Shindaiwa 68241-94310, EB501-EVC User Manual

SHINDAIWA OWNER’S/0PERATOR'S MANUAL

EB501/EVC BLOWER

High Performance

WARNING!

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with the contents. Always wear eye and hearing protection when

operating this unit. Minimize the risk of injury: Read this

manual and familiarize yourself with its contents.

Part Number 68241-94310 Rev. 11/06

IMPORTANT!

Before using this product, consult

local regulations concerning noise

restrictions and hours of operation!

CONTENTSINTRODUCTION

PAGE

Attention Statements ........................... 2

Nomenclature ....................................... 3

The Shindaiwa EB501 has been

designed and built to deliver superior

performance and reliability without

compromise to quality, comfort, safety,

or durability.

Shindaiwa high performance

engines represent the leading edge of

2-cycle engine technology, and deliver

exceptionally high power at remarkably low displacement and weight. As

a professional owner/operator, you’ll

soon discover why Shindaiwa is simply

in a class by itself!

IMPORTANT!

The information contained in this

manual describes machines available

at the time of production. While every

attempt has been made to give you

the very latest information about your

Shindaiwa EB501 blower, there may

be some differences between your

machine and what is described here.

Shindaiwa Inc. reserves the right to

make changes in production without

prior notice, and without obligation to

make alterations to machines previously manufactured.

Specifications ........................................ 4

Assembling the Blower ....................... 4

Mixing Fuel .......................................... 6

Filling the Fuel Tank ........................... 7

Starting and Stopping the Blower ...... 8

Adjusting Engine Idle Speed ............. 10

Adjusting the Harness ....................... 11

Using the Blower ............................... 12

Routine Maintenance ......................... 13

Spark Arrester Maintenance ............ 15

Storage ................................................ 16

Troubleshooting Guide ..................... 17

Emission System Warranty ............... 21

CAUTION!

The engine exhaust from this

product contains chemicals known

to the State of California to cause

cancer, birth defects or other reproductive harm.

1

CAUTION!

This EB501 blower is equipped

with a spark-arresting mufer!

Never operate this machine

without both the mufer and spark

arrester installed and properly

functioning!

ATTENTION STATEMENTS

Read and follow this manual.

Failure to do so could result

in serious injury.

Wear eye and hearing

protection at all times during

the operation of this machine.

Do not operate this machine if

you are tired, ill or under the

influence of alcohol, drugs,

or medicine.

This manual contains special “attention

statements” surrounded by boxes and

preceded by the triangular Attention

Symbol.

WARNING!

A statement preceded by the word

“WARNING” contains information

that should be acted upon to prevent serious bodily injury.

The operational procedures described

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent damaging your machine.

Additional attention statements that

are not preceded by the Attention

Symbol are:

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special signicance.

NOTE:

A statement preceded by the word

“NOTE” contains information that is handy

to know and may make your job easier.

in this manual are intended to help

you get the most from your machine

and also to protect you and others

from harm. These procedures are

general guidelines only, and are not

intended to replace any safety rules/

laws that may be in force in your area.

If you have any questions regarding

your EB501 blower, or if you do not

understand something in this manual,

your Shindaiwa dealer will be glad to

assist you.

For additional information, you may

also contact Shindaiwa Inc. at the

address printed on the back of this

manual.

Do not make unauthorized modications to this machine!

IMPORTANT!

WARNING!

