Page 1

WARNING!

䊛

Minimize the risk of

injury to yourself

and others! Read

this manual and

familiarize yourself

with the contents.

Always wear eye

and hearing

protection when

operating this unit.

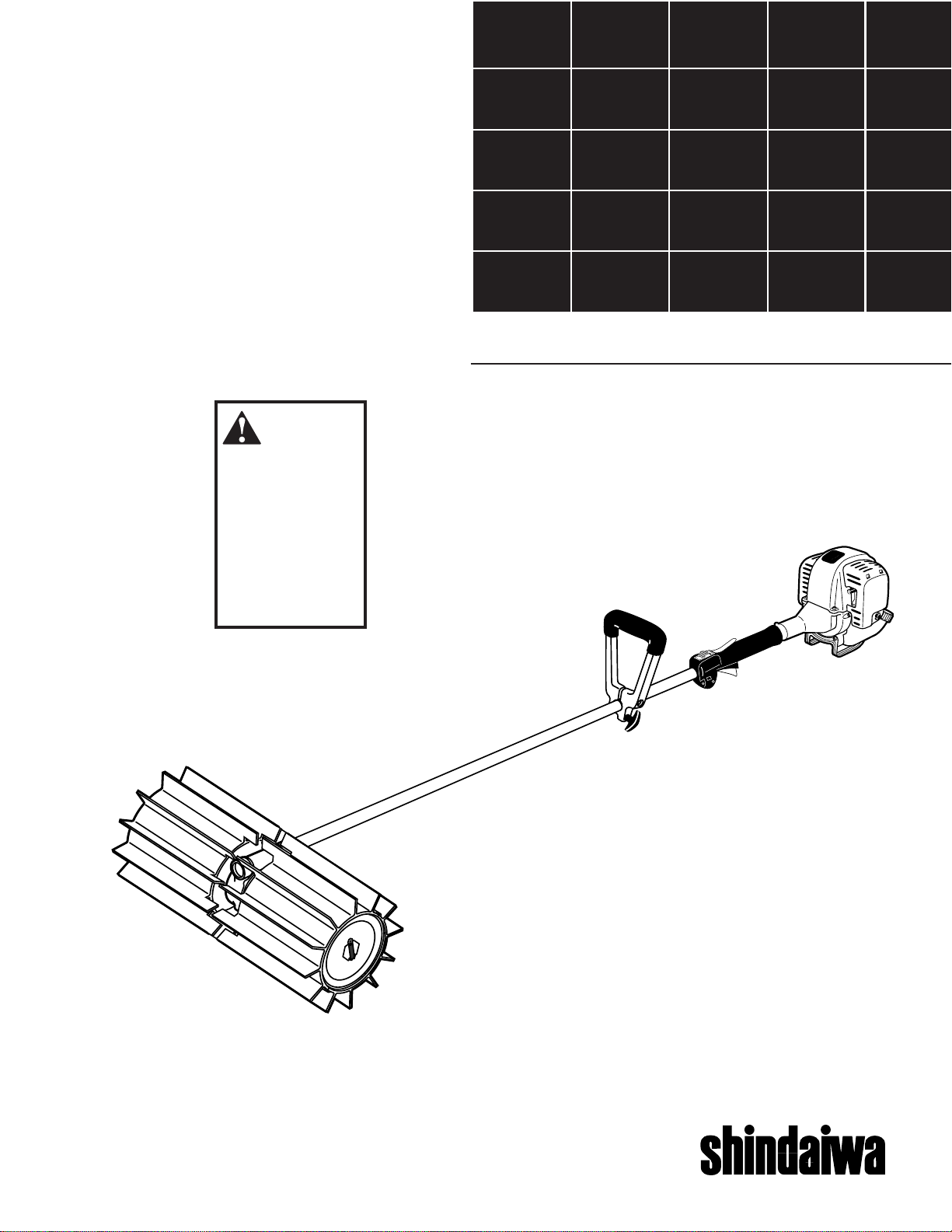

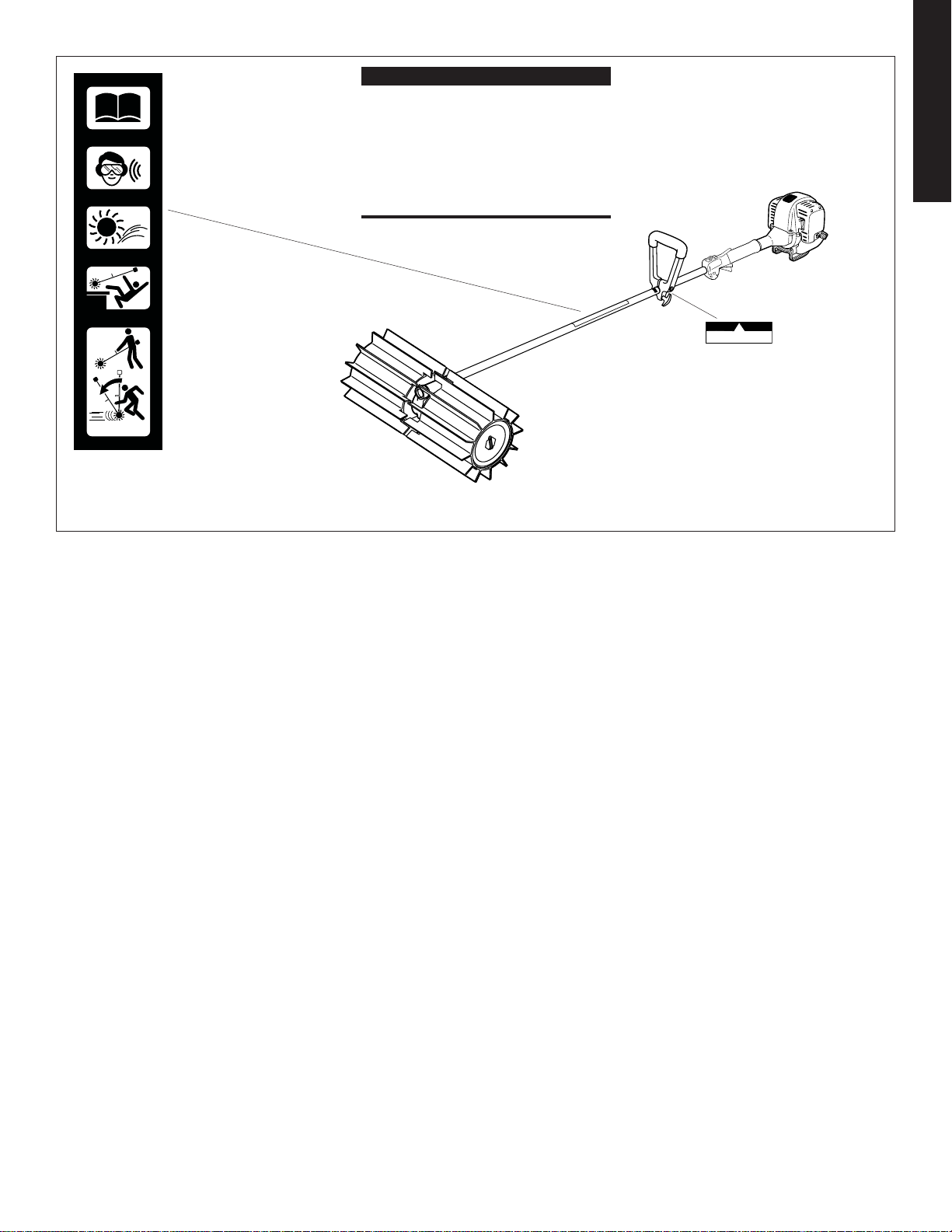

SHINDAIWA OWNER’S/

OPERATOR'S MANUAL

PB2500 PowerBroom娃

Part Number 80732 Rev. 4/03

Page 2

Introduction

Read and follow this

operators manual.

Failure to do so could

result in serious injury.

Do not operate this tool

if you are tired, ill or

under the influence of

alcohol, drugs, or

medication.

Beware of thrown

objects. Keep bystanders

at least 50 feet (15 m)

away during operation.

Wear eye and hearing

protection at all times

during the operation

of this unit.

ENGLISH

Shindaiwa 2500-series hand held

power equipment has been designed and

built to deliver superior performance and

reliability without compromise to quality,

comfort, safety or durability.

Shindaiwa’s high-performance engines

represent the leading edge of all position

4-cycle engine technology, delivering

exceptionally high power with remarkably low displacement and weight. As an

owner/operator, you’ll soon discover for

yourself why Shindaiwa is simply in a

class by itself!

IMPORTANT!

The information contained in this

owner's/operator's manual describes

units available at the time of publication.

Shindaiwa Inc. reserves the right to

make changes to products without prior

notice, and without obligation to make

alterations to units previously manufactured.

WARNING!

The engine exhaust from this unit

contains chemicals known to the

State of California to cause cancer,

birth defects or other reproductive

harm.

Attention Statements

Throughout this manual are special

attention statements.

WARNING!

A statement preceded by the triangular

attention symbol and the word “WARNING” contains information that should

be acted upon to prevent serious bodily

injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to prevent

mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special significance.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

IMPORTANT!

The operational procedures described in

this manual are intended to help you get

the most from this unit as well as to

protect you and others from harm.

These procedures are guidelines for

safe operation under most conditions,

and are not intended to replace any

safety rules and/or laws that may be in

force in your area. If you have questions

regarding your Shindaiwa power tool, or

if you do not understand something in

this manual, your Shindaiwa dealer will

be glad to assist you. You may also

contact Shindaiwa Inc. at the address

printed on the back of this manual.

Contents

PAGE

Attention Statements................................ 2

Safety Information .................................... 3

Checking Unit Condition......................... 3

Safety Labels ............................................. 5

Unit Description ....................................... 6

Specifications ............................................ 6

Assembly ................................................... 7

Engine Fuel ............................................. 10

Starting the Engine ................................ 11

Stopping the Engine............................... 11

Adjusting Engine Idle ............................ 12

Using the PowerBroom ......................... 12

Maintenance ........................................... 13

Long Term Storage ................................ 16

Accessories ............................................. 16

Troubleshooting Guide ......................... 17

Emission System Warranty ................... 19

2

Page 3

General Safety Instructions

Work Safely

PowerBrooms operate at very high speeds

and can do serious damage or injury if they

are misused or abused. Never allow a

person without training or instruction to

operate this unit!

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Never make unauthorized attachment

installations.

WARNING!

Never operate power equipment of

any kind if you are tired or if you are

under the influence of alcohol, drugs,

medication or any other substance

that could affect your ability or

judgement.

WARNING!

Minimize the Risk of Fire

NEVER smoke or light fires near the

unit.

ALWAYS stop the engine and allow it

to cool before refueling. Avoid overfilling and wipe off any fuel that may

have spilled.

ALWAYS inspect the unit for fuel

leaks before each use. During each

refill, check that no fuel leaks from

around the fuel cap and/or fuel tank. If

fuel leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily flammable materials before

starting the engine.

NEVER place flammable material

close to the engine muffler.

NEVER run the engine without the

spark arrester screen in place.

Checking Unit Condition

NEVER operate the unit with the

protective devices (ignition switch, etc.)

removed!

ALWAYS use authorized Shindaiwa parts

and accessories with your Shindaiwa

PowerBroom. Do not make modifications

to this unit without the written approval of

Shindaiwa, Inc.

ALWAYS make sure the sweeper drums

are properly installed before operation.

NEVER use a cracked or warped

PowerBroom drum or axle: replace it with

a servicable one.

ALWAYS stop the engine immediately

and check for damage if you strike a

foreign object or if the unit becomes

tangled. Do not operate with broken or

damaged equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could

damage the engine.

NEVER operate a unit with worn or

damaged fasteners or attachments.

ENGLISH

WARNING!

Use Good Judgment

NEVER run the engine when trans-

porting the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS use the proper tool for the

job.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly installed parts or attachments.

NEVER operate this unit on elevated

surfaces or roofs.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegetation, mud, etc.

ALWAYS hold the unit firmly with

both hands when sweeping, and

maintain control at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any

maintenance work.

