Shindaiwa DGW310MC, DGW310DMC User Manual

CERTIFIED

OWNER’S MANUAL

GENERATOR / WELDER

DGW310DMC

DGW310MC

Sound Proof

Vertical, Water-Cooled

4-Cycle Diesel Engine

Do not operate the generator/

welder, or any other appliance,

before you have read and

understand the instructions for use

and keep near for readily use

Caution

Table of Contents

1. Safety Guidelines ···················································2

2. Specifications ·························································6

3. Use ···········································································7

4. Parts ········································································7

5. Incorporated ···························································10

5-1.Eco Welding 10

5-2.Display 10

5-3.Frequency Change 10

5-4.Monitor Lamp

5-5.Remote Control (Option) 12

5-6.Earth Leakage Relay/Grounding 13

5-7.Slow-Down Feature 15

6. Initialization & Pre-check ·······································16

6-1.Checking Engine Oil 16

6-2.Checking Coolant/Water 17

6-3.Checking Fuel 18

6-4.Leakage Check for the above 18

6-5.Checking Battery 19

7. Operation ································································20

7-1.Start 20

7-2.Stop 22

8. Welding Operation ··················································22

8-1.Selection – Welding Cable 22

8-2.Polarity 23

8-3.Connection – Welding Cable 23

8-4.Welding 24

9

....

Generator Operation ·············································26

9.1.Output Range 26

9-2.Output Limitation 27

9-3.Operation 28

10

....

Simultaneous Use – Weld & Generate ··············30

11

....

Checking & Maintenance ····································31

12

....

Long-term Storage ··············································36

13

....

Trouble Shooting ················································37

14. Warranty Sheet (Type B) ········································39

10

Introduction

Thank yo u fo r purc h a s ing Shi n d aiwa S o u nd Pr o of D i e s el En g i n e Ge n e r ator.

●This user m a nual wa s prepar e d to e ns u re t h e safe o p eratio n of t h i s equipm e nt. Ther e f ore,

the m a nufac t u r er of t h is eq u i p m ent s t rongl y r e com m ends t h a t the u s er fol l o w the

instr u c tions h e rein , t o avoid u n nece s s ary ac c idents a nd repa i r s .

● P l e ase operat e this equipm e n t a f t e r t h o r oughl y r evie w i n g a n d u n d erstan d i n g t h e co n t ents of

this m a nual.

● Plea s e attac h this m a n u al, i f the e q u ipmen t w i l l be s u b-lea s ed.

● Plea s e st or e this m a n ual n e a r the e quipm e n t for e a s y ref e r ence.

● F ollowin g c o n vers i o n wi l l be us e d t h roug h o ut t h e m anual to indic a t e t h e d egree of cauti o n s.

<<<<

●

Even s o m e of t he it em s note d in

Please read every item and follow all the safety guidelines.

Dang e r : Can c ause s e r i ous i n j urie s o r death

Caut i o n : Ca n c ause m i nor in j uries o r dama g e to t h e equip m ent or o t her

prop e r t ies.

Caution

>>>>

: Other types of caution

『

Caution』may lead to serious injuries.

1

1. Safety Guidelines

1. Safety Guidelines1. Safety Guidelines

1. Safety Guidelines

Danger: Suffocation from exhaust fume

● Exhaust fume from the engine contains many elements harmful to human.

Do not operate this equipment in poorly ventilated areas, such as inside a

room or in a tunnel.

Danger: Electric Shock

● Do not touch the output terminals during operation

● Do not insert metal objects (such as pin or wire) into receptacle

● Do not touch wires or electric parts inside the equipment during operation.

● Before connecting or disconnecting a load cable from output terminals, always turn the circuit

breaker to OFF position.

● Before connecting or disconnecting a load cable from output terminals, always turn the circuit

breaker to OFF position.

● Before connection or disconnection a welding cable from DC output terminal, stop the engine

and remove the engine key.

● Before performing any equipment check or maintenance, stop the engine and remove the

engine key. A maintenance person should always keep the key.

Danger: Burns

● Do not open the radiator cap while operating this equipment or immediately after stopping the

equipment, to avoid sustaining burns from hot vapor.

Danger: Injuries

● Close all doors and place locks during operating this equipment, to avoid injuries by

unintentional touching a cooling fan and fan belt.

Caution: Suffocation from exhaust fume

● Do not point the exhaust fume toward pedestrians or building.

Caution: Suffocation from exhaust fume

● Be sure to wear a fume proof mask in operation, because welding fume contains poisonous gas

and dust. Pay attention to the airflow direction and ventilation also in order to prevent from

inhaling the fume.

2

Caution: Injuries to eye and skin

● Be sure to wear spark protection glass (es), long-sleeve shirts, gloves, etc. in order to protect

eyes and skin from harmful spark in welding.

● Battery fluid contains diluted sulfuric acid. Avoid contact with eyes skin or on clothing.

If the acid comes in contact, especially with eyes, flush water with a lot of water and contact a

physician immediately.

Caution: Electric Shock

● Do not flush water onto the equipment nor operate it in the rain.

Caution: Explosion

● Do not use the equipment or charge the battery, in the case the battery fluid level is lower than

the LOWER level.

