Shindaiwa DGW400DM-380A User Manual

OWNER’S AND

OPERATOR’S

MANUAL

SOUND PROOF DIESEL ENGINE

GENERATOR/WELDER

1.Safety Guidelines

2.Specifications

3.Use

4.Parts

5.Equipment

5-1.Eco Welding

5-2.Remote Control(Option)

5-3.Monitor Lamp

5-4.Frequency Change

5-5.Earth Leakage Relay

5-6.Single Phase Breaker for

5-7.The Slow-Down Feature

DGW400DM-380A

Vertical, Water-Cooled

4-Cycle Diesel Engine

CAUTION: Do not operate the Generator/Welder, or any other appliance, before you

have read and understood the instructions for use.

5-8.Voltage Adjusting Dial

6.Initialization and Pre-check

6-1.Checking Engine Oil

6-2.Checking Coolant/Water

6-3.Checking Fuel

6-4.Checking Fuel, Engine Oil

6-5.Checking Battery

7.Operation

7-1.Starting

7-2.Stopping

8.Welding Operation

8-1.Selection-Welding Cable

8-2.Polarity

8-3.Connection-Welding Cable

8-4.Duty Cycle

8-5.Welding

9.Generator Operation

9-1.Output Range

9-2.Output Limitation

9-3.Operation

10.Simultaneous Use of Welding and

Generating

11.Checking and Maintenance

12.Long-term Storage

13.Troubleshooting

14.Engine Wiring Diagram

15.Generator Wiring Diagram

Table of Contents Page

the receptacle circuit only

and water Leakage

2

5

6

6

7

7

7

8

10

11

13

13

14

14

14

15

16

17

17

19

19

20

21

21

21

21

22

23

24

24

25

26

28

28

33

33

35

36

Shindaiwa Corporation

Introduction

Thank you for purchasing Shindaiwa Sound Proof Diesel Engine Generator/Welder.

z This user manual was created to ensure the safe operation of this equipment.

Therefore, the manufacturer of this equipment strongly recommends that the

user follow the instructions herein, to avoid unnecessary accidents and repairs.

z Please operate this equipment after thoroughly reviewing and understanding

the contents of this manual.

z Please attach this manual, if the equipment will be sub-leased.

z Please store this manual near the equipment for easy reference.

■Following convention will be used throughout the manual to indicate the

degree of cautions.

Danger Can cause serious injuries or death.

Caution Can cause minor injuries or damage to the equipment or other

properties.

<Caution> Other types of caution

z Even some of the items noted in『 Caution 』may lead to serious injuries.

Please read all item and follow all the safety guidelines.

- 1 -

1. Safety Guidelines

Danger : Suffocation from exhaust fume

z Exhaust fume from the engine contains many elements harmful to human. Do

not operate this equipment in poorly ventilated area, such as inside a room or in

a tunnel.

Danger : Electric Shock

z Do not touch the output terminals during operation.

z Do not insert metal objects (such as pin or wire) into plug-in receptacles.

z Do not touch wiring or electric parts inside the equipment during operation.

z Before connecting or disconnecting a load cable from output terminals, always

turn the circuit breaker to OFF position.

z Before connecting or disconnecting a welding cable from output terminals, stop

the engine, and remove the engine key.

z Before performing any equipment check or maintenance, stop the engine, and

remove the engine key. A person performing the maintenance should always

keep the key.

Danger : Burns

z Do not open the radiator cap while operating this equipment or immediately

after stopping the equipment, to avoid sustaining burns from hot vapor.

Danger : Injuries

z Close all doors and place locks during operating this equipment, to avoid

injuries by unintentionally touching cooling fan and fan belt.

Caution : Suffocation from exhaust fume

z Do not point the exhaust fume toward pedestrians or building.

Caution : Suffocation from welding fume

z Be sure to wear a fume proof mask in operation, because welding fume

contains poisonous gas and dust. Pay attention to the airflow direction and

sufficient ventilation also in order to prevent from inhaling the fume.

Caution : Injuries to eyes and skin

z Be sure to wear spark protection glass(es), long-sleeve shirts, gloves, etc. in

order to protect eyes and skin from harmful spark in welding.

z Battery fluid contains diluted sulfuric acid. Avoid contact with eyes, skin or on

clothing. If the acid comes in contact, especially with eyes, flush with a lot of

water, and contact your physician immediately.

Caution : Electric shock

z Do not flush water onto the equipment nor operate it in the rain.

Caution : Explosion

z Do not use the equipment or charge the battery, in the case the battery fluid

level is lower than the LOWER level.

z Battery may emit some combustible gas, so keep it away from fire and sparks.

