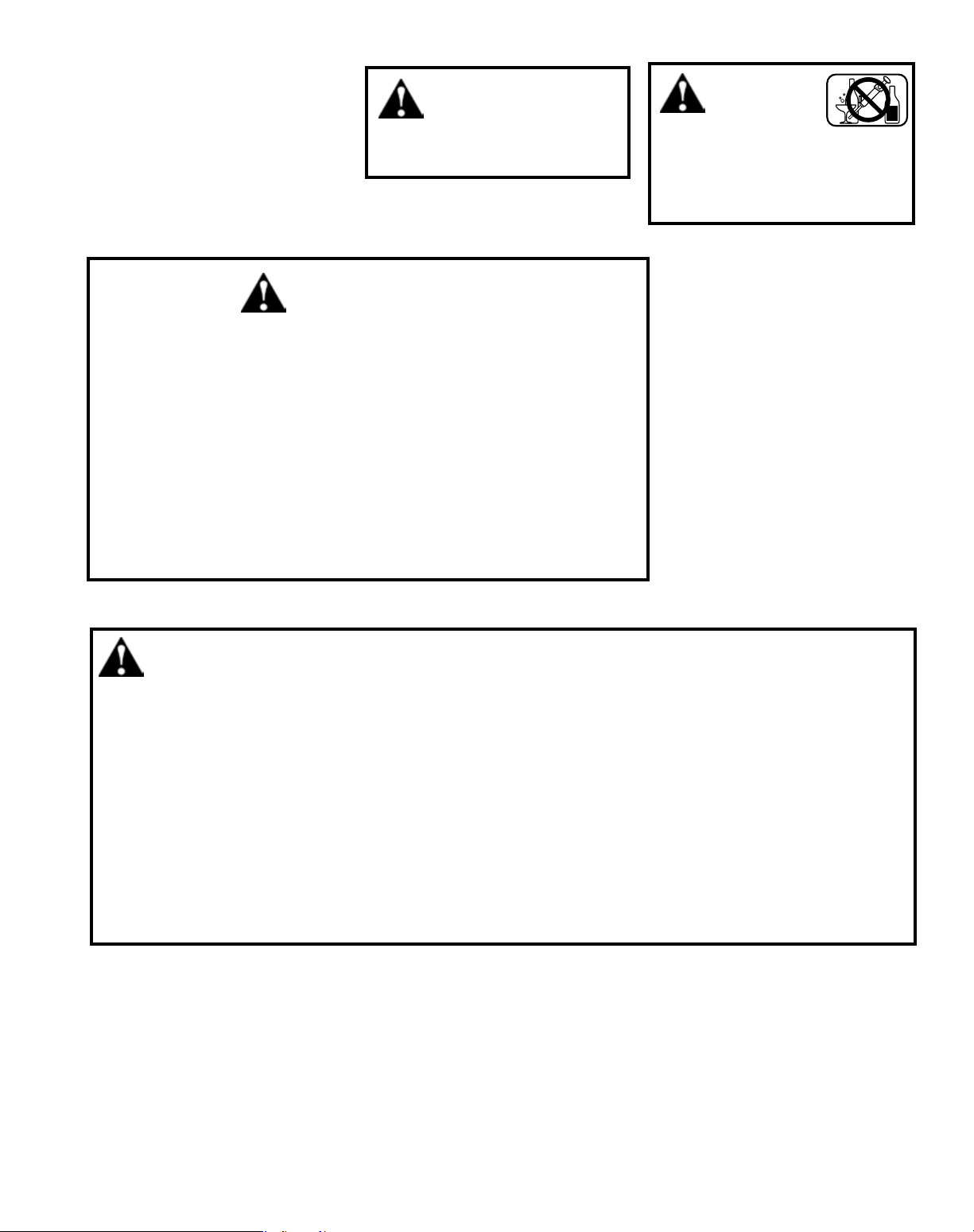

Safety Labels

This label indicates the minimum distance between

front handle and rear grip per ANSI B175.3.

IMPORTANT!

Safety and Operation Information Labels: Make sure all

information labels are undamaged and readable. Immediately

replace damaged or missing information labels. New labels are

available from your local authorized Shindaiwa dealer.

