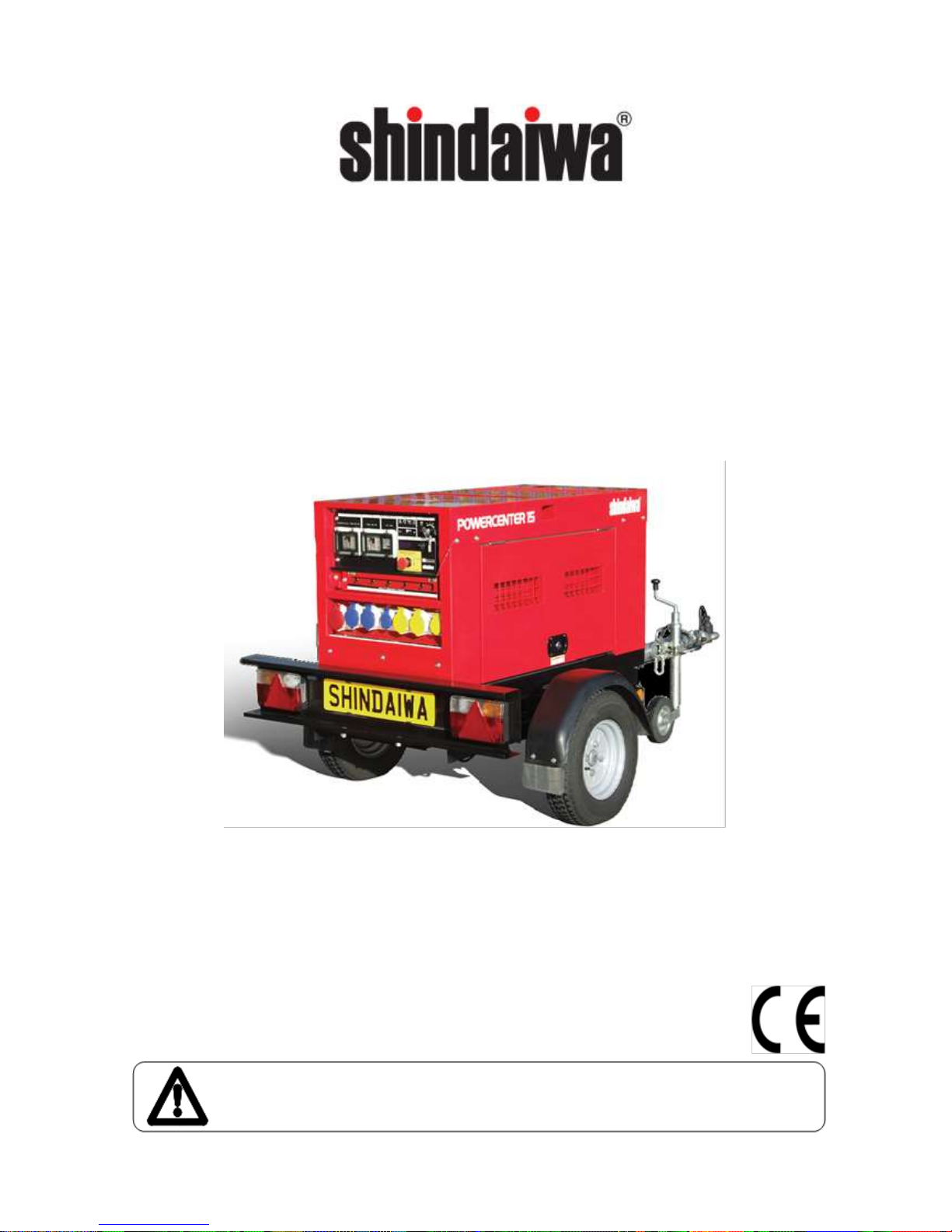

Shindaiwa POWERCENTER 15 Operator's Manual

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

OPERATOR’S MANUAL

POWERCENTER 15

CAUTION

Do not operate the Generator, or any other appliance, before you have read and

understood the instructions for use.

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

Table of Contents

Introduction .............................................................................................. 1

EC Declaration of Conformity ................................................................. 2

1. Safety Guidelines ................................................................................. 3

2. Specifications ....................................................................................... 9

2-1. Specifications ................................................................................ 9

2-2. Ambient Conditions ....................................................................... 9

3. Applications .......................................................................................... 9

4. Parts .................................................................................................... 10

5. Equipment ........................................................................................... 13

5-1. Spill Containment ........................................................................ 13

5-2. Multi digital meter ........................................................................ 13

5-3. Error Code Display ...................................................................... 14

5-4. Monitor Lamp .............................................................................. 14

5-5. Earth Leakage Circuit Breaker and Grounding .......................... 16

5-6. Emergency Stop Switch .............................................................. 19

5-7. Terminal Cover Switch ................................................................ 19

6. Load connections .............................................................................. 20

6-1. Load Cable Selection .................................................................. 20

6-2. Connecting Load Cable .............................................................. 21

7. Pre-Operation Inspection .................................................................. 25

7-1. Engine Oil Inspection .................................................................. 25

7-2. Cooling Water Inspection ............................................................ 26

