Shindaiwa T230,T230X,C230 Owner's/operator's Manual

ENGLISH

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

T230 GRASS TRIMMER

T230X GRASS TRIMMER

C230 BRUSHCUTTER

Part Number 62064-94013 Rev. 8/06

Minimize the risk of injury to

yourself and others! Read this

manual and familiarize yourself

with the contents. Always wear

eye and hearing protection

when operating this unit.

WARNING!

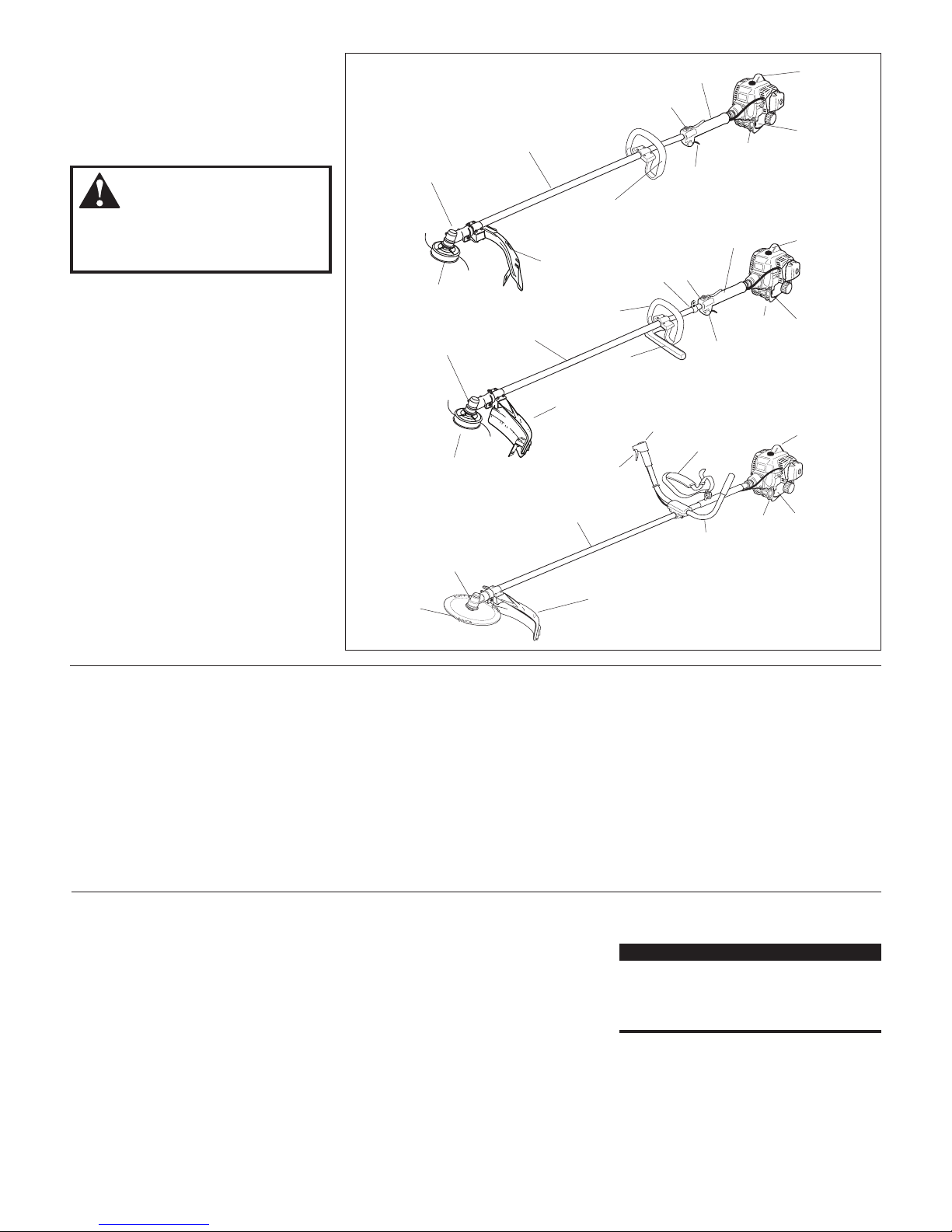

T230

T230X

C230

®

2

Contents

Introduction

PAGE

Shindaiwa 230-series hand held power

equipment has been designed and built to

deliver superior performance and reliability

without compromise to quality, comfort,

safety or durability.

Shindaiwa’s high-performance engines represent the leading edge of 2-cycle engine

technology, delivering exceptionally high

power with remarkably low displacement

and weight. As an owner/operator, you’ll

soon discover for yourself why Shindaiwa is

simply in a class by itself!

IMPORTANT!

