Page 1

English...............1

Spanish.......SP_1

French.........FR_1

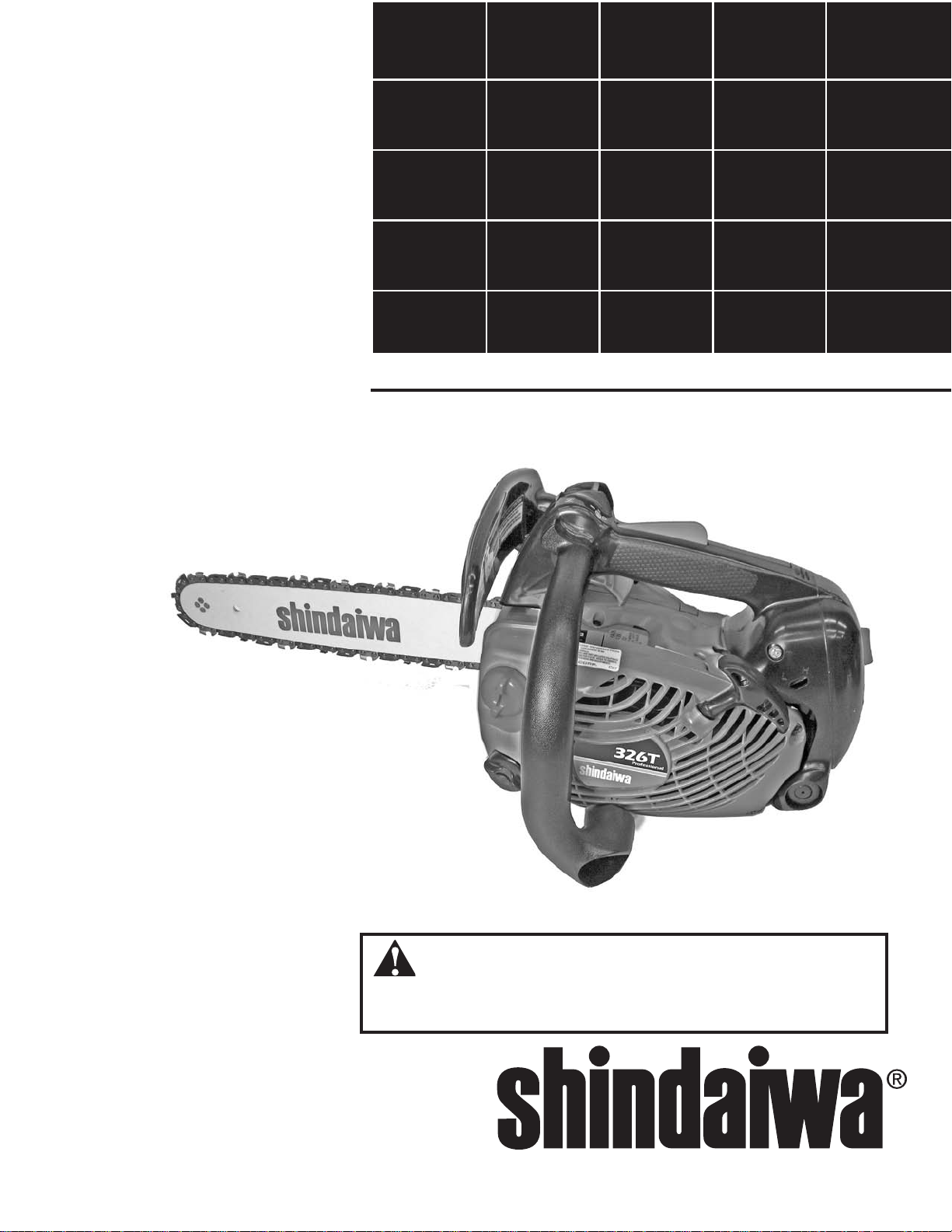

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

326T CHAINSAW

WARNING!

Minimize the risk of injury to yourself and others! Read this manual

and familiarize yourself with the contents. Always wear eye and hearing protection when operating this unit.

Part Number 82085 Rev. 8/2008

Page 2

English

Ru l e s f o R sa f e op e R a t i o n

A. Kickback safety precautions for chain saw users

WARNING!

KICKBACK may occur when the nose or tip of the guide

bar touches an object, or when the wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning fast

reverse REACTION, Kicking the guide bar up and back

towards the operator. Pinching the saw chain along the

top of the guide bar may push the guide bar rapidly back

towards the operator. Either of these reactions may cause

you to lose control of the saw which could result in serious

personal injury.

The Kick Guard ® device is not installed on the guide bar

when you purchase your Shindaiwa chain saw. The Kick

Guard ® can be used in a majority of cutting operations,

and is especially recommended for beginners, homeowners, or chain saw novices. Most cutting operations can be

accomplished with the Kick Guard® in place.

Do not rely exclusively upon the safety devices built into

your saw. As a chain saw user, you should take several

steps to keep your cutting jobs free from accident or injury.

1.

With a basic understanding of kickback, you can

reduce or eliminate the element of surprise. Sudden

surprise contributes to accidents.

2.

Keep a good rm grip on the saw with both hands, the

right hand on the rear handle, and the left hand on the

front handle, when the engine is running. Use a rm

grip with thumbs and ngers encircling the chain saw

handles. A rm grip will help you reduce kickback and

maintain control of the saw. Don’t’ let go.

3.

Make sure that the area in which you are cutting is free

from obstructions. Do not let the nose of the guide bar

contact a log, branch, or any other obstruction which

could be hit while you are operating the saw.

4.

Cut at high engine speeds.

Do not overreach or cut above shoulder height.5.

Follow manufacturer’s sharpening and maintenance 6.

instructions for the saw chain.

7.

Only use replacement bars and chains, or the equiva-

lent, specied by the manufacturer.

B. Other safety precautions

Do not operate a chain saw with one hand! Serious 1.

injury to the operator, helpers, bystanders, or any combination of these persons may result from one-handed

operation. A chain saw is intended for two-handed use.

2.

Do not operate a chain saw when you are fatigued.

Use safety footwear; snug-tting clothing; protective 3.

gloves; and eye, hearing and head protection devices.

Wear protective hair covering to contain long hair.

4.

Use caution when handling fuel. Move the chain saw at

least 3 m (10 feet) from the fueling point before starting

the engine.

5.

Do not allow other persons to be near the chain saw

when starting or cutting with the chain saw. Keep

bystanders and animals out of the work area.

6.

Do not start cutting until you have a clear work area,

secure footing, and a planned retreat path from the falling tree.

7.

Keep all parts of your body away from the saw chain

when the engine is running.

8.

Before you start the engine, make sure that the saw

chain is not contacting anything.

9.

Carry the chain saw with the engine stopped, the guide

bar and saw chain to the rear, and the mufer away

from your body.

10.

Do not operate a chain saw that is damaged, improperly adjusted, or not completely and securely assembled. Be sure that the saw chain stops moving when

the throttle control trigger is released.

11.

Shut off the engine before setting the chain saw down.

Use extreme caution when cutting small size brush and 12.

2

Page 3

Rules for Safe Operation, continued

English

saplings because slender material may catch the saw

chain and be whipped toward you or pull you off balance.

When cutting a limb that is under tension, be alert for 13.

spring back so that you will not be struck when the ten-

sion in the wood bers is released.

14.

Keep the handles dry, clean, and free of oil or fuel

mixture.

15.

Operate the chain saw only in well-ventilated areas.

Do not operate a chain saw in a tree unless you have 16.

been specically trained to do so.

17.

All chain saw service, other than the items listed in the

Instruction Manual maintenance instructions, should

be performed by competent chain saw service personnel. (For example, if improper tools are used to

WARNING DANGER

During operation, the mufer or catalytic mufer and surrounding cover become hot. ■

Never suspend the saw on a lanyard with the engine running. ■

Always use the saw from the right-hand side of your body – NEVER from the left side. ■

Always wear proper safety clothing to protect your lower body from sharp saw chain and hot mufer. ■

Always keep exhaust area clear of ammable debris during transportation or when storing, otherwise serious ■

property damage or personal injury may result.

remove the ywheel or if an improper tool is used to

hold the ywheel in order to remove the clutch, structural damage to the ywheel could occur and could

subsequently cause the ywheel to burst.)

18.

When transporting your chain saw, use the appropriate guide bar scabbard.

19.

Spark arrestor mufers approved to SAE Standard

J335b are Standard on Shindaiwa Chain saws to

reduce the possibility of forest res. Do not operate

the chain saw with a loose or defective mufer. Do not

remove the spark arrestor screen.

WARNING DANGER

Using improper replacement components or removing safety devices may result in serious or fatal injury. ■

3

Page 4

English

STOP

Co n t e n t s

Rules for Safe Operation .....................................................................................................................................................2

International Symbols

Technical Data

Emission Data

Description

Nomenclature of Parts

Labels

Fuel and Lubricant

Operation

Cutting Instructions

Maintenance and Care

Chain and Guide Bar Combinations

Storage After Use

Troubleshooting

Correct Use of Chain Brake

Warranty Statement

.................................................................................................................................................................................... 8

......................................................................................................................................................................5

.......................................................................................................................................................................6

............................................................................................................................................................................6

............................................................................................................................................................................. 14

.......................................................................................................................................................... 4

......................................................................................................................................................... 7

.............................................................................................................................................................12

...........................................................................................................................................................16

.......................................................................................................................................................19

................................................................................................................................. 24

............................................................................................................................................................... 25

.................................................................................................................................................................26

............................................................................................................................................... 28

............................................................................................................................................................ 29

