Shindaiwa C242-EVC, 89302 User Manual

English .................... 1

Español ..............SP_1

Français ............ FR_1

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

C242/EVC

BRUSHCUTTER

WARNING!

Always wear eye protection when operating

this machine. To minimize the risk of injury, read this

manual and familiarize yourself with its contents.

Part Number 89302 Rev. 6/09

Introduction

The Shindaiwa 242 series is designed and

built to deliver superior performance and

reliability without compromise to quality,

comfort, safety or durability.

Shindaiwa engines represent the leading

edge of high-performance engine

technology, delivering exceptionally high

power with remarkably low displacement

and weight. As an owner/operator, you’ll

soon discover for yourself why Shindaiwa

is simply in a class by itself!

IMPORTANT!

The information contained in these instructions describes units available at the time

of publication.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

WARNING!

The engine exhaust from this

product contains chemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

Contents

Safety...........................................................3

Product Description................................... 5

Specifications.............................................. 5

Assembly.....................................................6

Mixing fuel..................................................9

PAGE PAGEPAGE

Filling the fuel tank....................................9

Starting the Engine .................................10

Stopping the Engine ................................11

Adjusting Engine Idle..............................11

Checking Unit Condition.........................11

Operation ..................................................12

Maintenance.............................................14

Long Term Storage..................................17

Troubleshooting Guide ...........................18

Warranty Statement ................................21

IMPORTANT!

The operational procedures described in this manual are intended to help you get the most from this unit as well as to protect you and

others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended to replace any safety

rules and/or laws that may be in force in your area. If you have questions regarding your unit, or if you do not understand something in

this manual, contact your local authorized Shindaiwa dealer. You may also contact Shindaiwa Inc. at the address printed on the back of

this Manual.

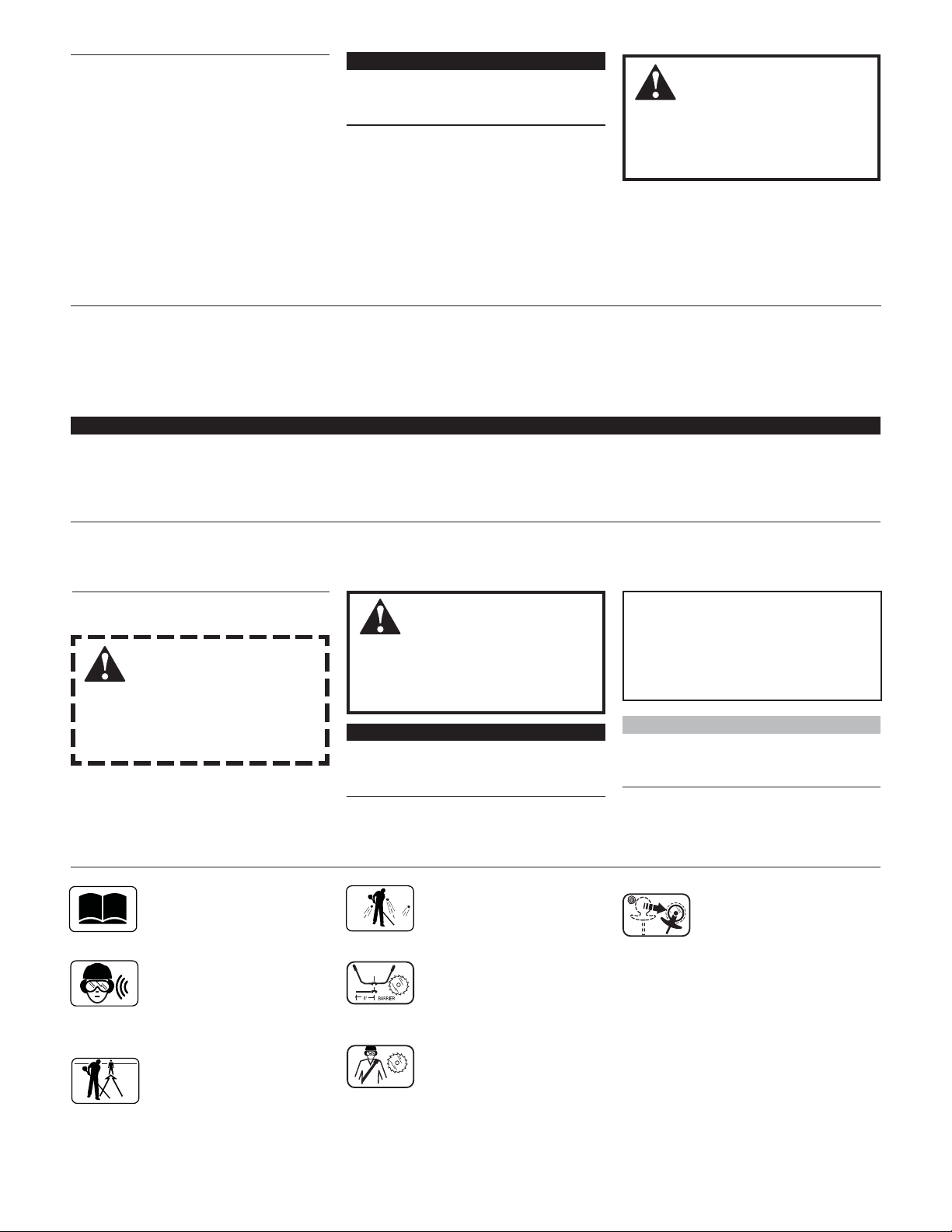

Attention Statements

Throughout this manual are special “attention statements”.

DANGER!

A statement preceded by the

triangular attention symbol and the

word “DANGER” contains information

that should be acted upon to prevent

serious injury or death.

triangular attention symbol and the

word “WARNING” contains information that should be acted upon to prevent serious bodily injury.

A statement preceded by the word

“IMPORTANT” is one that possesses special significance.

WARNING!

A statement preceded by the

IMPORTANT!

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent

mechanical damage.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

Warning and Operational Labels

Read and follow this operator's

manual. Failure to do so could

result in serious injury..

Wear eye and hearing protection at all times during operation of this unit. Wear head

protection where there is a risk

of falling objects.

Make sure no one is

50 FEET

within 15 M / 50 feet of

)

(15m

an operating machine.

2

Beware of thrown or

richocheted objects

DO NOT operate this unit with a

blade unless the unit is equipped

with a Shindawia-approved

handlebar or barrier.

Always wear a harness when

operating this unit with a blade.

A harness is also recommended

when using trimmer line.

If unit is used as a brushcutter,

beware of blade thrust. A

jammed blade can cause the unit

to jerk suddenly and may cause

the operator to lose control of

the unit.

Safety

Work Safely

Trimmers and brushcutters operate at

very high speeds and can do serious damage or injury if they are misused or abused.

Never allow a person without training or

instruction to operate this unit!

ALWAYS inspect unit before each use.

Replace any damaged parts.

NEVER run the engine when transporting the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly

installed parts or attachments.

WARNING!

Never make unauthorized

attachment installations.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Use Good Judgment

NEVER extend trimming line beyond the

OHQJWKVSHFL¿HGIRU\RXUXQLW

ALWAYS keep the unit as clean as practical. Keep it free of loose vegetation,

mud, etc.

ALWAYS KROGWKHXQLW¿UPO\ZLWKERWK

hands when cutting or trimming, and

maintain control at all times.

ALWAYS use the proper cutting tool for

the job.

WARNING!

Never operate

power equipment of any kind

if you are tired or if you are under the

LQÀXHQFHRIDOFRKROGUXJVPHGLFDtion or any other substance that could

affect your ability or judgement.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug wire

before performing any maintenance

work.

ALWAYS , if a saw blade should bind fast

in a cut, shut off the engine immediately.

Push the branch or tree to ease the bind

and free the blade.

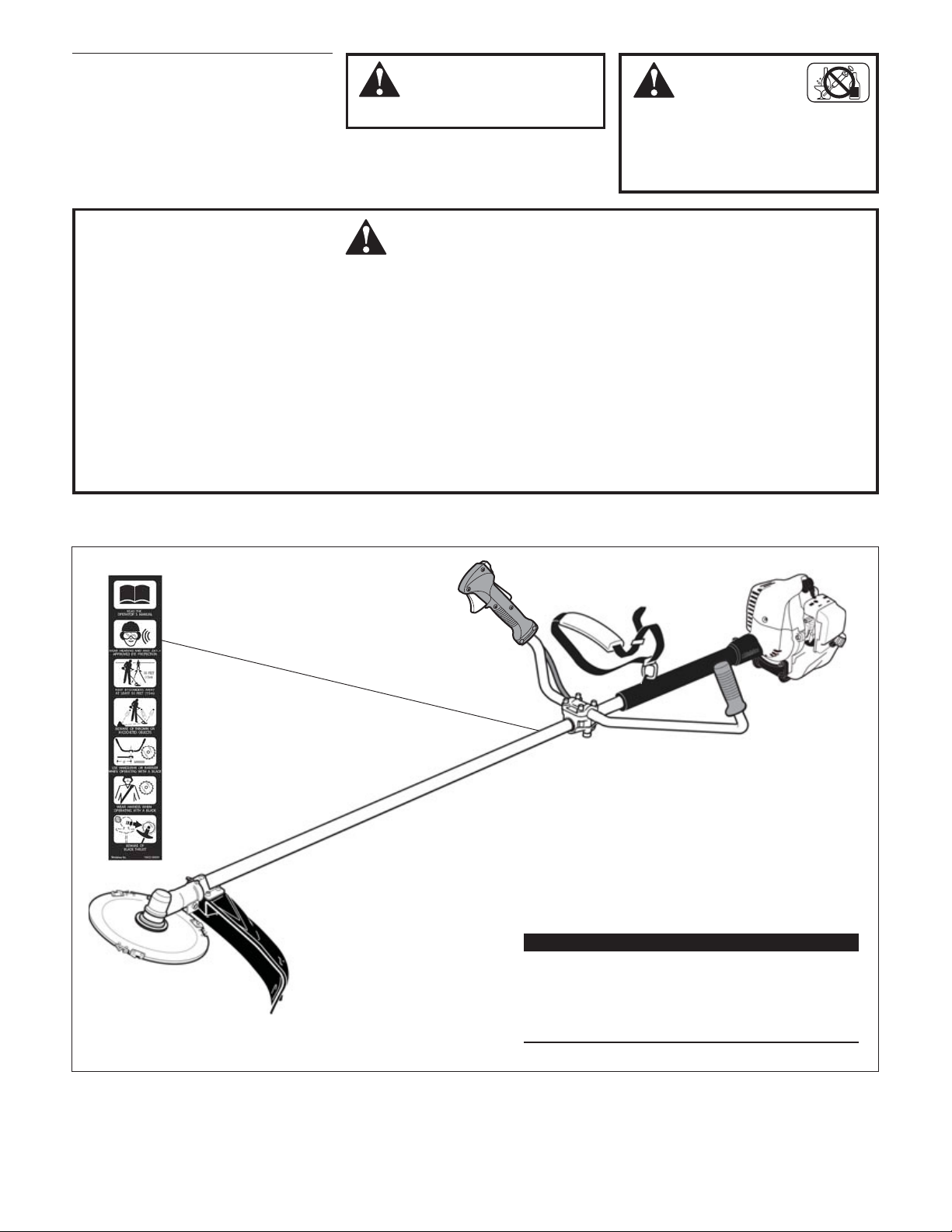

Safety Labels

IMPORTANT!

Safety and Operation Information Labels: Make sure all

information labels are undamaged and readable. Immediately replace damaged or missing information labels.

New labels are available from your local authorized

Shindaiwa dealer.

3

Safety (continued)

The Properly Equipped Operator

Wear hearing protection devices and a

broad-brimmed hat or helmet. A helmet

is required when using a blade-equipped

brushcutter to clear small trees.

Prolonged exposure to excessive noise

is fatiguing and could lead to impaired

hearing.

:HDUFORVH¿WWLQJFORWKLQJWR

protect legs and arms. Gloves

offer added protection and are

strongly recommended. Do not

wear clothing or jewelry that

could get caught in machinery

or underbrush. Secure long hair

so that it is above shoulder level.

NEVER wear shorts!

Long-term exposure to vibration

can damage your hands.

Keep a proper footing and do not

overreach. Maintain your balance at all

times during operation.

Wear appropriate footwear (non-skid

boots or shoes): do not wear opentoed shoes or sandals. Never work

barefooted!

Always wear eye protection such as

goggles or safety glasses to shield

against thrown objects.

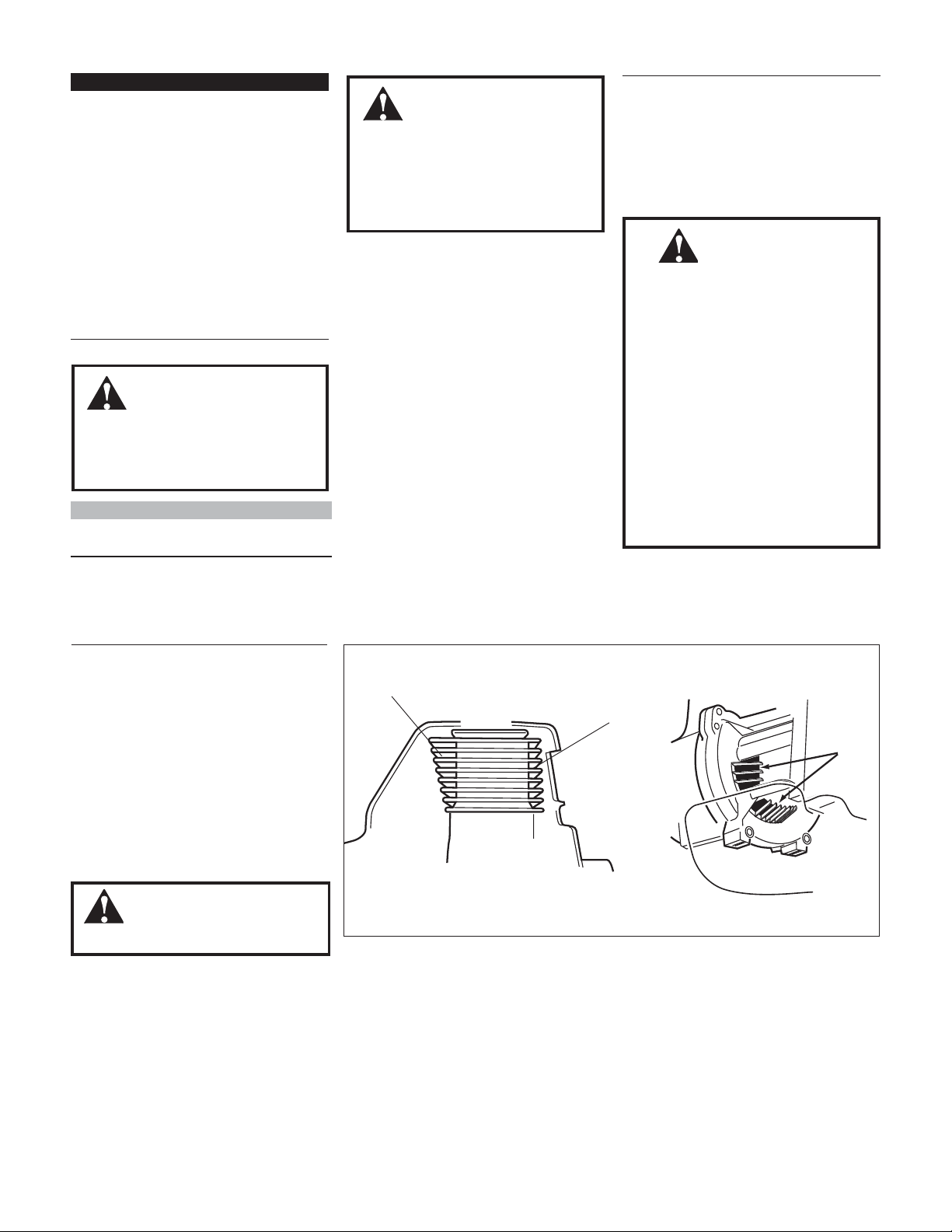

Always wear a harness when operating the unit .

