Page 1

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

GP3410 WATER PUMP

WARNING!

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with its

contents! Always wear eye and hearing protection

when operating this unit.

Part Number 68510-94310 Rev 3/07

1

Page 2

2

Introduction

This Shindaiwa GP3410 water pump has

been designed and built to deliver superior

performance and reliability without compromise to quality, comfort, or durability.

Shindaiwa high performance engines represent the leading edge of 4-cycle engine technology, delivering exceptionally high power

at remarkably low displacement and weight.

As an owner/operator, you’ll soon discover

why Shindaiwa is simply in a class by itself!

IMPORTANT!

The information contained in this manual

describes units available at the time of production. While every attempt has been

made to give you the very latest information

about your Shindaiwa GP3410 water pump,

there may be some differences between

your pump and what is described here.

Shindaiwa Inc. reserves the right to make

changes in production without prior notice,

and without obligation to make alterations

to units previously manufactured.

WARNING!

The engine exhaust from

this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm.

Attention Statements

Throughout this manual are special attention statements.

WARNING!

A statement preceded by

the word “WARNING” contains information that should be acted upon to

prevent serious bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to avoid damaging the unit.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your job

easier.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses special significance.

Read and follow this Owner’s/

Operator’s Manual. Failure to do

so could result in serious injury.

Wear eye and hearing protection

at all times during the operation of

this unit.

Do not operate this unit if you are

tired, ill, or under the inuence of

alcohol, drugs, or medicine.

To avoid water pump damage,

ll priming port with water

before use.

WARNING!

Do not make unauthorized

modications or alterations to this unit or

any of its components or accessories.

Contents

Attention Statements..............................2

General Safety Instructions................... 3

Unit Description .....................................4

Specifications .......................................... 5

Installing Hoses ......................................6

Priming the Pump ..................................7

Mixing Fuel.............................................7

Filling the Fuel Tank..............................7

Starting Procedure .................................8

Checking/Adjusting Engine Idle .........9

Operating Tips ........................................9

Maintenance .........................................10

Spark Arrester Maintenance ...............13

Long Term Storage ..............................13

Troubleshooting ................................... 14

Warranty................................................19

PAGE

IMPORTANT!

The operational procedures described in

this manual are intended to help you get

the most from this unit, and to protect you

and others from harm. These procedures

are guidelines for safe operation under

most conditions, and are not intended to

replace any safety rules and/or laws that

may be in force in your area. If you have

questions regarding your GP3410, or if

you do not understand something in this

manual, your Shindaiwa dealer will be

glad to assist you.You may also contact

Shindaiwa Inc. at the address printed on

the back of this manual.

Page 3

General Safety Instructions

Work Safely

Pumps operate at very high speeds and

can do serious damage or injury if they

are misused or abused. Never allow a

person without training or instruction to

operate this unit!

WARNING!

Never make unauthorized

attachment installations.

WARNING!

Use Good Judgment

NEVER operate the engine when

transporting the unit.

NEVER operate the engine indoors!

Make sure there is always good ventilation. Fumes from engine exhaust

can cause serious injury or death.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improperly installed parts.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegetation, mud, etc.

ALWAYS disconnect the spark plug wire

before performing any maintenance work.

Stay Alert

You must be physically and mentally fit to

operate this unit safely.

WARNING!

Never operate power equipment

of any kind if you are tired or if you

are under the inuence of alcohol,

drugs, medication or any other substance that could affect your ability

or judgement.

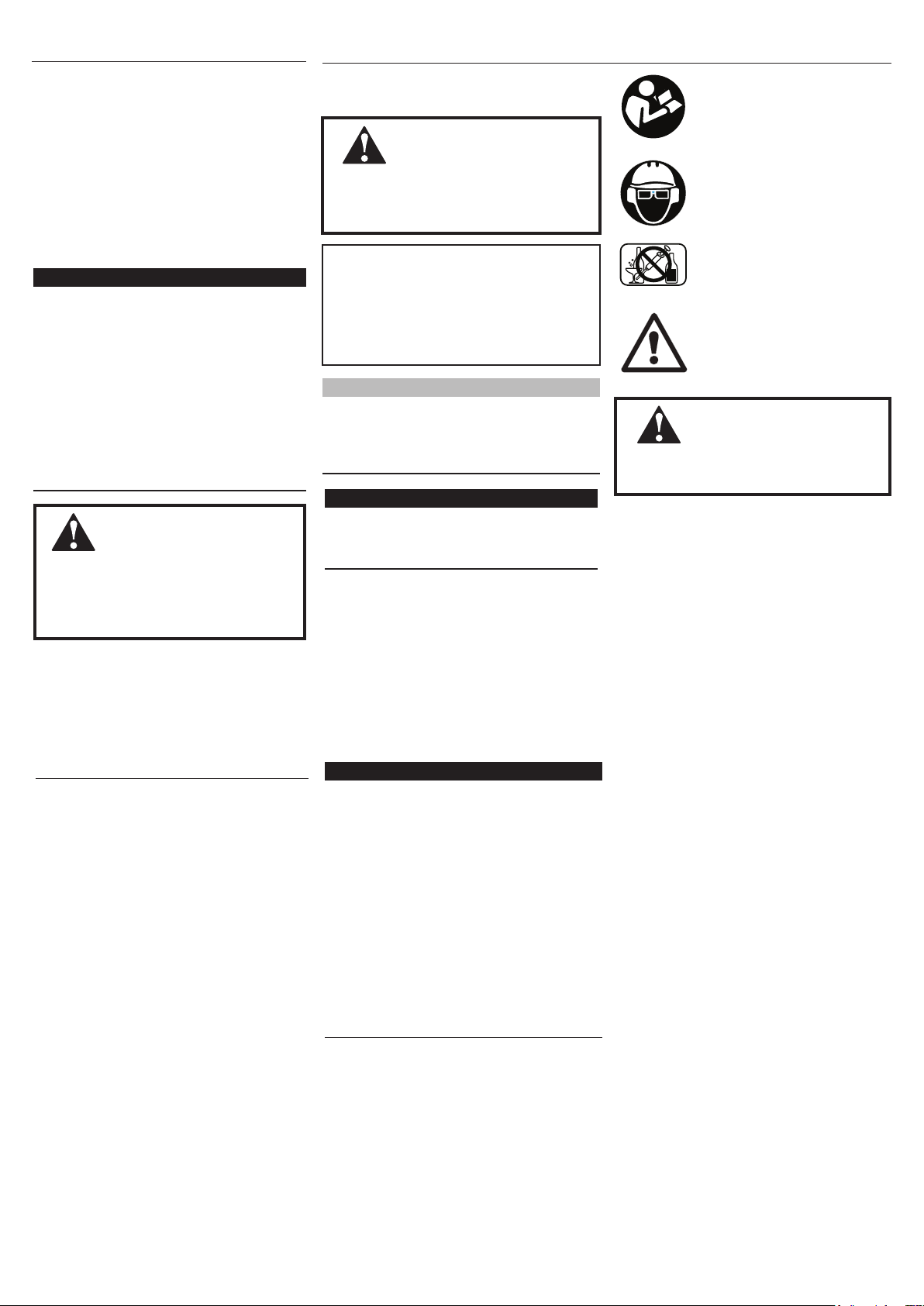

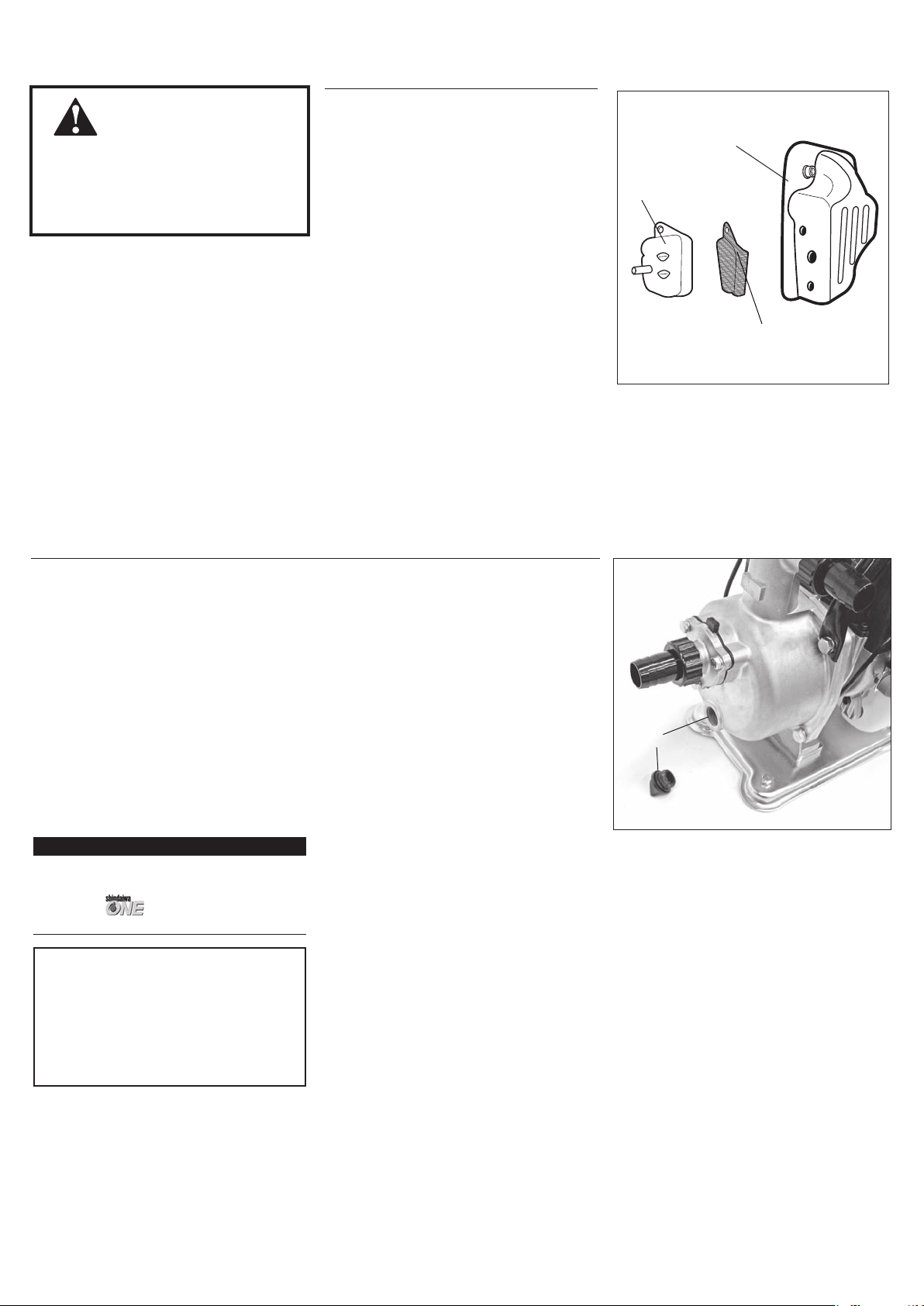

Safety labels

WARNING!

Minimize the Risk of Fire

NEVER smoke or light res near the unit.

ALWAYS stop the engine and allow

it to cool before refueling. Avoid

overlling and wipe off any fuel that

may have spilled.

ALWAYS inspect the unit for fuel leaks

before each use. During each rell,

check that no fuel leaks from around

the fuel cap and/or fuel tank. If fuel

Safety and Operation Information Labels:

Make sure all information labels are undamaged and readable. Immediately replace damaged or missing information labels. New

labels are available from your local authorized

Shindaiwa dealer.

leaks are evident, stop using the

unit immediately. Fuel leaks must be

repaired before using the unit.

ALWAYS move the unit to a place well

away from a fuel storage area or other

readily ammable materials before

starting the engine.

NEVER place ammable material

close to the engine mufer.

NEVER run the engine without the

spark arrester screen in place.

IMPORTANT!

