Page 1

WARNING!

Minimize the risk of injury to

yourself and others! Read this

manual and familiarize yourself with

the contents. Always wear eye

protection, gloves and a respirator

when operating this unit.

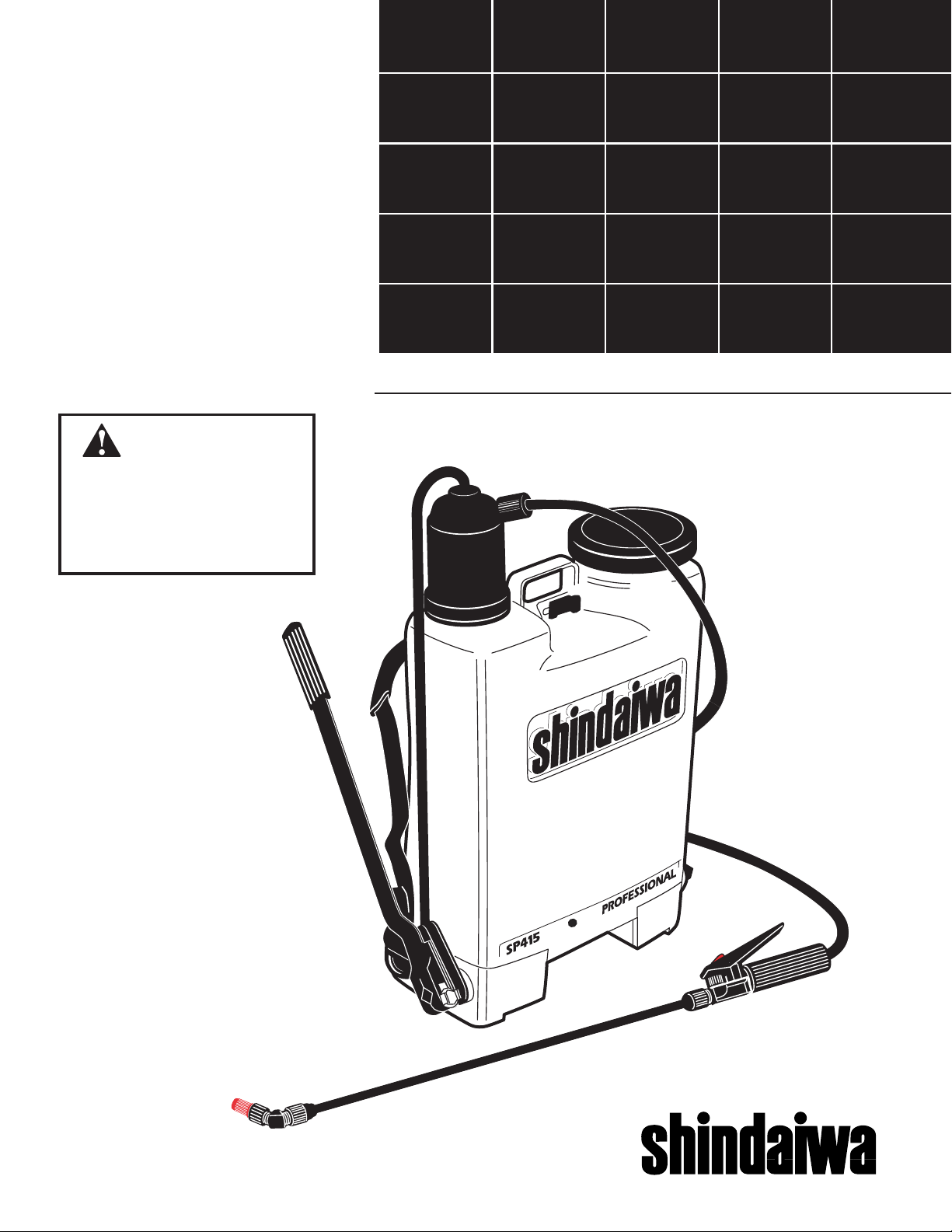

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

SP415 BACK PACK SPRAYER

Part Number 80836 Rev. 1/04

䊛

Page 2

Introduction

Prepare to Assemble

This manual contains information for the proper assembly,

operation and care of your SP415 sprayer. Carefully read and

follow the instructions contained in this manual before operating your sprayer.

Pump

Chamber

Packing Ring

Nut

Lever

Wand

Nozzle

Cap

Vent

Diaphragm

Tank

Trigger Valve

THE SERIAL NUMBER IS

LOCATED ON THE BOTTOM

OF THE TANK.