The information contained in this owner's/

operator's manual describes units available at the time of publication.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

Attention Statements ...................................3

Safety Information ........................................4

Safety Labels .................................................4

Unit Description ...........................................5

Specifications ................................................5

Assembly .......................................................6

Mixing Fuel ................................................11

Starting the Engine ....................................12

Stopping the Engine ..................................12

Adjusting Engine Idle ................................13

Checking Unit Condition...........................13

Shoulder Strap ............................................13

Using the Trimmer (T230) ......................14

Using the Brushcutter (C230) ..................15

Maintenance ...............................................16

Long Term Storage ....................................19

Blade Sharpening .......................................19

Troubleshooting Guide .............................20

Emission System Warranty .......................22

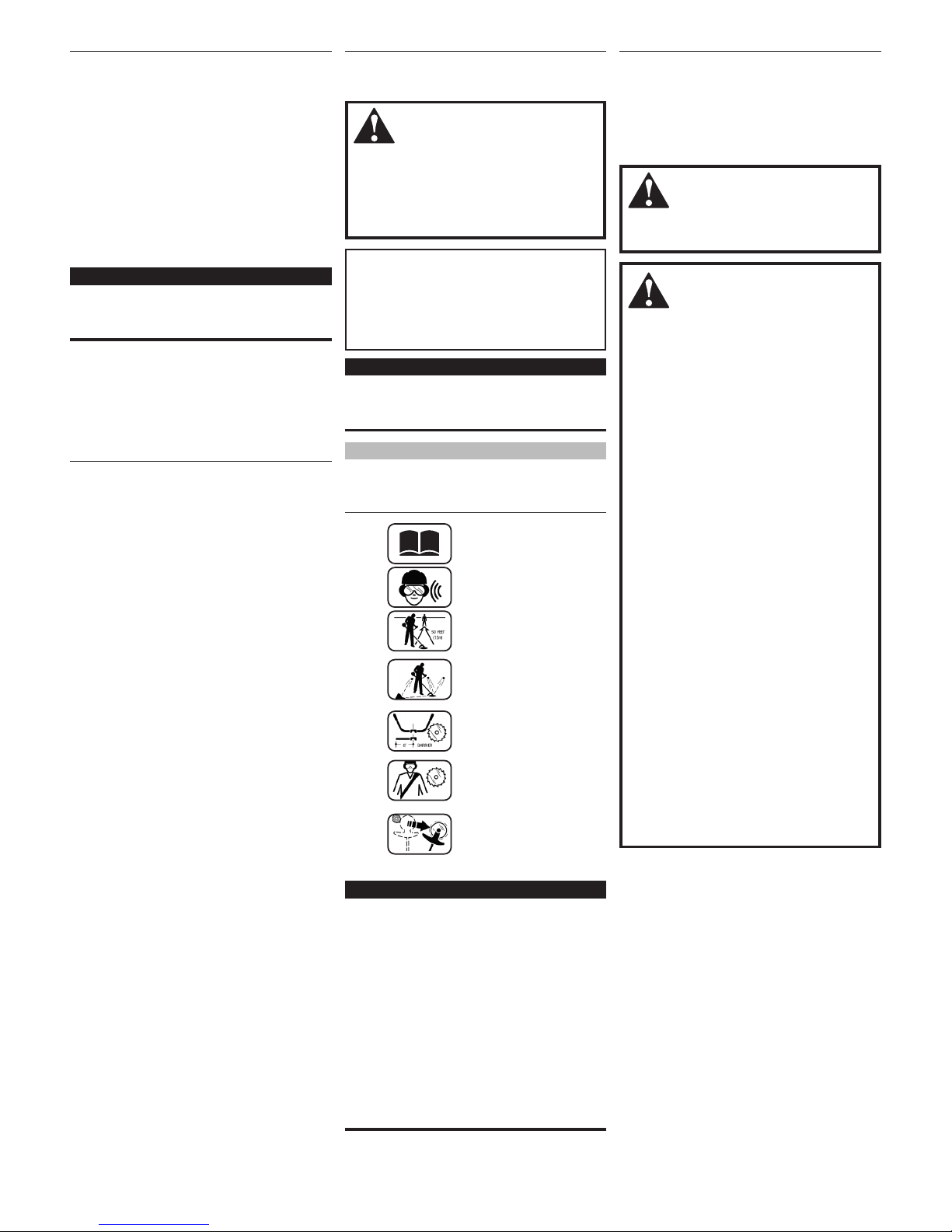

Throughout this manual are special

“Attention Statements.”

WARNING!

A statement preceded by the triangular attention symbol and the word

“WARNING” contains information that

should be acted upon to prevent serious bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to prevent mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

Attention Statements

IMPORTANT!

The operational procedures described in

this manual are intended to help you get

the most from unit as well as to protect

you and others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended

to replace any safety rules and/or laws

that may be in force in your area. If you

have questions regarding your Shindaiwa

power tool, or if you do not understand

something in this manual, your Shindaiwa

dealer will be glad to assist you. You may

also contact Shindaiwa, Inc. at the address printed on the back of this manual.

Read and follow this

operators manual.

Failure to do so could

result in serious injury.

Wear eye and hearing

protection at all times

during the operation

of this unit.

Keep bystanders

at least 50 feet (15 m)

away during operation.

Beware of thrown or

ricocheted objects.

Do not operate this unit

with a blade unless the

unit is equipped with a

Shindaiwa-approved

handlebar or barrier.

Always wear a harness

when operating this unit

with a blade. A harness

is also recommended when

using trimmer line.

If unit is used as a

brushcutter, beware of

blade thrust. A jammed

blade can cause the unit

to jerk suddenly and may

cause the operator to

lose control of the unit.

Work Safely

Trimmers and brushcutters operate at very

high speeds and can do serious damage or

injury if they are misused or abused. Never

allow a person without training or instruction to operate this unit!