It adds comfort and helps ensure safety by limiting

movement fore and aft. When the harness is

adjusted properly, the unit should balance with the

cutting attachment parallel to the ground.

Always operate with both hands

¿UPO\JULSSLQJWKHXQLW

When operating with a blade, make sure

the handle is positioned to provide you with

maximum protection from contacting the

blade. Always make sure the handlebar

is installed in accordance with the

manufacturers instructions.

Always make sure the

appropriate cutting attachment

shield is correctly installed and

in good condition. Do not

operate the unit if the

cutting attachment shield

is missing, loose, or

broken.

Keep away from the rotating

trimmer line or blade at all

times, and never lift a moving

attachment above waist-high.

Be Aware of the Working Environment

Avoid long-term

operation in very hot

or very cold weather.

Be extremely careful

of slippery terrain,

especially during rainy

weather.

Be constantly alert for

objects and debris that

could be thrown either

from the rotating cutting

attachment or bounced

from a hard surface.

If contact is made with a hard object,

stop the engine and inspect the cutting

Make sure

bystanders

or observers

outside the

15 meter (50

feet) “danger

zone” wear eye

protection.

15 METERS

(50 FEET)

Always make sure

the appropriate

cutting attachment

shield is correctly

installed.

attachment for damage.

Reduce the risk of bystanders being

VWUXFNE\À\LQJGHEULV0DNHVXUHQR

one is within 15 meters (50 feet)—

that’s about 16 paces of an operating

attachment. Stop immediately if a child,

pet, or person comes within a 15 meter

(50 feet)radius. Outside this radius,

there is still a risk of injury from thrown

objects.

Do not operate the unit

if the cutting attachment

shield is missing, loose,

or broken.

Beware of a coasting

blade when brushcutting or

edging. A coasting blade

can injure while it continues

to spin after the throttle

trigger is released or after

the engine is stopped.

ALWAYS clear your work area of trash

or hidden debris that could be thrown

back at you or toward a bystander.

When operating in rocky terrain or

near electric wires or fences, use

extreme caution to avoid contacting

such items with the cutting attachment.

4

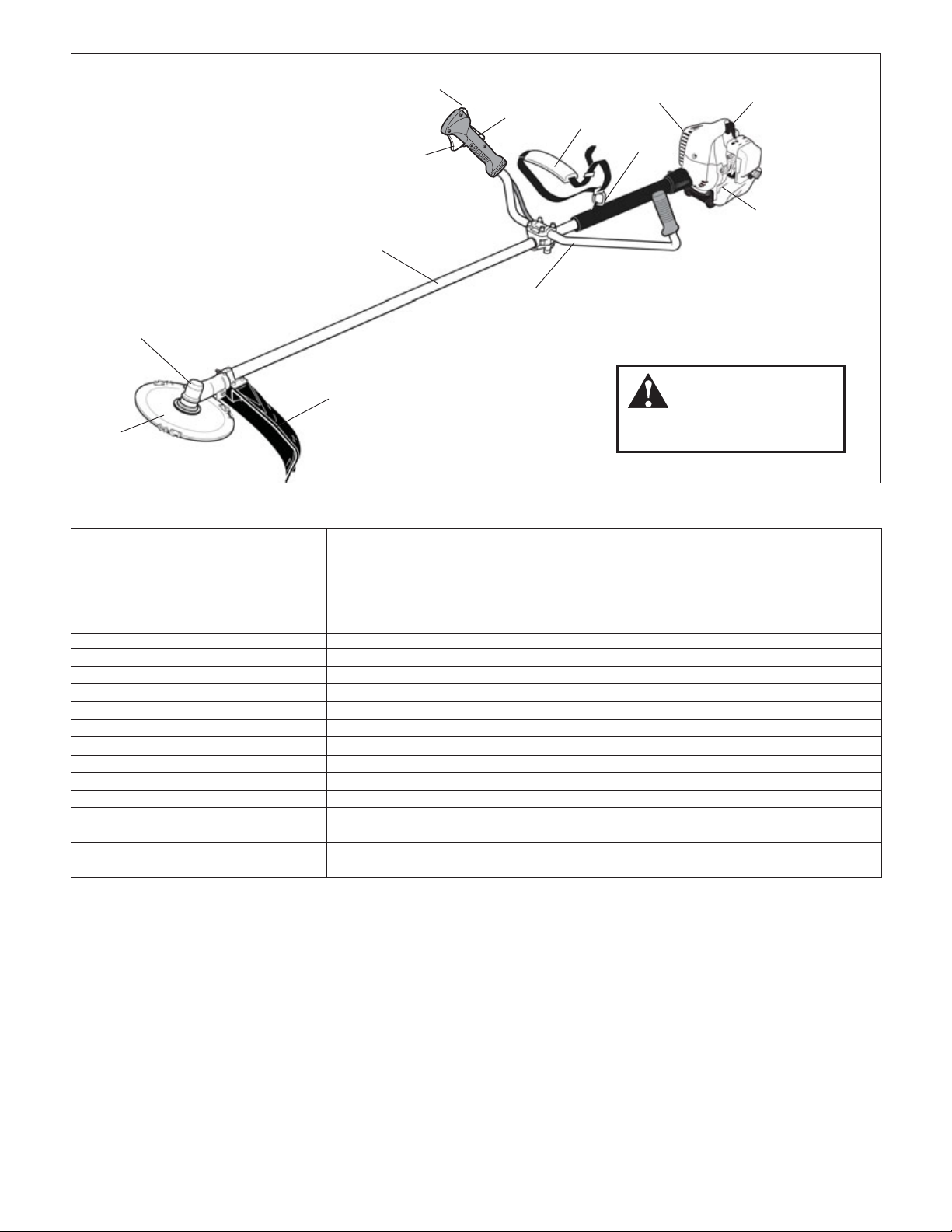

Product Description

Using the illustration as a guide,

familiarize yourself with your

machine and its various components. Understanding your

machine helps ensure top performance, long service life and safer

C242

Ignition

Throttle

Throttle

interlock

0XIÀHU

Strap

Hanger

operation.

Outer tube

Handlebar

Gearcase

Cutting attachment

shield

WARNING!

Do not make unauthorized

PRGL¿FDWLRQVRUDOWHUDWLRQVWRDQ\RI

Brushcutter

blade

these units or their components.

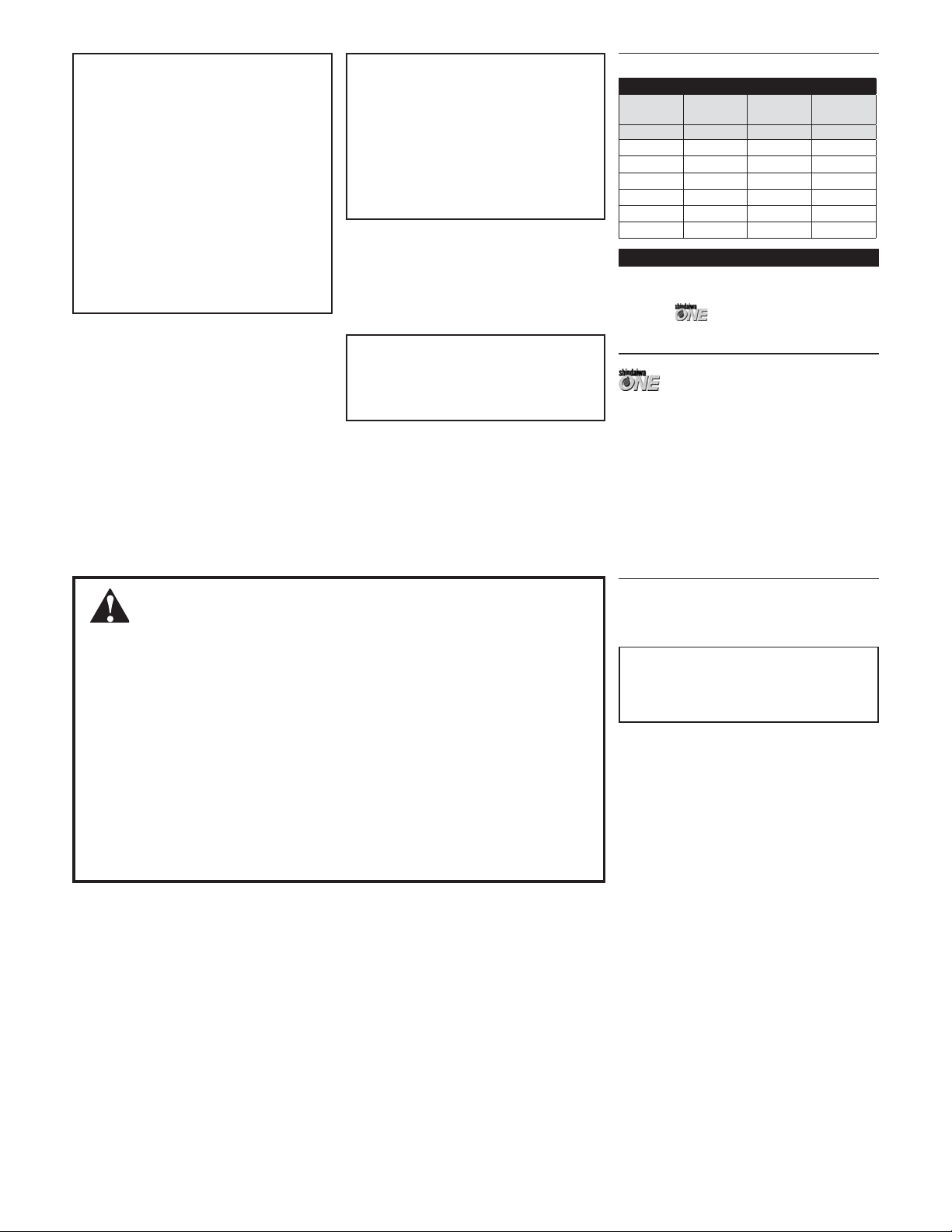

6SHFLÀFDWLRQV

Engine model SF242E

Dry weight (less attachment) 5.7 kg / 12.6 lb

Engine type 2-cycle catalyst

Bore x stroke 33 x 28 mm / 1.3 x 1.1 in.

Displacement 23.9 cc / 1.5 cu. in.

Maximum power 1.0 HP/0.8 kW @ 8000 min

Recommended idle speed 3,000 (±250) min

Fuel/oil ratio 50:1 with ISO-L-EGD or JASO FC class 2-cycle mixing oil*

Carburetor type Walbro WYK, diaphragm-type

Fuel tank capacity 670 mL / 22.3 oz

Ignition One-piece electronic, transistor contolled

Spark plug NGK BPMR6A

Electrode Gap 0.6 - 0.7 mm / .024 -.028 in.

Torque 170 - 190 kg cm / 16.7 - 18.6 N∙m

Air cleaner type Foam, non reversible

Starting method Recoil

Stopping method Slide switch

Transmission type Automatic, centrifugal clutch w/bevel gear

Handle Type Bicycle type

EPA Emission Compliance Period** Category A

-1

(rpm)

-1

(rpm)

Spark plug

Fuel tank

Specifications are subject to change without notice.

** The EPA emission compliance referred to on the emission compliance label located on the engine, indicates the number of operating

hours for which the engine has been shown to meet Federal emission requirements. Category C = 50 hours (Moderate), B = 125 hours

(Intermediate) and A = 300 hours (Extended).

* The NGK BPMR6A also meets the requirements for electro magnetic compliance (EMC).

5

Assembly

This unit comes fully assembled with the

exception of the handlebar, cutting attachment shield and cutting attachment.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front”

and “rear” refer to directions as viewed by

the operator during normal operation.