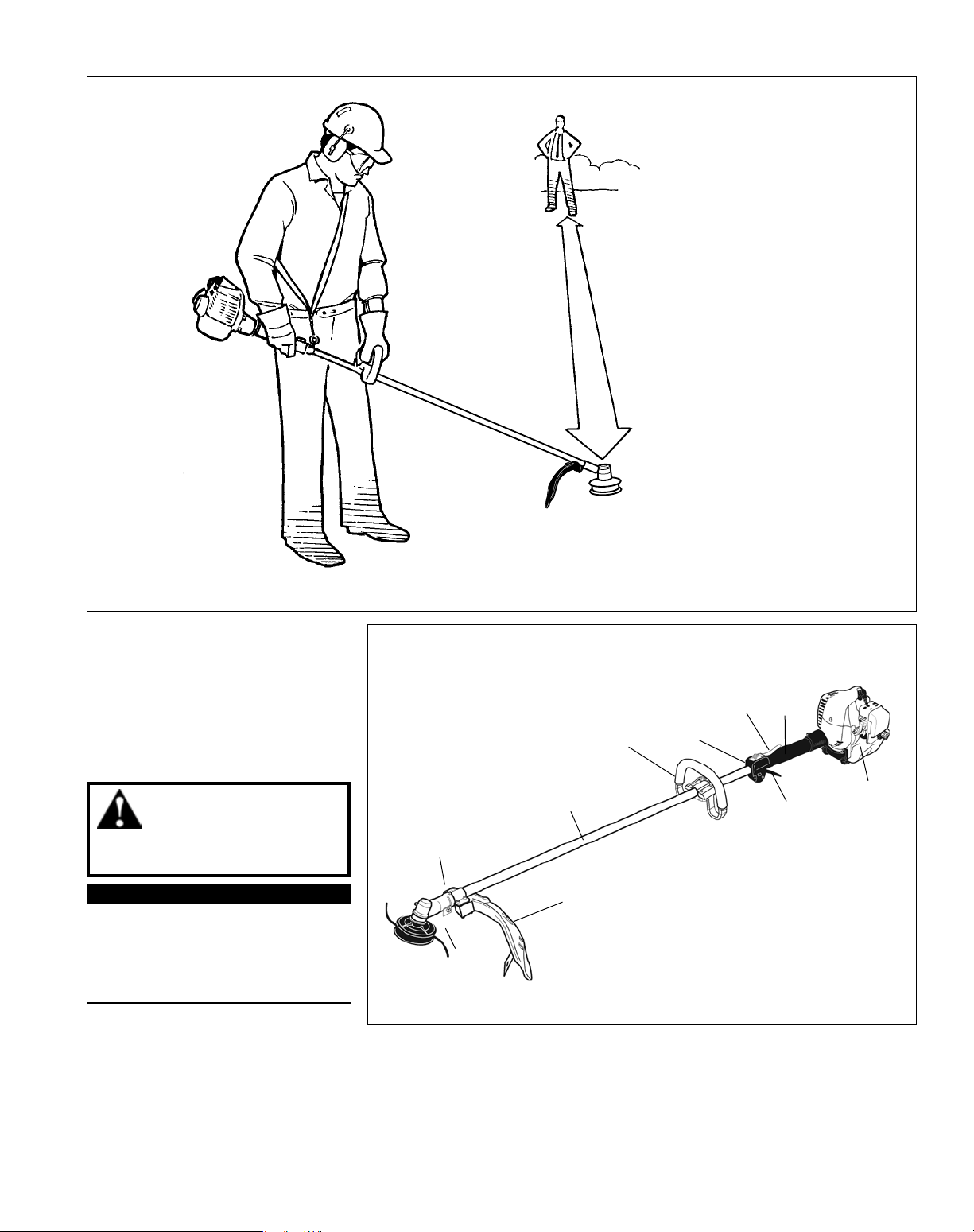

Figure 1

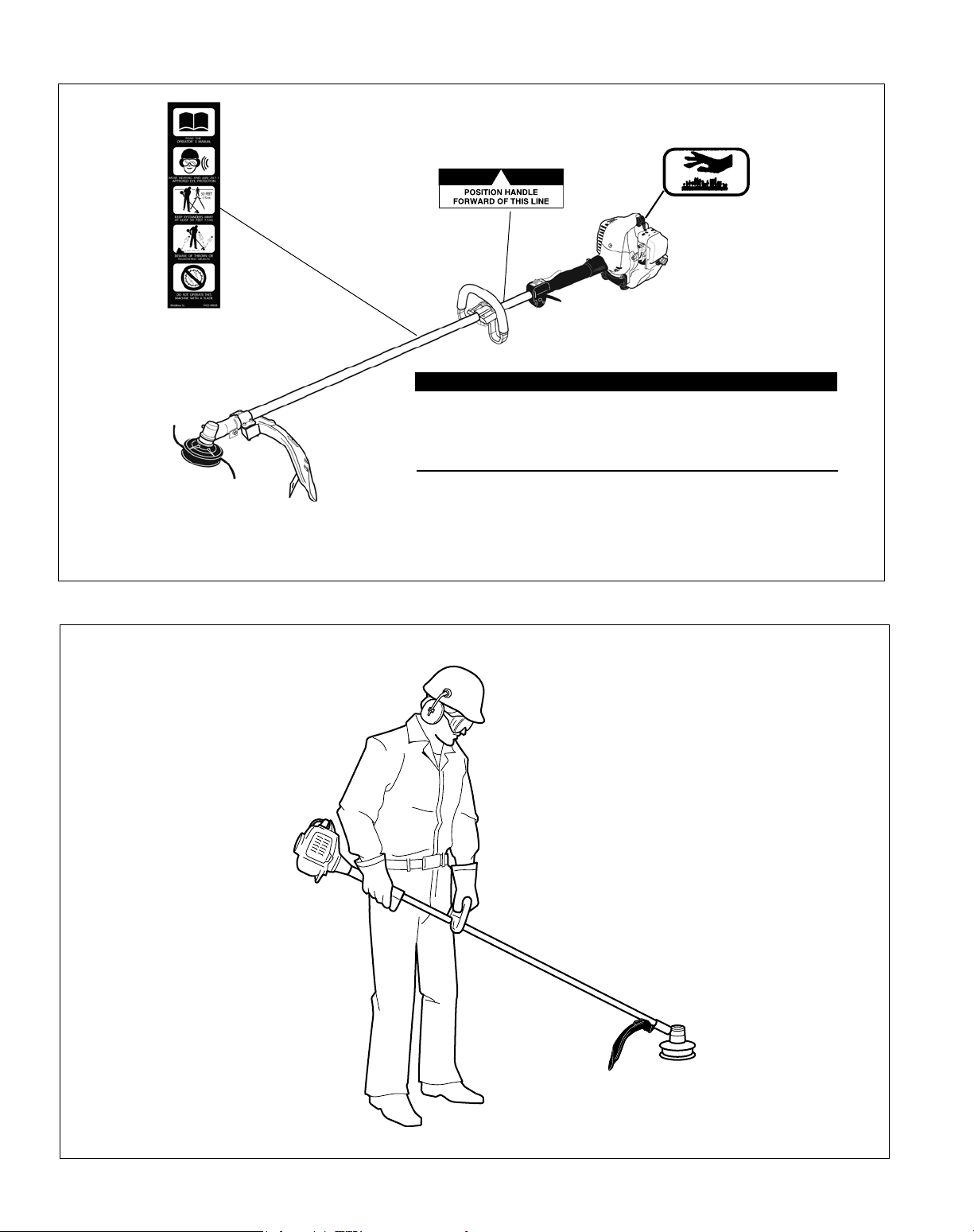

The Properly Equipped Operator

Wear hearing protection devices and a

broad-brimmed hat or helmet. A helmet

is required when using a blade-equipped

brushcutter to clear small trees.

Prolonged exposure to excessive noise

is fatiguing and could lead to impaired

hearing.

Wear close-tting clothing to

protect legs and arms. Gloves

offer added protection and are

strongly recommended. Do not

wear clothing or jewelry that

could get caught in machinery

or underbrush. Secure long hair

so that it is above shoulder level.

NEVER wear shorts!

Long-term exposure to vibration

can damage your hands.

Keep a proper footing and do not

overreach. Maintain your balance at all

times during operation.

Always wear eye protection such as

goggles or safety glasses to shield

against thrown objects.

Always wear a harness when operating the unit .

It adds comfort and helps ensure safety by limiting

movement fore and aft. When the harness is

adjusted properly, the unit should balance with the

cutting attachment parallel to the ground.

Always operate with both hands

rmly gripping the unit.

Always make sure the

appropriate cutting attachment

shield is correctly installed and

in good condition. Do not

operate the unit if the

cutting attachment shield

is missing, loose, or

broken.

Wear appropriate footwear (non-skid

boots or shoes): do not wear opentoed shoes or sandals. Never work

barefooted!

4

Keep away from the rotating

trimmer line at all times, and

never lift a moving attachment

above waist-high.

Page 5

Be Aware of the Working Environment

Avoid long-term

operation in very hot

or very cold weather.

Be extremely careful

of slippery terrain,

especially during rainy

weather.

Be constantly alert for

objects and debris that

could be thrown either

from the rotating cutting

attachment or bounced

from a hard surface.

If contact is made with a hard object,

stop the engine and inspect the cutting

Make sure

bystanders

or observers

outside the

15 meter (50

feet) “danger

zone” wear eye

protection.

15 METERS

(50 FEET)

Always make sure

the appropriate

cutting attachment

shield is correctly

installed.

attachment for damage.

Reduce the risk of bystanders being

struck by ying debris. Make sure no

one is within 15 meters (50 feet)—

that’s about 16 paces of an operating

attachment. Stop immediately if a child,

pet, or person comes within a 15 meter

(50 feet)radius. Outside this radius,

there is still a risk of injury from thrown

objects.

Do not operate the unit

if the cutting attachment

shield is missing, loose,

or broken.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

When operating in rocky terrain or

near electric wires or fences, use

extreme caution to avoid contacting

such items with the cutting attachment.

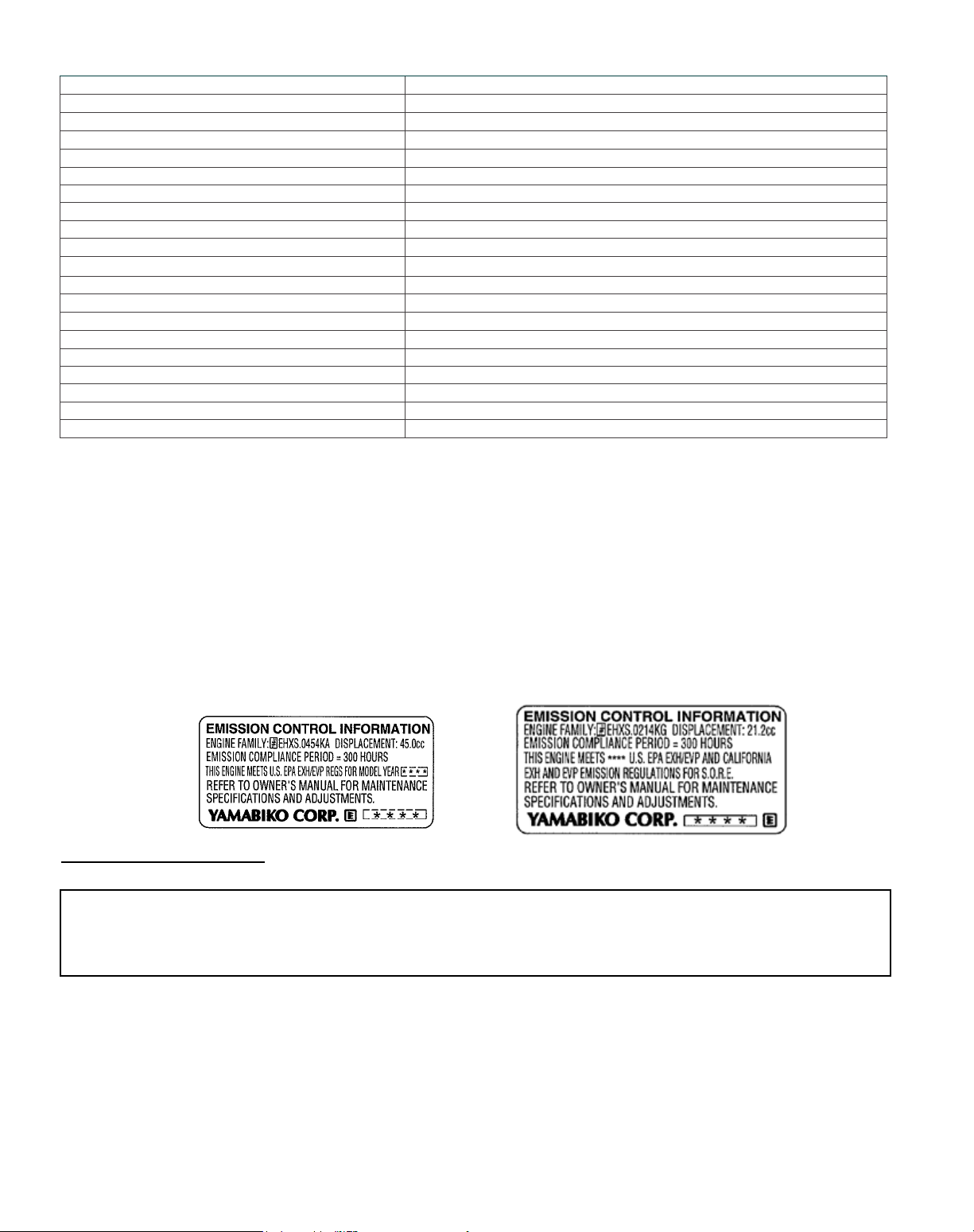

Product Description

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. See Figure

4. Understanding your unit helps ensure

top performance, long service life, and

safer operation.

WARNING!

Do not make unauthorized

modications or alterations to any of

these units or their components.

IMPORTANT!

The terms “left”, “left-hand”, and

“LH”; “right”, “right-hand”, and “RH”;

“front” and “rear” refer to directions as

viewed by the operator during normal

operation.

Gear case

Trimmer

Head

Handle

Outer Tube

Cutting

Attachment Shield

Ignition

Switch

Throttle

Interlock

T242 TRIMMER

Grip

Throttle

Trigger

Fuel

Tank

5

Page 6

Specications

Engine Name T242

Engine Type 2-cycle, catalyst

Dry Weight (less attachment) 5.3 kg/11.7 lb.

Dimensions (L x H x W) mm 1740 x 355 x 320 mm / 68.5 x 13.2 x 12.6 in.

Bore x Stroke 33 x 28 mm (1.3 x 1.1 in.)

Displacement 23.9 cc (146 cu. in.)

Fuel/Oil Ratio 50:1 with *ISO-L-EGD or JASO FD class engine oil

Fuel Tank Capacity 690 ml (23.3 oz.)

Carburetor Type Diaphragm-type carburetor

Ignition One-piece electronic, transistor-controlled

Spark Plug** NGK BPM8Y

Spark Plug Gap 0.6 mm (0.024 in)

Torque 16.7 - 18.6 N∙m (148-165 in • lbf)

Air Cleaner Type Non-reversible foam filter element

Starting Method Recoil Starter

Stopping Method Slide switch

Transmission Type Automatic, centrifugal clutch w/bevel gear

Engine Idle Speed 3,000 RPM

Clutch Engagement Speed 3,850 RPM

Wide Open Throttle Speed (W.O.T.) 9,600 RPM

Specifications are subject to change without notice.

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modication and 3-way Catalyst) and for the fuel tank

the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission may be applicable to

California models only.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY; information on label varies by engine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in the Maintenance Section of this manual.

6

Page 7

This unit comes fully assembled with the

251043

exception of the cutting attachment shield

and cutting attachment.

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete

unit and inspect unit and components for

any damage.