WARNING!

Use Good Judgment

NEVER run the engine when transport-

ing the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS use the proper cutting tool for

the job.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly installed parts or attachments.

NEVER extend trimming line beyond

the length specied for your unit.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegetation, mud, etc.

ALWAYS hold the unit rmly with both

hands when cutting or trimming, and

maintain control at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any maintenance work.

ALWAYS, if a saw blade should bind

fast in a cut, shut off the engine immediately. Push the branch or tree to ease

the bind and free the blade.

General Safety Instructions

WARNING!

Never make unauthorized attachment

installations.

3

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Never operate power

equipment of any kind

if you are tired or if you are under the

inuence of alcohol, drugs, medication

or any other substance that could affect

your ability or judgement.

WARNING!

Minimize the Risk of Fire!

NEVER smoke or light res near the

unit.

ALWAYS stop the engine and allow it

to cool before refueling. Avoid overlling and wipe off any fuel that may have

spilled.

ALWAYS inspect the unit for fuel leaks

before each use. During each rell,

check that no fuel leaks from around

the fuel cap and/or fuel tank. If fuel

leaks are evident, stop using the unit

immediately. Fuel leaks must be repaired before using the unit.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily ammable materials before

starting the engine.

NEVER place ammable material close

to the engine mufer.

NEVER run the engine without the

spark arrester screen in place.

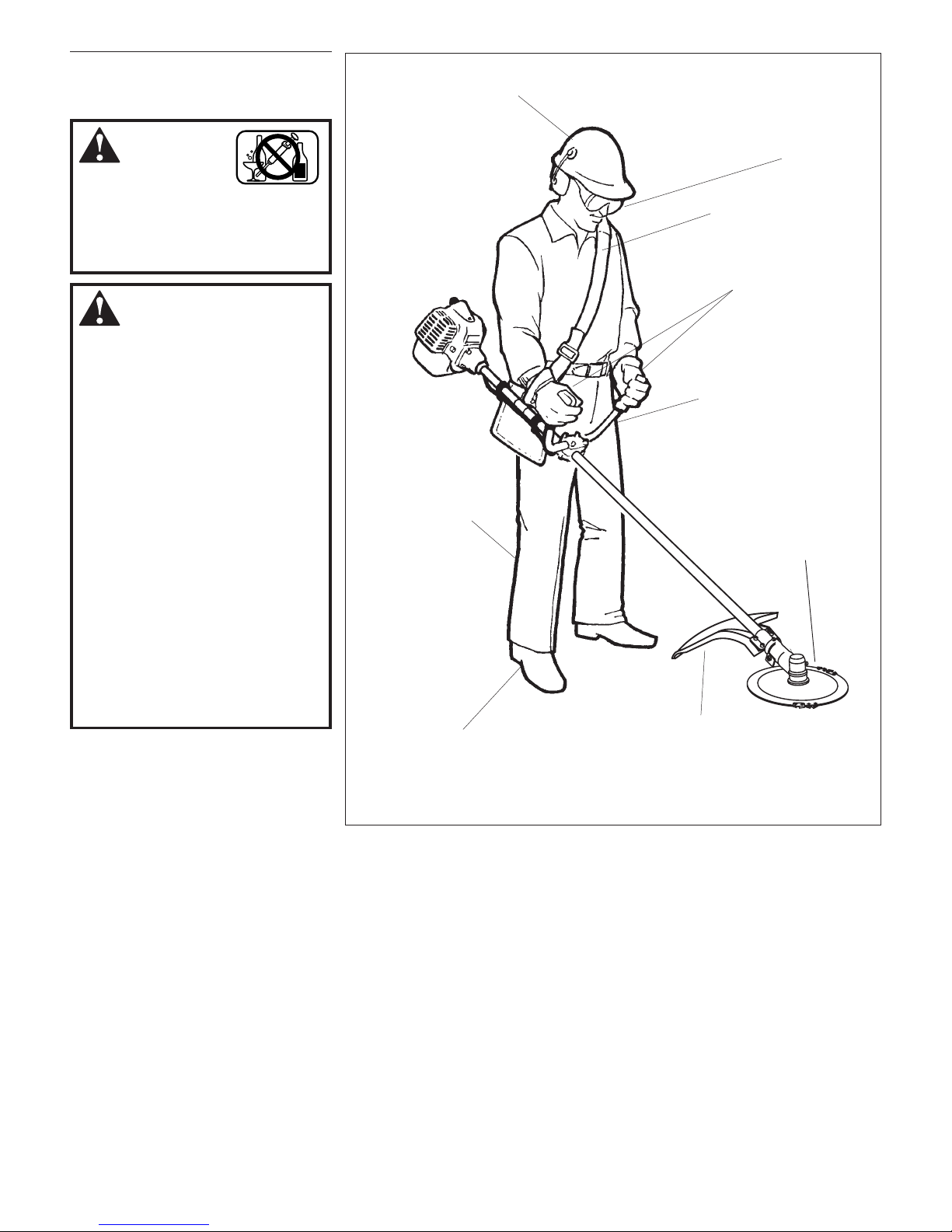

The Properly Equipped Operator

ALWAYS wear a

harness when operating a

unit equipped with a blade.

ALWAYS operate with

both hands firmly gripping

the unit.

