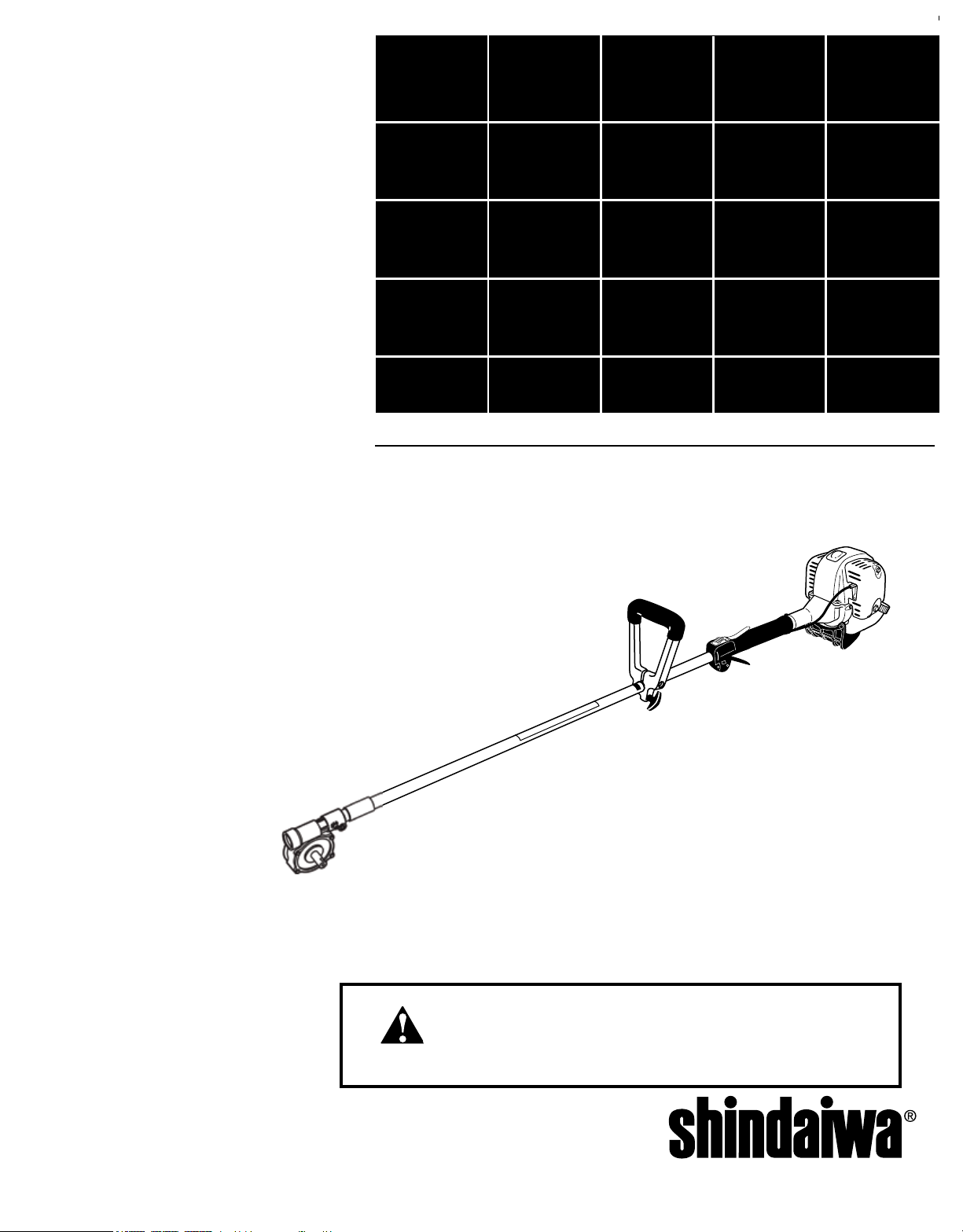

Shindaiwa PS344, X7502891200 User Manual

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

PS344 PowerBroom

TM

X7502891200

07/10

WARNING!

Minimize the risk of injury to yourself and others! Read this

manual and familiarize yourself with the contents. Always wear

eye and hearing protection when operating this unit.

Introduction

The Shindaiwa PS344 PowerBroom is

designed and built to deliver superior

performance and reliability without

compromise to quality, comfort, safety

or durability.

