Page 1

CERTIFIED

OWNER’S MANUAL

GENERATOR / WELDER

DGW310DMC

DGW310MC

Sound Proof

Vertical, Water-Cooled

4-Cycle Diesel Engine

Do not operate the generator/

welder, or any other appliance,

before you have read and

understand the instructions for use

and keep near for readily use

Caution

Table of Contents

1. Safety Guidelines ···················································2

2. Specifications ·························································6

3. Use ···········································································7

4. Parts ········································································7

5. Incorporated ···························································10

5-1.Eco Welding 10

5-2.Display 10

5-3.Frequency Change 10

5-4.Monitor Lamp

5-5.Remote Control (Option) 12

5-6.Earth Leakage Relay/Grounding 13

5-7.Slow-Down Feature 15

6. Initialization & Pre-check ·······································16

6-1.Checking Engine Oil 16

6-2.Checking Coolant/Water 17

6-3.Checking Fuel 18

6-4.Leakage Check for the above 18

6-5.Checking Battery 19

7. Operation ································································20

7-1.Start 20

7-2.Stop 22

8. Welding Operation ··················································22

8-1.Selection – Welding Cable 22

8-2.Polarity 23

8-3.Connection – Welding Cable 23

8-4.Welding 24

9

....

Generator Operation ·············································26

9.1.Output Range 26

9-2.Output Limitation 27

9-3.Operation 28

10

....

Simultaneous Use – Weld & Generate ··············30

11

....

Checking & Maintenance ····································31

12

....

Long-term Storage ··············································36

13

....

Trouble Shooting ················································37

14. Warranty Sheet (Type B) ········································39

10

Page 2

Page 3

Introduction

Thank yo u fo r purc h a s ing Shi n d aiwa S o u nd Pr o of D i e s el En g i n e Ge n e r ator.

●This user m a nual wa s prepar e d to e ns u re t h e safe o p eratio n of t h i s equipm e nt. Ther e f ore,

the m a nufac t u r er of t h is eq u i p m ent s t rongl y r e com m ends t h a t the u s er fol l o w the

instr u c tions h e rein , t o avoid u n nece s s ary ac c idents a nd repa i r s .

● P l e ase operat e this equipm e n t a f t e r t h o r oughl y r evie w i n g a n d u n d erstan d i n g t h e co n t ents of

this m a nual.

● Plea s e attac h this m a n u al, i f the e q u ipmen t w i l l be s u b-lea s ed.

● Plea s e st or e this m a n ual n e a r the e quipm e n t for e a s y ref e r ence.

● F ollowin g c o n vers i o n wi l l be us e d t h roug h o ut t h e m anual to indic a t e t h e d egree of cauti o n s.

<<<<

●

Even s o m e of t he it em s note d in

Please read every item and follow all the safety guidelines.

Dang e r : Can c ause s e r i ous i n j urie s o r death

Caut i o n : Ca n c ause m i nor in j uries o r dama g e to t h e equip m ent or o t her

prop e r t ies.

Caution

>>>>

: Other types of caution

『

Caution』may lead to serious injuries.

1

Page 4

1. Safety Guidelines

1. Safety Guidelines1. Safety Guidelines

1. Safety Guidelines

Danger: Suffocation from exhaust fume

● Exhaust fume from the engine contains many elements harmful to human.

Do not operate this equipment in poorly ventilated areas, such as inside a

room or in a tunnel.

Danger: Electric Shock

● Do not touch the output terminals during operation

● Do not insert metal objects (such as pin or wire) into receptacle

● Do not touch wires or electric parts inside the equipment during operation.

● Before connecting or disconnecting a load cable from output terminals, always turn the circuit

breaker to OFF position.

● Before connecting or disconnecting a load cable from output terminals, always turn the circuit

breaker to OFF position.

● Before connection or disconnection a welding cable from DC output terminal, stop the engine

and remove the engine key.

● Before performing any equipment check or maintenance, stop the engine and remove the

engine key. A maintenance person should always keep the key.

Danger: Burns

● Do not open the radiator cap while operating this equipment or immediately after stopping the

equipment, to avoid sustaining burns from hot vapor.

Danger: Injuries

● Close all doors and place locks during operating this equipment, to avoid injuries by

unintentional touching a cooling fan and fan belt.

Caution: Suffocation from exhaust fume

● Do not point the exhaust fume toward pedestrians or building.

Caution: Suffocation from exhaust fume

● Be sure to wear a fume proof mask in operation, because welding fume contains poisonous gas

and dust. Pay attention to the airflow direction and ventilation also in order to prevent from

inhaling the fume.

2

Page 5

Caution: Injuries to eye and skin

● Be sure to wear spark protection glass (es), long-sleeve shirts, gloves, etc. in order to protect

eyes and skin from harmful spark in welding.

● Battery fluid contains diluted sulfuric acid. Avoid contact with eyes skin or on clothing.

If the acid comes in contact, especially with eyes, flush water with a lot of water and contact a

physician immediately.

Caution: Electric Shock

● Do not flush water onto the equipment nor operate it in the rain.

Caution: Explosion

● Do not use the equipment or charge the battery, in the case the battery fluid level is lower than

the LOWER level.

● Battery may emit some combustible gas, so keep it away from fire and sparks.

Caution: Fire

●The equipment run on Diesel Oil. When refueling, always stop the engine and keep away from

fire. Moreover, always wait until the engine cools down before refueling.

● Always wire any drip of Diesel fuel or lubrication oil. Do not use this equipment when any leak is

found. Repair it before use.

●Tem per at u r e a r o u n d m uf f le r a nd e x h a us t c an g e t ex tr e m e l y h i g h . Ke e p an y

in f l a mm ab l e it e m s ( su ch as f ue l , ga s , pa i n t , et c . ) a wa y f ro m t h e e qu ipm en t.

● Always operate this equipment on flat surface, at least 1 meter away from any objects (wall, box,

etc.)

● Always operate this equipment on flat surface and at least

1 meter away from any objects (wall, box, etc.)

● Do not connect AC output to any indoor wiring.

● A l wa ys w a i t u nt i l t he eq u i p m e nt c o o ls do wn , b e f o re p l a ci ng an y c o v e ri n g

ma ter ia l f or s t o r ag e.

3

Page 6

Caution: Burns

● Do not touch the engine and muffler during operation and immediately after stopping the equipment,

for the temperature can reach extremely high.

● When checking engine oil or changing oil, always stop the engine, and wait until the engine cools

down. If you open either the oil gauge or the oil plug during operation, hot oil may cause some

injuries.

● Be sure to wear leather gloves, apron, shoe covers, eye protection glass (es) (mask), safety shoes,

and safety cap and long sleeve shirts, because welding splashes spatters.

Caution: Injuries

● When lifting the equipment, always use a lift hook. Do not lift the handle, for it may cause the

equipment to drop due to handle breaking off.

● When carrying the equipment by truck, fix it strongly to keep the equipment from sliding as roping

two points of handle.

● Always place the equipment on a flat and stable surface, to keep it from sliding. Be sure to lock the

wheels for with wheel type.

● When starting the engine, turn off the connected equipment

● And set the circuit breaker to『OFF』position.

● Do not move the equipment during operation.

● When performing equipment check and maintenance, always stop the engine.

● Do not operate the equipment if the equipment are modified or parts are removed