- 2 -

Caution : Fire

z The equipment uses Diesel Oil as a fuel. When refueling, always stop the

engine and keep away from fire. Moreover, always wait until the engine cools

down before refueling.

z Always wipe any drip of Diesel fuel or lubrication oil. Do not use this equipment

when a leak is found. Repair the equipment before use.

z Temperature around muffler and exhaust can get extremely high. Keep any

inflammable items (such as fuel, gas, paint, etc.) away from the equipment.

z Keep any inflammable items and easily burning items away from the place in

welding, because welding splashes spatters.

z Always operate this equipment on flat surface and, at least 1 meter away from

any objects (wall, box, etc.).

z Do not connect AC output to any indoor wiring.

z Always wait until the equipment cools down, before placing any covering

materials for storage.

Caution : Burns

z Do not touch the engine and muffler during operation and immediately after

stopping the equipment, for the temperature can reach extremely high.

z When checking engine oil or changing oil, always stop the engine, and wait until

the engine cools down. If you open either the oil gauge or the oil plug during

operation, hot oil may cause some injury.

z Be sure to wear leather gloves, apron, shoe covers, eye protection glass(es)

(mask), safety shoes, safety cap, and long sleeve shirts, because welding

splashes spatters.

Caution : Injuries

z When lifting the equipment, always use a lift hook. Do not lift a handle, for it

may cause equipment to drop due to handle breaking off.

z Always place the equipment on a flat and stable surface, to keep the

equipment from sliding. Be sure to lock the wheels for the wheeled models.

z When starting the engine, turn off the connected equipment and set the circuit

breaker to OFF position.

z Do not move the equipment during operation.

z When performing equipment check and maintenance, always stop the engine.

z Do not operate the equipment, if the equipment is being modified or if the parts

are removed.

- 3 -

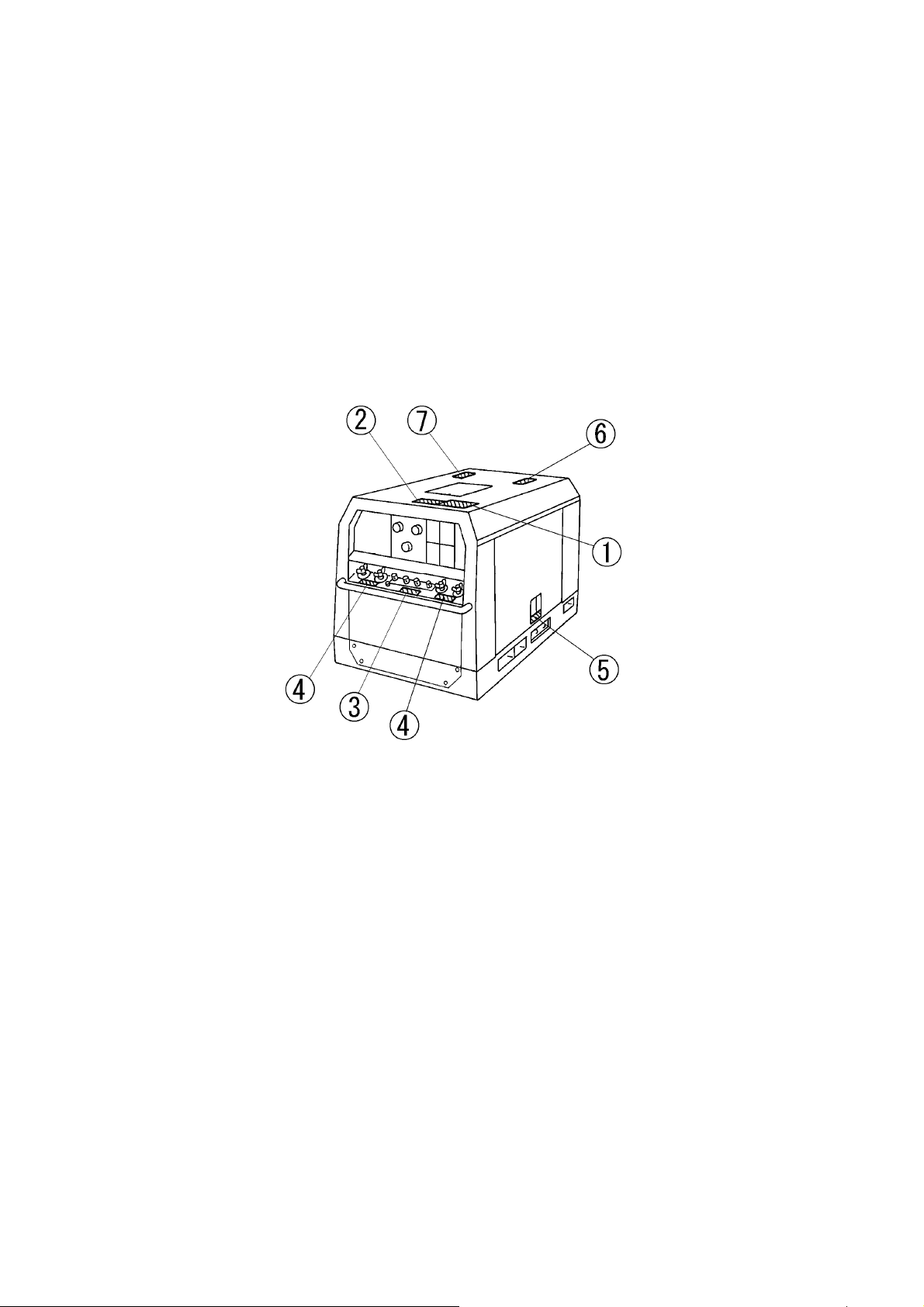

Location of Warning labels

When the warning labels become unreadable or damaged, place new labels on

the appropriate locations, as specified in the following figure.