Wear close-fitting

clothing to protect legs and

arms. Gloves offer added

protection and are strongly

recommended. Do not

wear clothing or jewelry

that could get caught in

machinery or

underbrush. Secure

long hair so that

it is above shoulder

level. NEVER

wear shorts!

Wear hearing protection devices and a

broad-brimmed hat or helmet.

ALWAYS wear eye

protection such as goggles or

safety glasses to shield against

thrown objects.

When operating with a blade, make

sure the handle is positioned to

provide you with maximum

protection from contacting

the blade.

Keep away from the rotating

trimmer line or blade at all times,

and never lift a moving

attachment above waist-high.

Wear appropriate footwear (non-skid

boots or shoes): do not wear open-toed

shoes or sandals. Never work bare-

footed!

Keep a proper footing

and do not overreach.

Maintain your balance

at all times during

operation.

ALWAYS make sure the appropriate

cutting attachment shield is correctly

installed and in good condition.

Figure 1

General Safety Instructions

4

26105

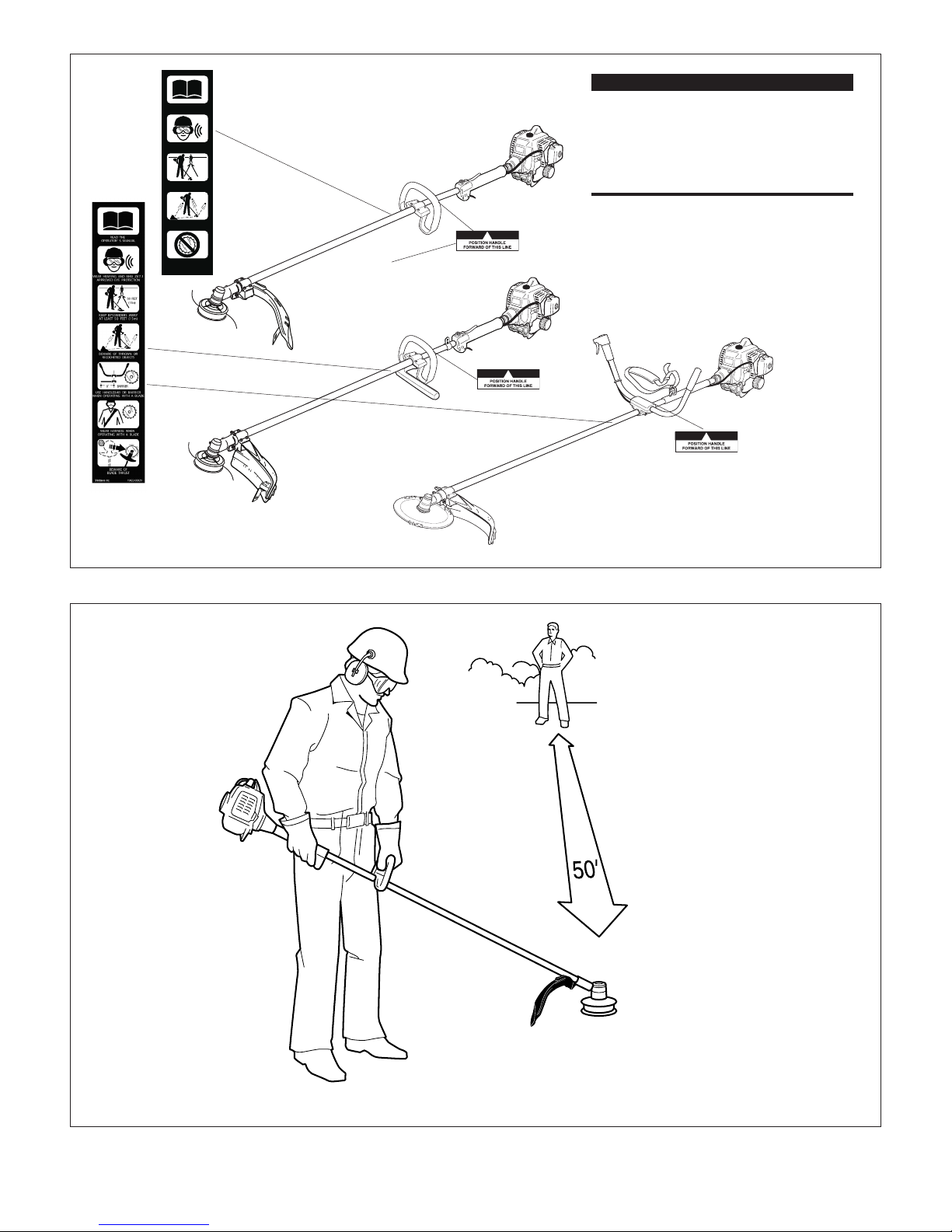

Be Aware of the Working Environment (all units)

Avoid long-term operation

in very hot or ver y cold

weather.

Make sure bystanders or observers

outside the 50-foot “danger zone”

wear eye protection.

Be extremely

careful of

slippery terrain,

especially during

rainy weather.

ALWAYS make sure

the appropriate cutting

attachment shield is

correctly installed.

If contact is made with

a hard object, stop the

engine and inspect the

cutting attachment for

damage.

Be constantly alert for objects

and debris that could be thrown

either from the rotating cutting

attachment or bounced from a

hard surface.