4

Page 7

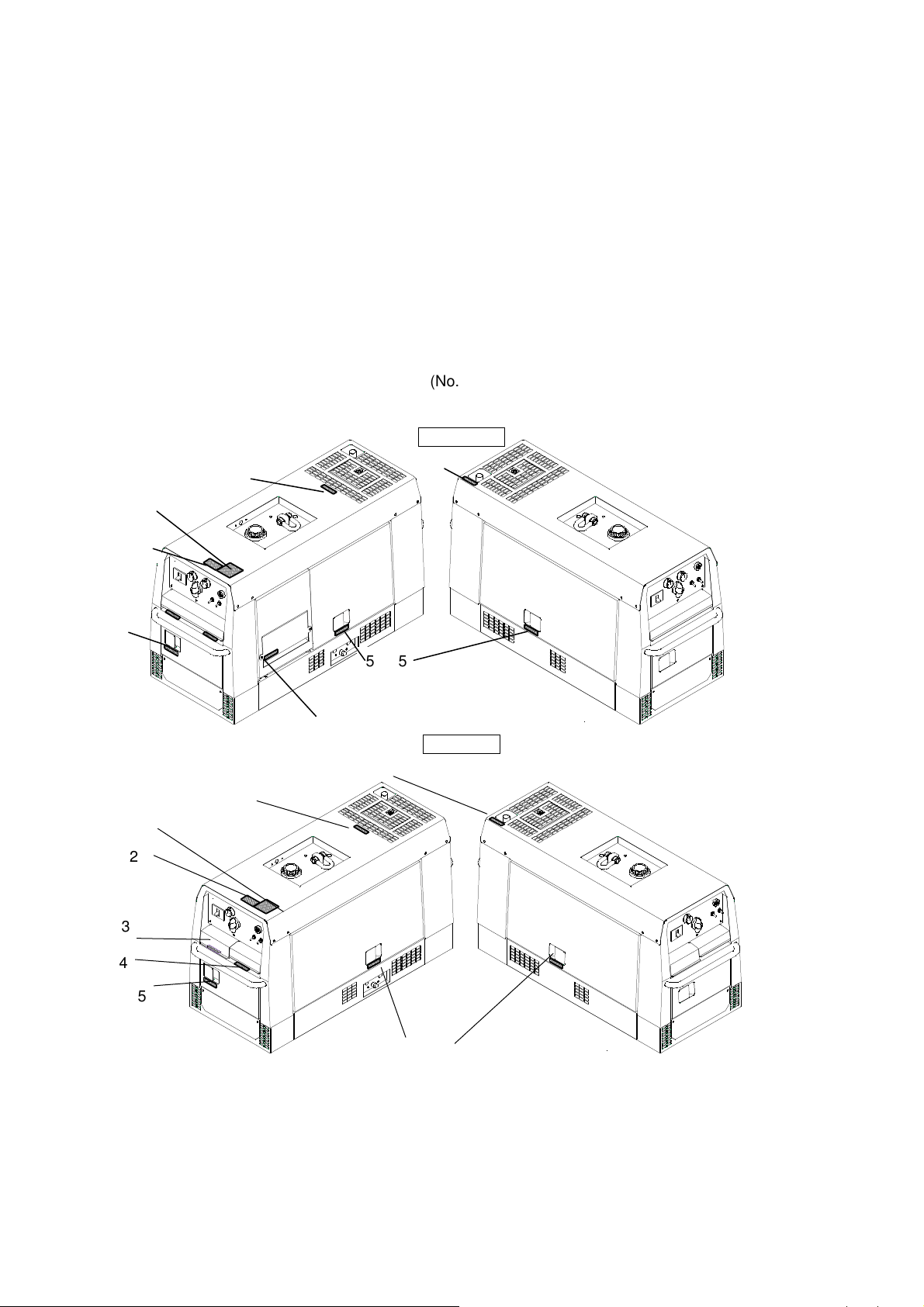

■Location of warning labels

When any warning label becomes unreadable or damaged, place a new label on the appropriate location.

When ordering a new label, use the following part number.

1. Suffocation from exhaust fume (No.19402-00106)

2. Suffocation from welding fume (No.19402-00107)

3. Electric Shock (No.19402-00102)

4. Electric Shock

5. Injuries

6. Burns

7. Burns

1

2

4

6

(No.19402-00103)

(No.19402-00109)

(No.19402-00108)

(No.19402-00112)

DGW310DMC

7

5 5

3

DGW310MC

7

2

3

4

5

1

6

5 5

5

Page 8

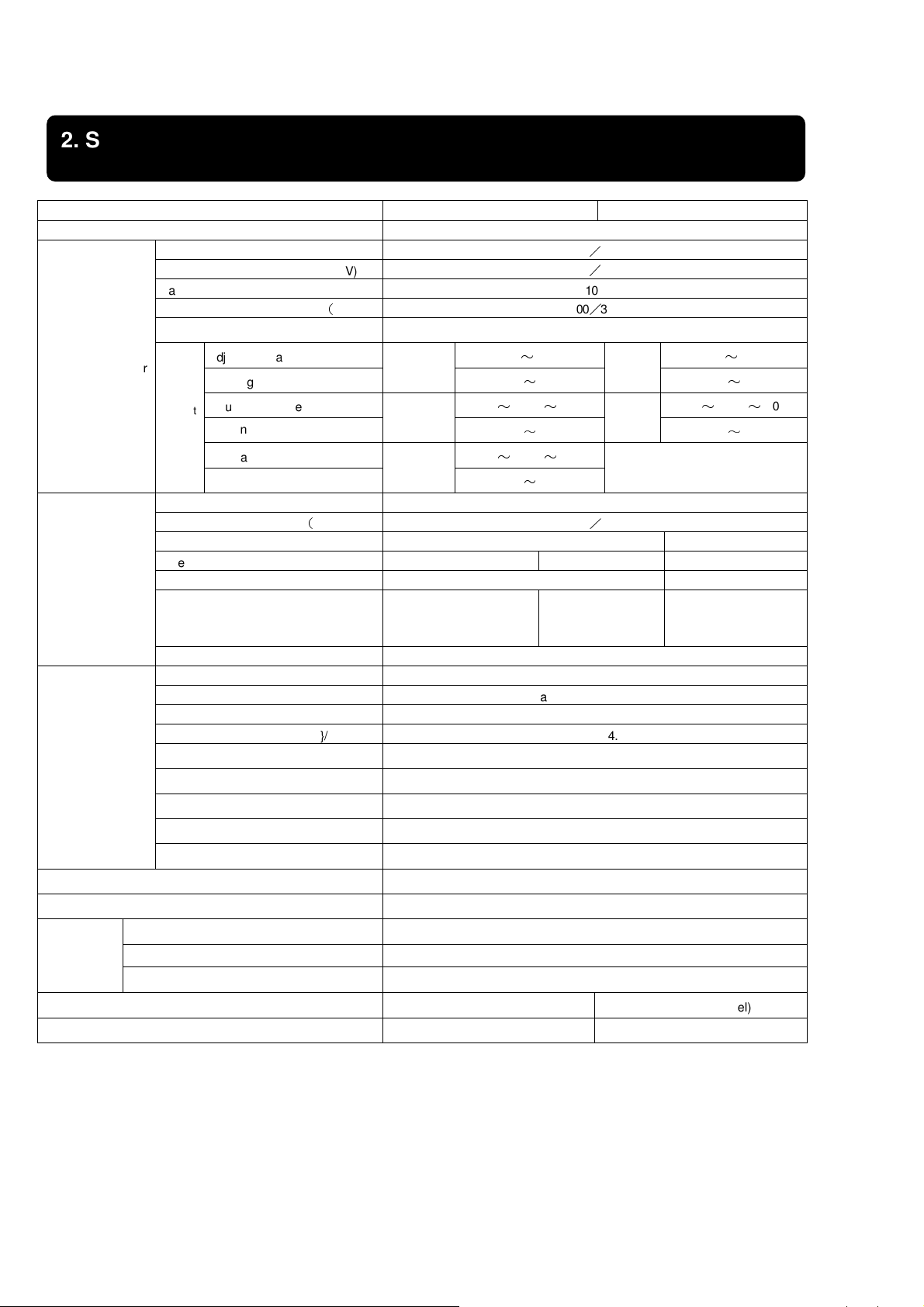

2. Specifications

Model DGW310DMC DGW310MC

Generating Method Rotating Field

Rated Current

Rated Load Voltage

Rated Duty Cycle

Rated Speed

No Load Voltage

Welding generator

Output

change

Rated Frequency (Hz) 50/60

Rated Speed (min-1) 3000/3600

Phase 1-Phase 3-Phase

Rated Voltage (V) 100/110 200/220 200/220

AC Generator

Engine

Battery

Fuel Tank Capacity (L)

Dimension

Dry Weight

Full Weight

Power Factor 1.0 0.8

Rated Output (kVA)

Rate Continuous

Model Kubota D722

Method Vertical In-lined Water Cooled 3 Cylinders Diesel Engine

Displacement

Rated Output

Fuel Diesel Fuel No.JIS2

Lubricant API Class CD or better

Lubricant Volume (L) 3.8(effective1.4)

Coolant Volume (L) 3.0(including sub tank 0.6)

Starting Method Starter Motor

Length (mm)

Width (mm)

Height (mm)

Adjustable Range (A)

Welding Rod (φ)

Adjustable Range (A)

Welding Rod (φ)

Adjustable Range (A)

Welding Rod (φ)

(kg)

(kg)

(A)

(V)

(%) 100

(

min-1) 3000/3600

(V)

Eco

Single

Dual

6

Receptacle1.5kVA×2 and

output terminal

(L) 0.719

(kW{PS}/ min-1) 11.7{15.9}/3000 14.0{19.0}/3600

338 (348 w/wheel) 333 (343 w/wheel)

382 (392 w/wheel) 377 (387 w/wheel)

30~160 30~160

2.0~4.0

70~280/85~310 35~280/45~310

2.6~6.0

35~150/45~160

2.0~4.0

1410 (1280 Canopy Length)

260/280

30.4/31.2

MAX 85

Eco

Normal

8

(Output Total)

46B24L

37

566

760 (870 with wheel)