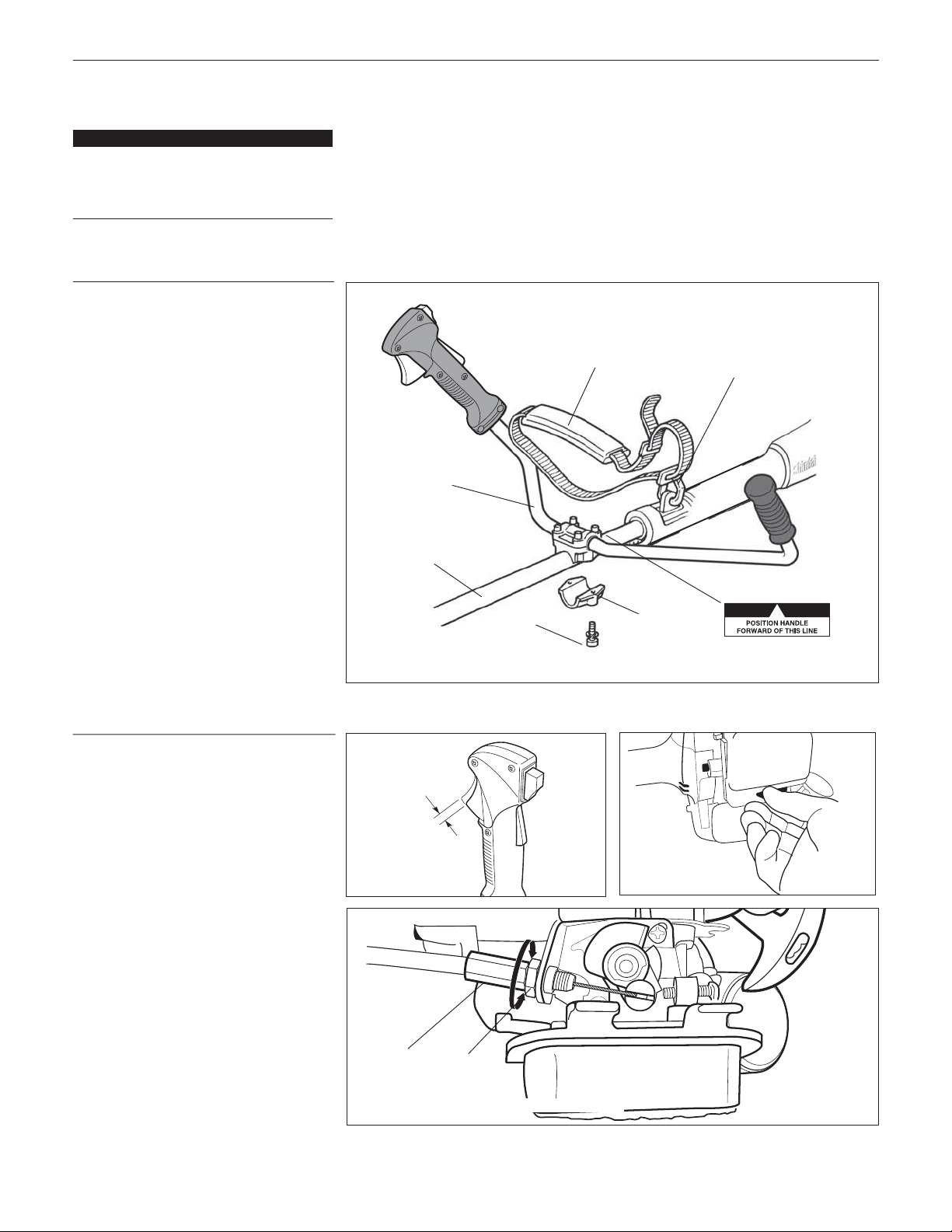

Handlebar

Install the handlebar:

Use the 4 mm hex wrench to remove 1.

the lower cap retaining screws from

the handlebar bracket. Remove the cap

from the bracket, and note the position

of the two spacers installed between the

bracket halves.

Position the handle on the outer tube 2.

forward of Handle Positioning Label as

shown. Reassemble the lower cap to the

handlebar bracket in the reverse order

of disassembly.

Locate the handle in the best position 3.

for operator comfort.

Firmly tighten both lower cap retaining 4.

screws.

Prior to Assembly

Before assembling, make sure you

have all the components required for a

complete unit and inspect unit and components for any damage.

Ŷ

Engine/Outer tube assembly

Handlebar and Throttle assemblyŶ

Cutting attachment shieldŶ

Cutting attachmentŶ

Handlebar

Outer Tube

Strap

Ŷ

Kit containing cutting attachment shield

mounting bracket and hardware, this

owner’s/operator’s manual and tool

kit for routine maintenance. Tool kits

vary by model and may include a hex

wrench, and a spark plug/screwdriver

combination wrench.

Hanger

Handle Positioning Label

Adjust throttle lever free play

The throttle lever free play should be

approximately 4-6 mm. Make sure that

the throttle lever operates smoothly

without binding. If it becomes necessary

to adjust the lever free play, follow the

procedures and illustrations that follow.

Loosen the air cleaner cover knob and 1.

remove the air cleaner cover.

Loosen the lock nut on the cable 2.

adjuster.

Turn the cable adjuster in or out as 3.

required to obtain proper free play.

Tighten the locknut.4.

Reinstall the air cleaner cover.5.

Lower Cap

Retaining Screws

Mounting the brushcutter handlebar

4-6 mm

Throttle lever free play

Cable

Adjuster

Lock

Nut

Lower cap

Remove air cleaner cover

Adjust as required to obtail 4-6 mm free play

6

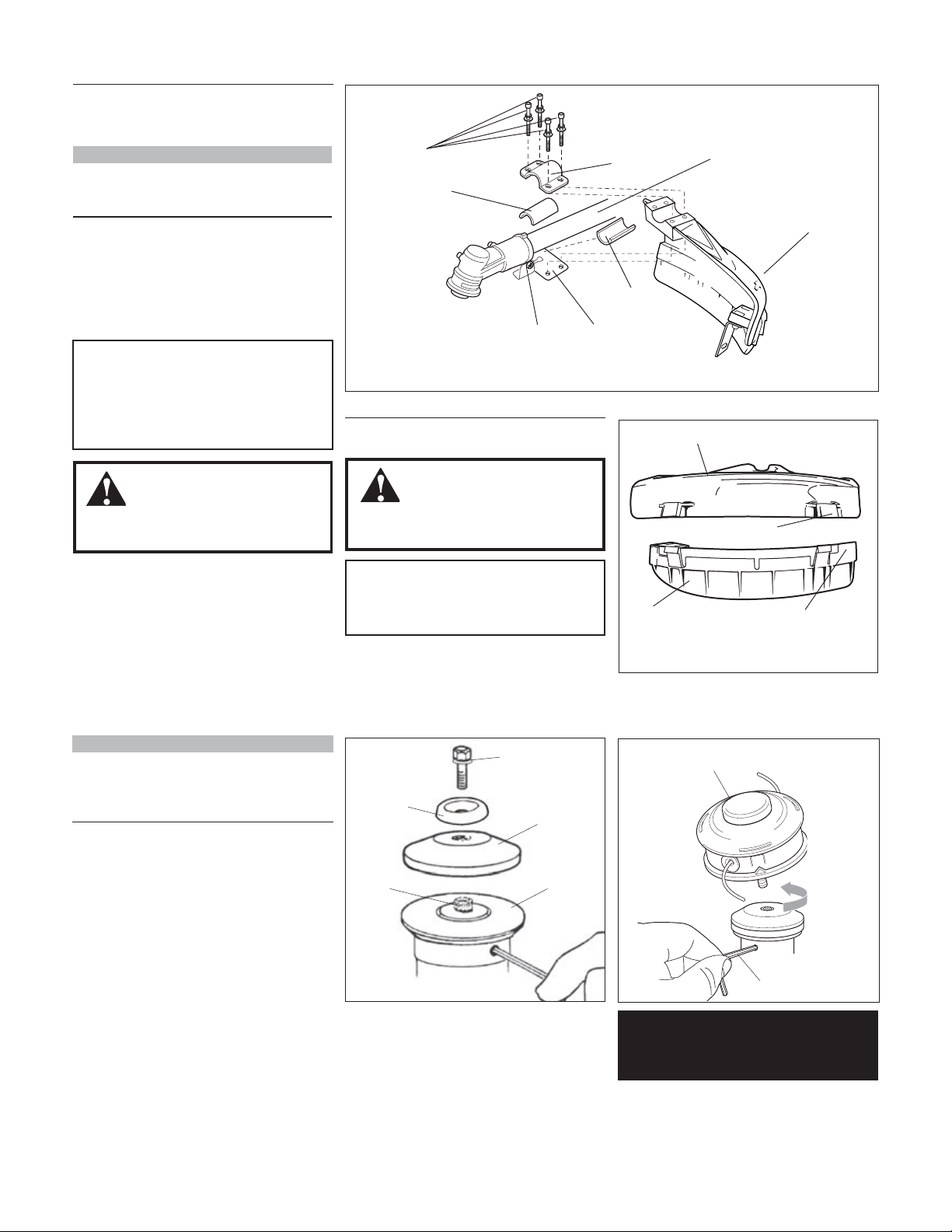

Assembly (continued)

Cutting Attachment Shield

Insert the cutting attachment shield 1.

between the outer tube and the cutting

attachment mounting plate.

NOTE:

It may be necessary to loosen the retaining nut and clamp screw to adjust cutting

attachment shield mounting plate.

Fit the two spacers and the bracket 2.

over the outer tube and loosely install

the four socket-head screws.

Tighten the four socket-head cap 3.

screws to secure the cutting attachment

shield.

CAUTION!

Make sure the clamp screw and

retaining nut are securely tightened

before tightening the four socket-head

cap screws.

Socket-Head

Cap Screws

Spacer

Retaining

Cutting attachment shield assembly

Nut

Bracket

Spacer

Mounting Plate

Sub-Shield (when trimmer head is in use)

Attach the shield extension to the cut-1.

ting attachment shield.

Cutting Attachment Shield

Outer Tube

Cutting Attachment

Shield w/subshield

WARNING!

NEVER operate the unit

without the cutting attachment shield

installed and tightly secured!

Installing a Trimmer Head

NOTE:

This unit is shipped with Holder A, Holder

B, shaft bolt, and bolt guard installed.

The shaft bolt is a LEFT-HAND thread.

Remove it by turning CLOCKWISE!

With the gearcase output shaft facing 1.

up, rotate the gearshaft and Holder A

until the hole in Holder A aligns with

the matching hole in the gearcase

flange, and then lock the holder to the

gearcase by inserting the long end of

the hex wrench through both holes.

Using the combination spark plug/2.

screwdriver wrench, remove the shaft

bolt, bolt guard and Holder B. (The bolt

guard and shaft bolt are not used with a

trimmer head).

Install Holder B on the gearcase shaft. 3.

The splined hole on Holder B must

engage with the gearcase shaft.

WARNING!

NEVER use this machine

without sub-shield when using a trimmer head.

CAUTION!

Make sure the sub-shield is completely

hooked at the hook receiver.

Shaft Bolt

Bolt Guard

Holder B

Gear Shaft

Holder A

Using the hex wrench to secure Holder 4.

A, install and hand-tighten the trimmer

head (counter-clockwise to install).

Remove the hex wrench from the 5.

gearcase and holder.

Hook Receiver

Sub-shield

Attach the shield extension to the cutting

attachment shield

Hand-tighten Trimmer Head (counter-

clockwise to install)

Hook

Hex Wrench

This unit is now completely

assembled and ready to use as a

trimmer.

7

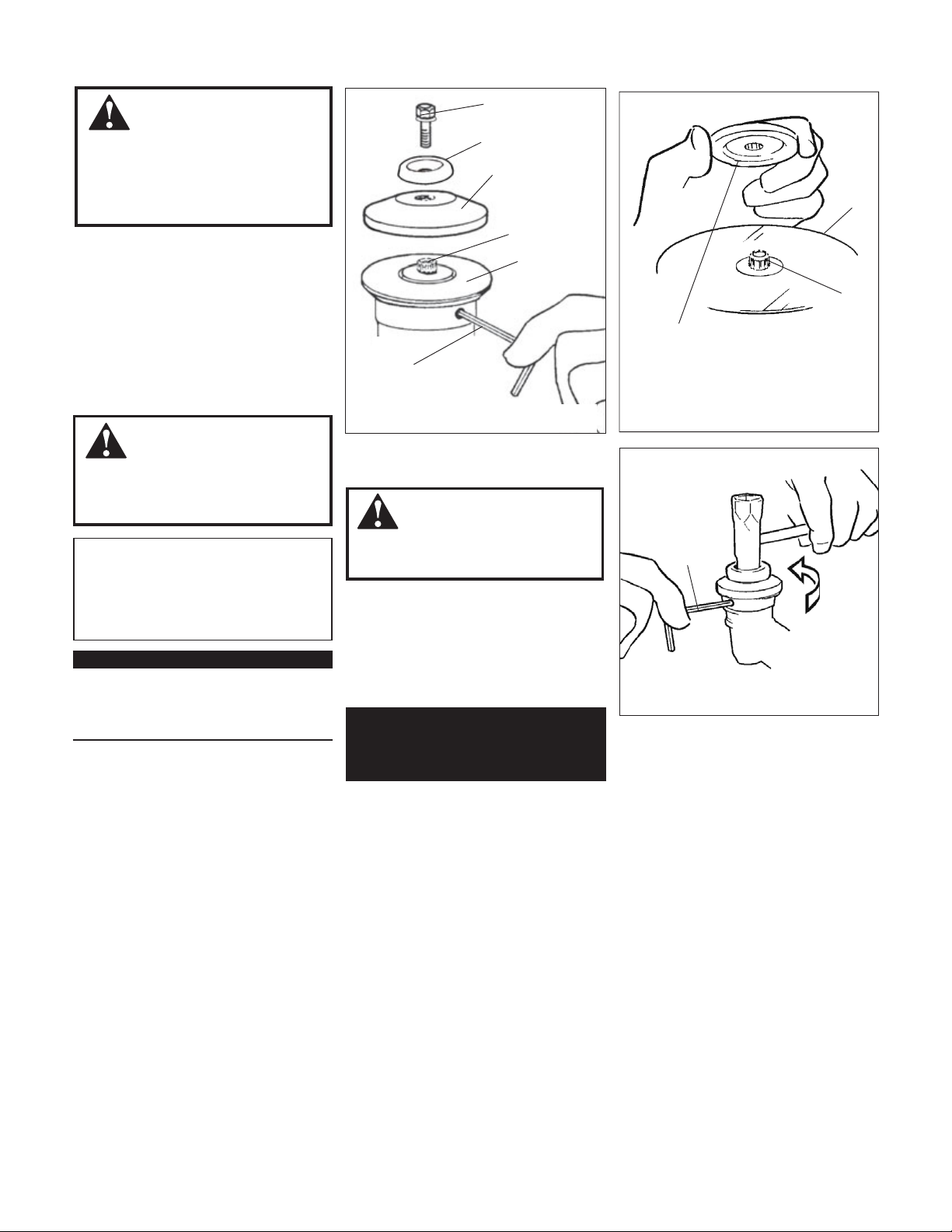

Assembly (continued)

Installing Brushcutter Blade

WARNING!

Do not attach any blade to

a unit without proper installation of

all required parts. Failure to use the

proper parts can cause the blade to

À\RIIDQGVHULRXVO\LQMXUHWKHRSHUDWRU

and/or bystanders.

Turn the unit upside down so the gear 1.

case output shaft is facing UP and

remove the shaft bolt, bolt guard and

holder B from the gear case shaft.

Align the hole in blade holder A with 2.

the matching hole in the gear case

flange and then temporarily lock the

output shaft by inserting a hex wrench

through both holes.

Fit the blade over the flange on holder A.3.

WARNING!

7KHEODGHPXVW¿WÀDWDJDLQVW

WKHKROGHUÀDQJH7KHEODGHPRXQWLQJ

hole must be centered over the raised

boss on blade Holder A.

CAUTION!