Specifications

Net Weight ..................................................... 10.5 pounds (4.8 kg)

Tank Capacity .......................................... 4 U.S. gallons (15 liters)

Tank Material ..............................................Polyethylene (Plastic)

Fill Opening Diameter .................................. 4.5 inches (114 mm)

Pump .............................................................................. Piston Type

Pump Material ......................... Polypropylene with UV Protector

Operating Pressure ....................... 15-90 psi (1.05-6.3 kg/sq. cm)

Wand Assembly Length .......................... 27.5 inches (698.5 mm)

Hose Length ............................................. 69.75 inches (1771 mm)

Nozzle Installed ............................................ Red Adjustable Cone

Specifications subject to change without notice.

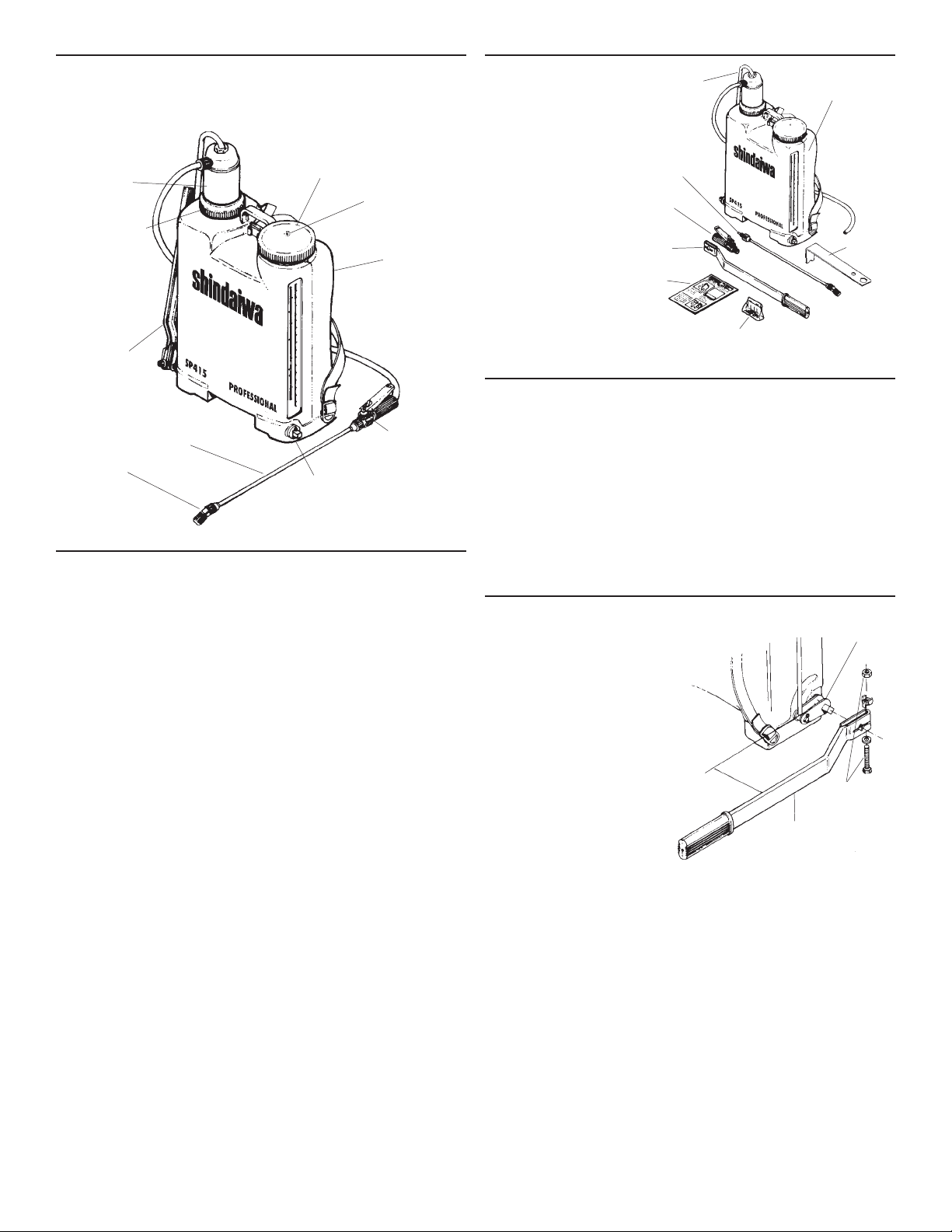

Unpack the following

items shipped in

Connecting

Rod

Tank

your sprayer box:

■ Wand

■ Pump Lever and

Connecting Rod

■ Tank Assembly

■ Small Parts Kit

■ From inside the

sprayer tank,

remove the

Wand

Trigger

Valve

Pump

Lever

Manual

Piston

Wrench

plastic bag from

the tank strainer.

(Includes the following components)

Small Parts Kit

P/N Description Qty.