3

Page 4

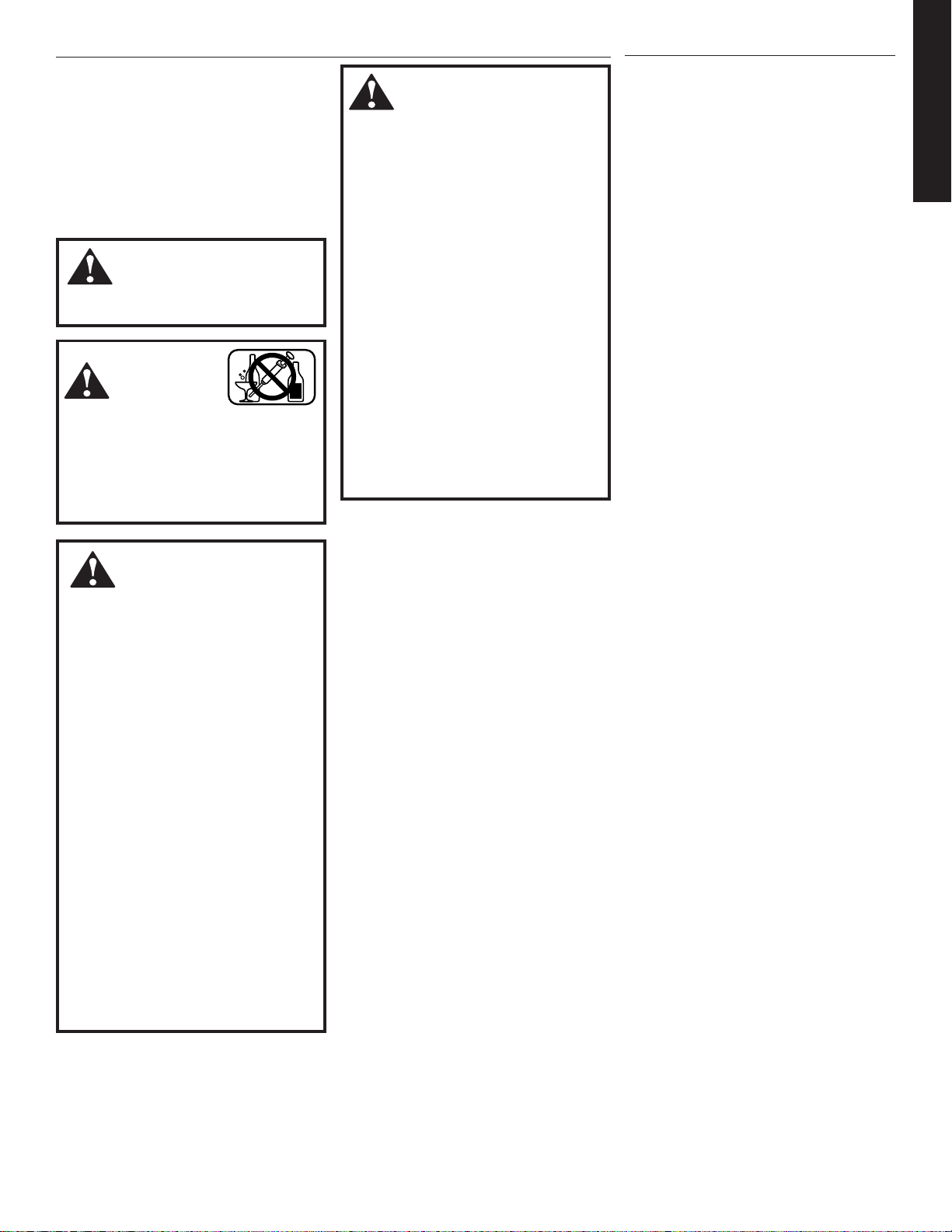

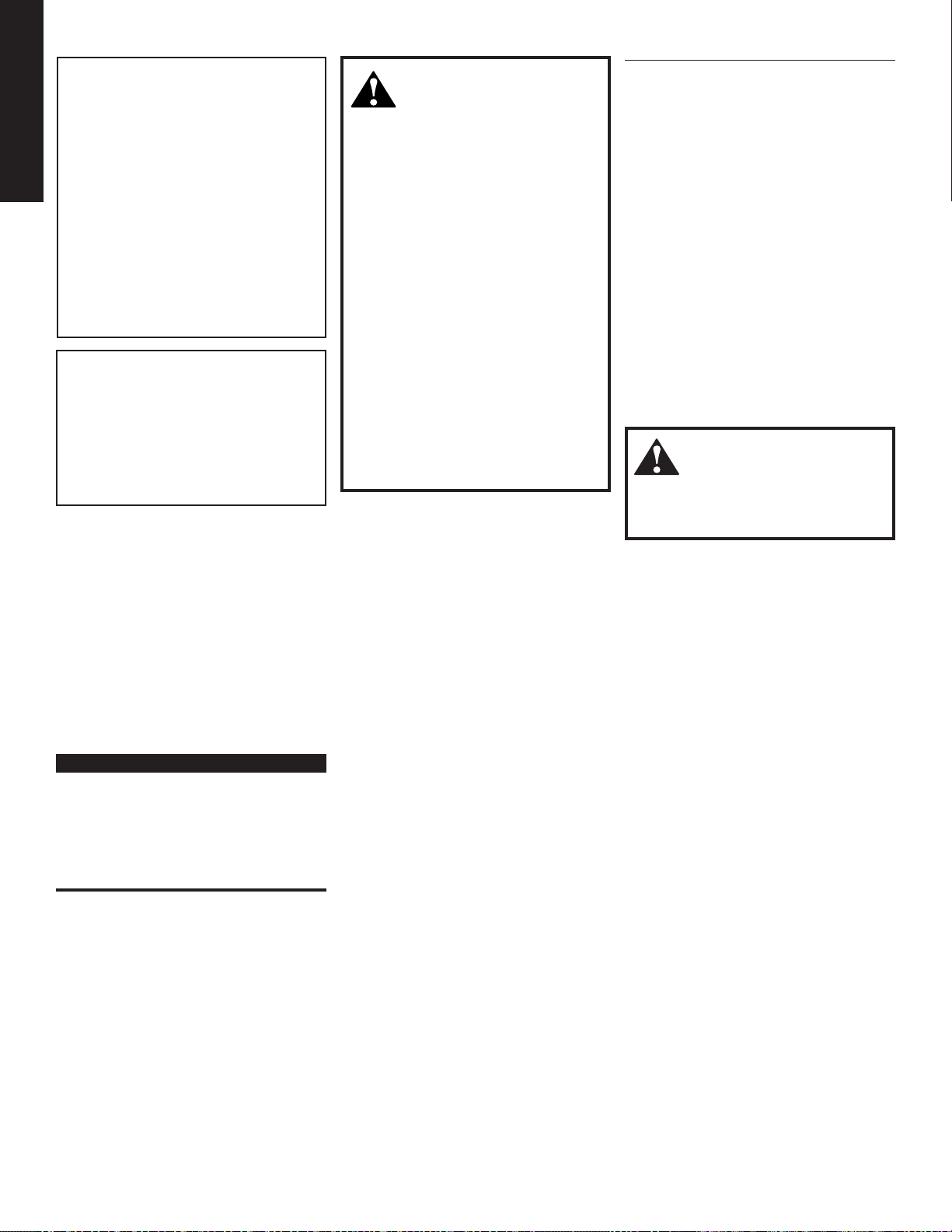

The Properly Equipped Operator

ENGLISH

Wear close-fitting clothing

to protect legs and arms.

Gloves offer added

protection and are

strongly recommended.

Do not wear clothing or

jewelry that could get

caught in machinery

or underbrush. Secure

long hair so that it is

above shoulder level.

NEVER wear shorts!

Keep a proper footing and do not

overreach. Maintain your balance at all

times during operation.

Wear hearing protection devices at all times

while operating the unit.

Always wear eye protection

such as goggles or safety

glasses to shield against thrown

objects.

Always wear respiratory

protection to avoid

breathing airborne debris.

Always operate with

both hands firmly

gripping the unit.

Keep away from the rotating

sweeper belts or bristles at all

times, and never lift a moving

attachment above waist-high.

Wear appropriate footwear (non-skid

boots or shoes): do not wear opentoed shoes or sandals. Never work

barefooted!

Figure 1

PB01

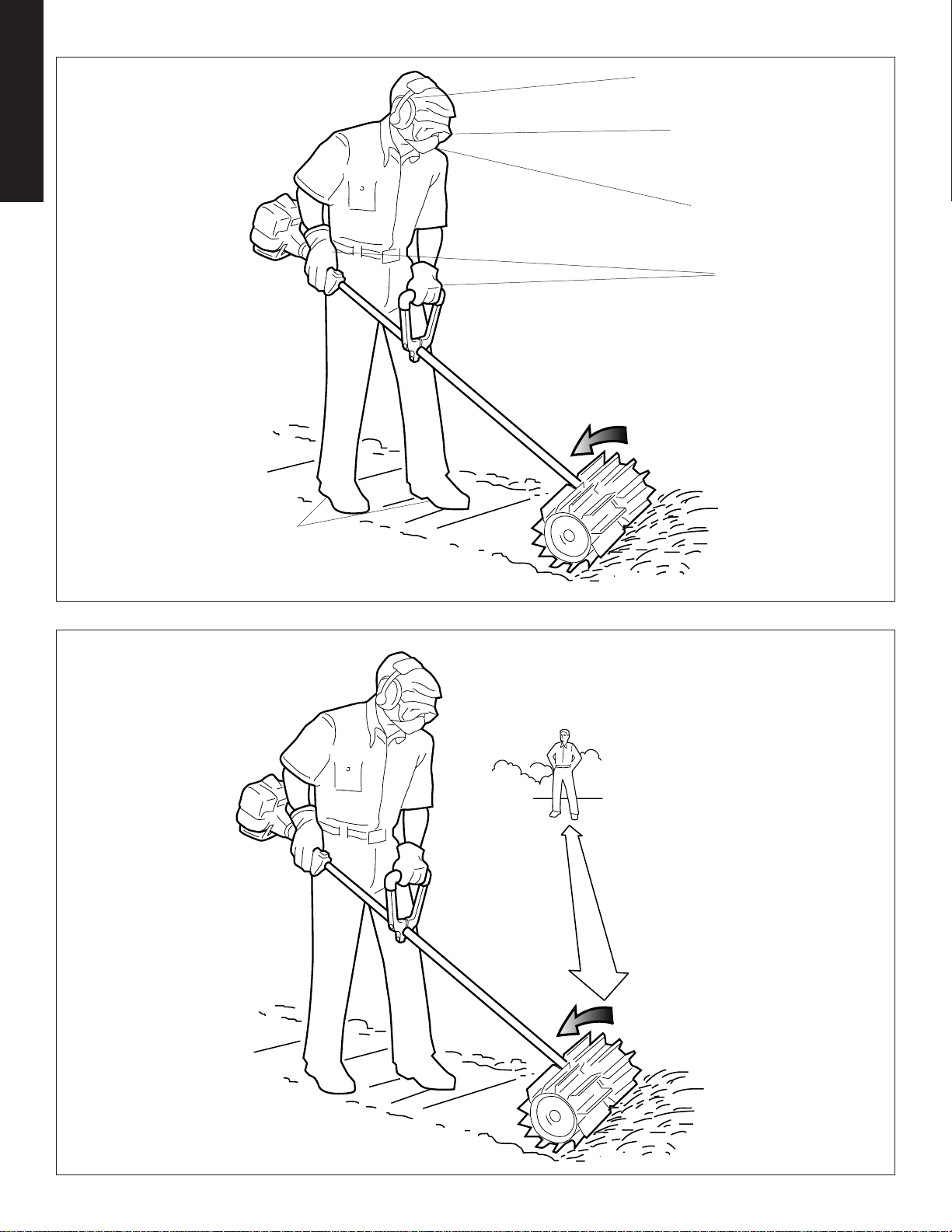

Be Aware of the Working Environment

Avoid long-term

operation in very hot or

very cold weather.

If contact is

made with a

hard object,

stop the

engine and

inspect the

sweepers and

drums for

damage.

Be extremely careful of

slippery terrain, especially

during rainy weather or

when pulling debris

towards you.

Be aware and keep

clear of bystanders.

ALWAYS clear your work area of trash or

hidden debris that could be thrown back at

you or toward a bystander. When operating

in rocky terrain or near electric wires or

fences, use extreme caution to avoid

contacting such items with the sweeper

belts.

Be constantly alert for objects and debris

that could be thrown either from the

sweeper belts or bounced from a hard

surface.

Figure 2

4

PB02

Page 5

Safety Labels

READ THE

OPERATOR’S MANUAL.

WEAR HEARING AND ANSI Z87.1

APPROVED EYE PROTECTION.

BEWARE OF THROWN

DIRT AND DEBRIS.

DO NOT USE ON UNGUARDED

ELEVATED SURFACES.

MAINTAIN A

SHALLOW

WORKING

ANGLE…

…AVOID MOVING TOWARD

VERTICAL.

80267Shindaiwa Inc.

IMPORTANT!

Safety and Operation Information

Labels: Make sure all information

labels are undamaged and readable.

Immediately replace damaged or

missing information labels. New

labels are available from your local

authorized Shindaiwa dealer.

PB03

PB2500

POSITION HANDLE

FORWARD OF THIS LINE

This label indicates the minimum

distance between front handle

and rear grip per ANSI B175.3.