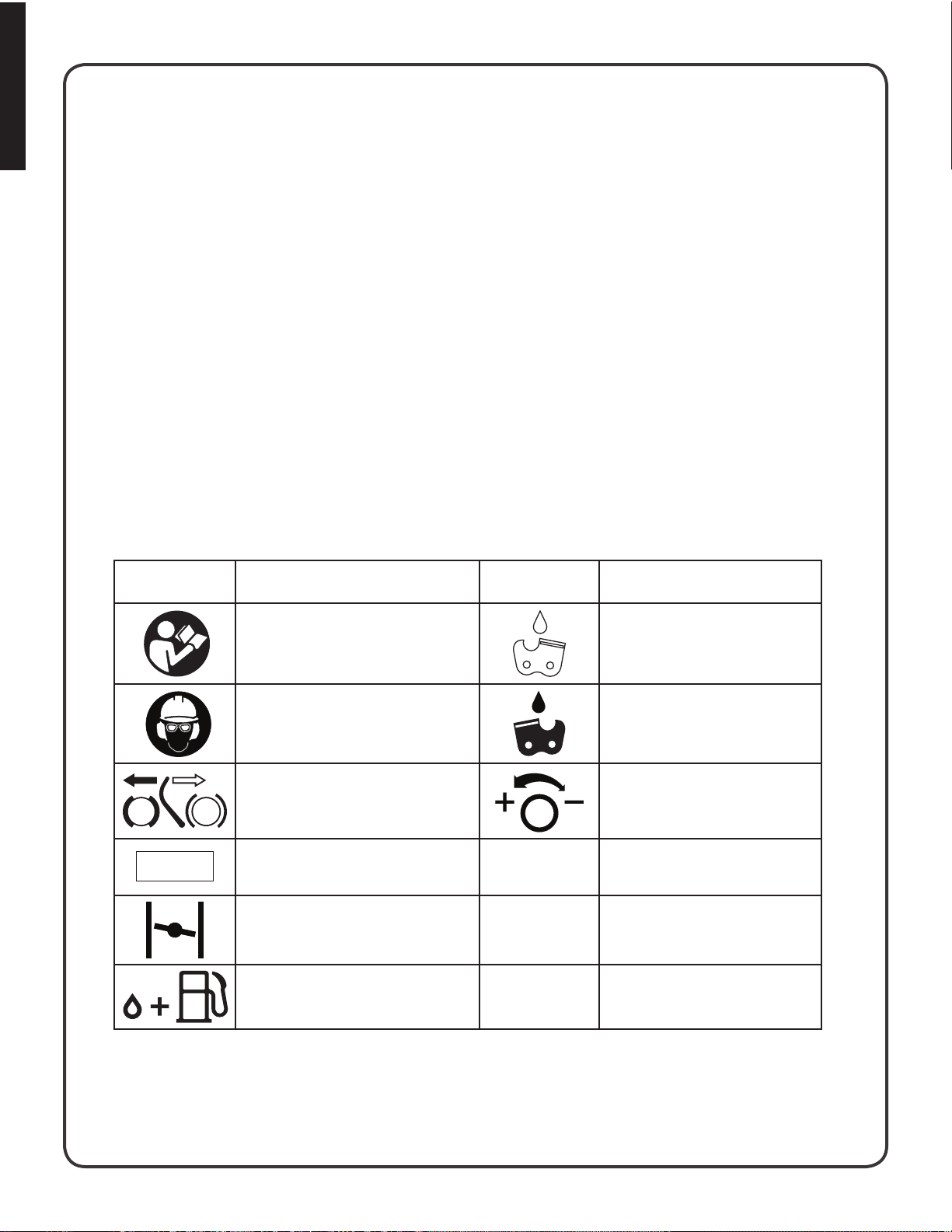

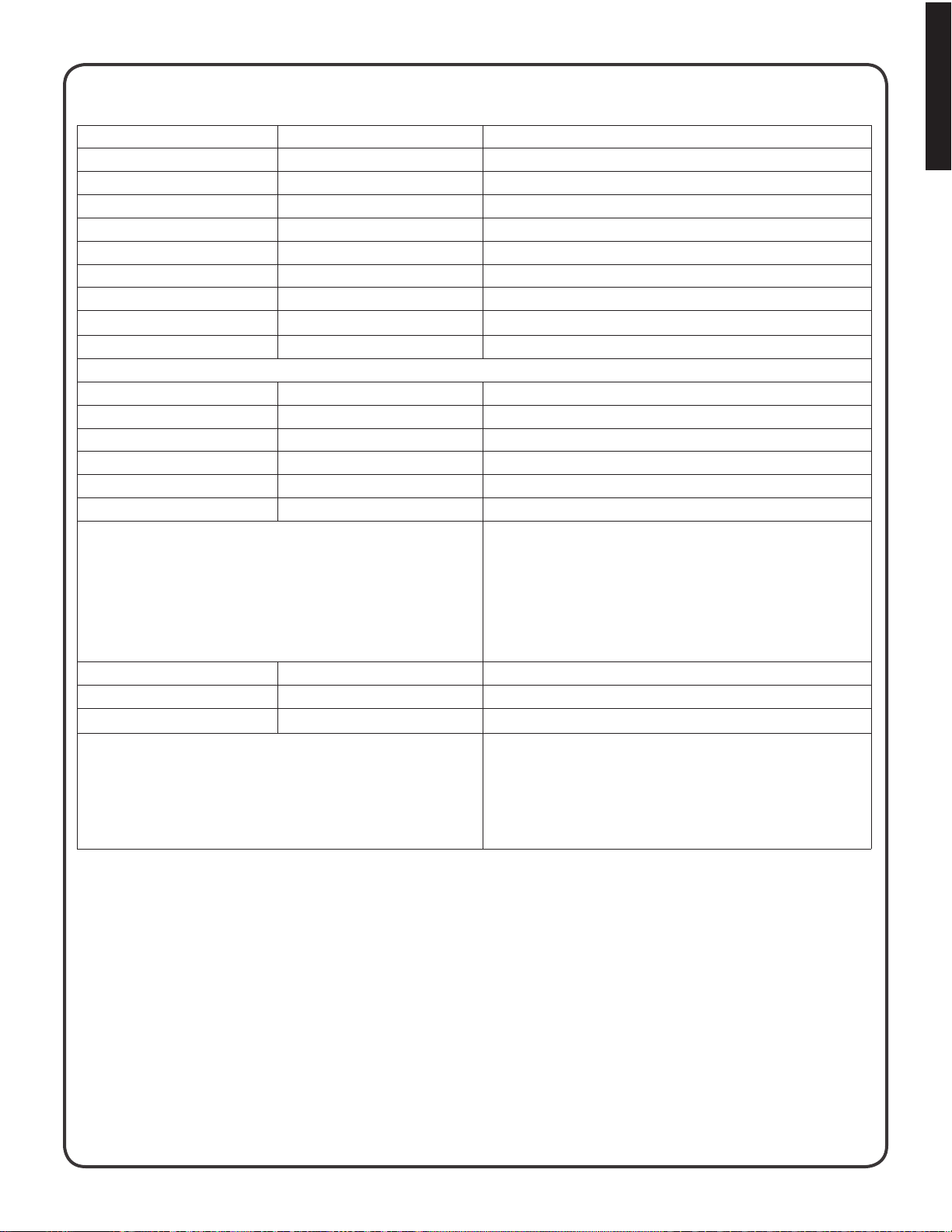

Symbol

form/shape

in t e R n a t i o n a l sy m b o l s

Symbol description/

application

Read and understand the

Operator’s Manual.

Wear eye, ear, and head protection Chain oil pump

Chain brake operation Chain oiler adjustment

Emergency stop

Choke control “Cold Start” position

(choke closed)

Symbol

form/shape

L

H

Symbol description/

application

Chain oil ll

Carburetor adjustment - low

speed mixture

Carburetor adjustment - high

speed mixture

4

Gasoline and oil mixture

T

Carburetor adjustment - idle

speed

Page 5

te C h n i C a l Da t a

Model 326T

Dimension L x W x H 277 x 245 x 214 mm (10.9 x 9.7 x 8.4 inch)

Weight Power head, dry 3.6 kg (7.9 lb) Without chain and guide bar

Engine Type Air-cooled, two-stroke, single cylinder

Displacement 32.6 (1.989 cu.in.)

Carburetor Diaphragm type

Magneto Flywheel magneto : CDI system

Spark Plug

Starter Recoil starter

Power transmission Automatic centrifugal clutch

Fuel Mixture ratio 50:1

Tank Capacity 310 ml (10.5 oz U.S.)

Oil Bar and chain Shindaiwa bar and chain oil (or motor oil)

Tank Capacity 290 ml (9.8 . oz. U.S.)

Lubrication Adjustable automatic oil pump

Guide bar / Saw chain Standard 14 in. (355 mm)

Optional

Standard features Top handle

Engine speeds Idle Speed 2,400 - 2,800

Clutch Engagement 4,000 - 4,600

Wide Open Throttle (WOT) 13,000 - 14,000

Kickback Safety Features Double Guard Low Kick Guide Bar

NGK BPM-8Y (Canada BPMR-8Y) .065 mm (.026 in.) Gap

12 in.(305 mm), 16 in.(406 mm)

Front hand guard

Anti-vibration device

Throttle control lockout

Chain catcher

Spark arrestor catalytic mufer

Low Kick Guard Link Saw Chain

Front Hand Guard/Chain Brake Lever

Chain Brake

Kick Guard

English

Specications subject to change without notice

5

Page 6

English

em i s s i o n Da t a

EMISSION CONTROL

EPA PhAsE 2 / C.A.R.B. TIER III

ENGINE FAMILY:

EMISSION COMPLIANCE PERIOD : 300 HRS.

THIS ENGINE MEETS U.S. EPA PH2 EXH AND 2007

AND

REGULATIONS FOR S.O.R.E.

FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

IMPORTANT ENGINE INFORMATION

7EXHS.0334KB DISPLACEMENT : 32.6 cc

LATER CALIFORNIA EXH AND EVAP EMISSION

REFER TO OWNER’S MANUAL

PRODUCT EMISSION DURABILITY

The 300 hour emission durability compliance period is the time span selected by the manufacturer certifying the engine emissions output meets applicable California and/or U.S. EP A emissions regulations, provided that approved maintenance procedures are followed as listed in the Maintenance Section of this manual.

The emission control system for the engine is EM/TWC (Engine

Modication and 3-way Catalyst) and for the fuel tank the Control

System is EVAP (Evaporative Emissions). Evaporative emission

may be applicable to California models only.

An Emission Control Label is located on the engine. (This is an

EXAMPLE ONLY, information on label varies by engine FAMILY).

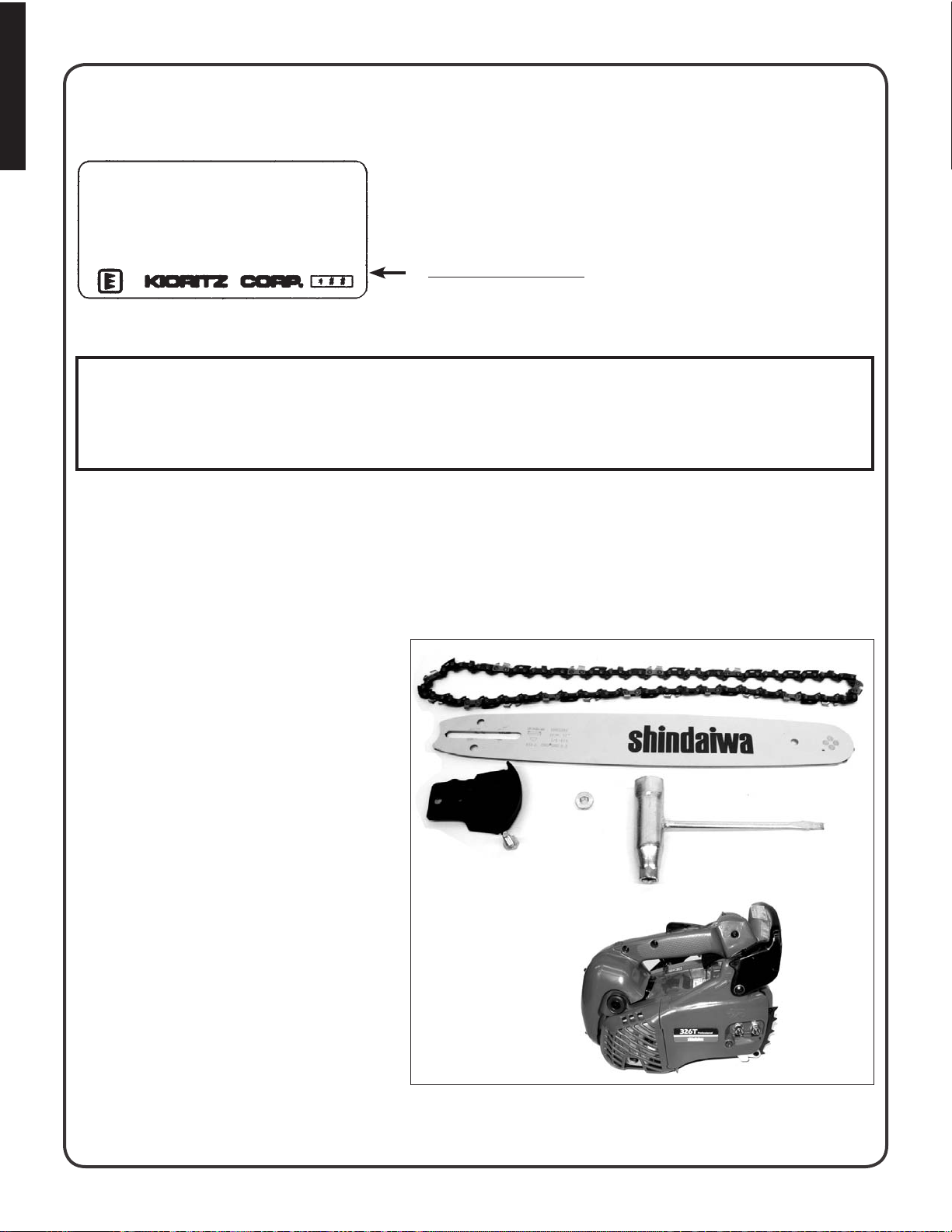

De s C R i p t i o n

The Shindaiwa product you purchased has been factory pre-assembled for your convenience. Due to packaging restrictions, guide bar and saw chain installation and other assembly may be necessary.

After opening the carton, check for damage. Immediately notify your retailer or Shindaiwa Dealer of damaged or missing

parts. Use the contents list to check for missing parts.