● Battery may emit some combustible gas, so keep it away from fire and sparks.

Caution: Fire

●The equipment run on Diesel Oil. When refueling, always stop the engine and keep away from

fire. Moreover, always wait until the engine cools down before refueling.

● Always wire any drip of Diesel fuel or lubrication oil. Do not use this equipment when any leak is

found. Repair it before use.

●Tem per at u r e a r o u n d m uf f le r a nd e x h a us t c an g e t ex tr e m e l y h i g h . Ke e p an y

in f l a mm ab l e it e m s ( su ch as f ue l , ga s , pa i n t , et c . ) a wa y f ro m t h e e qu ipm en t.

● Always operate this equipment on flat surface, at least 1 meter away from any objects (wall, box,

etc.)

● Always operate this equipment on flat surface and at least

1 meter away from any objects (wall, box, etc.)

● Do not connect AC output to any indoor wiring.

● A l wa ys w a i t u nt i l t he eq u i p m e nt c o o ls do wn , b e f o re p l a ci ng an y c o v e ri n g

ma ter ia l f or s t o r ag e.

3

Caution: Burns

● Do not touch the engine and muffler during operation and immediately after stopping the equipment,

for the temperature can reach extremely high.

● When checking engine oil or changing oil, always stop the engine, and wait until the engine cools

down. If you open either the oil gauge or the oil plug during operation, hot oil may cause some

injuries.

● Be sure to wear leather gloves, apron, shoe covers, eye protection glass (es) (mask), safety shoes,

and safety cap and long sleeve shirts, because welding splashes spatters.

Caution: Injuries

● When lifting the equipment, always use a lift hook. Do not lift the handle, for it may cause the

equipment to drop due to handle breaking off.

● When carrying the equipment by truck, fix it strongly to keep the equipment from sliding as roping

two points of handle.

● Always place the equipment on a flat and stable surface, to keep it from sliding. Be sure to lock the

wheels for with wheel type.

● When starting the engine, turn off the connected equipment

● And set the circuit breaker to『OFF』position.

● Do not move the equipment during operation.

● When performing equipment check and maintenance, always stop the engine.

● Do not operate the equipment if the equipment are modified or parts are removed