7-3. Fuel Inspection ............................................................................ 27

7-4. Spill Containment Inspection ...................................................... 27

7-5. Inspection for Fuel/Oil/Cooling Water Leakage .......................... 28

7-6. Battery Inspection ....................................................................... 28

8. Operating Procedures ....................................................................... 29

8-1. Initial Startup/Pre-Check ............................................................. 30

8-2. Stopping Operation ..................................................................... 32

8-3. Protective Functions ................................................................... 33

9. Inspection/Maintenance .................................................................... 34

10. Long-Term Storage .......................................................................... 41

11. Troubleshooting ............................................................................... 42

12. Engine Wiring Diagram.................................................................... 44

13. Generator Wiring Diagram .............................................................. 45

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

Introduction

Thank you for purchasing a Shindaiwa Sound Proof Diesel Engine

Generator.

This operation manual has been created to ensure the safe operation of this

equipment. Therefore, the manufacturer of this equipment strongly

recommends that the user follow the instructions herein, to avoid unnecessary

accidents and repairs.

Please operate this equipment after thoroughly reviewing and understanding the

contents of this manual.

Please supply this manual with the equipment.

■The following conventions will be used throughout the manual to indicate

the degree of caution.

Warning

Can cause serious injuries or death.

Caution

Can cause minor injuries or damage to the equipment or

other properties.

<Caution>

Other types of caution

Even some of the items noted in『 Caution 』may lead to serious injuries.

Please read all items and follow all the safety guidelines.

The following statement refers to the noise level data contained in the EC Declaration of

Conformity contained on page 2 of this manual:

“The figures quoted are emission levels and are not necessarily safe working levels. Whilst there is a

correlation between the emission and exposure levels, this cannot be used reliably to determine whether or

not further precautions are required. Factors that influence the actual level of exposure of work‐force

include the characteristics of the work place, the other sources of noise, etc. i.e. the number of machines

and other adjacent processes, and the length of time for which an operator is exposed to the noise. This

information, however, will enable the user of the machine to make a better evaluation of the hazard and

risk”.

-1-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

EC Declaration of Conformity

In accordance with EN ISO 17050-1:2004

We

Shindaiwa Ltd

of

Unit 6 The Dell, Enterprise Drive, Four Ashes, Wolverhampton WV10 7DF

in accordance with the following Directives:

2004/108/EC

The Electromagnetic Compatibility Directive

and its amending directives

2006/42/EC

The Machinery Directive

2000/14/EC

The Noise Emission in the Environment by Equipment for Use Outdoors Directive

2011/65/EU

The Restriction of Hazardous Substances Directive

hereby declare that:

Equipment

Engine driven generator

Model number

PowerCenter 15

Serial Number(s)

W0165500581

is in conformity with the applicable requirements of the following documents

Ref. No.

Title

Edition/date

BS EN ISO 12100

Safety of machinery. General principles for design. Risk assessment and risk reduction

2010

BS EN 60204-1

Safety of machinery. Electrical equipment of machines. General requirements

2006 +A1:2009

BS EN 61000-6-2

Electromagnetic compatibility - immunity

2005

BS EN 61000-6-4

Electromagnetic compatibility - emissions

2007

BS EN 12601

Reciprocating internal combustion engine driven generating sets. Safety

2010

Noise measurements have been made in accordance with ISO 3744 with internal control of production

(Schedule 8/Annex V). The declared noise values are as follows:

Measured sound power level

Guaranteed sound power level

( 90 ) dB Lwa

( 92 ) dB Lwa

I hereby declare that the equipment named above has been designed to comply with the relevant

sections of the above referenced specifications. The unit complies with all applicable Essential

Requirements of the Directives.

Signed by: ............................................................................................................................

Name:

D.Richards

Position:

Director

Done at

Wolverhampton

On

10/04/14

Document ref. No.

PC1500001

The technical documentation for the machinery is available from the manufacturer at the above

address.

-2-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

Warning: Suffocation from Exhaust Fumes

Do not operate the equipment in a poorly-ventilated area such as indoors or within a

tunnel because the engine exhaust fume includes components that are harmful to

humans.

Warning: Electric Shock

Do not operate the equipment with any doors or covers open.

Do not touch wirings or any electric parts inside the equipment during operation.

Do not touch the equipment during operation if the equipment or your body is wet.

Be sure to stop the engine whenever touching output terminals such as when installing or

removing cables.

Do not connect cables to any part other than output terminals.

Do not insert any metallic objects, such as pins or wires, into AC output receptacles or

terminals.

Always be sure to turn off all breakers before installing or removing devices using AC

output receptacles.

Always be sure to repair the corresponding earth leakage location when earth leakage

circuit breakers operate.

Always be sure to stop the engine and remove the starter key before performing any

equipment check or maintenance.

This machine is rated to IP23.

Warning: Fire

Always be sure to stop the engine when inspecting fuel or refueling, and absolutely never

perform such tasks near fire or other open flame. Wait until the engine has completely

cooled before inspecting fuel or refueling.

Always be sure to wipe up any spilled fuel or oil.

Spilled fuel and oil accumulates in the spill containment. Do not operate the equipment

with liquid accumulated in the spill containment.