568970 Trigger Valve Needle Assembly ....................................................... 1

105254 Trigger Valve Cap ............................................................................... 1

908905 Diaphragm ........................................................................................... 2

214585 45 x 12 Piston Cup .............................................................................. 1

210088 No. 12 Disc .......................................................................................... 1

210195 Swirl Core ............................................................................................ 1

457416 Kematal DEF-06 Deflector Flat Fan Nozzle (Grey) ....................... 1

437885 Kematal 110-LD-03 Low Drift Flat Fan Nozzle (Blue) ................... 1

217174 Stainless Steel Cone Nozzle ............................................................. 1

229724 Nozzle Cap ........................................................................................... 1

Install the Pump Lever

1. Align the pump lever with

the pump shaft linkage

as shown. (chamber side).

2.

Install the pump lever on

the pump shaft and secure

with the lever bolt

assembly.

3. Tighten the lever bolt until

the lever clamp grips the

pump shaft securely.

Parallel

Pump Lever

Shaft

Pump Shaft

Linkage

Bolt

Assembly

2

Page 3

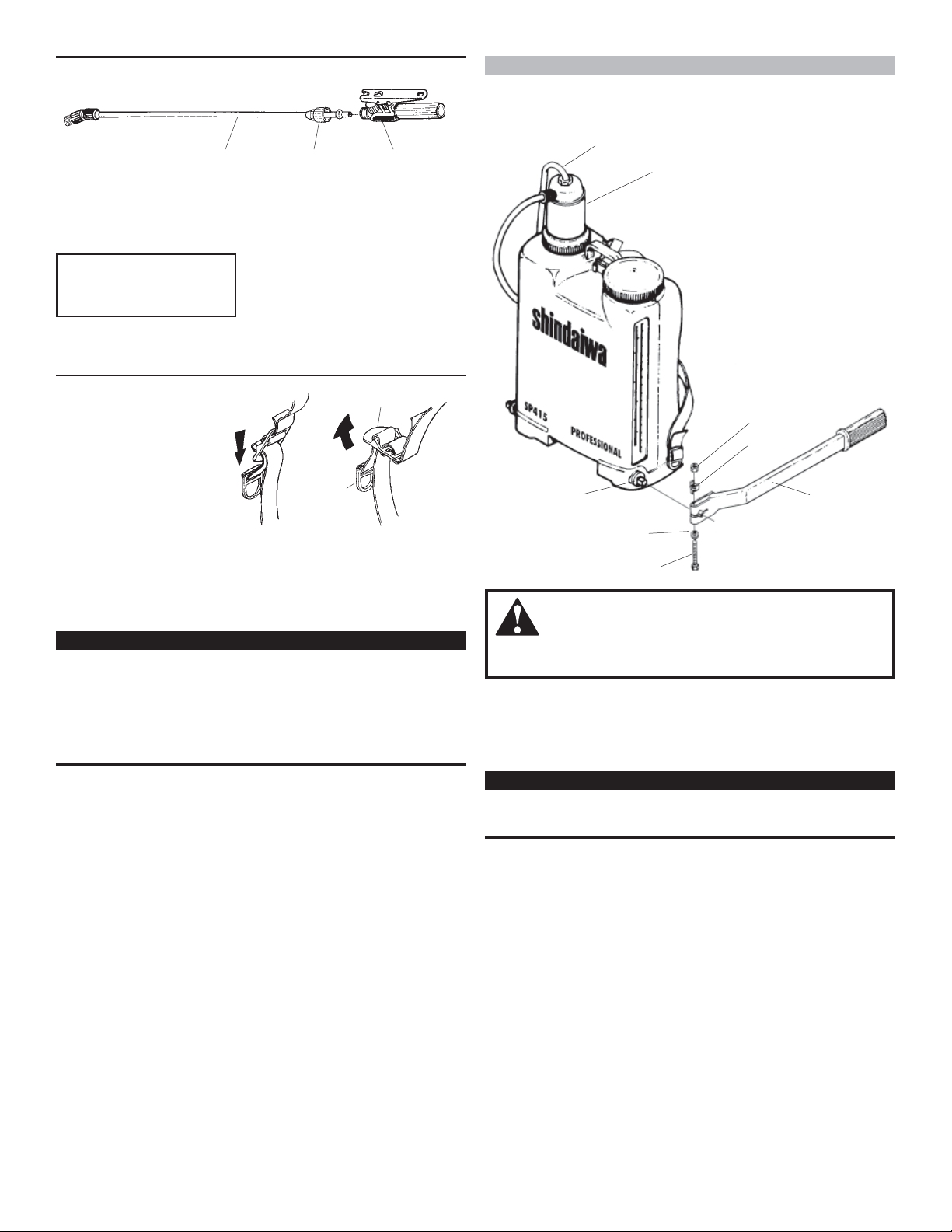

Assembling the Spray Wand

Wand Screw

Cap

Push the wand into the trigger valve and secure with screw

cap. Hand tighten to prevent leakage.

CAUTION!

Do not overtighten!