3

Page 4

4

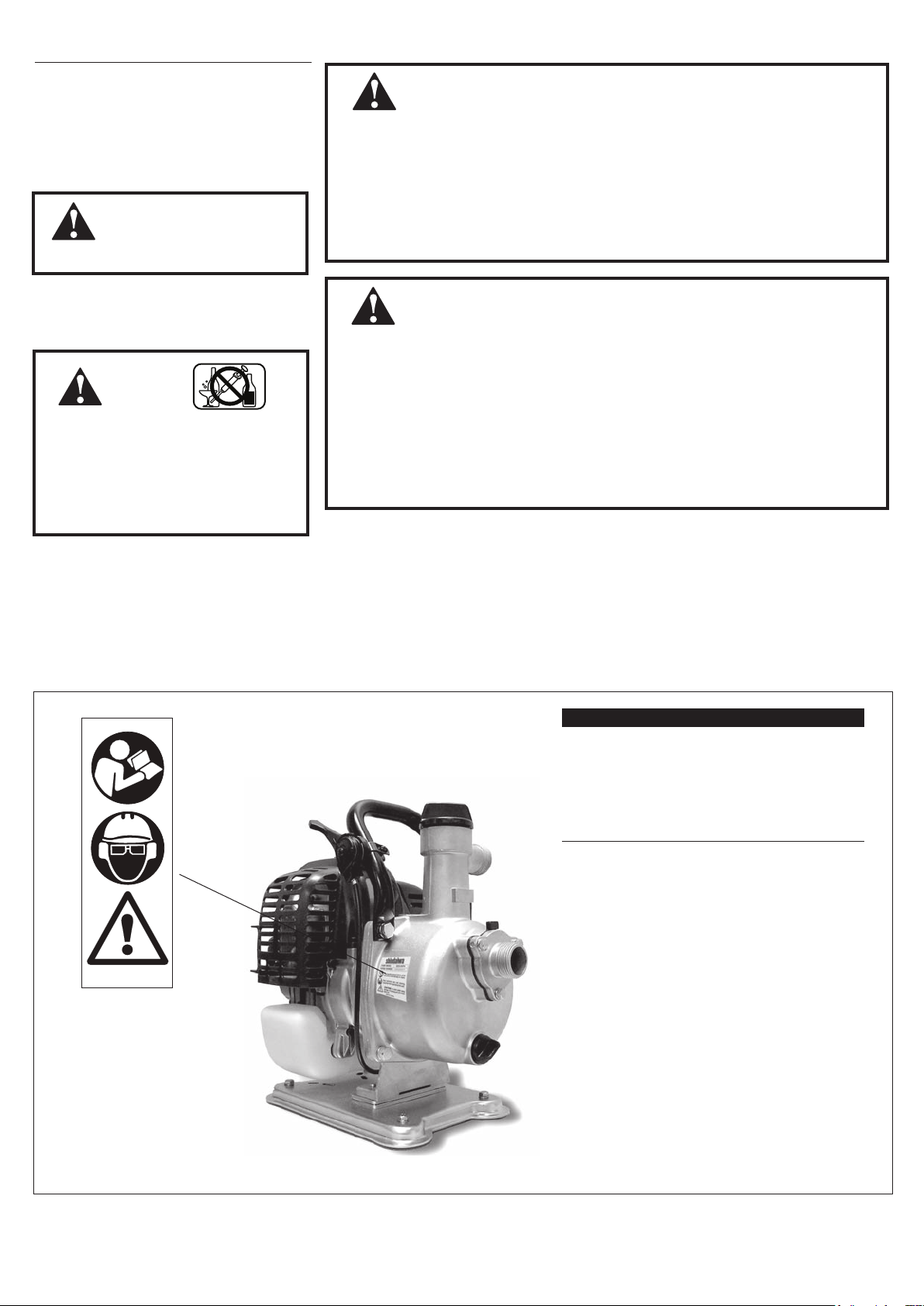

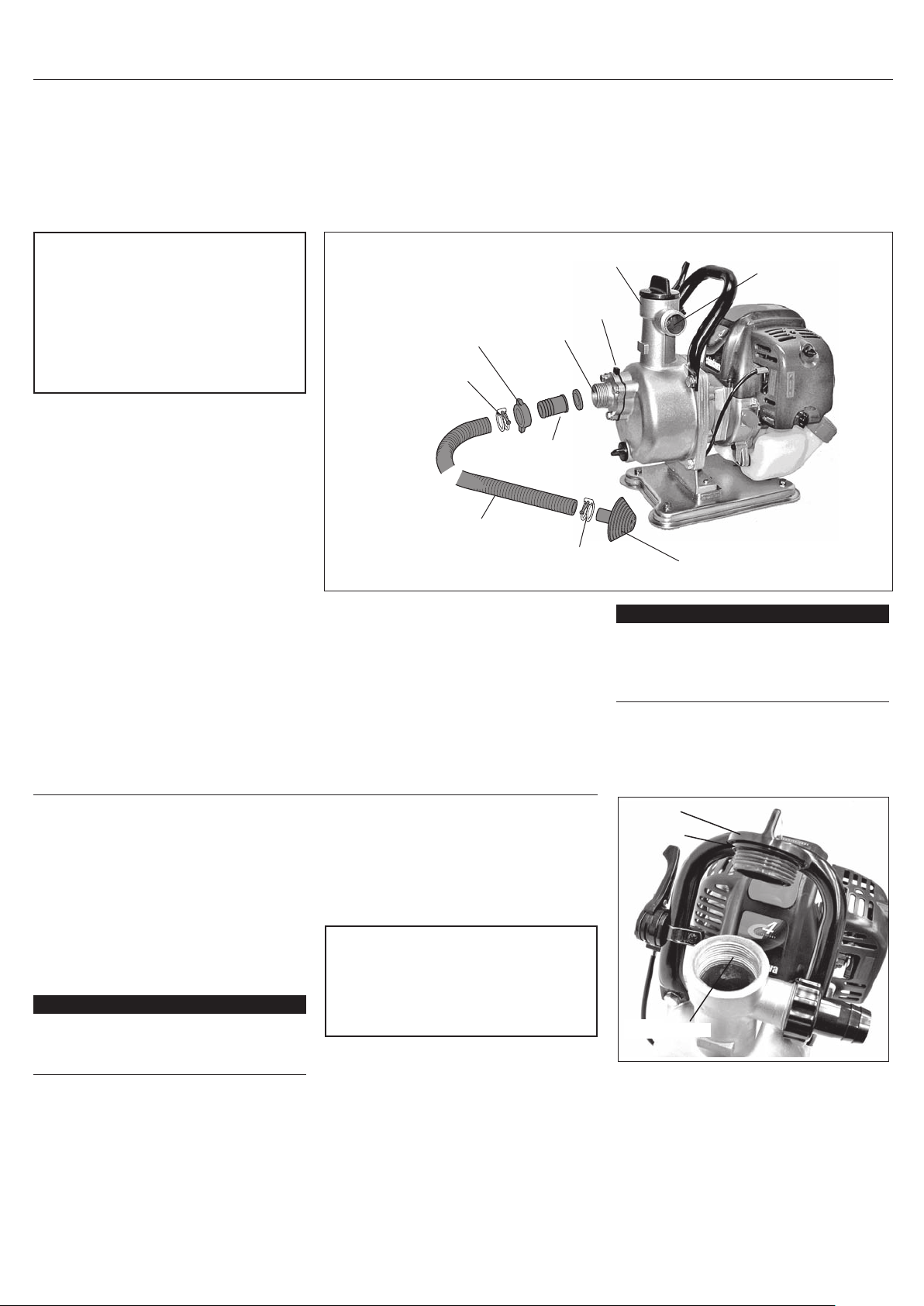

Unit Description

Filler Plug

Spark Plug

Discharge

Connection

Priming

Port

Choke

Figure 1A

Stop Switch

Using the illustrations above as a guide,

familiarize yourself with this unit and its

various components. Understanding the

unit helps ensure top performance, long

service life, and safer operation.

Air Cleaner

Fuel Tank

Recoil Starter

Handle

Fuel Filler

Cap

Mufer

Fuel Tank

Throttle

Lever

GP3410

Handle

Filler Plug

Priming Port

Discharge

Connection

Suction

Connection

Drain

Plug

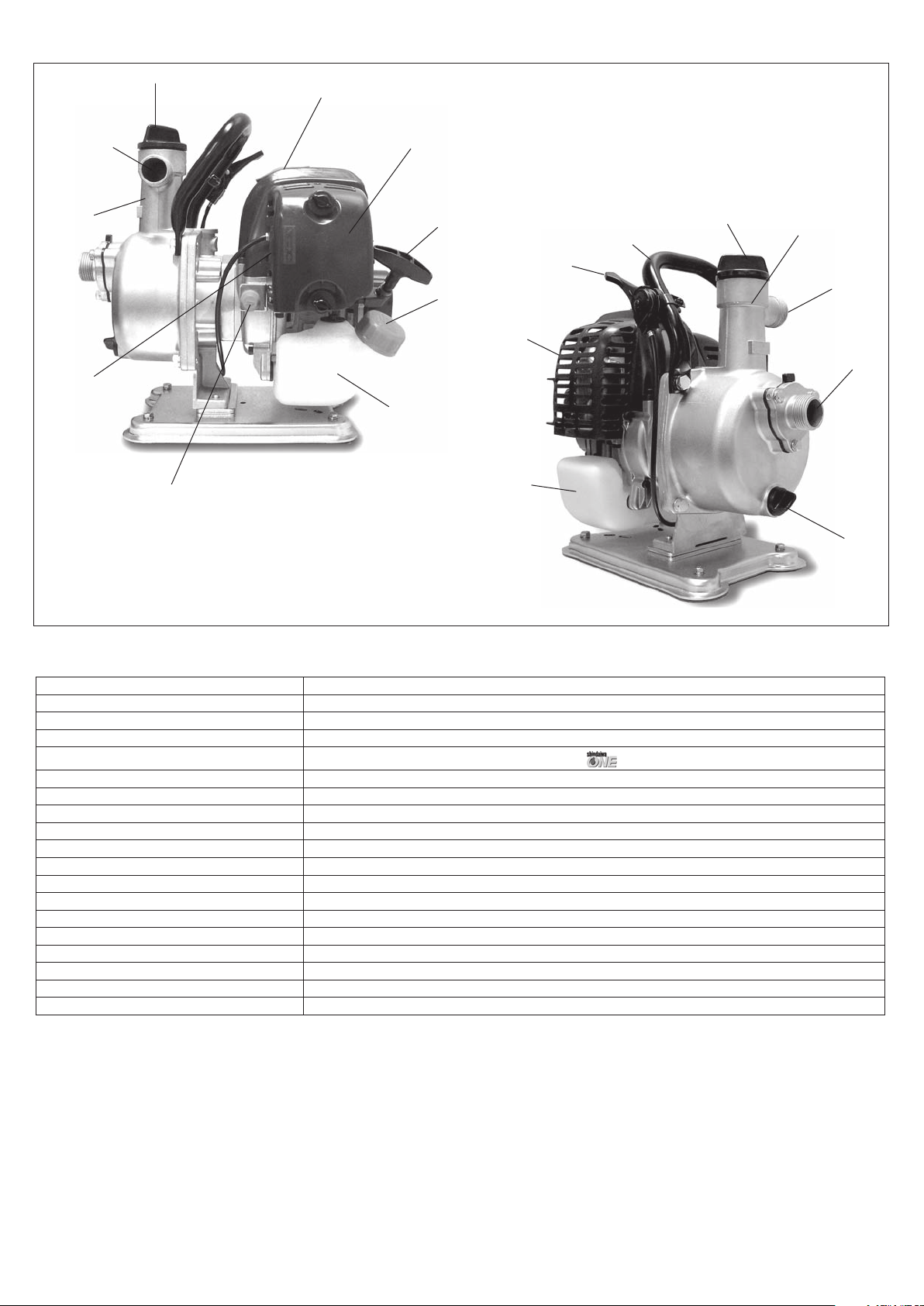

Specications

Model GP3410

Engine Type 4 cycle air-cooled gasoline engine, vertical cylinder

Displacement 34 cc (38mm x 30mm); 2.07 cu. in. (1.50 x1.18 in.)

Maximum Output 1.0 kw/1.4 HP @ 8000 min

Fuel/Oil Ratio 50:1 with Shindaiwa 2-cycle mixing oil

Carburetor Walbro rotary type with primer bulb

Ignition PCI

Spark Plug NGK CMR5H

Starting Recoil starter

Stopping Push button

Fuel tank capacity 20.0 oz. (0.6 liter)

Weight 15.6 pounds (7.1 kg)

PUMP

Type General purpose, centrifugal, self-priming

Suction Diameter 1.0 inches (25mm)

Discharge Diameter 1.0 inches (25mm)

Maximum Suction Head (vertical lift) 26.25 feet (8 meters)

Maximum Total Pump Head 164 feet (50 m)

Maximum Pump Discharge 34.3 gal/min (130 liters/min)

-1

Page 5

Assembly

Prior to Assembly

Before assembling this unit, make sure

you have all the components required for

a complete unit:

GP3410 engine-driven pump

Spark plug wrench

Install the Suction and Discharge Hoses

Spanner

3mm Hex Wrench

4mm Hex Wrench

Parts bag including:

●

1.0" hose clamps (3 each)

●

hose fittings and gaskets (2 each)

strainer

●

CAUTION!

This pump is intended for pumping

fresh water only.

Ingested debris can damage the

pump impeller and seals.

Never operate the pump if the

strainer is missing or damaged.

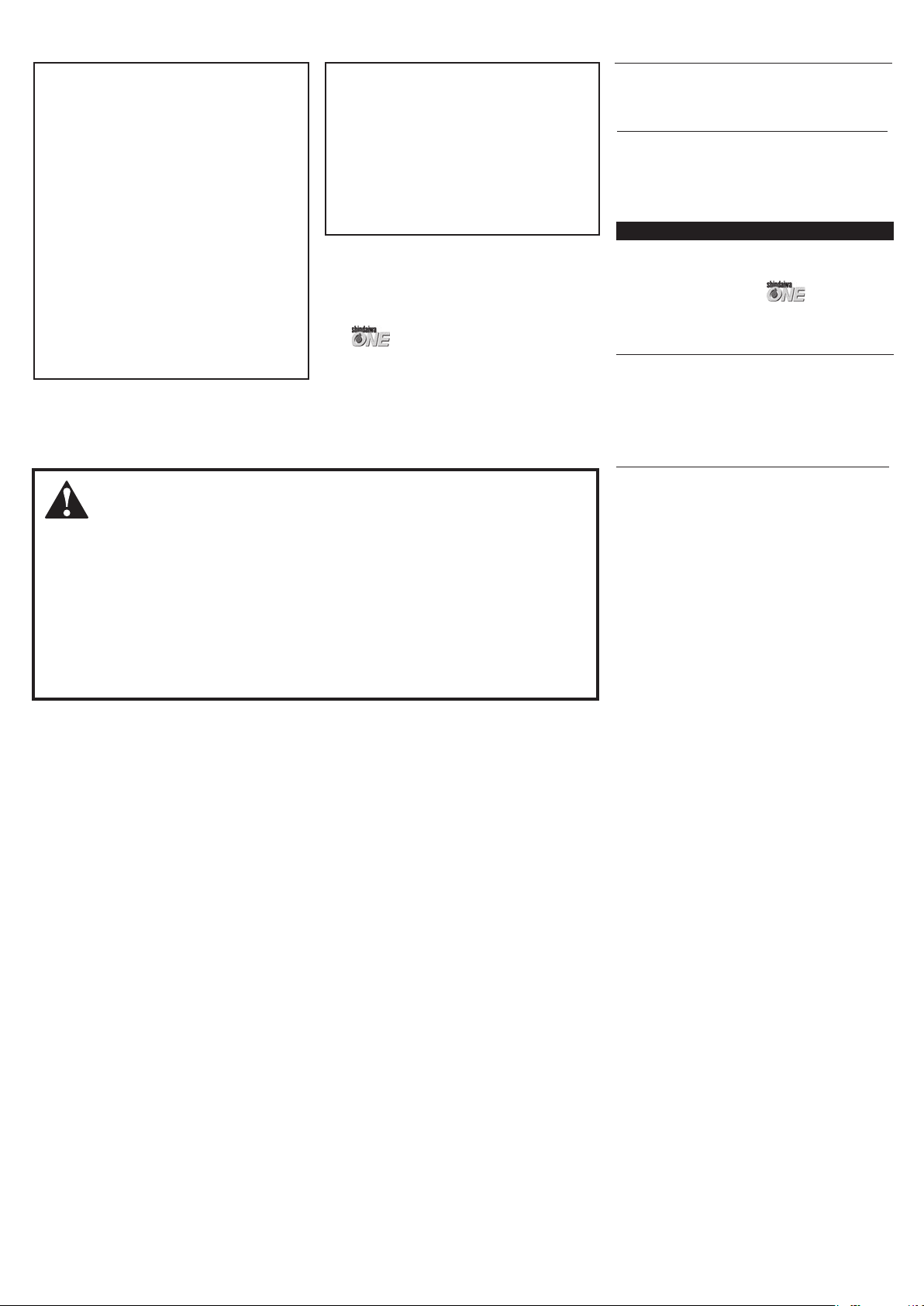

Assemble a barbed hose fitting, ring

1.

nut, and gasket as shown, and thread

the completed hose fitting assembly

onto the pump suction port. Assemble

the remaining hose fitting to the pump

discharge port.