Assembly and Adjustments

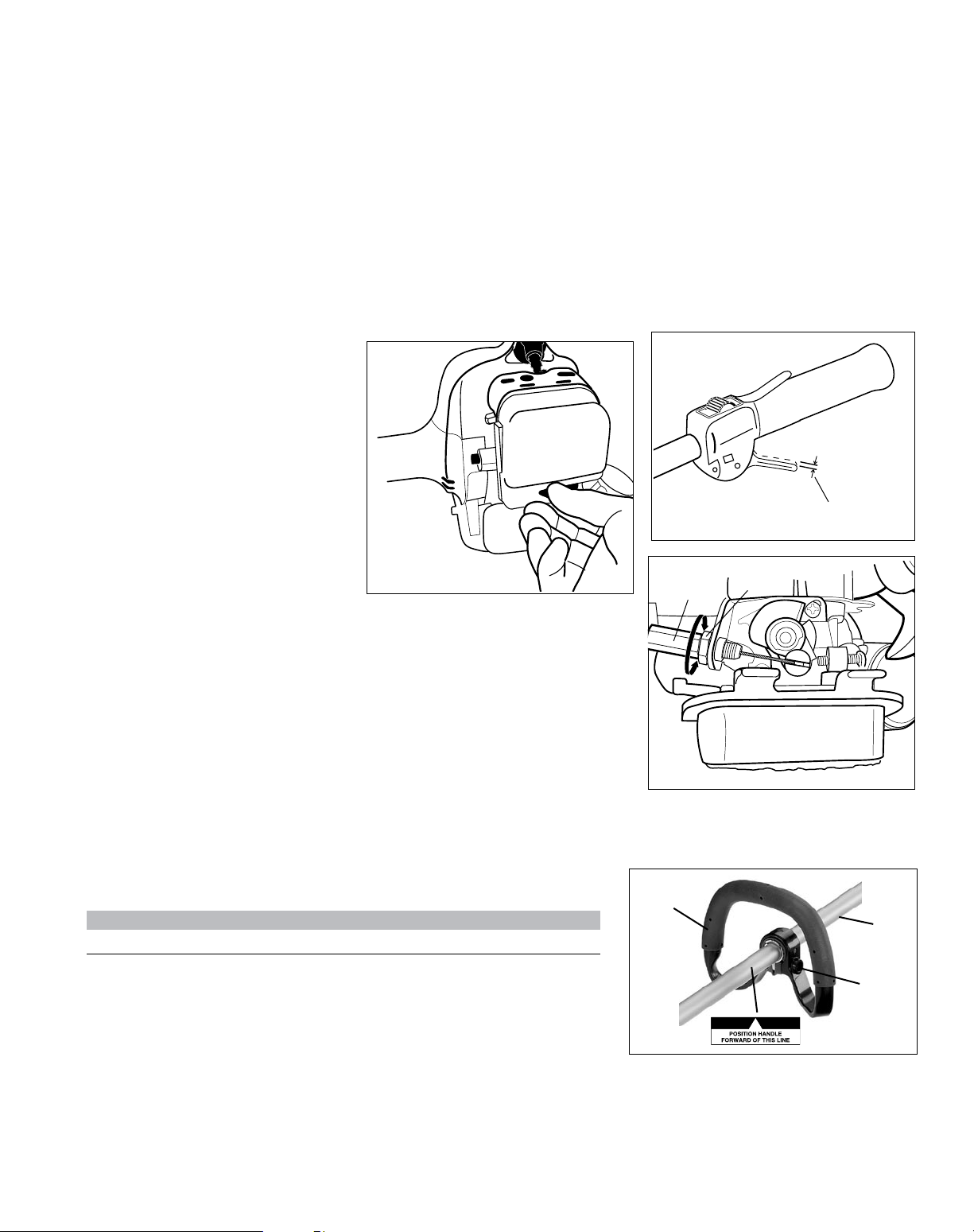

Adjust Throttle Lever Free Play

The throttle lever free play should

be approximately 3/16-1/4 inch (4-6

mm). See Figure 6. Make sure that the

throttle lever operates smoothly without

binding.

If it becomes necessary to adjust the

lever free play, follow the procedures

and illustrations that follow.

Loosen the air cleaner cover knob 1.

and remove the air cleaner cover.

See Figure 7.

Loosen the lock nut on the cable 2.

adjuster. See Figure 8.

Turn the cable adjuster in or out as 3.

required to obtain proper free play

3/16-1/4 inch (4-6 mm). See Figure

8.

Tighten the locknut.4.

Reinstall the air cleaner cover.5.

Figure 7

■

Engine and shaft assembly

Cutting attachment shield ■

Cutting attachment ■

Kit containing cutting attachment ■ shield, mounting bracket and hardware,

this owner’s/operator’s manual and tool kit for routine maintenance. Tool

kits vary by model and may include a spark plug/screwdriver combination

wrench, and a scraper.

3/16-1/4 inch (4-6 mm)

Figure 6

Cable

Adjuster

Lock

Throttle Free Play

Nut

Front handle installation

NOTE:

Label shows minimum spacing for front handle location.

Position front handle for comfortable operation and secure screw.1.

Figure 8

Handle

Outer

Tube

Screw

7

Page 8

26013

Assembly and Adjustments

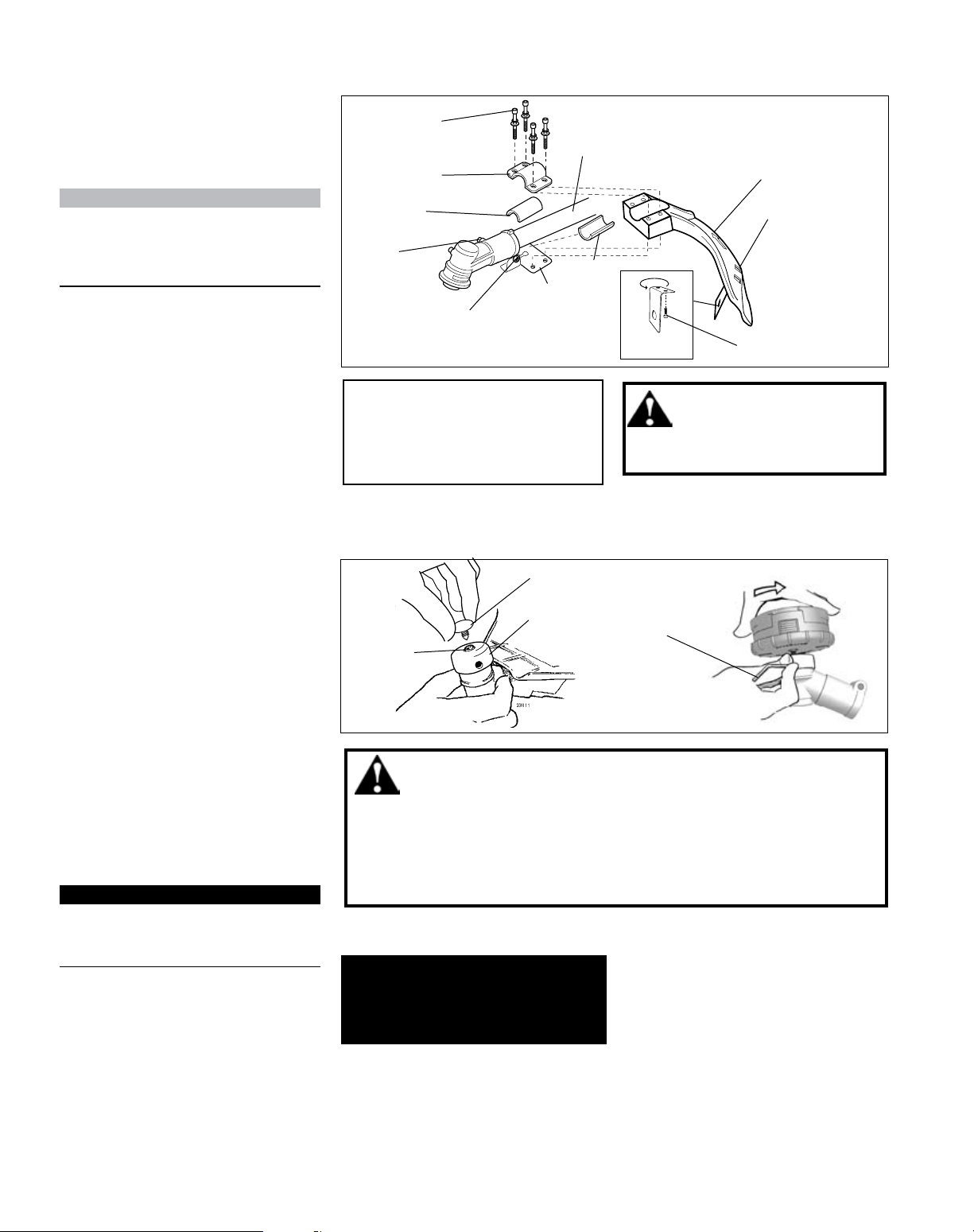

Install the Cutting Attachment

Shield T242

Insert the cutting attachment shield 1.

between the outer tube and the

cutting attachment mounting plate.

See Figure 9.

NOTE:

It may be necessary to loosen the

retaining nut and clamp screw to

adjust cutting attachment shield

mounting plate.

Fit the two shims and the bracket 2.

over the outer tube and loosely

install the four socket-head screws.

See Figure 9.

Tighten the four socket-head cap 3.

screws to secure the cutting

attachment shield.

Re-tighten clamp screw and 4.

retaining nut.

Socket-

Head Cap

Shim

Clamp

Screw

Figure 9

Screw

Bracket

Retaining

Nut

Attachment

Mounting

Outer

Tube

Shim

Cutting

Plate

CAUTION!

Make sure the clamp screw and

retaining nut are securely tightened

before tightening the four sockethead cap screws.

T242

Cutting

Attachment

Shield

Nuts

Line Cutter

Figure 9A

Hex

Screws

WARNING!

NEVER operate the unit without the cutting attachment shield

installed and tightly secured!

Assembly

Trimmer Head

Install the Trimmer Head.

Turn the trimmer over so that the 1.

gear case output shaft faces UP.

Remove and discard the black plastic 2.

protective cap from the output shaft.

See Figure 10.

Rotate the holder until the hole in the 3.

holder aligns with the notch on the

gear case. Use the long end of the

hex wrench to lock the holder and

output shaft. See Figure 10.