Reduce the risk of

bystanders being struck

by flying debris. Make

sure no one is within 50

feet (15 meters)—that’s

about 16 paces—of an

operating attachment.

Beware of a coasting blade when brushcutting

or edging. A coasting blade can injure while

it continues to spin after the throttle trigger is

released or after the engine is stopped.

Figure 3

50

FEET

ALWAYS clear your work area of trash or hidden debris that could be

thrown back at you or toward a bystander. When operating in rocky terrain

or near electric wires or fences, use extreme caution to avoid contacting such

items with the cutting attachment.

Safety Labels

Figure 2

IMPORTANT!

Safety and Operation Information Labels:

Make sure all information labels are

undamaged and readable. Immediately

replace damaged or missing information

labels. New labels are available from your

local authorized Shindaiwa dealer.

T230

C230

READTHE

OPERATOR’SMANUAL

WEARHEARINGAND ANSIZ87.1

APPROVEDEYEPROTECTION

KEEPBYSTANDERSAWAY

ATLEAST 50FEET (15m)

BEWAREOF THROWNOR

RICOCHETEDOBJECTS

DONOT OPERATETHIS

MACHINEWITHA BLADE

50FEET

(15m)

19422-00028ShindaiwaInc.

This label indicates the minimum

distance between front handle and

rear grip per ANSI B175.3.

T230X

5

Unit Description

Using the accompanying illustrations as

a guide, familiarize yourself with this unit

and its various components. Understanding

the product helps ensure top performance,

long service life, and safer operation. See

Figure 4.

WARNING!

Do not make unauthorized modications or alterations to any of these units

or their components.

Specications

T230 Dry Weight (less attachments) .........................4.6 kg/10.2 lb.

T230X Dry Weight (less attachments).......................4.7 kg/10.4 lb.

C230 Dry Weight (less attachments) .........................4.9 kg/10.8 lb.

Engine Model ............................................................ Shindaiwa S230

Engine Type ............................. 2-cycle, vertical-cylinder, air-cooled

Bore x Stroke ...........................................32 x 28 mm/1.26 x 1.10 in.

Displacement .......................................................... 22.5 cc/1.4 cu. in.

Maximum Power Output ...... 1.1 HP (0.8 kW) @ 7500 RPM (min-1)

Fuel/Oil Ratio ..................................................... 50:1 with Shindaiwa

Premium 2-cycle mixing oil

Fuel Tank Capacity ....................................................554 ml/18.7 oz.

Carburetor Type ................................ Walbro WYL, diaphragm-type

Ignition ..........................One-piece electronic, transistor-controlled

Spark Plug .................................................................... Champion CJ8

(for EMC compliance use NGK BMR6A)

Air Cleaner Type .................. Non-reversible flocked filter element

Starting Method .........................................................................Recoil

Stopping Method ..............................................................Slide switch

Transmission Type .............................Automatic, centrifugal clutch

w/bevel gear

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete

unit:

Engine assembly.

Outer tube assembly.

Cutting attachment shield.

Cutting attachment (trimmer head,

or brushcutter blade).

Correct operators handle (see page 8).

Kit containing cutting attachment

shield mounting bracket and hardware,

operator’s handle mounting bracket and

hardware, gearcase tool holder, this

manual and tool kit for routine maintenance. Tool kits vary by model and may

include a hex wrench, spanner and a

combination spark plug wrench/screwdriver.

Carefully inspect all components

for damage.

*Specifications are subject to change without notice.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

Figure 4

C230

BRUSHCUTTER

Outer Tube

Handlebar

Cutting Attachment

Shield

Shoulder

Strap

Brushcutter

Blade

Throttle

Trigger

Gearcase

Tank

Protector

Ignition

Switch

Fuel

Tank

Spark

Plug

Outer Tube

Trimmer Head

Grip

Cutting

Attachment

Shield

Gearcase

Throttle

Trigger

Tank

Protector

Ignition

Switch

Spark

Plug

Fuel

Tank

T230

GRASS TRIMMER

T230X

GRASS TRIMMER

Outer Tube

Trimmer Head

Grip

Cutting Attachment

Shield

Gearcase

Throttle

Trigger

Tank

Protector

Ignition

Switch

Spark

Plug

Fuel

Tank

Handle

(for trimmer use only)