Shindaiwa engines represent the

leading edge of high-performance

engine technology, delivering

exceptionally high power with

remarkably low displacement and

weight. As an owner/operator, you’ll

soon discover for yourself why

Shindaiwa is simply in a class by itself!

IMPORTANT!

The information contained in these

instructions describes units available at

the time of publication.

Echo, Inc. reserves the right to make

changes to products without prior

notice, and without obligation to

make alterations to units previously

manufactured.

WARNING!

The engine exhaust from

this product contains chemicals

known to the State of California

to cause cancer, birth defects, or

other reproductive harm.

Contents

Safety .............................................3

Product Description ........................ 5

Specications ................................. 5

Emission Control ............................ 6

Assembly ........................................ 6

Mixing fuel ...................................... 8

Filling the fuel tank.......................... 9

Starting the Engine ...................... 10

Stopping the Engine ......................11

Checking Unit Condition ................11

Operating ......................................12

Maintenance ................................. 13

Long Term Storage ....................... 17

Troubleshooting Guide ................. 18

Warranty Statement ...................... 21

PAGEPAGEPAGE

IMPORTANT!

The procedures described in this manual are intended to help you get the most from your unit as well as to protect you and

others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended to replace

any safety rules and/or laws that may be in force in your area. If you have questions regarding your power tool, or if you do not

understand something in this manual, your Shindaiwa dealer will be glad to assist you. You may also contact Shindaiwa at the

address printed on the back of this Manual.

Attention Statements

Throughout this manual are special

“attention statements”.

DANGER!

A statement preceded by

the triangular attention symbol and

the word “DANGER” contains information that should be acted upon

to prevent serious injury or death.

by the triangular attention symbol

and the word “WARNING” contains information that should be

acted upon to prevent serious bodily injury.

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

WARNING!

A statement preceded

IMPORTANT!

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent mechanical damage.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

Warning and operational labels

Read and follow this manual,

make sure anyone using the

unit does likewise. Failure to

do so could result in serious

personal injury or machine failure. Keep this manual for future

reference.

Always wear eye and hearing

protection. Shindaiwa recommends wearing a face shield

as additional face and eye

protection.

2

Beware of thrown objects. Keep

bystanders at least 15 M (50

feet) away during operation.

Do not use on unguarded elevated surfaces.

WARNING ! Surface can

be hot. Always wear gloves

when handling this unit.

Maintain a shallow working

angle and avoid moving toward

the vertical.

READ THE

OPERA TOR’S MAN UAL.

WEAR HEAR ING AN D ANSI Z87. 1

APPROVED EYE PROTE CTION .

BEWARE OF THRO WN

DIRT AND DEBR IS.

MAINTAIN A

SHALLOW

WORKING

ANGLE…

DO NOT U SE ON UNGU ARDED

ELEVA TED SURFACES .

…AVOID MO VING TOWARD

VERTICAL .

80267Shindaiwa Inc .

Safety

Work Safely

A PowerBroom operates at very high speeds

and has the potential to do serious damage

if misused, abused or mishandled. To reduce

the risk of injury, you must maintain control at

all times, and observe all safety precautions

during operation. Never permit a person

without training or instruction to operate this

attachment installations.

Stay Alert

You must be physically and mentally t to

operate this unit safely.

WARNING!

Never make unauthorized

WARNING!

Never operate

power equipment of any kind if you

are tired or if you are under the inuence of alcohol, drugs, medication or

any other substance that could affect

your ability or judgement.

machine!

WARNING!

The ignition components of this machine generate an electromagnetic eld during operation which may interfere with

some pacemakers. To reduce the risk of serious or fatal injury, persons with pacemakers should consult with their physician and the pacemaker manufacturer before operating this machine. In the absence of such information, ECHO does not

recommend the use of Shindaiwa products by anyone who has a pacemaker.

Sweeper belts may move when ■

starting engine. Place sweeper belts

on a smooth level surface when

starting.

Always make sure the PowerBroom

■

attachment is properly installed and

rmly tightened before operation.

Always wear eye protection to shield

■

against thrown objects.

Never modify or disable any of the

■

unit’s safety devices.

Do not make unauthorized modica-

■

tions to this unit.

Make sure there are no missing or

■

loose fasteners, and that the ignition switch and throttle controls are

working properly.