2

48002

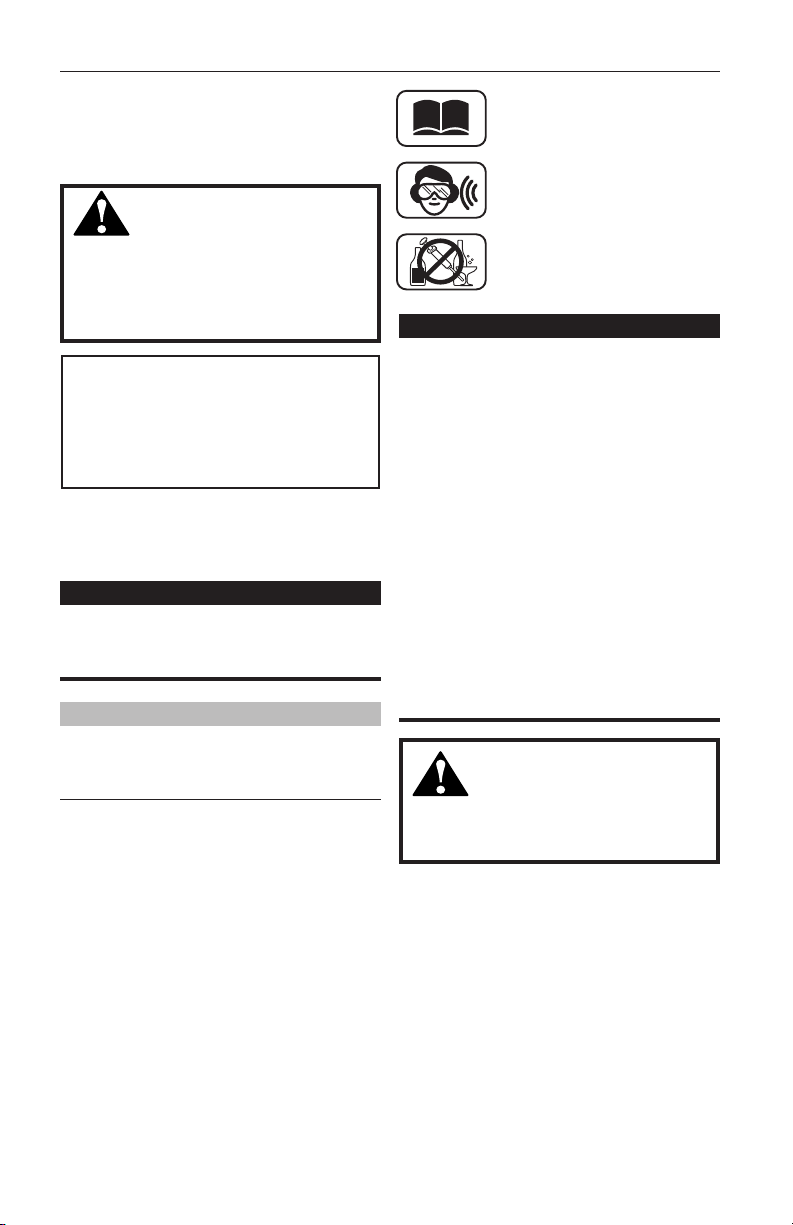

NOMENCLATURE

Throttle and

Stop Lever

Engine

Cover

Air Cleaner

Volute Case

Fuel Filler Cap

Carburetor with Choke

and Primer

Spark Plug

Starter

Handle

Exhaust

Outlet

Fuel Tank

Figure 1

3

90° Discharge

Tube

Flexible

Tube

Handgrip

Swivel

Tube

SPECIFICATIONS

Model .................................................................................................................. EB501

Dimensions (L x W x H) ..............................................................330 x 375x 475 mm

Engine Type ................... 2 cycle, catalyst, air cooled gas engine, vertical-cylinder

Bore & Stroke.............................................................. 41 x 33 mm (1.6 x 1.3 inches)

Displacement ........................................................................ 43.6 cc (2.66 cu. inches)

Fuel/oil ratio ............. Gasoline/oil mixture (50:1 with ISO EGD or JASO FC class

2- cycle EngineOil)

Carburetor ............................................. Walbro diaphragm-type with primer pump

Ignition ........................................................ All transistor electronic ignition system

Spark Plug ..............................................................................................Champion CJ8

Starting .................................................................................................... Recoil starter

Stopping .........................................................................Throttle lever (fuel shut-off)

Fuel Tank Capacity ........................................................................... 2.1 liters (71 oz.)

Exhaust System ....................................................................... Spark-arrester muffler

Air Filtration .............................................................................................Dr y element

Weight (dr y; without blower tubes), EB501 .....................................8.6 kg (19 lbs.)

Specifications are subject to change without notice.