Barrier

Hanger

Handle

6

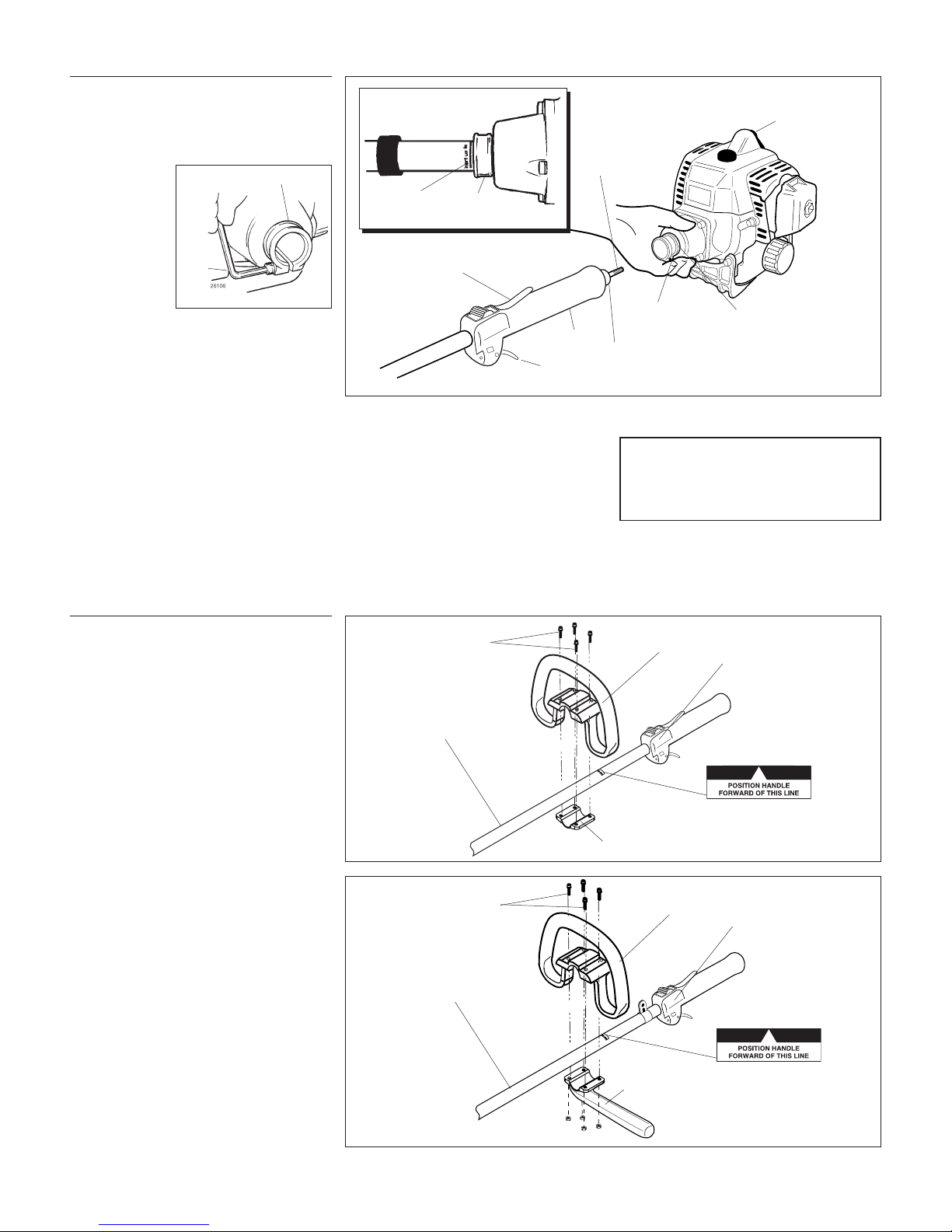

Driveshaft/Powerhead All Models

Grip

Spark Plug

Main

Shaft

Tube

Clamp

Outer Tube

T230

1. Place the powerhead on a clean, flat surface, spark plug facing up. See Figure 6.

2. Use the

4 mm hex

wrench to

loosen the

tube clamp

screw.

3. Add some

moly-type

EP grease to

the splines

on the end of the mainshaft.

4. Slide the outer tube into the tube clamp

until the tube bottoms. If installation is

difficult, rotate the outer tube or mainshaft slightly until you feel the mainshaft

splines engage with the powerhead.

5. Position the outer tube so that the ignition switch is facing up and the throttle

trigger is down.

Tube Clamp

Connect the Outer Tube

to the Powerhead.

CAUTION!

Do not force the shaft tube into the

powerhead! Excessive force can damage the shaft tube and mainshaft.

Clamp must fit next to line

on outer-tube decal

Decal

Clamp

C230 Brushcutter

Clamp

Screw

Figure 6

Figure 5

Assembly

Throttle

Trigger

Ignition

Switch

Hex

Wrench

Figure 6A

T230 Slide the outer tube into the

powerhead until the throttle grip

just contacts the tube clamp.

C230 Slide the outer tube into the

powerhead until the installation

decal aligns with the tube clamp.

See Figure 6A.