Trigger

Valve

Adjusting the Shoulder Straps

Buckle

Tightening

1. Place the sprayer on

your back with the

staps loosened.

2. Hold the adjustment

ring firmly and pull

until backpack is

secure in place.

Loosening

Lift up on the buckle to release tension.

IMPORTANT!

After assembling the sprayer, fill the tank with clear water and

lay it on its side. Check for leaks. Return sprayer to its upright

position. Pump the lever 10-15 times and check for leaks.

Most leaks can be stopped by tightening the appropriate

connection or fitting. Any leaks must be stopped prior to filling

the sprayer with chemicals.

Adjustment

Ring

Changing Lever Operating Side

NOTE:

The operating lever may be mounted on the left or right side of

the sprayer tank depending on operator preference.

Connecting

Rod

Pump Lever

Shaft

Washer

WARNING!

Remove all chemicals and wash the sprayer thoroughly

before beginning to change the lever operating side.

1. Loosen the pump lever bolt and slide pump lever off of the

pump shaft linkage.

2. Move the pump lever to the opposite side of the sprayer tank

and install onto the pump lever shaft linkage as shown.

Pump

Chamber

Nut

Retainer

Pump

Lever

Bolt

IMPORTANT!

Make sure that the pump lever is installed so that full up and

down movement of the pump chamber is available.

3. Tighten pump lever bolt securely.

3

Page 4

Calibrating the SprayerSafety Precautions

AIR

WATER

EARTH

Carefully read the labels on chemical containers

prior to use. Chemicals are classified in four

categories of toxicity:

■ Category I, High Toxicity, Red label

■ Category II, Moderate Toxicity, Yellow label

■ Category III, Low Toxicity, Blue label

■ Category IV, Light Toxicity, Green label

There are unique handling recommendations

for each category, and you should familiarize

yourself with them.

Always wear clothing and safety equipment that

will provide appropriate protection against the

materials you are handling. Equipment may

include, but not be limited to:

■ Long sleeve shirt

■ Impermeable apron or coverall

■ Impermeable gloves and boots

■ Wide-brim hat

■ Protective mask equipped with

appropriate filters

Do not eat, drink, or smoke while handling

chemicals or while you are spraying. Always

handle chemicals in a well ventilated area while

wearing appropriate protective clothing and

safety equipment. DO NOT STORE OR TRANSPORT CHEMICALS WITH FOOD OR MEDICINES, AND NEVER REUSE A CHEMICAL

CONTAINER FOR ANY OTHER PURPOSE.

Keep chemicals out of the reach of children,

animals, or other unauthorized people. When

not in use, store chemicals in a safe place.

Never blow through nozzles, valve, pipes or any

other component by mouth!

When handling chemicals and when spraying,

make sure you are operating in accordance with

local, state, and federal environmental protection rules and guidelines. Do not spray in very

hot or windy conditions. DO NOT POLLUTE

THE ENVIRONMENT!

After spray application, take a thoroughly

cleansing shower using plenty of water and

soap, then change into clean clothes. Protective

clothing and safety gear should also be cleaned

after each use. IN CASE OF EXPOSURE TO

DANGEROUS CHEMICALS, seek a physician

immediately and be prepared to provide the

label from the chemical container.