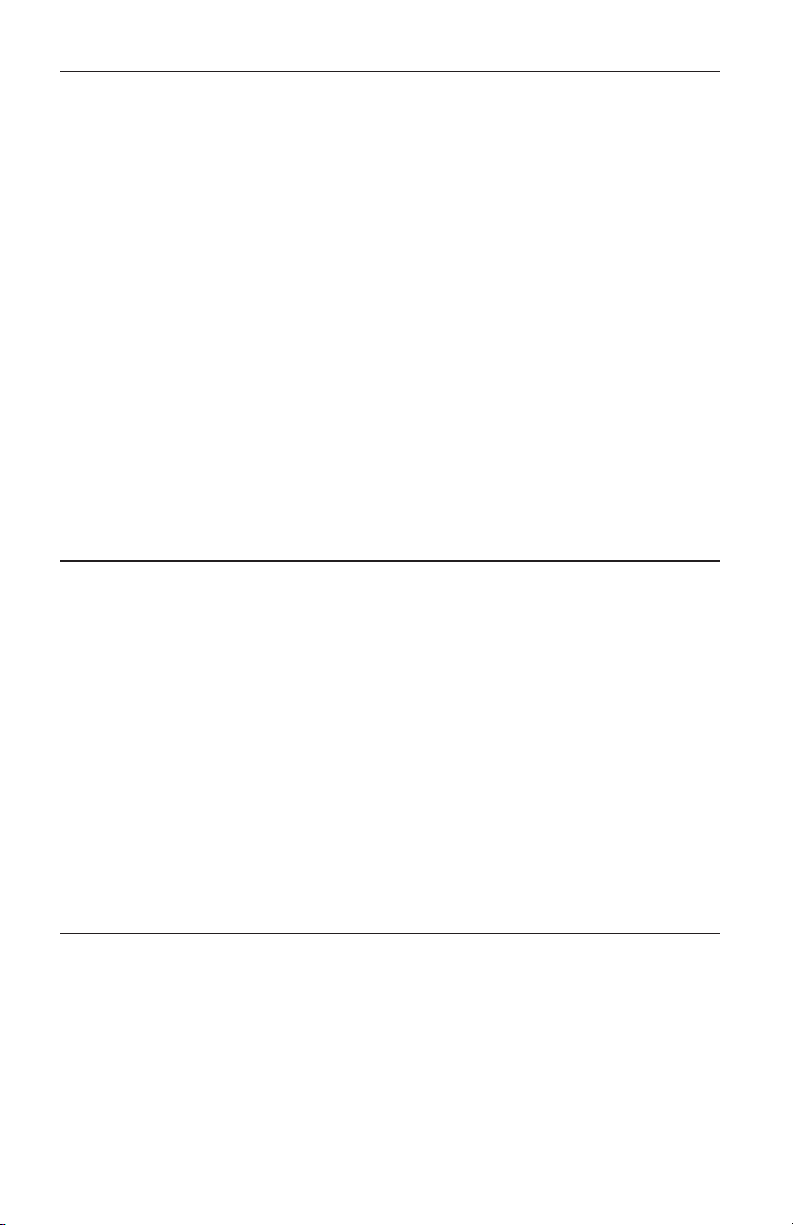

Prior to Assembly

Before assembling, make sure you

have all the components required for a

complete unit:

n 90° Discharge Tube

n Flexible Tube

n Swivel Tube

n Straight Tube

n Nozzle Tube

n Handgrip (removable)

n Three Tube Clamps (115 mm,

100 mm, 85 mm) See figure 2.

Standard Tools

n Spark Plug Wrench

n Three Hex Wrenches

(3 mm, 4mm, 5mm)