ENGLISH

Figure 3

5

Page 6

Unit Description

ENGLISH

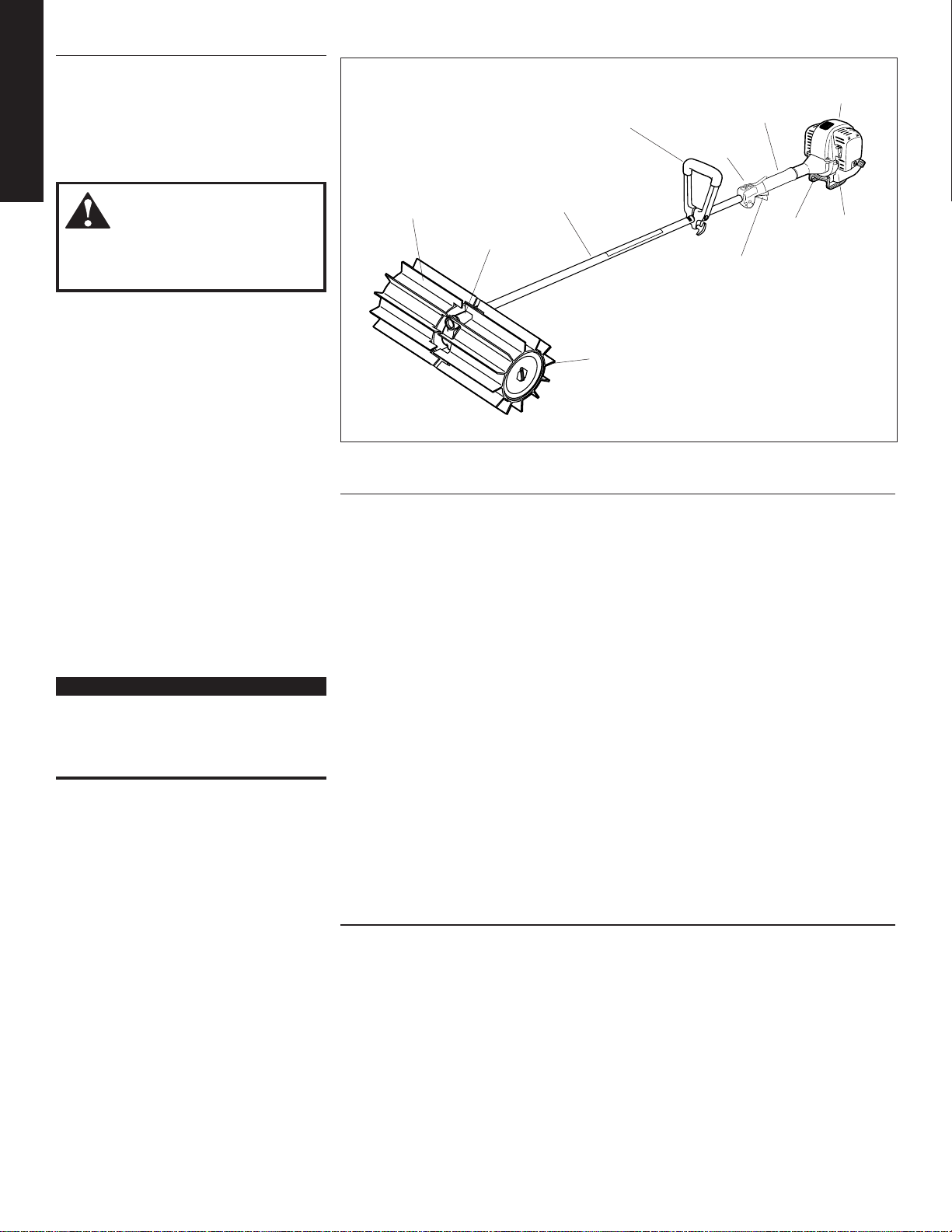

Using the accompanying illustrations as a

guide, familiarize yourself with this unit

and its various components. Understanding the product helps ensure top performance, long service life, and safer operation. See Figure 4.

Handle

Spark

Plug

Grip

Ignition

Switch

WARNING!

Do not make unauthorized modifications or alterations to this unit or

components.

Prior to Assembly

Before assembling, make sure you have

all the components required for a complete unit:

■ Engine assembly

■ Outer tube assembly

■ Drum kit w/gearcase

■ Correct operators handle (see preced-

ing page)

■ Kit containing operator’s handle and

hardware, this manual and tool kit for

routine maintenance. Tool kits vary by

model and may include a hex wrench,

spanner and a combination spark plug

wrench/screwdriver.

Carefully inspect all components for

damage.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front”

and “rear” refer to directions as viewed

by the operator during normal operation.

Sweeper

Belt

Gearcase

Figure 4

Outer Tube

PB03

Sweeper

Drum

Throttle

Trigger

Tank

Protector

Fuel

Tank

Specifications

PB2500 Dry Weight (less sweepers) ............................................................4.7 kg/10.4 lb.

PB2500 Dry Weight (Including sweepers) .................................................. 9.5 kg/21.0 lb.

Engine Model ........................................................................................ Shindaiwa SF2500E

Engine Type ..................................................... Shindaiwa C4, vertical-cylinder, air-cooled

Bore x Stroke .................................................................................. 34 x 27 mm/1.3 x 1.1 in.

Displacement ............................................................................................. 24.5 cc/1.5 cu. in.

Maximum Power Output .......................................... 1.1 HP (0.8 kW) @ 7500 rpm (min

Fuel/Oil Ratio ........................................50:1 with Shindaiwa Premium 2-cycle mixing oil

Fuel Tank Capacity ....................................................................................... 600 ml/20.3 oz.

Carburetor Type ................................................................... Walbro WYL, diaphragm-type

Ignition ............................................................. One-piece electronic, transistor-controlled

Spark Plug .........................................................................................................NGK CMR6H

Air Cleaner Type ..................................................... Non-reversible flocked filter element

Starting Method ............................................................................................................ Recoil

Stopping Method ................................................................................................. Slide switch

Transmission Type ............................................ Automatic, centrifugal clutch w/worm gear

EPA Emission Compliance Period* ................................................................... Category A

-1

)

*The EPA emission compliance period referred to on the emission compliance label located on the engine, indicates the

number of operating hours for which the engine has been shown to meet Federal emission requirements. Category C = 50

hours (Moderate), B = 125 hours (Intermediate) and A = 300 hours (Extended)

*Specifications are subject to change without notice.

6

Page 7

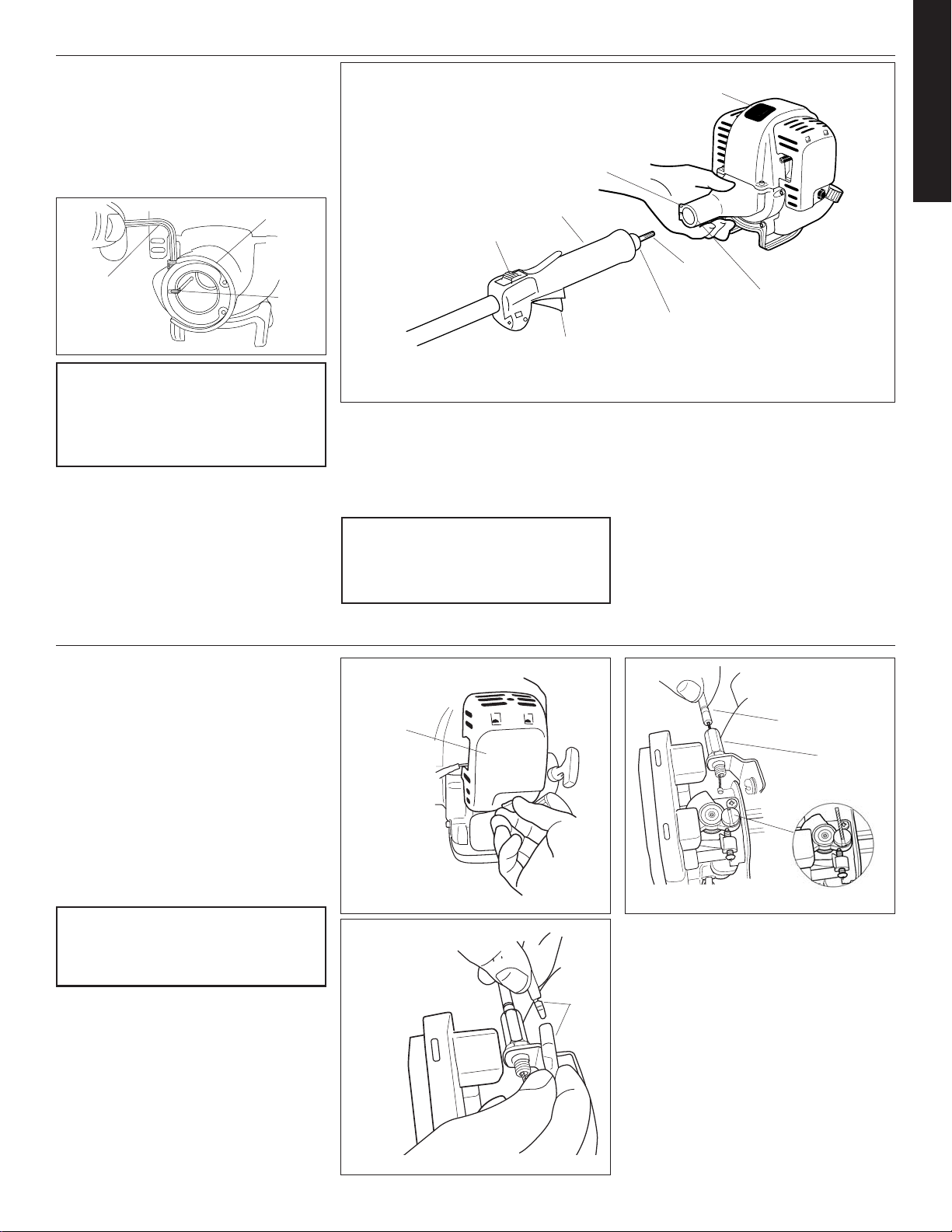

Assembly: Mainshaft/Powerhead

1. Place the powerhead on a clean, flat

surface, spark plug facing up.

See Figure 5.

2. Use the 4mm hex wrench to loosen

the tube clamp screw. Verify that the

D-shaped shim washer is positioned as

shown in Figure 6.

Tube

Clamp

PB2500 PowerBroom

Connect the Outer Tube to the

Powerhead

Ignition

Switch

ENGLISH

Spark

Plug

Clamp

Screw

Grip

Hex

Wrench

PB2500.04

Figure 6

Shim

Washer

CAUTION!

Do not remove the D-shaped shim

washer! The shim washer prevents

damage from overtightening the tube

clamp screw.

3. Add some moly-type EP grease to the

splines on the end of the mainshaft.

Figure 5

4. Slide the outer tube into the tube

clamp until the tube bottoms.

5. Position the outer tube so that the

ignition switch is facing up and the

throttle trigger is down.

CAUTION!

Do not force the shaft tube into the

powerhead! Excessive force can

damage the shaft tube or mainshaft.

Assembly: Throttle Linkage and Ignition Leads

Connect the Throttle Cable

1. Loosen the air cleaner cover knob and

remove the air cleaner cover.

See Figure 7.

2. Slip the throttle cable into the cable

adjuster and hook the bullet end of the

cable onto the swivel. See Figure 8.

Connect the Ignition Leads

3. Connect the two ignition wires by

pushing the bullet connectors

together. See Figure 9.

4. Reinstall the air cleaner cover.

CAUTION!

Routing of wiring must not interfere

with throttle operation.

Filter

Cover

PB2500.05

Figure 7

PB2500.08

Throttle

Trigger

Ignition

Lead

Main

Shaft

PB08

Outer Tube

Tube

Clamp

6. Slide the outer tube into the powerhead until the throttle grip just

contacts the tube clamp.

7. Tighten the clamp screw firmly.

Connect the throttle

cable

PB2500.06

Figure 8

Throttle

Cable

Cable

Adjuster

Cable Swivel

Figure 9

7

Page 8

Assembly: Adjust Throttle Lever Free Play

ENGLISH

The throttle lever free play should be

approxiamtely 3/16-1/4 inch(4-6 mm).

See Figure 10. Make sure that the throttle

lever operates smoothly without binding.

If it becomes necessary to adjust the lever

freeplay, follow the procedures and

illustrations that follow.

3. Turn the cable adjuster in or out as

required to obtain proper free play

3/16-1/4 inch(4-6 mm).

See Figure 12.