2.0~4.0

2.0~6.0

9.9

6

Page 9

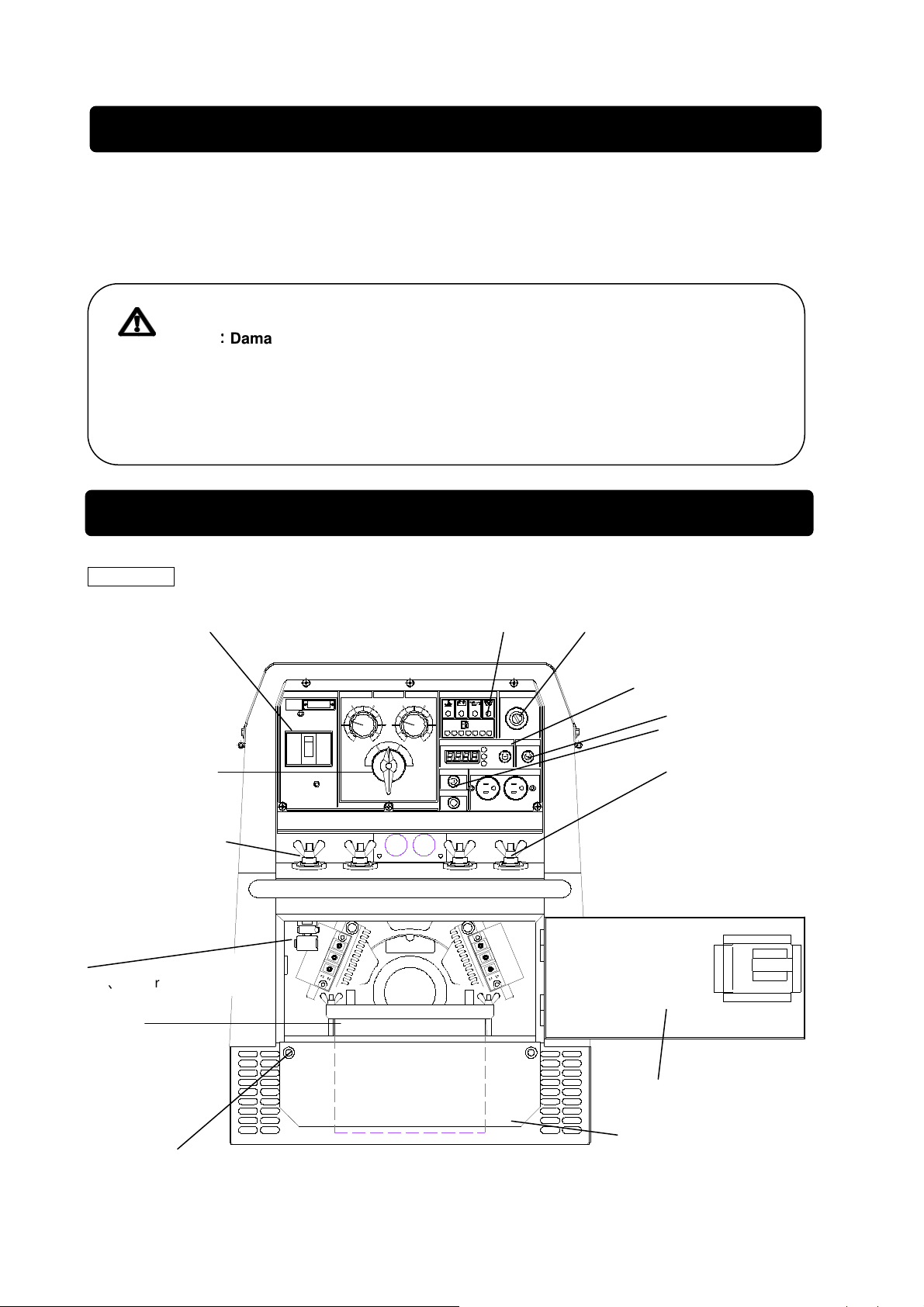

3. Use

● Arc Welding

● Electric Tools and Home Appliances

● Power Supply to lights

Caution

::::

Damage to the property and secondary damage

●Do not use other than the above purposes

●Never use it without consulting with medical equipment

obtaining confirmation in Hospital.

4. Parts

manufacturer,

doctor, hospital and

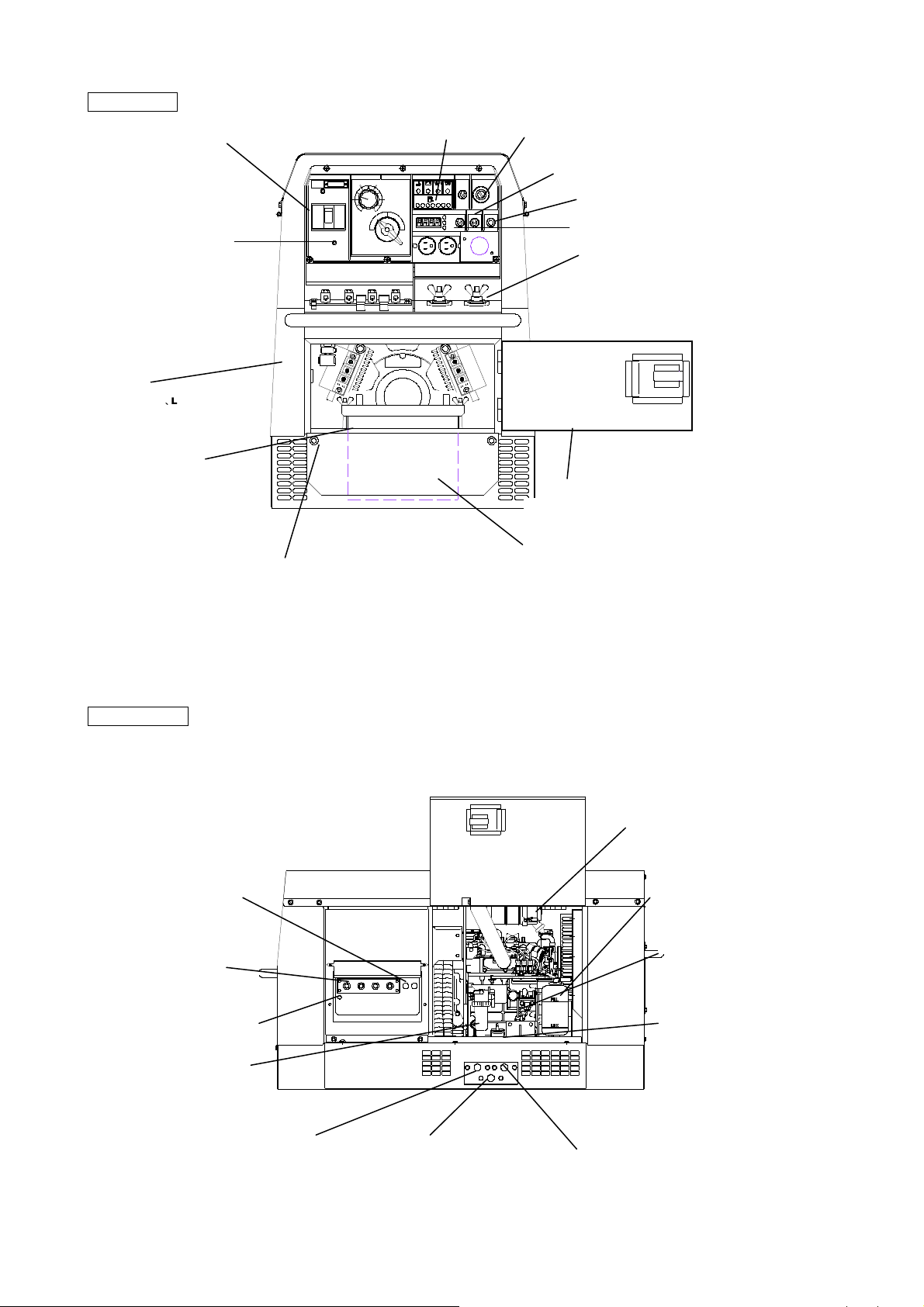

DGW310DMC

Breaker

Output Change SW

Welding Terminal A

Fuse

(Upper10A、Lower 50A)

Battery

Display

Starter Switch

Display Change SW

Slow Down SW

Frequency Change SW

Welding Terminal B

Front Door

Grounding Terminal

7

Under Plate

Page 10

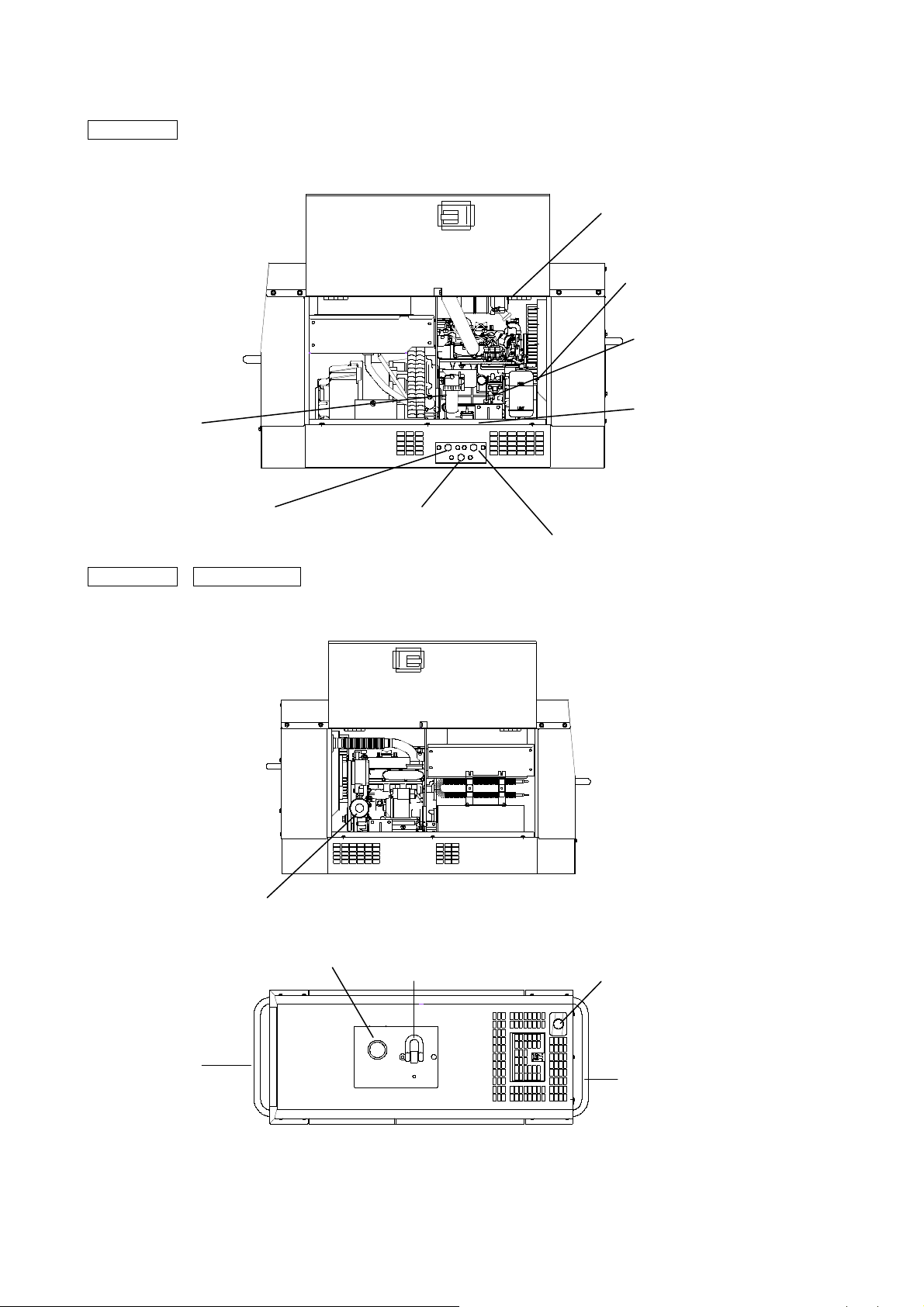

DGW310MC

Breaker

Starter Switch

Output Change SW

Slow Down SW

D

isplay Change SW

Display

Frequency Change SW

Welding Terminal

Battery

Groun

ding Terminal

Front Door

Under Plate

3P Output Terminal

Fuse(Upper10A、Lower 50A)