While holding the hex wrench, 4.

thread the trimmer head onto

the output shaft, turning counterclockwise. Using hand pressure only,

tighten the trimmer head firmly on

the output shaft.

IMPORTANT!

The trimmer head has a left-hand

thread. For removal turn the trimmer

head clockwise.

Remove the hex wrench.5.

Trim the trimmer line length to 6.

reach no further than the line

cutter on the cutting attachment

shield. Trim to the correct length if

necessary.

Retaining

Plug

Holder

Output

shaft

Figure 10

Hex Wrench

WARNING!

A standard grass trimmer with a loop handle should NEVER be

operated with blade-type attachments. For blade use the trimmer must be

tted with a bicycle-type handlebar or a barrier bar that is located in front of

the operator to reduce the risk of the operator from coming in contact with

the cutting attachment (per ANSI B175.3). When using a blade, the unit must

also be equipped with a harness or strap.

The unit should now be

completely assembled and

ready for use with a trimmer

head.

8

Page 9

Mixing Fuel

WARNING!

Alternative fuels, such as E15 (15% ethanol), E-85 (85% ethanol) or any fuels not meeting Shindaiwa

requirements are NOT approved for use in Shindaiwa gasoline engines. Use of alternative fuels may cause

performance problems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including,

but not limited to, improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel

lines, gaskets, carburetors and other engine components.

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain

up to 10% Ethanol (grain alcohol) or 15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood

alcohol) is NOT approved.

2 Stroke Mixture Oil - A 2-stroke engine oil meeting ISO-L-EGD (ISO/CD 13738) and J.A.S.O. M345/FD standards

must be used. Shindaiwa OneTM 2-Stroke Oil is strongly recommended as it meets this standard and is specically

formulated for use in all Shindaiwa 2-stroke engines. Engine problems due to inadequate lubrication caused by fail-

ure to use an ISO-L-EGD (ISO/CD 13738) and J.A.S.O. M345/FD certied oil will void the engine warranty.

For increased engine protection, Shindaiwa recommends using Shindaiwa Red ArmorTM engine oil to protect the

engine from harmful carbon build up, maintain engine performance, and increase engine life. Shindaiwa Red ArmorTM

engine oil exceeds ISO-L-EGD and J.A.S.O. M345/FD performance requirements.

IMPORTANT!

Shindaiwa One

ratio for application in all Shindaiwa engines sold in the past, regardless of ratio

specified in those manuals.

Stored fuel ages. Do not mix more fuel than you expect to use in thirty (30) days,

ninety (90) days when a fuel stabilizer is added. Use of unmixed, improperly

mixed, or stale fuel, may cause hard starting, poor per formance, or severe engine

damage and void the product warranty. Read and follow instructions in the Long

Term Storage section of this manual.

TM

2-Stroke oil or Red ArmorTM engine oil may be mixed at 50:1

IMPORTANT!

Examples of 50:1 mixing

quantities

Handling Fuel

DANGER

Fuel is VERY ammable. Use extreme care when mixing, storing or handling or serious personal injury may result.

• Use an approved fuel container.

• DO NOT smoke near fuel.

• DO NOT allow ames or sparks near fuel.

• Fuel tanks/cans may be under pressure. Always loosen fuel caps slowly allowing pressure to equalize.

• NEVER refuel a unit when the engine is HOT or RUNNING!

• DO NOT ll fuel tanks indoors. ALWAYS ll fuel tanks outdoors over bare ground.

• DO NOT overll fuel tank. Wipe up spills immediately.

• Securely tighten fuel tank cap and close fuel container after refueling.

• Inspect for fuel leakage. If fuel leakage is found, do not start or operate unit until leakage is repaired.

• Move at least 3m (10 ft.) from refueling location before starting the engine.

9

Page 10

Mixing Instructions

1. Fill an approved fuel container with half of the

required amount of gasoline.

2. Add the proper amount of engine oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline, close fuel container, and

remix.

IMPORTANT!

Spilled fuel is a leading cause of hydrocarbon emissions.

Some states may require the use of automatic fuel shut-off

containers to reduce fuel spillage.

Filling the fuel tank

After use

• DO NOT store a unit with fuel in its tank. Leaks can

occur. Return unused fuel to an approved fuel storage container.

Storage - Fuel storage laws vary by locality. Contact

your local government for the laws affecting your area.

As a precaution, store fuel in an approved, airtight

container. Store in a well-ventilated, unoccupied build-

ing, away from sparks and ames.

IMPORTANT!

Stored fuel may separate. ALWAYS shake fuel container

thoroughly before each use.

Slowly remove the fuel cap only after stopping the engine

Remove the fuel cap, and fill the tank with clean, fresh fuel.3.

Reinstall the fuel filler cap and tighten firmly.4.

Wipe away any spilled fuel before starting engine.5.

WARNING!

Minimize the Risk of Fire

NEVER ■ smoke or light res near the engine.

■ stop the engine and allow it to cool before

ALWAYS

refueling.

■ Wipe all spilled fuel and move at least 3

ALWAYS

meters (10 feet) from the fueling point and source before

starting.

■ place ammable material close to the engine

NEVER

mufer.

NEVER ■ operate the engine without the mufer and spark

arrester screen in place and in good working condition.

FUEL IS HIGHLY FLAMMABLE. ■

Place the unit on a flat, level surface.1.

Clear any dirt or other debris from around the fuel filler cap.2.

CAUTION!

ALWAYS ■ store gasoline in a container approved for

ammable liquids.

■ inspect the unit for fuel leaks before each

ALWAYS

use. During each rell, check that no fuel leaks from

around the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using the unit immediately. Fuel leaks must be repaired before using the unit.

ALWAYS ■ move the unit at least 3 meters (10 feet)

away from a fuel storage area or other readily am-

mable materials before starting

the engine.

10

Page 11

XST013

Starting the Engine

IMPORTANT!!

Engine ignition is controlled by a two position switch mounted on the throttle housing labeled, “I” for ON or START and

“O” for OFF or STOP.

Slide the ignition switch to the “I” 1.

position. See Figure 14.

Press the primer bulb until fuel can 2.

be seen flowing in the transparent

return tube.

3. Set the choke lever to the CLOSED

position if engine is cold.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly

pressing the primer bulb will not flood

the engine with fuel.

4. While holding the outer tube firmly

with left hand. Use your other hand

to slowly pull the recoil starter

handle until resistance is felt, then

pull quickly to start the engine.

Figure 14

Closed

Figure 16

ON

Return Tube

Primer Bulb

Figure 15

Make sure

the cutting

attachment

is clear of

obstructions!

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

WARNING!

The cutting attachment may

rotate when the engine is started!

5. When the engine starts, slowly

move the choke lever to the “OPEN”

position. See Figure 18. (If the engine

stops after the initial start, close the

choke and restart.)

WARNING!

Never start the engine from

the operating position.

Figure 17

Open

Figure 18

11

Page 12

251029

Starting the Engine (continued)

When the Engine Starts...

n After the engine starts, allow the engine to warm up at idle 2 or 3 minutes before operating the unit.

n Advancing the throttle makes the cutting attachment turn faster; releasing the throttle permits the attachment to stop

turning. If the cutting attachment continues to rotate when the engine returns to idle, carburetor idle speed should be

adjusted (see “Adjusting Engine Idle” below).

Starting A Flooded Engine

Slide the ignition switch to the “I” (ON) position1. .

Open the choke, put the throttle lever in the full throttle position, then clear 2.

excess fuel from the combustion chamber by cranking the engine several

times.

If the engine still fails to start or fire, refer to the troubleshooting flow chart 3.

at the end of this manual.

Stopping the Engine

Idle the engine briefly before stopping (about 2 minutes), then slide the ignition

switch to the “O” (Engine OFF) position.

OFF

Checking Unit Condition

NEVER operate the unit with the

cutting attachment shield or other

protective devices removed!

WARNING!

A cutting attachment shield

or other protective device is no

guarantee of protection against

ricochet. YOU MUST ALWAYS

GUARD AGAINST FLYING DEBRIS!

Use only authorized Shindaiwa parts

and accessories with your Shindaiwa

trimmer. Do not make modifications to

this unit without written approval from

Shindaiwa.

ALWAYS make sure the cutting

attachment is properly installed and

firmly tightened before operation.

NEVER use a cracked or warped

cutting attachment: replace it with a

serviceable one.

ALWAYS make sure the cutting

attachment fits properly into the

appropriate attachment holder. If a

properly installed attachment vibrates,

replace the attachment with new one

and re-check.

Figure 19

ALWAYS stop the engine immediately

and check for damage if you strike a

foreign object or if the unit becomes

tangled. Do not operate with broken or

damaged equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could

damage the engine.

NEVER operate a unit with worn

or damaged fasteners or attachment

holders.

12

Page 13

Cutting Grass—Units equipped with a trimmer head

Your Shindaiwa unit may be equipped

with one of several Shindaiwa trimmer

head models, each with features for

specific applications and/or operational

requirements.

NOTE:

For proper operation, always refer to

the instructions accompanying the

trimmer head being used. Available

trimmer head styles include:

n Semi-automatic. Trimmer line is

indexed when the operator taps the

trimmer head on the ground during

operation.

n Manual. The operator indexes line

manually with the grass trimmer

stopped.

n Fixed. The operator must stop the

unit and add new lengths of trimmer

line manually.

n Flail. This device, designed for

clearing weeds and light brush,

features three nylon blades attached

to the head by pivots.

NOTE:

Additional hardware may be required

to mount the Fixed Line or the Flail

type trimmer heads.

CAUTION!

Do not push the rotating line into

trees, wire fences or any material

that could tangle or break line ends.

Engine Operating Speeds

Operate the unit at full throttle while

cutting grass.

CAUTION!

Operation of trimmer without a

cutting attachment shield and using

excessive line length can lead to

premature clutch failure.

CAUTION!

Operation at low RPM can lead to

premature clutch failure.

Hold the trimmer so the trimmer head

is angled slightly into the area to be

cut. To ensure maximum trimmer-line

service life, cut only with the tip of the

trimmer line. Cut grass by swinging

the trimmer from left to right. Keep the

trimmer head

horizontal. See Figure 22.