4. Tighten the locknut.

Lock

Nut

Cable

Adjuster

PB2500.09

3/16-1/4 inch (4-6 mm)

Throttle Freeplay

Figure 10

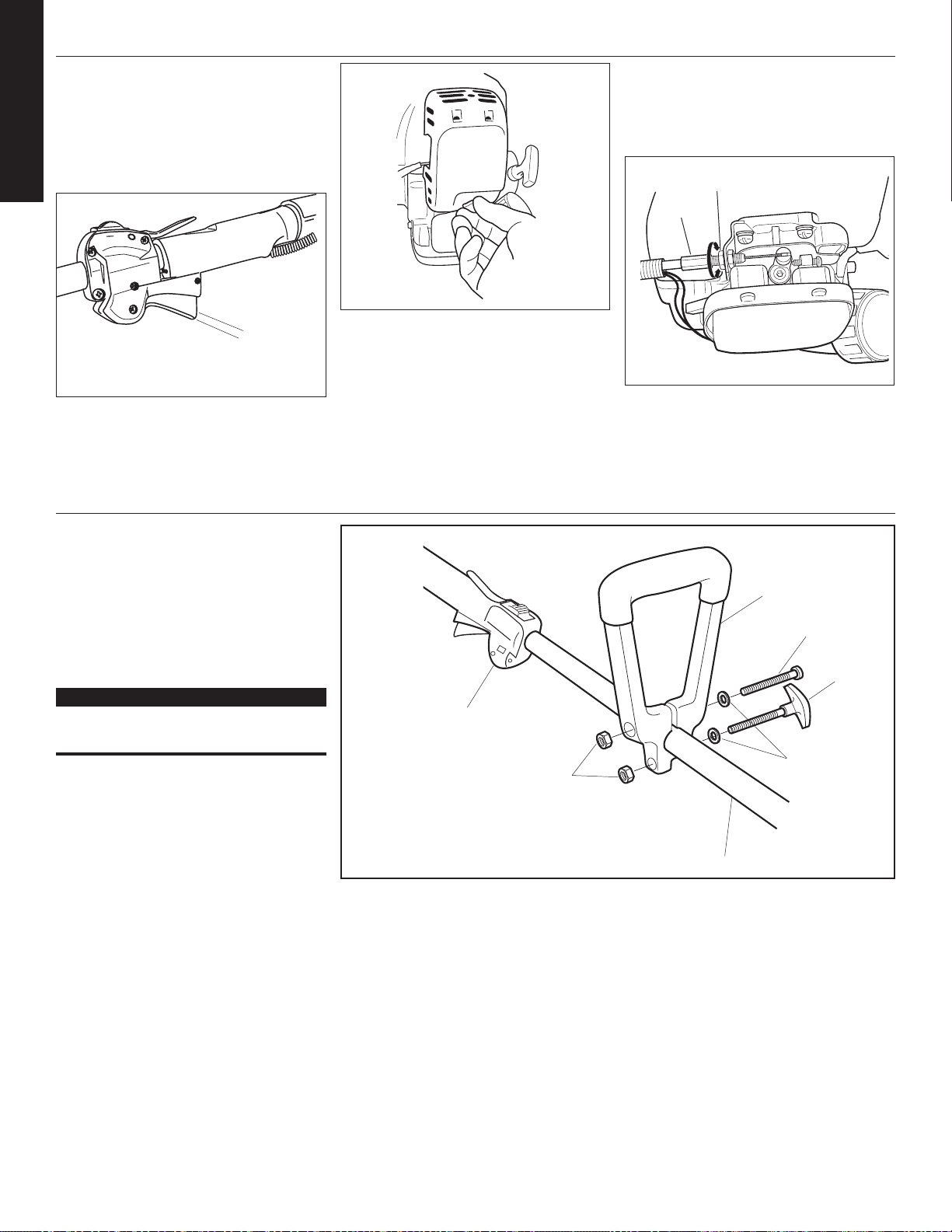

Assembly: Handle

Connect the Handle to the Outer Tube

1. Remove both screws from the handle.

2. While spreading the handle at the

mounting hole, position the handle on

the outer tube as shown.

3. Reinstall the two mounting screws in

the handle, but do not tighten them at

this time.

IMPORTANT!

One side of the handle is recessed to

receive the hex nuts.

4. Locate the handle at the best position

for operator comfort (usually about 10

inches ahead of the throttle lever), and

secure it by tightening the knob at the

handle base.

PB2500.05

Figure 11

1. Loosen the air cleaner cover knob

and remove the air cleaner cover.

See Figure 11.

2. Loosen the lock nut on the cable

adjuster. See Figure 12.

Throttle

Assembly

Hex Nut

Figure 13

Figure 12

PB2500.10

5. Reinstall the air cleaner cover.

Handle

Mounting

Screw

Adjustment

Washer

PB10

Outer Tube

Knob

8

Page 9

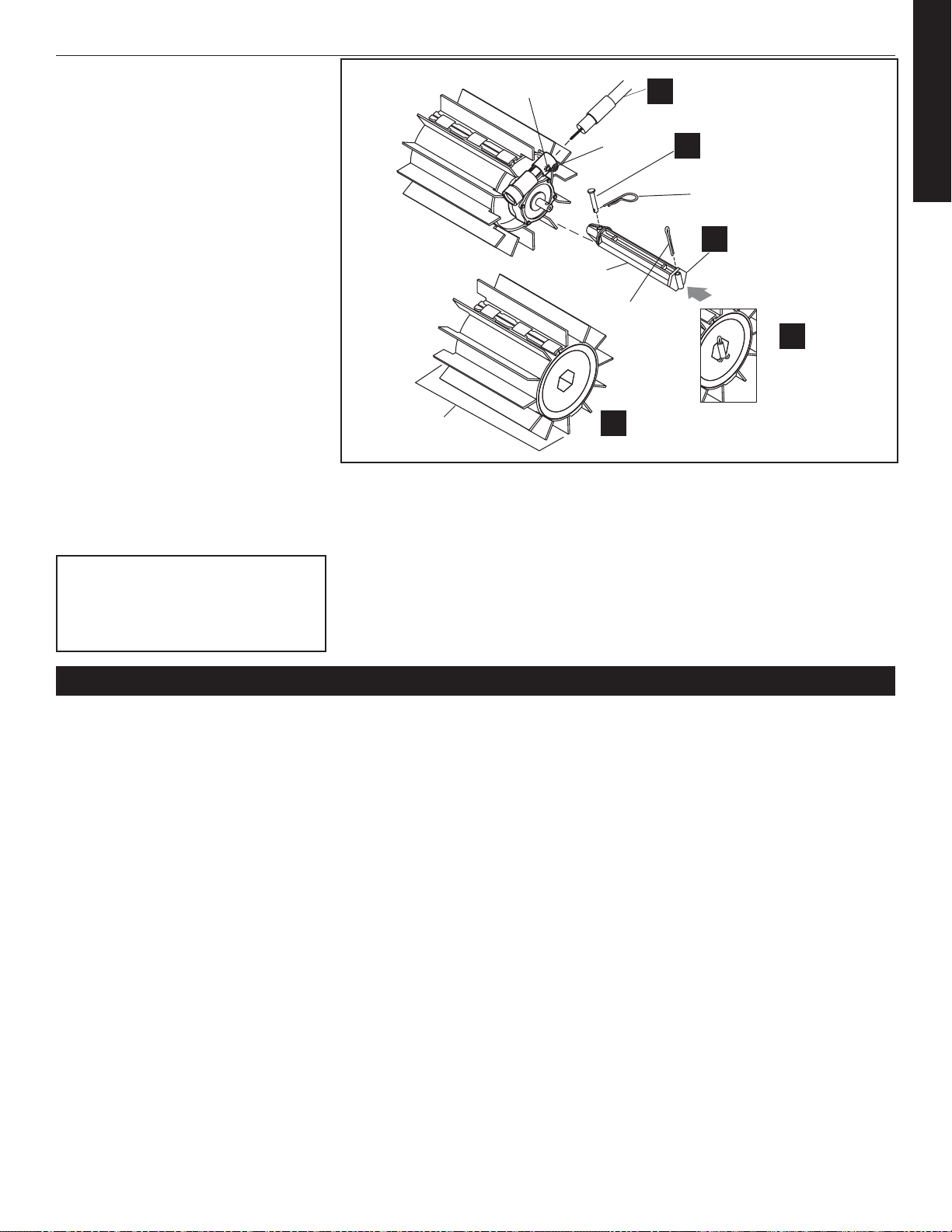

Assembly: Gearcase and Sweeper Assembly

1. Insert the end of the outer tube into

the gearcase and push until it bottoms.

The outer tube should go into the

gearcase about 1-1/2 in. (38 mm). If

the outer tube stops before bottoming,

rotate it until you feel the inner

mainshaft (driveshaft) splines engage

the gearcase. Then push the outer

tube all the way in. See Figure 14.

2. Rotate the gearcase assembly so that

the index screw aligns with hole in the

outer tube.

3. Use a 4 mm hex wrench to tighten the

gearcase index screw first, then the

gearcase clamp screw.

4. Push one of the drum axles onto either

of the two gearcase output shafts. If

necessary, rotate the drum axle until

the clevis pin hole in the axle aligns

with the matching hole in the gearcase

output shaft.

5. Use a clevis pin and hitch pin to secure

the drum axle to the shaft.

6. Slide the recessed end of a sweeper

drum assembly over the installed axle,

and then push the drum down the axle

until the cotter pin hole in the axle

extends above the drum surface.

CAUTION!

The two drum assemblies are

identical, but each drum must be

installed with its recessed end facing

toward the gearcase.

Drum Assembly

Figure 14

7. Use a cotter pin to secure the drum

assembly on the axle (see inset). The

cotter pin is designed to fit tightly

against the outboard end of the drum,

so you may need to compress the

drum face slightly during installation.

Spread the ends of the cotter pin to

secure.

8. Repeat Steps 4-7 to install the remaining axle and drum assembly.

Index Screw

Drum Axle

Clamp

Screw

Cotter Pin

Install the sweeper

4

drum assembly

PB17

Install outer tube into

1

the gearcase

Secure the drum axle to

3

the shaft with the clevis pin

Hitch Pin

Install drum axle

2

onto output shaft

ENGLISH

4

Secure

with a

cotter pin

The PB2500 PowerBroom should now be completely assembled.

9

Page 10

Mixing Fuel

ENGLISH

CAUTION!

Some gasolines contain alcohol as an

oxygenate! Oxygenated fuels may

cause increased operating temperatures. Under certain conditions,

alcohol-based fuels may also reduce

the lubricating qualities of some

mixing oils. Never use any fuel

containing more than 10% alcohol by

volume!

Generic oils and some outboard

motor oils may not be intended for

use in high-performance air cooled 2cycle engines, and should never be

used in your Shindaiwa engine!

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and a premium 2-cycle

mixing oil only. Use of non-approved

mixing oils can lead to excessive

maintenance costs and/or engine

damage.

■ Use only fresh, clean unleaded

gasoline with a pump octane rating of

87 or higher.

■ Mix gasoline with 50:1 Shindaiwa

Premium 2-cycle mixing oil or with an

equivalent high quality 2-cycle mixing

oil.

Example of 50:1 mixing quantites:

■ 1 gallon of gasoline to 2.6 oz. mixing

oil.

■ 5 liters of gasoline to 100 ml. mixing

oil.

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than

30 days and Shindaiwa One oil with fuel

stabilizer is not used, it should first be

treated with a fuel stabilizer such as

StaBil™.

Filling the Fuel Tank

WARNING!

Minimize the risk of fire!

■ STOP the engine before refueling.

■ ALWAYS allow the unit to cool

before refueling!

■ Wipe all spilled fuel and move the

unit at least 10 feet (3 meters) from

the fueling point before restarting!

■ NEVER start or operate this unit if

there is a fuel leak.

■ NEVER start or operate this unit if

the carburetor, fuel lines, fuel tank

and/or fuel tank cap are damaged.

■ NEVER smoke or light any fires

near the unit or fuels!

■ NEVER place any flammable

material near the engine muffler!

■ NEVER operate the engine without

the muffler and spark arrester in

place and properly

functioning!

1. Place the PowerBroom on a flat, level

surface.

2. Clear any dirt or other debris from

around the fuel filler cap.

3. Remove the fuel cap, and fill the tank

with clean, fresh fuel.

4. Reinstall the fuel filler cap and tighten

firmly.

Break-in and Operation

The PowerBroom works best when its

rubber fins can quickly slide or “skim”

over the surface being swept.

New or replacement sweeper belts

tend to grip or drag on hard surfaces, and

should be thoroughly broken in or

“scuffed” before the broom is actually put

to work.

Break-in is easily accomplished by

operating the PowerBroom at full throttle

for 3 to 5 minutes in loose gravel or

similar abrasive material. Once broken in,

a PowerBroom will effortlessly move an

amazing variety of materials, ranging

from snow or standing water to heavier

objects such as gravel or wood chips.

Experience will help you understand

the operating principles of the

PowerBroom, but safe operation must be

practiced from the start.

WARNING!

BURN DANGER! The gearcase will

become very hot during normal

operation.