Push a 1.0" suction hose (not provided)

2.

over the suction hose fitting on the pump

body, and secure with a 1.0" hose clamp as

shown. Working at the opposite end of the

suction hose, use a second 1.0" hose clamp

to install and secure the suction strainer.

Submerge the suction hose strainer in

3.

the water source. For maximum performance, avoid placing the strainer

directly in heavy accumulations of

leaves, silt, or other debris.

Ring Nut

Hose Clamp

Barbed Hose

Suction

Hose

Figure 1B

Install the discharge hose (not pro-

4.

vided) and secure with the remaining

1.0" hose clamp.

Recheck that both the suction and dis-

5.

charge hoses are free from obstructions, and that all connections are

tightly secured.

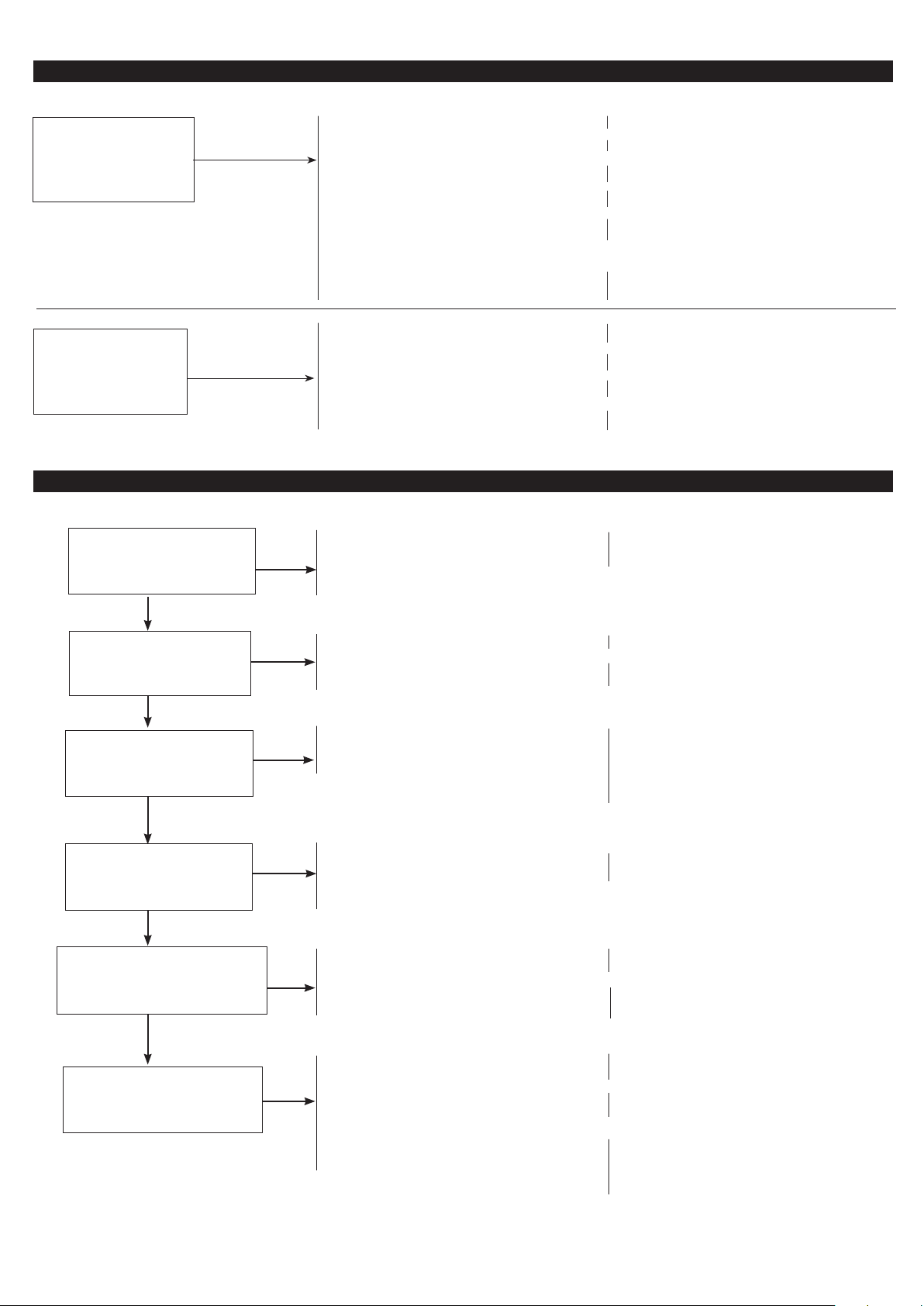

Priming Port

Gasket

Suction Port

Fitting

Hose Clamp

Discharge Port

Suction

Strainer

IMPORTANT!

Place the pump as close to the water

source as possible. Increases in suction

lift will lower pump performance. Do not

exceed maximum suction head of 26 feet.

Priming

Before the pump can develop suction

or “lift” at the water source, the pump

impeller must first be primed by filling

the pump housing with water. Once the

GP3410 has been primed, additional prim

ing should be required only if the pump

has been drained or otherwise emptied.

Remove the filler plug at the top of the

1.

pump housing. Use care not to lose the

sealing ring beneath the filler plug.

IMPORTANT!

A damaged or missing filler plug seal may

allow air to leak into the pump housing.

Air leakage can lower performance!

Fill the pump housing through the

2.

priming port (Figure 2) with clean

water until water overflows from the

filler plug hole on the pump body.

-

Replace and securely tighten the filler

3.

plug.

CAUTION!

Never allow the pump to run dry!

Operation without water can permanently damage the pump seals.

Filler Plug

Sealing ring

Priming port

Figure 2

5

Page 6

6

Mixing Fuel

CAUTION!

Never use any fuel containing more

than 10% alcohol by volume. Some

gasolines contain alcohol as an oxygenate! Oxygenated fuels may cause

increased operating temperatures.

Under certain conditions, alcoholbased fuels may also reduce the lubricating qualities of some mixing oils.

Generic oils and some outboard

motor oils may not be intended

for use in high-performance aircooled 4-cycle and 2-cycle engines,

and should never be used in your

Shindaiwa engine!

Filling the Fuel Tank

WARNING!

Minimize the risk of re!

STOP the engine before refueling.

■

ALWAYS allow the unit to cool

■

before refueling!

Wipe all spilled fuel and move the

■

unit at least 10 feet (3 meters) from

the fueling point before restarting!

NEVER start or operate this unit if

■

there is a fuel leak.

CAUTION!

This engine is designed to operate on a 50:1 mixture consisting of

unleaded gasoline and a premium

2-cycle mixing oil only. Use of nonapproved mixing oils can lead to

excessive maintenance costs and/or

engine damage.

Use only fresh, clean unleaded gaso-

line with a pump octane rating of 87 or

higher.

Mix gasoline with 50:1 Shindaiwa

4 cycle or 2-cycle mixing oil or

with an equivalent high quality 2-cycle

mixing oil.

NEVER start or operate this unit if

■

the carburetor, fuel lines, fuel tank

and/or fuel tank cap are damaged.

NEVER smoke or light any res near

■

the unit or fuels!

NEVER place any ammable mate-

■

rial near the engine mufer!

NEVER operate the engine without

■

the mufer and spark arrester in

place and properly functioning!

Example of 50:1 mixing

quantites

Gasoline 2-cycle mixing oil

liters milliliters

2.5 - 1

50 ml

5 - 1 100 ml

10 - 1 200 ml

20 - 1 400 ml

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer than

30 days and Shindaiwa oil with fuel

stabilizer is not used, it should first be

treated with a fuel stabilizer such as

StaBil™.

Place the unit on the ground or on a flat

1.

surface.

Clear any dirt or other debris from

2.

around the fuel filler cap.

Remove the fuel cap, and fill the fuel

3.

tank with clean, fresh fuel mixture.

Replace and firmly tighten the fuel cap.

4.

Page 7

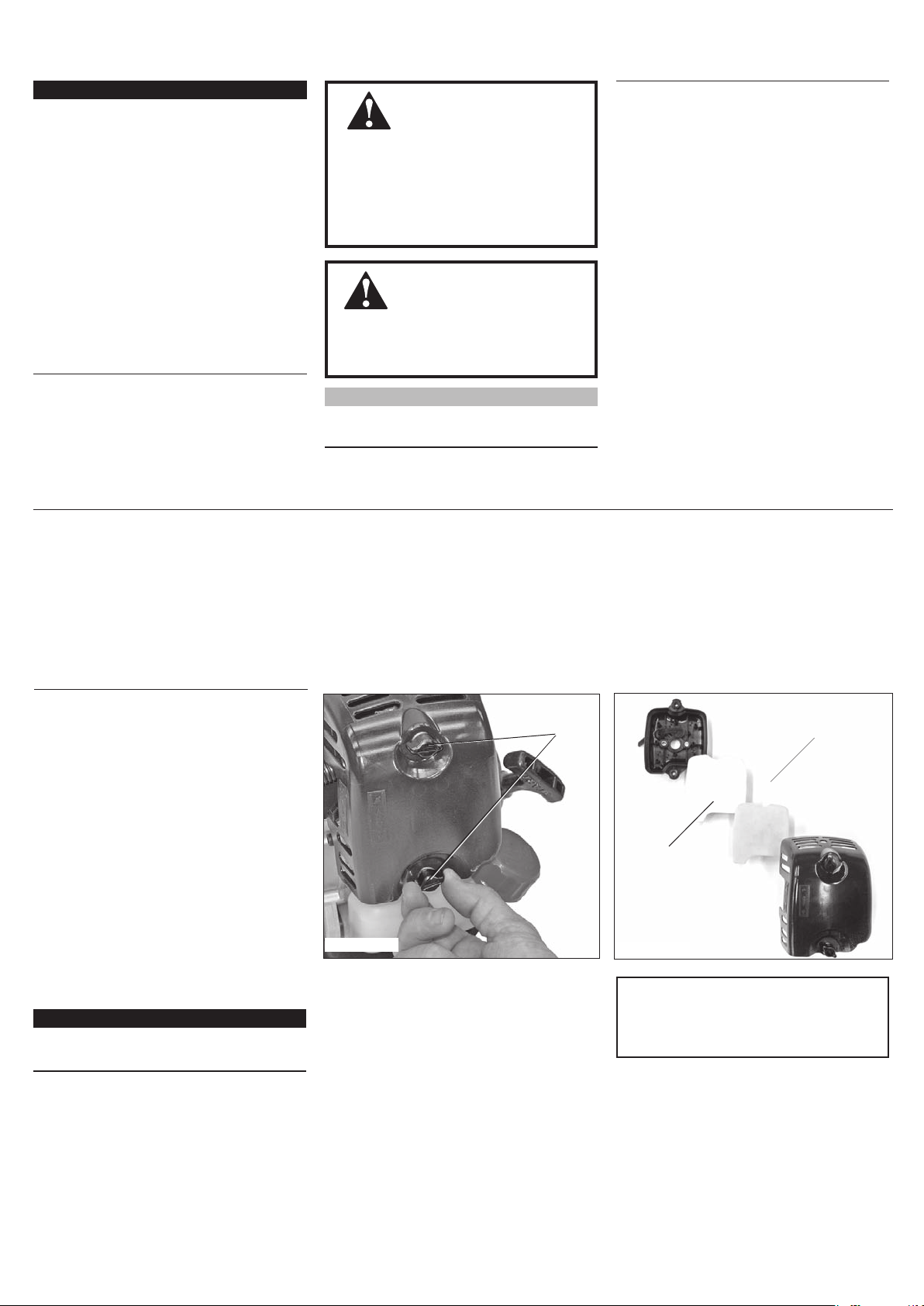

Starting the Engine

WARNING!

Never start the engine from

the operating position.

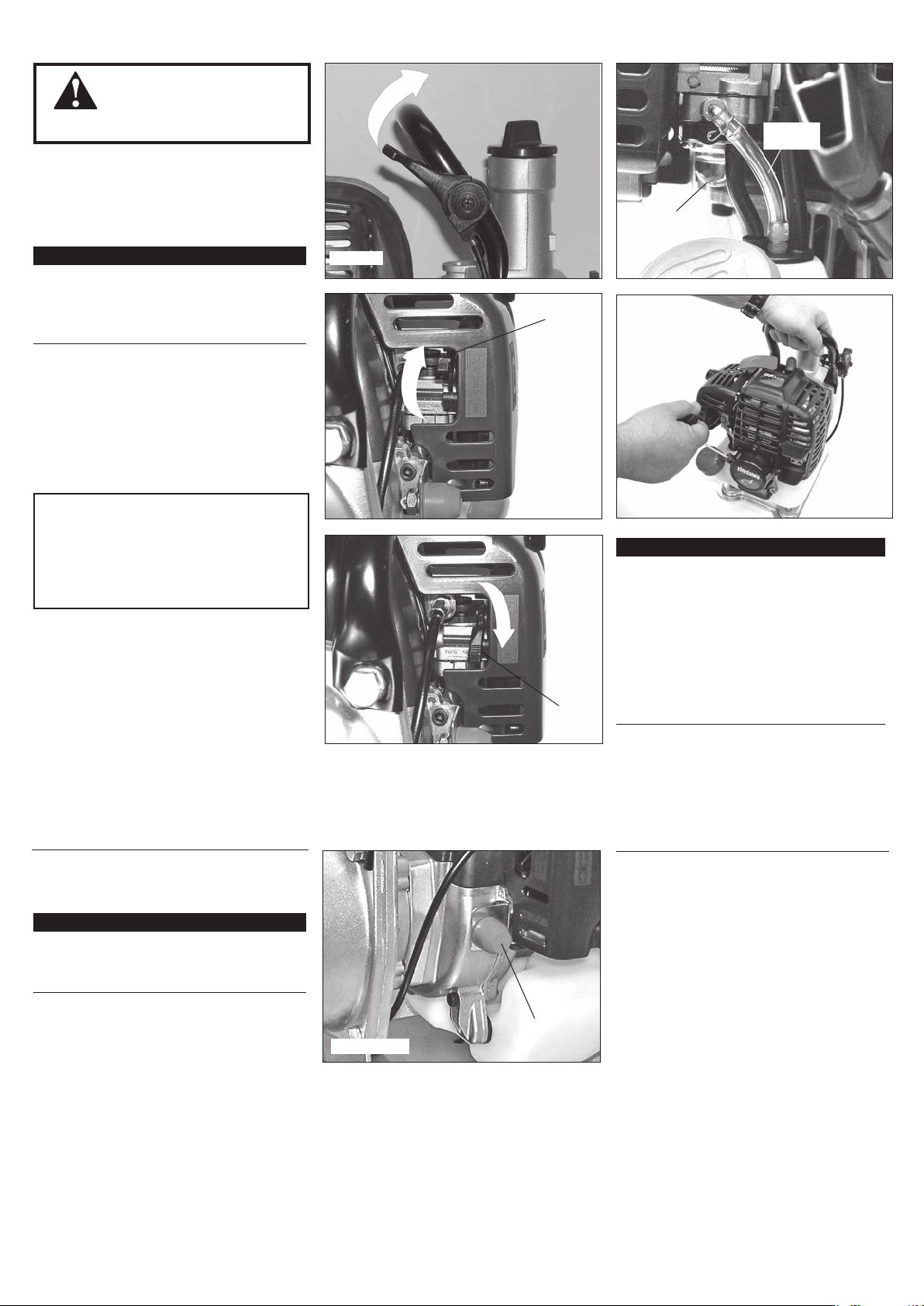

Set throttle control lever to the half

1.

open position. See Figure 3.