Trimming and

Mowing Grass

Figure 22

Edging

Tilt the handle

about 100° to

the left (from

horizontal) and

move forward,

holding the

trimmer vertically

as shown in Figure

23.

Figure 23

Maintenance

General maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY

ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A DEALER

OR SERVICE CENTER AUTHORIZED BY ECHO,INC. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE

AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

NOTE:

Using non-standard replacement parts could invalidate your Shindaiwa warranty.

WARNING!

Before performing any maintenance, repair, or cleaning work on

the unit, make sure the engine and

cutting attachment are completely

stopped. Disconnect the spark plug

wire before performing service or

maintenance.

ting attachment, or replacement parts

may not operate properly with your unit

and may cause damage and lead to

personal injury.

WARNING!

Non-standard accessories, cut-

13

Page 14

Mufer

This unit must never be operated with a faulty or missing spark arrester or muf fler. Make sure the muffler is well secured and

in good condition. A worn or damaged muffler is a fire hazard and may also cause hearing loss.

Spark Plug

Keep the spark plug and wire connections tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except carburetor adjusting screws) are tight.

Daily Maintenance

Prior to each work day, perform the following:

■

Remove dirt or debris from the

engine, check the cooling fins and air

cleaner for clogging and clean them

as necessary.

10-Hour Maintenance

Unscrew

Fastener

Figure 26

■

Carefully remove any accumulation

of dirt or debris from the muffler or

the fuel tank. Dirt build-up in these

areas could cause engine overheating, induce premature wear, or create a fire hazard.

Remove and

clean or replace

the element

■

Check for loose or missing screws or

components. Make sure the cutting

attachment is securely fastened.

Check the entire unit for leaking fuel

■

or grease.

Every 10 hours of operation (more

frequently in dusty or dirty conditions):

■

Remove the air cleaner element.

See Figure 26. Clean or replace as

necessary. To clean element: wash it

thoroughly in soap and water. Let it

dry before reinstalling the element.

CAUTION!

Do not operate the unit if the air

cleaner or element is damaged, or if

the element is wet.

14

Page 15

Maintenance (continued)

10/15-Hour Maintenance

Clean the

0.6 mm

(0.024 inch)

spark plug and

check the gap

at the electrode.

Every 10 to 15 hours of operation:

■

Remove and clean the spark plug.

Adjust the spark plug electrode gap

0.6 mm to (0.024 inch). If the spark

plug must be replaced, use only an

BPM8Y or equivalent resistor type

spark plug of the correct heat range.

See Figure 27.

NOTE:

The BPM8Y also meets the

requirements for electro magnetic

compliance (EMC).

Figure 27

50-Hour Maintenance

Every 50 hours of operation

(more frequently in dusty or dirty

conditions):

■

Remove and clean the cylinder cover

and clean grass and dirt from the cylinder fins.

Remove the cutting attachment, cut-

■

ting attachment holder and gear

shaft collar. Remove the filler plug

from the side of the gear case and

press new grease into the gear case

until old grease is pushed out. Use

only lithium-base grease such as

Shindaiwa Gear Case Lubricant or

equivalent. See Figure 28.

■

Remove mainshaft and lubricate both

ends of the splines.

Use a hooked wire to extract the fuel

■

filter from inside the fuel tank.

See Figure 29.

Remove and replace the

lter element.

Before reinstalling the new filter

element, inspect the condition of all the

fuel system components (fuel pick-up

line, fuel return line, tank vent line, tank

vent, fuel cap and fuel tank). If damage,

splitting or deterioration is noted, the

unit should be removed from service

until it can be inspected or repaired by a

Shindaiwa-trained service technician.

Figure 28

CAUTION!

Before removing the spark plug,

clean the area around the plug to

prevent dirt and debris from getting

into the engine’s internal parts.

New

Grease

Old

Grease

Gear

Shaft

Collar

CAUTION!

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be

damaged easily.

Figure 29

Hooked

Wire

Filter Element

15

Page 16

135-hour Maintenance

Every 135 hours of operation,

remove and clean the muffler.

WARNING!

Never operate this trimmer

with a damaged or missing mufer

or spark arrester! Operating with

missing or damaged exhaust

components is a re hazard, and

can also damage your hearing!

Remove the spark plug boot.1.

With a 3 mm hex wrench remove 2.

the 1 muffler cover and 3 engine

cover screws and the engine cover.

See Figure 30.

With a Phillips type screwdriver 3.

remove the 5 screws holding the

spark arrester screen and cover to

the muffler. See Figure 30.

Remove the screen and clean it with 4.

a stiff bristle br ush.

With a 4 mm hex wrench remove 5.

the 3 muffler bolts and the muf fler.

See Figure 30.

Inspect the cylinder exhaust port for 6.

any carbon buildup.

Gently tap the muffler on a wood 7.

surface to dislodge any loose

carbon.

Engine Cover

Screws

Figure 30

Engine

Cover

Mufer

Gasket

IMPORTANT!

If you note excessive carbon buildup,

consult with an authorized Shindaiwa

servicing dealer.

Mufer

Cover

Mufer

Cover Screw

Mufer

Mufer

Spark Arrester

Screen

Screws

Gasket

Spark Arrester

Cover

Reassemble the spark arrester, 8.

muffler and engine cover in the

reverse order of disassembly.

Screws

Outlet

Carburetor Adjustment

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be

made. During the break-in period your engine performance will increase and exhaust emissions will stabilize. Idle speed can

be adjusted as required.

High Altitude Operation

This engine has been factory adjusted to maintain satisfactory starting, emission, and durability performance up to

1,100 feet above sea level (ASL) (96.0 kPa). To maintain proper engine operation and emission compliance above

1,100 feet ASL the carburetor may need to be adjusted by an authorized Shindaiwa service dealer.

IMPORTANT!!

If the engine is adjusted for operation above 1,100 feet ASL, the carburetor must be re-adjusted when operating the

engine below 1,100 feet ASL, otherwise severe engine damage may result.

NOTE:

Every unit is run at the factory and the carburetor is set in compliance with emission regulations. Carburetor adjustments,

other than idle speed, must be performed by an authorized Shindaiwa dealer.

16

Page 17

Adjusting Engine Idle

Figure 20

Idle Adjusting

Screw

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch

to disengage the cutting attachment.

WARNING!

The cutting attachment must

NEVER rotate at engine idle! If the

idle speed cannot be adjusted by the

procedure described here, return the

trimmer to your Shindaiwa dealer for

inspection.

Idle Speed Adjustment

1. Place the trimmer on the ground,

then start the engine, and then allow

it to idle 2-3 minutes until warm.

2. If the attachment rotates when the

engine is at idle, reduce the idle

speed by turning the idle adjustment

screw counter-clockwise. See Figure

20.

3. If a tachometer is available, the engine

idle speed should be final adjusted to

3,000 (±250) rpm (min

4. Carburetor fuel mixture adjustments

are preset at factory and cannot be

serviced in the field.

-1

).

Loading Trimmer Line

1. Cut one piece of line to recommended length.

2. Align arrows on top of knob with openings in eyelets.

3. Insert one end of trimmer line into an eyelet, and push

line equal distance through trimmer head.

4. Hold trimmer head while turning knob clockwise to

wind line onto spool until about 5” (13 cm) of each line

remains exposed.

Trimmer head is now fully loaded and ready for

operation.

Long Term Storage

Whenever the unit will not be used for

30 days or longer, use the following

procedures to prepare it for storage:

■

Clean external parts thoroughly and

apply a light coating of oil to all metal

surfaces.

Drain all the fuel from the carburetor

■

and the fuel tank.

To do so:

Prime the primer bulb until no more 1.

fuel is passing through.

Start and r un the engine until it stops 2.

running.

Repeat steps 1 and 2 until the engine 3.

will no longer start.

CAUTION!

Gasoline stored in the carburetor

for extended periods can cause

hard starting, and could also lead to

increased service and maintenance

costs.

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL™.

Damage resulting from stale or

contaminated fuel is not covered by the

Shindaiwa warranty policy.

1 2

.080 (2.0 mm) dia. - 10’ (3 m)

.095 (2.4 mm) dia. - 10’ (3 m)

IMPORTANT!

NOTE:

3

Remove the spark plug and pour ■

about 1/4 oz. of engine oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3

times so oil will evenly coat the interior of the engine. Reinstall the spark

plug.

■

Before storing the unit, repair or

replace any worn or damaged par ts.

Remove the air cleaner element from

■

the carburetor and clean it thoroughly with soap and water. Let dry

and reassemble the element.

Store the unit in a clean, dust-free

■

area.

4

17

Page 18

Troubleshooting Guide

Vaporlock.

Engine hot/heat soaked.

Low fuel quality.

Let cool completely and restart.

Refi ll with fresh, clean unleaded gasoline with a pump octane

of 89 or higher mixed with an air cooled engine oil that

meets or exceeds ISO-L-EGD and/or JASO FD classifi ed oils

at 50:1 gasoline/oil ratio.

What To Check

Possible Cause

Remedy

ENGINE DOES NOT START OR HARD TO START

NO

NO

NO

NO

Does the engine crank?

Good compression?

Does the tank contain fresh

fuel of the proper grade?

Is fuel visible and moving

in the return line when

priming?

Is there spark at the spark

plug wire terminal?

Check the spark plug.

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Loose spark plug.

Excess wear on cylinder,

piston, rings.

Fuel incorrect, stale, or

contaminated; mixture incorrect.

Check for clogged fuel fi lter

and/or vent.

Priming pump not functioning properly.

The ignition switch is in

“O” (OFF) position.

Shorted ignition ground.

Faulty ignition unit.

If the plug is wet, excess

fuel may be in the cylinder.

The plug is fouled or improperly

gapped.

The plug is damaged internally

or of the wrong size.

Consult with an authorized Shindaiwa servicing dealer.

Tighten and re-test.

Consult with an authorized Shindaiwa

servicing dealer.

Refi ll with fresh, clean unleaded gasoline with a pump octane

of 89 or higher mixed with an air cooled engine oil that

meets or exceeds ISO-L-EGD and/or JASO FD classifi ed oils

at 50:1 gasoline/oil ratio.

Replace fuel fi lter or vent as required.

Re-start.