When ordering the label, use the following part numbers.

① Suffocation from exhaust fume (No. 19402-00194)

② Suffocation from welding fume (No. 19402-00195)

③ Electric shock (No. 19402-00192)

④ Electric shock (No. 19402-00193)

⑤ Injuries (No. 19402-00199)

⑥ Burns (No. 19402-00201)

⑦ Burns (No. 19402-00200)

- 4 -

2. Specifications

Model DGW400DM

Generating Method Rotating Field

Rated Current (A) 370 / 390

Rated Voltage (V) 34.8 / 35.6

Duty Cycle (%) 60

Rated Speed (min

No Load Voltage (A) MAX 85

Welding Generator

Rated Frequency (Hz) 50 / 60

Rated Speed (min

Eco

Output Change

-1

) 3000 / 3600

Current Adj. Range (A) 90 – 380 / 110 - 400 Single

Welding Rod (Ф) 2.6 - 8.0

Current Adj. Range (A) 50 – 190 / 55 - 210 Dual

Welding Rod (Ф) 2.0 - 4.0

Current Adj. Range (A) 40 - 240

Welding Rod (Ф) 2.0 - 5.0

-1

) 3000 / 3600

Phase 1-Phase 3-Phase

Rated Voltage (V)

Power Factor 1.0 0.8

AC Generator

Rated Output (kVA) 3 12 15

Rating Continuous

Model Kubota D1005

Type Vertical, Water-Cooled 4-Cycle Diesel Engine

Displacement (L) 1.001

Rated Output (kW/min-1) 16.5 / 3000 or 19.1 / 3600

Fuel ASTM No.2 Diesel Fuel or Equivalent

Lubricant Oil API Class CC or Higher

Engine

Lubrication Oil Volume (L) 5.1 (Effective 1.4)

Cooling Water Volume (L) 4.3 (Sub Tank Capacity 0.6 L included)

Starting Method Starter Motor

Battery 55B24L

Fuel Tank Capacity (L)

220-240

380-415 380-415

37

Length (mm)

Width (mm)

Height (mm)

Dimension

Dry Weight (kg)

- 5 -

1519

700

760

469

3. Usage

z Arc Welding

z Electric Tools and Home Appliances

z Power Source for lights

Caution : Damage to the equipment or other properties

z The equipment is designed for the above purposes only. Do not use it for the other

purpose. When it will be used for the equipment with the microcomputers control or

for the ultra-precision devices, the load may be malfunctioned.

z Whenever connecting to use medical equipment or appliances, be sure to consult

with the medical equipment company, doctor or hospital personnel.