Press the primer bulb until fuel can be

2.

seen flowing in the transparent return

tube. See Figure 4.

IMPORTANT!.

The primer system only pushes fuel

through the carburetor. Repeatedly pressing the primer bulb will not flood the

engine with fuel.

Set the choke lever to the CLOSED

3.

position if the engine is cold.

While holding the pump handle firmly

4.

with your left hand, use your other

hand to slowly pull the recoil starter

handle until resistance is felt, then pull

quickly to start the engine.

Figure 3

Return tube

Primer bulb

Figure 4

Close

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

When the engine starts, slowly move

5.

the choke lever to the "OPEN" position. See Figure 7. (If the engine stops

after the initial start, close the choke

and restart.)

When the engine starts, gradually

6.

move the throttle control lever back to

the idle position (counterclockwise).

When the Engine Starts

After the engine starts, allow the

engine to warm up at idle 2 or 3 min

utes before operating the unit.

IMPORTANT!

To stop the GP3410 pump engine, push

the red ignition switch until the engine

completely stops. See Figure 8.

Figure 5

Figure 6

IMPORTANT!

If the engine fails to start after several

attempts with the choke in the closed

position, the engine may be flooded

with fuel. If flooding is suspected, move

the choke lever to the open position

and repeatedly pull the recoil starter to

remove excess fuel and start the engine.

If the engine still fails to start, refer to the

Open

Figure 7

-

troubleshooting section of this manual.

If the engine does not start

Repeat the appropriate procedures

1.

for starting a warm or cold engine.

If the engine fails to starts, fol-

2.

low the procedures in “Starting a

Flooded Engine”.

Figure 8

Ignition

Switch

7

Page 8

8

Starting the Engine (continued)

Starting a ooded engine

Follow the starting procedures for a

Disconnect the spark plug lead, and

1.

then use the spark plug wrench to

unscrew the spark plug (counter- clockwise to remove.) See Figure 9

If the spark plug is fouled or is soaked

2.

5.

warm engine.

If the engine still fails to start or fire,

6.

refer to the troubleshooting chart at the

end of this manual.

with fuel, clean or replace the plug as

necessary. For spark plug specificiations and gapping procedure, see the

Maintenance section.

While the spark plug is removed, crank

3.

CAUTION!

Incorrect spark plug installation can

result in serious engine damage!

the engine several times to clear excess

fuel from the combustion chamber.

Replace the spark plug and tighten it firmly

4.

with the spark plug wrench. If a torque

wrench is available, torque the spark plug

to 148-165 inch-lbs. (170-190 kg/cm).

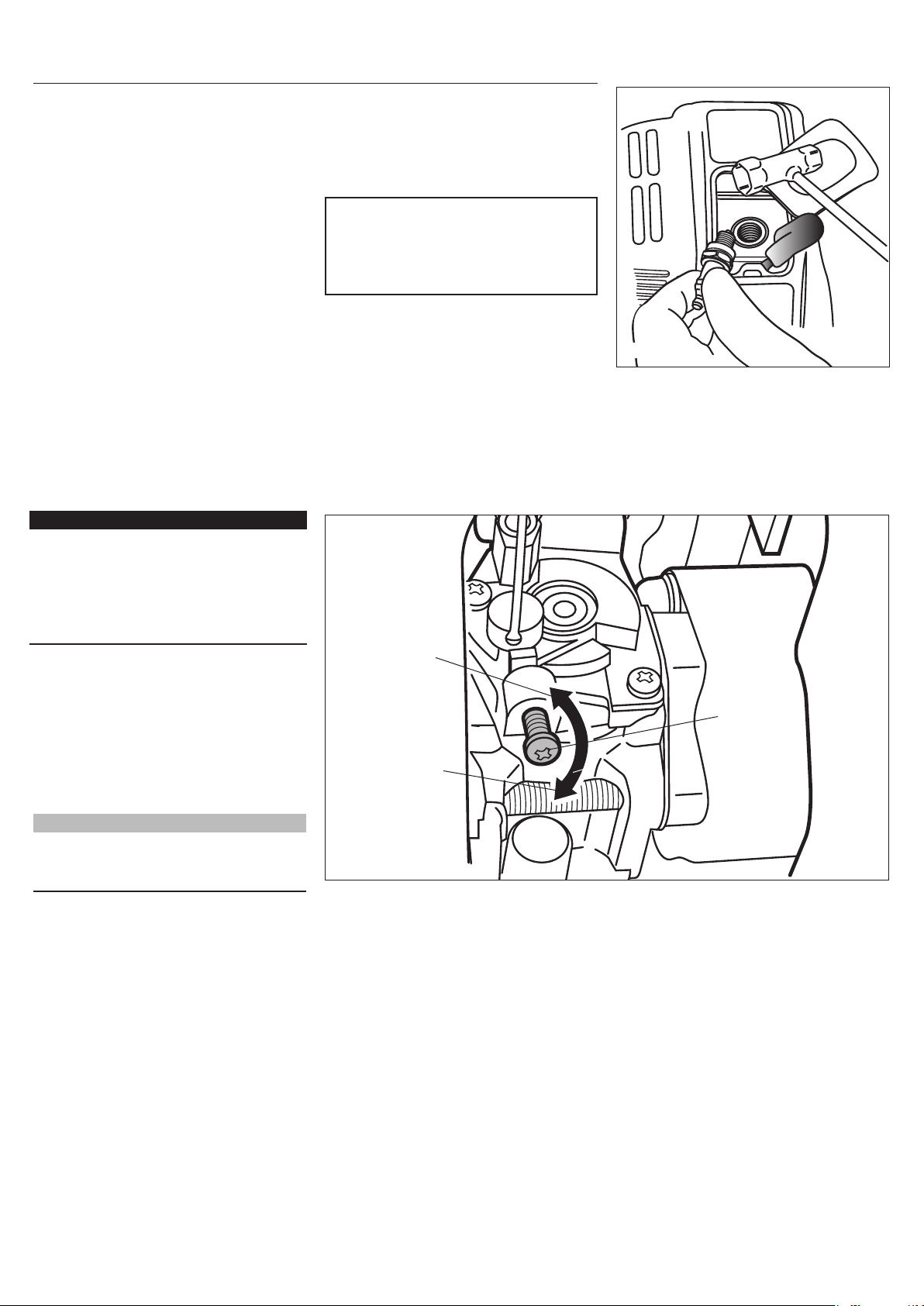

Adjusting Engine Idle

IMPORTANT

A clean and unrestricted airflow is essential to your pump’s engine performance

and durability! Before attempting any carburetor adjustments, inspect and clean the

engine air filter as described in the Maintenance section of this manual.

Idle Speed Adjustment

Place the unit on the ground and start

1.

the engine, and then set throttle control

lever to idle postion. Allow engine to

idle 2-3 minutes until warm.

If a tachometer is available, the engine idle

2.

speed should be adjusted to 3,000 (±300)

RPM (min-1).

Decrease Idle

Increase Idle

Figure 9

Idle

Adjustment

Screw

NOTE

Carburetor fuel mixture adjustments are

preset at factory and cannot be serviced

in the eld.

Figure 10

Page 9

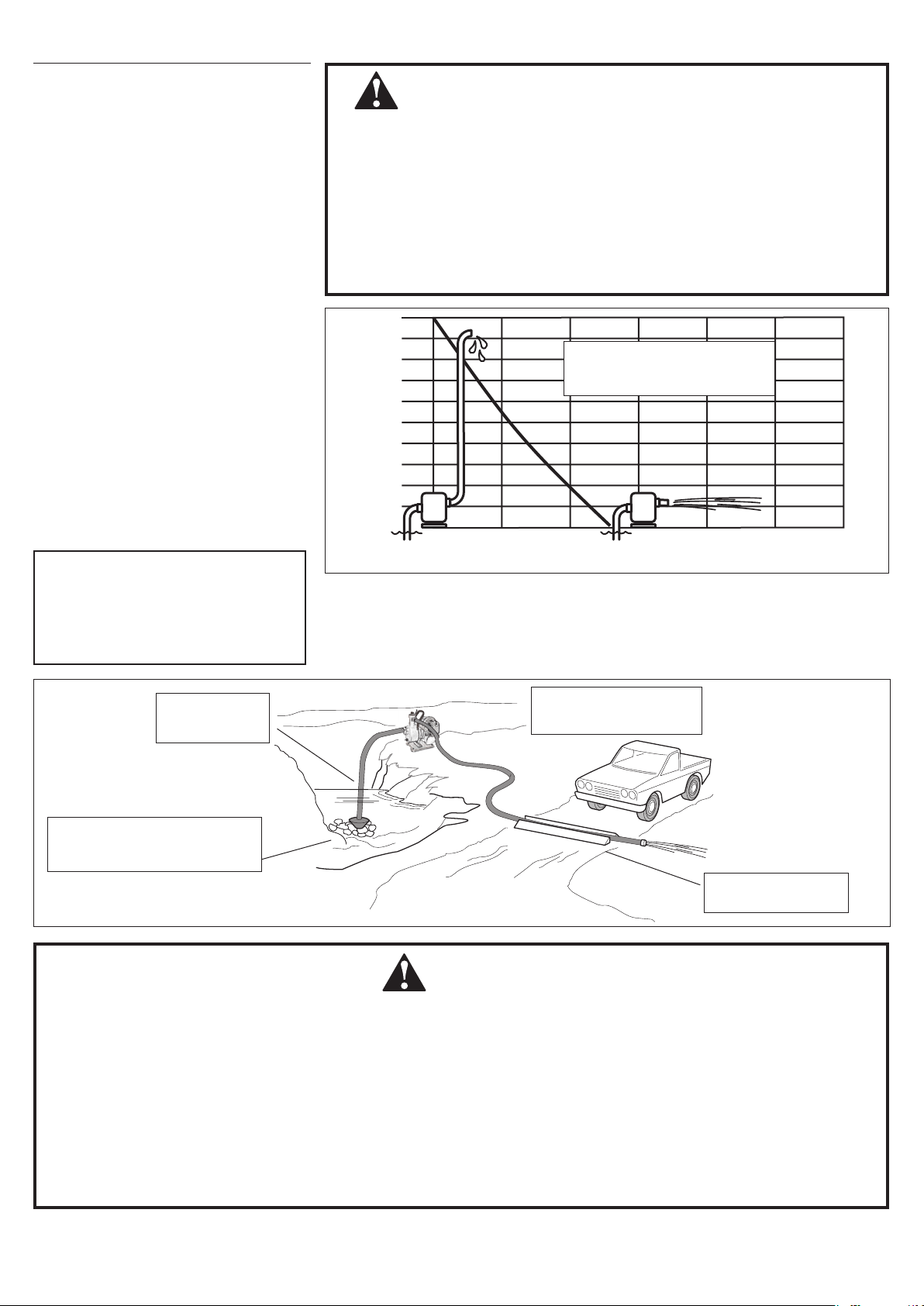

50

45

40

35

30

25

20

15

10

5

0 50 100 150 200 250 300

Operating Tips for Maximum Performance

Minimize friction by using the

1.

correct 1.0" ID suction and discharge

hoses specified, with a minimum of

connections. Keep all hose runs as

short as possible.

Keep the suction head (vertical lift)

2.

as short as possible. Do not exceed

the pump’s maximum suction head of

26 feet.

Avoid air leaks.

3.

All suction-side connections must

a.

be tightly secured.

Make sure the filler cap and drain

b.

plug on the pump housing are

tight and free from leakage.

Protect the discharge hose from

4.

crushing-type damage, especially

from motor vehicles.

Abrasive debris can damage the

5.

pump impeller and seals, and should

be avoided.

To minimize clogging the strainer

6.

when pumping near mud or debris,

place the strainer in a bucket or on a

bed of stones.

CAUTION!

Sudden pressure increases (such as

from vehicles driving on the discharge

hose) can split the discharge hose and

may also damage the pump body.

Keep all pets and bystanders away

■

from the pump during operation and

fueling.

Beware the pump may shift sud-

■

denly during operation, especially

when the hoses rst ll with water.

Do not wear loose clothing, jewelry,

■

or long hair that could get caught in

machinery.

Figure 11

WARNING!

Total head (meters)

Discharge Quantity ( liters per minute)

Always wear eye protection such as

■

goggles or safety glasses.

Always wear hearing-protection

■

devices when operating this unit.

Wear appropriate footwear such

■

as nonskid boots or shoes. Steeltoed rubber boots are strongly

recommended. NEVER WORK

BAREFOOT!

Gloves are recommended.