Consult with an authorized Shindaiwa

servicing dealer.

Move switch to “I” (ON) position

and re-start.

Consult with an authorized Shindaiwa

servicing dealer.

See "Starting a Flooded Engine"

Clean and gap the spark plug. Check the Specifi cations

section for the correct plug and gap for your unit. Restar t.

Replace the spark plug. Check the Specifi cations section for

the correct plug and gap for your unit. Restar t.

NO

YES

What To Check

Possible Cause Remedy

ENGINE DOES NOT START

YES

YES

YES

YES

18

Page 19

Refi ll with fresh, clean unleaded gasoline with a pump octane of 89 or higher

mixed with an air cooled engine oil that meets or exceeds ISO-L-EGD and/

or JASO FD classifi ed oils at 50:1 gasoline/oil ratio.

Is the engine overheating?

Engine is rough at all

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fi ns dirty

or damaged.

Carbon deposits on the piston or

in the muffl er.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm.

Overheating condition.

Improper fuel.

Carbon deposits in the

combustion chamber.

Use a lower throttle setting.

Consult with an authorized Shindaiwa

servicing dealer.

Refi ll with fresh, clean unleaded gasoline with a pump octane

of 89 or higher mixed with an air cooled engine oil that meets

or exceeds ISO-L-EGD and/or JASO FD classifi ed oils at 50:1

gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized Shindaiwa

servicing dealer.

Service the air cleaner element.

Tighten or replace the spark plug.

Check the Specifi cations section for the correct plug and gap

for your unit.

Repair or replace fuel fi lter and/or

fuel line.

Refi ll with fresh, clean unleaded gasoline with a pump octane

of 89 or higher mixed with an air cooled engine oil that meets

or exceeds ISO-L-EGD and/or JASO FD classifi ed oils at 50:1

gasoline/oil ratio.

Consult with an authorized Shindaiwa servicing dealer.

Consult with an authorized Shindaiwa

servicing dealer.

Refi ll with fresh, clean unleaded gasoline with a pump octane

of 89 or higher mixed with an air cooled engine oil that meets

or exceeds ISO-L-EGD and/or JASO FD classifi ed oils at 50:1

gasoline/oil ratio.

Consult with an authorized Shindaiwa

servicing dealer.

What To Check

Possible Cause

Remedy

LOW POWER OUTPUT

Engine is knocking.

Troubleshooting Guide (continued)

19

Page 20

ADDITIONAL PROBLEMS

Poor acceleration.

Clogged air fi lter.

Clogged fuel fi lter.

Lean fuel/air mixture.

Idle speed set too low.

Ignition switch turned off.

Fuel tank empty.

Water in the fuel.

Clogged fuel fi lter.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Ground (stop) wire is disconnected,

or switch is defective.

Overheating due to incorrect spark plug.

Overheated engine.

Clean the air fi lter.

Replace the fuel fi lter.

Consult with an authorized Shindaiwa

servicing dealer.

Adjust idle. Check Specifi cations page for correct idle speed.

Reset the switch and re-start.

Refi ll with fresh, clean unleaded gasoline with a pump octane

of 89 or higher mixed with an air cooled engine oil that

meets or exceeds ISO-L-EGD and/or JASO FD classifi ed oils

at 50:1 gasoline/oil ratio.

Replace fuel fi lter.

Clean or replace spark plug. Check the Specifi cations section

for the correct plug and gap for your unit. Tighten

the terminal.

Replace the ignition unit.

Consult with an authorized Shindaiwa

servicing dealer.

Test and replace as required.

Replace the spark plug. Check the Specifi cations section for

the correct plug and gap for your unit. Restar t.

Idle engine until cool.

Symptom

Possible Cause

Remedy

Engine stops abruptly.

Engine diffi cult to shut off.

Troubleshooting Guide (continued)

Engine idle too high.

Broken clutch spring or worn clutch

spring boss.

Loose attachment holder.

Warped or damaged attachment.

Loose gearcase.

Cutting attachment

moves at engine idle.

Excessive vibration.

Cutting attachment will not

move.

Adjust idle. Check Specifi cations page for correct idle

speed.

Replace spring/shoes as required, check idle speed.

Inspect and re-tighten holders securely.

Inspect and replace attachment as

required.

Tighten gearcase securely.

Bent main shaft/worn or damaged bushings.

Shaft not installed in powerhead or gearcase.

Broken shaft.

Damaged gearcase.

Inspect and replace as necessary.

Inspect and reinstall as required.

Idle set too high.

Adjust idle. Check Specifi cations page for correct

idle speed.

Engine will not idle

down.

Engine has an air leak.

Consult with an authorized Shindaiwa servicing

dealer.

Consult with an authorized Shindaiwa servicing

dealer.

SHINDAIWA LIMITED WARRANTY STATEMENT FOR

PRODUCT SOLD IN USA AND CANADA BEGINNING 01/01/2010

ECHO, INC’S RESPONSIBILITY

ECHO Incorporated’s (ECHO, INC.) Limited Warranty, provides to the original purchaser that this Shindaiwa product is free from

defects in material and workmanship. Under normal use and maintenance from date of purchase, ECHO, INC. agrees to repair

or replace at it’s discretion, any defective product free of charge at any authorized Shindaiwa servicing dealer within listed below

application time periods, limitations and exclusions. THIS LIMITED WARRANTY IS ONLY APPLICABLE TO SHINDAIWA PROD-

UCTS SOLD BY AUTHORIZED SHINDAIWA DEALERS. IT IS EXTENDED TO THE ORIGINAL PURCHASER ONLY, AND IS

NOT TRANSFERABLE TO SUBSEQUENT OWNERS EXCEPT FOR EMISSION RELATED PARTS. Repair parts and accesso-

ries replaced under this warranty are warranted only for the balance of the original unit or accessory warranty period. Any dam-

age caused by improper installation or improper maintenance is not covered by this warranty. All parts or products replaced under

warranty become the property of ECHO, INC. This warranty is separate from the Emission control warranty statement supplied with

your new product. Please consult the Emission Control Warranty Statement for details regarding emission related parts. For a list

of Authorized Shindaiwa Dealers refer to WWW.SHINDAIWA.COM or call 1-877-986-7783.

OWNER’S RESPONSIBILITY

To ensure trouble free warranty coverage it is important that you register your Shindaiwa equipment on-line at WWW.SHINDAIWA.

COM or by lling out the warranty registration card supplied with your unit. Registering your product con rms your warranty cover-

age and provides a direct link if we nd it necessary to contact you.

The owner shall demonstrate reasonable care and use, and follow preventative maintenance, storage, fuel and oil usage as pre-

scribed in the operator’s manual. Should a product dif culty occur, you must, at your expense, deliver or ship your Shindaiwa unit

to an authorized Shindaiwa servicing dealer for warranty repairs (within the applicable warranty period), and arrange for pick-up

or return of your unit after the repairs have been made. For your nearest authorized Shindaiwa servicing dealer, call Shindaiwa’s

Dealer Referral Center, at 1-877-986-7783 or you can locate a Shindaiwa servicing dealer at WWW.SHINDAIWA.COM. Should you

require assistance or have questions concerning Shindaiwa’s Warranty Statement, you can contact our Consumer Product Support

Department at 1-800-673-1558 or contact us through the web at WWW.SHINDAIWA.COM.

PRODUCT WARRANTY PERIOD

RESIDENTIAL APPLICATION

• 2 YEAR WARRANTY - Units for residential, or non-income producing use will be covered by this limited warranty for

two (2) years from date of purchase.

EXCEPTIONS:

• For engine powered products, the electronic ignition module, exible drive cable, and solid drive shaft are warranted for

the life* of the product on parts only.

• Cutting attachments such as, but not limited to, bars, chains, sprockets, tines, blades, PowerBroom

TM

, belts, and nylon

trimmer heads for residential or non-income producing use will be covered for failures due to defects in material or

workmanship for a period of 60 days from original product purchase date. Any misuse from contact with concrete,

rocks, or other structures is not covered by this warranty.

• Multipurpose Tool Attachments carry the same warranty duration as the units they are designed to t.

COMMERCIAL APPLICATION

• 90 DAY WARRANTY - All Chain Saws and Cut-Off Saws for commercial, institutional, agricultural, industrial, or income produc-

ing use will be covered by this limited warranty for 90 Days from the date of purchase.

• 2 YEAR WARRANTY - Units for commercial, institutional, agricultural, industrial, or income producing use will be covered by

this limited warranty for two (2) years from the date of purchase.

EXCEPTIONS:

• For engine powered products, the electronic ignition module, exible drive cables, and solid drive shafts are warranted

for the life* of the product on parts only.

• Cutting attachments such as, but not limited to, bars, chains, sprockets, tines, blades, PowerBroom

TM

, belts, and nylon

trimmer heads for commercial, institutional, agricultural, industrial, rental, or income producing will be covered for fail-

ures due to defects in material or workmanship for a period of 30 days from original product purchase date. Any misuse

from contact with concrete, rocks, or other structures is not covered by this warranty.

• Multipurpose Tool Attachments carry the same warranty duration as the units they are designed to t.

RENTAL APPLICATION - 90 DAYS WARRANTY

• Units for rental use will be covered against defects in material and workmanship for a period of 90 days from the date of pur-

chase.

* ECHO INC’s liability under the “Lifetime” coverage is limited to furnishing parts speci ed under the PRODUCT Warranty

PERIOD section of this warranty statement for “Life” free of charge for a period of ten (10) years after the date of the complete

unit’s nal production.