Install the blade so its printed surface

is visible to the operator when the

brushcutter is in the normal operating

position.

IMPORTANT!

Discard blades that are bent, warped,

cracked, broken or damaged in any way.

Use a sharp blade. A dull blade is more

likely to snag and thrust.

Shaft Bolt

Bolt Guard

Holder B

Gear Shaft

Holder A

Hex wrench

Temporarily lock the output shaft by

inserting a hex wrench through both holes

Install blade holder B on the output 4.

shaft.

WARNING!

+ROGHU%PXVW¿WÀXVKDJDLQVW

the blade and the splines engaged to

the output shaft.

Install the bolt guard and then the blade 5.

retaining bolt. Using the combination

spark plug wrench/screwdriver, tighten

the bolt firmly in a counter-clockwise

direction.

Remove the hex wrench.6.

The unit should now be complete-

ly assembled and ready for use

with a blade.

Output

Shaft

Blade Holder B

Install blade holder B on the output shaft.

Tighten the assembly

(blade not shown for

clarity)

Hex Wrench

Using the combination spark plug wrench/

VFUHZGULYHUWLJKWHQWKHEROW¿UPO\LQD

counter-clockwise direction.

Blade

8

Mixing fuel

CAUTION

Never use any type of gasoline containing more than 10% alcohol by volume!

Some types of gasoline contain alcohol

as an oxygenate. Oxygenated gasoline may cause increased operating

temperatures. Under certain conditions, alcohol-based gasoline may also

reduce the lubricating qualities of some

2-cycle mixing oils.

Generic oils and some outboard

oils should never be used in your

Shindaiwa engine.

CAUTION

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and ISO-L-EGD or JASO FD

class 2-cycle mixing oil only. Use of

non-approved mixing oils can lead to

excessive carbon deposits.

Use only fresh, clean unleaded gasoline Ŷ

with a pump octane of 87 or higher.

Mix all fuel with a 2-cycle air-cooled

Ŷ

mixing oil that meets or exceeds ISO-LEGD and/or JASO FD classified oils at

50:1 gasoline/oil ratio.

CAUTION!

Mix and pour fuel outdoors where there

DUHQRVSDUNVDQGÀDPHV

Examples of 50:1 mixing quantities

U.S. METRIC

Gasoline

US Gallons Fl.oz. Liter cc.

1 2.6 4 80

2 5.2 8 160

5 13 20 400

10 25.6 30 600

20 51.2 50 1000

50 128 100 2000

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than 30

days and

used, it should first be treated with a fuel

stabilizer such as STA-BIL™.

fied oil and also meets or exceeds ISO-L-EGD

performance requirements. Shindaiwa One is

recommended for use in all Shindaiwa low emissions engines. Shindaiwa One also includes a

fuel stabilizer.

2-cycle

mixing oil

IMPORTANT!

oil with fuel stabilizer is not

Oil is a registered JASO FD classi-

Gasoline

2-cycle

mixing oil

Filling the fuel tank

WARNING!

Minimize the Risk of Fire

NEVERŶ VPRNHRUOLJKW¿UHVQHDUWKH

engine.

Ŷ stop the engine and allow

ALWAYS

it to cool before refueling.

ALWAYS

Ŷ Wipe all spilled fuel and

move at least 3 meters (10 feet)

from the fueling point and source

before starting.

NEVER

Ŷ SODFHÀDPPDEOHPDWHULDO

FORVHWRWKHHQJLQHPXIÀHU

Ŷ operate the engine with-

NEVER

RXWWKHPXIÀHUDQGVSDUNDUUHVWHU

screen in place and in good working condition.

FUEL IS HIGHLY FLAMMABLE.

Ŷ

ALWAYS Ŷ store gasoline in a con-

WDLQHUDSSURYHGIRUÀDPPDEOH

liquids.

ALWAYSŶ inspect the unit for fuel

leaks before each use. During each

UH¿OOFKHFNWKDWQRIXHOOHDNVIURP

around the fuel cap and/or fuel tank.

If fuel leaks are evident, stop using

the unit immediately. Fuel leaks must

be repaired before using the unit.

ALWAYSŶ move the unit at least 3

meters (10 feet) away from a fuel

VWRUDJHDUHDRURWKHUUHDGLO\ÀDPmable materials before starting

the engine.

Place the unit on a flat, level surface.1.

Clear any dirt or other debris from 2.

around the fuel filler cap.

CAUTION!

Slowly remove the fuel cap only after

stopping the engine

Remove the fuel cap, and fill the tank 3.

with clean, fresh fuel.

Reinstall the fuel filler cap and tighten 4.

firmly.

Wipe away any spilled fuel before start-5.

ing engine.

9

Starting the Engine

IMPORTANT!

Engine ignition is controlled by a two position switch mounted on the throttle housing labeled, “I” for ON or START and “O” for OFF or STOP.

WARNING!

Never start the engine from

the operating position.

Slide the ignition switch to the “I” 1.

position.

Press the primer bulb until fuel can 2.

be seen flowing in the transparent

return tube.

IMPORTANT!

The primer system only pushes fuel

through the carburetor. Repeatedly pressing the primer bulb will not flood the

engine with fuel.

Set the choke lever to the CLOSED 3.

position if engine is cold.

While holding the outer tube firmly 4.

with left hand. Use your other hand

to slowly pull the recoil starter handle

until resistance is felt, then pull quickly

to start the engine.

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

When the engine starts, slowly move 5.

the choke lever to the “OPEN” position. If the engine stops after the initial

start, close the choke and restart.

Ignition

switch

ON

Throttle lever

Slide ignition to ON

Closed

Set the choke lever to the CLOSED position

WARNING!

The cutting attachment may

move when the engine is started!

Keep your hands and your body away

from the cutter assembly while starting the engine!

IMPORTANT!

If the engine fails to start after several

attempts with the choke in the closed

position, the engine may be flooded with

fuel. If flooding is suspected, refer to the

“Starting a Flooded Engine” section of

this manual.

Primer

bulb

Press the primer bulb

...and pull recoil

starter handle

upward

When the engine starts, slowly move the

choke lever to the “OPEN” position

Return tube

Hold

the unit

¿UPO\

Make sure the

attachment is clear

of obstructions!

Open

When the Engine Starts...

After the engine starts, allow the Ŷ

engine to warm up at idle 2 or 3 minutes before operating the unit.

After the engine is warm, pick up the

Ŷ

unit and clip on the shoulder strap, if

so equipped.

10

Advancing the throttle makes the cutting

Ŷ

attachment move faster; releasing the

throttle permits the attachment to stop

moving. If the cutting attachment con-

tinues to move when the engine returns

to idle, carburetor idle speed should be

adjusted (see “Adjusting Engine Idle”.).

Starting the Engine (continued)

Starting A Flooded Engine

Disconnect the spark plug lead and use 1.

the spark plug wrench to remove the

spark plug (turn counter clockwise to

remove).

Slide the ignition switch to the “O” 2.

(STOP) position.

Ŷ

If the spark plug is fouled or

soaked with fuel, clean the plug as

necessary.

Stopping the Engine

Idle the engine briefly before stopping 1.

(about 2 minutes).

Slide the ignition switch to the “O” 2.

(Engine OFF) position.

Adjusting Engine Idle

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must be set

low enough to permit the engine clutch to

disengage the cutting attachment.

WARNING!

The cutting attachment must

NEVER rotate at engine idle! If the

idle speed cannot be adjusted by the

procedure described here, return the

trimmer to your Shindaiwa dealer for

inspection.

Open the choke and fully depress the 3.

throttle lever with your left hand, then

pull the starter handle rapidly with your

right hand to clear excess fuel from the

combustion chamber.

Replace the spark plug and tighten it 4.

firmly with the spark plug wrench. If a

torque wrench is available, torque the

spark plug to the values recommended

in the “Specifications” section.

Ignition

switch

OFF

Idle Speed Adjustment

Place the unit on the ground, then start 1.

the engine, and then allow it to idle 2-3

minutes until warm.

If the attachment rotates when the 2.

engine is at idle, reduce the idle speed

by turning the idle adjustment screw

counter-clockwise.

If a tachometer is available, adjust idle. 3.

Check Specifications page for correct

idle speed

NOTE

Carburetor fuel mixture adjustments are

preset at factory and cannot be serviced

LQWKH¿HOG

Repeat the starting procedure for a 5.

warm engine.

If the engine still fails to start, refer to 6.

the troubleshooting section near the

end of this manual.

IMPORTANT

When the unit is turned off make sure the

cutting attachment has stopped before the

unit is set down.

Idle

adjustment

screw

Adjusting

engine idle

Checking Unit Condition

NEVER operate the unit with the cutting attachment shield or other protective devices removed!

Use only authorized Shindaiwa parts and

accessories with your Shindaiwa trimmer.

Do not make modifications to this unit without written approval from Shindaiwa, Inc.

ALWAYS make sure the cutting attachment is properly installed and firmly

tightened before operation.

NEVER use a cracked or warped

cutting attachment: replace it with a

serviceable one.

ALWAYS make sure the cutting attachment fits properly into the appropriate

attachment holder. If a properly installed

attachment vibrates, replace the attachment with new one and re-check.

ALWAYS stop the engine immediately

and check for damage if you strike a

foreign object or if the unit becomes

tangled. Do not operate with broken or

damaged equipment.

NEVER allow the engine to run at high

RPM without a load. Doing so could damage the engine.

NEVER operate a unit with worn or damaged fasteners or attachment holders.

WARNING!

A cutting attachment shield or

other protective device is no guarantee

of protection against ricochet. YOU

MUST ALWAYS GUARD AGAINST

FLYING DEBRIS!