Absolutely never use the equipment if there is a fuel, oil or cooling water leak, and be

sure to always repair the leak before using.

Absolutely never inspect or perform maintenance to the equipment near fire or other

open flame.

Keep any ignitable items (such as fuel, gas and paint) or inflammable items away from

the equipment because the muffler, exhaust fume and other parts attain high

temperatures.

Provide at least 1 meter (3 feet) of distance between the equipment and walls and other

obstacles, and operate the equipment on a flat surface.

Allow the equipment to cool before covering with protective covers and similar items.

Do not ground wiring of earth leakage circuit breakers of the equipment to piping that

passes through flammable material.

Warning: Injuries

Do not operate the equipment with any doors or covers open. There is a danger of hair,

body parts and other items being caught up in moving parts such as cooling fans and

belts.

Do not modify the equipment and do not operate with parts removed.

Always be sure to stop the engine and remove the starter key before performing any

equipment check or maintenance.

1. Safety Guidelines

-3-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

Warning: Injuries to Eyes and Skin

Use protective gear, such as rubber gloves, when inspecting or replacing the battery due

to the dilute sulfuric acid in the battery fluid. Be sure that fluid does not get into eyes, or

on skin or clothing.

If battery fluid gets into the eyes, or on the skin or clothing, immediately wash with a large

amount of water, and always be especially sure to seek medical attention if it gets into

the eyes.

Warning: Explosion

Do not operate the equipment or recharge the battery when the battery fluid level is

below the lower level.

Do not generate any sparks near the battery and do not allow any fire or other open

flame near the equipment because the battery generates ignitable gas.

Warning: Electromagnetic Interference

Persons using a heart pacemaker are not allowed near the Generator work area while

Generator is being performed without the permission of a doctor. The welder generates a

magnetic field while energized that can negatively affect pacemaker operation.

Caution: Suffocation from Exhaust Fumes

Do not direct the engine exhaust towards passersby, private homes or similar

persons/locations because the engine exhaust fume includes components that are

harmful to humans.

Caution: Electric Shock

Do not sprinkle water on the equipment and do not use where exposed to rain.

If wearing gloves, be sure to always wear gloves with dry insulation properties. Do not

wear gloves that are damaged or wet.

Caution: Burns

The engine, muffler and similar parts are extremely hot during operation and immediately

after stopping the equipment. Never touch hot parts.

Never open the radiator cap during operation or immediately after stopping the

equipment. Hot cooling water and steam will spurt out.

Always be sure to stop the engine and allow it to cool before inspecting or changing the

engine oil. Opening the oil gauge or oil plug during operation will result in hot oil spurting

out.

-4-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

Caution: Injuries

Use this equipment with it situated on a stable level surface so that it is prevented from

moving.

Do not move the equipment during operation.

Always be sure to turn off the switches of all devices using the equipment and turn off the

equipment breakers before starting the engine.

Always be sure to turn off the power switches of all devices using the equipment when

turning on the equipment breakers. Leaving on the power switch of a device using the

equipment when the equipment breakers are turned on could result in the sudden

operation of the corresponding device.

Do not leave on the power switch of a device using the equipment and do not connect a

device to an AC output receptacle.

The lifting lug is designed to be used only for lifting the equipment. Do not lift the

equipment with any heavy items (such as a trailer and additional fuel tank) added to the

equipment.

Always be sure to use the lifting lug when lifting the equipment, and lift slowly and directly

straight above.

Wear a helmet, safety shoes, gloves and similar protective gear when performing lifting

work. Do not stand or get under the equipment while it is suspended.

Securely fix the equipment with rope or similar item so that it cannot move when

transporting by truck or other vehicle.

Caution: Physical and Secondary Damage

Do not use the equipment for any improper applications. Improper usage can result in an

accident or malfunction.

Do not connect the AC power source to indoor wiring.

If using the equipment as a power source for medical equipment, you must check with

the medical equipment manufacturer, doctor and hospital before using the equipment.