CONTENTS

Power Head 1 -

Guide Bar1 -

Kick Guard1 -

Hex Head Bolt1 -

Hex Nut1 -

Saw Chain1 -

Instruction Manual1 -

Warranty Registration Card1 -

Limited Warranty Statement1 -

T-Wrench1 -

6

Page 7

15

English

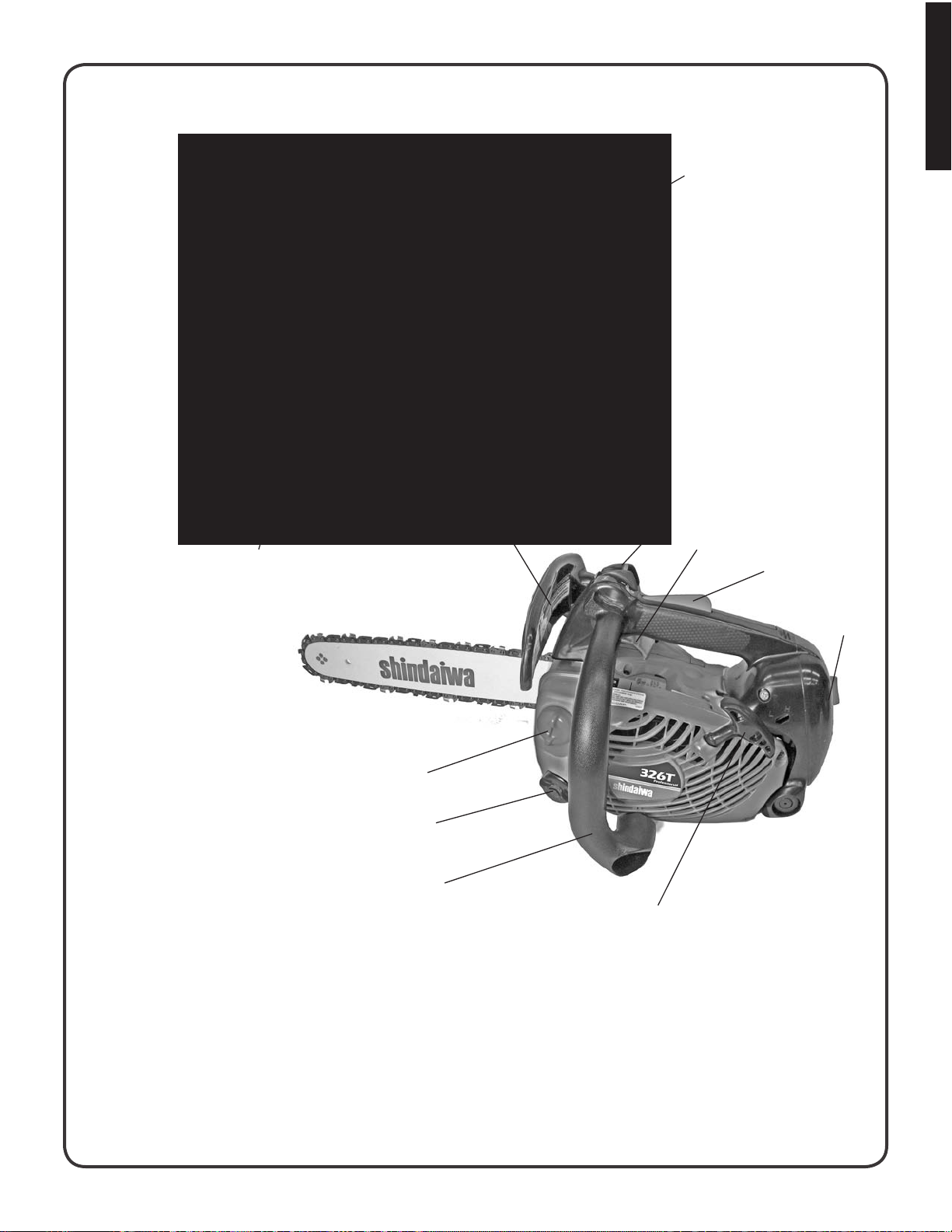

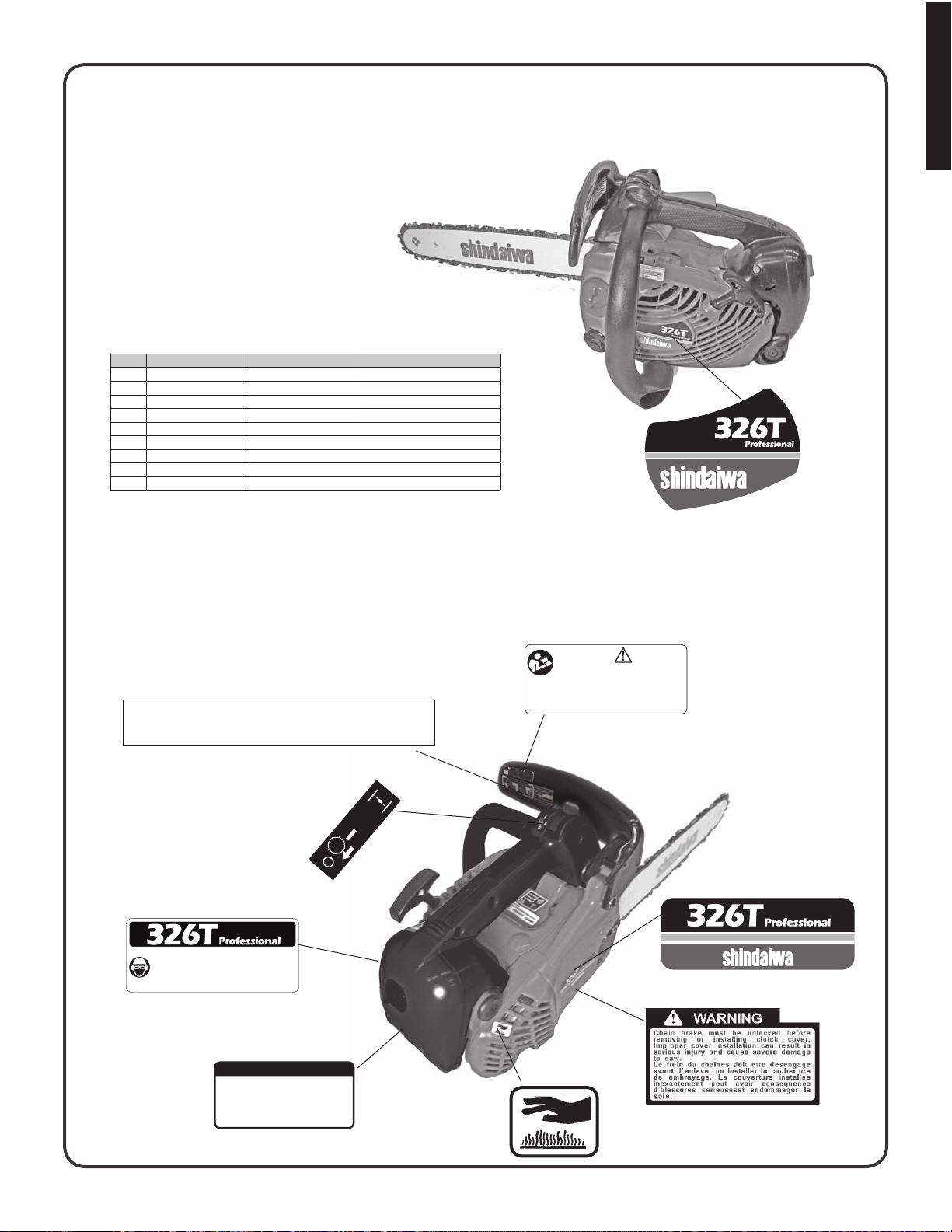

no m e n C l a t u R e o f pa R t s

326T

10

11

12

14

13

1

9

8

7

2

4

3

5

6

Hand guard (Chain brake actuating lever)1.

Ignition/Choke Lever2.

Throttle control trigger3.

Throttle control lockout4.

Air cleaner cover5.

Pull starter6.

Front handle7.

Oil tank cap8.

Fuel tank cap9.

Saw chain10.

Guide bar11.

Sprocket guard12.

Catalytic mufer13.

Spark Plug14.

Rear (Top) Handle15.

7

Page 8

English

CAUTION: This saw shall be used only by certified tree

service professionals. For safe operation follow all safety

precautions and instructions in the operator’s manual.

(Replacement operator’s manuals are available from your

Shindaiwa dealer. Hold chain saw firmly with both hands.

Cette tronçonneuse doit être utiliser seulement

par des professionnels de l’abattage. Pour un

travail en sécurité et les indications du manual

d’utilisation. (Le manual d’utilisation est

disponible chez votre agent Shindaiwa. Te nez

fermement la tronçonneuse des deux mains.

STOP

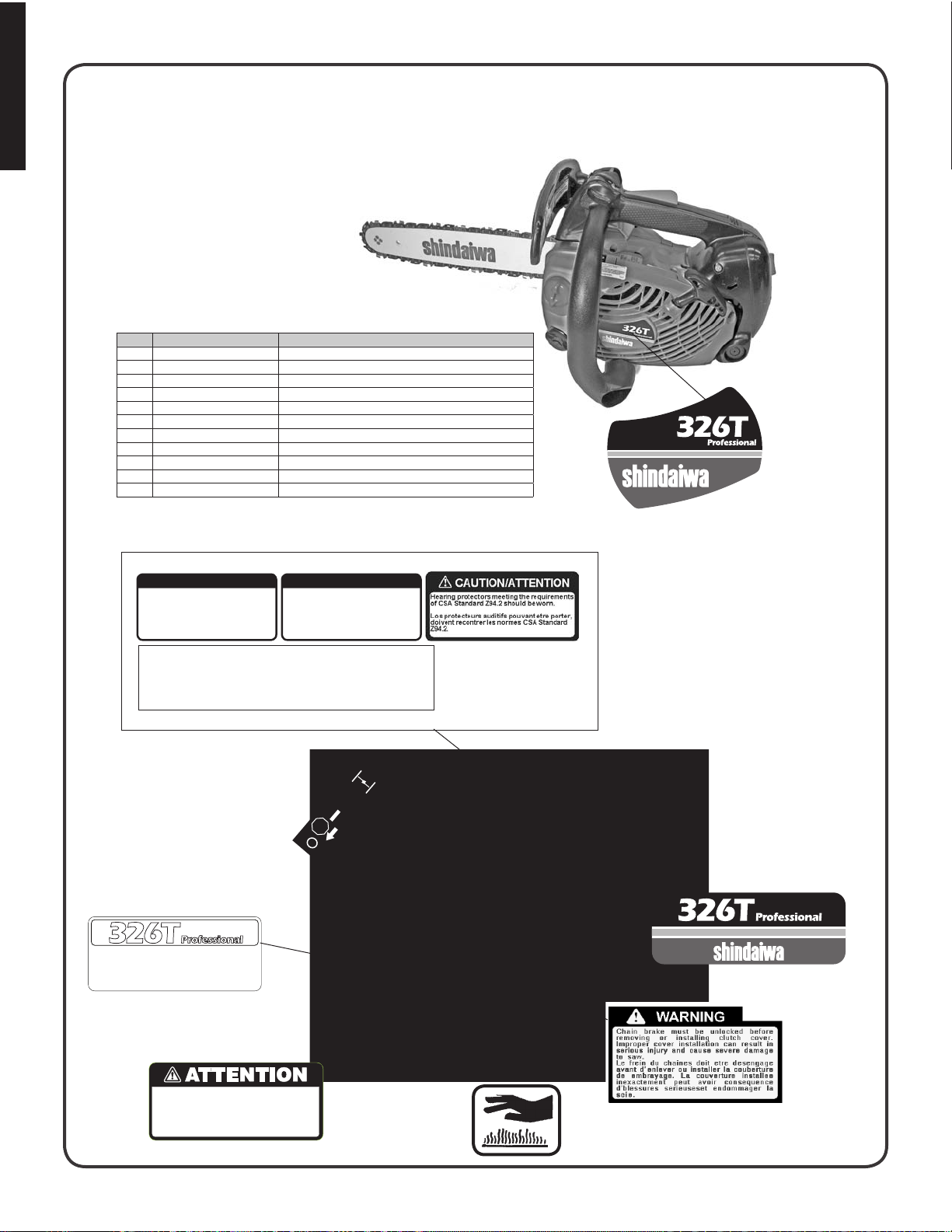

LABELS

fo R Ca n a D i a n mo D e l s

326T

NO PART NUMBER DESCRIPTION

1 X505000460 KICKBACK LABEL (FRENCH)

2 X505000450 KICKBACK LABEL

3 89017639431 NOISE LABEL (ENGLISH / FRENCH)

4 X524002240 BAR & CHAIN LABEL

5 X503009450 326T ID LABEL

6 X505002071 WARNING LABEL

7 X505002310 HOT CAUTION LABEL

8 X505002580 ATTENTION LABEL

9 X503009480 326T ID / WARNING LABEL

10 X524001450 IGNITION SWITCH LABEL

11 X504000940 326T ID LABEL

*If a label is illegible, a replacement can be ordered from a

Shindaiwa dealer.