4

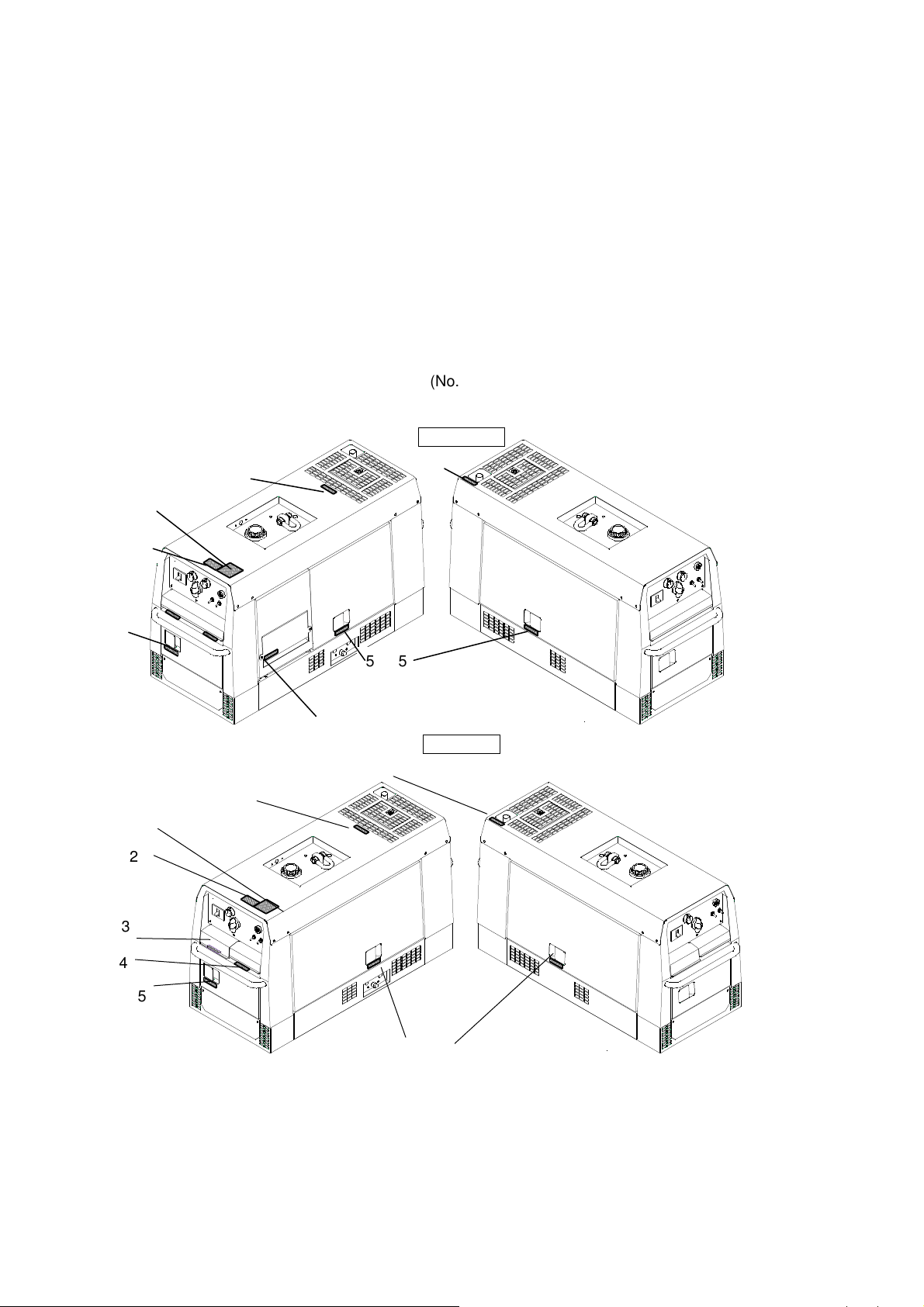

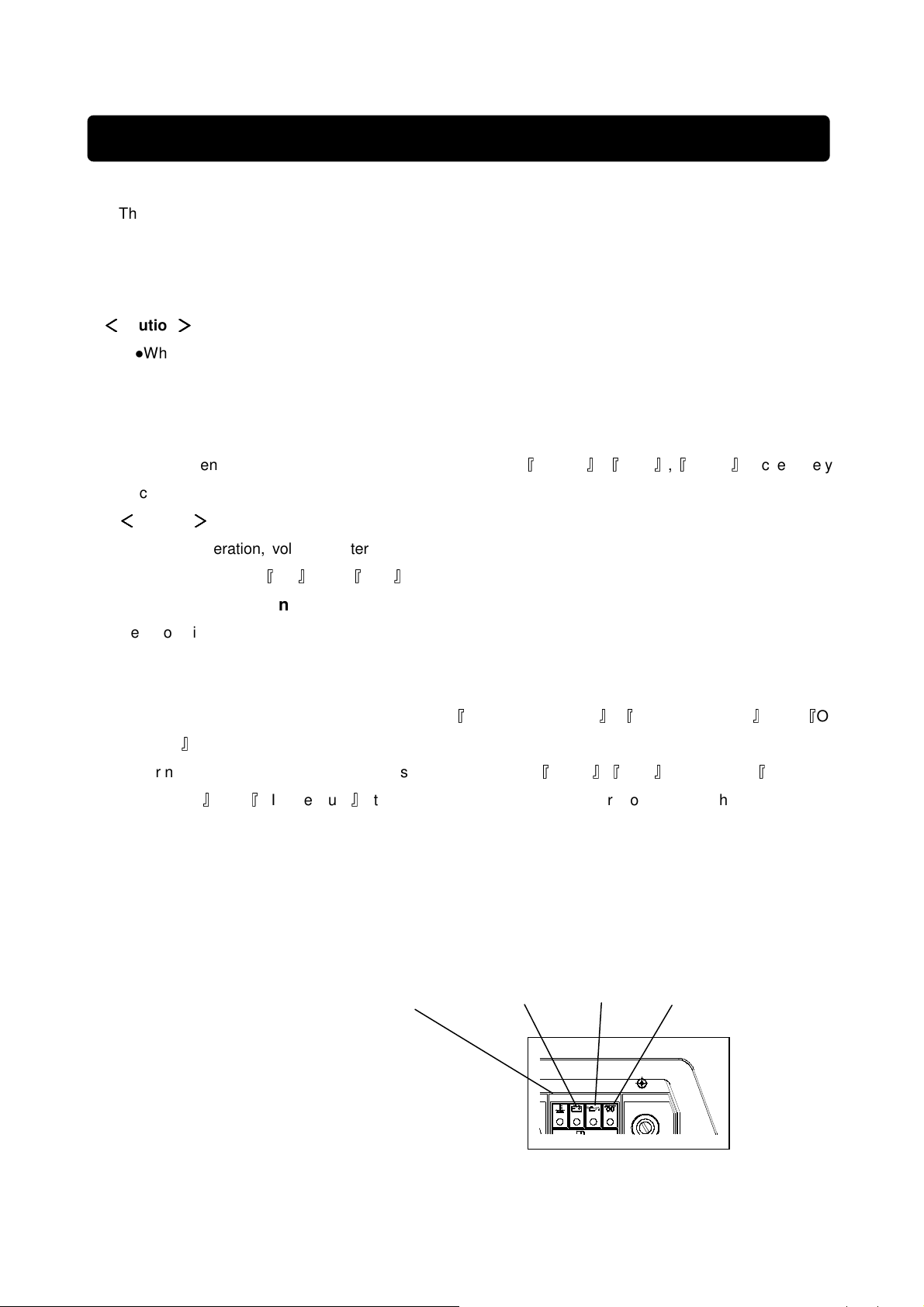

■Location of warning labels

When any warning label becomes unreadable or damaged, place a new label on the appropriate location.

When ordering a new label, use the following part number.