-5-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

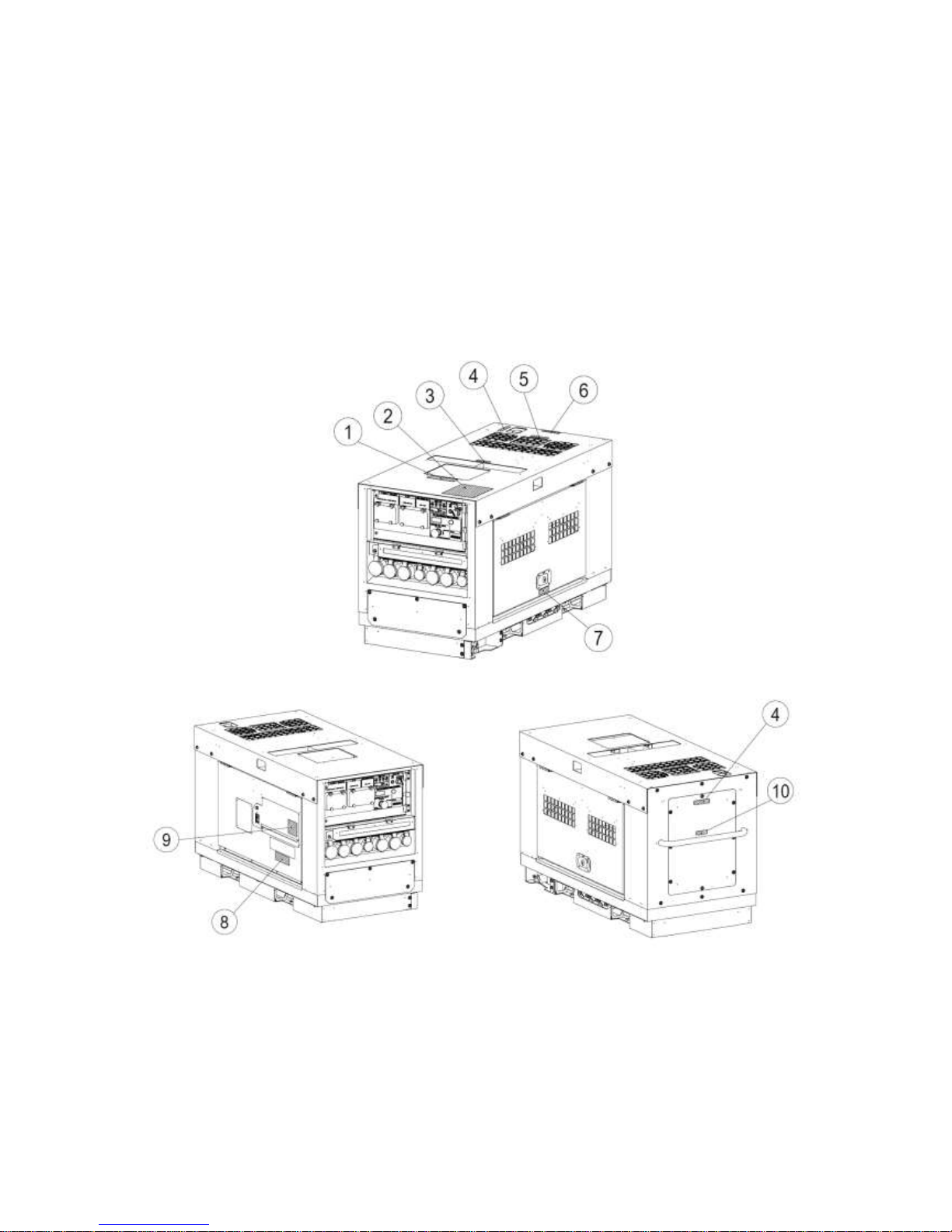

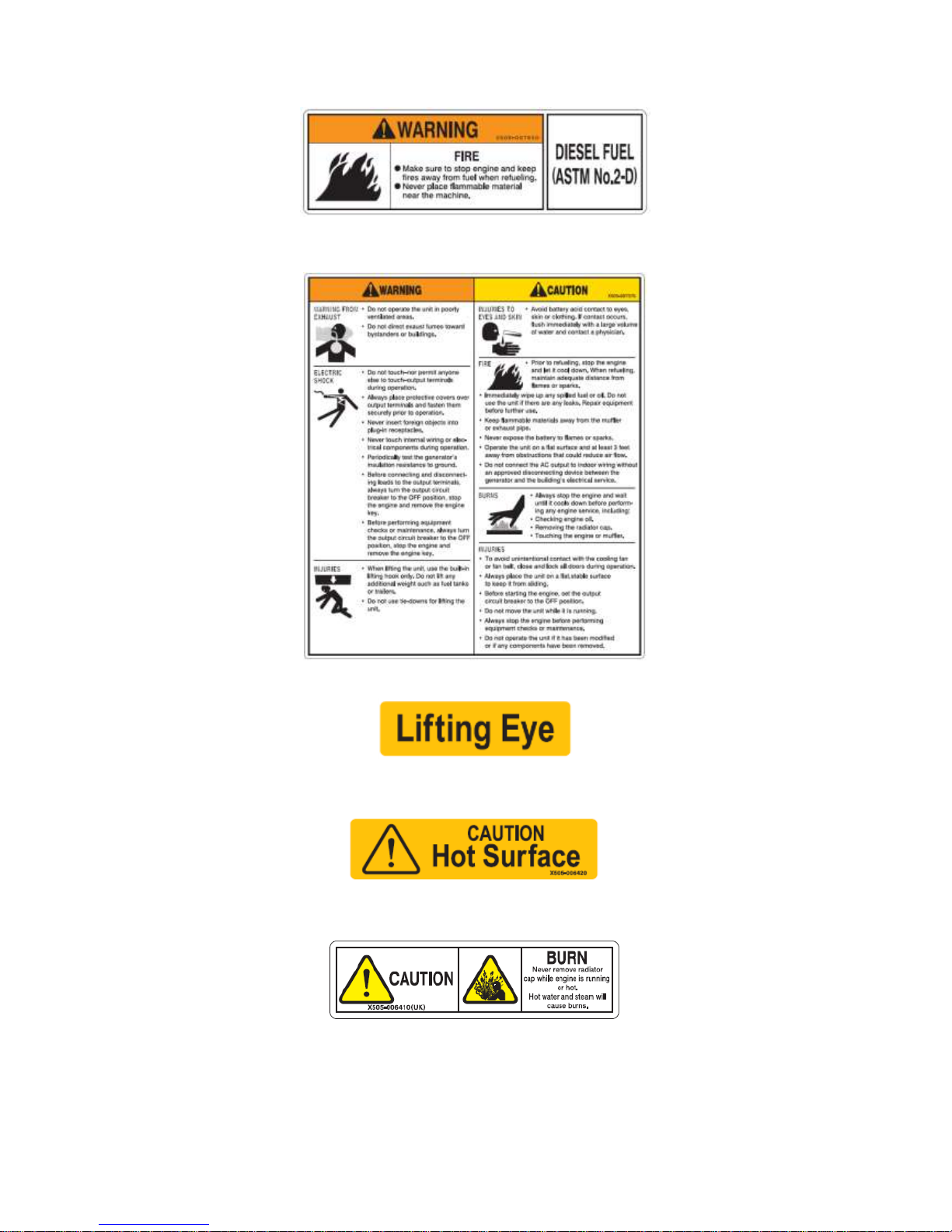

■Location of Warning Labels

Replace warning labels when they become difficult to see or damaged by affixing new labels

in the specified locations. Order the necessary labels by numbers in parentheses.

(1) Fire(No. X505-007650)

(2) Suffocation from exhaust fume(No. X505-007570 )

(3) Lifting eye(No. X505-000240)

(4) Hot surface (X505-006420)

(5) Burns(No. X505-006410)

(6) Keep 1 meter(No. M707-000260)

(7) Injuries(No. X505-007630)

(8) Electric shock(No. X505-007560)

(9) Earth leakage relay(No. X505-004890)

(10) Positioning handle(No. X505-006430)