10

Page 11

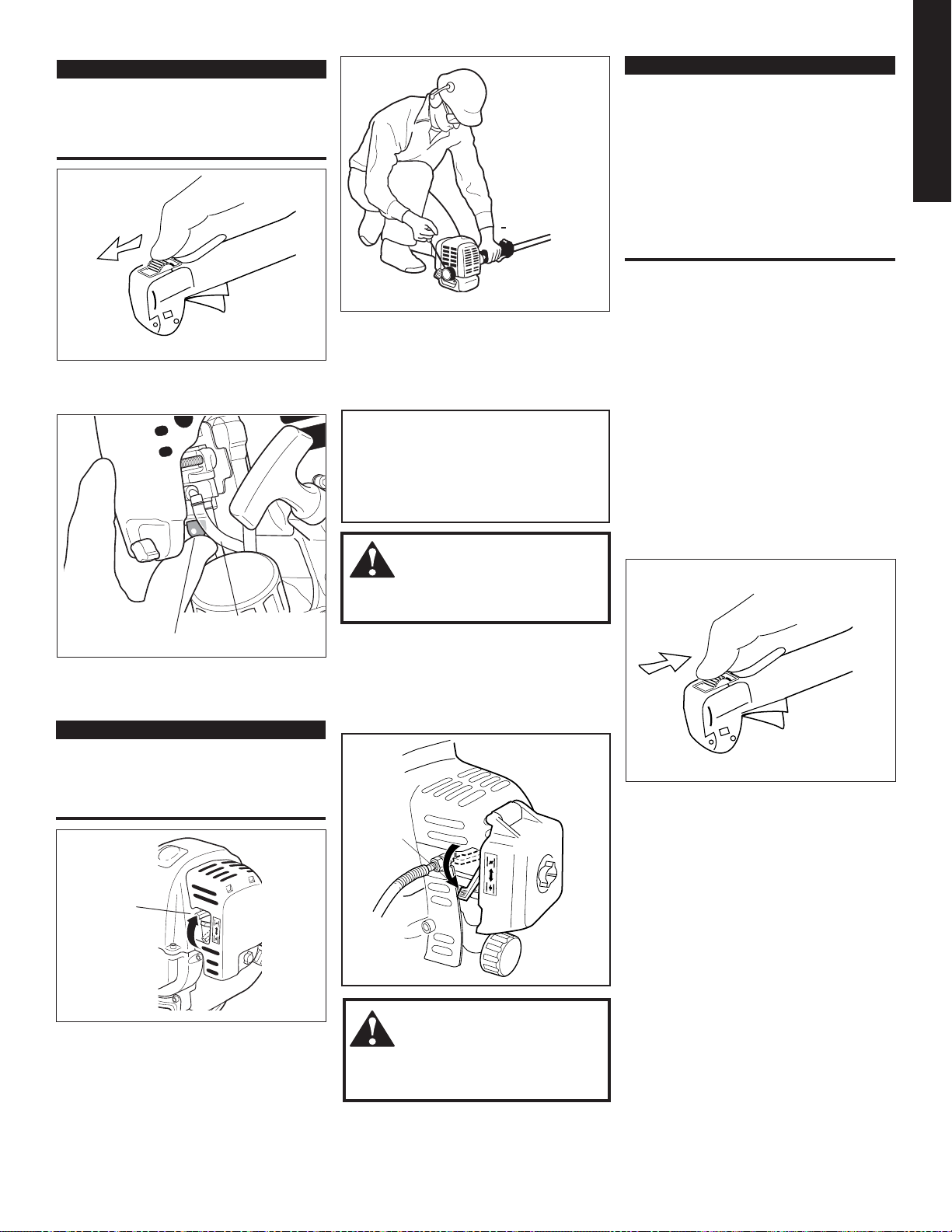

Starting the Engine

2

IMPORTANT!

Engine ignition is controlled by a two

position switch mounted on the throttle

housing labeled, "I" for ON or START

and "O" for OFF or STOP.

ON

Make sure the

sweeper belts

are clear of

obstructions!

IMPORTANT!

If the engine fails to start after several

attempts with the choke in the closed

position, the engine may be flooded with

fuel. If flooding is suspected, move the

choke lever to the open position and

repeatedly pull the recoil starter to

remove excess fuel and start the engine.

If the engine still fails to start, refer to the

troubleshooting section of this manual

(Starting a flooded engine).

ENGLISH

PB18

Figure 15

1. Slide the ignition switch to the “I”

position (engine ON).

PB2500.11

Return

Figure 16

Primer Bulb

Tube

2. Press the primer bulb until fuel can be

seen flowing in the transparent return

tube.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly

pressing the primer bulb will not flood

the engine with fuel.

PB2500.13

Figure 18

4. While holding the outer tube firmly

with left hand. Use your other hand to

slowly pull the recoil starter handle

until resistance is felt, then pull

quickly to start the engine.

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

WARNING!

The sweeper belts may rotate when

the engine is started!

5. When the engine starts, slowly move

the choke lever to the "OPEN"

position. See Figure 19. (If the engine

stops after the initial start, close the

choke and restart.)

Open

When the Engine Starts...

■ After the engine starts, allow the

engine to warm up at idle 2 or 3

minutes before operating the unit.

■ After the engine is warm, pick

up the unit and clip on the shoulder

strap if so equipped. See page 16.

■ Advancing the throttle makes the

sweeper belts turn faster; releasing the

throttle permits the attachment to stop

turning. If the sweeper belts continue

to rotate when the engine returns to

idle, carburetor idle speed should be

adjusted (see the next page).

Stopping the Engine

PB19

Figure 20

Idle the engine briefly before stopping

(about 2 minutes), then slide the ignition

switch to the “O” (Engine OFF) position.

Closed

Figure 17

PB2500.1

3. Set the choke lever to the CLOSED

position if engine is cold.

Figure 19

PB2500.14

WARNING!

Never start the engine from the

operating position.

11

Page 12

Adjusting Engine Idle

ENGLISH

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch

to disengage the cutting attachment.

Idle Speed Adjustment

WARNING!

The cutting attachment must NEVER

rotate at engine idle! If the idle speed

cannot be adjusted by the procedure

described here, return the trimmer to

your Shindaiwa dealer for inspection.

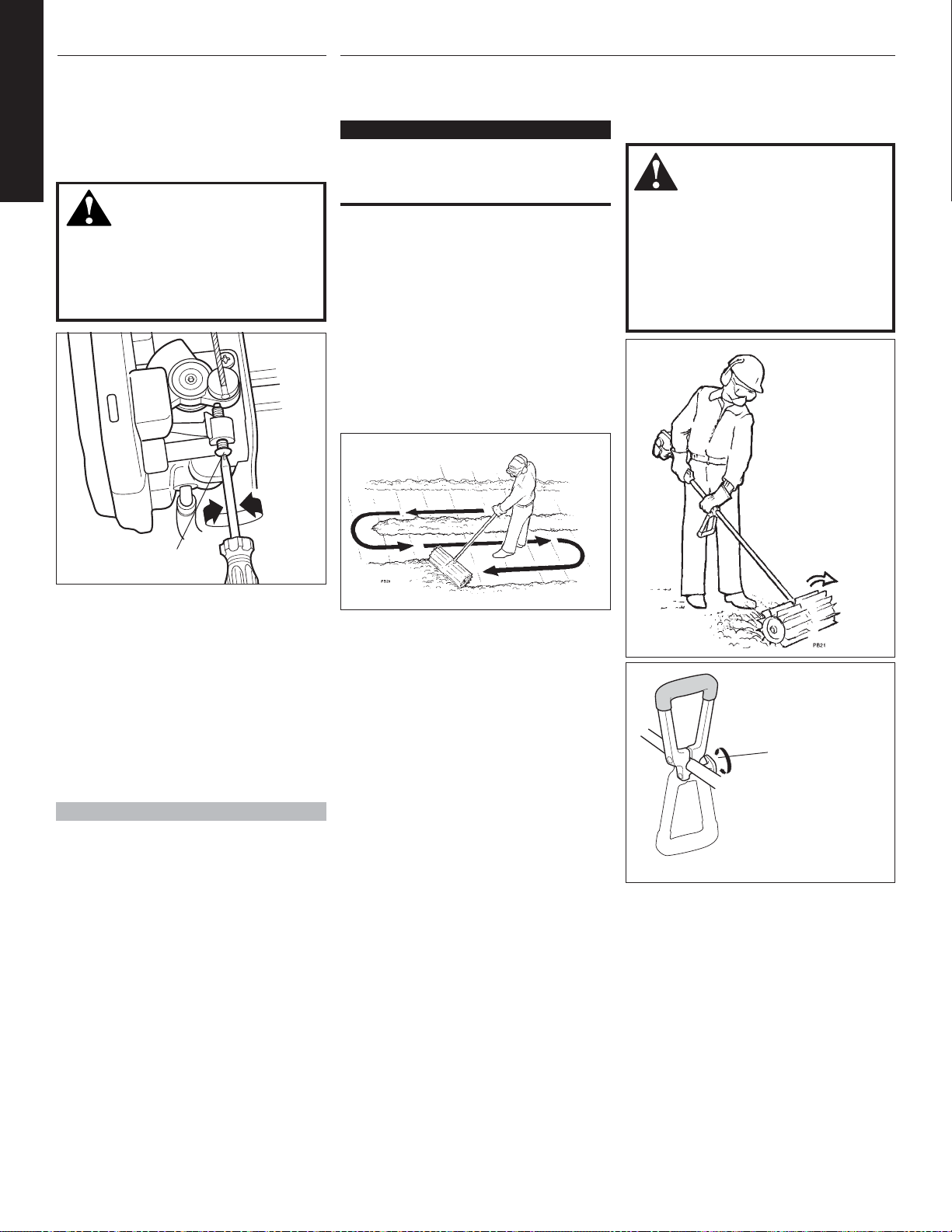

Operating Techniques

Operate the PowerBroom at or near full

throttle with its sweeper fins resting on

the work surface.

IMPORTANT!

It is both tiring and unnecessary to lift or

hold the fins from the work surface

during sweeping.

When sweeping narrow areas such as

sidewalks, the PowerBroom can be used

to throw material directly ahead of the

operator. Clearing wider areas may

require sweeping at an angle to create

windrows to one side of the path being

cleared.

Windrows of lighter materials often

can be combined into one main row or

pile for eventual pickup, while heavy or

bulky material may need to be collected

row-by-row. See Figure 22.

To pull debris from corners, reverse

sweeper drum rotation by turning the

powerhead over (throttle facing “up”).

See Figures 23 and 24.

WARNING!

Reversing the PowerBroom will cause

debris to be thrown back toward the

operator. When reversing the

PowerBroom, use lower throttle

settings and be aware that thrown

debris may also affect your footing!

PB2500.16

Idle Adjusting

Figure 21

Screw

1. Place the trimmer on the ground, then

start the engine, and then allow it to

idle 2-3 minutes until warm.

2. If the attachment rotates when the

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise.

See Figure 21.

3. If a tachometer is available, the engine

idle speed should be final adjusted to

3,200 (±300) rpm (min

NOTE:

-1

).

Carburetor fuel mixture adjustments are

preset at factory and cannot be serviced

in the field.

Sweeping Windrows

Figure 22

Figure 23

PB22

Figure 24

Sweeping corners

with the

PowerBroom

upside down

DIRECTION OF

ROTATION

For long-term inverted

operation…

Adjustment

Knob

…loosen the

adjustment knob to

reverse the handle.

12

Page 13

General Maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT OR

REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE

PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE

PERFORMED BY A DEALER OR

SERVICE CENTER AUTHORIZED BY

SHINDAIWA KOGYO CO., LTD. THE

USE OF PARTS THAT ARE NOT

EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS

OF THE EMISSION CONTROL SYSTEM

AND MAY HAVE A BEARING ON THE

OUTCOME OF A WARRANTY CLAIM.

Daily Maintenance

WARNING!

Before performing any maintenance,

repair or cleaning work on the unit,

make sure the engine and sweeper

belts are completely stopped. Disconnect the spark plug wire before

performing service or maintnenance

work.

ENGLISH

WARNING!

Non-standard parts may not operate

properly with your unit and may

cause damage and lead to personal

injury.

Prior to each work day, perform the

following:

■ Remove all dirt and debris from the

engine, check the cooling fins and air

cleaner for clogging, and clean as

necessary.

■ Carefully remove any accumulations of

dirt or debris from the muffler and fuel

tank. Dirt build-up in these areas can

lead to engine overheating, fire, or

premature wear.

10-Hour Maintenance

Every 10 hours of operation (more

frequently in dusty or dirty conditions):

Remove the air cleaner element.

See Figure 25. Clean or replace as

necessary. To clean element: wash it

thoroughly in soap and water. Let it

dry before reinstalling the element.

■ Check for loose or missing screws or

components. Make sure the sweeper

drums are securely fastened.

■ Check the entire unit for leaking fuel

or grease.

Unscrew

Fastener

Muffler

This unit must never be operated with a

faulty or missing spark arrester or muffler.

Make sure the muffler is well secured and

in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections tight and clean.

Fasteners

Make sure nuts, bolts, and screws

(except carburetor adjusting screws) are

tight.

Remove and clean

or replace

the element

CAUTION!