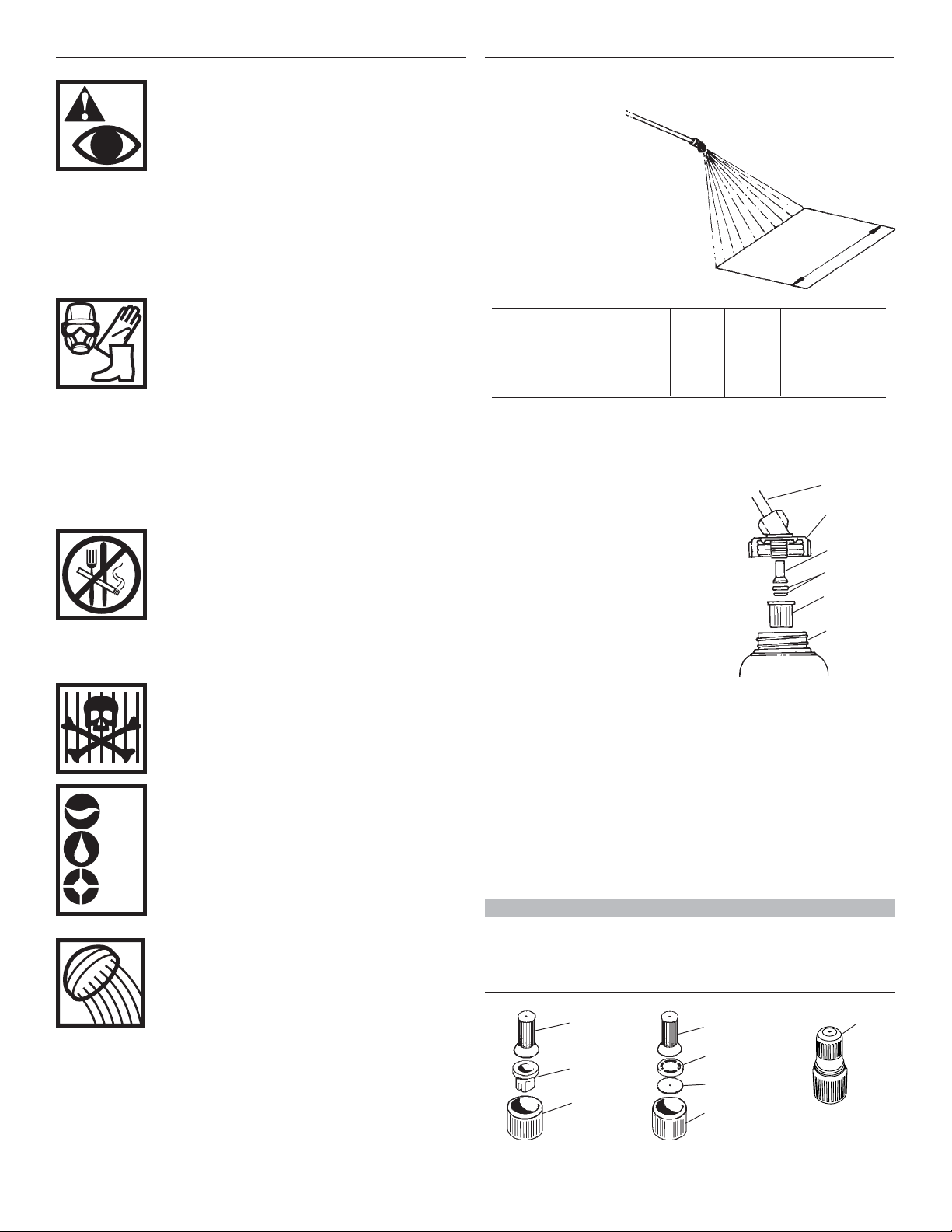

(Requires optional flow calibrator bottle, P/N 646901)

1. Hold the wand at

the working

height and spray

a test pattern to

measure the

application band

width.

2. Based on the band width,

identify from the table

Band

Width

below the walking distance

required to calibrate the sprayer.

Band width 1.6 ft 2.3 ft 3.3 ft 4.0 ft 5.0 ft

0.5m 0.7m 1.0m 1.2m 1.5m

Distance to walk 165 ft 120 ft 80 ft 70 ft 55 ft

50.0m 35.7m 25.0m 20.8m 16.7m

3. Attach the flow calibrator bottle to the wand:

a. Remove the nozzle, cap and filter from the spray wand.

b. Mount the flow calibrator cover

to the spray wand.

c. Reinstall the nozzle, filter and

Wand

Cover

nozzle cap.

d. Screw the flow calibrator bottle

into the cover.

4. Using the flow calibrator bottle:

a. Operate the pump lever to

maintain spray system pressure

Filter

Nozzle

Nozzle

Cap

Calibrator

Bottle

when using the flow calibrator

bottle.

b. Hold the wand at your normal

working position and spray into the bottle while walking the

distance identified in step 2 above.

c. Place the bottle on a level surface and observe the liquid

level visible through the side of the bottle. Match the liquid

level to the l/acre (liter per acre) scale on the calibration

bottle.

d. Multiply the l/acre (liter per acre) reading identified in

step 4-c by .264 to determine your application coverage rate

in gallons per acre.

e. Empty the bottle contents back into the sprayer tank.

NOTE:

For improved accuracy in calibrating your application coverage,

repeat steps 4-a through 4-e and average the results.

Typical Nozzle Assemblies

Filter

Tip

Cap

Filter

Swirl

Core

Disc

Cap

Cone NozzleFlat Fan Nozzle

The spraying angle is

changed by turning

Adjustable Cone

Tip

the tip

Nozzle

4

Page 5

Optional Accessories

Part Number Description

761882 Spray hood is used for nonselec-

tive herbicides when spraying under windy

conditions. Comes with Kematal 110-DEF-06

deflector fan nozzle and parts to assemble

spray hood to your existing Shindaiwa spray

wand.

902296 Brass spray boom (27.5") for use

with agrochemicals and foliar fertilizers

applied to row crops. Provides 40" coverage.

JD-12P cone nozzles and 40 mesh stainless

steel filter included.

907873 Flexible annealed copper boom

fitted with three JD-12P cone nozzles. For

use with agrochemicals and foliar fertilizers

on row crops. Can be easily shaped as

appropriate to provide proper coverage.

40 mesh stainless steel filter included.

831107 Brass extension (11.8") complete

with plastic fittings for extra reach. Attachable to original wand .