DGW310DMC

AC 1-P 100V output

AC 3-P 200V out

ELCB grounding terminal

Fuel lever /Strainer

Air Cleaner

Sub tank

Oil gauge

Oil inlet

Fuel drain plug Oil drain plug

Water drain plug

8

Page 11

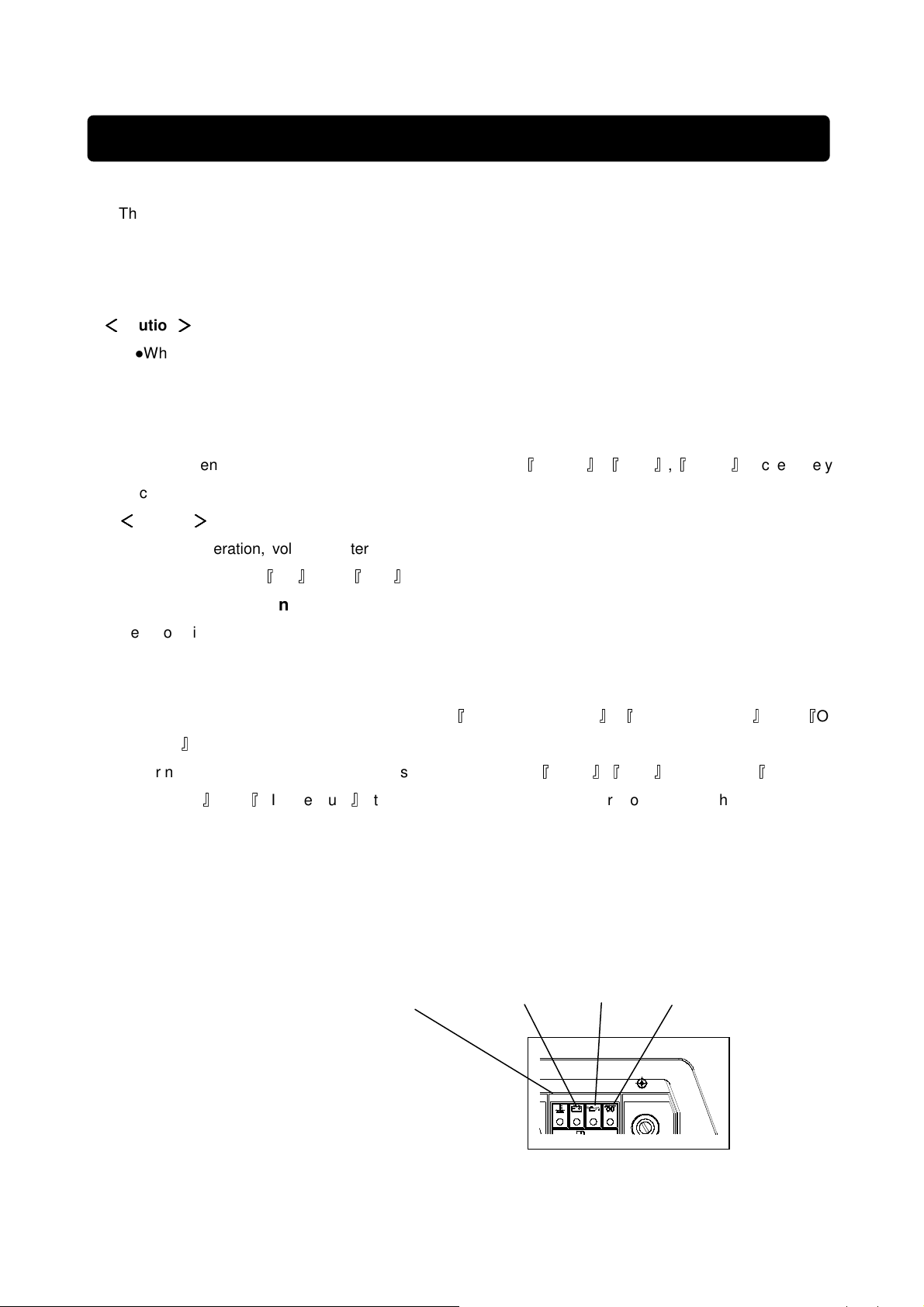

DGW310MC

Fuel lever /Strainer

Fuel drain plug Oil drain plug

DGW310MC DGW310DMC

Air Cleaner

Sub tank

Oil gauge

Oil inlet

Water drain plug

Oil filter

Fuel inlet

Lift hook

Exhaust gas outlet

Handle

Handle

9

Page 12

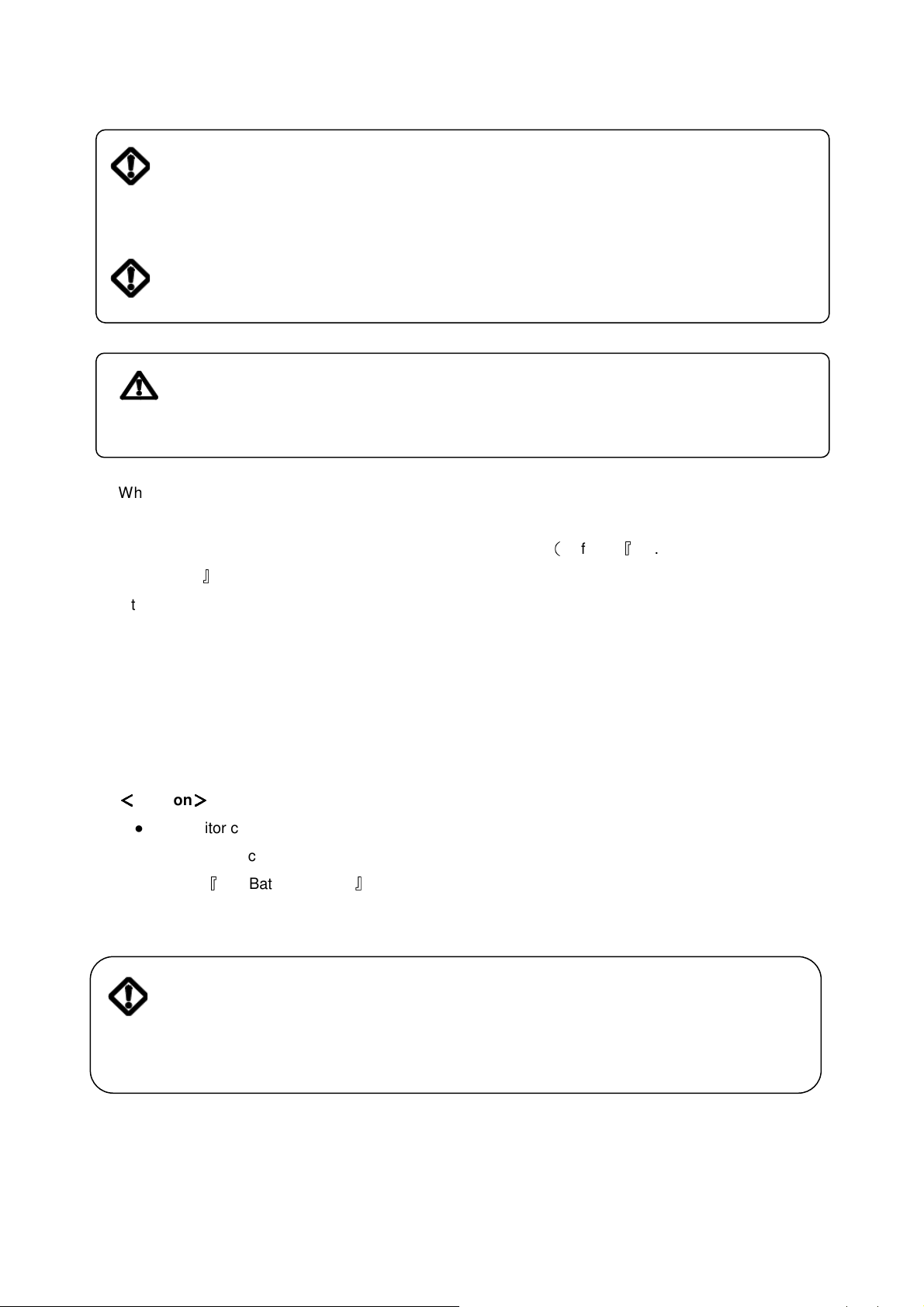

Water Temp

Charge

Oil Pres

Preheat

5. Incorporated

5-1. Eco Welding

The equipment is incorporated in Eco Welding Feature that is aiming at performing

The low noise, the lower fuel consumption and the low gas emission than those of conventional models.

When you turn the selector switch to Eco, you will be able to weld with Max 4.0mmφ rod at the slow

down speed.