Do not operate the unit if the air

cleaner or element is damaged, or if

the element is wet.

PB2500.17

Figure 25

13

Page 14

10/15-Hour Maintenance

ENGLISH

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.024 -

0.028 inch (0.6 - 0.7 mm). If the spark plug

must be replaced, use only an NGK

CMR6H or equivalent resistor type spark

plug of the correct heat range.

See Figure 26.

NOTE:

The NGK CMR6H also meets the

requirements for electromagnetic

compliance (EMC).

CAUTION!

Before removing the spark plug,

clean the area around the plug to

prevent dirt and debris from getting

into the engine’s internal parts.

50-hour Maintenance

Every 50 hours of operation

(more frequently in dusty or dirty conditions):

■ Remove and clean the cylinder cover

and clean grass and dirt from the

cylinder fins.

■ Use a hooked wire to extract the fuel

filter from inside the fuel tank. Remove

and replace the filter element. Before

reinstalling the filter, inspect the

condition of the fuel line. If damage or

deterioration are noted, the unit should

be removed from service until it can be

inspected by a Shindaiwa-trained

service technician. See Figure 27.

Figure 26

0.024–0.028 inch

(0.6–0.7 mm)

Clean the spark plug

and check the gap

at the electrode.

PB23

PB2500.18

Filter Element

CAUTION!

Make sure you do not pierce the fuel

line with the end of the hooked wire,

the line is delicate and can be

Figure 27

damaged easily.

135-hour or Annual Maintenance.

■ The valve clearance should be adjusted annually or every 135 hours. It

is highly recommended that this is

done by a Shindaiwa-trained service

technician.

14

■ Replace the spark plug annually: Use

Hooked

Wire

only NGK CMR6H or equivalent

resistor type spark plug of the

correct heat range. Set spark plug

electrode gap to 0.024-0.028 inch

(0.6 -0.7 mm).

PB2500.19

NOTE:

The NGK CMR6H also meets the

requirements for electromagnetic

compliance (EMC).

Page 15

Spark Arrester Screen Maintenance.

If the engine becomes sluggish and low

on power, check and clean the spark

arrester screen.

WARNING!

BURN DANGER! The engine will

become very hot during normal

operation. Let engine cool before

servicing.

WARNING!

Never operate the unit with a damaged or missing muffler or spark

arrester! Operating with a missing or

damaged spark arrester is a fire

hazard and could also damage your

hearing.

1. With a 3 mm hex wrench remove the

4 engine cover screws and the engine

cover. See Figure 28.

2. With a 4 mm hex wrench remove the

3 muffler bolts and the muffler.

See Figure 28.

3. With a small flat bladed screwdriver

remove the 2 screws holding the

spark arrester screen and cover to

the muffler. See Figure 28.

Figure 28

4. Remove the screen and clean it with a

stiff bristle brush.

5. Inspect the cylinder exhaust port for

any carbon buildup.

6. Reassemble the spark arrester, muffler

and engine cover in the reverse order

of disassembly.

300-hour Maintenance

Engine Cover

Screws

PB2500.20

ENGLISH

Cover

Muffler

Muffler

Gasket

Muffler

Bolts

Spark Arrester

Screen

Spark Arrester

Cover

Cover Screws

IMPORTANT!

If you note excessive carbon buildup,

consult with an authorized Shindaiwa

servicing dealer.

Gearcase Lubrication

The gearcase should be filled with 60 cc

(2.0 fl.oz.) of Mobil SHC634 Synthetic

Gear Oil. A maximum of 75-80 cc can be

used, but never to exceed 80 cc. Operation with excessive oil level will result in

high operating temperatures. Do not

overfill!

PB2500.21

Figure 29

Replacing the gearcase oil

WARNING!

BURN DANGER! The gearcase will

be extremely hot after use!

1. Disconnect spark plug wire at engine.

2. Remove the LH Drum and axle

assembly (as viewed from the operating position). Wipe the sideplate clean

and remove four screws (it is not

necessary to remove the gearcase

from the outer tube).

3. Turn gearcase side plate to break the

seal and lift the plate from the gearcase. See Figure 29.

NOTE:

It may be necessary to use a heat gun to

soften the sealer material.

4. Turn the gearcase to the LH side and

allow all used gearcase oil to drain into

a small container and properly dispose

of as in accordance with your local

regulations.

5. Place the gearcase on the RH side and

supported so the outer tube is parallel

to the ground. Refill the gearcase with

60 cc (2.0 fl.oz) of Mobil SHC634

Synthetic Gear Oil to the bottom of the

chamfer on the output gear. The

Fill to

this level

Figure 30

PB2500.22

correct oil depth is 5/8" (15.5 mm).

See Figure 30. DO NOT OVERFILL!

6. Inspect the sideplate for damage and

clean off all remaining liquid gasket

material with brake cleaner or acetone.

Coat the outer sealing flange of the

sideplate with Loctite Ultragrey Silicon

Sealant or Threebond No. 1104

Liquid Gasket.

7. Replace the cover and install the four

sideplate screws. Tighten securely.

8. Reinstall the drum and axle assembly

per the sweeper assembly instructions.

See page 9.

15

Page 16

Long Term Storage

ENGLISH

Whenever the unit will not be used for 30

days or longer, use the following procedures to prepare it for storage:

■ Clean external parts thoroughly.

■ Drain all the fuel from the carburetor

and the fuel tank.

IMPORTANT!

All stored fuels should be stabilized with

a fuel stabilizer such as

STA-BIL姞.

Remove remaining fuel from the fuel lines

and carburetor with the fuel drained from

the fuel tank.

1. Prime the primer bulb until no more

fuel is passing through.

2. Start and run the engine until it stops

running.

3. Repeat steps 1 and 2 until the engine

will no longer start.

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard

starting, and could also lead to

increased service and maintenance

costs.

Strap and Hanger Debris Shield

p/n 22410-17201 and 60840-98020

(optional)

Although a strap and hanger is not

required for use with a Shindaiwa

PB2500 PowerBroom, it is recommended to reduce operator fatigue

during extended periods of operation.

Make sure all hooks and adjusting

devices are secure. Adjust the harness

shoulder strap so the shoulder pad

rests comfortably on the off-side

shoulder. See Figure 31.

Recommended

Strap and

Hanger

Figure 31

p/n 99909-33021 (optional)

A plastic debris shield is available from

your Shindaiwa dealer as a useful option

to your PowerBroom. The shield helps

prevent broadcasting debris when large

volumes of material are forced over the

top of the drum during operation.

See Figure 32.

Figure 32

PB25

■ Remove the spark plug and pour

about 1/4 ounce of 2-cycle mixing oil

into the cylinder through the spark

plug hole. Slowly pull the recoil starter

2 or 3 times so oil will evenly coat the

interior of the engine. Reinstall the

spark plug.

■ Before storing the unit, repair or

replace any worn or damaged parts.

■ Remove the air cleaner element from

the carburetor and clean it thoroughly

with soap and water, let dry and

reassemble the element.

■ Store the unit in a clean, dust-free area.

16

Page 17

Troubleshooting Guide

What To Check Possible Cause Remedy

Does the engine crank?

YES

Good compression?

YES

Does the tank contain

fresh fuel of the proper

grade?

YES

Is fuel visible and moving

in the return line when

priming?

YES

Is there spark at the spark

plug wire terminal?

YES

Check the spark plug.

ENGINE DOES NOT START

Faulty recoil starter.

NO

Fluid in the crankcase.

Internal damage.

Loose spark plug.

NO

Excess wear on cylinder, piston, rings.

Valves not seating.

Fuel incorrect, stale or contaminated;

NO

mixture incorrect.

Check for clogged fuel filter and/or vent.

NO

Priming pump not functioning properly.

The ignition switch is in “O” (OFF)

NO

position.

Shorted ignition circuit.

Faulty ignition unit.

If the plug is wet, excess fuel may be in

the cylinder.

ENGLISH

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Tighten and re-test.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Refill with fresh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with

a 2-cycle air cooled mixing oil that meets or

exceeds ISO-L-EGD and/or JASO FC classified

oils at 50:1 gasoline/oil ratio.

Replace fuel filter or vent as required; restart.

Consult with an authorized servicing dealer.

Move switch to “I” (ON) position and restart.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Crank the engine with the plug removed,

reinstall the plug, and restart.

The plug is fouled or improperly gapped.

The plug is damaged internally or of the

wrong size.

What To Check Possible Cause

Is the engine overheating?

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty

or damaged.

Carbon deposits on the piston or in

the muffler.

Engine is rough at all

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Water in the fuel.

Clean and regap the plug to 0.024 - 0.028

inch (0.6 - 0.7 mm). Restart.

Replace the plug with an NGK CMR6H or

equivalent resistor type spark plug of the

correct heat range. Set spark plug electrode

gap to 0.024-0.028 inch (0.6-0.7 mm).

LOW POWER OUTPUT

Remedy

Apply less presure on the sweeper drums.

Consult with an authorized servicing dealer.

Refill with fresh, clean unleaded gasoline with a pump

octane of 87 or higher mixed with a 2-cycle air cooled

mixing oil that meets or exceeds ISO-L-EGD and/or

JASO FC classified oils at 50:1 gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing dealer.

Service the air cleaner element.

Tighten or replace.

Repair or replace filter and/or fuel line.

Replace the fuel. See page 10.

Engine is knocking.

Piston seizure.

Faulty carburetor and/or diaphragm.

Valve clearance set incorrectly.

Overheating condition.

Improper fuel.

Carbon deposits in the combustion

chamber.

Valve clearance set incorrectly.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

See above.

Check fuel octane rating; check for presence of

alcohol in the fuel (pg. 10). Refuel as necessary.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

17

Page 18

Troubleshooting Guide (continued)

ENGLISH

Symptom Possible Cause

Poor acceleration.

Clogged air filter.

Clogged fuel filter.

ADDITIONAL PROBLEMS

Remedy

Clean the air filter.

Replace the fuel filter.

Engine stops abruptly.

Engine difficult to shut off.

Top of engine is getting

dirty and oily.

Lean fuel/air mixture.

Idle speed set too low.

Clogged spark arrester.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Ground (stop) wire is disconnected or

switch is defective.

Overheating due to incorrect spark plug.

Overheated engine.

Valve cover is leaking.

Consult with an authorized servicing dealer.

Adjust: 3,200 (Ⳳ300) rpm (min

Clean spark arrester. (Pg. 15).

Reset the switch and restart.

Refuel. See page 10.

Replace fuel filter.

Drain; replace with clean fuel. See page 10.

Clean and replace spark plug, tighten

the terminal.

Replace the ignition unit.

Consult with an authorized servicing dealer.

Test and replace as required.

Idle engine until cool.

Clean and regap the plug to 0.024 - 0.028

inch (0.6 - 0.7 mm). Correct plug: NGK CMR6H

or equivalent resistor type spark plug of the

correct range.

Idle engine until cool.

Consult with an authorized servicing dealer.

-1

).

Sweeping attachment

rotates at engine idle.

Engine will not idle down.

Engine idle too high.

Broken clutch spring or worn clutch

spring boss.

Loose attachment holder.

Engine idle set too high.

Engine has an air leak.

Set idle: 3,200 (Ⳳ300) rpm (min-1)

Replace spring/shoes as required, check

idle speed.

Inspect and re-tighten holders securely.

Set idle: 3,200 (Ⳳ300) rpm (min-1)

Consult with an authorized servicing dealer.

ADDITIONAL PROBLEMS

Symptom Possible Cause Remedy

Excessive vibration.

Sweeper belts will

not rotate.

Warped or damaged sweeper attachment.

Loose gearcase.

Bent main shaft/worn or damaged

bushings.

Shaft not installed in powerhead or

gearcase.

Broken shaft.

Damaged gearcase.

Inspect and replace attachment as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Inspect and reinstall as required.

Consult with an authorized servicing dealer.

Consult with an authorized servicing dealer.

18

Page 19

Emission System Warranty Statement

Your Warranty Rights and

Obligations

The California Air Resources Board, the U.S. Environmental

Protection Agency and Shindaiwa Kogyo Co., Ltd. are pleased to

explain the emission control system warranty on your new small

off-road (non-road) engine.

In California, new small off-road engines must be designed,

built, and equipped to meet the State’s stringent anti-smog

standards. In other states, new 1997 and later non-road engines

must meet the Federal EPA’s stringent anti-smog standards.

Shindaiwa Kogyo Co., Ltd. must warrant the emission control

system on your small off-road engine for the periods of time

listed below, provided there has been no abuse, neglect, or

improper maintenance of your small off-road engine.

Your engine emission control system includes parts such as

the carburetor, the ignition system and, if equipped, the

catalytic converter. These components are specifically listed

below.

Where a warrantable condition exists, Shindaiwa Kogyo Co.,

Ltd. will repair your small off-road engine at no cost to you

including diagnosis, parts, and labor.

