Shindaiwa RS76, RS76S Owner's Manual

COMMERCIAL BROADCAST SPREADER

COMMERCIAL BROADCAST SPREADER

COMMERCIAL BROADCAST SPREADERCOMMERCIAL BROADCAST SPREADER

MODEL RS76

MODEL RS76

MODEL RS76MODEL RS76

MODEL

MODEL

MODELMODEL

RS76S

RS76S

RS76SRS76S

OWNER’S MANUAL

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONS

ASSEMBLY INSTRUCTIONSASSEMBLY INSTRUCTIONS

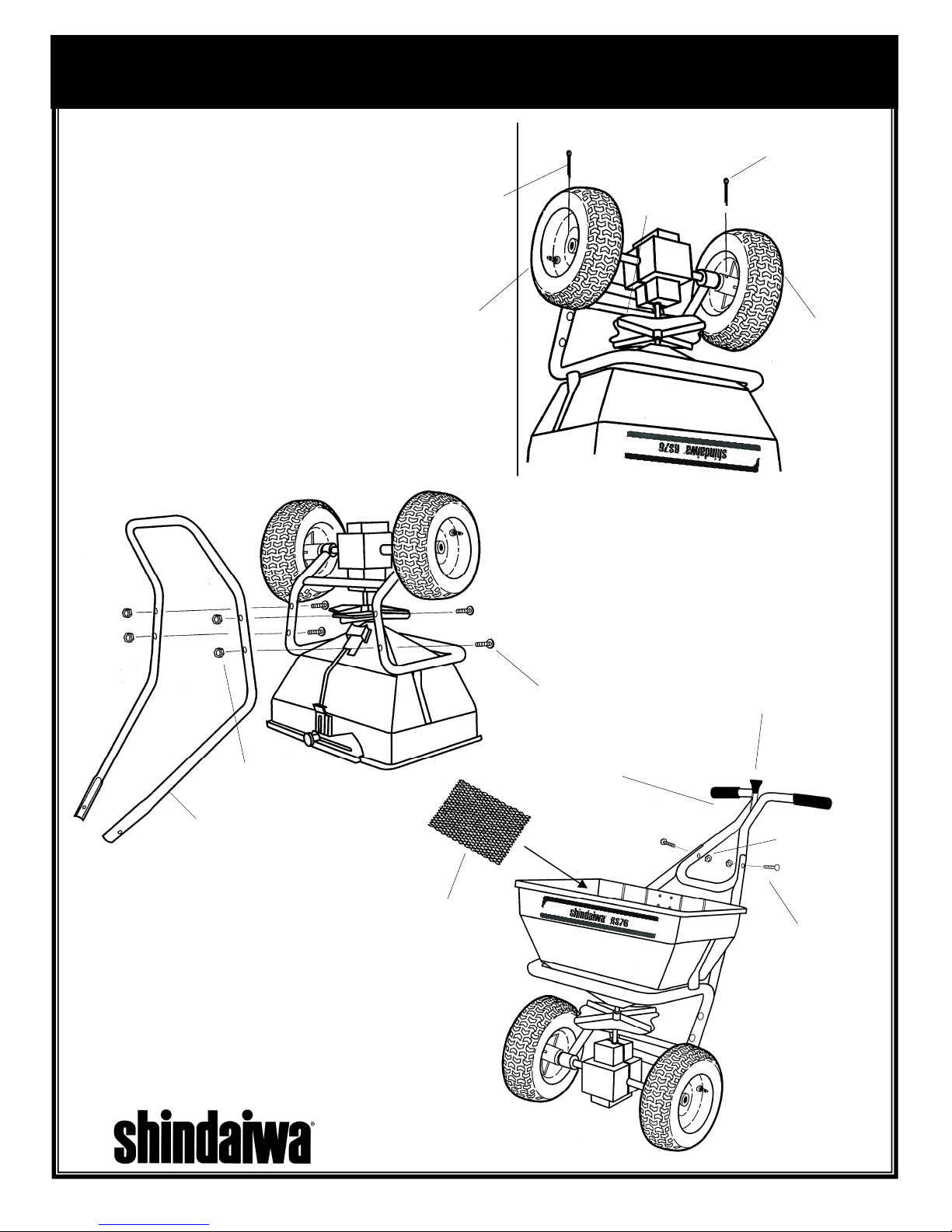

1.

Remove the spreader and

components from carton and

place hopper up-side down on

a padded surface as shown.

Slide drive and free wheel

onto axle as shown with the

longer portion of wheel hub

facing the frame. Secure free

wheel with (1) 1/8 dia. x 1 1/4”

cotter pin. Attach drive wheel

to axle with (1) 3/16 dia. x 2”

cotter pin.

3/16 Dia. x

2” Cotter Pin

1/8 Dia. x

1 1/4” Cotter

Pin

Drive Wheel Free Wheel

1/4-20 Locknut

Handle Brace/

Leg

3.

Turn spreader upright on

wheels. Insert screen into

hopper sliding it under the

screen clips. Attach the upper

handle assembly to handle

brace with the handle lever

facing as shown. Secure with

(2) 1/4-20 x 1 1/2” carriage

bolts, and locknuts.

Screen

2.

Attach leg/brace to frame as

shown using (4) 1/4-20 x 2 1/4”

carriage bolts and locknuts.