<<<<

Caution

●When welding is performed, do not turn the output selector switch which causes the burnout of the

>>>>

switch

●Eco is designed for welding only. The breaker activates to TRIP, in case it is used for AC Output

5-2. Display

The equipment is incorporated in Digital Display. It displays『Voltage』,『Hour』,『Speed』successively,

by changing the display selector switch.

<<<<

Caution

●During operation, voltage meter always displays the voltage in 200/220V, 3-Phase both at the

5-3. Frequency Selection

Selector either 50 or 60Hz by the selector switch on the front panel, in accordance with the load

frequency.

5-4. Monitor Lamp

The equipment incorporates monitor lamps as 『Water Temperature』,『Battery Charging』 and『Oil

Pressure』.

Under normal condition, when the starter switch is turned from『STOP』to『REN』, the lamps of,『BATTERY

CHARGING』and『OIL Pressure』 turned To ON and all the lamps turn to OFF after the Engine starts.

When abnormality happens in running, monitor lamps flicker

And the engine stops automatically.

In the case the automatic shutdown is engaged, turn the starter switch to STOP once, and then restart

>>>>

breaker position『ON』 and『OFF』.

the engine. When the automatic shutdown is engaged again, check which lamp turns ON or OFF and

point out where the abnormality is.

10

Page 13

(1) Water Temperature Monitor Lamp

Danger: Injuries

●

Close all the doors and place lock during operation, to avoid injuries by unintentional touch of cooling

fan or fan belt.

Danger: Burns

●Do not touch the engine and muffler during operation and immediately after stopping it, for

Caution: Burns

When the water temperature rises abnormally, the water temperature lamp flashes and the automatic

shutdown will be engaged.

When this happens, check water tank and replenish if needed.(Refer to『6-2. Check the water

temperature』

If the water level is normal, there may be possibility of overload. Always use the equipment within the

rated duty cycle and output power.

(2) Battery Charge Monitor Lamp

When the battery charge becomes unable during operation, the monitor lamp flashes and the automatic

shutdown is engaged.

Please consult with our authorized distributor or service section.

<<<<

Caution

●The monitor cannot detect battery degradation or insufficient battery liquid.

Be sure to check battery liquid level periodically.

(Refer to『6-5. Battery Check 』)

(3) Oil Pressure Monitor Lamp

>>>>

Danger: Injuries

●Close all the doors and place lock during operation, to avoid injuries by unintentional touch

of cooling fan or fan belt.

11

Page 14

Caution: Burns

●Do not touch the engine and muffler during operation and immediately after stopping it, for the

temperature can reach extremely high

●When checking engine oil or changing oil, always stop the engine, and wait until the engine

cools down. If you open either the oil gauge or the oil plug during operation, hot oil may cause

some injuries.

When the oil pressure drops during operation, the monitor lamp flashes and the automatic shutdown is

engaged. When this occurs, check the engine oil level and replenish the maximum level if needed.

<<<<

Caution

>>>>

●The monitor cannot detect the degradation of engine oil. Please check engine oil periodically and replenish if

needed.

(Refer to『11. Checking and Maintenance』)

●Check fuse next, when the abnormality other than『Water Temp』,『Charge』or『Oil Pressure』is detected.

If a fuse is burnet, consult with our authorized distributor or our service section, because there may be an

abnormality of electric/electronic parts or wiring and repairing may be required.

(Refer to『4. Parts』)

5-5. Remote Control Box (Option)

You can make remote control by connecting our remote control box

■How to connect remote control box

DMC

DMC

DMCDMC

cover

1. Remove the remote control

Receptacle cover.

screw

(DMC: M5 Screw x 2 pcs)

(

MC: M4 Screw x 2 pcs)

MC

MC

MCMC

cover

screw

12

Page 15

2 Insert the extension cord plug into

The receptacle.

In case of DGW310DMC, insert either A or B to be remote controlled.

3 Insert the plug into the receptacle of extension cord reel.

You can use 3 reels in series (30mx3)

<<<<

Caution

●Never connect a remote control box plug to a receptacle of extension reel connected to AC100/110 Output

receptacle in the equipment. The abnormality lamp in the box turns ON to show abnormality when it is

connected by mistake.

●Never connect any device to a receptacle in the extension reel other than a remote controller.

●In case of using the cord reel incorporating ELCB set the ELCB ON and use.

>>>>

5-6. ELCB and Grounding

Danger: Electric Shock

●Ground every grounding terminal to the earth as set in the manual. If even one of all is unconnected by

mistake or accident, it will make much more dangerous for human than the NO RELAY case, because

leaking current inevitably goes through the body.

●Even though all the terminals of the loads have been grounded to the earth, the bonnet grounding

thermal should be grounded to the earth.

●Grounding should be made after the engine stopped.

●Whenever the ELCB relay has activated, you should repair the leaking part always first of all.

<<<<

Caution

●The ELCB activates only for AC output.

●ELCB activates when AC output is used with the output selector switch at『ECO』position for protection

>>>>

load damage.

The circuit breaker is incorporated with ELCB to protect electric shock

The breaker trips when current leakage is detected due to insufficient insulation of loads

The specifications of ELCB are as follows.

●Rated Sensitive Current

●Activation Time

less than 30mA (Grounding Resistance less than 500Ω)

less than 0.1 second

13

Page 16

(1) Grounding

A qualified electrician should perform the grounding work for the following 3 points. (Ground Resistance

less than 500Ω)

●The ELCB grounding terminal

●The bonnet grounding terminal

●The load bonnet terminal

<<<<

Caution

>>>>

●In the event you cannot ground, consult with our

authorized distributor or our service section.

(2) Operation Check

1. Turn a tarter switch from『STOP』to『RUN』.

2. Set the breaker lever to『ON』.

3. Push a test button in the breaker.

(The device is normal when ELCB Lamp (Red) turns ON and the lever positions at the middle of

『ON』

and 『OFF』).

4. Push the reset button.

(The ELCB lamp (red) turns OFF)

5. Push down the breaker lever『OFF』.

ELCB Grounding terminal

Bonnet Grounding terminal

Earth lod

6. Proceed with engine start procedure once returning a starter switch to 『STOP』.

In the event you cannot complete all steps as above, the device is out of order. Consult with our

authorized distributor or our service section.

ELCB Lamp

Reset Button Test Button

14

Page 17

(3) The ELCB has activated

Caution: Electric Shock/Injuries

●Be sure to disconnect all the loads to the equipment when turning the breaker ON

again after ELCB has activated.

ELCB lamp (Red) turns ON and the breaker lever positions at the middle of

In that case, reset the ELCB per the following procedure after having finished the leaked points.

1. Push the reset button.

2. Push the breaker lever down to『OFF』.

The above procedure brings restoration of the breaker lever to『ON』.

<<<<

Caution

● In the case ELCB monitor lamps keep OFF on using, it means that

AC Output over supply or AC output Supply under output selector switch positions at ECO. Refer to 『9-3.

Operation』 to recover.

5-7. Slow-down Feature

The Slow-down feature is to set the engine speed low automatically (in about 8seconds) for the purpose of

reducing noise and fuel consumption, whenever no welding operation or electric supply is performed.

In the case of using the Slow-Down feature, turn the slow-down switch to ON. By the condition, the engine

automatically moves to high speed, whenever welding operation or electric supply starts.

>>>>

『ON』

and『OFF』.

△ Caution: Damage to properties

●When using the load with magnet switch, turn the slow-down switch 『OFF』.

<<<<

Caution

● When the load less than 0.5A are connected to use, the slow-down feature does not function

sometimes. So, turn the switch『OFF』.

● When welding and AC supply are used alternately or intermittently, turn the switch 『OFF』.

● When the output selector switch is at 『ECO』,the engine does not turn to high speed.

>>>>

15

Page 18

6. Initialization and Pre-check

△ Caution: Fire/Burns/Injuries

● When checking engine, always stop the engine and keep away from hire.

Wait until the engine cools down before performing any check.

6-1. Engine Oil

When checking engine oil, be sure to

Keep the equipment leveled and insert

Oil Gage

゙

The oil gauge all the way in.

Before starting the equipment, make

Sure to fill the engine oil to the UPPER

Line through the oil inlet.

<<<<

Caution

>>>>

Oil Drain Plug

゙

Oil Plug

Oil Inlet

●If the equipment is not levels, you cannot obtain accurate oil level. Do not overfill (over UPPER line) the

engine oil. The excessive oil may damage the engine (inside cylinder).

■Selection of proper engine oil

Select the proper viscosity engine oil in compliance with ambient temperature. (Refer to the chart below)

<<<<

Caution

>>>>

●Use the API class CD or higher.

Viscosity and temperature

Temperature Over+20℃ +10~+20℃ -10~+40℃

Viscosity SAE30 SAE20 SAE10W/30

16

Page 19

6-2. Coolant and Water

Cap

Danger: Injuries

● Close all doors and locks during operating equipment to avoid injuries by accidental touch cooling fan or

fan belt.

Danger: Burns

● Do not open the radiator cap while operating the equipment or immediately after stopping the equipment to

avoid sustaining burn from hot vapor.

Caution: Burns

● Do not touch the engine or muffler during operation or immediately after stopping the equipment for

the temperature can reach extremely high.

Check to see if the coolant/water level is between『FULL』and『LOW』in the sub tank.

If it is below 『LOW』level, fill he tank and the radiator accordingly.

(1) Filling the sub tank

1. Remove the sub tank cap.

2. Fill up the sub tank to『FULL』level.

3. Install the cap again.

(2) Filling the radiator

1. Open the top plate.

2. Remove the radiator cap.

3. Fill the radiator up to the top/

4. Install the cap again and tighten.

5. Close the top plate.

Sub tank

Cap

Sub Tank

<<<<

Caution

>>>>

● Use Long Life Coolant to prevent from freeze and rust.