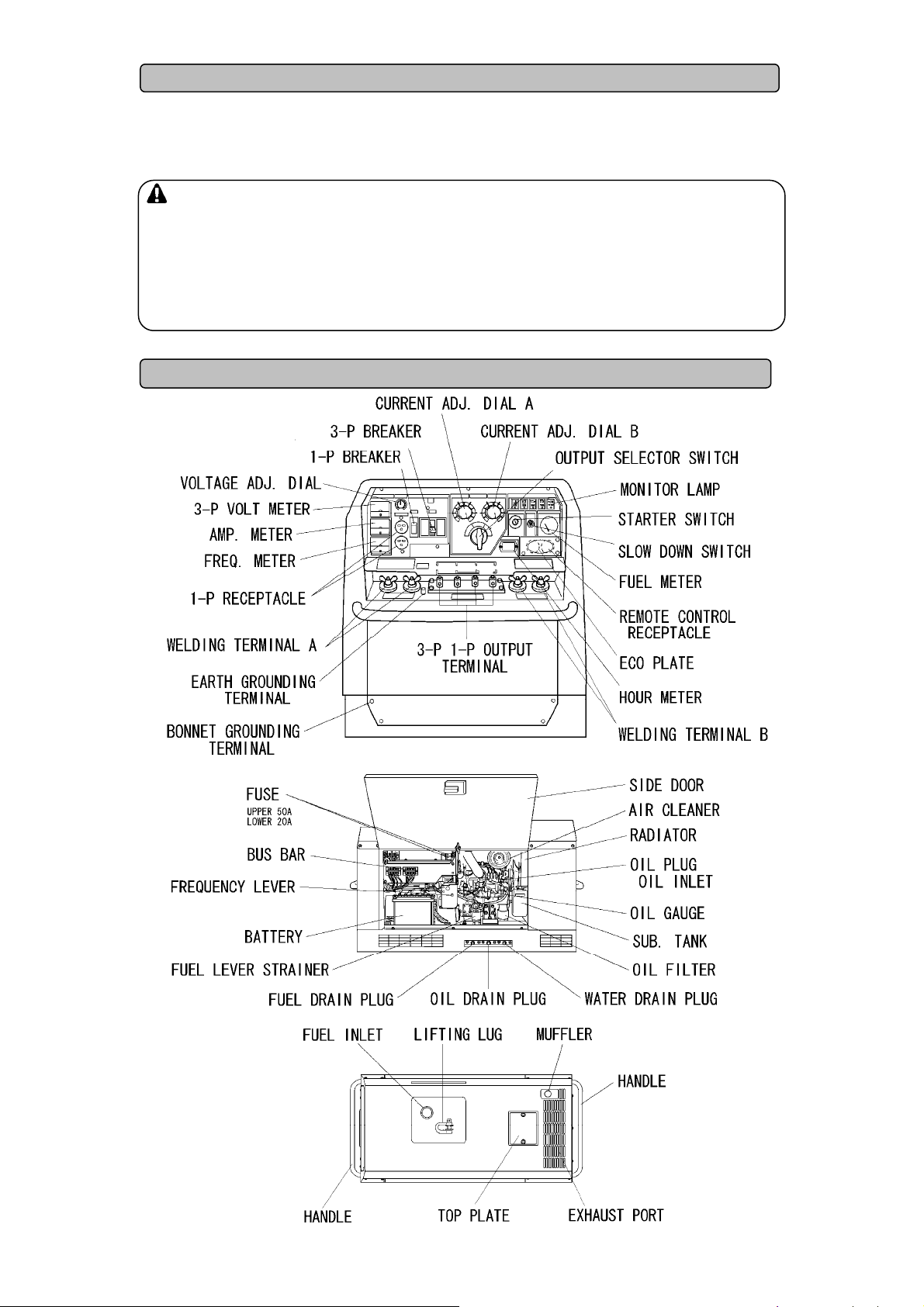

4. Parts

- 6 -

5. Equipment

5-1 Eco Welding

The equipment is incorporated in Eco welding features that are aimed at performing

the lower noise, the lower fuel consumption and the lower gas emission than

conventional models.

When you turn the selector switch to Eco, you will be able to weld with Max.

5.0mmφwelding rod at the slow down speed.

<Caution>

z When welding is performed, do not turn the output selector switch, which causes

the burnout of the switch.

z Eco is designed for welding only. The 3-phase circuit breaker trips and

simultaneously the outputs of welding and generating would fall down and you will

not do anything when Eco is used for AC power supply.