1/4-20 X 2 1/2”

Carriage Bolt

Upper Handle

Assembly

NOTE POSITION OF

HANDLE LEVER

1/4-20 X 1 1/2”

Carriage Bolt

1/4-20 Locknut

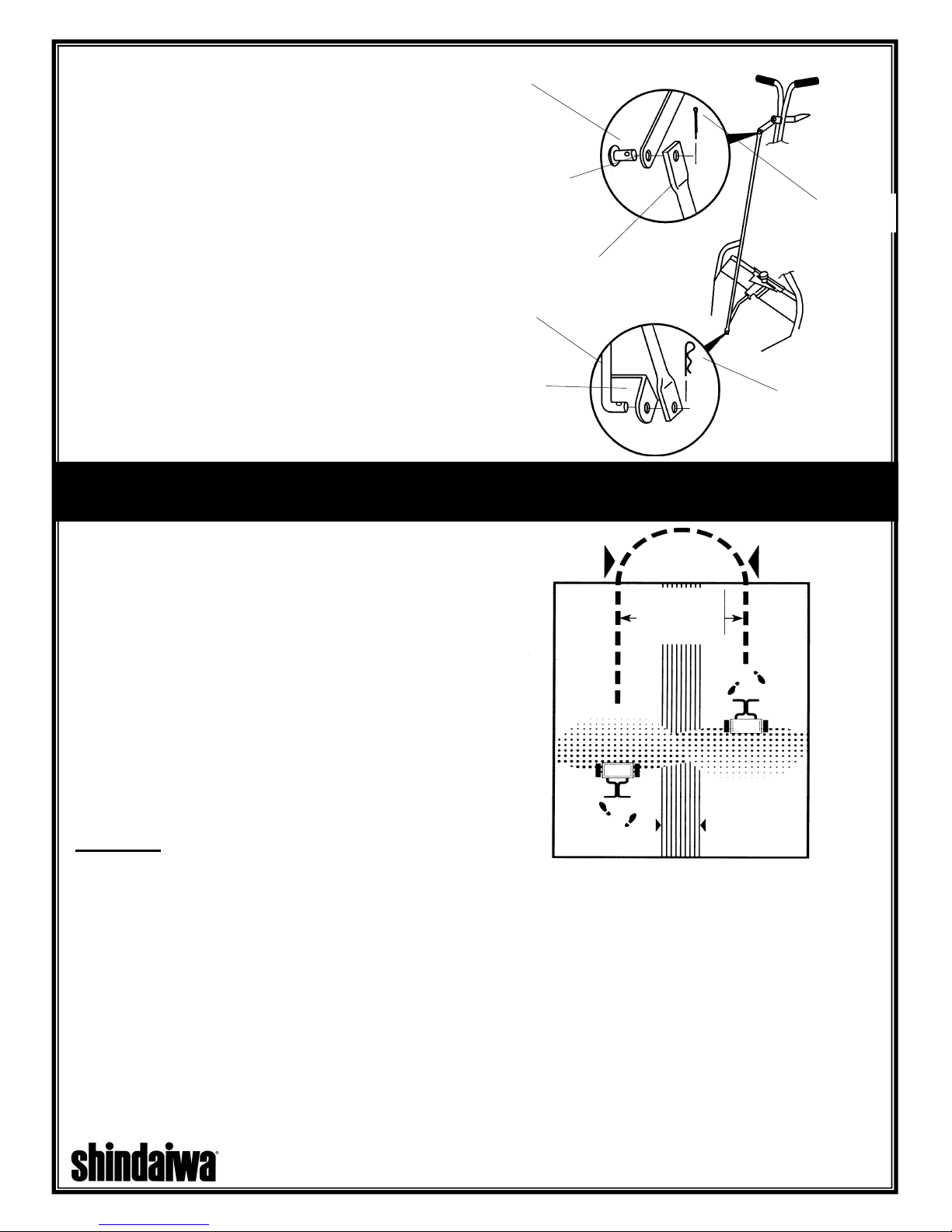

4.

Install control tube to handle

lever with (1) 1/4 dia. clevis pin

and a 3/32” dia. cotter pin. Slip

opposite end of control tube over

lower control rod making sure

shutoff plate is between the lower

rod and the control tube. Secure

with a 3/32” dia. Hitch pin cotter.

1/4 Dia.

Clevis Pin

Handle

Lever

3/32” Dia.

Cotter Pin

Control Tube

Lower Rod

OPERATION

OPERATION

OPERATIONOPERATION

1.

Check the product package for the rate

setting, and recommended swath width. Loosen

rate control knob and slide rate plate to the

proper setting. The pattern is controlled by

loosening the two knobs on the discharge chute

and moving the chute closer or farther away

from the impeller (setting A, B, or C). See

“PATTERN ADJUSTMENT” for details.

2.

Always fill the spreader on the driveway or

sidewalk-not on the lawn. Make sure screen is in

hopper and spreader is in the “OFF” position

3.

Start spreader moving before opening port.

.

Close before stopping. Always push spreader,

never pull.

4.

Hold handle so top of spreader is level.

Tipping the spreader too far can cause uneven

spreading.

5.

The settings and swath widths on the product

label are recommended starting points. Always

check the delivery rate and pattern on a small

area before treating a large area. Actual delivery

rate can vary due to weather conditions,

operating variables, and condition of the

product being applied. See “HOW TO

DETERMINE SPREADER SETTINGS AND

SPREAD WIDTH” for details.

Shutoff

USE SWATH WIDTH

ON PACKAGE OR

ADJUST PER

OPERATOR’S

WALKING SPEED

OVERLAP

6.

Push spreader at a normal walking speed -

3/32” Dia.

Hitch Pin

2 1/2 m.p.h. (18 feet in 5 seconds). Apply

header strips around area to be treated.

Space trips across the area as shown. Keep

material off flower beds, sidewalks, etc.

7.

When transporting spreader, make sure that

it is in the “OFF” position.

8.

Empty spreader after each use. Return

leftover material to its original container.

Cotter

Loading...

Loading...