-6-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

LABEL REPRODUCTION

①X505-007650

②X505-007570

③X505-000240

④X505-006420

⑤X505-006410

-7-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

⑥M707-000260

⑦X505-007630

⑧X505-007560

⑨X505-004890

⑩X505-006430

-8-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

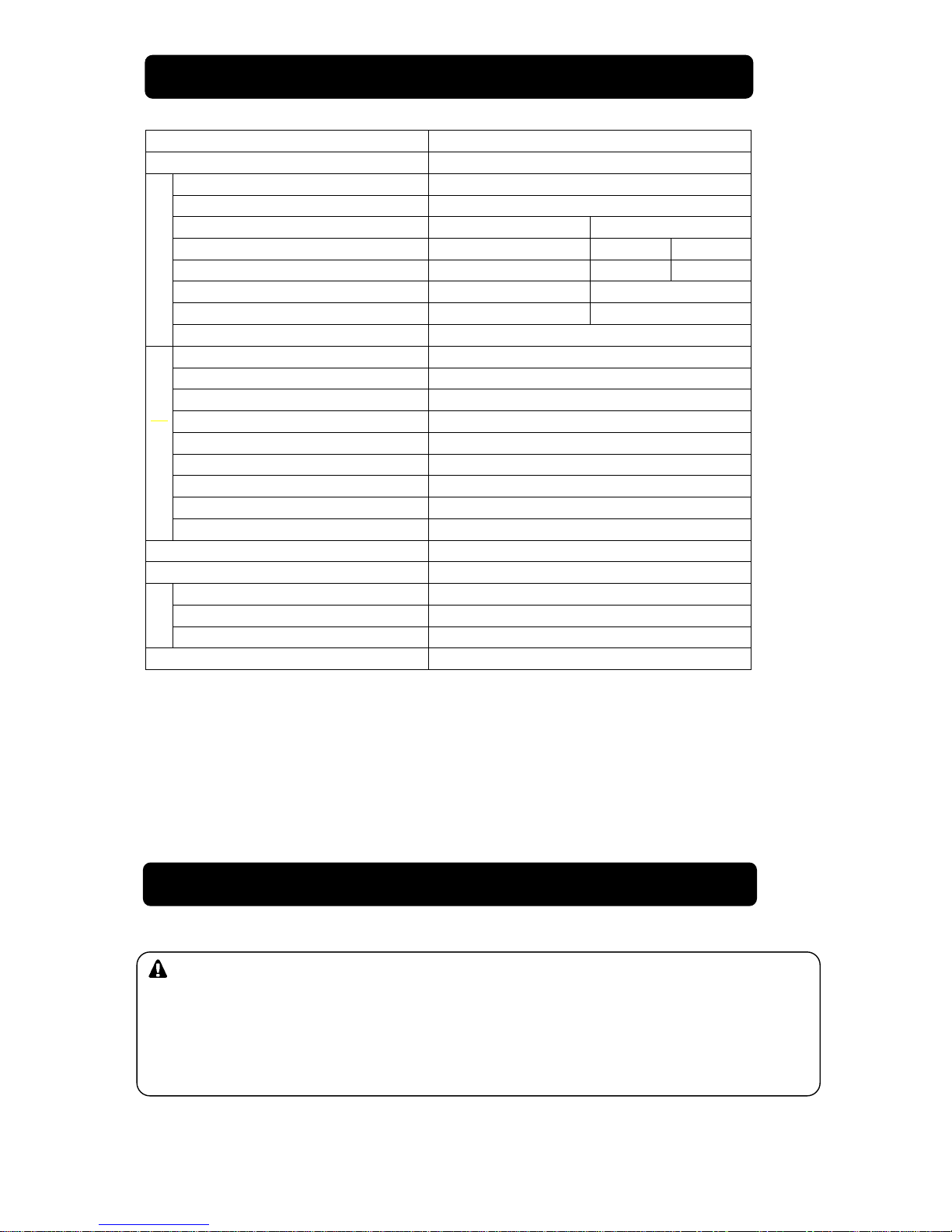

2-1.Specifications

Model

POWERCENTER15

Generating Method Rotating Field

AC Generator

Rated Frequency

(Hz)

50

Rated Speed

(min

-1

)

3000

Phase 3-Phase

1-Phase

Rated Voltage

(V)

415

240

110

Rated Current

(A)

21

50

110

Power Factor 0.8

1.0

Rated Output

(kVA)

15

12

Rating

Continuous

Engine

Model

Kubota D902

Type Vertical, Water-Cooled 4-Cycle Diesel Engine

Displacement

(L)

0.898

Rated Output

(kW/min

-1

)

13.1/3000

Fuel ASTM No.2-D Diesel Fuel or Equivalent

Lubricant Oil API Class CD or Higher

Lubrication Oil Volume

(L)

3.6 (Effective 1.7)

Cooling Water Volume

(L)

4.0 (Sub Tank Capacity 0.6 L included)

Starting Method Starter Motor

Battery 46B24L (Japanese Industrial Standard)

Fuel Tank Capacity

(L)

37

Dimen-

sion

Length

(mm)

1344

Width

(mm)

640

Height

(mm)

778

Dry Weight

(kg)

387

Generating Set ISO 8528-8/G2

EMC Group 2 class A

2-2.Ambient Conditions

・Temperature : -15~40℃

・Humidity : 80% or less

・Elevation : 300m or less

Power Source for Light, Electric Tools and Appliances

Caution: Physical and Secondary Damage

Do not use the equipment for any applications not listed above. Improper usage

can result in an accident or malfunction.

If using the equipment as a power source for medical equipment, you must check

with the medical equipment manufacturer, doctor and hospital before using the

equipment.