(30% mixture LLC is filled when shipped out from factory)

17

Top Door

Radiator

Water Inlet

Page 20

● Mixture ratio of the coolant should be 30%-45% depending on the ambient temperature.

● Replace LLC at every year or 2000 hours.

Recommended LLC concentration (for reference only)

Lowest Temp. -15℃ -20℃ -30℃

Mixture Ratio 30% 35% 45%

6-3 Fuel

Caution: Fire

●Always wipe any drip of fuel. Do not use the equipment when any leak is found.

Repair the equipment before use.

Check the fuel level and add the fuel if it is necessary.

<<<<

Caution

●Use Diesel Fuel JIS No.2 in the event ambient temperature down to -5℃

To -15

fuel inlet.

>>>>

●In colder area, use JIS No.3 (down

℃

.)

or JIS No. Special 3

(down to -25℃)

●Always use fuel strainer in the

●Fill the fuel tank slightly less

Tank Cap

Strainer

than the FULL tank.

Fuel Inlet

6-4.Fuel, Engine Oil and Water Leakage

Caution: Fire

●Do not use the equipment when any leak is found. Repair the equipment before use.

Be sure to check any leakage for fuel, oil and coolant/water at the hose connections by opening the side

doors. Whenever checking leakage, turn the fuel lever OPEN and be sure to close the fuel lever after

checking.

18

Page 21

6-5 Battery

Ins Cap

Caution: Injuries to eye and skin

● Battery Fluid contains diluted sulfuric acid. Avoid contact

with eyes, skin or clothing.

● If the acid comes to contact, especially with eyes, flush with a lot of water and contact to a doctor

immediately.

Caution: Explosion

● Do not use the equipment or charge the battery in the case battery

Fluid level is lower than the LOWER level.

● Battery emits some combustible gas, so keep it away from fire and spark.

1. Check the fluid level. If the level is near or

lower than the LOWER level, add distilled

water until the fluid level reaches UPPER.

2 Make sure that the battery cables are firmly

secured to the posts.

Lower level

Tighten the clamps if it is necessary.

<<<<

Caution

>>>>

● Check the hydrometer of the battery fluid. If it falls below 1.23, the battery requires recharging. Consult

with our authorized distributor or our service department.

■Replacing battery

1. Remove the under plate.

(M6 bolt x 2)

2. Remove the cable on『-』side.

+ terminal

Fix Plate

Terminal

Upper level

Terminal

(Always on『+』side first)

3. Remove the battery fixing plate.

4. Remove the cable on『+』side.

5. Remove the battery.

Under Plate

Reinstall a new battery in the reverse order.

(Install always the cable to the『+』positive post first in a new battery.

<<<<

Caution

● Use the following battery.

>>>>

<

46B24L>

● When replacing a battery, remove the under plate firstly. Otherwise the battery slanted and the fluid

may leak and contact to eye or skin.

19

Page 22

7. Operation

7. Operation7. Operation

7. Operation

Danger: Suffocation from exhaust fume

●Exhaust fume from engine contains many elements harmful to human. Do not operate this

equipment in poorly ventilated area such as inside room or in tunnel

Caution: Suffocation from exhaust fume

●

Do not point the exhaust fume toward pedestrians or building.

Caution: Fire

●Temperature around muffler and exhaust can get extremely high. Keep any inflammable items

(such as fuel, gas, paint, etc.) away from the equipment.

●Always operate this equipment on flat surface and at least 1 meter away from any objects (wall,

box, etc.)

Caution: Injuries

●Always place the equipment on flat and stable surface to keep the equipment from sliding and lock

wheels if they have.

●Before starting, turn the load switch OFF and set the

Equipment breaker『OFF』.

7-1. Starting

1. Turn the breakers to『OFF』.

2. Turn the fuel lever to『OPEN』.

3. Turn the Slow-Down Switch to『ON』.

4. When the temperature is below 5℃ turn and keep the starter Switch at『PREHEAT』until the preheat

lamp turns OFF (about 5 seconds).

5. Turn the starter switch to『START』. And then the engine starts by the starter motor.

<<<<

● Do not drive the starter motor for more than 15 seconds successively.

● If you need to restart, wait for 30 seconds or more before retry.

6. Once the engine has started, release hand offs the starter switch.

<<<<

Caution

● Once the engine has started, never turn the switch to

CAUTION

>>>>

>>>>

『

START』.

20

Page 23

7. Keep the engine idle for about 5 minutes.

Breaker

Slow-down switch

Starter

Fuel lever Close

Open

■Restarting after stopping due to fuel shortage

This equipment is incorporated in automatic vacuuming air feature. Therefore, even though the engine

stops due to fuel run out, you can restart the engine easily by the following steps.

1. Turn the breakers to『OFF』

2. Turn the starter switch to『STOP』.

3. Fill the fuel.

4. Turn the slow-down switch to『ON』.

5. Turn the starter switch to『START』and drive the starter motor for about 10 seconds.

6. Release the starter switch, promptly as the engine started.

7. Wait for about 1 minute to vacuum the air out. The engine peed becomes stable when the air is

extracted.

<<<<

Caution

>>>>

● Never turn the engine NORMAL speed or connected the loads until the air is extracted completely (until

the engine becomes stable).

21

Page 24

7-2 Stopping

Return

1. Turn the breaker to『OFF』.

2 .Turn the slow-down switch to『ON』.

3. Keep the engine (cool down) for about 5 minutes.

4. Turn the starter switch to『STOP』.

5. After the engine stops, turn the fuel lever to『CLOSE』.

<<<<

Caution

● When the engine will not stop in spite of turning the starter switch to STOP, turn the fuel lever to CLOSE,

then the engine will stop in a few minutes. In this case, be sure to consult with our authorized distributor

or our service section and ask to repair.

>>>>

8. Welding Operation

8-1. Selection – Welding Cable

Select the cable in proper gauge, based on the allowable amperage and the length, per the table shown

below.

The welding capacity is to reduce if the small gauge or long cable is used.

<<<<

Caution

● Welding cables should be used unstrained. When the welding cable are used in swirl, the welding

capacity is to reduce

Current

>>>>

Length

300A 30 38 50 80 100 125

250A 22 30 38 60 80 100

200A 22 30 30 50 60 80

150A 22 22 22 38 50 60

20m 30m 40m 60m 80m 100m

Size of Cable(Unit:mm

2

)

100A 22 22 22 30 30 38

22

Page 25

8-2. Polarity

There are 2 welding output terminals『+』and

『-』

.

Select the polarity according to the operation, referring to the table below.

<<<<

Caution

>>>>

●Welding Rods

Application Connection

General Welding such as

- to Holder (Rod)

Normal

construction + to Earth (Material)

Thin Plate, Build-UP Welding - to Earth (Material)

Reverse

Stainless Steel + to Holder (Rod)

8-3. Connection – Welding Cable

Danger: Electric Shock

● Before connecting or disconnecting welding cable to terminal, stop the engine and

Remove the engine key. A person performing should always keep the key.

1. Stop the engine

2. Connect a cable to a crimping terminal, a rod holder and

a material holder.

3. As to DGW310DMC, connect the cable

referring the chart below.

ECO (Single) Single Dual

<<<<

Caution

Rod

Φ2.0~φ4.0

Welding Output

Terminal A

>>>>

Rod

Φ2.6~φ6.0

Welding Output

Terminal A

●Be sure to crimp a crimping terminal to a cable and connect the cable to welding cable to welding

Rod Holder Cable

Crimping terminal

Holder

Rod

Φ2.0~φ4.0

Welding Output Terminal

A

&

Welding Output Terminal

B

output terminal. Otherwise the terminal may burn out by the heat due to insufficient connections.

● Use a cable with a crimping terminal. To weld binding bare wires to an output terminal, the terminal

may burn out by the heat caused by insufficient connections and also bare wires may touch the

bonnet to bring short-circuit.

23

Page 26

8-4. Welding

Termina

l A

Termina

l B

Caution: Suffocation from welding fume

● Be sure to wear a welding mask in operation, because welding fume contains poisonous

gas and dust. Pay full attention to the airflow and direction and sufficient ventilation also in

order to prevent from inhaling fume.

Caution: Injuries to eyes and skin

● Be sure to wear spark protection glass (refer to the table below), long-

sleeve shirts, gloves, etc. in order to protect eyes and skin from harmful

spark in welding.

Standard for Spark Protection Glass (Japan Industrial Standard)

No. 7 8 8 10 11 12 13

Current (A) 30~75 76~200 201~400

Caution: Fire

● Keep any inflammables and easily burning item away from the place in welding, because

welding splashes spatter.

Caution: Burn

●

Be sure to wear leather gloves, apron, shoe covers, eye protection glass, safety shoes, safety cap and

long-sleeve shirts, because welding splashes spatter.

<<<<

Caution

>>>>

●Never turn the output selector switch during welding, because

it must cause the burnout of the switch.

(1) DGW310DMC

The equipment can be operated 2 persons simultaneously.

Each person can adjust the welding current individually.

The current adjustable range by the dial changes at the output

selector switch position.

1 Turn the selector switch properly according to operation.

2 Adjust the voltage by the current adjustable dial. Refer to

the following chart next.

Current

Dial A

Current

Dial B

Selector

Switch

24

Page 27

Current

Selector

Output

1 Person

Position

ECO

Freq

50Hz

Welding Current

MIN

30 45 70 95 120 145 160

70 90 135 175 215 260 280

1 2 3 4 5 MAX

at the dial position (A)

Single

60Hz

50Hz

85 110 155 200 245 290 310

35 45 70 95 115 140 150

2 Persons Dual

60Hz

45 55 80 105 125 150 160

The values are for reference only. The length or the ambient temperature each affects the value.