Do not operate the unit with the muf-

■

er removed.

Safety Labels

WARNING!

Use Good Judgement

NEVER operate this unit indoors.

■

Operate this unit only in a well ventilated area. Be aware of carbon monoxide poisoning. Exhaust gases and

lubrication oil mist can cause serious

injury or death.

Always hold the machine rmly with

■

both hands when sweeping, and

maintain control at all times.

Always stop the engine immediately

■

and check for damage if you strike a

foreign object or if the unit becomes

tangled. Do not operate with broken or

damaged equipment.

Always clear your work area of trash

■

or hidden debris to help ensure good

footing.

Always use genuine Shindaiwa parts

■

and accessories when repairing or

maintaining this unit.

This label indicates the minimum distance between

front handle and rear grip per ANSI B175.3.

Stop the unit immediately if

■

it suddenly begins to vibrate or

shake. Inspect for broken, missing or improperly installed parts or

attachments.

Never transport the unit nor set it

■

down with the engine running. An

engine that’s running could be accidentally accelerated causing the

drum assemblies to rotate.

Always disconnect the spark plug

■

wire before performing any maintenance work.

Always maintain this unit accord-

■

ing to this owner’s manual and follow the recommended scheduled

maintenance.

Keep a Solid Stance. Maintain foot-

■

ing and balance at all times. Do

not stand on slippery, uneven or

unstable surfaces. Do not work in

odd positions or on ladders. Do not

over reach.

IMPORTANT!

Safety and Operation Information Labels: Make sure

all information labels are undamaged and readable.

Immediately replace damaged or missing information labels. New labels are available from your local

authorized Shindaiwa dealer.

3

Safety (continued)

The Properly Equipped Operator

Always protect yourself from hazards

such as thorny brush and ying debris

by wearing gloves and close tting

clothing that covers arms and legs.

Never wear shorts. Don’t wear loose

clothing or items such as jewelry that

could get caught in machinery or under

brush. Secure long hair so it is above

shoulder level.

Keep a proper footing and do not

overreach—maintain your balance

at all times during operation.

Wear sturdy footwear with nonslip

soles to provide good footing. Steeltoed safety boots are recommended.

Never operate unit bare-footed!

Always wear eye and hearing protection.

Shindaiwa recommends wearing a face shield as

additional face and eye protection.

Always operate with both hands

rmly gripping the unit.

Keep away from rotating

sweeper belts or bristles at

all times, and NEVER lift a

moving attachment above

waist-height.

Be Aware of the Working Environment

Be careful when operating on a slope or on slippery

terrain, especially during rainy weather or when pulling

debris toward you.

If the drum assemblies jam, switch the

engine OFF and inspect the drums,

axles and gearcase for damage.

Do not use this unit on

rooftops or elevated surfaces

When transporting the unit in a

vehicle, tie it down securely to

prevent damage and fuel spillage.

Never operate the PowerBroom around

objects that could tangle in the drums

and cause loss of control.

Never allow the engine to run at

high RPM without a load. Doing

so could damage the engine.

Be constantly alert for objects and debris that could be

thrown either from the sweeper belts or bounced from a

hard surface.

Keep bystanders

at least 15 meters

away from the unit

while operating

to reduce the risk

of being struck by

thrown debris.

ALWAYS clear your work area of trash or

hidden debris that could be thrown back at

you or toward a bystander. When operating

in rocky terrain or near electric wires or

fences, use extreme caution to avoid

contacting such items with the sweeper belts.

Keep the unit as clean as

possible. Keep it free of

loose vegetation, mud,

etc.

Maintain a low working angle

and avoid steep angles of

operation. A steep working

angle risks loss of control of

the machine.

Transport the

machine with the

engine OFF.

Always keep the

handles clean.