■

The higher the lift, the less

the discharge quantity.

Keep the suction lift

distance as short as

possible.

Minimize clogging from debris: Place the

suction strainer on a bed of stones or tied

Figure 12

Burn danger/Danger from spilled

■

fuel! Always stop the pump engine

before transporting the pump. The

engine mufer and other components

may be very hot during or after pump

operation. Carry the pump by the handle only. The pump must remain level at

all times.

Danger of Asphyxiation! This pump

■

is intended for outdoor use in well

ventilated areas only!

in a bucket.

Be careful when locating the

pump; the pump may shift

suddenly during operation!

Protect the discharge hose

from crushing.

WARNING!

Danger from moving parts! The pump

■ Explosion Hazard! Never attempt

rotor will rotate whenever the engine is

cranked or operated. Stop the engine

and disconnect the spark plug terminal

before performing any maintenance or

installations on this pump. Never operate this pump unless all covers and

shields are in place, and both the suction and discharge hoses are installed

and rmly connected to the pump.

■

to start or operate this pump in the

presence of explosive or combustible

materials!

Never attempt to transfer fuels or

■

other hazardous liquids with the

GP3410! This pump is designed

and warranted for pumping FRESH

WATER ONLY!

9

Page 10

10

Maintenance

General Maintenance

IMPORTANT!

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES

AND SYSTEMS MAY BE PERFORMED

BY ANY REPAIR ESTABLISHMENT OR

INDIVIDUAL; HOWEVER, WARRANTY

REPAIRS MUST BE PERFORMED BY A

DEALER OR SERVICE CENTER AUTHORIZED BY SHINDAIWA CORPORATION.

THE USE OF PARTS THAT ARE NOT

EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS

MAY IMPAIR THE EFFECTIVENESS OF

THE EMISSION CONTROL SYSTEM AND

MAY HAVE A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

Daily Maintenance

Prior to each work day, perform the

following:

Remove dirt or debris from the engine,

1.

check the cooling fins and air cleaner for

clogging and clean them as necessary.

WARNING!

Before performing any

maintenance, repair or cleaning

work on the unit, make sure the

engine and cutting attachment are

completely stopped. Disconnect the

spark plug wire before performing

service or maintenance work.

WARNING!

Mufer

This unit must never be operated with

a faulty or missing spark arrester or

muffler. Make sure the muffler is well

secured and in good condition. A worn or

damaged muffler is a fire hazard and may

also cause hearing loss.

Spark Plug

Keep the spark plug and wire connections

tight and clean.

Non-standard parts may not

operate properly with your unit and

may cause damage and lead to personal injury.

Fasteners

Make sure nuts, bolts, and screws (except

carburetor adjusting screws) are tight.

NOTE:

Using non-standard replacement parts

could invalidate your Shindaiwa warranty.

Carefully remove any accumulation of

2. Check for loose or missing screws or

dirt or debris from the muffler or the

fuel tank. Dirt build-up in these areas

could cause engine overheating, induce

3.

components.

Check the entire unit for leaking fuel.

4.

premature wear, or create a fire hazard.

10-Hour Maintenance

(more frequently in dusty conditions)

Remove the air filter cover by loosening

1.

the two thumbscrews. See Figure 13A.

Remove and inspect the pre-filter. If

2.

the pre-filter is torn or otherwise damaged, replace it with a new one. See

Figure 13B.

Clean the pre-filter with soap and water.

3.

Let dry before reinstalling.

Inspect the air filter element. If the ele-

4.

ment is damaged or distorted, replace

it with a new one.

Tap filter gently on a hard surface to dis-

5.

lodge debris from element or use compressed air from the inside to blow debris

out and away from the air filter element.

IMPORTANT!

Direct the air stream at the inside face of

the filter only!

Loosen

thumbscrews

Figure 13A

Install the filter element, pre-filter and

6.

cover in the reverse order of removal.

Pre-lter

Filter

Element

Figure 13B

CAUTION!

Never operate the unit if the air lter

assembly is damaged or missing!

Page 11

Maintenance (continued)

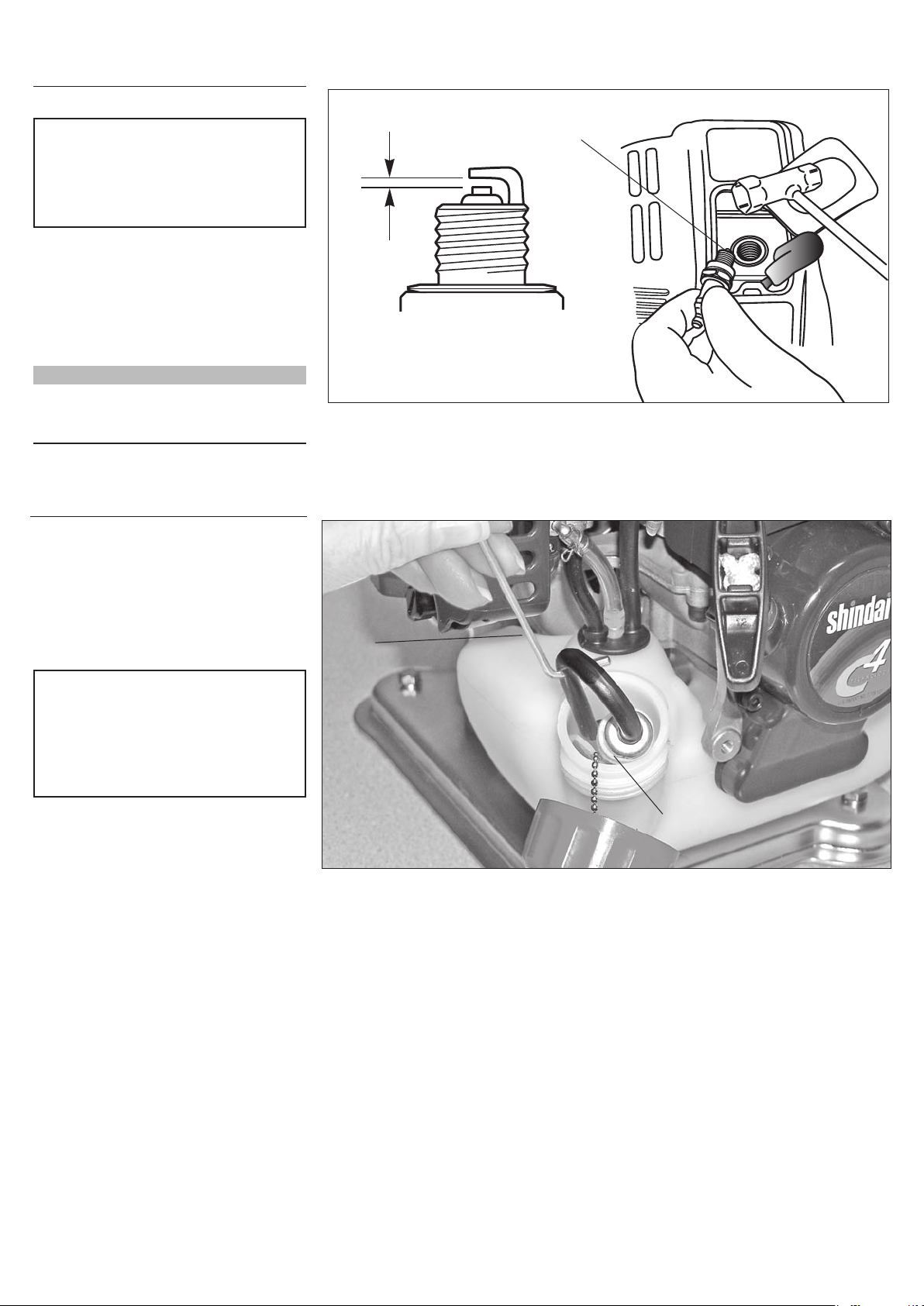

10/15-Hour Maintenance

Every 10 to 15 hours of operation:

CAUTION!

Before removing the spark plug,

clean the area around the plug to

prevent dirt and debris from getting

into the engine’s internal parts.

Remove and clean the spark plug.

■

Adjust the spark plug electrode gap to

0.024 - 0.028 inch (0.6 - 0.7 mm). If the

spark plug must be replaced, use only

an NGK CMR5H or equivalent resistor type spark plug of the correct heat

range. See Figure 14.

0.024–0.028 inch

(0.6–0.7 mm)

Clean the spark plug

and check the gap at

the electrode.

NOTE:

The NGK CMR5H also meets the

requirements for electro magnetic compliance (EMC).

50-hour Maintenance

Every 50 hours of operation

(more frequently in dusty or dirty

conditions):

Remove and clean the cylinder cover

1.

and clean dirt from the cylinder fins.

Use a hooked wire to extract the fuel filter

2.

from inside the fuel tank. See Figure 15.

CAUTION!

Make sure you do not pierce the

fuel line with the end of the hooked

wire. The line is delicate and can be

damaged easily.

Remove and replace the filter element.

3.

Before reinstalling the new filter element, inspect the condition of all the fuel

system components (fuel pick-up line,

fuel return line, tank vent line, tank vent,

fuel cap and fuel tank). If damage, splitting or deterioration is noted, the unit

should be removed from service until it

can be inspected or repaired by a Shindaiwa-trained service technician.

Figure 14

Hooked

Wire

Figure 15

Filter Element

11

Page 12

12

Maintenance (continued)

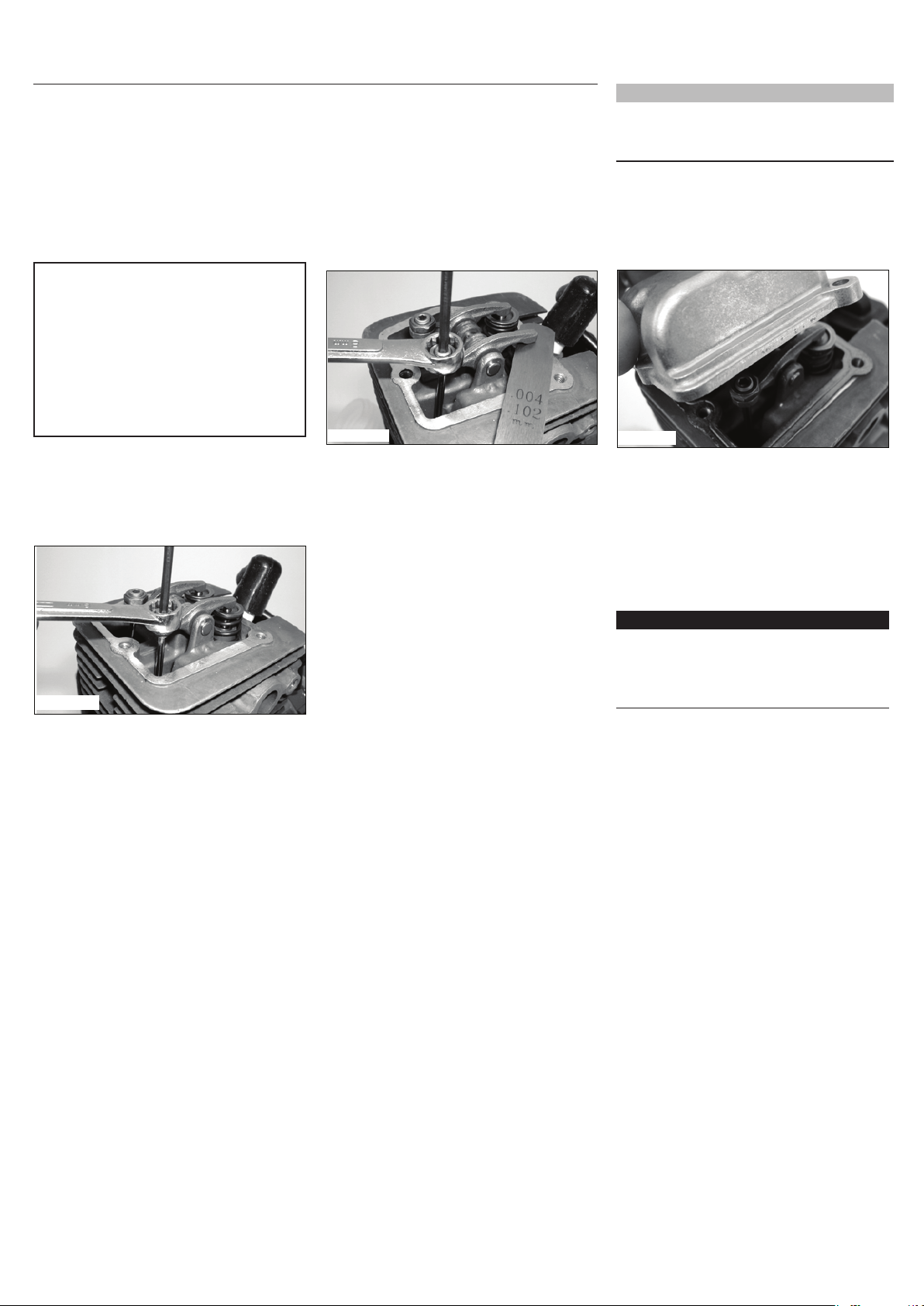

139/150-Hour Maintenance

Maintenance after first 139-hours,

then every 150-hours thereafter.

Combustion chamber should be decar-

1.

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

Valve Adjustment

CAUTION!

Performing a valve adjustment

incorrectly may cause hard starting and/or can damage the engine.

If you are unfamiliar with this engine

or uncomfortable with this procedure, consult with an authorized

Shindaiwa servicing dealer.

Remove cylinder cover, rocker arm cover,

1.

and set piston at TDC-compression.

Loosen adjuster locknut so that the

2.

2.5 mm Allen socket head adjustment

screw can turn freely.

Figure 16

Replace the spark plug annually: Use

2.

only NGK CMR5H or equivalent resistor type spark plug of the correct heat

range. Set spark plug electrode gap to

0.024-0.028 inch (0.6 -0.7 mm).

Figure 17

3.

Insert .004" (0.10 mm) feeler gauge for

both intake and exhaust between valve

stem tip and rocker arm.

Turn adjustment screw (clockwise =

4.

tighter, counter-clockwise = looser)

until feeler gauge is almost snug. Back

off just enough to allow gauge to slip

out with limited resistance.

While holding adjustment screw in

5.

place with Allen driver, tighten locknut

with wrench.