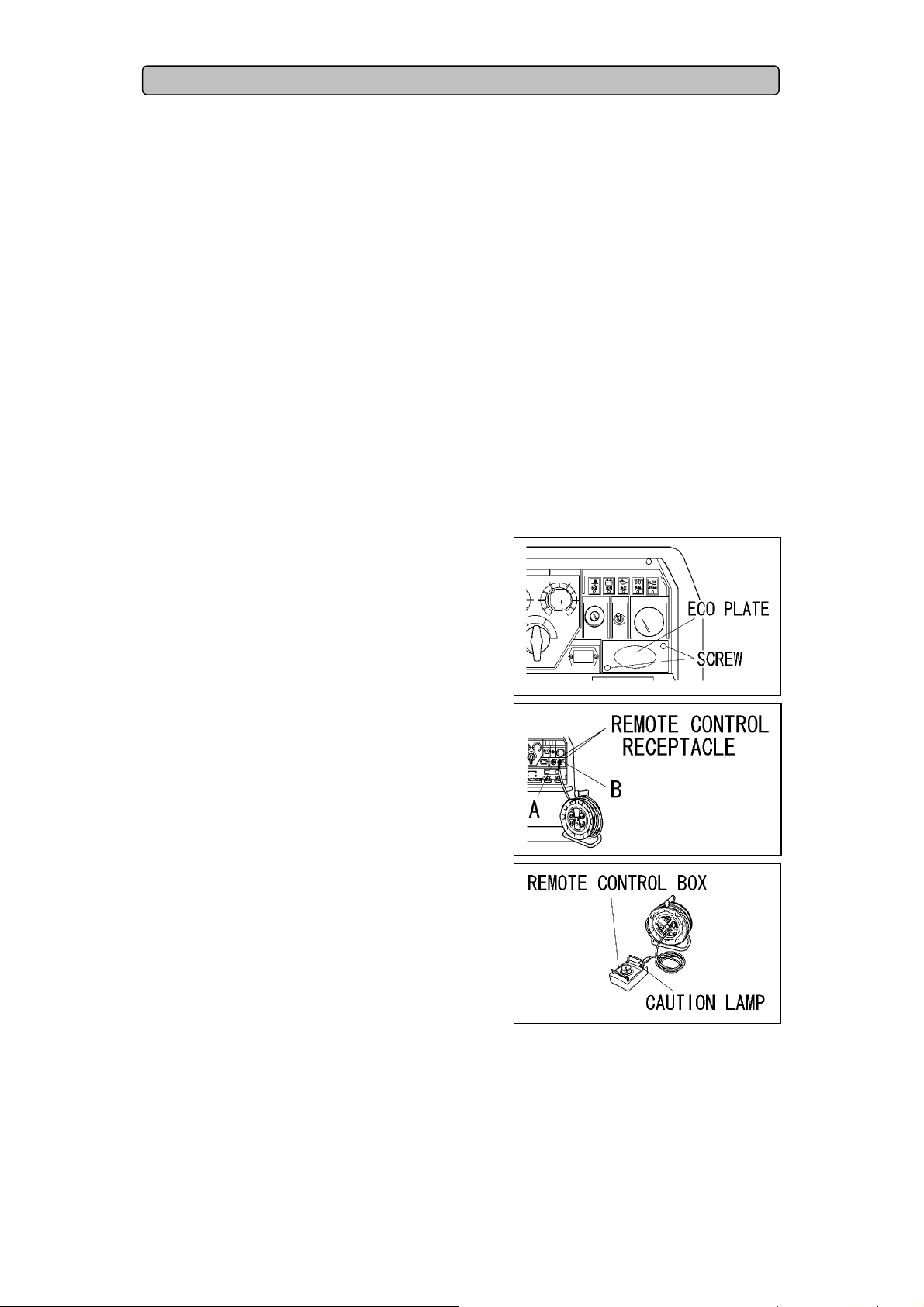

5-2 Remote Control (Option)

Using the remote control box, the remote control to adjust the welding current

makes it possible.

Remote Control Box Connection

Remove “Eco” plate. (M4 Screw 2 pieces)

Insert the plug of the extension cable reel

into A side or B side receptacle

Insert the plug of the remote control box

into the receptacle of the extension cable

reel.

<Caution>

z Never connect the plug of the remote control box to the receptacle of the

extension cable reel when the reel is connected to 1-P receptacle.

z Never connect the other loads additionally than the remote control box.

z In the case the extension cable reel is installing the breaker, use the equipment to

have turned the breaker ON.