20

Page 21

SHINDAIWA LIMITED WARRANTY STATEMENT FOR

PRODUCT SOLD IN USA AND CANADA BEGINNING 01/01/2010

ECHO, INC’S RESPONSIBILITY

ECHO Incorporated’s (ECHO, INC.) Limited Warranty, provides to the original purchaser that this Shindaiwa product is free from

defects in material and workmanship. Under normal use and maintenance from date of purchase, ECHO, INC. agrees to repair

or replace at it’s discretion, any defective product free of charge at any authorized Shindaiwa servicing dealer within listed below

application time periods, limitations and exclusions. THIS LIMITED WARRANTY IS ONLY APPLICABLE TO SHINDAIWA PROD-

UCTS SOLD BY AUTHORIZED SHINDAIWA DEALERS. IT IS EXTENDED TO THE ORIGINAL PURCHASER ONLY, AND IS

NOT TRANSFERABLE TO SUBSEQUENT OWNERS EXCEPT FOR EMISSION RELATED PARTS. Repair parts and accesso-

ries replaced under this warranty are warranted only for the balance of the original unit or accessory warranty period. Any damage caused by improper installation or improper maintenance is not covered by this warranty. All parts or products replaced under

warranty become the property of ECHO, INC. This warranty is separate from the Emission control warranty statement supplied with

your new product. Please consult the Emission Control Warranty Statement for details regarding emission related parts. For a list

of Authorized Shindaiwa Dealers refer to WWW.SHINDAIWA.COM or call 1-877-986-7783.

OWNER’S RESPONSIBILITY

To ensure trouble free warranty coverage it is important that you register your Shindaiwa equipment on-line at WWW.SHINDAIWA.

COM or by lling out the warranty registration card supplied with your unit. Registering your product con rms your warranty cover-

age and provides a direct link if we nd it necessary to contact you.

The owner shall demonstrate reasonable care and use, and follow preventative maintenance, storage, fuel and oil usage as pre-

scribed in the operator’s manual. Should a product dif culty occur, you must, at your expense, deliver or ship your Shindaiwa unit

to an authorized Shindaiwa servicing dealer for warranty repairs (within the applicable warranty period), and arrange for pick-up

or return of your unit after the repairs have been made. For your nearest authorized Shindaiwa servicing dealer, call Shindaiwa’s

Dealer Referral Center, at 1-877-986-7783 or you can locate a Shindaiwa servicing dealer at WWW.SHINDAIWA.COM. Should you

require assistance or have questions concerning Shindaiwa’s Warranty Statement, you can contact our Consumer Product Support

Department at 1-800-673-1558 or contact us through the web at WWW.SHINDAIWA.COM.

PRODUCT WARRANTY PERIOD

RESIDENTIAL APPLICATION

• 2 YEAR WARRANTY - Units for residential, or non-income producing use will be covered by this limited warranty for

two (2) years from date of purchase.

EXCEPTIONS:

• For engine powered products, the electronic ignition module, exible drive cable, and solid drive shaft are warranted for

the life* of the product on parts only.

• Cutting attachments such as, but not limited to, bars, chains, sprockets, tines, blades, PowerBroom

TM

, belts, and nylon

trimmer heads for residential or non-income producing use will be covered for failures due to defects in material or

workmanship for a period of 60 days from original product purchase date. Any misuse from contact with concrete,

rocks, or other structures is not covered by this warranty.

• Multipurpose Tool Attachments carry the same warranty duration as the units they are designed to t.

COMMERCIAL APPLICATION

• 90 DAY WARRANTY - All Chain Saws and Cut-Off Saws for commercial, institutional, agricultural, industrial, or income produc-

ing use will be covered by this limited warranty for 90 Days from the date of purchase.

• 2 YEAR WARRANTY - Units for commercial, institutional, agricultural, industrial, or income producing use will be covered by

this limited warranty for two (2) years from the date of purchase.

EXCEPTIONS:

• For engine powered products, the electronic ignition module, exible drive cables, and solid drive shafts are warranted

for the life* of the product on parts only.

• Cutting attachments such as, but not limited to, bars, chains, sprockets, tines, blades, PowerBroom

TM

, belts, and nylon

trimmer heads for commercial, institutional, agricultural, industrial, rental, or income producing will be covered for failures due to defects in material or workmanship for a period of 30 days from original product purchase date. Any misuse

from contact with concrete, rocks, or other structures is not covered by this warranty.

• Multipurpose Tool Attachments carry the same warranty duration as the units they are designed to t.

RENTAL APPLICATION - 90 DAYS WARRANTY

• Units for rental use will be covered against defects in material and workmanship for a period of 90 days from the date of pur-

chase.

* ECHO INC’s liability under the “Lifetime” coverage is limited to furnishing parts speci ed under the PRODUCT Warranty

PERIOD section of this warranty statement for “Life” free of charge for a period of ten (10) years after the date of the complete

unit’s nal production.

21

Page 22

PURCHASED REPAIR PARTS AND ACCESSORIES

• 90-day all applications

ATTENTION ENGINE POWERED PRODUCT OWNERS

This Shindaiwa engine powered product is a quality-engineered unit which has been manufactured to exact tolerances to provide

superior performance. To help ensure the performance of the unit, it is required to use engine oil which meets the ISO-L-EGD

Standard per ISO/CD 13738 and JASO M345/FD Standards. Shindaiwa Red Armor

TM

and Shindaiwa OneTM are a premium engine

oil speci cally formulated to meet ISO-L-EGD (ISO/CD 13738) and JASO M345/FD Standards. The use of engine oils designed

for other applications, such as for outboard motors or lawnmowers can result in severe engine damage, and will void your engine

limited warranty.

THIS WARRANTY DOES NOT COVER DAMAGE CAUSED BY:

• Lack of lubrication or engine failure, due to the use of engine oils that do not meet the ISO-L-EGD (ISO/CD 13738) and JASO

M345/FD Standards. Shindaiwa Red Armor

TM

and Shindaiwa OneTM Engine Oil meets the ISO-L-EGD and JASO M345/FD

Standard. Emission related parts are covered for 2 years regardless of engine oil used, per the statement listed in the EPA or

California Emission Control Warranty Explanation.

• Damage caused by use of gasohol, containing methanol (wood alcohol), or gasoline containing less than 89 octane. Only use

gasoline which contains 89 octane or higher. Gasohol which contains a maximum 10% ethanol (grain alcohol) or 15% MTBE

(methyl/tertiary/butyl/ether) is also approved. The prescribed mixing ratio of gasoline to oil is listed on the Shindaiwa oil label and

covered in your operator’s manual.

• Engine damage caused by use of ether or any starting uids.

• Damage caused by tampering with engine speed governor or emission components, or running engines above speci ed and

recommended engine speeds as listed in your operator’s manual.

• Operation of the unit with improperly maintained/removed cutting shield or removed/damaged air lter.

• Damage caused by dirt, pressure or steam cleaning the unit, salt water, corrosion, rust, varnish, abrasives, and moisture.

• Defects, malfunctions or failures resulting from abuse, misuse, neglect, modi cations, alterations, normal wear, improper servic-

ing, or use of unauthorized attachments.

• Incorrect storage procedures, stale fuel, including failure to provide or perform required maintenance services as prescribed in

the operator’s manual. Preventative maintenance as outlined in the operator’s manual is the customer’s responsibility.

• Failures due to improper set-up, pre-delivery service or repair service by anyone other than authorized Shindaiwa servicing

dealer during the warranty period.

• Certain parts and other items are not warranted, including but not limited to: lubricants, starter cords, and engine tune-ups.

• Use of spark plugs other than those meeting performance and durability requirements of the OEM spark plug listed in the Opera-

tor’s Manuals.

• Overheating or carbon scoring failures due to restricted, clogged exhaust port or combustion chamber, including damage to

spark arrester screen.

• Adjustments after the rst (30) thirty days and beyond, such as carburetor adjustment and throttle cable adjustment.

• Damage to gears or gear cases caused by contaminated grease or oil, use of incorrect type or viscosity of lubricants, and/or

failure to comply with recommended grease or oil change intervals.

• Damage caused by pump or sprayer running dry, pumping or spraying caustic or ammable materials, or lack of or broken

strainers.

• Additional damage to parts or components due to continued use after operational problem or failure occurs. Should operational

problem or failure occur, the product should not be used, but delivered as is to an authorized Shindaiwa servicing dealer.

It is a dealer’s and/or customer’s responsibility to complete and return the warranty registration card supplied with your Shindaiwa

product or by visiting WWW.SHINDAIWA.COM. Your receipt of purchase including date, model and serial number must be main-

tained and presented to an authorized Shindaiwa servicing dealer for warranty service. Proof of purchase rests solely with the customer. Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so you may also have other speci c

legal rights which vary from state to state. This limited warranty is given by ECHO Incorporated, 400 Oakwood Rd., Lake Zurich, IL

60047.

DISCLAIMER OF IMPLIED WARRANTIES

This limited warranty is in lieu of all other expressed or implied warranties, including any warranty of FITNESS FOR A PARTICULAR PURPOSE OR USE and any implied warranty of MERCHANTABILITY otherwise applicable to this product. ECHO, INC. and

its af liated companies shall not be liable for any special incidental or consequential damage, including lost pro ts. There are no

warranties extended other than as provided herein. This limited warranty may be modi ed only by ECHO, INC.

99922201031

06/2010

ECHO INCORPORATED EMISSION CONTROL WARRANTY STATEMENT

FOR ECHO AND SHINDAIWA BRANDS

The Environmental Protection Agency (EPA) and the California Air Resources Board (C.A.R.B.) and ECHO Incorporated (ECHO Inc.) are pleased

to explain the emission control system warranty on your 2010 and later equipment/small off-road engine (SORE). New equipment/SORE must be

designed, built and equipped to meet stringent EPA and C.A.R.B. anti-smog standards. ECHO Inc. must warrant the emission control system on

your equipment/SORE for the periods of time listed below, provided there has been no abuse, neglect or improper maintenance of your equipment/

SORE. Your emission control system may include parts such as: carburetor, fuel-injection system, ignition system, catalytic converter/muf er, fuel

tank, fuel feed lines, fuel cap assembly, spark plug, air lters, and other associated components. Where a warrantable condition exists, ECHO

Inc will repair your equipment/SORE at no cost to you including diagnosis, parts and labor. The Emission Control System warranty is extended

to the original owner including all subsequent owners.

MANUFACTURER'S WARRANTY COVERAGE:

The emission control system is warranted for 2 years or the length of the ECHO Inc. warranty, whichever is longer. If any emission-related part

on your equipment is defective, the part will be repaired or replaced by ECHO Inc. or its Authorized Service Representative.