11

1

POUR ÉVITER LES REBONDISSEMENTS

Eviter touit contact entre le nez du guide-chaine 1.

et un objet quelconque.

Tout contact du nez peut provoquer un mouve-

2.

ment brusque vers le haut ou vers les bas et

entrainer de graves blessures.

Toujours employer lex deux mains pour opérer

3.

la scie á chaine.

REPLACEMENT BAR AND CHAIN NOTE: There may be other placement components for

REMPLACEMENT DU GUIDE ET DE LA CHAÎNE

GUIDE BAR CHAIN

PART NO. TYPE. LINKS

12" 120GPEA041 OREGON 91VG 45

14" 140GPEA041 OREGON 91VG 52

16" 160GPEA041 OREGON 91VG 57

2

TO AVOID KICKBACK

Contact of the guide bar tip with any object 1.

should be avoided.

2.

Tip contact may cause the guide bar to move

suddenly upward and backward which may

cause serious injury.

3.

Always use two hands when operating the

chain saw.

achieving kickback protection. For details, please refer

to the chain and bar combination sheet shown in in

the operator's manual

REMARQUE : Il y puet y avoir d'autres composantes, de

remplacement qui protèsent en cas de ebondissement.

Pour plus de détails, se réferér á la feuille sur les

combinasion de guide et de chaîne du manuel de

l'utilsaleur

3

4

10

5

9

6

8

8

7

Page 9

CAUTION: This saw shall be used only by certified tree

service professionals. For safe operation follow all safety

precautions and instructions in the operator’s manual.

(Replacement operator’s manuals are available from your

Shindaiwa dealer. Hold chain saw firmly with both hands.

STOP

Esta unidad puede ser peligrosa y producir

lesiones personales graves si no se usa en forma

adecuada. Para reducir ei riesgo de lesionarse,

los operadores, lost ayudantes,y los espectadores

deben leer y comprender el Manual Del Operador

y los Manuales de Seguridad que se entregan

escritos en espanol.

ADVERTENCIA PELIGRO

LABELS

fo R Ca l i f o R n i a m o D e l s

326T

NO PART NUMBER DESCRIPTION

1 89022839131

2 X524002220

3 X503009450

4 X505002061

5 X505002310

6 89019130131

7 X503009460

8 X524001450

9 X504000940

*If a label is illegible, a replacement can be ordered from a

Shindaiwa dealer.

CAUTION LABEL

BAR & CHAIN LABEL

326T ID LABEL

WARNING LABEL

HOT CAUTION LABEL

KICKBACK LABEL

326T ID / WARNING LABEL

IGNITION SWITCH LABEL

326T ID LABEL

English

9

2

GUIDE BAR CHAIN REPLACEMENT BAR AND CHAIN

PART NO. TYPE. LINKS

12" 120GPEA041 OREGON 91VG 45

14" 140GPEA041 OREGON 91VG 52

16" 160GPEA041 OREGON 91VG 57

NOTE: There may be other placement components for

achieving kickback protection. For details, please refer

to the chain and bar combination sheet shown in in

the operator's manual

7

6

TO AVOID KICKBACK

Contact of the guide bar tip with any object 1.

should be avoided.

2.

Tip contact may cause the guide bar to move

suddenly upward and backward which may

cause serious injury.

3.

Always use two hands when operating the

chain saw.

1

8

3

4

5

9

Page 10

English

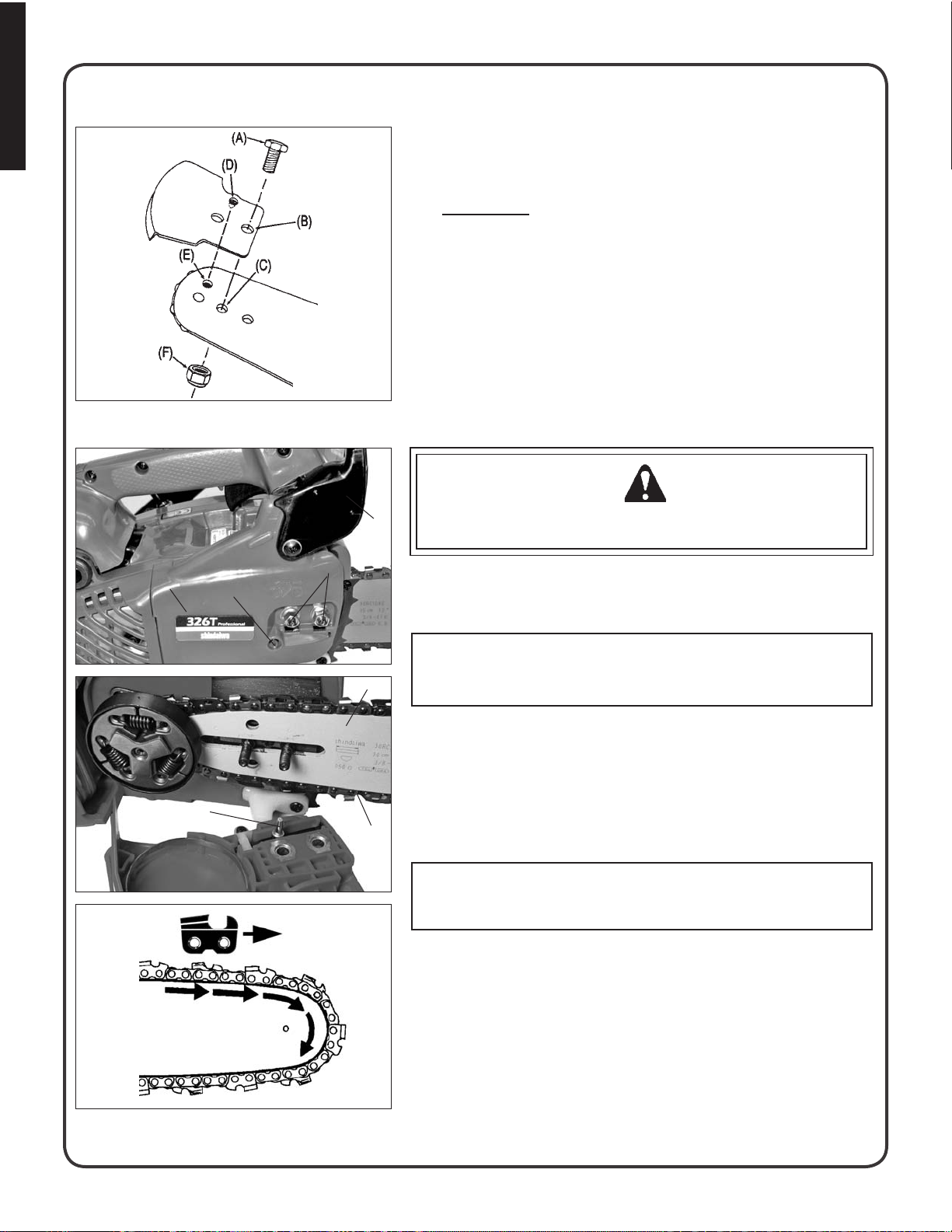

KICK GUARD® TO BAR INSTRUCTIONS

For saws with Kick Guard® and symmetrical or asymmetrical lowkick type guide bars.

1.

Install bolt (A) in rear hole (B) of Kick Guard® and through front

hole (C) in guide bar.

2. IMPORTANT: Dimple in Kick Guard® (D) must engage recess in

guide bar (E).

3.

Tighten nut (F) and bolt (A) until snug. Make certain Kick Guard®

is ush against guide bar.

GUIDE BAR AND SAW CHAIN-INST ALL/ REMOVE

WARNING DANGER

G

Saw Chain is sharp! Always wear gloves when handling assembly, otherwise serious personal injury may result.

K

J

H

Move chain brake lever (G) fully rearward to unlock chain brake.1.

Remove two guide bar nuts (H). Turn tension adjustment screw (J) 2.

counterclockwise 2 to 3 turns if bar and chain are installed.

IMPORTANT

L

Always loosen guide bar nuts before turning chain tension adjuster, otherwise clutch cover and tensioner will be damaged

Push clutch cover (K) forward, pull rear of cover out slightly, then 3.

remove.

4.

Remove guide bar and saw chain if necessary.

Mount guide bar (L) on studs, and slide toward sprocket to make 5.

N

M

saw chain installation easier. Install saw chain (M) over clutch and

place around sprocket and guide bar as shown, with cutters on

top of guide bar facing forward.

NOTE: See “MAINTENANCE AND CARE” instructions for guide

bar, sprocket, and saw chain maintenance.

Align holes of clutch cover (K) with guide bar studs, and tensioner pin 6.

(N) with lower guide bar adjuster hole. Install cover, then press and

hold rear of cover to fully seat. Tighten guide bar nuts nger tight.

10

Page 11

English

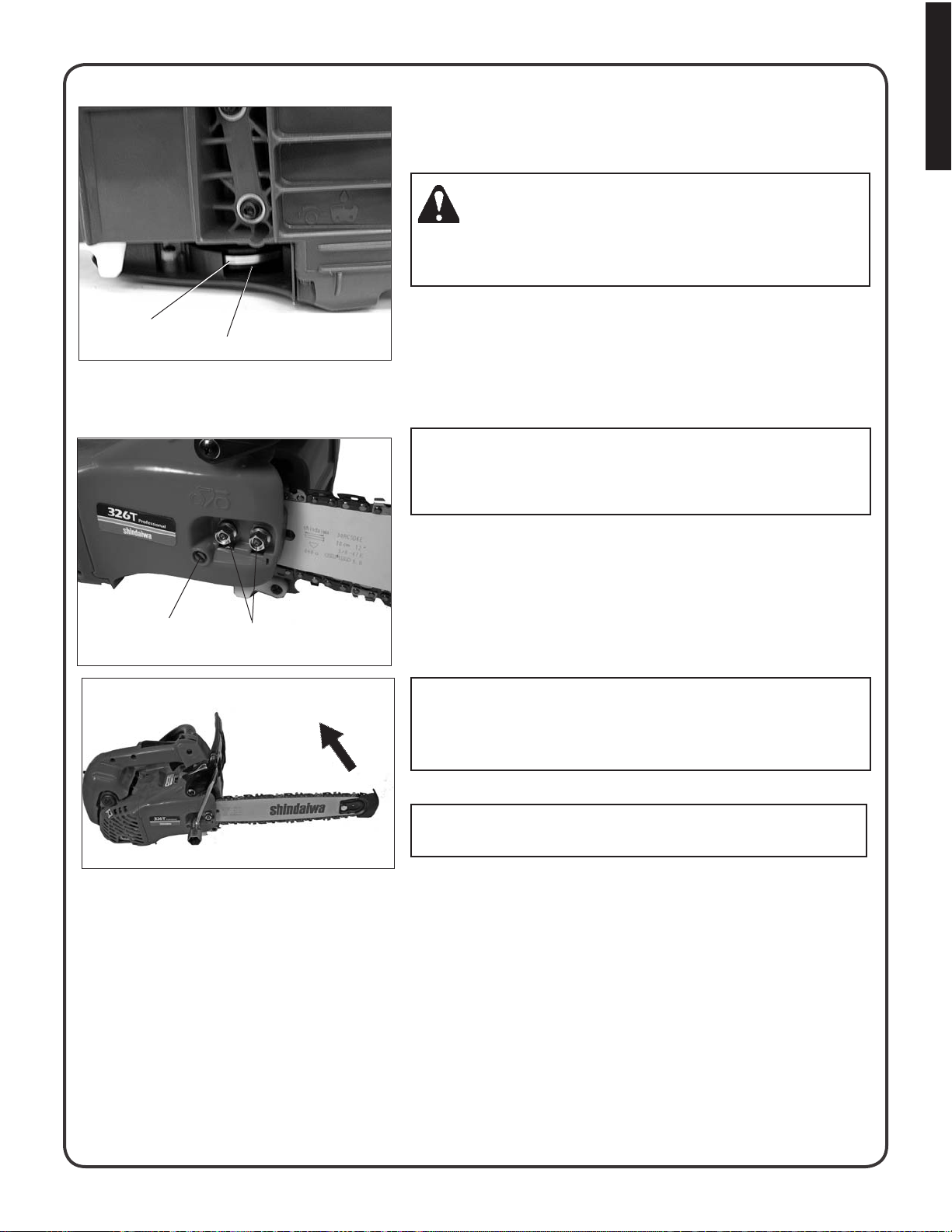

Kick Guard to bar instructions, continued

Turn saw over and check brake band (O) for correct position 7.

around clutch drum (P). If brake band is not in place around drum,

remove clutch cover, make sure brake is released, and reinstall.