4

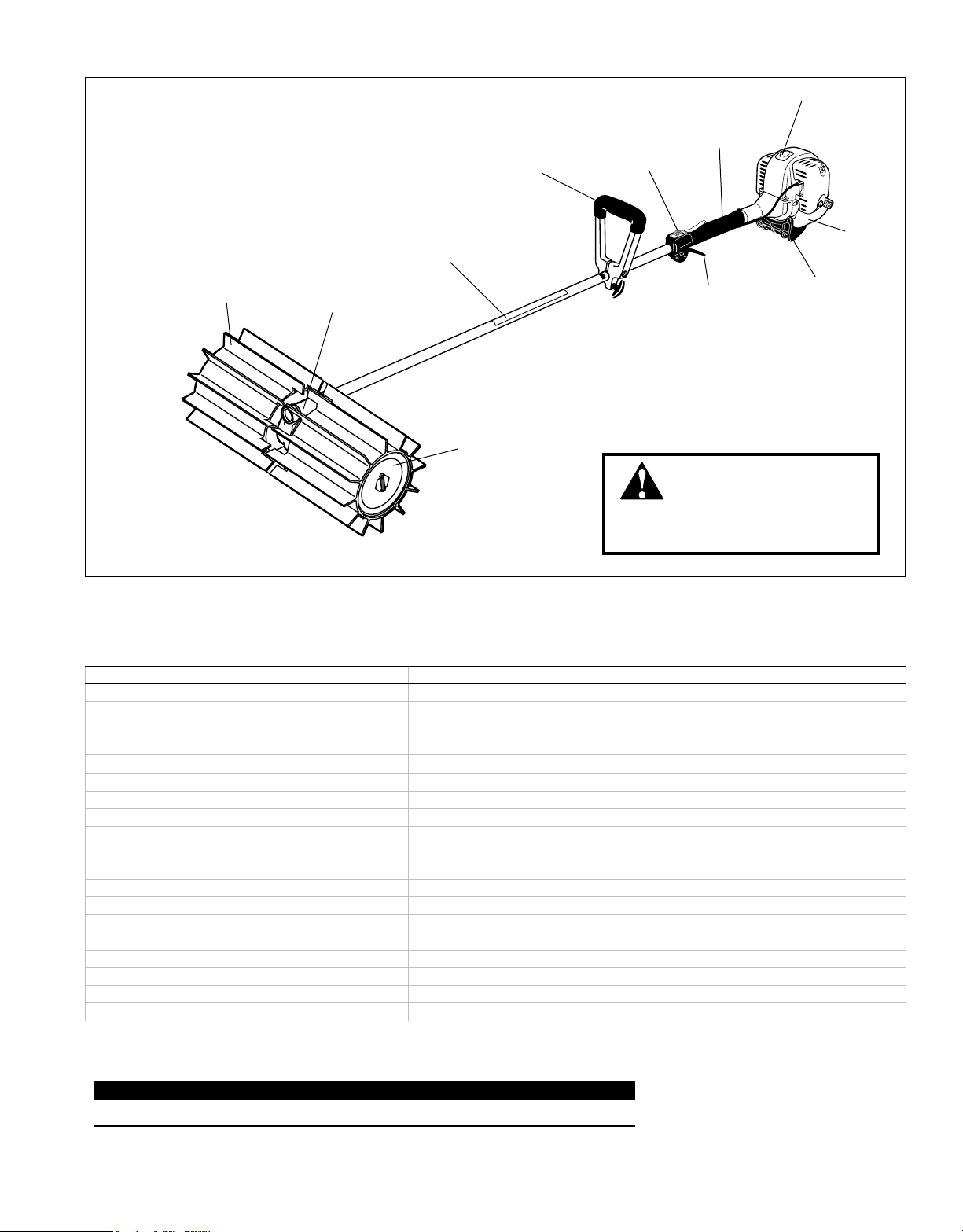

Product Description

Using the illustration as a guide, familiarize yourself with your machine and its

various components. Understanding your

machine helps ensure top performance,

long service life and safer operation.

Sweeper Belt

Gearcase

Outer Tube

PS344

Sweeper Drum

Handle

Spark Plug

Grip

Ignition Switch

Throttle

Trigger

WARNING!

Do not make unauthorized

modications or alterations to any of

these units or their components.

Fuel Tank

Tank

Protector

Specications

Model PS344

Dry Weight (less sweepers) 6.0 kg/13.2 lb.

Engine Type 4-cycle, vertical cylinder, air cooled

Bore x Stroke 38 x 30 mm/1.5 x 1.2 in.

Displacement 34 cc/2.1 cu. in.

Fuel/Oil Ratio 50:1 with *ISO-L-EGD or JASO FD class engine oil

Fuel Tank Capacity 660 ml/22.4 oz.

Carburetor Type Diaphragm-type

Ignition Electronic

Spark Plug NGK CMR5H

Electrode Gap 0.6 mm/ .024 in.