When the remote control box is used, the value may change to some degree.

(2) DGW310MC

The current adjustable range by the dial changes at the output selector switch position.

1 Turn the selector switch properly according to operation.

2 Adjust the voltage by the current adjustable dial. Refer to

Dial

the following chart next.

Welding Current at the dial position (A)

Position Freq

MIN 1 2 3 4 5 MAX

ECO 30 45 70 95 120 145 160

50Hz 35 60 110 160 205 255 280

Regular

60Hz 45 70 125 180 230 285 310

The values are for reference only. The length or the ambient temperature each affects the value.

When the remote control box is used, the value may change to some degree.

25

Page 28

U VVVV

W O

UP to 9.9 kVA

Total 6kVA

Receptac

le

Terminal

9. Genrating Operation

9-1. Output Range

(1) 3-P 200/220V (3-P 4-Wires)

Maximum output from the terminals at 200/220

9.9kVA

(2)1-P 200/220V

1-P 200/220V is supplied by 1 pair out of 3 terminals.

UUUU

V

W

O

Max. output by 1 pair is 6kVA and the maximum

output for 3 pairs total is 8kVA, which please note.

You should connect the load for 3 pairs evenly as

Up to 6kVA

Up to 6kVA

possible to terminals.

Up to 6kVA

Total 8kvA m a x

(3) 1-P 100/110V

1-P 100/110V is supplied by 2 receptacles and1-P

terminal set. Max 1.5kVA is supplied through 1

receptacle and max 3kVA is supplied from 1-P

terminal set.

Max output by 2 receptacles and

1 terminal set is 6kVA.

up

up to

to 1.5kVA

1.5kVA

upup

toto

1.5kVA1.5kVA

Up

Up to

to 1.5kVA

1.5kVA

UpUp

toto

1.5kVA1.5kVA

up

up to

to 3kVA

3kVA

upup

toto

3kVA3kVA

26

Page 29

9-2. Output Limitation

Please refer to the table below, because electric tools and home appliances cannot be judged only by the

rated.

The rated output or the power consumption due to the efficiency and character of components.

Applicable Load (For reference only)

Capacity(kW)

3-P 200/

220V

Terminal

Loads

Receptacle

1pce

1-P 100/110V

Terminal

1 set

Terminal

receptacle

total

&

1-P 200/220V

Terminal

1 set

Total 3 terminal

set

Electric Bulb, Heater, etc.

Electric Tools, etc. (Series

motor)

Mercury Lamp (high power

factor type)

Submersible Pump,

Compressor, etc. (induction

motor)

-26-

1.5 3.0 6.0 6.0 8.0 ―

0.7 1.5 3.0 3.0 4.0 ―

0.6 1.2 2.4 2.4 3.2 ―

0.6 1.2 2.4 2.4 3.2 4.0

Series Motor

:

Motor with brush

Induction Motor :Brushless Motor

The value described is『OUTPUT』for induction motor load and

『POWER CONSUMPTION』 for the other equipment.

<<<<

Caution

>>>>

● Be sure to use the frequency designated in the equipment incorporated in mercury

bulb or induction motor.

● The load incorporated in motor may require bigger power than the rated power

consumption.

So, consult with our authorized distributor or our engineering section to clarify.

● When connection to use 2 or more sets, start the load one by one, not to start them simultaneously.

● When starting a mercury bulb ON again, wait for about 15 minutes until it cools down.

27

Page 30

9-3. Operation

Danger: Electric Shock

●Before connection or disconnecting a load cable from the receptacle, always turn the circuit breakers

(3-P and 1-P) to OFF. And stop engine and remove the engine key. A person to perform it should

always keep the key.

●Ground every grounding terminal to the earth as set in the manual.

If even one of all is unconnected, by mistake or accident, it must be much more dangerous for human

body than NO CONNECTION, because a leaking current inevitably goes through the body.

●Even though all the current leakage relays in the loads have been grounded to the earth, the

grounding terminal and the bonnet (canopy) should be grounded to the earth.

●Grounding should be made after the engine is stopped.

●Whenever the current leakage breaker activates, you should repair the leaking point first of all.

Caution: Injuries

●Be sure to connect to the output terminals or insert a plug to a receptacle, after confirming that all the

switches in the loads are positioned at OFF.

●Be sure to select the correct frequency, designated in the loads.

Caution: Damage to the property – Aftermath

●Whenever connecting to use medical equipment or appliances, be sure to consult

with the medical equipment company, doctor or hospital personnel.

●Be sure to select the correct frequency, designated in the loads.

Otherwise the loads may be damaged.

28

Page 31

<<<<

Breaker

3-P/1-P 200/220V

Output Terminals

Rece

ptacle

Breaker

Caution

>>>>

●The AC volt meter reads 3-P 200/200V apart from the circuit breakers position at 『ON』 or『OFF』

when the engine driving.

After the engine starts(Refer to 『7-1.Starting』, operate as per the following procedures.

1 Turn the power switch off on the load.

2 Check and confirm the breakers position at 『OFF』.

3 Select the correct frequency, designated in the loads.

4 Connect the loads to receptacle or terminals.

5 Close the terminal cover and fix it with the bolts.

6 Turn the breakers to 『ON』.

DMC

1-P 100/110V

Output Terminals

MC

Output

Terminal

Cover

Receptacle

■ Return -The circuit breaker has activated due to overload

Terminal

Cover

1-P/3-P

200/220V

Output

Terminals

1-P 100/110V

Output Terminals

Caution: Injuries

●Be sure to turn the power switch to OFF on the load when returning the circuit breaker to ON again,

when the circuit breaker has activated.

When the electric supply exceeds the rated output, the breaker activates to trip in order to shut down the

circuit. Check the breakers when the load stops operation.

ELCB lamp is to turn OFF in the case of overload shutdown. When the lamp keeps ON, refer to『5-6.

ELCB and Grounding』.

When any breaker has activated, return the circuit breaker per the followings procedure.

1 Turn OFF all the power switches on the loads.

2 Once push down the breaker lever to『OFF』, push up the lever to『ON』.

<<<<

Caution

>>>>

●Take care for overload, referring to『9-2 Output Limitation』

●The breaker activates when having used AC output in the selector switch at 『ECO』position. In the

case stop using AC supply and return the breaker as above.

29

Page 32

10. Simultaneous use of Generating and Welding

The circuit breakers react on the AC power supply circuit only. In the simultaneous use of welding and

generating, there may be happen overload to the engine. Refer to the following table and limit AC power use.

Limitation of AC Power Supply in the simultaneous use of welding and generating (60Hz)

DGW310DMC

Welding Output AC Power Output

Rod/Current Select 3-P Output (PF 0.8) 1-P Output

φ2.0mm/60A Dual 9.3kVA 7.4kVA

φ2.6mm/120A Dual 7.2kVA 5.7kVA

φ3.2mm/140A Dual 6.4kVA 5.1kVA

φ4.0mm/170A Dual 5.2kVA 4.1kVA

φ5.0mm/240A Single 2.0kVA 1.6kVA

φ6.0mm/300A Single 0kVA 0kVA

The 1-P figure shown is the total output of 1-P 100/110V and 200/220V.

DGW310MC

Welding Output AC Power Output

Rod/Current Select 3-P Output 1-P Output

φ2.0mm/60A Regular

φ2.6mm/120A Regular

φ3.2mm/140A Regular

φ4.0mm/170A Regular

φ5.0mm/240A Regular

φ6.0mm/300A Regular

9.3kVA 7.4kVA

7.2kVA 5.7kVA

6.4kVA 5.1kVA

5.2kVA 4.1kVA

2.0kVA 1.6kVA

0kVA 0kVA

The 1-P figure shown is the total output of 1-P 100/110V and 200/220V.

<<<<

Caution

>>>>

●Simultaneous use of Welding and AC Power is NOT available.

●Avoid simultaneous use in the case high welding quality is required.

30

Page 33

11. Check and Maintenance

●Before checking, stop the engine and remove the engine key which to be kept by the person to do.

●Do not open the doors during operation or just after, because the cooling fan or driving belts can enwind the

●Never open a radiator cap during operation or just after operation, because of avoid

burns from hot vapor.

Danger: Electric Shock/Injuries

body.

Danger: Burns

Caution: Fire/Burns

● Keep the equipment far away from fire.

● Do not touch the engine and muffler during operation or immediately after stopping the equipment, for the

temperature reaches extremely high.

Caution: Injuries to eyes and skin

● Battery fluid contains diluted sulfuric acid. Avoid contact with eyes, skin or on clothing.

● If the fluid comes in contact, especially with eyes, flush with a lot of Water and contact to a physician

immediately.

Caution: Explosion

● Do not use the equipment or charge the battery, in the case the

battery fluid level is lower than LOWER

level.

● Battery may emit some combustible gas, so keep it away from fire and sparks.

<<<<

Caution

● Besides pre-check before operation, qualified person only should do check and maintenance.

● Our authorized distributor or our service section only should do the job marked ● in the table.

● Use the genuine parts only for replacement.

● Use the tray to receive when draining the waste fluids.

●

>>>>

Be sure to comply with the regulations when discarding hazardous substances such as oil, fuel, coolant (LLC), filter,

battery, etc.

● To protect the environment, never discard the waste fluid to the grounds, the rivers, lakes, the oceans,

etc.