728139 Brass extension (23.6") complete

with plastic fittings for extra reach. Attachable to original wand .

100016 Brass extension (6.3") complete

with two JD-12P cone nozzles for doubling

output of agrochemicals and foliar fertilizers

on perennials. 40 mesh stainless steel filter

included.

646901 Flow calibrator bottle. For

accurate calibration of backpack sprayers to

prevent waste and damage to the environment.

336115 Brass Y nozzle for use on plants

requiring heavy applications of fungicides.

Complete with two JD-12P cone nozzles, 40

mesh stainless steel filter and plastic

fittings.

AVAILABLE SPRAY NOZZLES

Part Number Description

838052 Constant pressure valve reduces

pumping action, reduces drift and delivers

uniform spraying. Improves productivity and

saves chemicals.

565648 Plastic anti-drip valve for

agrochemicals and foliar fertilizer application. Attaches to wand and is compatible

with any type of cone or flat fan nozzle.

568774 Spray wand assembly (21.6")

Plastic handle, trigger valve and spray tube.

40 mesh stainless steel nozzle and trigger

valve filters included. Fitted with adjustable

cone nozzle.

725267 All brass spray wand assembly

(21.6") for extra duty applications. Trigger

valve and spray tube are brass. 40 mesh

stainless steel nozzle and trigger valve filters

included. Fitted with JD-12P cone nozzle.

568816 Standard Repair Kit and Nozzle

for SP415. Includes (1) Piston cup, trigger

valve needle, trigger valve needle cap,

JD-12P cone nozzle and disc, nozzle cap,

deflector nozzle, flat fan nozzle,

(2) diaphragms and o-ring.

229724* Nozzle cap for attaching flat fan

and cone type nozzles.

452284 All Purpose Wrench for periodic

maintenance and repair.

Nozzle Type

Flat Fan

Cone

Flat Fan

Low Drift

Cone

Flat fan

Deflector

Adjustable

Cone

Part Number

437756 110-SF-015 Kematal green, 0.16 gpm @ 45 psi

437764 110-SF-02 Kematal yellow, 0.21 gpm @ 45 psi

437772 110-SF-03 Kematal blue, 0.33 gpm @ 45 psi

717942 JD-10A Stainless steel

217174* JD-12P Stainless steel

437855 110-LD-03 Kemetal blue, 0.33 gpm @ 45 psi

457317 HC-02 Kematal yellow

457325 HC-04 Kematal red

457333 HC-05 Kematal brown

457390 DEF-04 Kematal red

457408 DEF-05 Kematal brown

457416* DEF-06 Kematal gray

323725 Yellow 0.08 gpm @ 45 psi.

015024 Red 0.17 gpm @ 45 psi. (Standard w/SP415)

325787 Blue 0.18 gpm @ 45 psi.

* Denotes nozzles included in the SP415

standard repair kit.

Application

Herbicides

Agrochemicals

and foliar

fertilizers

Pressure

psi (kg/cm2)

45 (3.2)

45 (3.2)

45 (3.2)

45 (3.2)

45 (3.2)

45 (3.2)

45 (3.2)

45 (3.2)

15 (1.0)

15 (1.0)

15 (1.0)

45 (3.2)

45 (3.2)

45 (3.2)

Flow Rate

gal (ml)/min

0.16 (610)

0.21 (810)

0.33 (1250)

0.08 (300)

0.16 (615)

0.22 (830)

0.33 (1250)

0.44 (1680)

0.54 (2060)

0.25 (950)

0.32 (1200)

0.41 (1540)

0.08 (315)

0.17 (640)

5

Page 6

Maintenance

Cleaning the Sprayer

Pump Disassembly (cont.)

After finishing the spray application, empty the sprayer and

wash all equipment in an approved decontamination area.

Pump the lever with

the trigger valve

disconnected until

the discharge runs

clear

WARNING!

Remove all chemicals and wash before storing the

sprayer. Chemical products have different reactions and

can cause damage to the sprayer components and the

environment. Unidentified chemicals left in the sprayer

tank can pose a serious health threat to anyone servicing

the unit and unaware of its presence!

Lubricate

(disassembly

required)

Lubricate

2. Using the 452284 all-purpose wrench,

remove the piston cup fastener and

cup. Replace piston cup as necessary.

5. From the bottom of the piston cup

fastener, push the diaphragm out

towards the top.

4. Remove the two Phillips head screws

and washers located at the bottom of

the cylinder and remove the cylinder

base.

5. From the bottom of the cylinder, push

the diaphragm out towards the top of

the cylinder.

7. Clean all parts and carefully inspect

for worn or damaged parts and replace

as necessary.

8. Reassemble in the reverse order.

NOTE:

Lubricating diaphragms and all moving

parts with a high quality lithium grease

will ease assembly and prolong the life of

the unit.