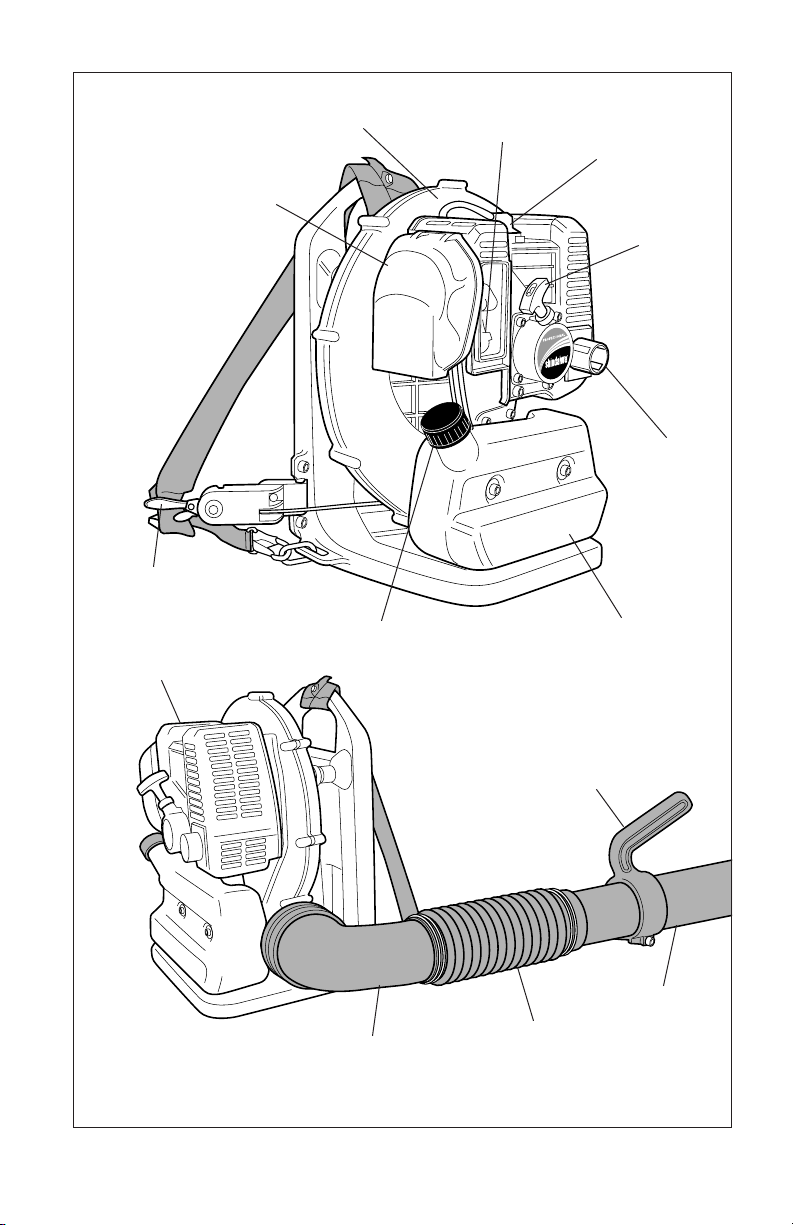

ASSEMBLING THE BLOWER

1. Place the blower upright on the

ground or a sturdy work surface.

2. Fit the 90° discharge tube over the

blower outlet port, and secure with

the 115mm dia. clamp.

3. Slip the flexible tube over the opposite end of the 90° discharge tube,

and secure with the 100mm clamp.

4. Push the swivel tube into the

flexible tube, and then install and

tighten the 85mm clamp over the

rotating band on the swivel tube.

5. Slide the handgrip over the swivel

tube, and secure with the bolt,

washer, and nut.

4

48002A

48003

48004D

48004C

ASSEMBLING THE BLOWER (continued)