11

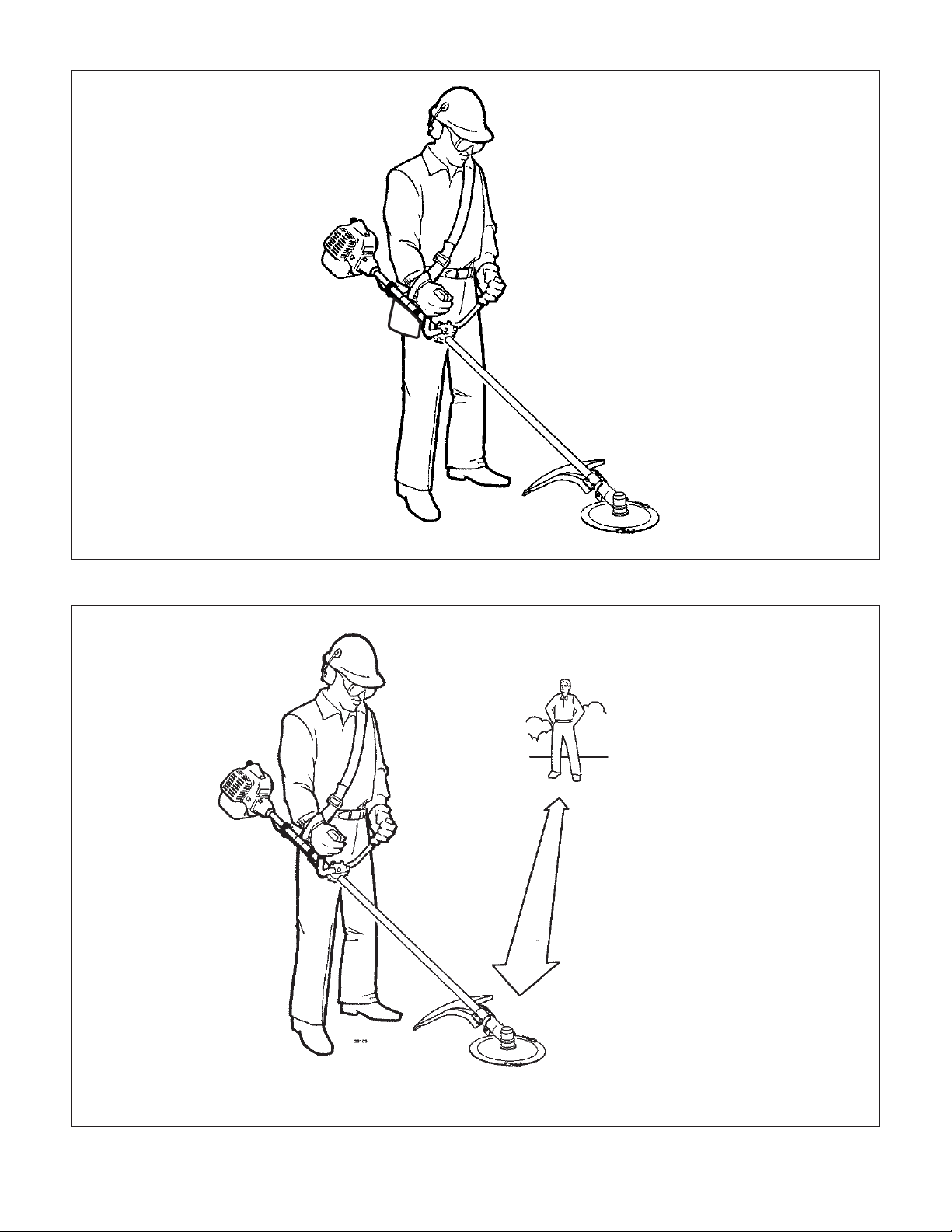

Operation

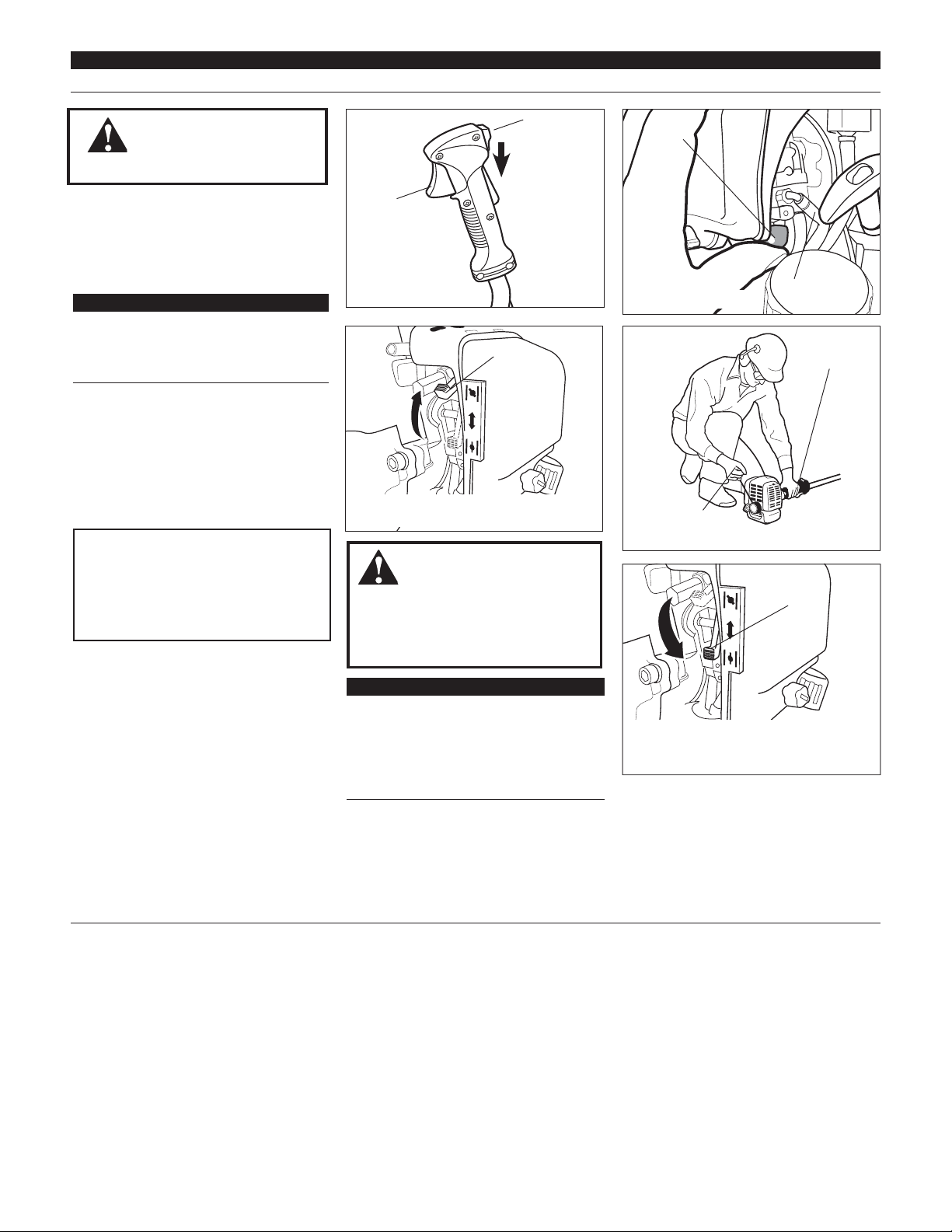

Shoulder strap

WARNING!

Always wear a shoulder strap

or harness when operating this unit.

Using a harness with a brushcutter

allows you to maintain proper control

of the unit and reduces fatigue during

extended operation.

IMPORTANT!

Adjust the shoulder strap so the shoulder pad rests comfortably on the off-side

shoulder and the cutting path of the cutting attachment is parallel to the ground.

Make sure all hooks and adjustment

devices are secure.

Shoulder strap

required for use

with Brushcutters

Hook the strap hook to the hanger on 1.

the outer tube.

Wear the shoulder strap so that the 2.

hook stays at your right hand side.

Adjust the length of the shoulder strap 3.

so that you can hold and operate the

machine comfortably.

Cutting grass with a trimmer head

Your Shindaiwa unit may be equipped with

one of several Shindaiwa trimmer head models, each with features for specific applications and/or operational requirements.

NOTE:

For proper operation, always refer to the

instructions accompanying the trimmer

head being used.

Trimmer head styles:

Semi-automatic. Trimmer line is indexed

when the operator taps the trimmer head

on the ground during operation.

Manual. The operator indexes line manually with the grass trimmer stopped.

Fixed. The operator must stop the unit

and add new lengths of trimmer line

manually.

Flail. This device, designed for clearing weeds and light brush, features

three nylon blades attached to the

head by pivots.

NOTE:

Additional hardware may be required to

mount the Fixed Line or the Flail type

trimmer heads.

NOTE:

Using a shoulder strap when operating

this unit with a blade allows you to maintain proper control of the unit and reduces

fatigue during extended operation.

Engine Operating Speeds

Operate at full throttle while cutting grass.

CAUTION!

Operation at low rpm can lead to premature clutch failure.

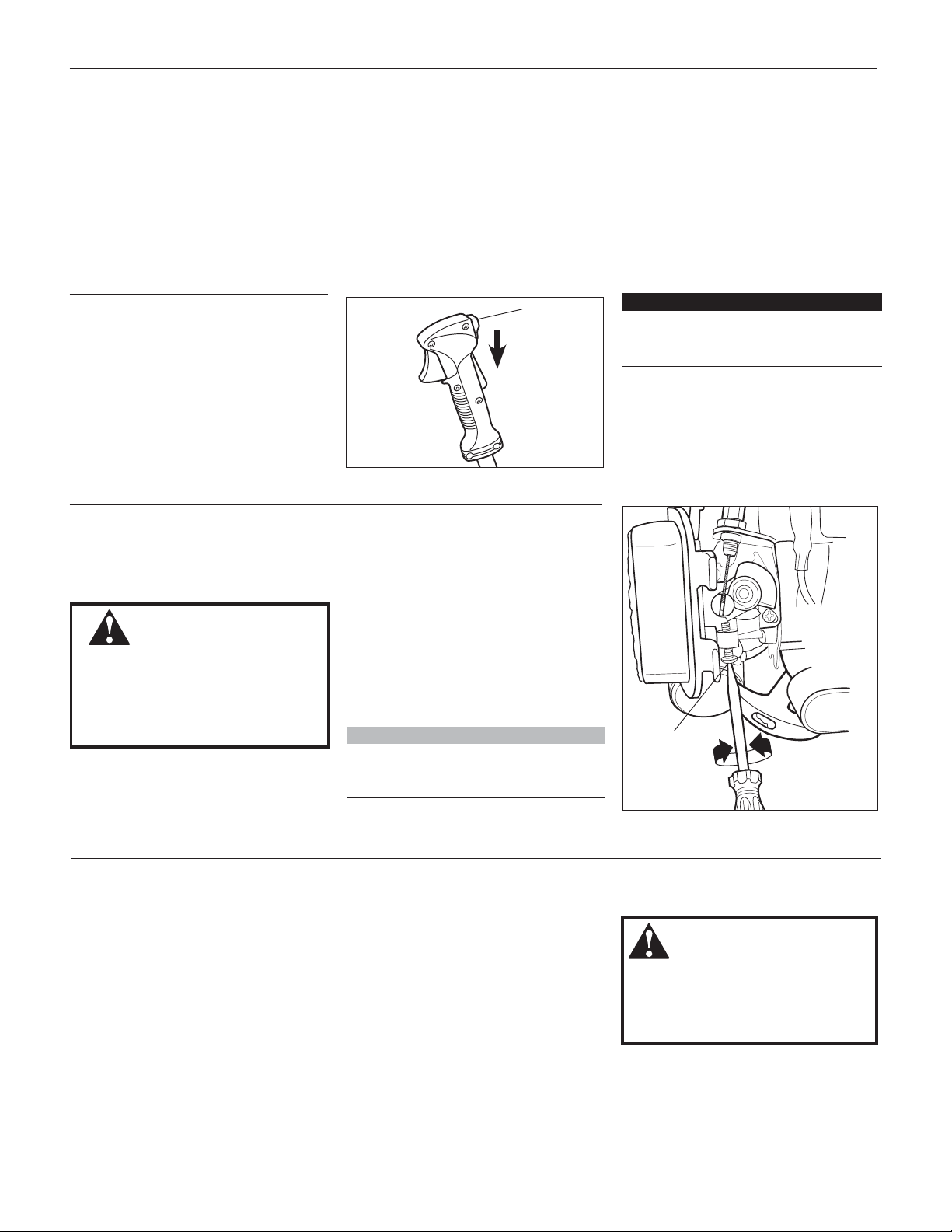

Trimming and Mowing Grass

Hold the grass trimmer so the trimmer head

is angled slightly into the area to be cut. To

ensure maximum trimmer-line service life, cut

only with the tip of the trimmer line. Cut grass

by swinging the unit's trimmer head from left

to right. Keep the trimmer head horizontal.

CAUTION!

Do not push the rotating line into trees,

wire fences or any material that could

tangle or break line ends.

CAUTION!

8VHRQO\ÀH[LEOHQRQPHWDOOLFOLQH

recommended by the manufacturer.

Never use, for example, wire or wirerope, which can break off and become

a dangerous projectile.

Cut from left to right

Cut

Return

WARNING!

Remove all objects such as

rocks, broken glass, nails, wire, or

string, which can be thrown or become

entangled in the cutting attachment.

CAUTION!

Operation of trimmer without a cutting

Ŷ

attachment shield and using excessive line length can lead to premature

clutch failure.

Operation at low rpm can lead to Ŷ

premature clutch failure.

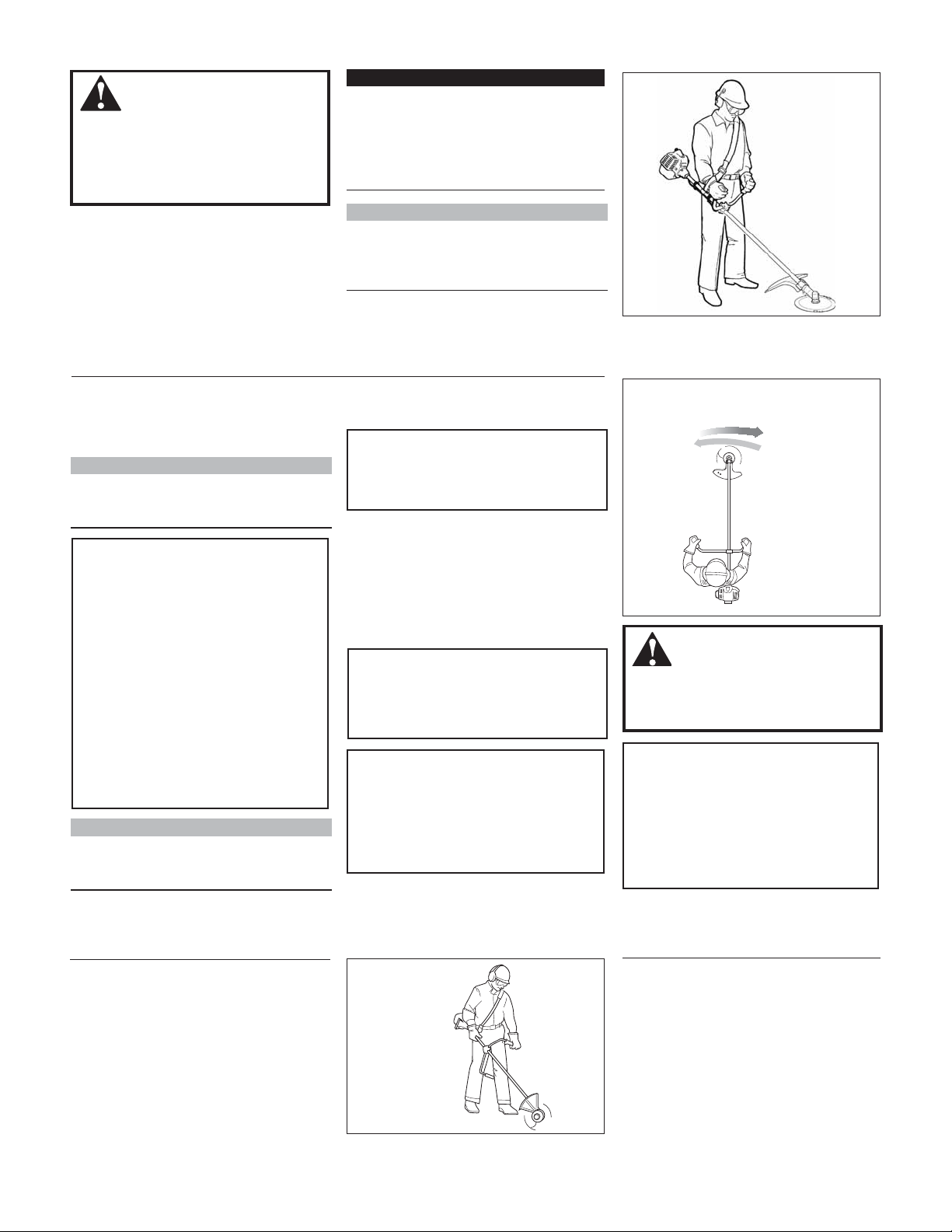

Edging

Tilt the handle about 100° to the left (from

horizontal) and move forward, holding

the trimmer or brushcutter vertically as

shown.

12

Tilt the handle about

100° to the left

Operation (continued)

Using a blade

WARNING!

Before working with a blade-equipped Ŷ

unit, always inspect and clean the

area of objects that could interfere

with or damage the blade.

Never use a blade near sidewalks,

Ŷ

fence posts, buildings or other objects

that could cause injury or damage.

Never use a blade for purposes other

Ŷ

than those for which it was designed.

Blade Thrust

“Blade thrust” is a sudden sideways or backward motion of the brushcutter. Such motion

may occur when the blade jams or catches

on an object such as a sapling tree or tree

BE CONSTANTLY ALERT FOR

stump.

BLADE THRUST AND GUARD AGAINST

ITS EFFECTS!

WARNING!

Blade thrust can occur without

warning if the blade snags, stalls or

binds.

Whenever you strike a hard object

Ŷ

with a blade, always stop the

brushcutter and carefully inspect the

blade for damage. NEVER OPERATE THE BRUSHCUTTER WITH A

DAMAGED BLADE!

A blade-equipped unit must be

Ŷ

equipped with a bicycle-type handlebar or barrier bar as well as a harness or shoulder strap.

Always make sure the cutting attach-

Ŷ

ment shield is properly installed

before operating this unit.

WARNING!

Blade thrust is more likely to

RFFXULQDUHDVZKHUHLWLVGLI¿FXOWWR

see the material being cut.

Brushcutter Handlebar

A brushcutter handlebar or barrier bar

helps prevent the operator from moving

forward, or the unit moving rearward,

thus preventing inadvertent bodily contact

with the blade. ALWAYS KEEP THE HANDLEBAR OR BARRIER BAR SECURELY

IN PLACE ON THE UNIT!

Brushcutter Shoulder Strap

A shoulder strap provides additional protection against blade thrust. In addition, a

shoulder strap gives significant support and

comfort to help ensure safe and efficient

operation. When operating a unit with a

blade, make sure both the handle and shoulder strap are adjusted to the size of the operator using the unit.

Engine Operating Speeds

Operate the unit at full throttle while cutting.

Best fuel efficiency is obtained by releasing

the throttle when swinging back after a cut.

To prevent possible engine damage, do Ŷ

not allow the brushcutter to run at high

speeds without a load.

Avoid operating the engine at low speeds.