DANGER

Never operate saw if chain brake does not function properly, otherwise saw damage and serious personal injury could result. See

“Testing the Brake” instructions.

Adjust saw chain tension, as instructed in “Adjustment, Chain 8.

O

P

Tension”

ADJUSTMENT, CHAIN TENSION

IMPORTANT

Always loosen guide bar nuts before turning chain tension adjuster, otherwise clutch cover and tensioner will be damaged.

Remove air lter cover and spark plug lead.

1.

Loosen two guide bar nuts (H).2.

Hold the bar nose up, and turn the adjuster screw (J) clockwise 3.

until the chain touches the bottom of the bar.

4.

J

H

Tighten both guide bar nuts with bar nose held up.

Pull the saw chain around the guide bar by hand. Reduce chain 5.

tension, if you feel tight spots.

IMPORTANT!

Tighten guide bar nuts to 90 – 110 kgf/cm (80 – 95 in. lbs.) DO

NOT over-tighten nuts. Damage to saw may result.

Keep chain properly tensioned at all times.

6.

NOTE

All chains require frequent adjustments.

Replace spark plug lead and air lter cover.7.

11

Page 12

English

fu e l a n D lu b R i C a n t

NOTICE: Use of unmixed, improperly mixed, or fuel older than 90 days, (stale fuel), may cause hard starting, poor performance, or severe engine damage and void the product warranty. Read and follow instructions in the Storage section

of this manual.

FUEL STATEMENT

WARNING

Alternative fuels, such as E-20 (20% ethanol), E-85 (85% ethanol) or any fuels not meeting Shindaiwa requirements

are NOT approved for use in Shindaiwa 2-stroke gasoline engines. Use of alternative fuels may cause performance

problems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including, but not limited

to, improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel lines, gaskets, carburetors and other engine components.

Gasoline: Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain up to

10% Ethanol (grain alcohol) or 15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood alcohol) is

NOT approved.

Two Stroke Oil:

requirements. Shindaiwa One is recommended for use in all Shindaiwa low emissions engines.Shindaiwa One also

includes a fuel stabilizer.

Oil is a registered JASO FC classified oil and also meets or exceeds ISO-L-EGD performance

IMPORTANT

Mix only enough fuel for your immediate needs! If fuel must be stored longer than 30 days and oil with fuel stabi-

lizer is not used, it should rst be treated with a fuel stabilizer such as STA-BIL™.

Handling Fuel

WARNING DANGER

Fuel is VERY ammable. Use extreme care when mixing, storing or handling or serious personal injury may result.

■

Use an approved fuel container.

DO NOT smoke near fuel. ■

DO NOT allow ames or sparks near fuel. ■

Fuel tanks/cans may be under pressure. Always loosen fuel caps slowly allowing pressure to equalize. ■

NEVER refuel a unit when the engine is HOT or RUNNING! ■

DO NOT ll fuel tanks indoors. ALWAYS ll fuel tanks outdoors over bare ground. ■

DO NOT overll fuel tank. Wipe up spills immediately. ■

Securely tighten fuel tank cap and close fuel container after refueling. ■

Inspect for fuel leakage. If fuel leakage is found, do not start or operate unit until leakage is repaired. ■

Move at least 3m (10 ft.) from refueling location before starting ■ the engine.

12

Page 13

Fuel and lubricant, continued

Mixing Instructions

English

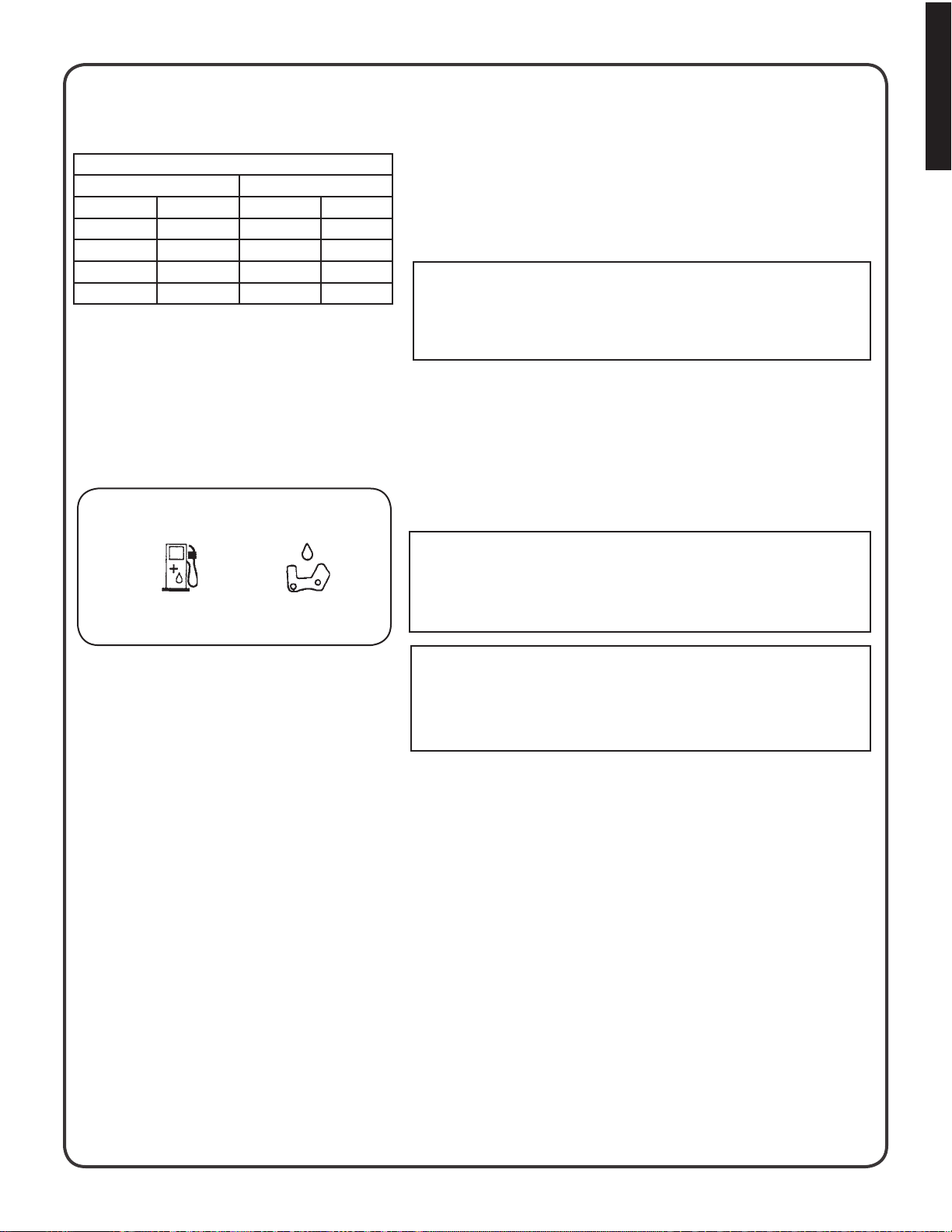

Fuel Mix Chart

Fuel to Oil Mix-50:1 Ratio

U.S. METRIC

GAS OIL GAS OIL

Gallons Fl.oz. Liter cc.

1 2.6 4 80

2 5.2 8 160

5 13 20 400

TANK INDICATION

FUEL TANK OIL TANK

Fill an approved fuel container with half of the required amount of 1.

gasoline.

2.

Add the proper amount of 2-stroke oil to gasoline.

Close container and shake to mix oil with gasoline.3.

Add remaining gasoline, close fuel container, and remix.4.

IMPORTANT

Spilled fuel is a leading cause of hydrocarbon emissions. Some

states may require the use of automatic fuel shut-off containers to

reduce fuel spillage.

After use

DO NOT store a unit with fuel in its tank. Leaks can occur. Return

unused fuel to an approved fuel storage container.

Storage: Fuel storage laws vary by locality. Contact your local government for the laws affecting your area. As a precaution, store fuel in

an approved, airtight container. Store in a well-ventilated, unoccupied

building, away from sparks and ames.

IMPORTANT

Stored fuel ages. Do not mix more fuel than you expect to use in

thirty (30) days, ninety (90) days when a fuel stabilizer is added.

IMPORTANT

Stored two-stroke fuel may separate. ALWAYS shake fuel container

thoroughly before each use.

CHAIN LUBRICANT

Proper lubrication of the chain while in operation reduces friction

between the chain and the guide bar to a minimum and assures a longer service life.

■

Use bar and chain oil of high quality for this purpose.

Do not use used or reclaimed oil to avoid various oiler problems. ■

Use Shindaiwa bar and chain oil. ■

When Shindaiwa bar and chain oil is not available, use motor oil, ■

etc.

■

Use bar and chain oil of the following grades:

SAE NO. 30 ... in summer

SAE NO. 10 ... in winter or when cutting resinous trees.

■

When refueling, also rell chain oil.