1. Suffocation from exhaust fume (No.19402-00106)

2. Suffocation from welding fume (No.19402-00107)

3. Electric Shock (No.19402-00102)

4. Electric Shock

5. Injuries

6. Burns

7. Burns

1

2

4

6

(No.19402-00103)

(No.19402-00109)

(No.19402-00108)

(No.19402-00112)

DGW310DMC

7

5 5

3

DGW310MC

7

2

3

4

5

1

6

5 5

5

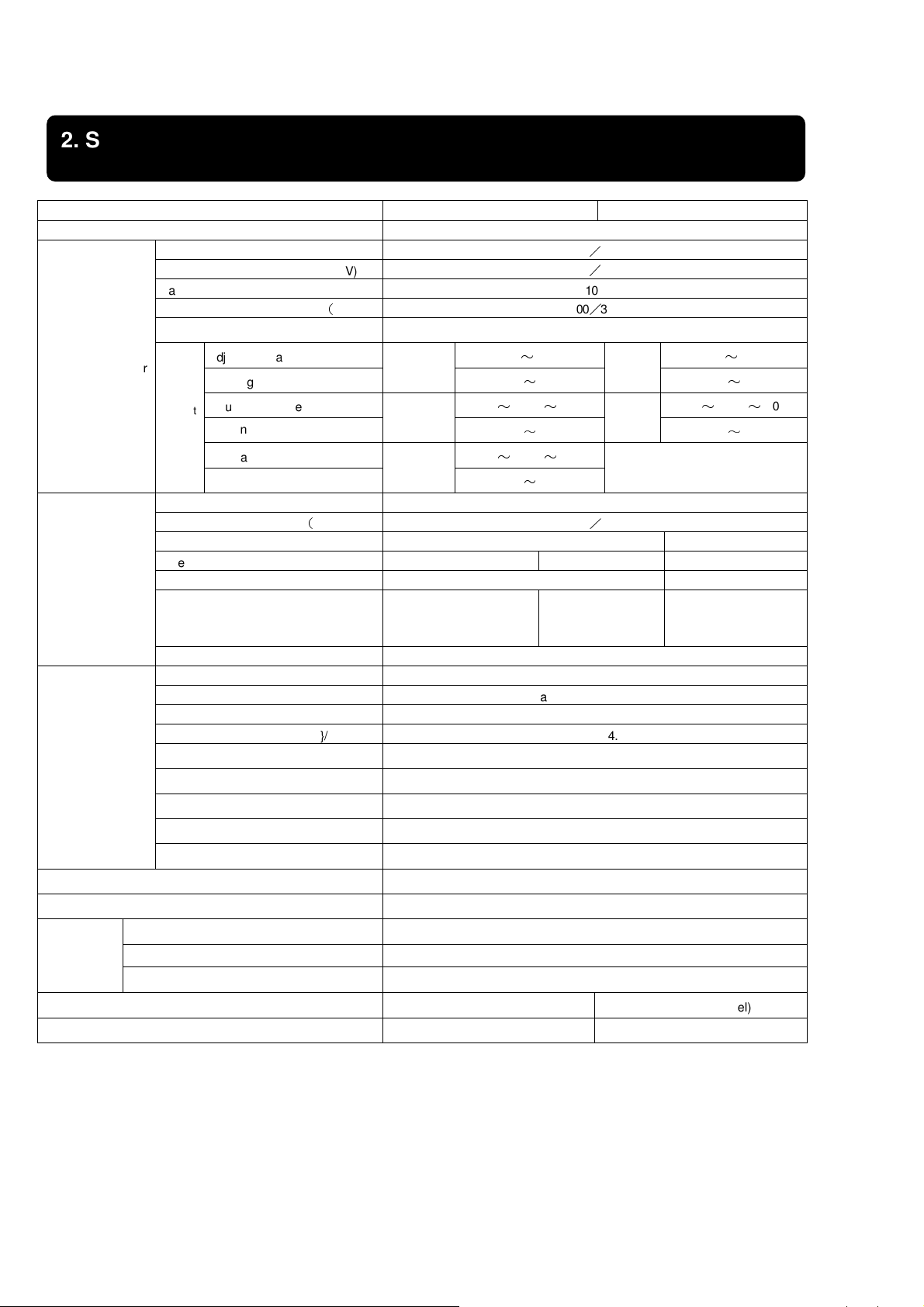

2. Specifications

Model DGW310DMC DGW310MC

Generating Method Rotating Field

Rated Current

Rated Load Voltage

Rated Duty Cycle

Rated Speed

No Load Voltage

Welding generator

Output

change

Rated Frequency (Hz) 50/60

Rated Speed (min-1) 3000/3600

Phase 1-Phase 3-Phase

Rated Voltage (V) 100/110 200/220 200/220

AC Generator

Engine

Battery

Fuel Tank Capacity (L)

Dimension

Dry Weight

Full Weight

Power Factor 1.0 0.8

Rated Output (kVA)

Rate Continuous

Model Kubota D722

Method Vertical In-lined Water Cooled 3 Cylinders Diesel Engine

Displacement

Rated Output

Fuel Diesel Fuel No.JIS2

Lubricant API Class CD or better

Lubricant Volume (L) 3.8(effective1.4)

Coolant Volume (L) 3.0(including sub tank 0.6)

Starting Method Starter Motor

Length (mm)

Width (mm)

Height (mm)

Adjustable Range (A)

Welding Rod (φ)

Adjustable Range (A)