Ŷ

Doing so can lead to rapid clutch wear. In

addition, slow-speed operation tends to

cause grass and debris to wrap around

the cutting head.

Using a blade

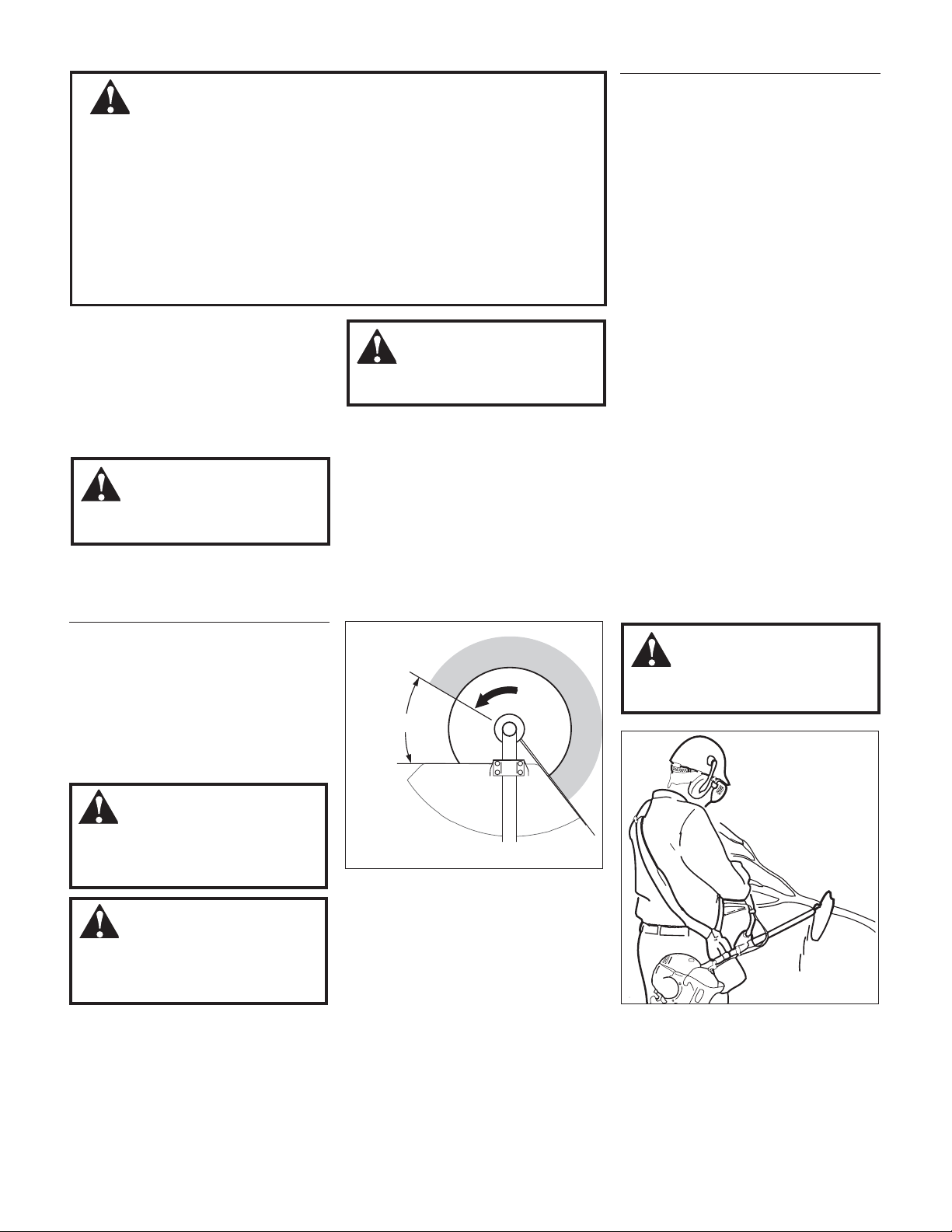

The blade rotates counter-clockwise.

For best performance and to minimize

being stuck by debris, move the blade

from right to left while advancing on

your work. Position the blade so cuts are

made between the blade’s 8 o’clock and 10

o’clock positions (as viewed from above).

DO NOT cut between the 10 o’clock and 5

o’clock positions.

WARNING!

When cutting wood with a

blade, feed the blade slowly—never

strike or “slam” a spinning blade

against the wood.

WARNING!

DO NOT use 2-tooth or nonShindaiwa approved 4-tooth cutting

blades with Shindaiwa trimmers and

brushcutters.

Ten

O'clock

OK To Cut

D

Blade

Rotation

O

N

O

T

C

U

T

Eight

O'clock

Five

O'clock

Vertical Cuts

Hold the brushcutter with the blade at

a 90° angle to the ground so the blade’s

bottom edge rotates toward the operator. Move the blade from top to bottom

through the cut, and cut only with the bottom edge of the blade.

WARNING!

When making vertical cuts,

never allow the blade to exceed waist

height.

Cut on the left

side of the blade.

KEEP YOUR BODY

OUTSIDE THE

PATH OF BLADE

ROTATION

13

Maintenance

General maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT

OR REPAIR OF EMISSION CONTROL

DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED

BY A DEALER OR SERVICE CENTER

AUTHORIZED BY SHINDAIWA INC. THE

USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY TO AUTHORIZED PARTS MAY IMPAIR

THE EFFECTIVENESS OF THE EMISSION

CONTROL SYSTEM AND MAY HAVE A

BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

WARNING!

Non-standard accessories,

cutting attachment, or replacement

parts may not operate properly with

your unit and may cause damage and

lead to personal injury.

NOTE:

Using non-standard replacement parts

could invalidate your Shindaiwa warranty.

WARNING!

Before performing any maintenance, repair, or cleaning work on

the unit, make sure the engine and

cutting attachment are completely

stopped. Disconnect the spark plug

wire before performing service or

maintenance.

0XIÁHU

This unit must never be operated with a

faulty or missing spark arrester or muffler. Make sure the muffler is well secured

and in good condition. A worn or damaged

muffler is a fire hazard and may also cause

hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

Blades

Keep blades sharp and check blade

condition frequently. If a blade’s performance changes suddenly, stop the

engine and check the blade for cracks or

other damage. Replace a damaged blade

IMMEDIATELY!

WARNING!

Ŷ

Never repair a damaged blade by

welding, straightening, or by modifying its shape. An altered blade may

break during operation, resulting in

serious personal injury.

DO NOT use 2-tooth or NON-Shin-

Ŷ

daiwa approved 4-tooth cutting

blades on Shindaiwa trimmers or

brushcutters.

Blades are not interchangeable

Ŷ

between Shindaiwa edgers and

trimmer/brushcutter models. Operating any unit with a blade or

attachment not approved for that

unit can be hazardous and may

cause serious injury.

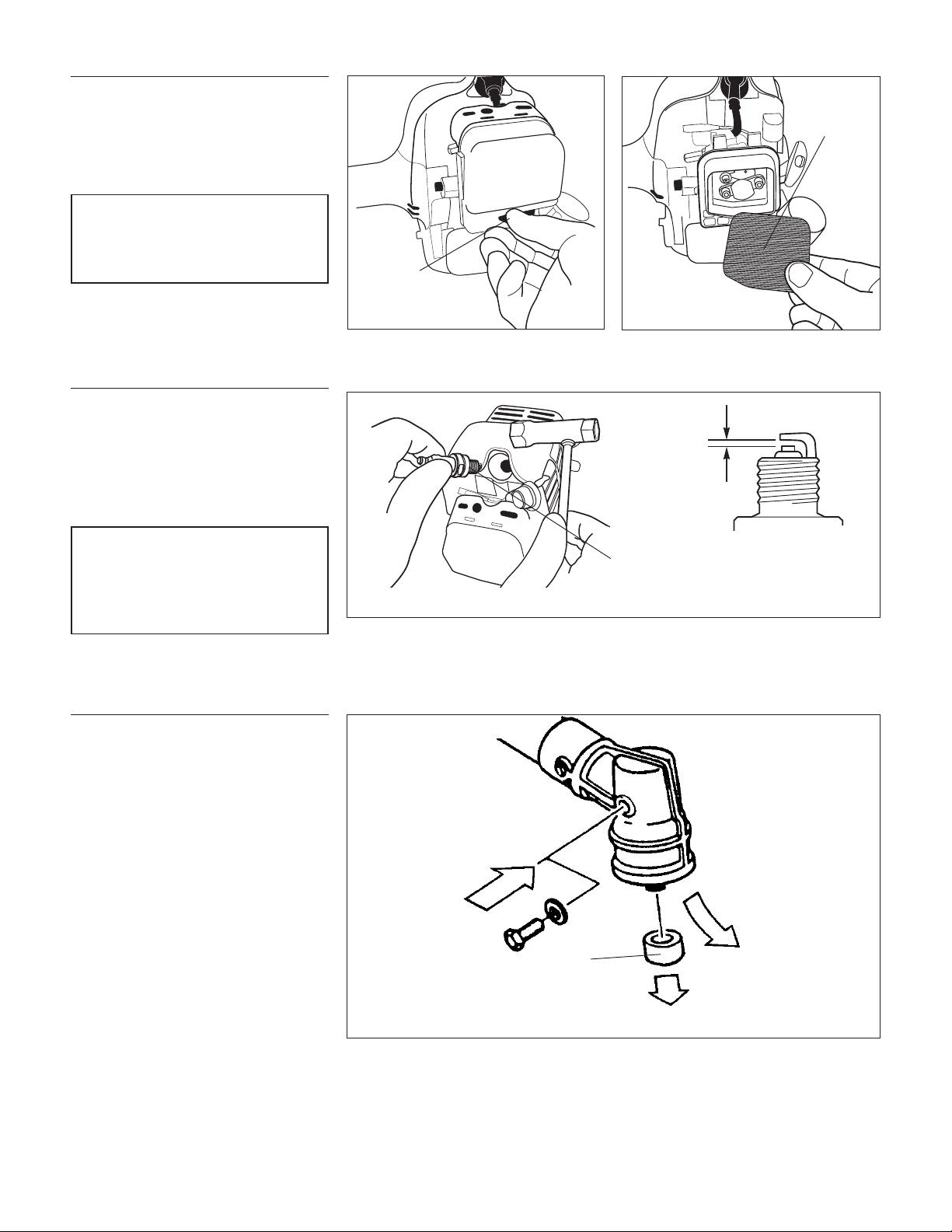

Daily maintenance

Prior to each work day, perform the

following:

Remove all dirt and debris from the

Ŷ

engine, check the cooling fins and

air cleaner for clogging, and clean as

necessary.

Carefully remove any accumulations

Ŷ

of dirt or debris from the muffler and

fuel tank. Check cooling air intake

area at base of crankcase. Remove

all debris. Dirt build-up in these areas

can lead to engine overheating, fire,

or premature wear.

WARNING!

Always wear gloves when

working around the cutter assembly.

Lubricate the blades before use and

Ŷ

after refueling. Check the cutters for

damage or incorrect adjustment.

Clean any debris or dirt from the cut-

Ŷ

ting attachment.

Cooling

¿QV

Cooling

¿QV

5HPRYHDOOGLUWDQGGHEULVIURPWKHHQJLQHDQGFKHFNWKHFRROLQJ¿QV

Check for loose or missing screws or Ŷ

components. Make sure the cutter

attachment is securely fastened.

Check the entire unit for leaking fuel

Ŷ

or grease.

Ŷ

Make sure nuts, bolts, and screws

(except carburetor idle speed adjusting

screws) are tight.

Air

intake

14

Maintenance (continued)

10-hour maintenance

Perform more frequently in dusty or

dirty conditions.

Remove the air cleaner filter. Clean or

replace as necessary. To clean filter wash

it thoroughly in soap and water. Let it dry

before reinstalling the filter.

CAUTION!

Do not operate the unit if the air

FOHDQHURU¿OWHULVGDPDJHGRULIWKH¿Oter is wet or water soaked.

10/15 hour maintenance

Remove and clean or replace the spark plug.

Clean the spark plug. Adjust electrode

Ŷ

gap according to the values listed in the

”Specifications” section. If the spark plug

must be replaced, use only the type recommended in ”Specifications” or equivalent resistor type spark plug of the correct

heat range.

Unscrew

Fastener

Remove and clean or

replace the element

0.6–0.7 mm

(0.024–0.028 inch)

Air Filter

Element

CAUTION!

Before removing the spark plug, clean

the area around the plug to prevent

dirt and debris from getting into the

engine’s internal parts.

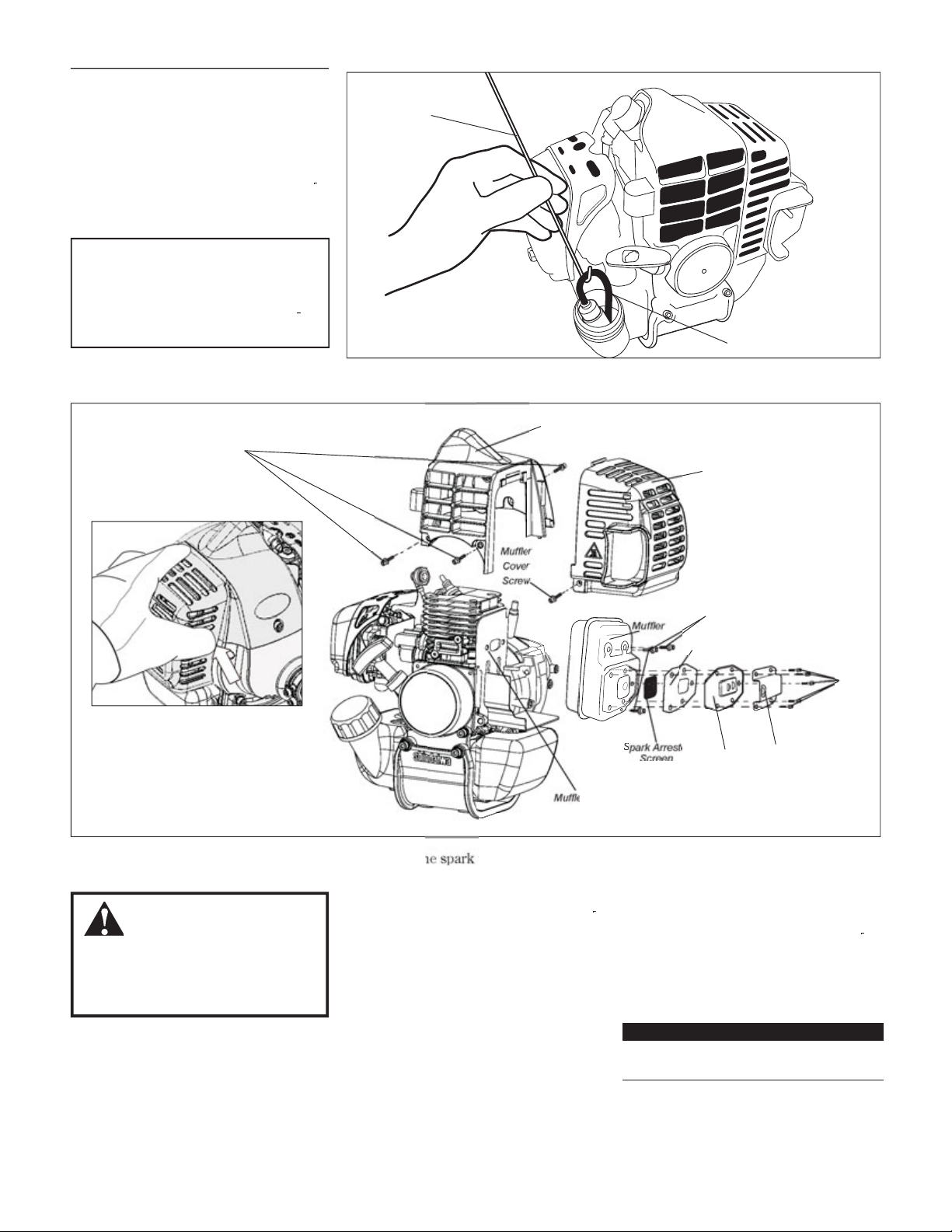

50 hour maintenance

Every 50 hours of operation; more

frequently in dusty conditions:

Ŷ

Remove and clean the cylinder cover

and clean dirt and debris from the cylinder cooling fins.