13

Page 14

English

op e R a t i o n

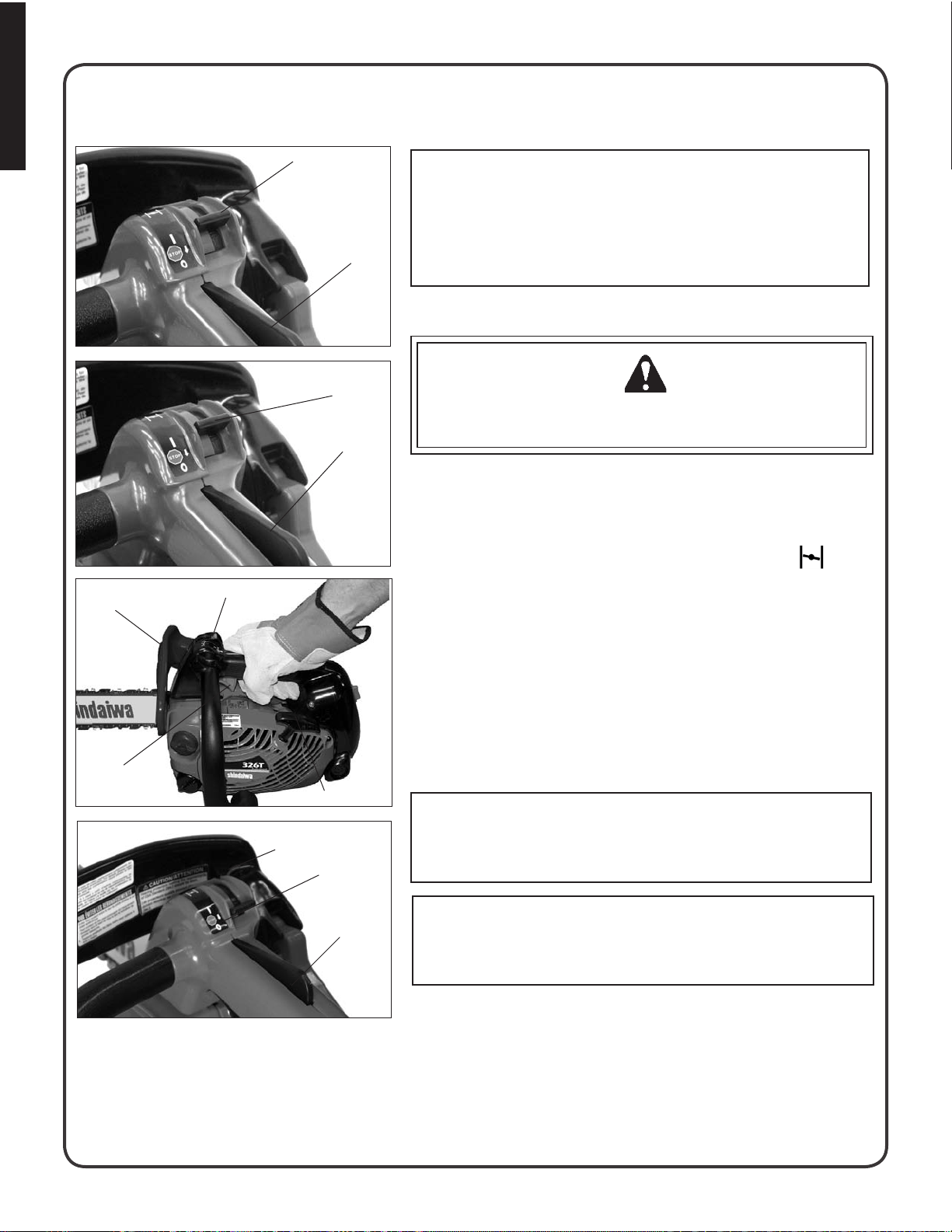

A

IMPORTANT

This saw features a combination ignition/choke switch that automatically sets the throttle speed to fast idle for quick starting. Do not

squeeze trigger during cold starts until after unit has started, or fast

C

idle and choke settings will be released, and engine may not start.

STARTING COLD ENGINE

B

Make sure bar and chain are not touching anything when starting

the saw.

C

Move chain brake lever (E) fully forward to lock chain brake before 1.

starting.

2.

Fill the fuel tank with fuel. Do not over ll.

Fill the chain oil tank with lubricant. Do not over ll.3.

Move ignition/choke lever (A) forward to “close choke” (4. )

position.

E

D

G

F

E

G

5.

Lay unit on a at, clear area and keep bar and chain clear of all

obstacles. Hold top handle with one hand, and depress throttle

trigger lockout (C), but do not depress throttle trigger (D).

6.

Pull starter handle (F) several times until engine starts, or rst

starting sound is heard. (7 pulls maximum)

7.

Move ignition/choke lever back to “run” ( I ) position (B). (Do not

move to “Stop” position [G].) If necessary, start the engine.

8.

After engine starts, wait 5 seconds then depress and release throttle trigger (D). Allow unit to warm up at idle for several minutes.

NOTE

If engine does not start after 3 pulls with choke in “run” ( I ) position,

repeat cold start instructions 4-6.

WARNING DANGER

14

C

NOTE

Do not allow recoil handle to snap back against the casing. ■

Do not pull starter rope out to the maximum possible position. ■

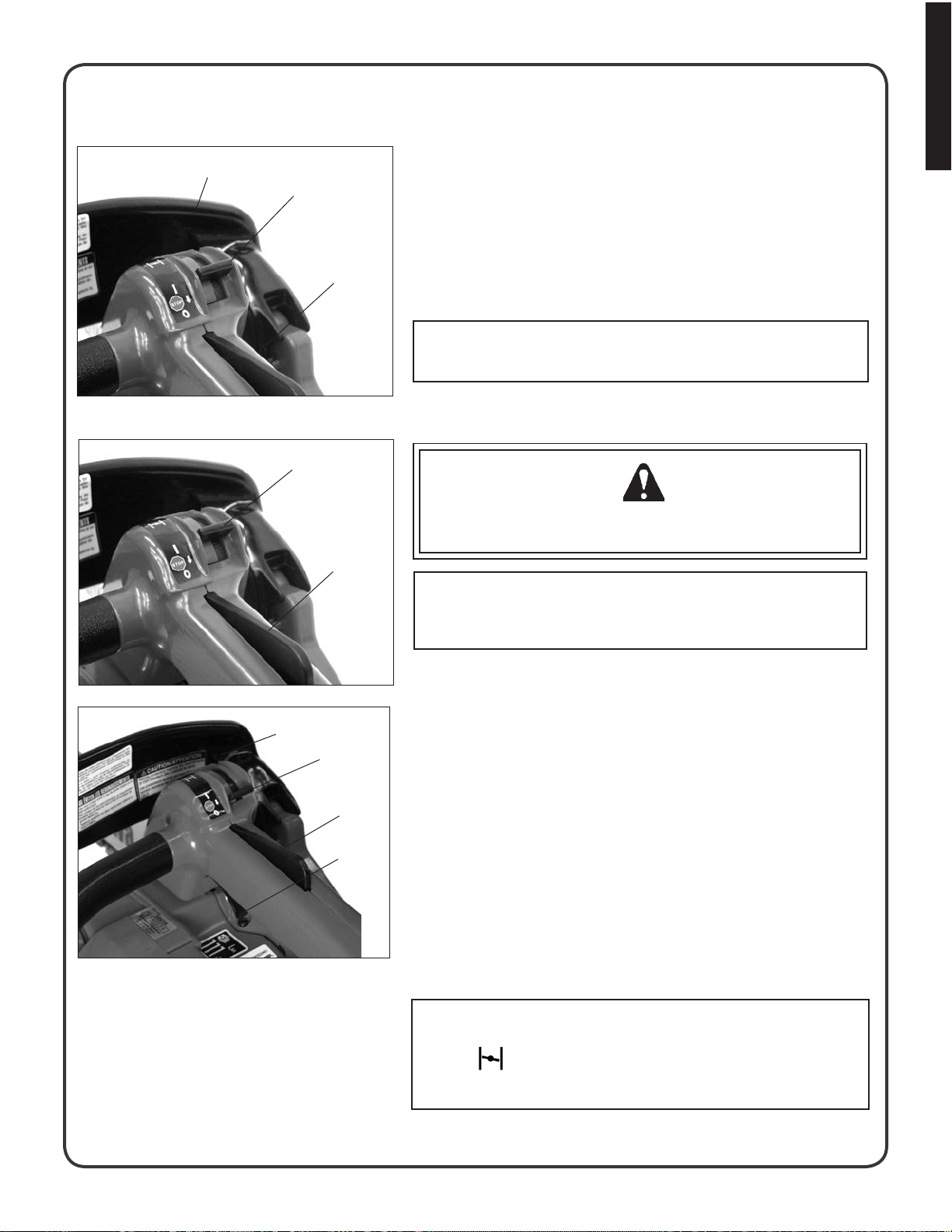

Page 15

English

Operation, continued

STARTING WARM ENGINE

Ensure that there is fuel and chain oil in the tanks. 1.

E

A

C

Move chain brake lever (E) fully forward to lock chain brake 2.

before starting.

Lay unit on a at, clear area and keep bar and chain clear of all 3.

obstacles. Hold top handle with one hand, and depress throttle trigger

lockout (C), but do not depress throttle trigger.

Move ignition/choke lever (A) forward to “Run” position ( I ).4.

Pull starter handle. 5.

NOTE

If engine does not start after 5 pulls, use cold start procedure.

RUNNING

A

WARNING DANGER

The saw chain should not move at idle, otherwise serious personal injury may result.

C

NOTE

If saw chain moves, adjust carburetor according to “Carburetor Adjustment” instructions in this manual, or see your dealer.

After engine starts, allow it to return to idle and warm up before using. ■

Move chain brake lever (E) fully rearward to unlock chain brake. ■

E

A

C

D

Press throttle control lockout (C) then gradually squeeze throttle ■

trigger (D) to increase engine speed.

■

Saw chain starts moving when the engine reaches approximately

4200 rpm.

Ensure proper acceleration and lubrication of chain and bar. ■

Do not run the engine at high speed unnecessarily. ■

Be sure that saw chain stops moving when throttle trigger is ■

released.

STOPPING

Release throttle trigger (D) and move lever (A) rearward to STOP 1.

(O) position.

Move chain brake lever (E) fully forward to lock chain brake. 2.

NOTE

If engine does not stop, move ignition/choke lever forward to choke

position (

Shindaiwa dealer to check and repair stop switch before starting

the engine again

) to stop engine. Return the unit to your authorized

15

Page 16

English

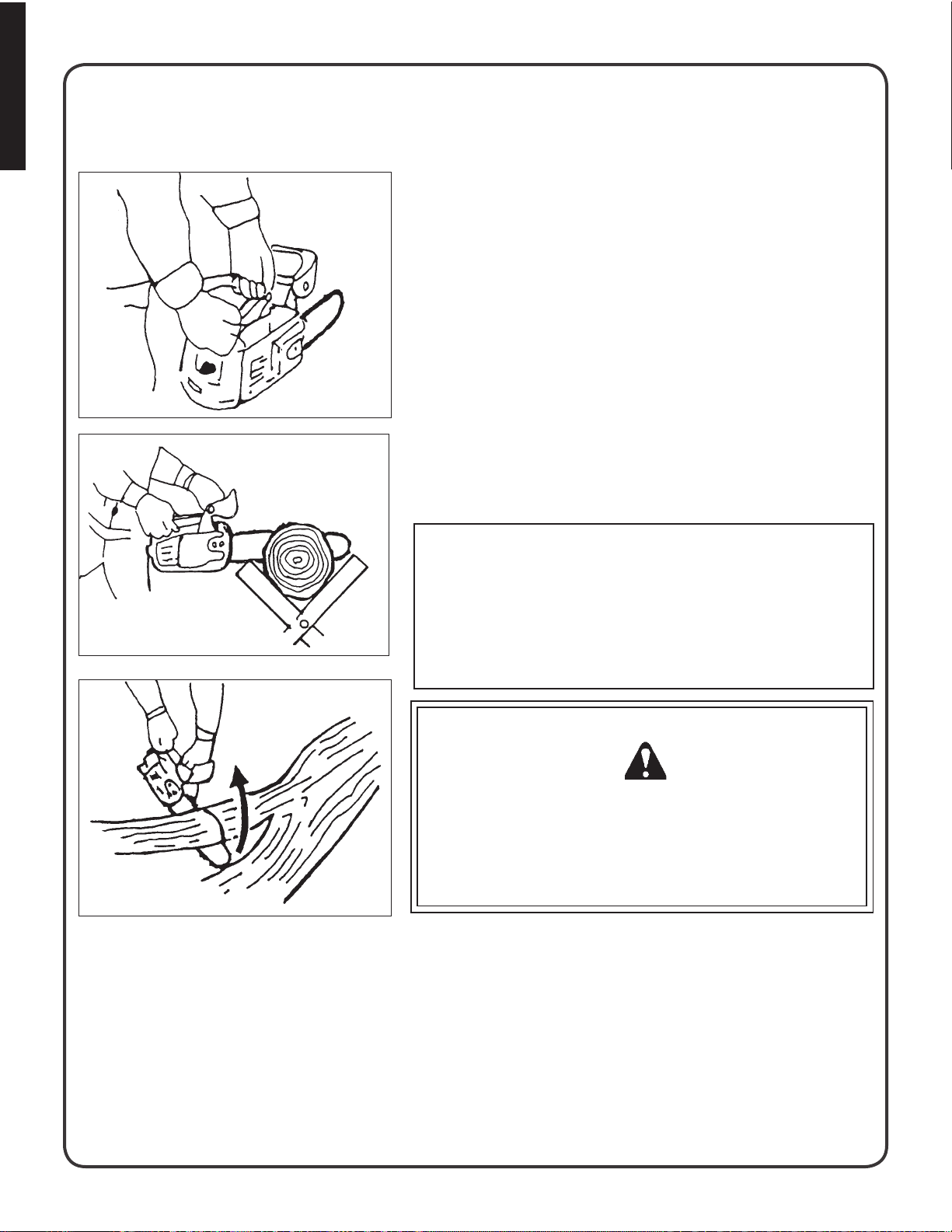

Cu t t i n g in s t R u C t i o n s

GENERAL

In all circumstances the operation of the chain saw is a one-man

job. It is difficult at times to take care for your own safety, so don’t

assume the responsibility for a helper as well. After you have

learned the basic techniques of using the saw, your best aid will

be your own good common sense.