NOTE:

The NGK CMR5H also meets the

requirements for electro magnetic compliance (EMC).

Figure 18

Turn engine over several times, and

6.

return to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change as

a result of tightening locknut. Re-adjust

as necessary.

Replace rocker arm cover gasket to

7.

assure proper sealing and install cover.

IMPORTANT!

If a new gasket is not available and/or the

old gasket is not damaged, the old gasket may be reused. Never use cracked or

damaged gaskets!

Page 13

Maintenance (continued)

Spark Arrester Maintenance

WARNING!

Never operate this unit with

a damaged or missing mufer or

spark arrester! Operating with missing or damaged exhaust components

is a re hazard, and can also damage your hearing!

Hard starting or a gradual loss of performance

can be caused by carbon deposits lodged in

the spark arrester screen. For maximum performance, the spark arrester screen should be

periodically cleaned as follows.

Remove engine cover to expose muf-

1.

fler. Remove the spark arrester from

the muffler. The arrester is press-fit in

place; there are three screws to remove.

Use a plastic scraper or wire brush

2.

to remove carbon deposits from

the arrester screen and wipe clean

exhaust base.

Inspect the screen carefully, and

3.

replace any screen that has been perforated, distorted, or is otherwise

unserviceable.

Press the spark arrester into the

4.

exhaust base.

If carbon accumulation in the muffler

or cylinder are severe, or if you do not

notice an improvement in performance

after servicing, have the unit inspected by

an authorized servicing Shindaiwa dealer.

Spark Arrester

Screen Cover

Figure 19

Mufer

Spark Arrester

Screen

Long Term Storage

Whenever the unit will not be used for 30

days or longer, use the following procedures to prepare it for storage:

Clean external parts thoroughly.

Drain all the fuel from the fuel tank.

Remove the remaining fuel from the

fuel lines and carburetor. To do so:

Prime the primer bulb until no more

1.

fuel is passing through.

Start and run the engine until it stops

2.

running.

3.

Repeat steps 1 and 2 until the engine

will no longer start.

IMPORTANT!

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL™, if

Shindaiwa oil with fuel stabilizer is

not used.

CAUTION!

Gasoline stored in the carburetor for extended periods can cause

hard starting and could also lead

to increased service and maintenance cost.

Remove the spark plug and pour about

1/4 ounce of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3

times so oil will evenly coat the interior

of the engine. Reinstall the spark plug.

Before storing the unit, repair or

replace any worn or damaged parts.

Remove the air cleaner element from

the carburetor and clean it thoroughly

with soap and water. Let dry and reassemble the element.

Remove the drain plug and drain all water

from the pump housing. See Figure 20.

Store the unit in a clean, dust-free area.

Drain plug

Figure 20

13

Page 14

14

Troubleshooting Guide (continued)

Symptom Possible Cause

Pump

Remedy

No output/low

output.

Poor output at

higher suction lifts

What to Check Possible Cause Remedy

Does the engine crank?

NO

Pump was not primed.

Pump head too high.

Suction hose too long.

Air leak in suction hose.

Suction strainer or hose is clogged or

damaged. (NOTE: liner-type hoses

can also collapse internally).

Pump is internally damaged.

Air leak in suction hose.

Air leakage in pump.

Worn pump impeller or volute.

Engine not operating at full rpm.

Engine Does Not Start

Faulty recoil starter.

Fluid in the crankcase.

Internal damage.

Prime pump.

Move discharge pipe.

Use shortest suction length possible.

Tighten all connections.

Clean or replace components as

required.

Consult with an authorized servicing

dealer.

Tighten all connections.

Inspect and repair as required.

Repair or replace components as required.

Consult with an authorized

servicing dealer.

Consult with an authorized

servicing dealer.

YES

Good compression?

YES

Does the tank contain

fresh fuel of the proper

grade?

YES

Is fuel visible and

moving in the return

line when priming?

YES

Is there spark at the spark

plug wire terminal?

YES

Check the spark plug.

NO

NO

NO

NO

Loose spark plug.

Excess wear on cylinder, piston,

rings.

Fuel incorrect, stale, or contaminated;

mixture incorrect.

Check for clogged fuel filter

and/or vent.

The ignition switch is in “O” (OFF)

position.

Shorted ignition ground.

Faulty ignition unit.

If the plug is wet, excess fuel may be

in the cylinder.

The plug is fouled or improperly

gapped.

Tighten and re-test.

Consult with an authorized

servicing dealer.

Refill with fresh, clean unleaded gasoline

with a pump octane of 87 or higher

mixed with 50:1 Shindaiwa Premium

2-cycle mixing oil or with an equivalent

high quality 2-cycle mixing oil.

Replace fuel filter or vent as required.

Restart.

Move switch to “I” (ON) position

and restart.

Consult with an authorized

servicing dealer.

Crank the engine with the plug

removed, reinstall the plug, and restart.

Clean and regap the plug to .024” /

0.6mm-0.7mm

. Restart.

The plug is damaged internally or of

the wrong size.

Replace the spark plug. Check the

“Specifications” section for the correct

plug for your unit. Restart.

Page 15

Troubleshooting Guide (continued)

What To Check Possible Cause Remedy

LOW POWER

Is the engine overheating?

Engine is rough at all

speeds. May also have black

smoke and/or unburned

fuel at the exhaust.

Operator is overworking the unit.

Carburetor mixture is too lean.

Improper fuel ratio.

Fan, fan cover, cylinder fins dirty or

damaged

Carbon deposits on the piston or in the

muffler.

Clogged air cleaner element.

Loose or damaged spark plug.

Air leakage or clogged fuel line.

Cut at slower rate.

Consult with an authorized servicing

dealer.

Refill with clean fresh unleaded gasoline

with a pump octane of 87 or higher, mixed

with Premium 2-cycle mixing oil at a 50:1

gasoline/oil ratio.

Clean, repair or replace as necessary.

Consult with an authorized servicing

dealer

Clean or replace the air filter

Tighten or replace the spark plug.

Restart. Check the Product Specifications

page in this manual for the correct spark

plug for this unit.

Repair or replace fuel filter and/or fuel

line.

Engine is knocking.

Water in the fuel.

Piston seizure.

Faulty carburetor and/or diaphragm

Overheating condition.

Improper fuel.

Carbon deposits in the combustion

chamber.

Refill with fresh fuel/oil mixture.

Consult with an authorized servicing

dealer.

Consult with an authorized servicing

dealer.

Check fuel octane rating; check for

presence of alcohol in the fuel. Refuel as

necessary.

Consult with an authorized servicing

dealer.

15

Page 16

16

Troubleshooting Guide (continued)

ADDITIONAL PROBLEMS

What To Check Possible Cause Remedy

Poor acceleration.

Engine stops abruptly.

Clogged air filter.

Clogged fuel filter.

Lean fuel/air mixture.

Idle speed set too low.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or loose terminal.

Ignition failure.

Piston seizure.

Clean or replace the air filter.

Replace the fuel filter.

Consult with an authorized

servicing dealer.

Adjust: 2,700 (±300) min-1.

Reset the switch and re-start.

Refuel. See Fuel section of manual.

Replace fuel filter.

Drain; replace with clean fuel. See Fuel

section of manual..

Clean or replace spark plug. Check

the Specifications page in this manual

for the proper spark plug for your unit.

Tighten the terminal.

Replace the ignition unit.

Consult with an authorized

servicing dealer

Engine difficult to shut

off.

Excessive vibration.

Ground (stop) wire is disconnected or

switch is defective

Overheating due to incorrect spark plug

Overheated engine.

Warped or damaged attachment.

Loose gearcase.

Bent main shaft/worn or damaged

bushings.

Test and replace as required.

Replace the spark plug. Check the

Specifications page in this manual for

the proper spark plug for your unit.

Idle engine until cool.

Inspect and replace attachment

as required.

Tighten gearcase securely.

Inspect and replace as necessary.

Page 17

Shindaiwa Corporation

Federal Emission Design And Defect Limited Warranty Utility And Lawn

And Garden Engines

Shindaiwa Corporation warrants to the initial purchaser and

each subsequent owner, that this utility equipment engine

(herein engine) is designed, built and equipped to conform at

the time of initial sale, to all applicable regulations of the U.S.

Environmental Protection Agency (EPA), and that the engine

is free of defects in materials and workmanship that would

cause this engine to fail to conform with EPA regulations during its warranty period. This emission warranty is applicable

in all States, except the State of California.

For parts listed under PARTS COVERED, the dealer authorized by Shindaiwa Corporation will, at no cost to you, make

the necessary diagnosis, repair, or replacement of any defective emission-related component to ensure that the engine

complies with applicable U.S. EPA regulations.

MANUFACTURERS WARRANTY COVERAGE

When sold within the U.S., this engine’s emission control system is warranted for a period of two (2) years from the date this product is first

delivered to the original retail purchaser.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the

required maintenance listed in your owner’s manual. Shindaiwa Corporation recommends that you retain all receipts covering maintenance on your engine, but Shindaiwa Corporation cannot deny a warranty claim solely for the lack of receipts or for your failure to ensure

the performance of all scheduled maintenance.

As the engine owner, you should however be aware that Shindaiwa Corporation may deny your warranty coverage if your engine or a part has failed

due to abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest dealer

authorized by Shindaiwa Corporation when a problem exists.

If your Shindaiwa Dealer is unable to answer questions regarding

your warranty rights and responsibilities, you should then contact

your Shindaiwa Distributor.

For the name and telephone number of the Shindaiwa Distributor in

your area, please call Shindaiwa Inc. at (503) 692-3070 between the

hours of 8:00 AM and 5:00 PM Pacific Standard Time.

PARTS COVERED

Listed below are the parts covered by the Federal Emission Design

and Defect Warranty. Some parts listed below may require scheduled

maintenance and are warranted up to the first scheduled replacement of that part. The warranted parts include:

1. Carburetor Internal Components

• Valve Assembly-throttle, Jet, Metering Diaphragm

2. Ignition System Components

• Ignition Coil

• Flywheel Rotor

The emission control system for your particular Shindaiwa engine

may also include certain related hoses and connectors.

LIMITATIONS

The Federal Emission Design and Defect Warranty shall not cover

any of the following:

(a) conditions resulting from tampering, misuse, improper adjust

ment (unless they were made by the dealer or service center authorized by Shindaiwa Corporation during a warranty

repair), alteration, accident, failure to use the recommended

fuel and oil, or not performing required maintenance services,

(b) the replacement parts used for required maintenance

services,

(c) consequential parts used for required maintenance services,

(d) diagnosis and inspection fees that do not result in eligible war-

ranty service being performed, and

(e) any non-authorized replacement part, or malfunction of autho

rized parts due to use of non-authorized parts.

MAINTENANCE AND REPAIR REQUIREMENTS

You are responsible for the proper use and maintenance of the

engine. You should keep all receipts and maintenance records covering the performance of regular maintenance in the event questions

arise. These receipts and maintenance records should be transferred

to each subsequent owner of the engine. Shindaiwa Corporation

reserves the right to deny warranty coverage if the owner has not

properly maintained the engine. Shindaiwa Corporation will not deny

warranty repairs, however, solely because of the lack of repair, maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY

REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A DEALER OR SERVICE

CENTER AUTHORIZED BY SHINDAIWA CORPORATION THE USE

OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND

DURABILITY TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE

A BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by Shindaiwa Corporation are used

for maintenance replacements or for the repair of components affecting emission control, you should assure yourself that such parts are

warranted by their manufacturer to be equivalent to the parts authorized by Shindaiwa Corporation in their performance and durability.

OBTAINING WARRANTY SERVICE

All repairs qualifying under this limited warranty must be performed

by a dealer authorized by Shindaiwa Corporation

If any emission-related part is found defective during the warranty

period, it is your responsibility to present the product to an authorized Shindaiwa dealer. Bring your sales receipts showing the date

of purchase for this engine. The dealer authorized by Shindaiwa Corporation will perform the necessary repairs or adjustments within

a reasonable amount of time and furnish you with a copy of the

repair order. All parts and accessories replaced under this warranty

become the property of Shindaiwa Corporation

To locate an authorized Shindaiwa dealer near you, contact your

Shindaiwa Distributor. For the name and telephone number of the

Shindaiwa Distributor in your area, please call Shindaiwa Inc. at

(503) 692-3070 between the hours of 8:00 AM and 5:00 PM Pacific

Standard Time.

THIS WARRANTY IS ADMINISTERED BY

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin OR. 97062

(503) 692-3070

-

-

17

Page 18

18

NOTES:

Page 19

NOTES:

19

Page 20

NOTES:

20

Page 21

MANUAL DEL PROPIETARIO O USUARIO DE SHINDAIWA

BOMBA DE AgUA gP3410

¡ADVERTENCIA!

Reduzca al mínimo el riesgo de lesiones, tanto a usted

mismo como a otras personas. Lea detenidamente este

manual y familiarícese con su contenido. Protéjase los

ojos y los oídos siempre que trabaje con esta unidad.

Número de pieza 68510-94310 Rev. 3/07

Page 22

Introducción

Notas de especial interés

Esta bomba Shindaiwa GP3410 ha sido

diseñada y fabricada para ofrecer un

excelente rendimiento y fiabilidad sin

comprometer la calidad, la comodidad de

uso, la seguridad ni la durabilidad.

Los motores de alto rendimiento de Shindaiwa

son fruto de la más avanzada tecnología en

motores de 4 tiempos y desarrollan una potencia excepcionalmente alta con una cilindrada

Español

y un peso notablemente bajos. Como propietario o usuario, pronto descubrirá por qué

Shindaiwa destaca por encima de los demás.

¡IMPORTANTE!

La información contenida en este manual

describe unidades disponibles en el momento

de su impresión. Aunque en todo momento

hemos intentado incluir en este documento la

información más actualizada sobre su bomba

de agua Shindaiwa GP3410, puede haber algunas diferencias entre su bomba y el contenido

de este manual. Shindaiwa Inc. se reserva el

derecho de efectuar cambios en la producción

sin aviso previo y sin obligación de modificar

las unidades fabricadas con anterioridad.

¡ADVERTENCIA!

Las emisiones emitidas por el

tubo de escape de este producto contienen substancias químicas que en el

estado de California son consideradas

como causantes de cáncer, defectos

congénitos u otros efectos nocivos a

la reproducción humana.

A lo largo de este manual aparecen “notas

de especial interés” dentro de recuadros,

precedidas por el símbolo triangular de

atención.