Welding Rod (φ)

Adjustable Range (A)

Welding Rod (φ)

(kg)

(kg)

(A)

(V)

(%) 100

(

min-1) 3000/3600

(V)

Eco

Single

Dual

6

Receptacle1.5kVA×2 and

output terminal

(L) 0.719

(kW{PS}/ min-1) 11.7{15.9}/3000 14.0{19.0}/3600

338 (348 w/wheel) 333 (343 w/wheel)

382 (392 w/wheel) 377 (387 w/wheel)

30~160 30~160

2.0~4.0

70~280/85~310 35~280/45~310

2.6~6.0

35~150/45~160

2.0~4.0

1410 (1280 Canopy Length)

260/280

30.4/31.2

MAX 85

Eco

Normal

8

(Output Total)

46B24L

37

566

760 (870 with wheel)

2.0~4.0

2.0~6.0

9.9

6

3. Use

● Arc Welding

● Electric Tools and Home Appliances

● Power Supply to lights

Caution

::::

Damage to the property and secondary damage

●Do not use other than the above purposes

●Never use it without consulting with medical equipment

obtaining confirmation in Hospital.

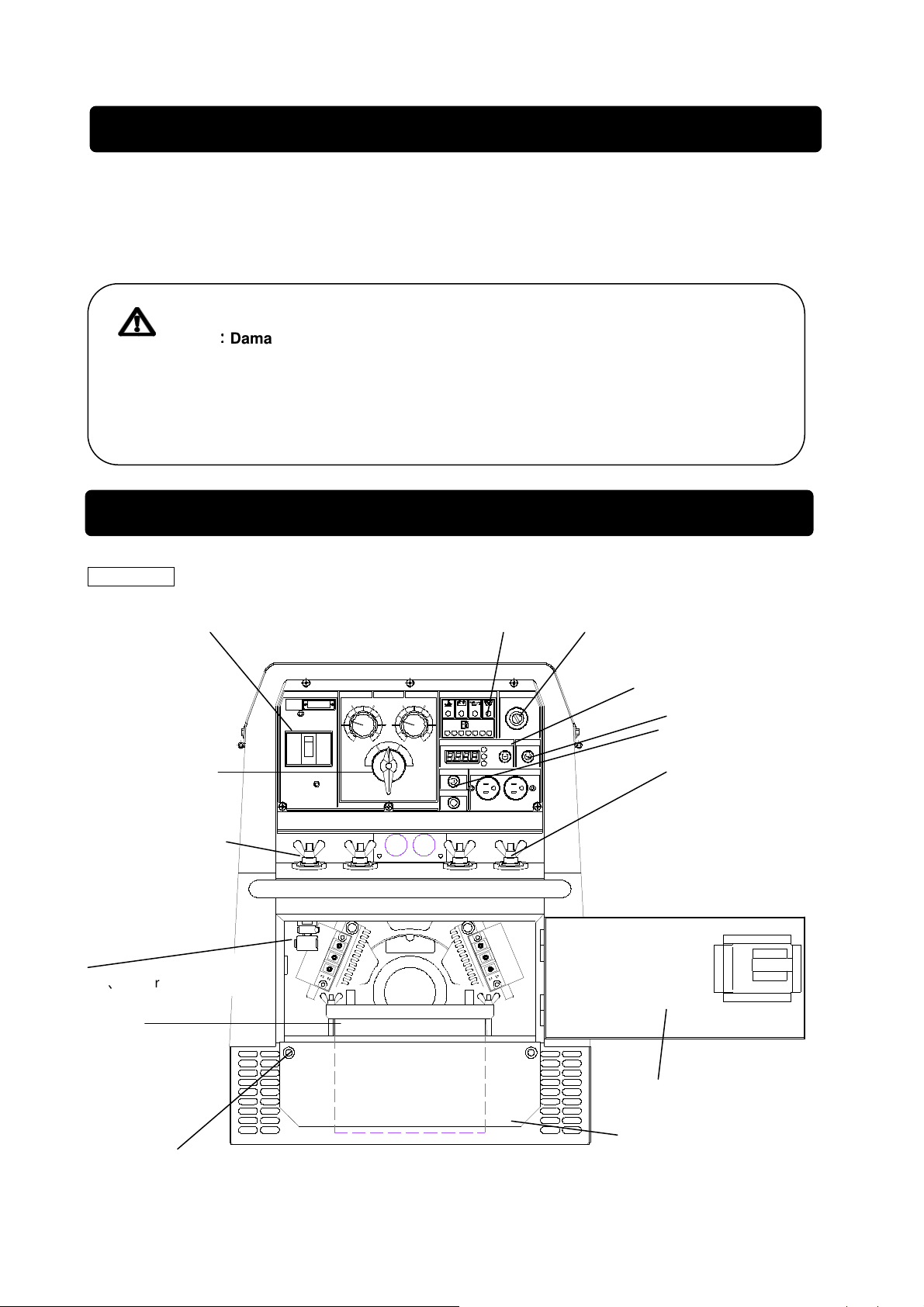

4. Parts

manufacturer,

doctor, hospital and

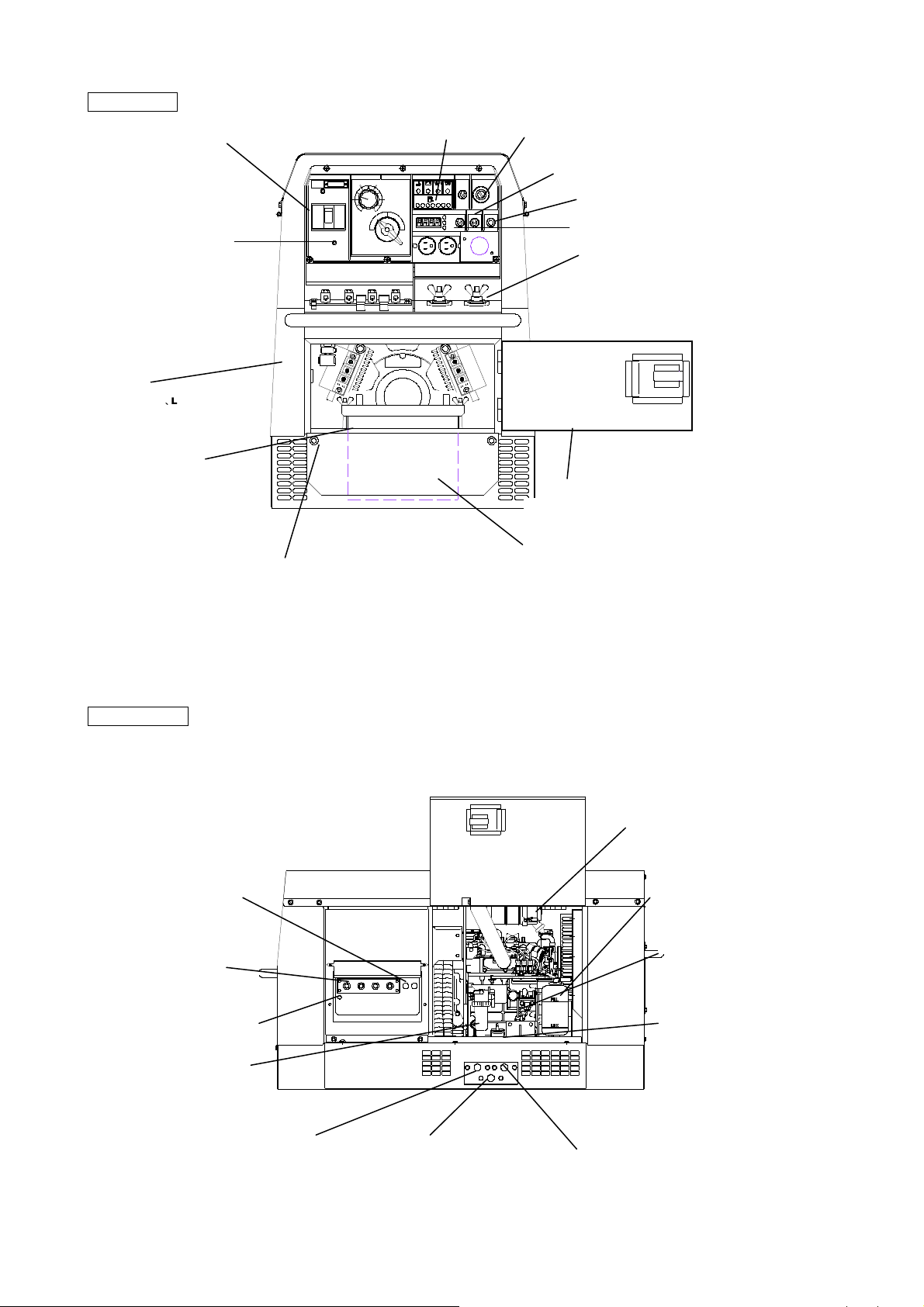

DGW310DMC

Breaker

Output Change SW

Welding Terminal A

Fuse

(Upper10A、Lower 50A)

Battery

Display

Starter Switch

Display Change SW

Slow Down SW

Frequency Change SW

Welding Terminal B

Front Door

Grounding Terminal

7

Under Plate

DGW310MC

Breaker

Starter Switch

Output Change SW

Slow Down SW

D

isplay Change SW

Display

Frequency Change SW

Welding Terminal

Battery

Groun

ding Terminal

Front Door

Under Plate

3P Output Terminal

Fuse(Upper10A、Lower 50A)