The accepted way to hold the saw is to stand to the left of the

saw with your left hand on the front handlebar and your right

hand on the rear handle so you can operate the throttle trigger

with your right index finger.

Before attempting to fell a tree, cut some small logs or limbs.

Become thoroughly familiar with the controls and the responses

of the saw.

Start the engine, see that it is running properly. Squeeze the trigger to open the throttle wide open and start the cut. If the chain is

properly sharpened, the cutting should be relatively effortless. It

is not necessary to press down hard to make the saw cut. Pushing the saw too hard will slow the engine and cutting will actually

be more difficult.

Kickback

NOTE

Some material may adversely affect the housings of your Shindaiwa

chain saw.

(Example: Palm Tree Acid, fertilizer, etc.) To avoid housing deterioration, carefully remove all packed saw dust around clutch and

guide bar area and wash with water. Coat metal parts with light oil.

WARNING DANGER

Do not let the tip of the bar touch anything while the engine is running. At cutting speed the chain is moving at a high rate of speed.

Should the tip contact a limb or log while the chain is moving, the

tip will be pushed upward with considerable force. This is known

as kickback. Avoid it!

16

Page 17

Select path of retreat

English

Cutting, continued

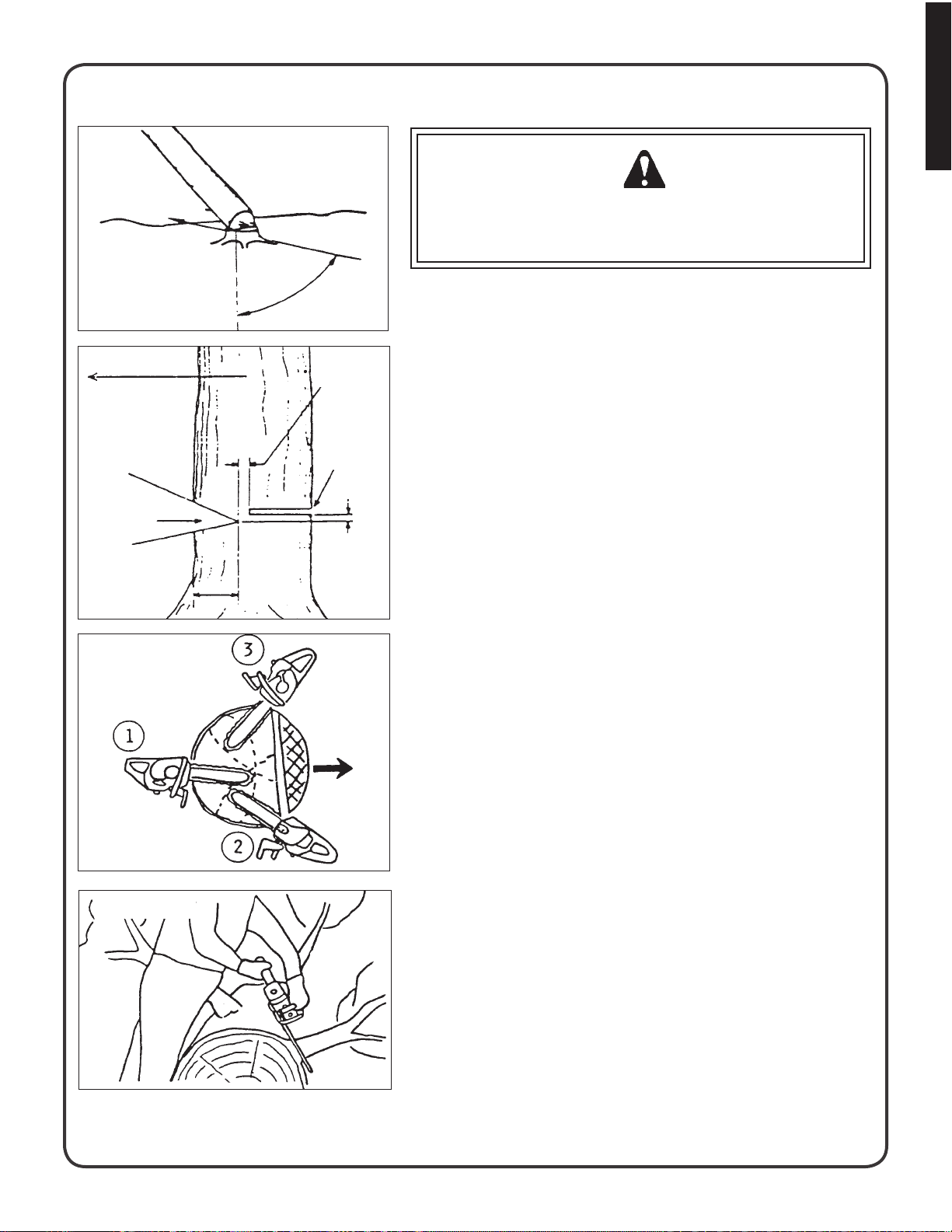

FELLING A TREE

DIRECTION

OF FALL

Direction of fall

First cut

Notch

Second cut

One-third tree

diameter

Felling big trees

2”

45°

Hinge

Felling cut

2”

WARNING DANGER

A falling tree can seriously damage anything it may hit: a car, a

house, a fence, a power line, or another tree. There are ways to

make a tree fall where you want it, so rst decide where that is!

Before cutting, clear the area around the tree. You will need good

footing while working and you should be able to work the saw

without hitting any obstacles. Next, select a path of retreat. When

the tree begins to fall you should retreat away from the direction

of fall at a 45 degree angle and at least 3m from the trunk to avoid

the trunk kicking back over the stump.

Begin the cut on the side to which the tree is to fall. Cut a notch

about 1/3 of the way into the tree as shown. The position of this

notch is important since the tree will try to fall “into” the notch. The

felling cut is made on the side opposite the notch and at a level

about 2” above the bottom of the notch. Do not try to cut through

to the notch with the felling cut. The remaining wood between the

notch cut and felling cut (about 2”) will act as a hinge when the

tree falls, guiding it in the desired direction. When the tree starts

to fall, kill the engine, place the saw on the ground and make your

retreat quickly.

To fell big trees with a diameter exceeding twice the bar length, start

the notching cuts from one side and draw the saw through to the

other side of the notch. Start the back cut on one side of the tree,

pivoting the saw through to form the desired hinge on that side.

LIMBING

Then remove the saw for the second cut. Insert the saw in the

rst cut, very carefully so as not to cause kickback. The nal cut is

made by drawing the saw forward in the cut to reach the hinge.

Limbing a fallen tree is much the same as bucking. Never limb on

the tree that you are standing. When limbing, caution is the word.

Be careful of the tip touching other limbs. Always use both hands.

17

Page 18

English

Cutting, continued

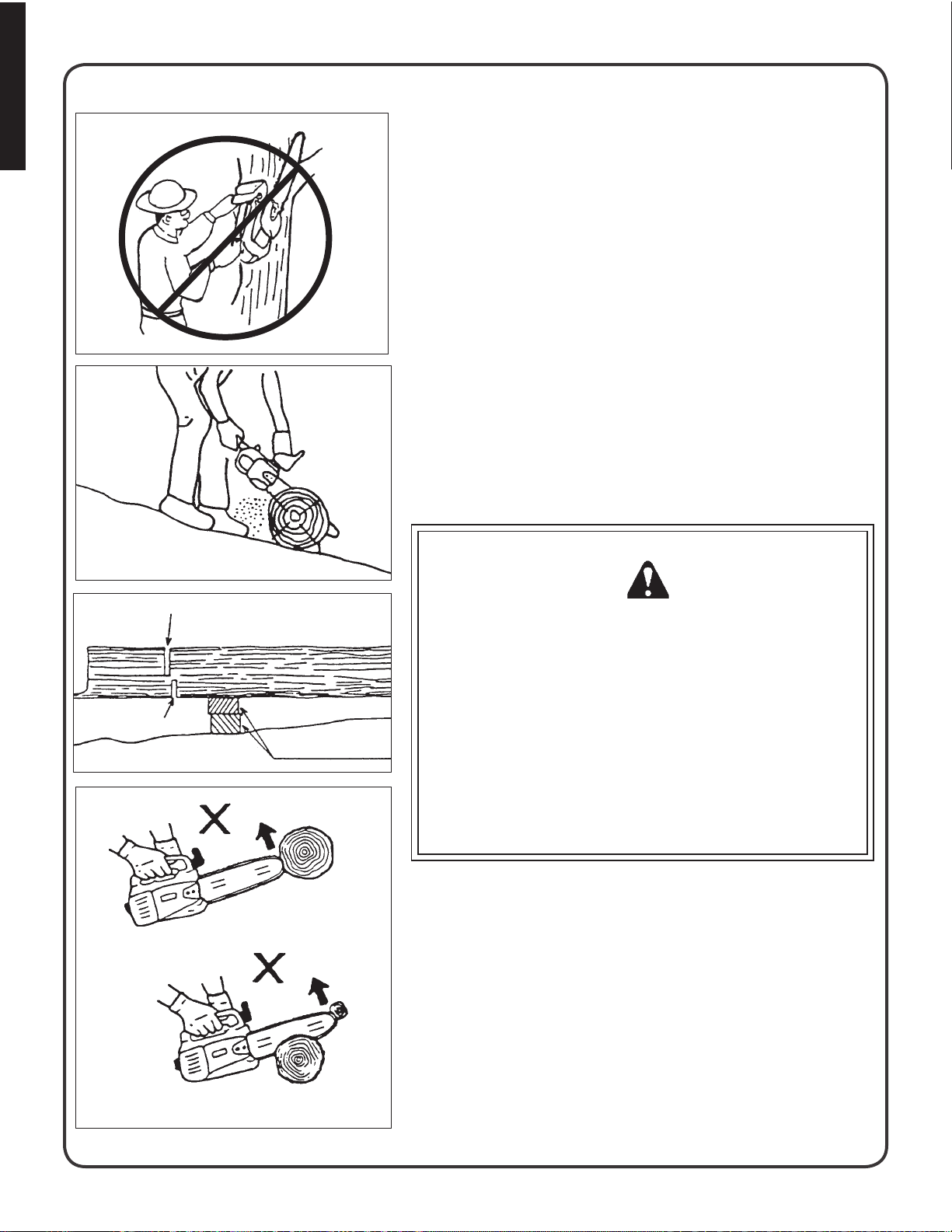

DON’T cut with saw overhead!

Uphill position

BUCKING

Don’t cut with the saw overhead or the bar in a vertical position. If the

saw should kick back you may not have good enough control to prevent possible injury.

Bucking is the sawing of a log or fallen tree into smaller pieces. There

are a few basic rules which apply to all bucking operations.

Keep both hands on the handles at all times.

Support logs if possible.

When cutting on a slope or hillside, always stand uphill.

Keep in mind that the wood is heavy and that it will bend and pinch

the saw if improperly supported.

The trunk will weaken at the point where you make the cut unless the

tree is lying on perfectly at ground or supported as shown.

If you make the cut with the tree on the ground, don’t let the saw’s

chain dig into the earth; it is harmful for the saw, and you stand a

good chance of being struck by ying debris. To cut the trunk, use

the bucking and two-cut sequence shown. The rst cut should be no

deeper than one-third the trunk diameter.

FINISH CUT

FIRST CUT

KICKBACK

■

Improper thrust cutting.

Board or at stones

WARNING DANGER

KICKBACK IS DANGEROUS

Kickback is generated when the rotation of the chain is arrested

for some reason. The most dangerous effect of this action occurs

when the nose of the bar contacts another object, the chain is

momentarily stopped and all the energy of the engine throws the

bar upwards and backwards towards the operator.

The chain saw industry and government agencies have

attempted to prescribe various safety devices, but the best protection is to avoid kickback.