Troubleshooting: Lack of Pressure

SYMPTOM

Leakage through

the upper cylinder.

After pumping and

pressurizing the

chamber, the pump

lever drops rapidly

CAUSE

Worn or dried out

piston cup.

Cylinder diaphragm

not sealing properly

due to wear or

impurities.

when released.

Pump

Chamber

Piston

Cup

Chamber

Valve

Piston Cup

Fastener

Cylinder

Washer

Screw

REMEDY

Lubricate or replace

the piston cup.

Clean or replace the

cylinder diaphragm.

Lubricate

Periodically clean and lubricate the pump chamber and

actuating linkage with a high quality lithium grease.

Pump Disassembly

Packing

Ring Nut

Tank Lid

1. Loosen the pump lever

connecting rod nut and

remove the connecting rod

from the chamber. Loosen

Pump Lever

Connecting

Rod Nut

the packing ring nut that

secures the chamber to

the tank. Remove the tank

lid and strainer, reach

inside the tank and

remove the agitator from

the pump chamber, then

remove the chamber from

the cylinder.

After pumping and

pressurizing the

chamber, the pump

lever rises slowly

when released.

Low pressure and

pump lever hard to

operate.

Chamber diaphragm not sealing

properly due to

wear or impurities.

Pump chamber

filled with liquid.

Pump Chamber

Chamber Diaphragm

Piston Cup

Cylinder

Cylinder Diaphragm

Clean or replace the

chamber diaphragm.

Tighten screw cap

at top of chamber.

With an empty tank,

pump lever with

trigger valve open

until all liquid is

purged from pump.

6

Page 7

Shindaiwa Limited Warranty

Shindaiwa Inc. manufactures its products to superior standards

of quality to ensure customers obtain the highest level of

satisfaction. In keeping with this goal, Shindaiwa Inc. warrants

the SP415 sprayer to the original purchaser as follows:

Warranty Period

One year from the delivery date to the original purchaser for

consumer and commercial applications.

90 days for rental applications.

Warranty Administration

Within the covered warranty period, Shindaiwa Inc. will, at

their option, repair or replace any defect in material or workmanship, without charge for parts or labor, if this product is

presented at an authorized Shindaiwa dealer.

Warranty Exclusions and Limitations

Shindaiwa Inc. assumes no responsibility for damages, loss, or

injury resulting from:

■ Normal wear and tear

■ Misuse or neglect

■ Modifications to or removal of original component parts

The warranty is limited to the terms stated herein. Shin-

daiwa Inc. disclaims all liability for incidental or consequential

damages. Some states do not allow the exclusion of incidental

or consequential damages, so these limitations may not apply to

you.

This warranty give you specific legal rights, and you may

also have other rights which may vary from state to state.

Shindaiwa reserves the right to change the design or

specifications of this product without obligation to modify

previously manufactured products.

Owner’s Responsibilities

The owner of the sprayer must demonstrate reasonable care

in the use, maintenance, and storage of this Shindaiwa product.

If a warrantable failure should occur, the owner must deliver

the product to an authorized Shindaiwa servicing dealer for

correction. All residual chemicals must be flushed from the

sprayer prior to delivery.

Unidentified chemicals left in the sprayer tank can pose

a serious health threat to anyone servicing the unit and

unaware of its presence!

To obtain warranty service, proof of purchase must be

presented to the authorized Shindaiwa servicing dealer when

the product is presented for repairs.

Proof of purchase must include date of purchase and the

name and address of the selling dealer.

7

Page 8

Illustrated Parts List (SP415) After s/n 198698C4

45

46

51

47

50

30

28

29

31

25

26

27

24

22

10

21

3

12

13

2

4

5

1

9

6

48

44

43

34

35

34

32

33

49

37

38

36

42

41

40

39

20

11

13

12

14

15

17

18

19

16

8

Page 9

Illustrated Parts List (SP415)

No. Part Number ItemDescription Qty.