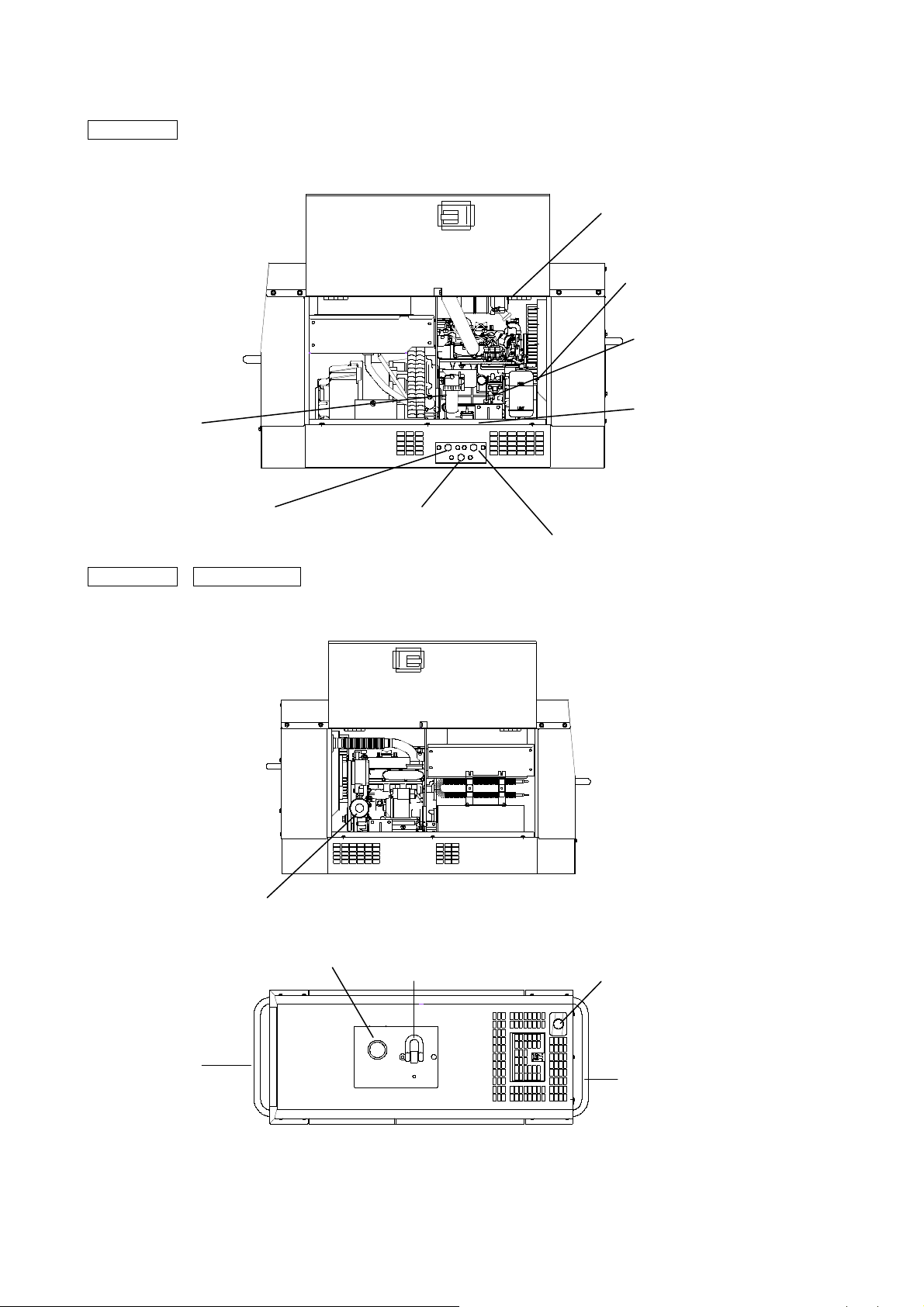

DGW310DMC

AC 1-P 100V output

AC 3-P 200V out

ELCB grounding terminal

Fuel lever /Strainer

Air Cleaner

Sub tank

Oil gauge

Oil inlet

Fuel drain plug Oil drain plug

Water drain plug

8

DGW310MC

Fuel lever /Strainer

Fuel drain plug Oil drain plug

DGW310MC DGW310DMC

Air Cleaner

Sub tank

Oil gauge

Oil inlet

Water drain plug

Oil filter

Fuel inlet

Lift hook

Exhaust gas outlet

Handle

Handle

9

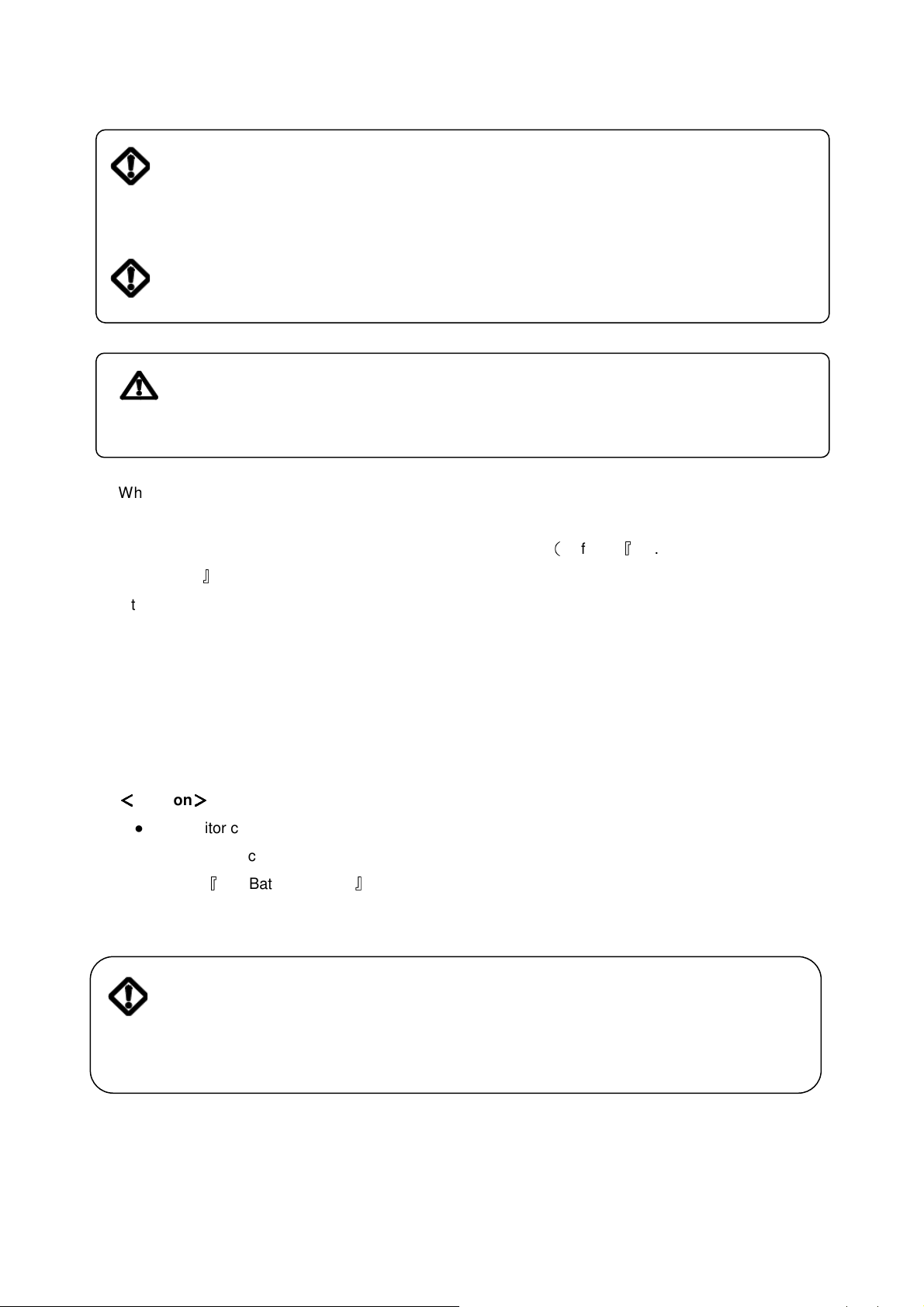

Water Temp

Charge

Oil Pres

Preheat

5. Incorporated

5-1. Eco Welding

The equipment is incorporated in Eco Welding Feature that is aiming at performing

The low noise, the lower fuel consumption and the low gas emission than those of conventional models.

When you turn the selector switch to Eco, you will be able to weld with Max 4.0mmφ rod at the slow

down speed.

<<<<

Caution

●When welding is performed, do not turn the output selector switch which causes the burnout of the

>>>>

switch

●Eco is designed for welding only. The breaker activates to TRIP, in case it is used for AC Output

5-2. Display

The equipment is incorporated in Digital Display. It displays『Voltage』,『Hour』,『Speed』successively,

by changing the display selector switch.

<<<<

Caution

●During operation, voltage meter always displays the voltage in 200/220V, 3-Phase both at the

5-3. Frequency Selection

Selector either 50 or 60Hz by the selector switch on the front panel, in accordance with the load

frequency.

5-4. Monitor Lamp

The equipment incorporates monitor lamps as 『Water Temperature』,『Battery Charging』 and『Oil

Pressure』.

Under normal condition, when the starter switch is turned from『STOP』to『REN』, the lamps of,『BATTERY