Torque 16.7 - 18.6 N∙m / 148-165 in • lbf

Air Cleaner Type Foam pre-lter; sealed felt main lter

Starting Method Recoil

Stopping Method Slide switch

Transmission Type Automatic, centrifugal clutch w/worm gear

Gear Reduction Ratio 40:1

Engine Idle Speed 3,000 RPM

Clutch Engagement Speed 4,200 RPM

Wide Open Throttle Speed (W.O.T.) 10,500 RPM

*Specications are subject to change without notice.

IMPORTANT !

This spark ignition system complies with the Canadian standard ICES-002.

5

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modication and 3-way Catalyst) and for the fuel tank

the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission may be applicable to

California models only.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY; information on label varies by en-

gine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in the Maintenance Section of this manual.

Assembly

Prior to assembly

Before assembling, make sure you have

all the components required for a complete unit:

PowerBroomUnit ■

Kit with this manual and tool kit for ■

routine maintenance..

Carefully inspect all components for

■

damage before assembling.

WARNING!

Do not make unauthorized

modications or alterations to your

machine or its components.

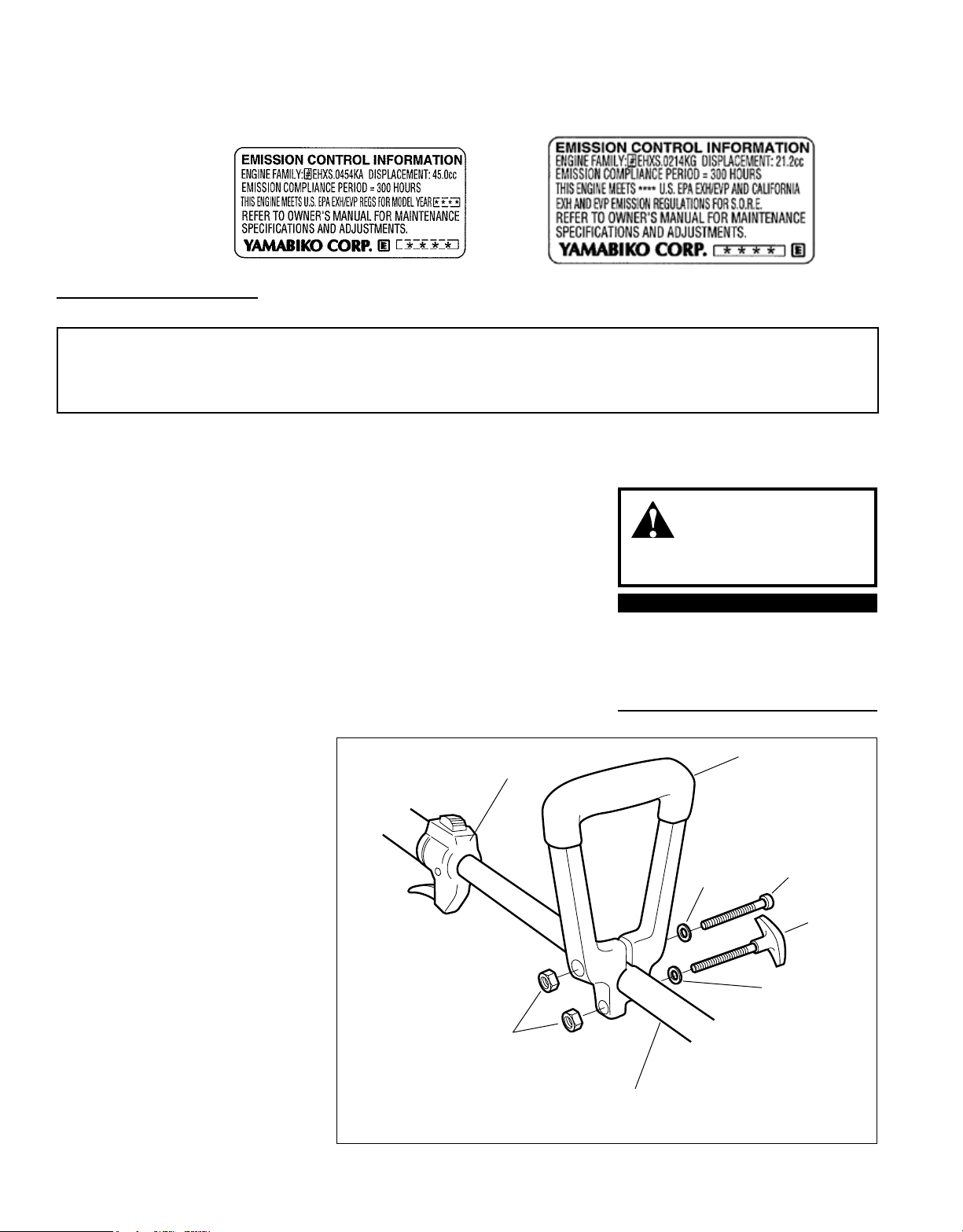

Adjustable Handle

This unit comes with the handle

installed. It can be re-adjusted for

operator comfort in the following

manner.

Loosen adjustment knob. 1. Locate

the handle at the best position for

operator comfort (usually about

10 inches ahead of the throttle

trigger), and secure it by tightening

the adjustment knob at the handle

base.

IMPORTANT!

The terms “left”, “left-hand”, and

“LH”; “right”, “right-hand”, and “RH”;

“front” and “rear” refer to directions as

viewed by the operator during normal

operation.

Handle

Throttle Assembly

Mounting Screw

Washer

Adjustment Knob

Washer

Hex Nut

Outer Tube

6

Assembly (continued)