2. Specifications

3. Applications

-9-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

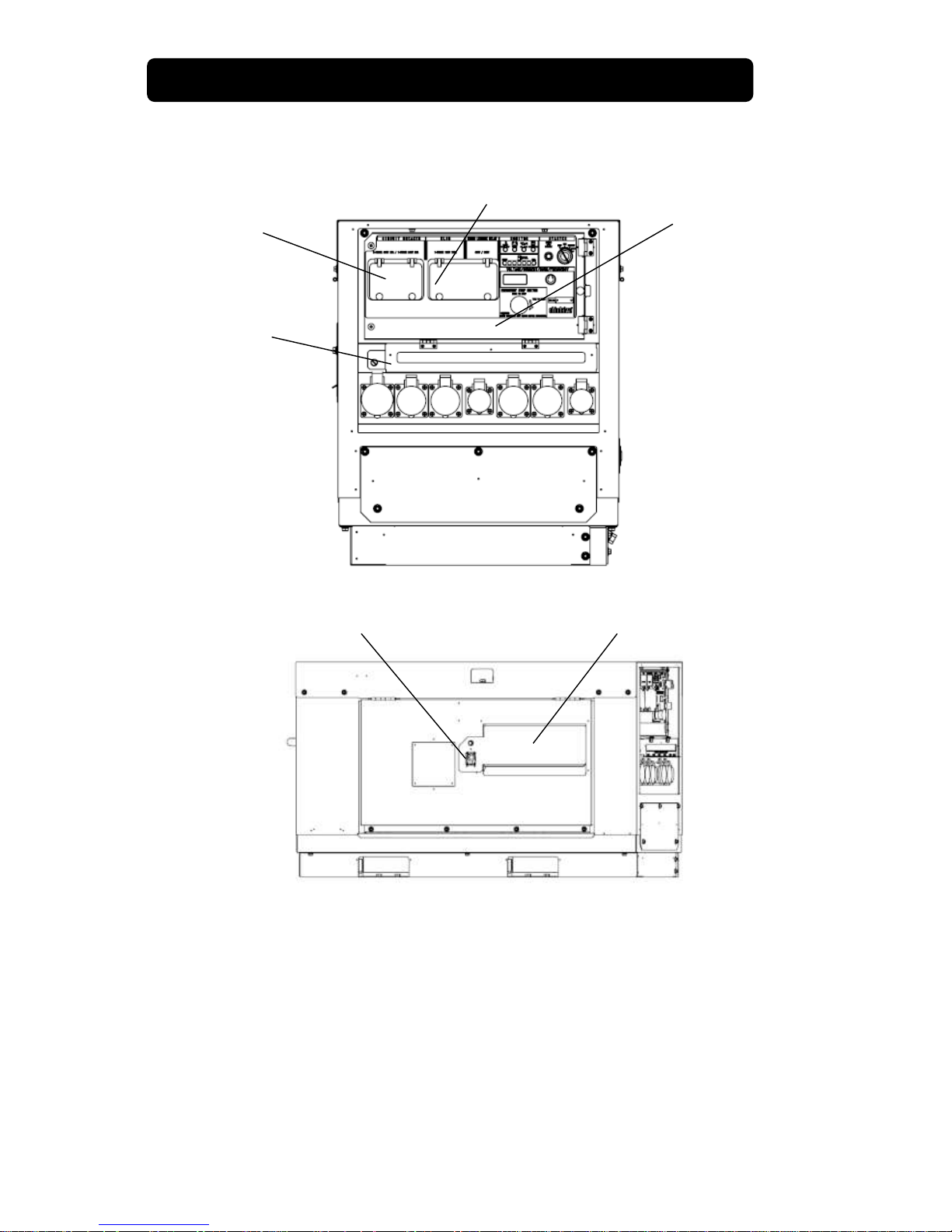

4. Parts

Operation Panel

1-Phase

Breaker Cover

3-Phase

Breaker Cover

Circuit Breaker

Cover

Terminal Cover

Ring Latch

-10-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

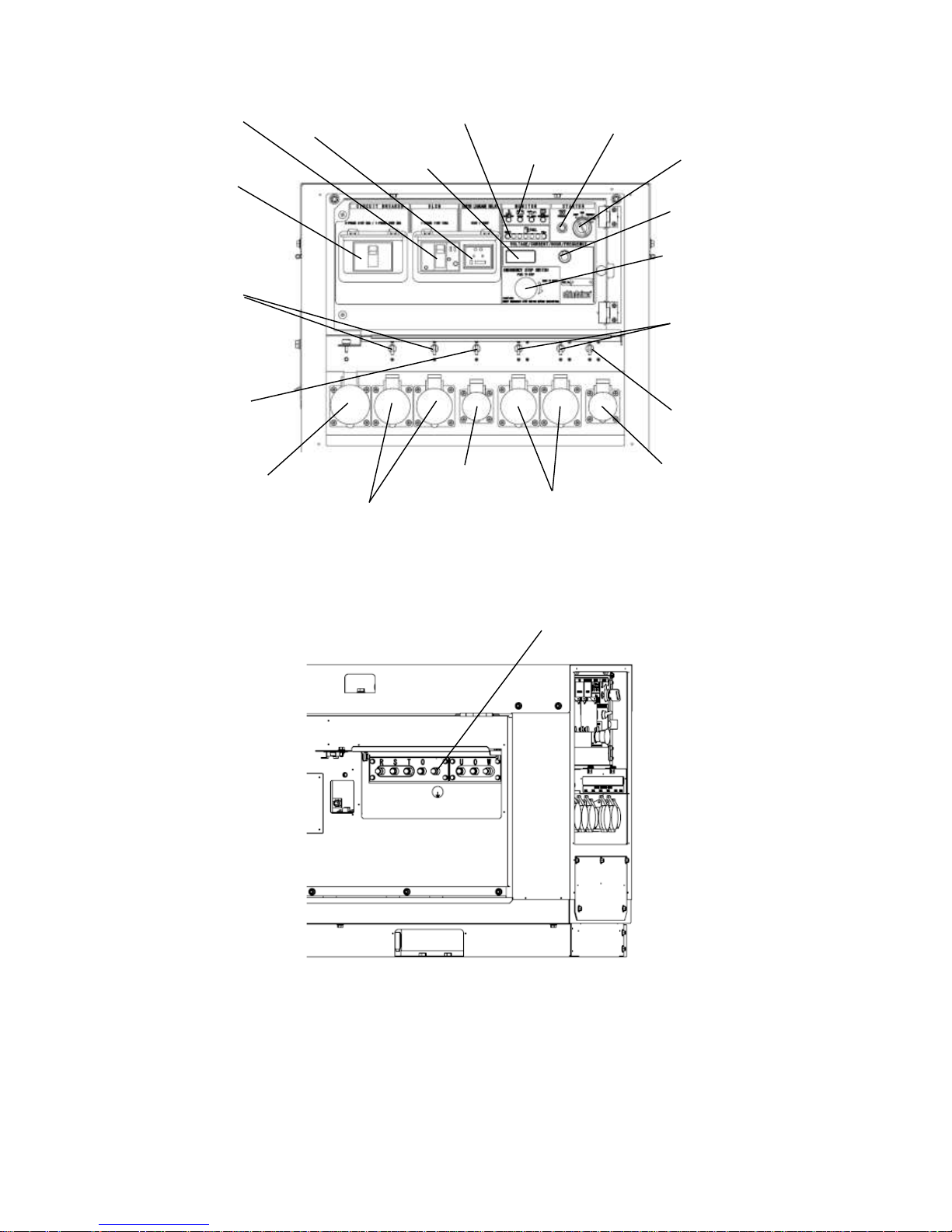

Bonnet Grounding

Terminal

1-PHASE

ELCB

Meter Selector

Monitor Lamp

Fuel Meter

Multi digital

Meter

Starter Switch

3-PHASE

Breaker

3-PHASE

Receptacle

(415V 32A)