Manufacturer’s Warranty

Coverage

When sold within the U.S., this engine’s emission control

system is warranted for a period of two (2) years from the date

this product is first delivered to the original retail purchaser.

During the warranty period, Shindaiwa Kogyo Co., Ltd. will,

at their option, repair or replace any defective emission-related

component on this engine. During the original Warranty Period,

these Warranty Rights are automatically transferable to subsequent owners of this product.

What is Covered by this

Warranty

1. Carburetor Internal Components

■ Throttle Valve, Needle, Jet, Metering Diaphragm

2. Ignition System Components

■ Ignition Coil

■ Flywheel Rotor

3. Catalytic Converter (if originally equipped)

The emission control system for your particular Shindaiwa

engine may also include certain related hoses

and connectors.

Owners Warranty

Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in this

owners manual. Shindaiwa Kogyo Co., Ltd. recommends that

you retain all receipts covering maintenance on your small offroad engine, but Shindaiwa Kogyo Co., Ltd. cannot deny

warranty solely for the lack of receipts or for your failure to

ensure the performance of all scheduled maintenance.

As the small off-road engine owner, you should be aware,

however, that Shindaiwa Kogyo Co., Ltd. may deny you warranty coverage if your small off-road engine or a part has failed

due to abuse, neglect, improper maintenance, or unapproved

modifications.

You are responsible for presenting your small off-road

engine to an authorized Shindaiwa Dealer as soon as a problem

exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a Shindaiwa customer

service representative at (503) 692-3070 or your local Shindaiwa

Dealer.

Consequential Damages

In the event that other component parts of this product are

damaged by the failure of a warranted part, Shindaiwa Kogyo

Co., Ltd. will repair or replace such component parts at no

charge to you.

What is Not Covered

■ Failures caused by abuse, neglect, or improper

maintenance procedures.

■ Failures caused by the use of modified or non-approved parts

or attachments.

This Warranty is Administered by:

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, OR 97062

(503) 692-3070

ENGLISH

19

Page 20

NOTES:

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, Oregon 97062

Telephone: 503 692-3070

Fax: 503 692-6696

www.shindaiwa.com

Shindaiwa Kogyo Co., Ltd.

Head Office: 6-2-11 Ozuka

Nishi, Asaminami-ku

Hiroshima, 731-3167, Japan

Telephone: 81-82-849-2220

Fax: 81-82-849-2481

䊚2003 Shindaiwa, Inc.

Part Number 80732

Revision 4/03

Printed in Japan

Shindaiwa Tornado is a trademark,

and Shindaiwa is a registered trademark

of Shindaiwa, Inc.

Page 21

AVERTISSEMENT !

䊛

Veuillez lire le présent

manuel et vous familiariser

avec son contenu pour

réduire le risque de vous

blesser ou de blesser les

autres. Toujours porter un

dispositif de protection des

yeux et des oreilles pendant

l’utilisation de l’appareil.

MANUEL D’UTILISATION SHINDAIWA

Balai motorisé PB2500娃

Numbero 80733 Rev. 4/03

Page 22

Introduction

Les mises en gardes

La série d'outils motorisés Shindaiwa

2500 a été conçue et fabriquée dans le but

d’offrir une performance et une fiabilité

supérieures sans compromettre la qualité,

le confort ou la durabilité. Les moteurs

Shindaiwa sont à la fine pointe de la

technologie et offrent un rendement

exceptionnel, avec une cylindrée

remarquablement basse et une conception des plus légères. Comme propriétaire

ou utilisateur, vous comprendrez vite

pourquoi Shindaiwa est tout simplement

une classe en soi!

IMPORTANT!

Les renseignements contenus dans le

présent manuel d’utilisation décrivent le

taille-herbe T2500 disponible au moment de la publication.

Shindaiwa Inc. se réserve le droit

d’apporter des modifications au produit

sans préavis et se dégage de toute

obligation d’apporter des modifications

aux appareils déjà fabriqués.

AVERTISSEMENT !

Les échappements du moteur de ce

produit contiennent des substances

chimiques répertoriées en Californie

comme susceptibles de causer le

cancer, des anomalies congénitales

ou d’autres affections congénitales.

Table des matières

PAGE

Mises en garde ......................................... 2

Consignes de sécurité.............................. 3

Vérification de l’appareil .......................... 3

Étiquettes de sécurité .............................. 5

Vérification de l’appareil .......................... 6

Caractéristiques techniques ................... 6

Assemblage ............................................... 7

Carburant du moteur ............................. 10

Démarrage du moteur ........................... 11

Arrêt du moteur ...................................... 11

Ajustement du ralenti............................. 12

Utilisation du balai motorisé ................. 12

Entretien .................................................. 13

Remisage à long terme .......................... 16

Accessoires ............................................. 16

Guide de dépannage .............................. 17

Garantie du dispositif antipollution ...... 19

Vous trouverez des mises en garde tout

au long du manuel.

AVERTISSEMENT !

Une mise en garde précédée du mot

"AVERTISSEMENT" contient de

l’information dont il faut tenir compte

pour éviter les blessures graves.

MISES EN GARDE

Une mise en garde précédée du mot

"MISE EN GARDE" contient de

l’information dont il faut tenir compte

pour éviter d’endommager.

IMPORTANT!

Une mise en garde précédée du mot

"IMPORTANT" est une mise en garde

d’une importance particulière.

NOTE:

Une mise en garde précédée du mot

"NOTE" contient de l’information utile qui

pourrait faciliter votre travail.

VEUILLEZ LIRE ET SUIVRE LES

CONSIGNES ÉNONCÉES DANS

CE MANUEL D’INSTRUCTIONS

SANS QUOI IL POURRAIT

S’ENSUIVRE DES BLESSURES

GRAVES.

IL EST RECOMMANDÉ DE PORTER

DES DISPOSITIFS DE PROTECTION

POUR LES YEUX ET POUR LES

OREILLES EN TOUT TEMPS

PENDANT L’UTILISATION

DE L’APPAREIL.

PRENDRE GARDE AUX DÉBRIS

PROJETÉS ET GARDER LES

OBSERVATEURS À UNE DISTANCE

D’AU MOINS 50 PIEDS (15 MÈTRES)

EN TOUT TEMPS PENDANT

L’UTILISATION DE L’APPAREIL.

Ne pas utiliser l'appareil si vous

êtes fatigués, malades ou sous

l'influence d'alccol, de drogues

ou de médicament.

IMPORTANT!

Les procédures d’utilisation décrites

dans ce manuel visent à vous aider à

tirer le maximum de votre appareil et à

vous protéger (vous-mêmes et les

autres) contre les blessures. Ces

procédures constituent des lignes

directrices pour l’utilisation de l’appareil

en toute sécurité dans la plupart des

situations mais elles ne remplacent

d’aucune façon d’autres mesures de

sécurité ni les lois en vigueur dans votre

région.

Pour toute question sur votre appareil ou

pour toute clarification sur les

renseignements contenus dans ce

manuel, votre vendeur Shindaiwa se

fera un plaisir de vous aider. Vous

pouvez aussi communiquer avec

Shindaiwa Inc. à l’adresse imprimée à

l’endos du manuel.

2

Page 23

Mesures de sécurité générales

Vérification de l’appareil

Travailler en toute sécurité

Le balai motorisé fonctionne à très haute

vitesse et peut causer de sérieux

dommages et de sérieuses blessures s’il

est mal utilisé ou si l'on en fait un emploi

abusif. Ne jamais laisser une personne

qui n'a pas lu les directives d'utilisation

ou reçu la formation pertinente utiliser

l'appareil.

Demeurer alerte

Vous devez être physiquement et

mentalement alerte pour utiliser cet

appareil en toute sécurité.

AVERTISSEMENT !

Ne jamais installer des accessoires

non autorisés.

AVERTISSEMENT !

Ne jamais utiliser de l’équipement

motorisé si vous êtes fatigué, sous

l’influence d’alcool, de drogues ou de

toute autre substance qui pourrait

nuire à votre concentration ou à votre

jugement.

AVERTISSEMENT !

Faire preuve de jugement

Ne jamais laisser l’appareil en

marche pour le transporter.

Ne jamais faire fonctionner le

moteur à l’intérieur. S’assurer qu’il

y a toujours une bonne ventilation.

Les gaz émanant du tuyau

d’échappement peuvent causer de

graves blessures voire causer la

mort.

Toujours utiliser l’outil de coupe

approprié pour le travail à

effectuer.

Toujours arrêter l’appareil s’il se

met à vibrer ou s’il devient instable.

Inspecter l’appareil dans le but de

trouver les pièces ou les

accessoires brisés, mal installés ou

manquants.

Ne jamais utiliser l’appareil sur des

surfaces élevées ou des toits.

Toujours garder l’appareil aussi

propre que possible. Enlever

l’accumulation d’herbe, de boue,

etc.

Toujours tenir l’appareil fermement

avec les deux mains pour balayer

et garder le contrôle en tout temps.

Toujours garder les poignées

propres.

Toujours débrancher le fil de la

bougie avant de faire l’entretien de

l’appareil.

AVERTISSEMENT !

Pour réduire les risques de feu

Ne jamais fumer ni allumer de feu

à proximité de l’appareil.

Toujours arrêter le moteur et le

laisser refroidir avant de le remplir

d’essence. Éviter de trop remplir et

essuyer tout carburant qui pourrait

s’être répandu ou qui pourrait avoir

débordé.

TOUJOURS vérifier les fuites de

carburant avant chaque usage. À

chaque remplissage, s’assurer que

le carburant ne s’écoule pas du

bouchon et (ou) du réservoir. En

cas de fuite apparente, cesser

immédiatement d’utiliser l’appareil.

Réparer toute fuite avant d’utiliser

l’appareil.

TOUJOURS déplacer l’appareil à

distance du lieu de remplissage ou

d’autres substances inflammables

avant de démarrer lemoteur.

Ne jamais laisser de substances

inflammables à proximité du

silencieux.

Ne jamais mettre le moteur en

marche sans le pare-étincelles.

Ne jamais utiliser l’appareil sans les

dispositifs de protection

(commutateur d’allumage, etc.)!

Utiliser seulement des pièces de

remplacement et des accessoires

Shindaiwa avec le balai motorisé

Shindaiwa. Ne pas apporter de

modification à l’appareil sans

l’approbation écrite par Shindaiwa

Inc.

S’assurer que les tambours sont

installés de façon appropriés avant le

fonctionnement.

Ne jamais utiliser le balai motorisé

avec un aileron ou un tambour fendu

ou gauchi : le remplacer.

Toujours arrêter le moteur

immédiatement et vérifier si l’outil de

coupe est endommagé s’il frappe un

objet solide ou si l’appareil devient

instable. Ne pas utiliser un outil de

coupe brisé ou endommagé.

Ne jamais laisser le moteur tourner à

régime élevé (rpm) sans résistance

car le moteur pourrait briser.

Ne jamais faire fonctionner l’appareil

si les attaches ou les supports sont

usés ou endommagés.

3

Page 24

L’utilisateur bien équipé

Porter des vêtements

ajustés pour protéger les

jambes et les bras. Il est

fortement recommandé

de porter des gants car ils

offrent une sécurité

supplémentaire. Ne pas

porter de vêtements ou

de bijoux qui pourraient

facilement se coincer

dans l’appareil ou dans

les broussailles. Ne

jamais porter de culottes

courtes.

Garder le pied ferme et ne pas s’étirer

outre mesure. Garder l’équilibre en tout

temps.

Porter en tout temps pendant le

fonctionnement de l'appareil un dispositif de

protection pour les oreilles.

Toujours porter un dispositif de

protection pour les yeux comme

lunettes de travail ou des

lunettes de sécurité.

Toujours porter un

dispositif de protection

respiratoire pour éviter

d'inhaler les poussières en

suspension dans l'air.

Toujours garder les deux

mains fermement

agrippées sur l’appareil.

Se tenir éloigné des ailerons du

balai en rotation ou des soies

en tout temps et ne jamais lever

un accessoire en mouvement

au dessus du niveau de la taille.

Porter des articles chaussant (bottes

ou souliers antidérapants). Ne jamais

porter des sandales ou des

chaussures à bouts ouverts. Ne

jamais travailler nu-pieds.

Figure 1

PB01

Tenir compte de l’environnement de travail

Éviter l’utilisation à long

terme à température très

chaude ou très froide.

Si l'appareil

percute un

objet solide,

arrêter le

moteur et

vérifier que

les ailerons et

le tambour ne

sont pas

endommagés.

Prendre garde aux

terrains glissants,

particulièrement lorsqu’il

pleut ou quand les débris

sont repoussés en

direction de l'utilisateur.

Tenir compte des

observateurs et les

garder là distance.

Toujours nettoyer l'aire de travail; enlever

tout débris ou déchet qui pourrait être

projeté dans votre direction ou celle d’un

observateur. Lors de l’utilisation sur un

terrain rocailleux ou à proximité de fils

électriques ou de clôtures, s’assurer que

ces éléments n’entrent pas en contact avec

les ailerons du balai.