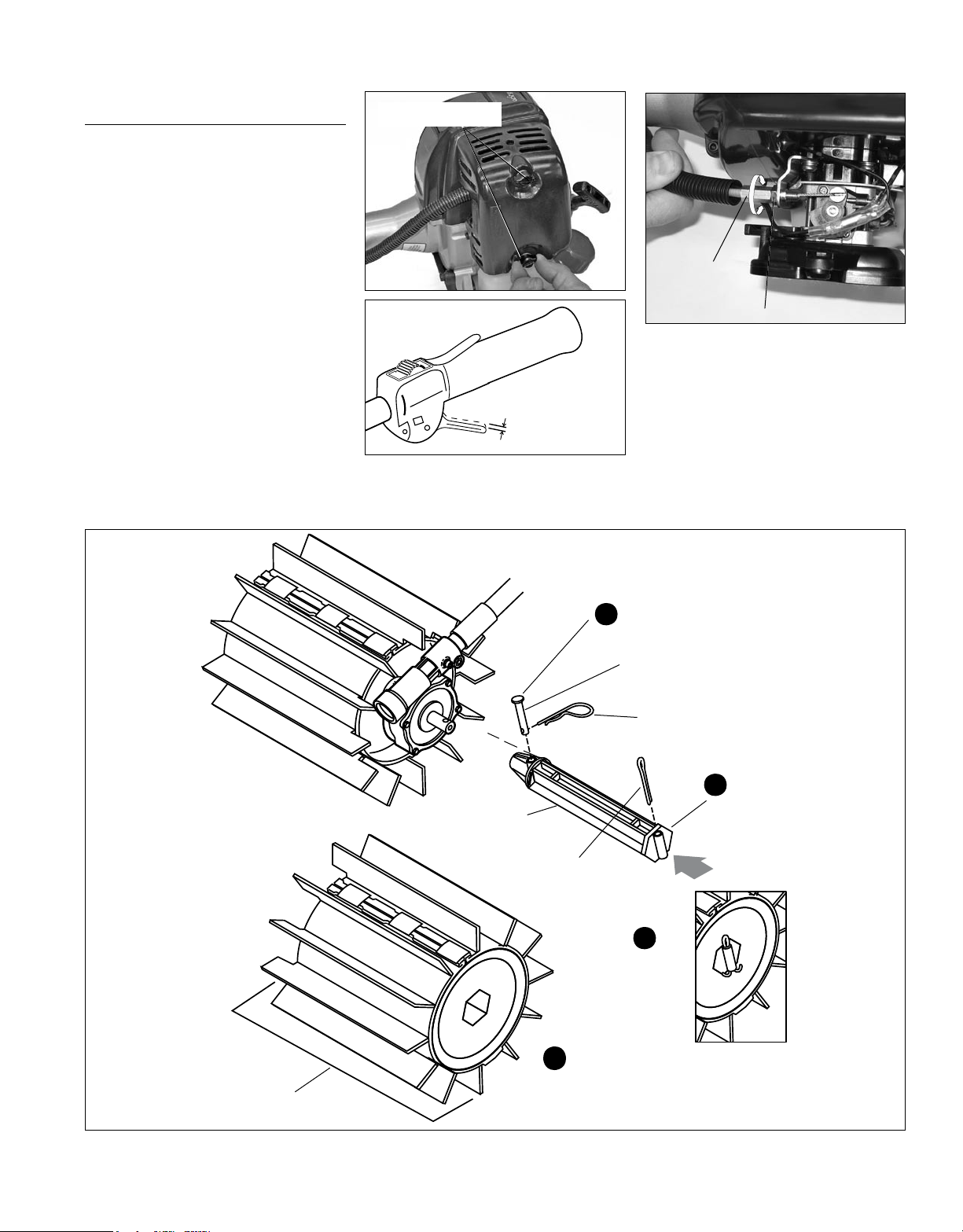

Adjust Throttle Trigger Free Play

The throttle trigger free play should

be approximately 3/16-1/4 inch (4-6

mm). Make sure that the throttle trigger

operates smoothly without binding. If it

becomes necessary to adjust the trigger free play, follow the procedures and

illustrations that follow.

Loosen the air cleaner cover knobs 1.

and remove the air cleaner cover.

Loosen the lock nut on the cable 2.

adjuster.

Turn the cable adjuster in or out as 3.

required to obtain proper free play

3/16-1/4 inch (4-6 mm).

Tighten the locknut.4.

Reinstall the air cleaner cover.5.

Sweeper Assembly (sold separately)

Loosen the air cleaner

cover knobs

3/16-1/4 inch (4-6 mm)

Throttle Free Play

Cable

Adjuster

Lock Nut

Drum

Assembly

Drum

Axle

Secure the drum

2

axle to the shaft

Clevis

Pin

Cotter

Pin

Secure with a

cotter pin

Install the sweeper drum

3

assembly

Hitch

Pin

4

1

Install drum

axle onto

output shaft

7

Assembly (continued)

Push one of the drum axles onto 1.

either of the two gearcase output

shafts. If necessary, rotate the drum

axle until the clevis pin hole in the

axle aligns with the matching hole

in the gearcase output shaft.

CAUTION!

The two drum assemblies are

identical, but each drum must be

installed with its recessed end

facing toward the gearcase.

Use a clevis pin and hitch pin to 2.

secure the drum axle to the shaft.

Slide the recessed end of a 3.

sweeper drum assembly over the

installed axle, and then push the

drum down the axle until the cotter

pin hole in the axle extends above

the drum surface.

Use a cotter pin to secure the drum 4.

assembly on the axle (see inset).

The cotter pin is designed to t

tightly against the outboard end of

the drum, so you may need to compress the drum face slightly during

installation. spead the ends of the

cotter pin to secure.

Repeat Steps 1-4 to install the 5.

remaining axle and drum assembly.

The PowerBroom tool should now be

completely assembled.

Mixing Fuel

WARNING!

Alternative fuels, such as E15 (15% ethanol), E-85 (85% ethanol) or any fuels not meeting Shindaiwa

requirements are NOT approved for use in Shindaiwa gasoline engines. Use of alternative fuels may cause

performance problems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including,

but not limited to, improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel

lines, gaskets, carburetors and other engine components.