6. Tighten the clamp screw firmly.

Assembly

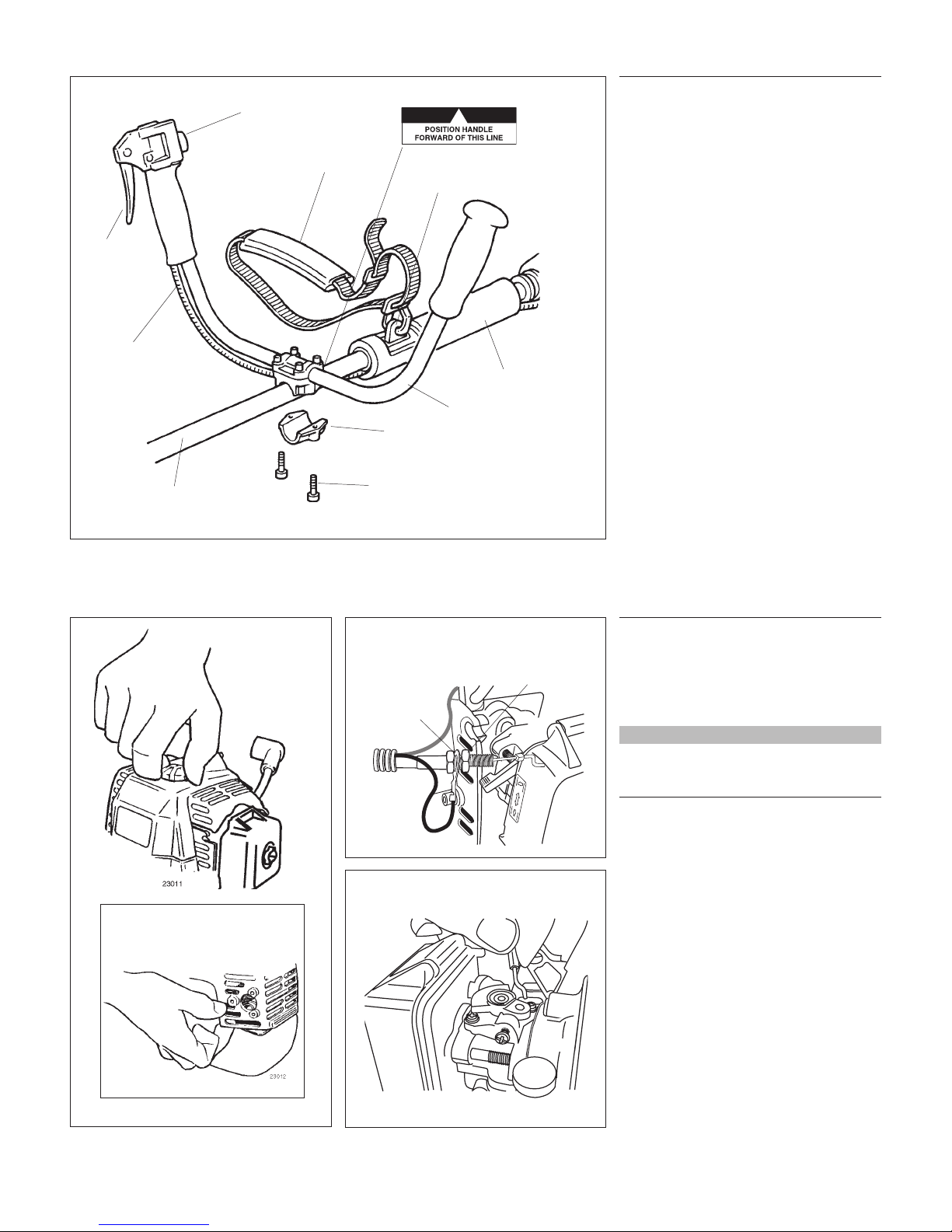

Handle

T230 - Connect the Handle to

the Outer Tube.

1. Position the handle on the outer tube

forward of Handle Positioning Label as

shown in Figure 7.

2. Install the mounting bracket with the

socket head cap screws. Tighten the

screws finger-tight ONLY at this time.

3. Locate the handle in the best position

for operator comfort (usually about 10

inches ahead of the throttle housing).

4. Secure the handle by alternately tightening the four socket-head screws in a

diagonal or “crisscross” fashion.

Outer Tube

Socket-head

Caps Screws

Handle

Mounting Bracket

Throttle

Assembly

Figure 8

Handle Positioning Label

T230X - Connect the Handle to

the Outer Tube.

1. Position the handle on the outer tube

forward of Handle Positioning Label as

shown in Figure 8.

2. Install the barrier bar with the socket

head cap screws and nuts. Tighten the

screws finger-tight only at this time.

3. Locate the handle in the best position

for operator comfort (usually about 10

inches ahead of the throttle housing).

4. Secure the handle by alternately tightening the four socket-head screws in a

diagonal or “crisscross” fashion.