Toujours prendre garde aux objets et aux

débris qui peuvent être projetés par les

ailerons du balai ou rebondir sur une

surface solide.

Figure 2

4

PB02

Page 25

Étiquettes de sécurité

READ THE

OPERATOR’S MANUAL.

WEAR HEARING AND ANSI Z87.1

APPROVED EYE PROTECTION.

BEWARE OF THROWN

DIRT AND DEBRIS.

DO NOT USE ON UNGUARDED

ELEVATED SURFACES.

MAINTAIN A

SHALLOW

WORKING

ANGLE…

…AVOID MOVING TOWARD

VERTICAL.

80267Shindaiwa Inc.

IMPORTANT!

Étiquettes de consigne sur le

fonctionnement et la sécurité :

s’assurer que les endommagées et

qu’elles restent lisibles. Remplacer

immédiatement toute étiquette

manquante ou endommagée. On

peut obtenir de nouvelles étiquettes

en s’adressant au distributeur

Shindaiwa autorisé le plus près.

PB03

PB2500

POSITION HANDLE

FORWARD OF THIS LINE

Cette étiquette indique la

distance minimum entre la

poignée avant et la poignée

arrière qu’il faut garder

conformément à la norme ANSI

B175.3.

Figure 3

5

Page 26

Vérification de l’appareil

Vous pouvez utiliser les illustrations cidessus pour vous familiariser avec votre

appareil et ses différentes composantes.

Comprendre l’appareil permet d’obtenir

une performance optimale, de prolonger

sa vie utile et favorise une utilisation plus

sécuritaire. Voir l’illustration 4.

AVERTISSEMENT !

Ne pas modifier ni altérer soi-même

l’appareil ou ses composantes.

Aileron du

balai

Boîtier

d’engrenage

Tube extérieur

Poignées

Poignée

caoutchoutée

Commutateur

d’allumge

Levier

d’accélération

Protecteur

du

réservoir

Bougie

Réservoir à

essence

Avant l’assemblage

Avant d’assembler, s’assurer que toutes

les composantes requises pour l’unité

sont présentes :

■ Ensemble du moteur

■ Ensemble d’axe d’entraînement

■ Tambour avec boîtier d'engrenage.

■ Poignée appropriée (voir la page

précédente).

■ L'ensemble comprend le support de

fixation de la poignée et les ferrures, le

présent manuel d'utilisation ainsi que

la trousse nécessaire à l'entretien

régulier. La trousse d'outils varie selon

le modèle et peut comprendre une clé

hexagonale, une clé mixte à bougie et

une clé d'écartement.

S’assurer qu’aucune composante n’est

endommagée.

IMPORTANT!

Les termes "gauche", "à gauche" et

"vers la gauche"; "droite", "à droite" et

"vers la droite"; "devant" et "arrière" font

référence à la direction telle que vue par

l’opérateur lors d’une utilisation normale.

PB03

Tambour

du balai

Figure 4

Caractéristiques techniques

Poid net du PB2500 (sans les ailerons) ....................................................... 4,7 kg/12,3 lbs

Poid net du PB2500 (avec les ailerons) .......................................................9,5 kg/20,3 lbs

Modèle du moteur.................................................................................... Shindaiwa S2500E

Moteur type................................. Shindaiwa C4, cylindre vertical, refroidissement à l’air

Alésage / course .................................................................... 1.3 x 1.1 in./34 mm x 27 mm

Cylindrée ...................................................................................................... 24.5 cc / 1,5 po3

Puissance maximum ................................................... 1.1 hp (0.8 kw) @7500 rpm (min-1)

Ratio essence/huile .................................................................................................................

......... 50:1 avec de l’huile Shindaiwa de première qualité pour moteur à deux temps

Capacité du réservoir d'essence ............................................................. 20,3 onces/600 ml

Carburateur.......................................................................... Walbro WYL, type diaphragne

Allumage ......................................................................................... Monobloc par transistor

Bougies ..............................................................................................................NGK CMR6H

Filtre à air .................................................................................. Filtre floqué non réversible

Démarrage ................................................................................................................. À rappel

Arrêt ...................................................................................................interrupteur à glissoire

Type de transmission ................................................. Automatique, centrifuge à vis sans fin

*Dispositif antipollution conforme aux normes de l'EPA période de conformité ..................

........................................................................................................................... Catégorie A

*La référence à la conformité à l’EPA sur l’étiquette de conformité du dispositif antipollution du moteur indique le nombre

d’heures de fonctionnement pendant lesquelles le moteur reste conforme aux prescriptions relatives aux émissions.

Catégorie C = 50 heures (Modéré), B = 125 heures (Intermédiaire) et A = 300 heures (Prolongé).

*Les caractéristiques techniques sont sujettes à changements sans préavis.

6

Page 27

Assemblage: Arbre d'entraînement / tête motorisée

1. Déposer la tête motorisée sur une

surface plane et propre, la bougie

orientée vers le haut.

Voir illustration 5.

2. À l'aide de la clé hexagonale de 4mm,

desserrer la vis du collier de serrage

du tube. Vérifier que la cale en forme

de "D" est positionnée tel qu'indiqué à

l'illustration 6.

Collier de serrage du

Clé

hexagonale

PB2500.04

Figure 6

tube

Cale

d’épaisseur

MISES EN GARDE

Ne pas enlever la cale d'épaisseur en

forme de "D"! La cale empêche de

trop serrer le collier de serrage du

tube.

3. Ajouter de la graisse EP à base de

molybdène dans les cannelures à

l'extrémité de l'arbre principal.

Balai motorisé PB2500

Relier le tube extérieur au moteur

Vis de

serrage

Poignée

Commutateur

d’allumge

Figure 5

caoutchoutée

Levier

d’accélération

4. Glisser le tube extérieur dans le collier

de serrage du tube jusqu'au fond.

5. Placer le tube extérieur de manière à

ce que le commutateur d'allumage soit

orienté vers le haut et que le levier

d'accélération soit orienté vers le bas.

MISES EN GARDE

Ne pas forcer le tube dans la tête

motorisée. L'emploi d'une force

excessive risque d'endommager le

tube de l'arbre et l'arbre principal.

Bougie

Axe

Principal

PB08

Collier de serrage du

Tube extérieur

tube

6. Glisser le tube extérieur sur la tête

motorisée jusqu'à ce que la poignée

appuie contre le collier de serrage du

tube.

7. Serrer fermement la vis du collier de

serrage.

Assemblage: Tringlerie de l'accélérateur et câbles d'allumage

Brancher le câble d'accélération

1. Desserrer le bouton du couvercle du

filtre à air et enlever le couvercle du

filtre à air. Voir illustration 7.

2. Glisser le câble d'accélération dans le

règleur du câble et fixer l'extrémité

métallique du câble au pivot du câble.

Voir l'illustration 8.

Branchement des câbles d'allumage

3. Brancher les deux câbles d'allumage

joignant les deux (2) connecteurs

métalliques. Voir l'illustration 9.

4. Réinstaller le couvercle du filtre à air.

MISES EN GARDE

Le cheminement des câbles ne doit

pas gêner le mouvement

l'accélérateur.

Filtre à

Figure 7

PB2500.08

air

PB2500.05

Figure 8

Fils

d'allumage

Branchement du câble

de l'accélérateur

PB2500.06

Câble de

l'accélérateur

Régleur du

câble

Pivot du câble

Figure 9

7

Page 28

Assemblage: Ajuster le jeu de garde du levier d’accélération

Le jeu de garde du levier d’accélération

doit être réglé à environ 3/16 à 1/4 po (4 à

6 mm). Voir l’illustration 10. S’assurer que

le levier d’accélération se déplace en

douceur sans se coincer. Pour ajuster le

jeu de garde du levier d’accélération,

suivre les procédures et les illustrations

suivantes.

PB2500.05

Figure 10

PB2500.09

3/16 à 1/4 po (4 à 6 mm)

Jeu de garde de

l’accélérateur

Figure 11

1. Desserrer le bouton du couvercle du

filtre à air et l’enlever. Voir

l’illustration 11.

2. Desserrer l’écrou de blocage du

régleur du câble. Voir l’illustration 12.

3. Ajuster le régleur du câble pour

obtenir le jeu de garde adéquat de

3/16 à 1/4 po (4 à 6 mm).

Voir l’illustration 12.

4. Resserrer l’écrou de blocage.

Régleur du

câble

Figure 12

Écrou de

blocage

PB2500.10

5. Réinstaller le couvercle du filtre à air.

Assemblage: Poignées

Fixer la poignée au tube extérieur

1. Enlever les deux vis de la poignée

2. Tout en glissant la poignée jusqu'à

l'orifice de fixation, positionner la

poignée sur le tube extérieur tel

qu'indiqué.

3. Réinstaller les deux vis de fixation sur

la poignée sans les serrer pour

l'instant.

IMPORTANT!

L'un des côtés de la poignée est incurvé

de manière à accueillir les deux écrous

hexagonaux.

4. Trouver la position de la poignée la

plus confortable pour l'utilisateur

(habituellement environ 10 pouces

devant le levier d'accélération) et la

fixer en serrant le bouton de réglage à

la base de la poignée.

Figure 13

Accélérateur

Écrou

hexagonal

Poignées

Vis de

montage

Boutons

d'ajustement

Rondelle

PB10

Tube extérieur

8

Page 29

Assemblage: Boîtier et balai

1. Insérer l'extrémité du tube extérieur

dans le boîtier d'engrenage jusqu'au

fond. Le tube extérieur devrait

pénétrer dans le boîtier d'engrenage

environ 1 et 1/2 po (38 mm). Si le tube

extérieur s'arrète avant d'arriver au

fond, faire pivoter jusqu'à ce que les

cannelures de l'arbre principal

intérieur (arbre d'entraînement)

s'engagent dans le boîtier

d'engrenage. Pousser ensuite le tube

extérieur jusqu'au fond. Voir

l'illustration 14.

2. Pivoter le boîtier d'engrenage de façon

à ce que la vis de centrage soit alignée

avec l'orifice du tube extérieur.

3. À l'aide d'une clé hexagonale de 4 mm

(Allen), visser d'abord les vis de

centrage du boîtier d'engrenage puis la

vis du collier de serrage du boîtier

d'engrenage.

4. Pousser l'un des axes du tambour dans

l'un des deux axes de sortie du boîtier

d'engrenage. Au besoin, faire pivoter

l'axe du tambour jusqu'à ce que

l'orifice de la goupille trouée de l'axe

soit alignée avec l'orifice

correspondant dans l'axe de sortie du

boîtier d'engrenage.

5. Utiliser une goupille trouée et une

cheville pour fixer l'axe du tambour à

l'arbre.

Vis de centrage

Aileron du

tambour

Balai

Figure 14

6. Glisser l'extrémité incurvée du

tambour du balai sur l'axe installé puis

glisser le tambour sur l'axe jusqu'à ce

que l'orifice de la goupille fendue de

l'axe soit appuyé contre la surface du

tambour.

MISE EN GARDE !

Les deux tambours sont identiques,

mais chaque tambour doit être

installé avec l'extrémité incurvée

orientée vers le bas du boîtier

d'engrenage.

Installer le tube extérieur dans

1

le boîtier d'engrenage

Vis de

serrage

Goupille

fendue

Installation du balai

4

PB17

Fixer l'aileron du tambour à

3

l'aide de la goupille trouée

Cheville

Installation de l'aileron du

2

tambour sur l'arbre de sortie

Fixer à l'aide de

4

7. Utiliser une goupille fendue pour fixer

le tambour sur l'axe (voir illustration).

La goupille fendue est conçue pour

appuyer parfaitement la surface

extérieure du tambour; vous devrez

peut-être enfoncer légèrement la

surface du tambour pendant

l'installation. Étendre les extrémités de

la goupille fendue pour fixer.

8. Répéter les étapes 4 à 7 pour installer

les axes et tambours restants.

la goupille

fendue

Le balai motorisé PB2500 devrait maintenant être entièrement assemblé.

9

Page 30

Carburant

Remplir le réservoir

Rodage et utilisation

MISE EN GARDE !

Certaines essences contiennent de

l’alcool comme oxygénant. L’essence

oxygénée peut élever la température

de fonctionnement du moteur. Dans

certaines conditions, les essences à

base d’alcool peuvent réduire les

propriétés lubrifiantes de certains

mélanges d’huile pour moteur à deux

temps. Ne jamais utiliser une essence contenant plus de 10 %

d’alcool par volume! Les huiles

génériques et certaines huiles pour

moteurs hors-bord risquent de ne pas

convenir à l’utilisation dans des

moteurs à deux temps à haut

rendement refroidis à l’air. Ne jamais

les utiliser avec les outils de coupe

Shindaiwa!

MISE EN GARDE !

Ce moteur fonctionne avec un

mélange d’essence sans plomb et

d’huile pour moteur à deux temps

seulement, dans une proportion de