Gearcase lubrication

Remove and clean the cylinder cover

Ŷ

and clean grass and dirt from the cylinder fins.

Remove the cutting attachment, cut-

Ŷ

ting attachment holder and gearshaft

collar. Remove the filler plug from

the side of the gearcase and press

new grease into the gearcase until old

grease is pushed out. Use only lithium-base grease such as Shindaiwa

Gearcase Lubricant or equivalent.

Lubricate mainshaft splines.

Ŷ

Lubricate gearcase

New

grease

Gear shaft

collar

Clean the spark plug

and check the gap at

the electrode.

Old

grease

15

W

H

e

)

H

S

s

U

E

r

Spark Arrester

Screen

S

r

t

S

G

t

0XIÀHU

s

16

ntenan

ce

)

a

.

h

With a

a

w

g

With

the screen and clea

.

.

p

.

W

G!

h

g.

R

y

p

l

l

noted, the unit should be removed from ser

v

technician.

ce

e

e.

m

.

.

.

y.

FH

continued

hour maintenan

emove and replace the fuel filter element.

Before reinstalling the new filter element,

inspect the condition of all the fuel s

onents (fuel pick-up line, fuel return

com

stem

ine, tank vent line, tank vent, fuel cap and fue

tank). If damage, splitting or deterioration is

ice until it can be inspected or repaired by a

indaiwa-trained service

AUTION!

ake sure you do not pierce the fuel

with the end of the hooked wir

lin

he line is delicate and can be da

ged easily

IÁHUPDLQWHQDQ

Engine Cover

crew

ooked wir

XHO¿OWHUPDLQWHQDQF

)XHO¿OWHUHOHPHQ

ngine Cove

0XIÀHU&RYH

Every 135 hours of operation, remove

nd clean the muffler

ARNIN

ever operate the unit wit

GDPDJHRUPLVVLQJPXIÀHURUVSDUN

rrester! Operating with a missing or

DPDJHGVSDUNDUUHVWHULVD¿UHKD]DUG

nd could also damage your hearin

f the engine becomes sluggish and low on

ower, check and clean the spark arrester

reen

U*DVNHW

4mm hex wrench remove the

muffler cover and 3 engine cover

fler cover is attached to the engine

over at the top and front by tabs. To

remove push inward at arrow are

hile pulling outward. See insert

e.

ima

a Phillips type screwdriver

remove the 5 screws holding the

spark arrester screen and cover to the

muffler.

move

n it with a 4

iff bristle brush

Screw

aske

crews

park Arrester

Cove

Outle

move the 3 muffler bolts and the

muffler.

nspect the cylinder exhaust port for 6

ny carbon buildup.

face to dislodge any loose carbon

eassemble the spark arrester, muffler

nd engine cover in the reverse order

of disassembl

IMPORTANT!

f you note excessive carbon buildup, consult

an authorized Shindaiwa servicing dealer.

wit

Maintenance (continued)

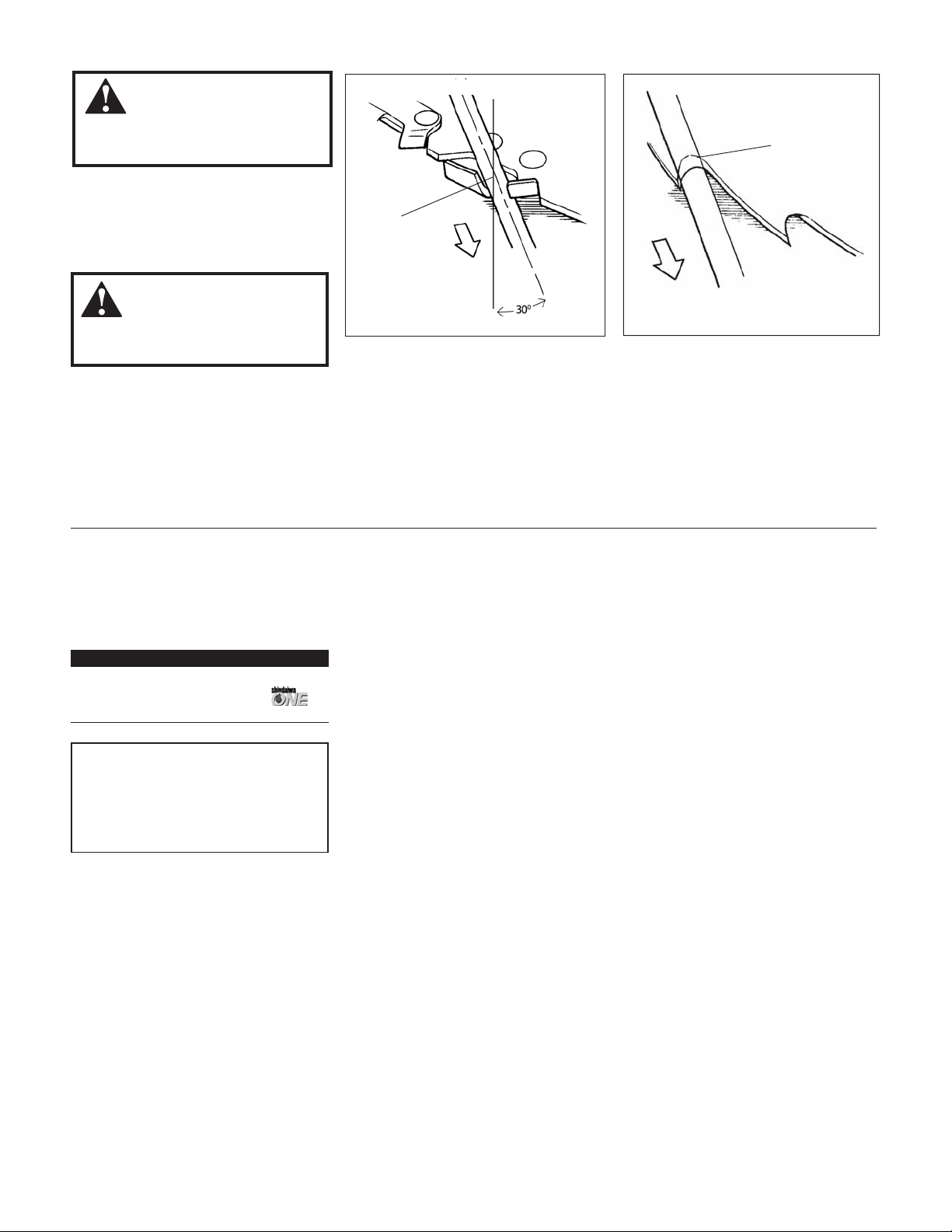

Blade Sharpening

WARNING!

Wear protective gloves when

handling or performing maintenance

on the blade.

When the cutting edges of the blade

become dull, they can be resharpened with

a few strokes of a file. In order to keep the

blade in balance, all cutting edges must be

sharpened equally.

Shindaiwa Tornado™ Blade

Round

File

Multiple-tooth Circular Blade

Round

File

WARNING!

Sharpen only the cutting teeth

of a blade. DO NOT alter the contour

of the blade in any way.

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following procedures to prepare it for storage:

Ŷ

Clean external parts thoroughly.

Drain all the fuel from the carburetor Ŷ

and the fuel tank.

IMPORTANT!

All stored fuels should be stabilized with a

fuel stabilizer such as STA-BIL, if

with fuel stabilizer is not used.

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard starting, and could also lead to increased

service and maintenance costs.

oil

The top plate of each

tooth should angle

back 30°

Shindaiwa Tornado™ Blade

To sharpen the cutters on a Shindaiwa

Tornado™ Blade, use a 7/32-inch round

file. File the leading edge of each tooth to

a razor edge. The top plate of each tooth

should angle back 30°.

Remove remaining fuel from the fuel Ŷ

lines and carburetor with the fuel

drained from the fuel tank. To do so:

Prime the primer bulb until no more 1.

fuel is passing through.

Start and run the engine until it stops 2.

running.

Repeat steps 1 and 2 until the engine 3.

will no longer start.

Ŷ

Remove the spark plug and pour about

7 mL (1/4 oz.) of 2-cycle mixing oil into

the cylinder through the spark plug

hole. Slowly pull the recoil starter 2 or 3

times so oil will evenly coat the interior

of the engine. Reinstall the spark plug.

Maintain a radius of 0.04 to 1 to 1.5 mm (0.06”)

at the base of each tooth. Cutting edges must

be offset equally on each side

Multiple-tooth Circular Blade

Use a round file to maintain a radius of 0.04

to 1 to 1.5 mm (0.06”) at the base of each

tooth. Cutting edges must be offset equally

on each side.

Before storing the unit, repair or Ŷ

replace any worn or damaged parts.

Ŷ

Remove the air cleaner element from

the carburetor and clean it thoroughly

with soap and water, let dry and reassemble the element.

Store the unit in a clean, dust-free area.

Ŷ

17

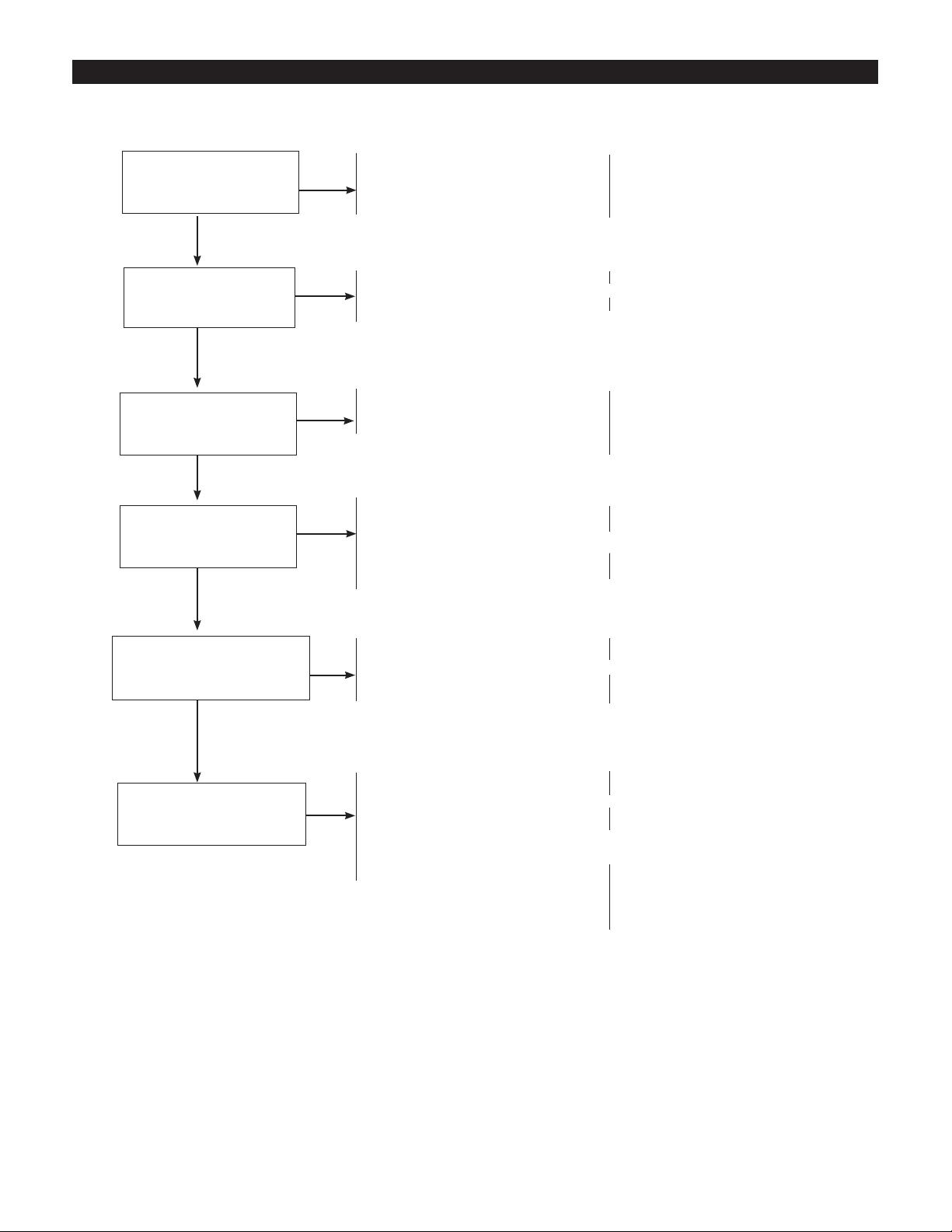

Troubleshooting Guide

What To Check Possible Cause Remedy

ENGINE DOES NOT START

Does the engine crank?

YES

Good compression?

YES

Does the tank contain

fresh fuel of the proper

grade?

YES

Is fuel visible and

moving in the return

line when priming?

YES

NO

NO

NO

NO

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Loose spark plug.

Excess wear on cylinder, piston,

rings.

Fuel incorrect, stale, or contaminated;

mixture incorrect.

Check for clogged fuel filter

and/or vent.