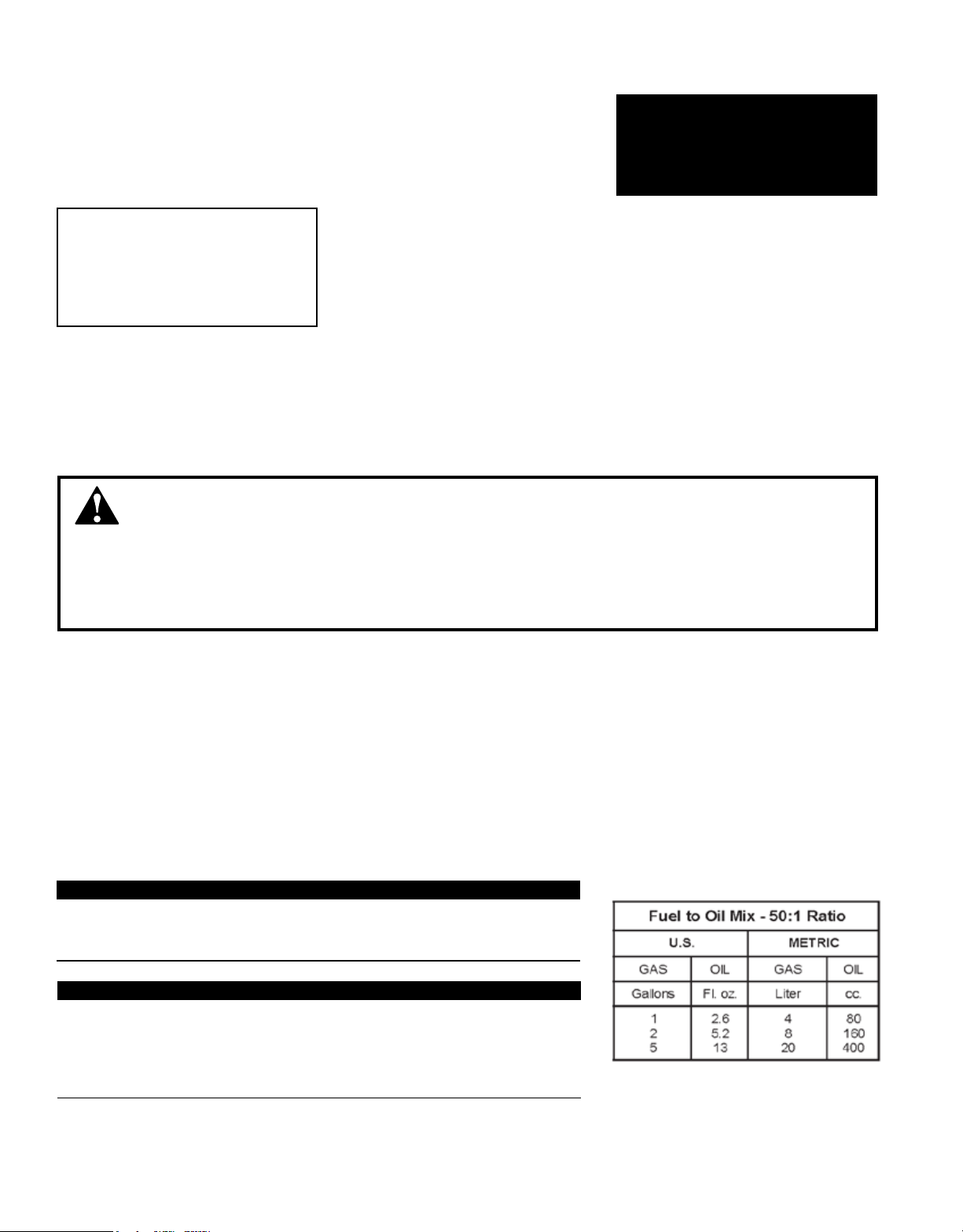

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain

up to 10% Ethanol (grain alcohol) or 15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood

alcohol) is NOT approved.

Hybrid 4TM Mixture Oil - Engine oil meeting ISO-L-EGD (ISO/CD 13738) and J.A.S.O. M345/FD standards must be

used. Shindaiwa highly recommends using Shindaiwa Red ArmorTM engine oil in all Shindaiwa Hybrid 4TM engines to

protect the engine from harmful carbon build up, maintain engine performance, and increase engine life. Shindaiwa

Red ArmorTM engine oil exceeds ISO-L-EGD and J.A.S.O. M345/FD performance requirements. Engine problems

due to inadequate lubrication caused by failure to use an ISO-L-EGD (ISO/CD 13738) and J.A.S.O. M345/FD certied

oil will void the engine warranty.

IMPORTANT!

Shindaiwa Red Armor

in all Shindaiwa engines sold in the past, regardless of ratio specied in those

manuals.

Stored fuel ages. Do not mix more fuel than you expect to use in thirty (30)

days, ninety (90) days when a fuel stabilizer is added. Use of unmixed, improperly mixed, or stale fuel, may cause hard starting, poor performance, or severe

engine damage and void the product warranty. Read and follow instructions in

the Long Term Storage section of this manual.

8

TM

engine oil may be mixed at 50:1 ratio for application

IMPORTANT!

Examples of 50:1 mixing quantities

Loading...

Loading...