OWNER'S WARRANTY RESPONSIBILITIES:

As the equipment/SORE owner, you are responsible for the performance of the required maintenance listed in your Operator's Manual. ECHO

Inc. recommends that you retain all receipts covering maintenance on your equipment/SORE however, ECHO Inc. cannot deny warranty solely

for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the equipment/SORE owner, you should be

aware that ECHO Inc. may deny you warranty coverage if your equipment/SORE or a part has failed due to abuse, neglect, improper maintenance

or unapproved modi cations.

You are responsible for presenting your equipment/SORE to an ECHO Inc. authorized service representative as soon as a problem exists. The

warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If a warrantable condition exists and there is no

Authorized Dealer within 100 miles, ECHO Inc. will pay to ship the unit to the nearest authorized dealer. If you have questions regarding your

warranty coverage, you should contact ECHO Inc. at 1-800-673-1558, web site WWW.ECHO-USA.COM or contact Shindaiwa at 1-877-986-

7783, web site WWW.SHINDAIWA.COM.

WHAT DOES THIS WARRANTY COVER?

ECHO Inc. warrants that your equipment/SORE was designed, built and equipped to conform with applicable EPA and C.A.R.B. emissions

standards and that your equipment/SORE is free from defects in material and workmanship that would cause it to fail to conform with applicable

requirements for 2 years or the length of the ECHO Inc. warranty, whichever is longer. The warranty period begins on the date the product is

purchased by an end user.

HOW WILL A COVERED PART BE CORRECTED?

If there is a defect in a part covered by this warranty, any ECHO Inc. Authorized Service Dealer will correct the defect. You will not have to pay

anything to have the part adjusted, repaired or replaced. This includes any labor and diagnosis for warranted repairs performed by the dealer. In

addition, engine parts not expressly covered under this warranty but whose failure is a result of a failure of a covered part will be warranted.

WHAT PARTS ARE COVERED?

Any applicable emission related part not scheduled for "required maintenance" will be repaired or replaced within the warranty period. The repaired

or replaced part will be warranted for the remaining ECHO Inc. warranty period.

Any warranted part that is scheduled only for regular inspection in the written instructions supplied is warranted for the warranty period stated

above. Any such part repaired or replaced under warranty will be warranted for the remaining ECHO Inc. warranty period.

Any emission related part scheduled for replacement during "required maintenance" is warranted for the period of time prior to the rst scheduled

replacement point for that part. Any such part repaired or replaced under warranty shall be warranted for the remainder of the period prior to the

rst scheduled replacement point for that part.

Any manufacturer-approved replacement part may be used in the performance of any warranty maintenance or repairs on emission related parts,

and must be provided without charge if the part is still under warranty.

Any replacement part that is equivalent in performance and durability may be used in non-warranty maintenance or repairs, and shall not reduce

the warranty obligations of the manufacturer.

Throughout the equipment/SORE warranty period, ECHO Inc. will maintain a supply of warranted parts suf cient to meet the expected demand

for such parts.

SPECIFIC EMISSION RELATED WARRANTED PARTS:

• Electronic Ignition System • Spark Plug

• Catalytic Converter / Muf er Assembly • Carburetor (complete assembly or replaceable components)

• Choke • Fuel-Injection Assembly (or replaceable components)

• Fuel Tank • Fuel Cap Assembly

• Air Filter • Fuel Feed Line (and associated clamps/connectors as applicable)

WHAT IS NOT COVERED?

Any failure caused by abuse, neglect, improper maintenance, unapproved modi cations, use of unapproved add-on parts/modi ed parts or

unapproved accessories.

This Emission Control Warranty is valid only for the U.S.A., it's Territories, and Canada.

99922201033

01/2010

22

Page 23

DECLARACIÓN DE GARANTÍA LIMITADA DE SHINDAIWA

VIGENTE PARA PRODUCTOS VENDIDOS EN ESTADOS UNIDOS Y CANADÁ COMENZAR

1° DE ENERO DE 2010

RESPONSABILIDAD DE ECHO

La garantía limitada de ECHO Incorporated (ECHO, INC.) indica al comprador original que este producto Shindaiwa carece de defectos de

materiales y fabricación. En condiciones de uso y mantenimiento normales a partir de la fecha de compra, ECHO, INC. acuerda reparar o

reemplazar, a su discreción, cualquier producto defectuoso de forma gratuita en cualquier distribuidor de servicio autorizado de ECHO en los

períodos de aplicación, limitaciones y exclusiones indicados abajo. ESTA GARANTÍA LIMITADA SE APLICA SOLAMENTE A PRODUCTOS

SHINDAIWA VENDIDOS POR DISTRIBUIDORES ECHO AUTORIZADOS. SE EXTIENDE AL COMPRADOR ORIGINAL SOLAMENTE, Y

NO SE PUEDE TRANSFERIR A PROPIETARIOS SUBSIGUIENTES EXCEPTO EN LO QUE SE REFIERE A PIEZAS RELACIONADAS CON

LAS EMISIONES. Las piezas de reparación y los accesorios reemplazados según esta garantía están garantizados solamente para el resto

del período de garantía de la unidad original o del accesorio. Cualquier daño causado por la instalación o el mantenimiento indebidos no está

cubierto por esta garantía. Todas las piezas o productos con garantía se convierten en propiedad de ECHO, INC. Esta garantía es indepen-

diente de la declaración de garantía de control de emisiones incluida con su nuevo producto. Consulte la declaración de garantía de control

de emisiones para obtener detalles sobre piezas relacionadas con emisiones. Para obtener una lista de distribuidores autorizados Shindaiwa,

consulte WWW.SHINDAIWA.COM o llame al 1-877-986-7783.

RESPONSABILIDAD DEL PROPIETARIO

Para asegurar una cobertura de la garantía sin problemas es importante que registre sus equipos Shindaiwa en línea en WWW.SHINDAIWA.

COM o rellenando la tarjeta de registro de garantía suministrada con su unidad. El registro de su producto con rma su cobertura de garantía y

proporciona un enlace directo entre usted si es necesario que nos pongamos en contacto con usted.

El propietario debe demostrar un cuidado y uso razonables, y seguir el mantenimiento preventivo, almacenamiento, uso de combustible y

aceite según se indica en el manual del operador. Si se producen di cultades en un producto, usted debe, por su cuenta, entregar o enviar su

unidad Shindaiwa a un distribuidor de servicio autorizado para las reparaciones cubiertas por la garantía (dentro del período de garantía corre-

spondiente), y hacer los arreglos para la recogida o devolución de su unidad después de haberse efectuado las reparaciones. Para localizar a

su distribuidor de servicio autorizado más cercano, llame al centro de distribuidores de Shindaiwa, al 1-877-986-7783, o también puede visitar

WWW.SHINDAIWA.COM. Si necesita asistencia o tiene dudas referentes a la declaración de garantía de Shindaiwa, puede ponerse en con-

tacto con el Departamento de Respaldo de Productos del Consumidor llamando al 1-800-673-1558 o puede ponerse en contacto con nosotros

a través de la web visitando WWW.SHINDAIWA.COM.

PERÍODO DE GARANTÍA DEL PRODUCTO

APLICACIÓN RESIDENCIAL

GARANTÍA DE 2 AÑOS• - Los unidads para aplicaciones residenciales, o que no producen ingresos, estará cubierta por esta garantía limi-

tada durante dos (2) años contados a partir de la fecha de compra.

EXCEPCIONES

Para productos impulsados por motores, el módulo de encendido electrónico, cables de mando exibles, ejes de impulsión sólido están •

garantizados durante la vida útil* del producto en lo que se re ere a piezas solamente.

Los accesorios de corte como barras, cadenas, ruedas dentadas, hojas y cabezas recortadoras de nilón para aplicaciones residenciales o •

que no producen ingresos estarán cubiertos por fallas debido a defectos de materiales y fabricación durante un período de 60 días contados

a partir de la fecha de compra del producto original. Cualquier uso indebido por contacto con hormigón, rocas u otras estructuras no está

cubierto por esta garantía.

Accesorios para la herramienta multiusos tienen una garantía de la misma duración que las unidades para las que están diseñadas.•

APLICACIÓN COMERCIAL

GARANTÍA DE DIA 90• - Todos los motorsierra y motorsierra de trocear para aplicaciones comerciales, institucionales, agrícolas, industriales

o para producir ingresos estará cubierta por esta garantía limitada durante un período de 90 dias contado a partir de la fecha de compra.

GARANTÍA DE 2 AÑOS• - Los unidads para aplicaciones comerciales, institucionales, agrícolas, industriales o para producir ingresos estará

cubierta por esta garantía limitada durante un período de dos (2) años contado a partir de la fecha de compra.

EXCEPCIONES

Para productos impulsados por motores, el módulo de encendido electrónico, cables de mando exibles, ejes de impulsión sólido están •

garantizados durante la vida útil* del producto en lo que se re ere a piezas solamente.

Los accesorios de corte como barras, cadenas, ruedas dentadas, hojas y cabezas recortadoras de nilón para aplicaciones residenciales o •

que no producen ingresos, pero sin limitarse a lo anterior, estarán cubiertos por fallas debido a defectos de materiales y fabricación durante

un período de 30 días contados a partir dela fecha de compra del producto original. Cualquier uso indebido por contacto con hormigón,

rocas u otras estructuras no está cubierto por esta garantía.

Accesorios para la herramienta multiusos tienen una garantía de la misma duración que las unidades para las que están diseñadas.•

APLICACIONES DE ALQUILER – GARANTÍA DE 90 DÍAS

Los unidads completa para uso de alquiler estará completa contra defectos de materiales y fabricación durante un período de 90 días conta-•

dos a partir de la fecha de compra.

* La responsabilidad de ECHO, INC. según la garantía “durante la vida útil” se limita a proveer piezas especi cadas en la sección de

PERÍODO DE GARANTÍA DEL PRODUCTO de esta declaración de garantía durante la “vida útil” de forma gratuita durante un período de

diez (10) años después de la fecha de producción nal de la unidad completa.

ECHO INCORPORATED EMISSION CONTROL WARRANTY STATEMENT

FOR ECHO AND SHINDAIWA BRANDS

The Environmental Protection Agency (EPA) and the California Air Resources Board (C.A.R.B.) and ECHO Incorporated (ECHO Inc.) are pleased

to explain the emission control system warranty on your 2010 and later equipment/small off-road engine (SORE). New equipment/SORE must be