- 7 -

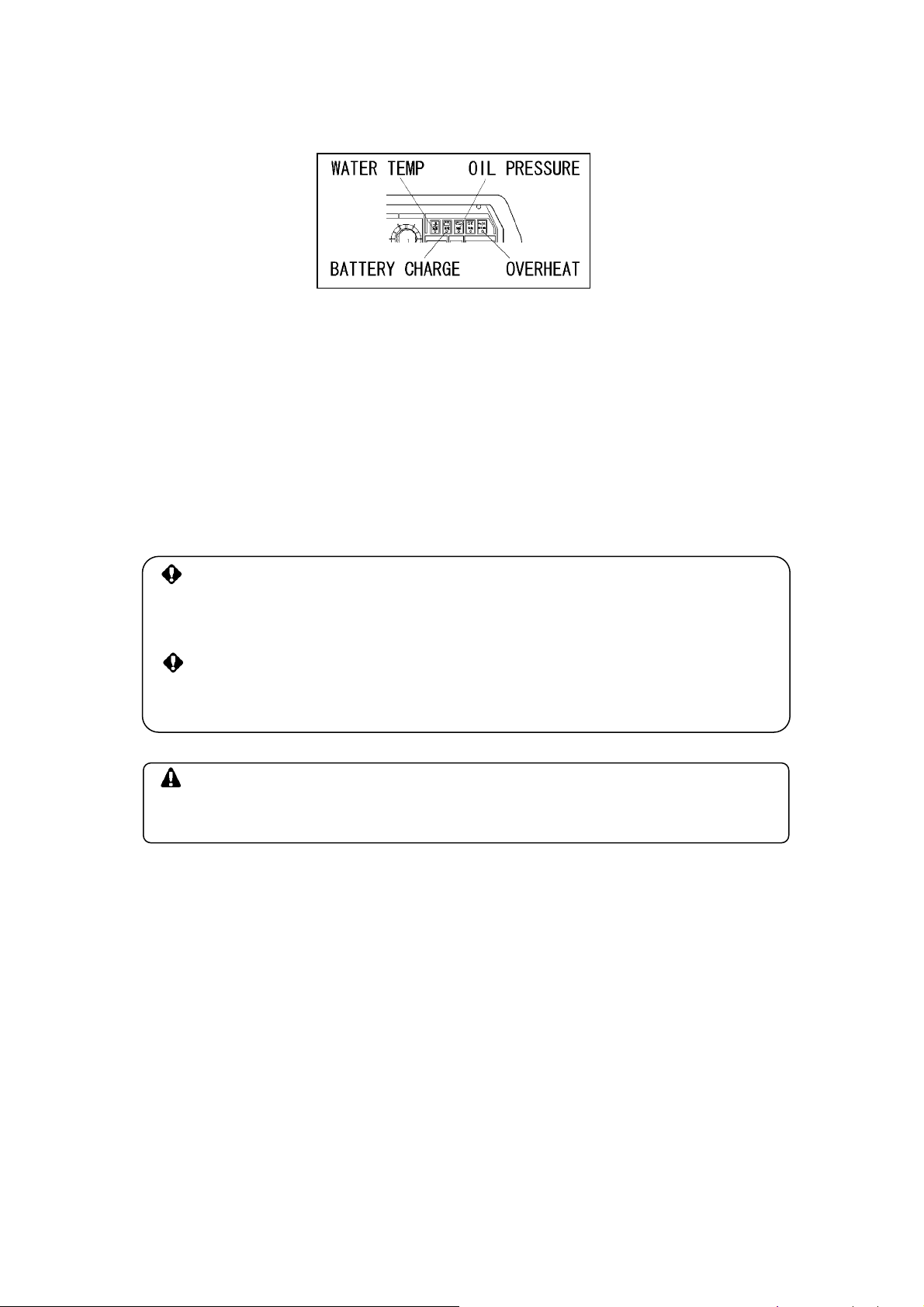

5-3 Monitor Lamp

The equipment is incorporated in monitoring function of WATER TEMP, BATTERY

CHARGING, OIL PRESSURE, Hz/OVERHEAT.

Under normal condition, when the starter switch changes from STOP to RUN, all the

lamps of BATTERY CHARGING, OIL PRESSURE and Hz/OVERHEAT turn ON.

When the engine starts, all the lamps turn OFF. When abnormality is detected on

other than Hz/OVERHEAT, the corresponding monitor lamp will flash, and the engine

automatically shutoff.

When the automatic shutoff is engaged, turn the starter switch to STOP position

once, and then restart the engine. In the event the automatic shutoff is engaged next

time, check which lamp turns ON or OFF and point out where is the abnormality.

(1) Coolant/Water Temperature Monitor Lamp

Danger: Injuries

z Close all doors and place during operating this equipment, to avoid injuries by

unintentionally touching cooling fan and fan belt.

Danger: Burns

z Do not open the radiator cap while operating this equipment or immediately

after stopping the equipment, to avoid sustaining burns from hot vapor.

Caution: Burns

z Do not touch the engine and muffler during operation and immediately after

stopping the equipment, for the temperature can reach extremely high.

When the water temperature rises abnormally, the coolant/water temperature

monitor lamp will flash, and the automatic shutoff will be engaged.

When this occurs, check the coolant/water reservoir tank, and replenish if needed.

(Refer to No. 6-2 Checking coolant/water temperature.)

If the water level is normal, there may be a possibility of overloading. Always use the

equipment within the rated duty cycle and output power.

(2) Battery Charge Monitor Lamp

When the battery turns unable to be charged during operation, the battery

charge monitor lamp will flash and the automatic shutoff will be engaged.

In the event this occurs, consult with the authorized distributor or our ngineering

section.

- 8 -

<Caution>

z The battery charge monitor cannot detect the degradation of the battery nor the

battery fluid level. Check the battery fluid level periodically. (Refer to No. 6-5

Checking Battery)

(3) Oil Pressure Monitor Lamp

Danger : Injuries

z Close all doors and place locks during operating this equipment, to avoid

injuries by unintentionally touching cooling fan and fan belt.

Caution : Burns

z Do not touch the engine and muffler during operation and immediately after

stopping the equipment, for the temperature can reach extremely high.

z When checking engine oil, always stop the engine, and wait until the engine

cools down. If you open either the oil gauge or the oil filter cap during operation,

hot oil may cause some injury.

When the engine oil pressure drops during operation, the oil pressure monitor lamp will

flash, and the automatic shutoff will be engaged.

When this occurs, check the engine oil level, and replenish to the maximum level if

needed.

<Caution>

z The engine oil pressure monitor cannot detect the degradation of engine

oil itself. Please check the engine oil periodically, and change if needed.

(Refer to No. 11. Maintenance.)

z Check the fuse next, when the abnormality, other than WATER TEMP,

BATTERY CHARGED OR OIL PRESSURE is detected. If the fuse is burned

out, consult with our authorized distributor or our engineering section, because

there may be an abnormality of electric/electronic parts or wiring and repairing

may be required.

(4) Hz/Overheat Monitor Lamp

z Unless the frequency selector lever position

and the bus bars in the equipment are

correspondent to each other, Hz/OVERHEAT

monitor lamp will turn ON.

z Hz/OVERHEAT monitor lamp may flash

in the case the machine is used excessively

over the duty cycle.

<Caution>

z When Hz/OVERHEAT monitor turns ON, as the output power reduces

remarkably, the AC output power can hardly be used.

z There may be a case that the lamp will not flash, depending on the welding

type or the weather condition.