1-PHASE

Receptacle

(240 32AV)

3-PHASE

ELR

(Relay)

Preheat Lamp

Emergency

Stop Switch

1-PHASE

Receptacle

(240V 16A)

1-PHASE

Receptacle

(110V 16A)

1-PHASE

Receptacle

(110V 32A)

1-PHASE

Breaker

(240V 20A)

1-PHASE

Breaker

(240V 15A)

1-PHASE

Breaker

(110V 30A)

1-PHASE

Breaker

(110V 15A)

-11-

Shindaiwa Limited POWERCENTER 15

Four Ashes, Wolverhampton, UK PC15-OM-Vs: 1

T: +44 (0)1902 791855

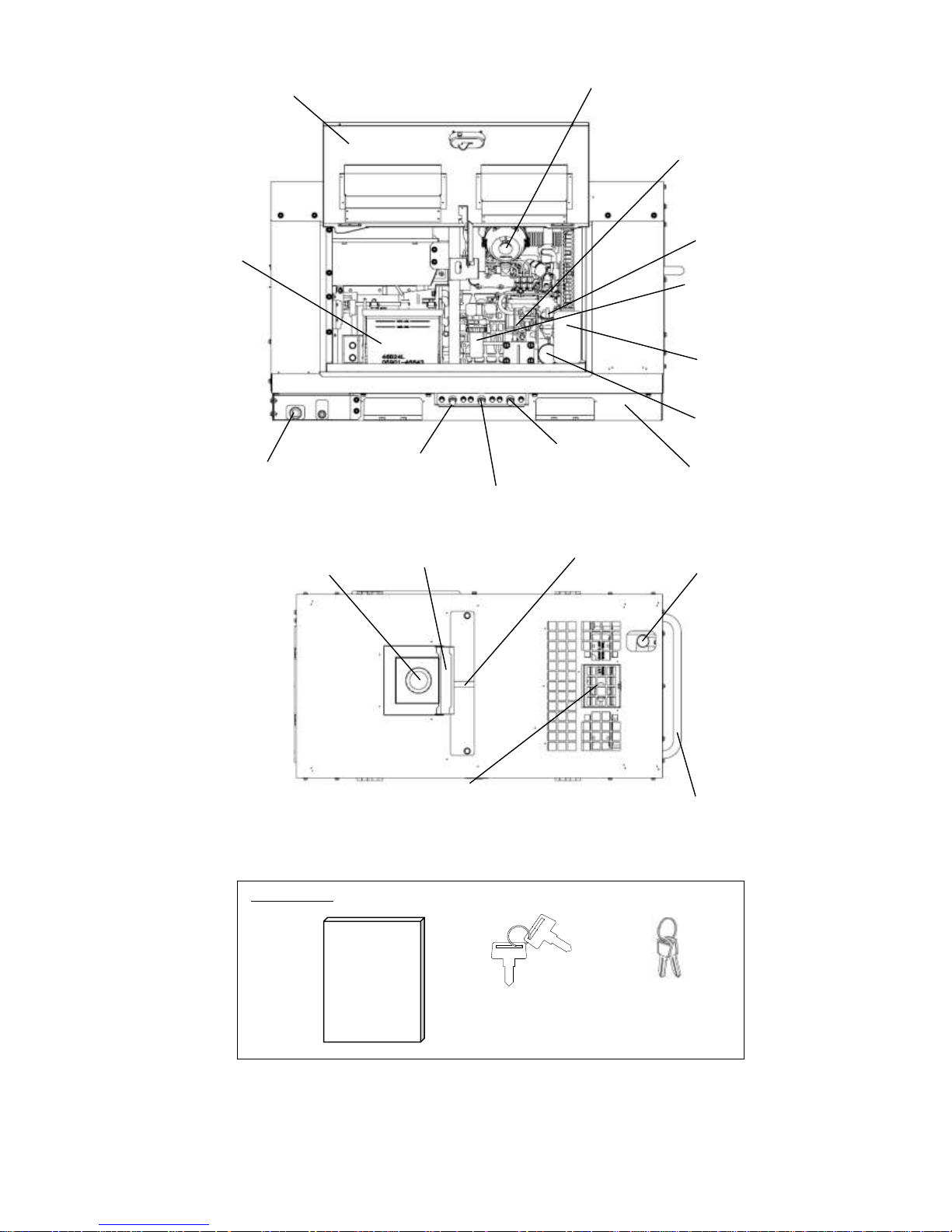

Owner’s

and

Operators

Manual

Accessories

Starter Key 1

Door Key 1

Top Plate

Muffler

Lifting Lug

Fuel Inlet

Fuel Inlet Cover

Spill Containment

Coolant

Sub Tank

Battery

Air Cleaner

Oil

Drain Plug

Side Door

Fuel Lever

(Fuel Strainer)

Fuel

Drain Plug

Oil Filter

Spill Containment

Drain Valve

Water

Drain Plug

Oil Gauge

Oil Plug

Oil Inlet

Positioning handle

(Not to be used for lifting)

-12-

Loading...

Loading...