CHARGING』and『OIL Pressure』 turned To ON and all the lamps turn to OFF after the Engine starts.

When abnormality happens in running, monitor lamps flicker

And the engine stops automatically.

In the case the automatic shutdown is engaged, turn the starter switch to STOP once, and then restart

>>>>

breaker position『ON』 and『OFF』.

the engine. When the automatic shutdown is engaged again, check which lamp turns ON or OFF and

point out where the abnormality is.

10

(1) Water Temperature Monitor Lamp

Danger: Injuries

●

Close all the doors and place lock during operation, to avoid injuries by unintentional touch of cooling

fan or fan belt.

Danger: Burns

●Do not touch the engine and muffler during operation and immediately after stopping it, for

Caution: Burns

When the water temperature rises abnormally, the water temperature lamp flashes and the automatic

shutdown will be engaged.

When this happens, check water tank and replenish if needed.(Refer to『6-2. Check the water

temperature』

If the water level is normal, there may be possibility of overload. Always use the equipment within the

rated duty cycle and output power.

(2) Battery Charge Monitor Lamp

When the battery charge becomes unable during operation, the monitor lamp flashes and the automatic

shutdown is engaged.

Please consult with our authorized distributor or service section.

<<<<

Caution

●The monitor cannot detect battery degradation or insufficient battery liquid.

Be sure to check battery liquid level periodically.

(Refer to『6-5. Battery Check 』)

(3) Oil Pressure Monitor Lamp

>>>>

Danger: Injuries

●Close all the doors and place lock during operation, to avoid injuries by unintentional touch

of cooling fan or fan belt.

11

Loading...

Loading...