- 9 -

FLASH

OVERHEAT

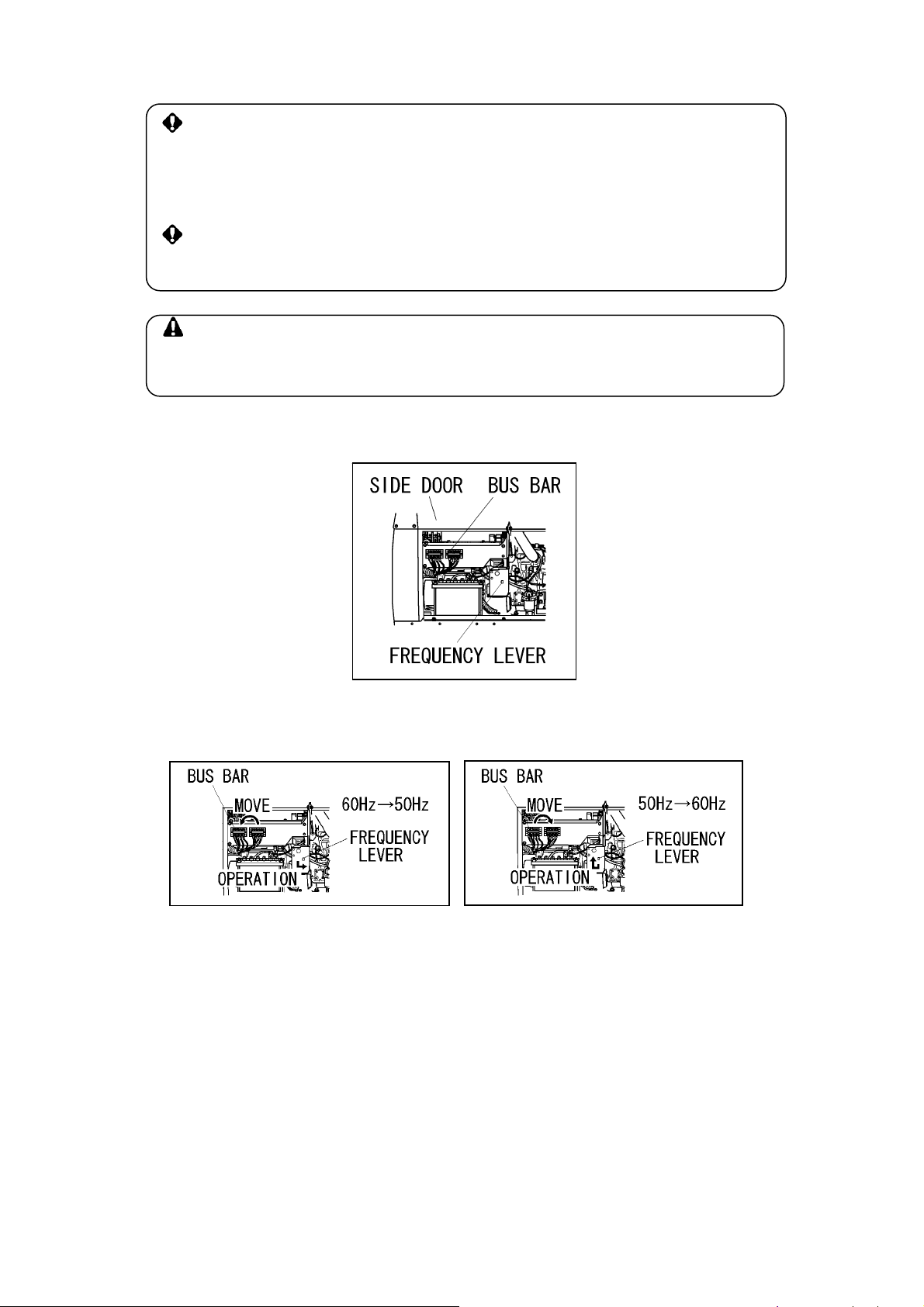

5-4 Frequency Change

Danger : Injuries

z Frequency change should be done, after stopping the engine. Moreover, close

doors and place locks during operating this equipment, to avoid injuries by

unintentionally touching cooling fan and fan belt.

Danger: Electric Shock

z Never touch the frequency change bus bar during operation.

Caution: Burns

z Do not touch the engine and muffler during operation and immediately after

stopping the equipment, for the temperature can reach extremely high.

The equipment can be used to 50Hz and 60Hz. Select the frequency according to the

load.

Stop the engine.

Open the side door.

Turn the selector switch and the metal bus bars to the other frequency as per the

drawing.

Start the engine. (Refer to 7-1. Starting)

Turn the slow-down switch to OFF. (Refer to 5-7. Slow-Down)

Check the frequency in the frequency meter in the control panel.