115mm Clamp

90° Discharge Tube

90° Discharge Tube Handgrip

Flexible Tube

100mm Clamp

Figure 2

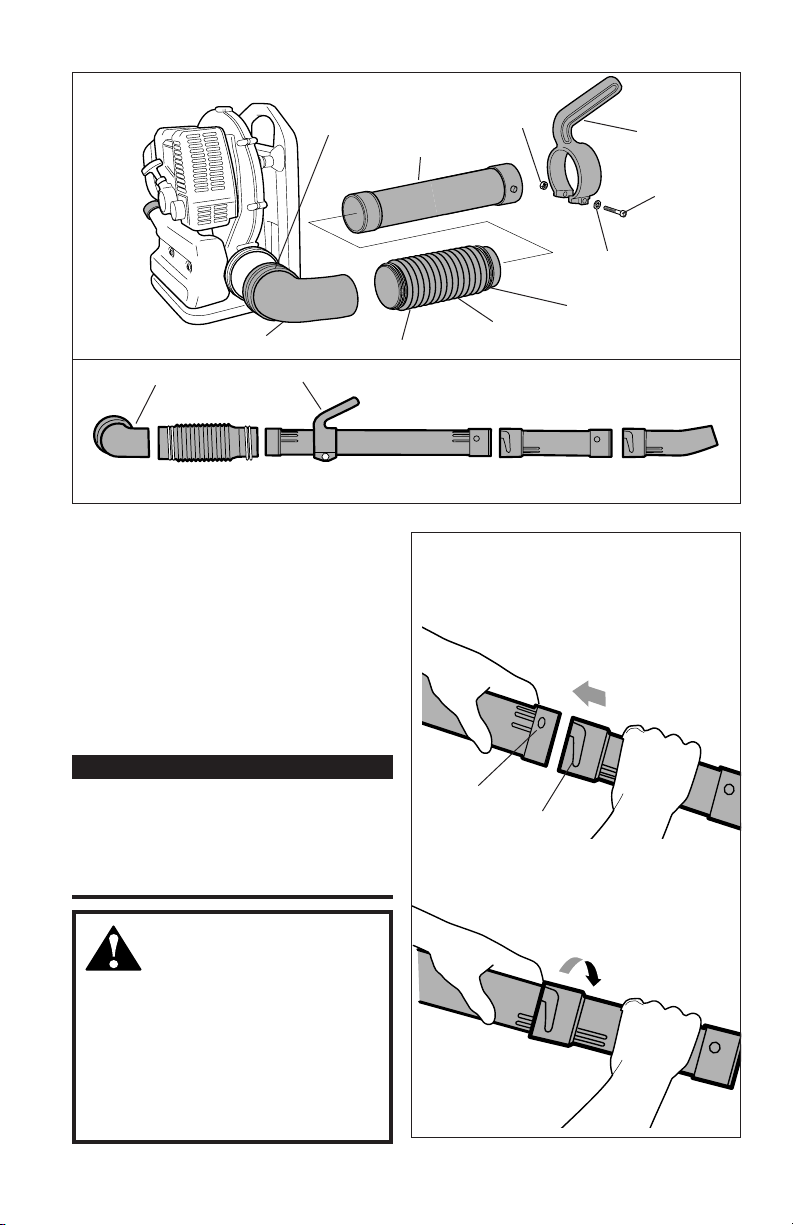

6. Grasp the straight tube as shown,

and push the tube over the

swivel tube locking pins (right).

See figure 3.

7. Lock the straight tube to the swivel

tube by rotating the straight tube.

8. Grasp the nozzle tube and lock the

nozzle to the straight tube as in

Steps 6 and 7.

Swivel

Tube

Swivel Tube Straight Tube Nozzle Tube

Tube Assembly

Nut

Handgrip

Bolt

Washer

85mm Clamp

Flexible Tube

Align the lock pins with the

lock slots, and push the tubes

together.

IMPORTANT!

Blower tube installation affects blower

balance and performance! Make sure

the tubes and nozzle are correctly

assembled per above, and that all

connections are tight.

WARNING!

Danger from rotating impeller!

Stop the engine before installing or

removing the blower tubes! Never

perform any maintenance or assembly procedures on this machine while the engine is running!

5

Lock Pin

Lock Slot

Rotate clockwise to lock, mak-

ing sure the 3 lines are aligned

on both tubes.

Figure 3

MIXING FUEL

Fuel Requirements

n Use only fresh, clean fuel.

n Use only fuel with an octane rating

of 87 or above.

n Mix all fuel with ISO EGD or JASO

FC class 2-cycle Engine Oil at a

gasoline/oil ratio of 50:1 (1 gallon

gasoline to 2.6 oz. mixing oil).

CAUTION!

Use of mixing oil other than ISO

EGD or JASO FC rated oil can

lead to exessive carbon deposits.

WARNING!

Danger of re!

Never transfer or store fuels in the

presence of combustible materials!

Before starting the engine, always

move the blower to a clear area

at least 10 feet (3 meters) away

from fuels and other combustible

materials!

IMPORTANT!

Mix only enough fuel for your immediate needs! If fuel must be stored

longer than 30-days, it should rst

be treated with a stabilizer such as

StaBil™ or equivalent product!

CAUTION!

Never attempt to mix fuel in the

blower fuel tank! Always mix all fuels in a clean, approved container!

Some gasolines contain ethanol alcohol as an oxygenate!

Oxygenated fuels may cause

increased engine operating temperatures! Under certain conditions, alcohol-based fuels may also

reduce the lubricating qualities of

some mixing oils!

Never use any fuel containing

more than 10% ethanol alcohol by

volume!

Generic oils and some outboard

mixing oils are not intended for

use in high-performance air cooled

2-cycle engines, and should never

be used in your Shindaiwa blower!