1 568774 Spray Wand Assembly 1

2 568782 Trigger Valve Assembly 1

3 909192 Trigger Valve Handle 1

4 920470 Hose Ferrule 1

5 909283 Trigger Valve Body 1

6 105239 Trigger Valve Needle Assembly 1

9 568972 Trigger 1

10 996058 Valve Cap 1

11 568873 Wand Tube/Elbow Assembly 1

12 909309 Cone Packing 2

13 915744 Cone Nut 2

14 635276 Elbow 1

15 592139 Nozzle Filter (40 mesh) 1

16 015024 Adjustable Cone Nozzle Assembly 1

17 166611 Nozzle Body 1

18 940106 Packing Ring, (ORI-009) 1

19 229724 Nozzle Cap 1

20 166637 Nozzle Cap, Adjustable (Red) 1

21 048116 Dip Tube W/Hose 1

22 942193 Nut, 20 x 1.5 1

24 878132 Lid Assembly 1

25 560573 Diaphragm, NBR Rubber 1

26 837922 Lid Seal 1

27 942920 Strainer 1

28 560672 Packing Ring Nut 1

29 560581 Packing Ring 1

30 087163 Chamber Assembly 1

31 990010 Chamber Body 1

32a 568535 Piston Cup 1

32b 214585 Piston Cup, Santoprene (Optional) 1

33 630749 Piston Cup Fastener 1

34 964270 Diaphragm, Viton䉸 1

35 630731 Cylinder 1

34 964270 Diaphragm, Viton䉸 1

36 336503 Self-tapping Screw (14 x 7/8) 2

37 229864 Seal Washer 2

38 214619 Agitator 1

39 630756 Bushings Set 1

40 214627 Pump Lever Shaft 1

41 925826 Pin Set 1

42 925818 Bolt Assembly 1

43 630723 Pump Lever Assembly 1

44 002683 Hand Grip 1

45 568717 Strap Assembly 1

46 568725 Shoulder Pads 1

47 214817 Shoulder Strap Lock 1

48 229286 Strap Buckle Set 1

49 120154 Strap Buckle Lock 2

50 214486 Pump Rod Assy. 1

51 925800 Wand Clamp Set 1

9

Page 10

Illustrated Parts List (SP415) Before s/n 198697L3

36

Item Part No. Description Qty.

01 214486 Pumping Rod Ass’y 1

02 925800 Spray Wand Holder Set 1

03 942136 Chamber Cover 1

04 120303 Gasket Holder 1

05 552703 Gasket 1

06 120055 Ring ORI-36 2

07 942235 Chamber Body 1

08 568717 Strap Assembly (includes

Items 10 and 15) 1

09 214619 Agitator 1

10 568725 Shoulder Pads 2

11 908905 Diaphragm 3

12 568535 Piston Cup, 45 x 12 1

13 630749 Piston Cup Fastener

with Diaphragm 1

14 630731 Cylinder w/ Diaphragm 1

15 229286 Strap Buckle Set

(supplied with 2 locks) 1

16 120154 Lock 2

17 002683 Handgrip 1

18 630723 Pumping Lever (supplied

with Items 17 and 18) 1

19 925818 Bolt Assembly 1

20 925826 Pin with Cotter Pin 1

21 214627 Pumping Lever Shaft 1

22 336503 Self-tapping Screw,

14 x 7/8" 2

23 630756 Bushings Set 1

24 214817 Carrying Straps Lock 1

25 942219 Chamber Assembly 1

26 942359 Dip Tube Assembly 1

27 942193 Nut, 20 x 1.5 1

28 654921 Cap with Diaphragm 1

— 560573 Cap Diaphragm 1

29 942920 Strainer 1

30 568634 Tank with Cap 1

— 568642 Tank only 1

31 568972 Trigger 1

32 352577 Lower Seal, 30 x 88 x 25 1

33 351585 Upper Seal, 50 x 96 x 35 1

34 105254 Trigger Valve Cap 1

35 568790 Trigger Valve Needle

Assembly (includes

Items 32 and 33) 1

01

02

27

26

03

04

02

05

24

06

07

10

08

11

09

12

13

15

14

11

16

22

17

19

18

36 530576 Hose, 5.6" x 1350 1

37 909192 Trigger Valve Handle 1

38 920470 Lock 1

39 909283 Trigger Valve Body 1

40 909309 Cone Packing 1

41 915744 Screw Cap 2

42 336263 Spray Tube 1

43 560649 Elbow Assembly 1

44 568873 Spray Tube Assembly

(includes Items 40, 41,

42 [2], and 43) 1

45 730366 40 Mesh Nozzle Filter 1

25

37

28

38

49

11

39

29

40

41

30

42

44

41

43

23

51

20

23

21

Item Part No. Description Qty.Item Part No. Description Qty.

46 009456 Nozzle Body 1

47 715052 Packing Ring, ORI-012 1

48 009464 Nozzle Cap (red) 1

49 568782 Trigger Valve Assembly

(includes Items 31, 34,

35, 37, 38 and 39) 1

50 568774 Spray Wand Ass’y (includes

Items 44 and 49) 1

51 015024 Adjustable Cone Nozzle

(w/ Items 46, 47 and 48) 1

35

32

31

33

34

50

45

46

47

48

10

Page 11

NOTES:

11

Page 12

Shindaiwa Inc.

11975 S.W. Herman Road

Tualatin, Oregon 97062

Telephone: 503 692-3070

Fax: 503 692-6696

www.shindaiwa.com

2004 Shindaiwa, Inc.

䊚

Part Number 80836

Revision 2/04

Shindaiwa is a registered trademark

of Shindaiwa, Inc.

Specifications subject to change without notice.

Printed in Brazil

䉸

Loading...

Loading...