- 10 -

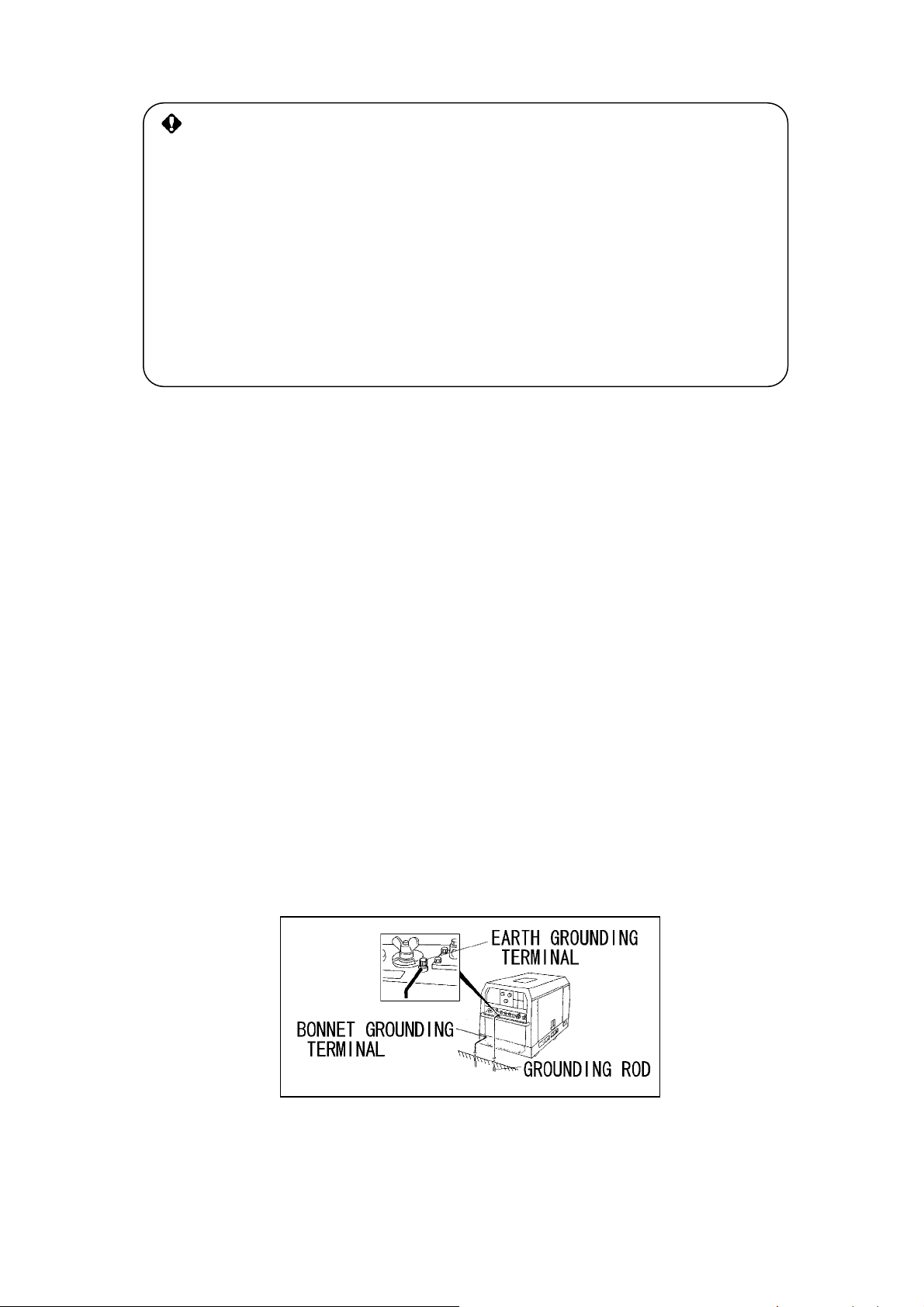

5-5 Earth Leakage Relay

Danger : Electric Shock

z Ground every grounding terminal to the earth as set out in the manual.

If even one of all is unconnected by mistake or accident, it will be much more

dangerous for human body than the NO RELAY case, because leaking current

inevitably goes through the body.

z Even though all the terminals of the loads have been grounded to the earth, the

earth grounding terminal and the bonnet (canopy) grounding terminal should be

grounded to the earth.

z Grounding should be made after the engine is stopped.

z Whenever the earth leakage relay has activated, you should always repair the

leaking place first of all.

The equipment is provided with the earth leakage relay in the 3-Phase Circuit Breaker

to detect any leakage arisen due to the troubles as insulation failure of the load while

the generator is running. And cutting off the circuit for protection against any accident

such as electrical shock resulting from the trouble.

<Caution>

z The earth leakage relays (3-Phase 380V and 1-Phase 220V) activate the AC

to the terminals but not to receptacles.

z The 3-phase circuit breaker trips to protect the loads, whenever AC power is

used where the selector switch is in the Eco position.

The specifications of the earth leakage relay:

z Rated Sensitive Current: 30mA (or below)

(Grounding resistance: 500Ω or below)

z Sensitive time: Within 0.1 second

(1) Grounding Work

The qualified electrician should perform the grounding work of the following 3 points

(500Ω or below).

z The earth grounding terminal in the output terminals

z The Outer Bonnet of the equipment (bonnet grounding terminal)

z The Outer Bonnet of the load

<Caution>

z In the event you cannot ground the generator to the earth, consult with the

authorized distributor or our engineering section.

- 11 -

Loading...

Loading...