¡ADVERTENCIA!

Toda explicación precedida

por la palabra “ADVERTENCIA” contiene información de obligado cumplimiento para evitar lesiones graves.

¡PRECAUCIÓN!

Toda explicación precedida por la

palabra “PRECAUCIÓN” contiene

información de obligado cumplimiento para evitar dañar esta unidad.

¡IMPORTANTE!

Toda explicación precedida por la palabra “IMPORTANTE” tiene especial

trascendencia.

NOTA:

Toda explicación precedida por la

palabra “NOTA” contiene información que

conviene conocer y que puede facilitarle

su trabajo.

Otras notas de atención no precedidas

por el símbolo de atención son:

Lea y siga las instrucciones del

manual del propietario o usuario.

El incumplimiento de esta norma

puede acarrear graves lesiones.

Protéjase en todo momento

los ojos y los oídos mientras

trabaje con esta unidad.

No utilice esta unidad si se

encuentra cansado, enfermo

o bajo los efectos del alcohol,

drogas o alguna medicación.

Para evitar daño de la bomba

de agua, llenar el conducto de

cebado de agua antes de usar.

¡ADVERTENCIA!

No efectúe ninguna

modicación ni arreglos no autorizados

a esta unidad ni a ninguno de sus

componentes o accesorios.

Índice

PÁGINA

Etiquetas de Seguridad .......................... 3

Descripción de la unidad ....................... 4

Especificaciones .....................................4

Montaje ...................................................5

Mezcla de combustible .......................... 6

Arranque del motor ...............................7

Ajuste del ralentí del motor ................... 8

Consejos de utilización ..........................9

Mantenimiento .....................................10

Almacenamiento a largo plazo ............13

Guia Diagnostico .................................. 14

Garantía limitada .................................17

¡IMPORTANTE!

Los procedimientos descritos en este

manual están pensados para ayudarle

a sacar el máximo provecho de esta

unidad y a la vez evitar posibles daños

y lesiones, tanto a usted como a otras

personas. Estos procedimientos deben

contemplarse sólo como directrices para

un manejo seguro en la mayoría de las

condiciones, y no pretenden reemplazar

ninguna norma ni legislación sobre seguridad que pueda estar vigente en su zona.

Si tiene alguna pregunta relacionada

con su GP3410 o si no entiende alguna

parte de la información que contiene este

manual, consulte a su distribuidor de

Shindaiwa, quien le atenderá con gusto.

También puede ponerse en contacto con

Shindaiwa Inc. en la dirección que aparece en la parte posterior de este manual.

SP_2

Page 23

Instrucciones generales de seguridad

Trabaje de manera segura

Las bombas funcionan a velocidades

elevadas y pueden causar lesiones y

daños graves si se utilizan incorrectamente o con fines para los que no fueron

diseñadas. Nunca permita que utilice

esta unidad una persona sin la capacitación o formación adecuada.

¡ADVERTENCIA!

Nunca instale accesorios no

autorizados.

Manténgase alerta

Debe encontrarse en óptimas condiciones físicas y mentales para operar esta

unidad en forma segura.

¡ADVERTENCIA!

Nunca maneje ninguna máquina

motorizada de ningún tipo si está

cansado o si se encuentra bajo la inuencia de alcohol, drogas o medicamentos o cualquier otra sustancia que

pueda afectar su habilidad y juicio.

NUNCA ponga en marcha el motor

mientras transporta la unidad.

NUNCA ponga en marcha el motor en

espacios cerrados. Cerciórese de que

siempre haya buena ventilación. El humo

o los gases de escape del motor pueden

causar lesiones graves o la muerte.

NUNCA fume ni encienda fuego cerca

de la unidad.

Antes de repostar, SIEMPRE detenga

el motor y deje que se enfríe. Evite

llenar en exceso el depósito y limpie el

combustible que se haya derramado.

SIEMPRE examine la unidad para

comprobar si existen posibles fugas

de combustible antes de cada uso.

Durante cada recarga, compruebe

que no haya fugas de combustible

alrededor de la tapa de combustible y/

o del depósito de combustible.

¡ADVERTENCIA!

Use su sentido común

¡ADVERTENCIA!

Minimice el riesgo de incendios

SIEMPRE detenga la unidad

inmediatamente si de repente comienza

a vibrar o a sacudirse. Compruebe que

piezas y que no haya ningún componente

dañado o instalado incorrectamente.

SIEMPRE mantenga la unidad lo más

limpia posible. Limpie los restos de

hierba, barro, etc.

SIEMPRE desconecte el cable de

la bujía antes de efectuar cualquier

trabajo de mantenimiento.

Si detecta alguna fuga, detenga la

unidad inmediatamente. Toda fuga de

combustible debe haberse reparado

antes de utilizar la unidad.

SIEMPRE lleve el equipo a una zona

alejada de la zona de almacenamiento

del combustible o de otros materiales

fácilmente inamables antes de

arrancar el motor.

NUNCA coloque material inamable

cerca del silenciador del motor.

NUNCA ponga en funcionamiento el

motor sin comprobar que la pantalla

del guardachispas del silenciador está

en su sitio.

Español

Etiquetas de Seguridad

IMPORTANTE

Asegurese que toda las etiquetas estén libres

de daños y legibles. Reemplace inmediatamente etiquetas dañadas o faltantes. Etiquetas nuevas están disponibles en su centro de

servicio local autorizado de Shindaiwa.

SP_3

Page 24

Descripción de la unidad

Tapón de llenado

Boca de

descarga

Bujía

Filtro de aire

Conducto de

cebado

Español

Estrangulador

Interruptor de parada

Utilice las ilustraciones como guía

para familiarizarse con esta unidad

y con sus diversos componentes.

Conociendo a fondo la unidad podrá

obtener su máximo rendimiento y un

funcionamiento más seguro, así como

prolongar su vida útil.

Depósito de

combustible

Arrancador

autorretráctil

Tapa del surtidor

de combustible

Silenciador

Depósito de

combustible

Palanca del

acelerador

GP3410

Empuñadura

Tapón de llenado

Conducto de

cebado

Boca de

descarga

Boca de

aspiración

Tapón de

purga

Figura 1A

Especicaciones

Modelo GP3410

Tipo de motor de gasolina, 4 tiempos, cilindro vertical, refrigerado por aire

Cilindrada 34 cc (38 mm x 30 mm)

Potencia máxima 1,0 kw/1,4 CV a 8000 rpm (min-1)

Proporción de combustible/aceite 50:1 con aceite de mezcla para motores de 2 tiempos

Carburador Walbro, rotativo, con cebador

Encendido PCI

Bujía NGK CMR5H

Arranque Arrancador autorretráctil

Parada Pulsador

Capacidad del depósito de combustible 0,6 litros

Peso 7,1 kg

BOMBA

Tipo de propósito general, centrífuga, autocebante

Diámetro de la boca de aspiración 25 mm

Diámetro de la boca de descarga 25 mm

Altura de aspiración máxima (elevación vertical) 8 metros

Altura máxima de bombeo 50 m

Caudal máximo 130 litros/min

SP_4

Page 25

Montaje

Antes del montaje

Antes de empezar a ensamblar esta

unidad, asegúrese de disponer de todos

los elementos que la componen:

Bomba motorizada GP3410

Llave de bujía

Llave plana

Llave hexagonal Allen de 3 mm

Llave hexagonal Allen de 4 mm

Bolsa de piezas con:

abrazaderas para mangueras de 2,54

●

cm (3)

manguitos y juntas (2 de cada)

●

alcachofa

●

Instalación de las mangueras de aspiración y de descarga

Ensamble un manguito embridado,

1.

un anillo roscado y una junta según

se indica en la figura, y enrosque el

conjunto en la boca de aspiración de la

bomba. Acople el otro manguito en la

boca de descarga de la bomba.

Deslice una manguera de aspiración de

2.

2,54 cm (no incluida) sobre el manguito

Abrazadera de manguera

Anillo roscado

de aspiración de la carcasa de la bomba

y fíjela con una abrazadera, según se

muestra. En el extremo opuesto de la

manguera de aspiración, utilice una

segunda abrazadera de 2,54 cm para

colocar y asegurar la alcachofa.

¡PRECAUCIÓN!

Esta bomba está diseñada para

■

bombear exclusivamente agua dulce.

La suciedad aspirada puede dañar el

■

impulsor y los sellos de la bomba.

Nunca utilice la bomba si la alca-

■

chofa falta o está dañada.

Figura 1B

Sumerja la alcachofa en la fuente de agua.

3.

Para obtener el máximo rendimiento,

evite introducir la alcachofa directamente

en acumulaciones de hojas, fango o

Manguera de

aspiración

demás suciedad.

¡IMPORTANTE!

Coloque la bomba tan cerca de la fuente de

agua como pueda. Cuanto más aumente

Acople la manguera de descarga

4.

(no incluida) y asegúrela con la otra

abrazadera de 2,54 cm.

la altura de elevación, menor será el rendimiento de la bomba. No supere la altura de

aspiración máxima de 8 metros.

Conducto de cebado

Boca de

aspiración

Manguito

embridado

Abrazadera de

Junta

manguera

Boca de descarga

Alcachofa

Vuelva a comprobar que las mangueras de

5.

aspiración y de descarga estén libres de

obstrucciones y que todas las conexiones

estén aseguradas firmemente.

Español

Cebado

Para que la bomba pueda desarrollar

vacío (aspiración o succión) en la fuente

de agua, primero es necesario cebar el

impulsor de la bomba llenando la carcasa

con agua. Una vez cebada la bomba

GP3410, sólo será necesario volver a

cebarla después de haberla purgado o

vaciado por alguna otra causa.

Retire el tapón de llenado de la parte

1.

superior de la carcasa de la bomba. Ponga

especial cuidado en no perder el anillo de

junta situado bajo el tapón de llenado.

¡IMPORTANTE!

Si esta junta se pierde o se daña, puede

penetrar aire en la carcasa de la bomba. La

entrada de aire puede reducir el rendimiento.

Llene la carcasa de la bomba vertiendo

2.

agua limpia a través del conducto de

cebado (Figura 2) hasta que el agua se

desborde por el orificio del conducto.

Vuelva a colocar el tapón de llenado y

3.

apriételo firmemente.

¡PRECAUCIÓN!

Nunca haga funcionar la bomba en

seco. El funcionamiento sin agua

puede dañar permanentemente los

sellos de la bomba.

Tapón de

llenado

Anillo de junta

Figura 2

Conducto de cebado

SP_5

Page 26

Mezcla de combustible

¡PRECAUCIÓN!

Nunca utilice un combustible con un

volumen de alcohol superior al 10%.

Algunas gasolinas contienen alcohol

como oxigenante. Los combustibles

oxigenados pueden generar temperaturas de funcionamiento elevadas.

En determinadas condiciones, los

Español

combustibles que contienen alcohol

también pueden reducir las propiedades lubricantes de algunos aceites

de mezcla.

Los aceites genéricos y algunos

aceites para motores fueraborda

pueden no estar diseñados para

motores de alto rendimiento de 2 y

4 tiempos refrigerados por aire, por

lo que no deberá utilizarlos nunca en

su motor Shindaiwa.

¡PRECAUCIÓN!

Este motor está diseñado para funcionar exclusivamente con una mezcla en proporción 50:1 de gasolina

sin plomo y aceite para mezcla de

alta calidad para motores de 2 tiempos. La utilización de aceites de

mezcla no autorizados puede incrementar los costes de mantenimiento

y causar daños en el motor.

Utilice solamente gasolina sin plomo,

reciente y limpia, con un octanaje de

87 o superior.

Mezcle gasolina en proporción 50:1 con

aceite de mezcla Shindaiwa para

motores de 2 o 4 tiempos, o bien con un

aceite para mezcla de alta calidad equivalente para motores de 2 tiempos.

Ejemplo de mezcla en

proporción de 50:1:

Gasolina

liters milliliters

2,5 - 1

Mezclar para motores

de 2 tiempos

50 ml

5 - 1 100 ml

10 - 1 200 ml

20 - 1 400 ml

¡IMPORTANTE!

Mezcle solamente el combustible que vaya

a necesitar. Si el combustible va a permanecer almacenado más de 30 días y no se

utiliza aceite Shindaiwa con estabilizador de combustible, primero deberá

tratarse el combustible con un estabilizador como Sta-Bil™.

Llenado del depósito de combustible

NUNCA arranque ni ponga en

¡ADVERTENCIA!

Minimice el riesgo de incendio.

DETENGA el motor antes de

■

repostar.

Antes de repostar, SIEMPRE deje

■

que el motor se enfríe.

Limpie todo resto de combustible

■

que pueda haberse derramado y

aleje la unidad al menos 3 metros

del punto de repostaje antes de

volver a ponerla en marcha.

NUNCA ponga en marcha ni utilice

■

esta unidad si hay algún escape de

combustible.

■

marcha esta unidad con el carburador,

cualquier conducto de combustible, el

depósito de combustible o el tapón del

depósito de combustible dañado.

NUNCA fume ni encienda fuego cerca

■

de la unidad o de combustibles.

NUNCA deposite ningún material

■

inamable cerca del silenciador del

motor.

NUNCA ponga en marcha el motor sin

■

antes comprobar que el silenciador y

el guardachispas están correctamente

colocados y funcionan adecuadamente.

Coloque la bomba GP3410 sobre el

1.

suelo o sobre una superficie plana.

Limpie toda suciedad que pueda haber

2.

alrededor del tapón de relleno de

combustible.

Quite el tapón y llene el depósito

3.

con una mezcla limpia y reciente de

combustible.

Vuelva a colocar el tapón y apriételo

4.

firmemente.

SP_6

Page 27

Arranque del motor

¡ADVERTENCIA!

Nunca arranque el motor

desde la posición de funcionamiento.

Sitúe la palanca de control del acelerador

1.

en posición semiabierta. Ver la Figura 3.

Presione el cebador hasta que vea fluir

2.

combustible por el tubo de retorno

transparente. Ver la Figura 4.

¡IMPORTANTE!

El sistema cebador sólo inyecta combustible a través del carburador. El cebador

no hará llegar el combustible al motor por

mucho que lo presione repetidamente.

Si el motor está frío, desplace la

3.

palanca del estrangulador de aire a la

posición cerrada.