Figure 7

Outer Tube

Socket-head

Caps Screws

Handle

Barrier

Throttle

Assembly

Handle Positioning Label

7

23013

Assembly

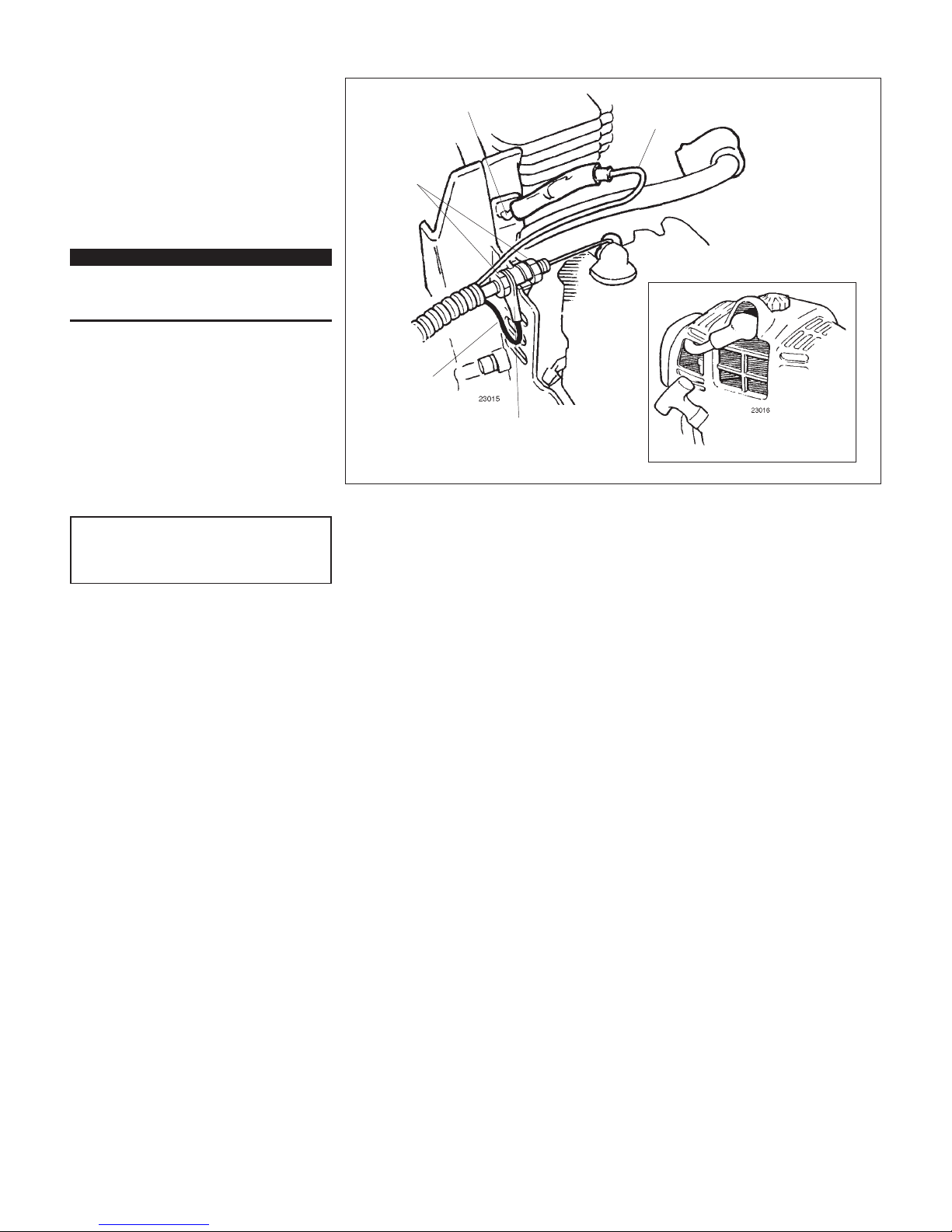

Throttle Linkage and Ignition Leads All Models

Remove the Cylinder Cover.

1. Remove the cap from the spark plug.

2. Loosen the black cylinder cover knob

(about a dozen full turns are required),

and then lift off the cylinder cover.

NOTE:

If the cover binds on the muffler outlet tube,

pull gently on the corner of the cover as

shown (see inset).

Connect the Throttle Cable.

1. Route the ribbed cable over the tube

clamp to the top left side of the engine.

2. Install the black wire between the two

cable adjuster nuts as shown. See

Figure 11.

3. Connect the S-shaped end of the throttle

cable to the throttle lever on top of the

carburetor. See Figure 12.

Install the black wire

between the two cable

adjuster nuts.

Connect the

throttle cable

Ignition

Ground

Lead

Cable Adjuster Nut

Figure 11

Figure 12

23014

Loosen the

cylinder cover

knob and

disconnect the

spark plug cap

Lift the corner of

the cover

Figure 10

Handle Positioning Label

Assembly

Handlebar C230

Assemble the Handlebar.

1. Position the handle over the outer tube.

See Figure 9. Make sure the throttle lever is on the right-hand side of the outer

tube.

2. Attach the handle mounting bracket

using the two socket-head cap screws.

Tighten the screws finger-tight ONLY at

this time.

3. Locate the handle forward of the Handle

Positioning Label at the best position for

operator comfort.

4. Using the hex wrench, securely tighten

the two handlebar cap screws.

5. Route the ribbed throttle cable tube

along the handlebar and outer tube. See

Figure 9. Install the protector sleeve on

the outer tube.

Outer Tube

Mounting Bracket

Socket-Head

Cap Screw

Throttle

Cable

Handlebar

Protector Sleeve

Figure 9

Ignition Switch

Throttle

Trigger

Hanger

Shoulder Strap

8

Assembly

Throttle Linkage and Ignition Leads All Models

Ground Wire

Terminal

Ground

Wire

Assemble and Adjust

the Throttle Cable.

1. Insert the throttle-cable housing into the

notch on the fan cover, and clamp the

ground wire terminal between the fan

cover and the outer cable adjuster nut.

See Figure 13.

2. Tighten the two throttle cable adjuster

nuts.

IMPORTANT!

Adjust and tighten the cable nuts to allow

approximately 1/4-inch free play at the

throttle trigger.

CAUTION!

Routing of wiring must not interfere with

throttle operation.

Figure 13

Reinstall the Spark

Plug Cap

Black Ignition

Wire

Red Wire

Cable Adjuster

Nuts

3. Using finger pressure only, connect

the black ignition wire from the cable

tube to the red ignition wire on the

powerhead. Wire routing must be as

shown in the illustration with the black

wire located away from the throttle cable

and carburetor linkage.

4. Reinstall the engine cover and tighten

the captive engine cover screw.

5. Reinstall the spark plug boot.

Loading...

Loading...