To optimize the use of the equipment, be sure to perform the check and maintenance based on the following

table. Use the hour meter on it as rough standard for operation time

31

Page 34

Adjust V Belt Tension

Check Time

Check Items

1 Check and supply fuel

Check and supply engine

2

oil

3 Change engine oil

4 Change oil filter

5 Check/Add water/coolant

6 Change Water/Coolant

7 Clean Fuel Strainer

Startup Every Every Every Every Every

At 50 hrs

100 hrs 200 hrs 400 hrs 1000 hrs 2000 hrs

○

○

○ ○

○

1st 2nd or after

1st

2nd or after

○

○

1st 2nd or after

○ ○

Or 2 yrs

○

8 Change Fuel Filter Element

Drain Water/Clean Fuel

9

Tank

Check Leakage Fuel, Oil,

10

Water

11 Check Battery Fluid/Add Fluid

12 Clean Air Element

13 Change Air Filter Element

14

15 Change V Belt

○

○

1st 2nd or after

○

○

○ ○

○

1st 2nd or after

● ●

Or 2 yrs

●

32

Page 35

Anti

Adjust/Plane Engine

Valve Clearance

Check Time

Check Items Startup

Clean Radiator Fin

16

(Outer)

17 Clean Radiator (Inner)

Change Fuel Hose, Coolant

Hose, Oil Hose,

18

-Vibration Rubber

19

20 Check/Adjust Injection Nozzle

Check/Adjust Injection

21

Nozzle

At 50 hrs

Every Every Every Every Every

100 hrs

200 hrs 400 hrs 1000 hrs 2000 hrs

●

●

● ●

Or 2 yrs

Adjust Plane

●

●

●

(1)Change Engine Oil

1st At 50 hrs

2nd or after Every 100 hrs

1 Remove the oil plug.

2 Remove the oil drain plug and

drain the oil completely.

3 Reinstall the oil drain plug tightly.

Oil Drain Plug

Oil Inlet Oil Gauge

4 Checking the oil level by the oil level

gauge, replenish oil up to the UPPER level though the oil inlet.

(About 38 Liter)

5 Reinstall the oil plug tightly.

<<<<

Caution

>>>>

●Refer to『6-1. Check Engine Oil』to decide Engine Oil.

●Change the packing to the new one in the oil drain plug whenever changing engine oil.

●Packing No.: 6C090―58961 (Kubota)

●After reinstalling the oil drain plug tightly, keep the engine drive for a while to check no engine oil leakage

Oil Gauge゙

and then stop the engine.

33

Page 36

Air Cleaner

Clip゚

Air Cleaner

cap

2) Change Oil Filter

1st At 50 hrs

2nd or after Every 200 hrs

1 Drain the oil as described in

『

(1)Change Engine Oil』.

2 Remove the oil filter using an oil filter wrench.

3 Smear a little engine oil on the rubber gasket of a new filter.

4 Screw the new filter into place and tighten it by

Hand until the gasket contact seat. Then give it

additional 1.1/4 turns using an oil filter wrench.

5 Supply engine oil.

<<<<

Caution

>>>>

Oil filter

Gasket

●If an oil filter wrench is not available to get, contact our authorized

distributor or our service section to change.

●Oil Filter Part No.:15853-32433 (Kubota)

●After supplying engine oil, keep the engine drive for

a while to check no engine oil leakage and then stop the engine

(3) Clean/Change Air Element

Clean 1st at 50 hrs 2nd or after 100 hrs

Change Every 400 hrs

1 Loosen the wing bolts in the cleaner and

remove the air element.

2 Clean or replace the air element.

<Dried contaminants adhere>

Blow up compressed air from inside

the element.

<Carbon or oil adhere>

Replace to a new one.

3 Reinstall it in reverse order.

34

Air element

Clip゚

Page 37

<<<<

Fuel Drain P

lug

Caution

>>>>

●Clean more frequently when it is used in dusty environment.

●Air Element Part No.: 1G347-11181 (Kubota)

(4) Clean/Change Fuel Strainer

Clean 1st at 50 hrs 2nd or after 200 hrs

Change Every 400 hrs

1 Turn the fuel lever to『CLOSE』.

2

Unscrew the retainer ring counterclockwise

3

and clean the filter by blowing compressed

air. (or replace element)

And remove the cup and filter element.

Discard any dust or water inside the cup

4 Reassemble it back.

Fuel lever

Close

Open

Cup

<<<<

Caution

>>>>

●Be sure to check for any contaminants on the packing whenever reinstalling the cup.

●Be sure to confirm no fuel leakage by opening the fuel lever

Retainer ring

to『OPEN』. Turn the lever to『CLOSE』finally after confirmation.

●Fuel Element Part No.: 16271-43561 (Kubota)

(5) Drain water in fuel tank

Drain At every 200 hrs

1 Unscrew the fuel drain plug.

2 Reinstall the drain plug after draining

water completely.

<<<<

Caution

●

>>>>

Change the packing whenever draining water

.

● Packing Part No.: 6C090―58961 (Kubota)

● Confirm no fuel leakage after reinstalling the fuel drain plug.

35

Page 38

Sub Tank

Coolant Drain Plug

(6) Change Coolant/Water

Change At 2000 hrs or 2 yrs

<

Total capacity: 3L (including Sub Tank: 0.6L

1 Open the top door.

2 Remove the radiator cap.

3 Remove the water drain plug.

4 After draining all the water, reinstall

the water drain plug.

<<<<

Caution

>>>>

●Change the packing whenever changing

coolant/water.

●Packing Part No.: 6C090―58961 (Kubota)

5 Replace all the water in the sub tank.

6 Fill water to Max Level (to the water inlet)

7 Reinstall the radiator cap.

)>

Top Door

Radiator

Cap

Water Inlet

゙

8 Close the top door.

<<<<

Caution

>>>>

●After supplying water, keep the engine drive for

a while to check no water leakage and then stop the engine

12. Long-Term Storage

●.

Danger: Electric Shock

When performing check and maintenance, always stop the engine

Caution: Injuries

●When performing check and maintenance always stop the engine

△

● Keep the equipment far away from fire.

Caution: Fire/Burns

● Do not touch the engine and muffler during operation or immediately after stopping the equipment for the

temperature reaches extremely high.

36

Page 39

If the equipment will not be used for more than 2 months, perform the following maintenance and storage

procedure.

1 Remove the battery. (Refer to『6-5. Check Battery』

2 Change the engine oil. (Refer to『11. Check & Maintenance』

3 Drain the fuel from the fuel tank and the strainer. Refer to『11. Check & Maintenance』

4 Clean all the parts, cover the equipment and keep in the clean and dry place.

<<<<

Caution

● Recharge the removed battery once a month.

13. Troubleshooting

>>>>

●Do not operate the equipment if the equipment or you are wet.

Danger: Electric Shock

●Before performing any equipment check or maintenance, stop the engine.

△ Caution: Injuries

●Before performing any equipment check or maintenance, stop the engine.

△

Caution: Fire/Burns

●Keep the equipment far away form fire.

●Do not touch the engine and muffler during operation or immediately after

stopping the equipment for the temperature reaches extremely high.

Follow the guideline below when performing any troubleshooting. If you can

not resolve the problem by the troubleshooting guide, contact our authorized

distributor or our service section to request the repair.

Symptoms Presumable Causes Actions

Starter motor will not start

1. Battery Weak 1. Recharge the Battery

2. Battery Dead 2. Replace the battery

1. Fuel Lever at 『CLOSE』 1. Fuel Lever to『CLOSE』

The engine will not start

2. Insufficient Fuel 2. Replenish fuel

3. Water or contaminants 3. Drain water or Clean

in the fuel Fuel Tank & Strainer

4. Fuse burnt 4. Repair

37

Page 40

Symptoms Presumable Causes Actions

1. Insufficient Oil 1. Replenish Oil

The engine starts but

stalls immediately

Black or white smoke exhaust

from the muffler successively

The engine wont stop

Welding Arc is weak

2.

High Water Temperature,

2. Keep the rated

Insufficient Coolant/Water Replenish coolant/water

3. Unable to charge 3. Repair

1. Overload 1. Keep the rated output

1. Stop Solenoid Disorder

1. Turn the lever to『CLOSE』

to stop and repair

1. Output Selector Switch 1. Change to『SINGLE』

at『ECO

』

or『DUAL』 or『REGULAR』

2. Freq. Switch at 50Hz』 2.Change to『60Hz』

3. Current Dial Position

4. Poor Contact on Cables

5. Improper Diameter or Length of Cable

6. Poor Contact to material

3. Turn it clockwise more

4.Connect sufficiently

5. Change the cable as per『SELECTION – WELD

CABLES』

6. Connect securely

7. Simultaneous use 7. Stop using AC Output

Welding Arc is too

strong

NO AC Output

Weak AC Output

Slow-down does not

activate

Remote Control does

not work

1. Output Selector Switch

at『SINGLE』or

『

REGULAR

』

1.Change to『ECO』

or『DUAL』

2. Current Dial Position 2. Turn it counterclockwise more

1. Breaker at『ON』 1.Change to『ON』

2.Selector Switch at『ECO』

1. Wrong Frequency

2. The rated current of load exceeds the rated

output of the equipment

2. Change to『SINGLE』,『DUAL』o

『

REGULAR

1. Change to the load frequency

2. Refer to『OUTPUT LIMITATION』

3. Simultaneous use Stop welding

1. Welding Cable short-circuit

2.The power consumption

Of the load is 0.5A or below

1. Repair the short-circuit

2. Chang the slow-down

switch to『OFF』

1. Connect to the remote control

1. Connected to AC100/110V receptacle by mistake

receptacle

2. Connected AC100V load to remote control

2. Disconnect the AC100V plug

receptacle

3. The switch (breaker) on the cord reel at『OFF』

3.Change the switch to『ON』

38

Page 41

Warranty Sheet

(

Type-B)

39

Page 42

MEMO

Shindaiwa Corporation

Hiroshima Japan

2006.10

Loading...

Loading...