Sostenga firmemente la empuñadura de

4.

la bomba con la mano izquierda y, con la

otra mano, tire lentamente del arrancador autorretráctil hasta que sienta que

opone resistencia. En ese momento, tire

rápidamente para encender el motor.

Figura 3

Figura 5

Cerrado

Cebador

Figura 4

Figura 6

Tubo de

retorno

Español

¡PRECAUCIÓN!

No tire del arrancador autorretráctil

hasta el nal de la carrera del cable.

Si tira del arrancador autorretráctil

hasta el nal de la carrera del cable,

puede dañarse el arrancador.

Cuando el motor arranque, desplace

5.

lentamente la palanca del estrangulador a la posición "ABIERTA". Ver la

Figura 7. (Si el motor se detiene tras el

arranque inicial, cierre el estrangulador

y vuelva a arrancarlo).

Cuando el motor arranque...

Una vez esté en marcha el motor, deje

que se caliente al ralentí durante 2 o 3

minutos antes de utilizar la unidad.

¡IMPORTANTE!

Para detener el motor de la bomba

GP3410, presione el interruptor rojo de

encendido hasta que el motor se detenga

totalmente. Ver la Figura 8.

Figura 7

Una vez encendido el motor, vuelva a

6.

desplazar gradualmente la palanca de

control del acelerador a la posición de

ralentí (en el sentido contrario al de las

agujas del reloj).

Interruptor de

Figura 8

encendido

Abierta

¡IMPORTANTE!

Si, tras varios intentos, no logra arrancar el motor con el estrangulador en la

posición cerrada, es posible que el motor

esté ahogado por el combustible. Si cree

que el motor está ahogado, coloque la

palanca del estrangulador en la posición

abierta y tire repetidamente del arrancador autorretráctil para extraer el exceso

de combustible y arrancar el motor. Si el

motor sigue sin arrancar, consulte la sección sobre resolución de problemas de

este manual.

Si el motor no arranca

Repita el procedimiento de arranque adecuado para el estado del motor: frío o caliente. Si el motor no arranca, consulte la

sección “Arranque de un motor ahogado”.

SP_7

Page 28

Arranque del motor (continuación)

Arranque de un motor ahogado

Vuelva a colocar la bujía y apriétela

1.

2.

Español

Desconecte el cable de la bujía y utilice

la llave de bujías para extraerla (girándola en el sentido contrario al de las

agujas del reloj). Ver la Figura 9.

Si la bujía está obstruida o empapada

de combustible, límpiela o sustitúyala,

según convenga. Si desea consultar las

especificaciones de la bujía y el procedimiento de separación de electrodos,

consulte la sección “Mantenimiento

4.

firmemente con la llave de bujías. Si

dispone de una llave dinamométrica,

apriete la bujía a 170-190 kg-cm.

Siga el procedimiento de arranque de

5.

un motor caliente.

Si el motor sigue sin arrancar ni girar,

6.

consulte la tabla de resolución de problemas al final de este manual.

cada 10 o 15 horas”.

Con la bujía desmontada, haga girar

3.

el motor varias veces para eliminar el

combustible sobrante de la cámara de

¡PRECAUCIÓN!

Una bujía instalada incorrectamente

puede dañar seriamente el motor.

combustión.

Ajuste del ralentí del motor

¡IMPORTANTE!

Un flujo de aire limpio y sin obstrucciones

es esencial para el rendimiento y la durabilidad de la bomba. Antes de intentar reajustar el carburador, revise y limpie el filtro

de aire del motor siguiendo las instrucciones de la página 10 de este manual.

Figura 9

Ajuste de la velocidad de ralentí

Coloque la unidad en el suelo, encienda

1.

el motor y sitúe la palanca de control

del acelerador en la posición de ralentí.

Deje el motor al ralentí entre 2 y 3 minutos hasta que se caliente.

Si dispone de un tacómetro, conviene

2.

ajustar la velocidad de ralentí del motor

en 3.000 (±300) min-1.

NOTA:

Los ajustes de mezcla de combustible del

carburador vienen programados de fábrica

y no se pueden modicar en campo.

Figura 10

Bajar ralentí

Subir ralentí

Tornillo de ajuste del

ralentí

SP_8

Page 29

50

45

40

35

30

25

20

15

10

5

0 50 100 150 200 250 300

Consejos de utilización para obtener el máximo rendimiento

Minimice la fricción utilizando mangueras de

aspiración y descarga con la identificación correcta de 2,54 cm y realizando el menor número

posible de empalmes y conexiones. Los tramos

de manguera deben ser lo más cortos posible.

Mantenga la menor altura de aspiración

1.

(elevación vertical) posible. No supere la

altura de aspiración máxima de 8 metros.

Evite la penetración de aire en el interior.

2.

Todas las conexiones del lado de

a.

aspiración deben estar firmemente

aseguradas.

Asegúrese de que el tapón de relleno y el

b.

tapón de purga en la carcasa de la bomba

estén bien apretados y libres de fugas.

Proteja la manguera de descarga de

4.

aplastamientos y daños similares, especialmente de los causados por automóviles.

¡PRECAUCIÓN!

Los aumentos repentinos de presión

(como los causados por vehículos al

pasar por encima) pueden partir la

manguera de descarga y dañar la carcasa de la bomba.

Durante el funcionamiento o

■

repostaje, mantenga lejos de la

bomba a toda persona y animal.

Tenga cuidado, porque la bomba

■

puede desplazarse repentinamente

durante su funcionamiento, sobre

todo cuando las mangueras se

llenan de agua por primera vez.

Para evitar que se enrede en la

■

máquina, no utilice ropa vaporosa ni

joyas, y recójase el pelo largo.

La suciedad abrasiva puede dañar el

5. Para minimizar el riesgo de que la alcaimpulsor y los sellos de la bomba, por lo

que debe evitarse.

¡ADVERTENCIA!

Utilice en todo momento protección

■

para los ojos, como gafas o anteojos

protectores.

Protéjase los oídos siempre que

■

vaya a trabajar con esta unidad.

Utilice calzado adecuado, como

■

zapatos o botas antideslizantes. Se

recomienda utilizar botas de seguridad con puntera de acero. NUNCA

TRABAJE DESCALZO.

Se recomienda utilizar guantes.

■

6.

chofa se atasque al bombear cerca de

fango o suciedad, introdúzcala en un

cubo o en una cama de piedras.

Cuanto mayor la altura de elevación,

menor el caudal de descarga.

Español

Mantenga la menor altura

de elevación posible.

Minimice las obstrucciones por suciedad:

Inserte la alcachofa en una cama de

piedras o en un cubo.

Figura 12

Riesgo de quemaduras/ Peligro

■

por derrame de combustible.

Pare siempre el motor antes de

transportar la bomba. Tanto durante

como después del funcionamiento

de la bomba, el silenciador del motor

y otros componentes pueden estar

muy calientes. Transporte la bomba

sujetándola sólo por la empuñadura.

La bomba debe permanecer nivelada

en todo momento.

Altura total de bombeo (metros)

Figura 11

¡ADVERTENCIA!

Peligro por piezas en movimiento.

■

El rotor de la bomba gira tan pronto

como el motor comienza a girar.

Antes de realizar cualquier trabajo de

mantenimiento o instalación en esta

bomba, pare el motor y desconecte

el cable de la bujía. Nunca ponga en

marcha esta bomba a menos que

todos los protectores y cubiertas

estén correctamente colocados y las

mangueras de aspiración y de descarga

rmemente conectadas a la bomba.

Caudal de descarga (litros por minuto)

Tenga cuidado al situar la bomba, ya

que puede desplazarse repentinamente

durante el funcionamiento.

Proteja la manguera

de descarga contra

aplastamientos.

Peligro de asxia. Esta bomba está dis-

■

eñada para trabajar al aire libre y exclusivamente en lugares bien ventilados.

Peligro de explosión. Nunca utilice

■

ni intente poner en marcha esta

bomba en presencia de materiales

explosivos o combustibles.

Nunca intente bombear combustibles

■

u otros líquidos peligrosos con la

bomba GP3410. Esta bomba está

diseñada y garantizada para bombear

SÓLO AGUA DULCE.

SP_9

Page 30

Mantenimiento

Mantenimiento general

IMPORTANTE!

EL MANTENIMIENTO, REEMPLAZO O

REPARACION DE LOS SISTEMAS Y DISPOSITIVOS DE CONTROL DE EMISION PUEDEN

SER EFECTUADOS POR CUALQUIER

ESTABLECIMIENTO O INDIVIDUO; SIN

EMBARGO, LAS REPARACIONES DE

GARANTIA DEBEN SER EFECTUADAS POR

Español

SU CENTRO DE SERVICIO O DISTRIBUIDOR

AUTORIZADO POR SHINDAIWA CORPORATION. EL USO DE PARTES QUE NO SON

EQUIVALENTES EN RENDIMIENTO Y

DURABILIDAD A LAS PARTES AUTORIZADAS PUEDEN AFECTAR LA EFECTIVIDAD

DE SU SISTEMA DE CONTROL DE EMISION

Y PUEDE INFLUENCIAR EL RESULTADO

DE SU RECLAMO DE GARANTIA.

Mantenimiento diario

Antes del trabajo diario, realice lo

siguiente

Limpie toda suciedad o residuo del

motor, revise las aletas de refrigeración y el filtro de aire para verificar

que no tengan obstrucciones, y límpielos si es necesario.

¡ADVERTENCIA!

Antes de efectuar mantenimiento, reparación o limpieza de la

máquina, cerciórese de que el motor

y el accesorio de corte estén completamente detenidos. Desconecte

el cable de bujía antes de efectuar

servicio de mantenimiento.

¡ADVERTENCIA!

Los repuestos no estándar

puedan que no operen propiamente

con su máquina y pueden causar daño

y conducir a una lesión personal.

El usar repuestos no estándar podría

invalidar su garantia Shindaiwa.

Silenciador

Esta máquina nunca debe ser operada con un

guardachispas o silenciador defectuoso o faltante. Cerciórese de que el silenciador esté

bien asegurado y en buena condición. Un

silenciador usado o dañado es un riesgo de

incendio y puede causar la perdida de audición.

Bujía

Mantenga la bujía y las conexiones de

cable apretadas y limpias.

NOTA:

Sujetadores

Cerciórese de que las tuercas, pernos y

tornillos (a excepción de los tornillos de

ajuste del carburador) estén apretados.

Extraiga cuidadosamente toda acu-

Revise que no falten componentes ni

mulación de suciedad del silenciador

o del depósito de combustible. La

suciedad acumulada en estos puntos

puede provocar sobrecalentamientos

del motor, un desgaste prematuro o

incluso riesgo de incendio.

tornillos, y que no estén sueltos.

Revise toda la unidad para comprobar

1.

que no haya pérdidas de combustible.

Mantenimiento cada 10 horas

(más frecuentemente en ambientes

polvorientos)

Retire la tapa del filtro de aire aflojando

1.

los dos tornillos de apriete manual. Ver

la Figura 13A.

Extraiga y revise el prefiltro. Si el prefil-

2.

tro está rasgado o presenta algún otro

daño, sustitúyalo por uno nuevo. Ver la

Figura 13B.

Limpie el prefiltro con agua y jabón.

3.

Déjelo secar antes de volver a colocarlo.

Revise el filtro de aire. Si el elemento

4.

está dañado o deformado, sustitúyalo

por uno nuevo.

¡IMPORTANTE!

Dirija el chorro de aire sólo hacia el interior del filtro.

Aoje los tornillos

de apriete manual

Figura 13A

Golpee suavemente el filtro contra una

5.

superficie dura para aflojar y hacer caer la

suciedad o inyecte aire comprimido en su

interior para expulsarla hacia fuera.

Vuelva a colocar el elemento filtrante, el

6.

prefiltro y la tapa en el orden inverso al

de desmontaje.

Preltro

Filtro

Figura 13B

¡PRECAUCIÓN!

Nunca ponga en marcha la unidad

si el conjunto del ltro de aire está

dañado o no está instalado.

SP_10

Page 31

Mantenimiento

Mantenimiento cada 10 o 15 horas

Cada 10 o 15 horas de uso:

Extraiga y limpie la bujía. Separe los electrodos de la bujía a 0,6 - 0,7 mm. Cuando sea

necesario reemplazar una bujía, utilice sólo

otra de tipo NGK CMR5H o equivalente, con

resistencia y con las mismas especificaciones térmicas. Ver la Figura 14.

0,6–0,7 mm

Limpie la bujía y

verique la separación

del electrodo.

NOTA:

La NGK CMR5H también cumple los requisitos de compatibilidad electromagnética (EMC).

¡PRECAUCIÓN!

Antes de extraer la bujía, limpie la

zona de alrededor para evitar que la

suciedad y los residuos penetren en

el interior del motor.

Mantenimiento cada 50 horas

Cada 50 horas de funcionamiento

(con más frecuencia en ambientes sucios

o polvorientos):

Desmonte y limpie la tapa del cilindro

1.

y retire la suciedad de las aletas del

cilindro.

Utilice un alambre en forma de gancho para

2.

extraer el filtro del interior del depósito de

combustible. Ver la Figura 15.

Figura 14

Gancho de

alambre

Español

¡PRECAUCIÓN!

Asegúrese de no perforar el conducto

de combustible con la punta del gancho de alambre. El conducto es delicado y se puede dañar fácilmente.

Extraiga y sustituya el filtro. Antes de

3.

instalar el nuevo elemento filtrante,

revise el estado de todos los componentes del sistema de combustible (conducto

de recogida, conducto de retorno, conducto de ventilación del depósito, respiradero del depósito, detecta cualquier

daño o deterioro, deberá poner la unitapón y depósito de combustible). Si dad

fuera de servicio hasta que un técnico de

mantenimiento formado por Shindaiwa

pueda examinarla.

Elemento de ltro

Figura 15

SP_11

Page 32

Mantenimiento

Mantenimiento cada 139 o 150 horas

Mantenimiento después de las primeras 139 horas, después cada 150

horas.

Debe eliminarse la carbonilla de la cámara

1.

de combustión y ajustarse el juego de las

válvulas. Se recomienda encarecidamente

encomendar este trabajo a un técnico

formado por Shindaiwa.

Español

Ajuste de la válvula

Retire la tapa del cilindro y la tapa de

1.

balancines y sitúe el pistón en el punto

muerto superior.

Afloje la contratuerca del ajustador para

2.

que el tornillo de ajuste Allen hembra

de 2,5 mm pueda girar libremente.