6

48005

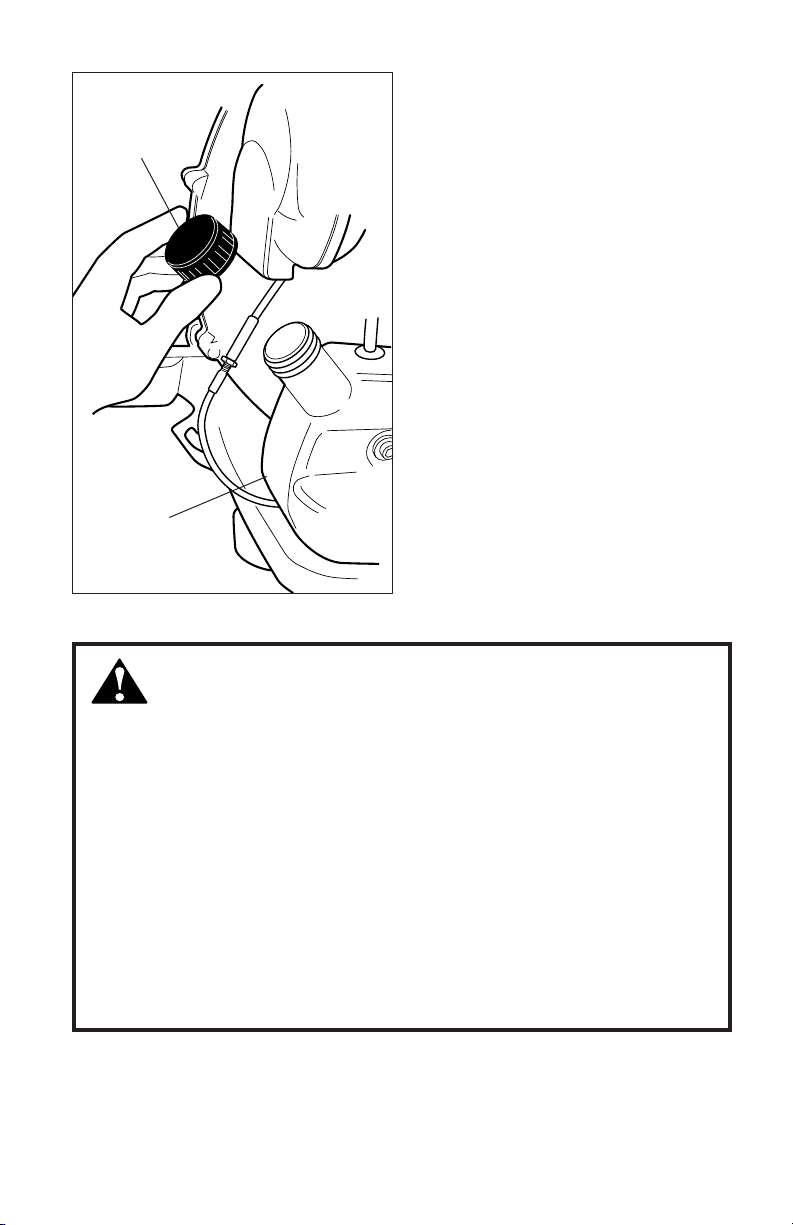

FILLING THE FUEL TANK

Remove the

Fuel Filler

Cap

Fuel

Tank

Figure 4

1. Place the blower upright on the

2. Remove the fuel cap. See figure 4.

3. Fill the tank with clean, fresh fuel

4. Replace the cap and wipe away

ground or on a sturdy work surface

and wipe any debris from around

the fuel cap.

(see page 6).

any spilled fuel before starting the

blower engine.

WARNING!

Danger of re and burn

injury!

n Always use extreme care when

handling fuel! Fuel is highly flammable!

n Never operate this blower if fuel

system components are damaged

or are leaking!

n Never attempt to refuel the

engine while it is running!

n Never attempt to refuel a hot

engine! Always allow the blower

engine to cool before fueling!

7

n Never smoke or light any fires

near the blower or fuels!

n Always transport and store fuels

in an approved container!

n Never place flammable material

close to the engine muffler!

n Never operate the blower with-

out a properly functioning muffler and spark arrester installed!

n Never operate this blower unless

it is properly assembled and in

good working condition!

Loading...

Loading...