Primer pump functioning

incorrectly.

Consult with an authorized

servicing dealer.

Tighten and re-test.

Consult with an authorized

servicing dealer.

Refill with fresh, clean unleaded gasoline

with a pump octane of 87 or higher mixed

with a 2-cycle mixing oil that meets or

exceeds ISO-L-EGD and/or JASO FD

classified oils at 50:1 gasoline/oil ratio.

Replace fuel filter or vent as required.

Restart.

Consult with an authorized

servicing dealer.

Is there spark at the spark

plug wire terminal?

YES

Check the spark plug.

NO

The ignition switch is in “O” (OFF)

position.

Shorted ignition ground.

Faulty ignition unit.

If the plug is wet, excess fuel may be

in the cylinder.

The plug is fouled or improperly

gapped.

The plug is damaged internally or of

the wrong size.

Move switch to “I” (ON) position

and restart.

Consult with an authorized

servicing dealer.

Crank the engine with the plug

removed, reinstall the plug, and restart.

Clean and regap the plug. Check the

“Specifications” section for the correct plug

electrode gap. Restart.

Replace the spark plug. Check the

“Specifications” section for the correct

plug for your unit. Restart.

18

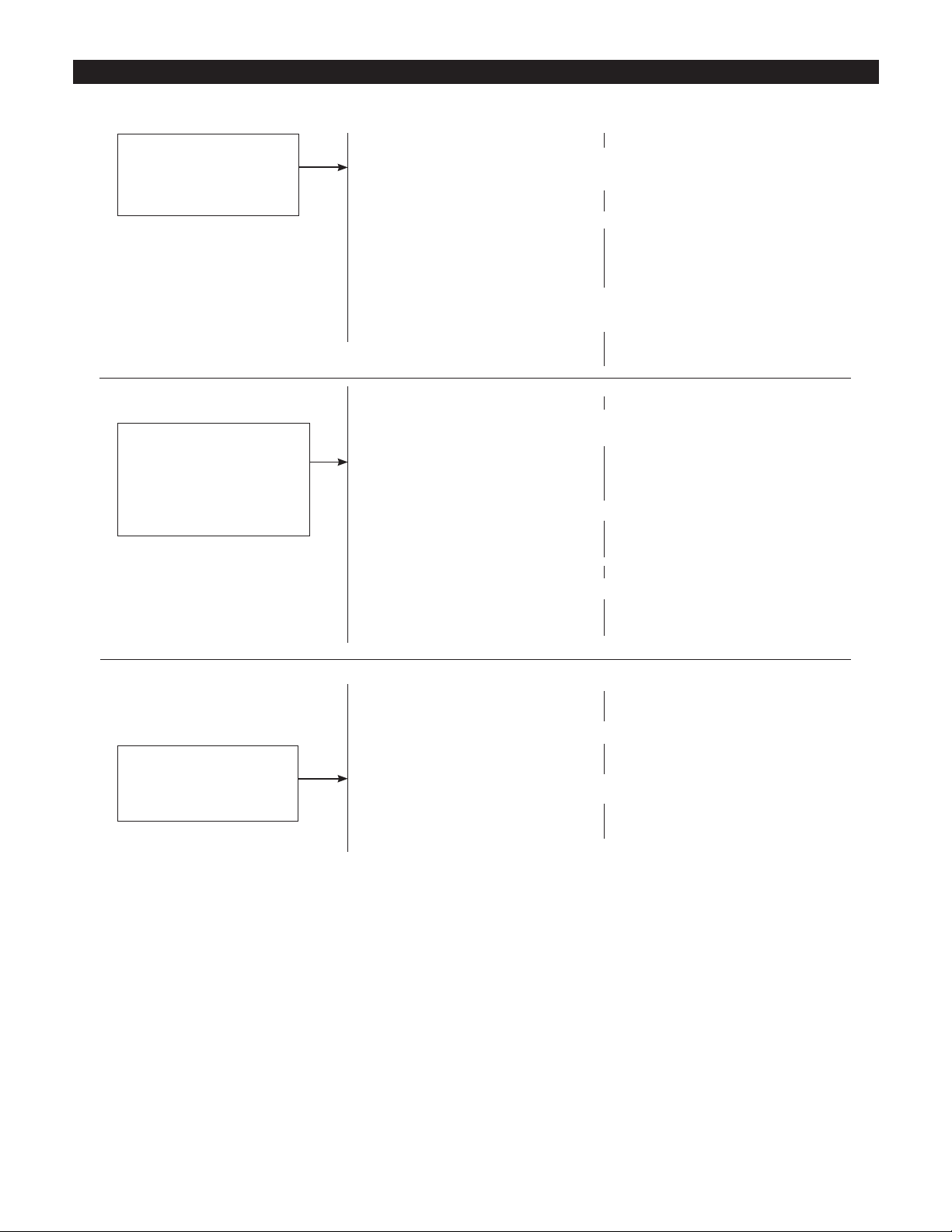

Troubleshooting Guide (continued)

What To Check Possible Cause Remedy

LOW POWER

Is the engine

overheating?

Engine is rough at all

speeds. May also have

black smoke and/or

unburned fuel at the

exhaust.

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty or

damaged

Carbon deposits on the piston or in the

muffler.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Water in the fuel.

Operate at slower rate.

Shorten trimmer line.

Consult with an authorized

servicing dealer.

Refill with fresh, clean unleaded gasoline with

a pump octane of 87 or higher mixed with a

2-cycle mixing oil that meets or exceeds ISOL-EGD and/or JASO FD classified oils at 50:1

gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing

dealer

Clean or replace the air filter

Tighten or replace the spark plug.

Restart. Check the Specifications page

in this manual for the correct spark

plug for this unit.

Repair or replace fuel filter and/or

fuel line.

Refill with fresh fuel/oil mixture.

Engine is knocking.

Piston seizure.

Faulty carburetor and/or diaphragm

Overheating condition.

Improper fuel.

Carbon deposits in the combustion

chamber.

Consult with an authorized

servicing dealer.

Consult with an authorized

servicing dealer.

Check fuel octane rating; check for

presence of alcohol in the fuel. Refuel

as necessary.

Consult with an authorized

servicing dealer.

19

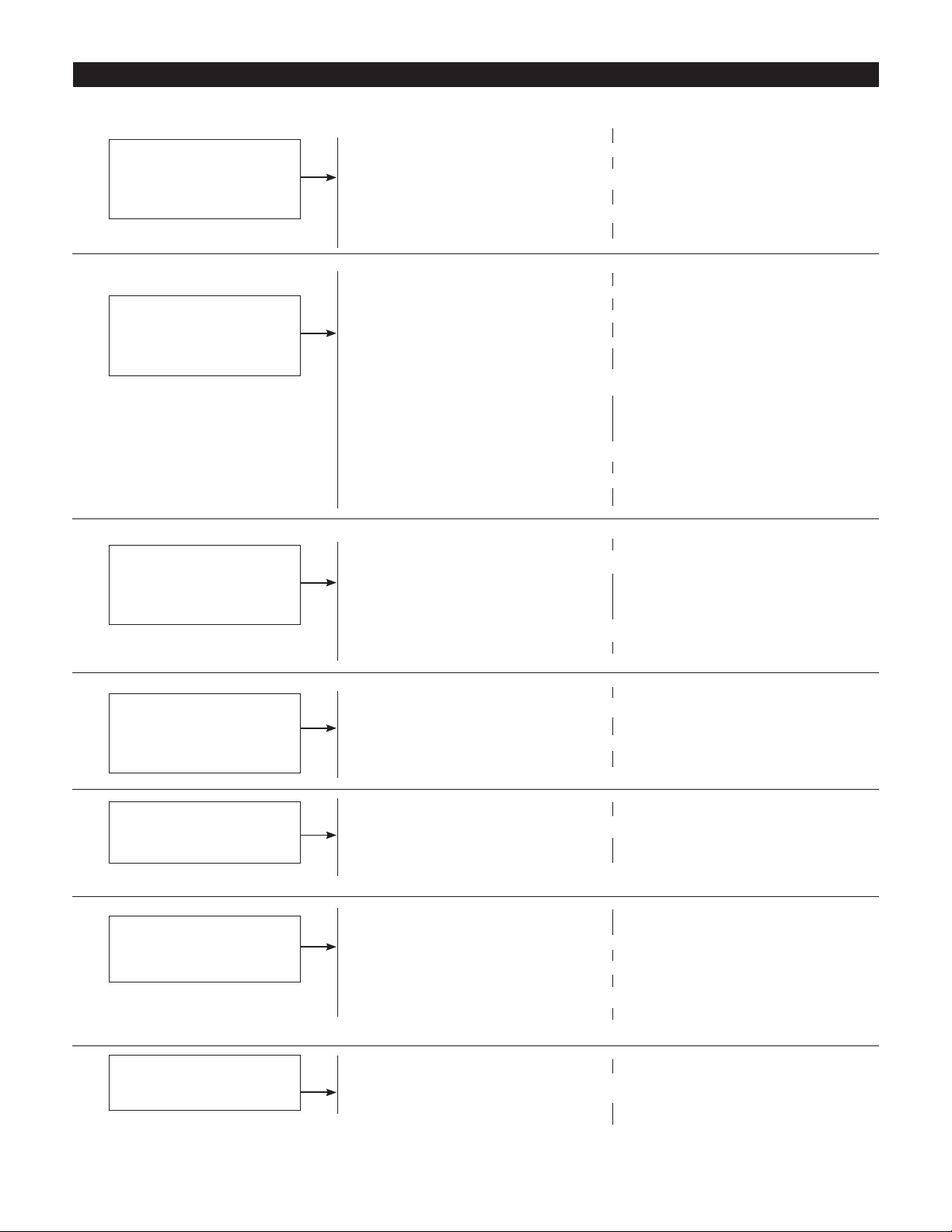

Troubleshooting Guide (continued)

ADDITIONAL PROBLEMS

What To Check Possible Cause Remedy

Poor acceleration.

Engine stops abruptly.

Engine difficult to shut

off.

Clogged air filter.

Clogged fuel filter.

Lean fuel/air mixture.

Idle speed set too low.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Ground (stop) wire is disconnected or

switch is defective

Overheating due to incorrect spark plug

Overheated engine.

Clean or replace the air filter.

Replace the fuel filter.

Consult with an authorized

servicing dealer.

Adjust idle. Check Specifications page

for correct idle speed.

Reset the switch and re-start.

Refuel. See Fuel section of manual.

Replace fuel filter.

Drain; replace with clean fuel. See Fuel

section of manual.

Clean or replace spark plug. Check

the Specifications page in this manual

for the proper spark plug for your unit.

Tighten the terminal.

Replace the ignition unit.

Consult with an authorized

servicing dealer

Test and replace as required.

Idle engine until cool. Replace the spark

plug. Check the Specifications page in this

manual for the proper spark plug for your

unit.

Idle engine until cool.

Cutting attachment moves

at engine idle.

Attachment will not move.

Excessive vibration.

Engine will not idle down.

Engine idle too high.

Broken clutch spring or worn clutch

spring boss.

Loose attachment holder.

Shaft not installed in powerhead or

gearcase.

Broken shaft.

Damaged gearcase.

Warped or damaged attachment.

Loose gearcase.

Bent main shaft/worn or damaged

bushings.

Trimmer line not wound properly on

spool.

Engine idle is set too high.

Engine has air leak.

Adjust idle. Check Specifications page

for correct idle speed.

Replace spring/shoes as required.

Inspect and re-tighten holders securely.

Inspect and reinstall as required.

Consult with a authorized

servicing dealer.

Inspect and replace attachment

as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Rewind trimmer line.

Adjust idle. Check Specifications page

for correct idle speed.

Consult with a authorized

servicing dealer.

20

Emission System Warranty Statement

Your Warranty Rights and Obligations

The California Air Resources Board, the U.S. Environmental Protection Agency and Shindaiwa Inc. are pleased

to explain the exhaust and evaporative emission control

system warranty on your new small off-road (non-road)

engine.

In California, new small off-road engines must be

designed, built, and equipped to meet the State’s stringent

anti-smog standards. In other states, new 1997 and later

non-road engines must meet the Federal EPA’s stringent

anti-smog standards.

Shindaiwa Inc. must warrant the emission control system on your small off-road engine for the periods of time

listed below, provided there has been no abuse, neglect,

or improper maintenance of your small off-road engine.

Your engine exhaust and evaporative emission control

system includes parts such as the carburetor, fuel tank,

the ignition system and, if equipped, the catalytic converter. These components are specifically listed below.

Where a warrantable condition exists, Shindaiwa Inc.

will repair your small off-road engine at no cost to you

including diagnosis, parts, and labor.

Manufacturer’s Warranty Coverage

When sold within the U.S., this engine’s emission control

system is warranted for a period of two (2) years from the

date this product is first delivered to the original retail

purchaser.

During the warranty period, Shindaiwa Inc. will, at their

option, repair or replace any defective emission-related

component on this engine. During the original Warranty

Period, these Warranty Rights are automatically transferable to subsequent owners of this product.

What is Covered by this Warranty

Carburetor Internal Components1.

Ŷ

Throttle Valve, Needle, Jet, Metering Diaphragm

Fuel Tank2.

Ignition System Components3.

Ŷ

Ignition Coil

Flywheel RotorŶ

Catalytic Converter (if originally equipped)4.

The emission control system for your particular

Shindaiwa engine may also include certain related hoses

and connectors.

Owners Warranty Responsibilities

As the small off-road engine owner, you are responsible

for the performance of the required maintenance listed in

this owners manual. Shindaiwa Inc. recommends that you

retain all receipts covering maintenance on your small

off-road engine, but Shindaiwa Inc. cannot deny warranty

solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

As the small off-road engine owner, you should be

aware, however, that Shindaiwa Inc. may deny you warranty coverage if your small off-road engine or a part has

failed due to abuse, neglect, improper maintenance, or

unapproved modifications.

You are responsible for presenting your small off-road

engine to an authorized Shindaiwa Dealer as soon as a

problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30

days.

If you have any questions regarding your warranty rights

and responsibilities, you should contact a Shindaiwa customer service representative at (503) 692-3070 or your local

Shindaiwa Dealer.

Consequential Damages

In the event that other component parts of this product

are damaged by the failure of a warranted part, Shindaiwa

Inc. will repair or replace such component parts at no

charge to you.

What is Not Covered

Failures caused by abuse, neglect, or improper main-

Ŷ

tenance procedures.

Ŷ

Failures caused by the use of modified or nonapproved parts or attachments.

This Warranty is Administered by:

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, OR 97062

(503) 692-3070

21

NOTES

NOTAs

REMARQUES

22

Loading...

Loading...