Comply with the Safety Precautions as listed on page 2 and 3 of

this manual.

18

When the bar nose hits another ■

tree, etc.

Page 19

ma i n t e n a n C e a n D Ca R e

Your Shindaiwa unit is designed to provide many hours of trouble free service. Regular scheduled maintenance will help your

unit achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an

Shindaiwa Service Dealer for maintenance. To help you decide whether you want to DO-IT-YOURSELF or have the Shindaiwa Dealer do it, each maintenance task has been graded. If the task is not listed see your Shindaiwa dealer for repairs.

SKILL LEVELS

Level 1 = Easy to do. Most required tools come with unit.

Level 2 = Moderate difculty. Some specialized tools may be required.

Level 3 = Experience required. Specialized tools are required. Shindaiwa recommends that the unit be

returned to your Shindaiwa dealer for servicing.

MAINTENANCE INTERVALS

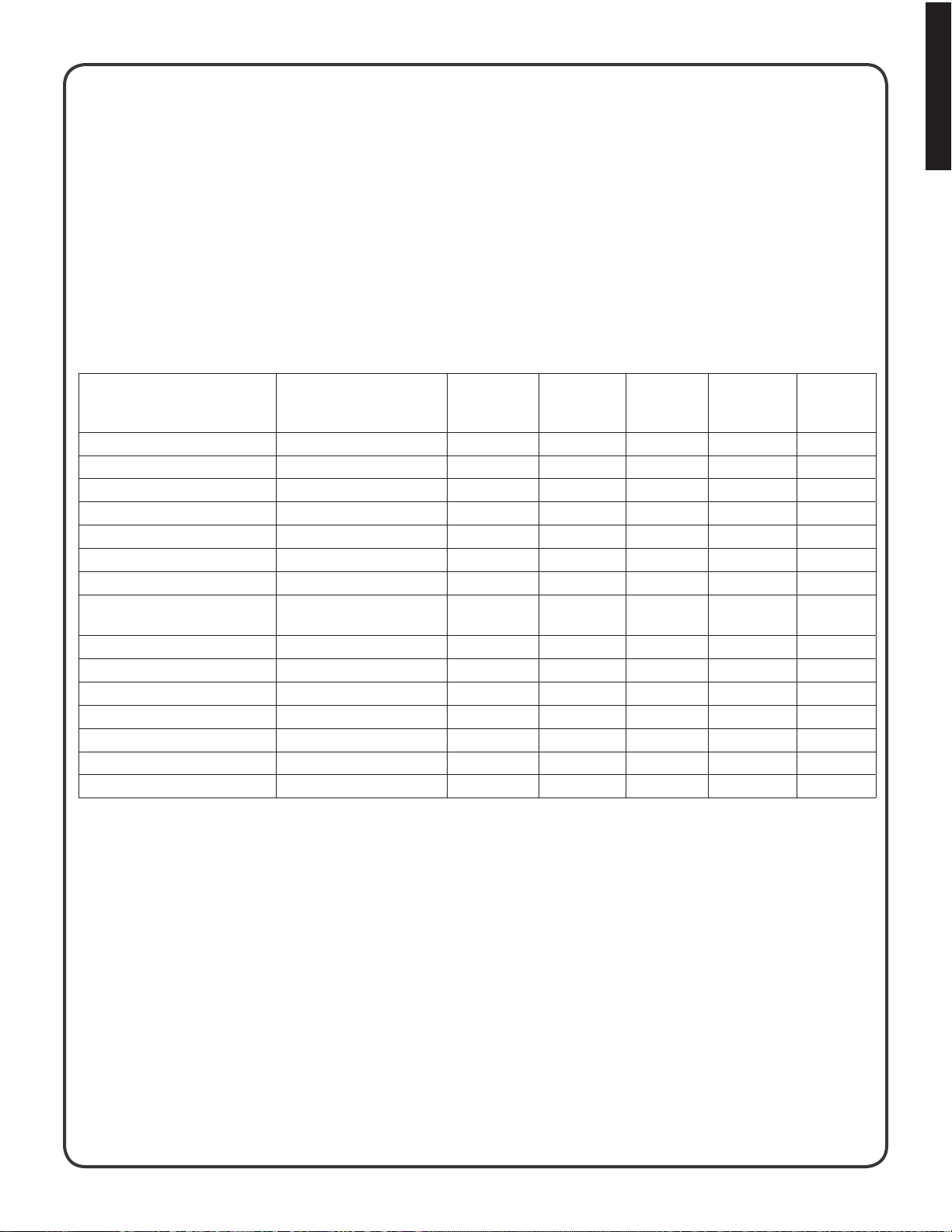

COMPONENT/SYSTEM MAINTENANCE

PROCEDURE

Air Filter Inspect/Clean 1 I / C * R *

Automatic Oiler Inspect/Adjust 1 I

Oil Filter Inspect/Replace 1 I / C *

Fuel System, leaks Inspect/Replace 1 I (1) * I (1) *

Fuel Filter Inspect 1 I *

Fuel Cap Gasket/O-ring Replace 1 R *

Guide Bar & oil holes Inspect/Clean/Lubricate 1 I / C * I

Saw Chain Inspect/Sharpen/

Replace/Tensioning

Sprocket Inspect/Replace 2 I *

Spark Plug Inspect/Clean 1 I / C/ R *

Cooling System Inspect/Clean 2 I / C

Mufer Spark Arrestor Inspect/Clean/Replace 2 I / C/ R *

Cylinder Exhaust Port Inspect/Clean/Decarbon 2 I / C

Recoil Starter Rope Inspect/Clean 1 I / C *

Screws/Nuts/Bolts Inspect/Tighten/Replace 1 I *

REQ’D

SKILL

LEVEL

2 I *

DAILY OR

BEFORE

USE

EVERY

REFUEL

3 MONTHS

OR 90

HOURS

YEARLY

English

“MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN”

IMPORTANT NOTE - Time intervals shown are maximum. Actual use and your experience will determine the frequency

of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

* Replacement is recommended based on the nding of damage or wear during inspection.

19

Page 20

English

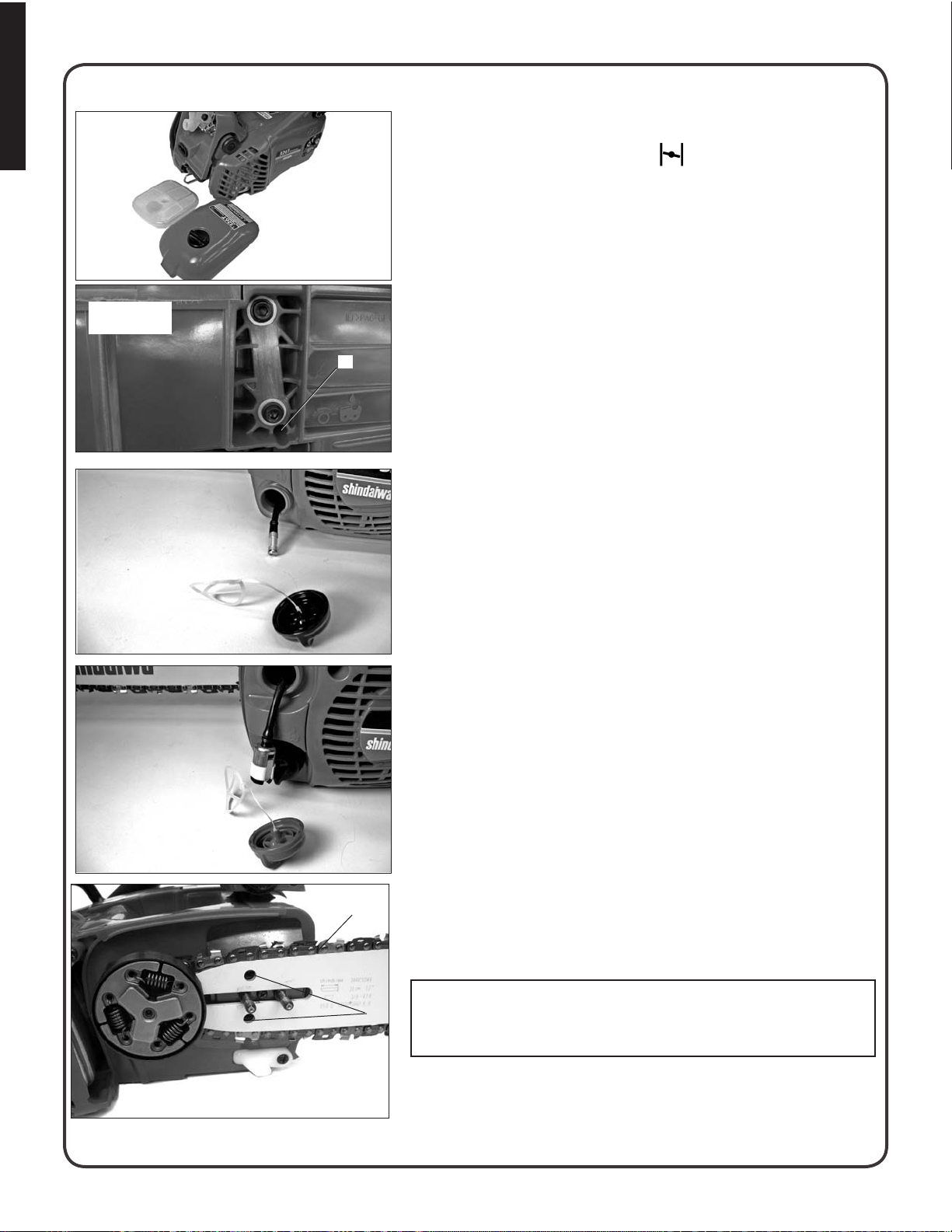

Maintenance, continued

Air lter

Automatic

oiler

Oil strainer

AIR FILTER

Close choke (Cold Start Position [1. ]). This prevents dirt from

entering the carburetor throat when the air lter is removed. Brush

accumulated dirt from air cleaner area.

2.

Remove air lter cover. Brush dirt from inside cover.

Remove air lter and lightly brush debris from lter. Replace lter if it 3.

is damaged, fuel soaked, very dirty , or deformed.

Install air lter cover.4.

AUTOMATIC OILER

The discharge volume of the automatic oiler is adjusted to 6 to 7 cc/ ■

D

min (@ 7000 rpm) prior to shipment from the factory .

Always check oil discharge when in use. ■

Turn adjusting screw (D) counter-clockwise to increase oil volume, ■

clockwise to decrease oil volume.

OIL STRAINER

Check periodically. ■

Do not allow dust to enter oil tank.1.

Clogged oil strainer will affect the normal lubricating system2.

Using a wire bent into the shape of a hook, pull strainer out 3.

through oil port and inspect strainer.

4.

If the strainer is dirty, clean with suitable cleaning uid.

If the inside of the oil tank is dirty, rinse with suitable cleaning uid. 5.

Fuel strainer

FUEL STRAINER

Do not allow dust to enter fuel tank. 1.

Clogged strainer will cause difculty in starting engine or abnor-2.

malities in engine performance.

3.

Using a wire bent into the shape of a hook, pull strainer out

through gas port, and inspect strainer.

4.

If the strainer is dirty, clean with suitable cleaning uid.

If the inside of the tank is dirty, rinse with suitable cleaning uid. 5.

GUIDE BARS AND OIL HOLES

Follow instructions for “Guide Bar and Saw Chain: Install/Remove”. ■

A

B

Clean after each use ■

Clean the grooves (A) of the guide bar with a small screwdriver. -

Clean oil holes (B) with a wire. -

NOTE:

Symmetrical shaped Guide Bars should be inverted each time the

chain is removed to extend guide bar life

20

Guide bars and oil holes

Page 21

Maintenance, continued

SPROCKET

English

Worn : 0.5 mm

A damaged sprocket (C) will cause premature damage or wear of ■

saw chain.

C

Clean sprocket, clutch and bar mount area before installation of bar. ■

Check sprocket when you install new chain. When outer diameter ■

of sprocket is worn 0.5mm (.020”) or more, replace it.

IMPORTANT

Some tree sap and resins are corrosive. Thoroughly wash the guide

bar and sprocket areas after each use, then coat metal parts with

light oil.

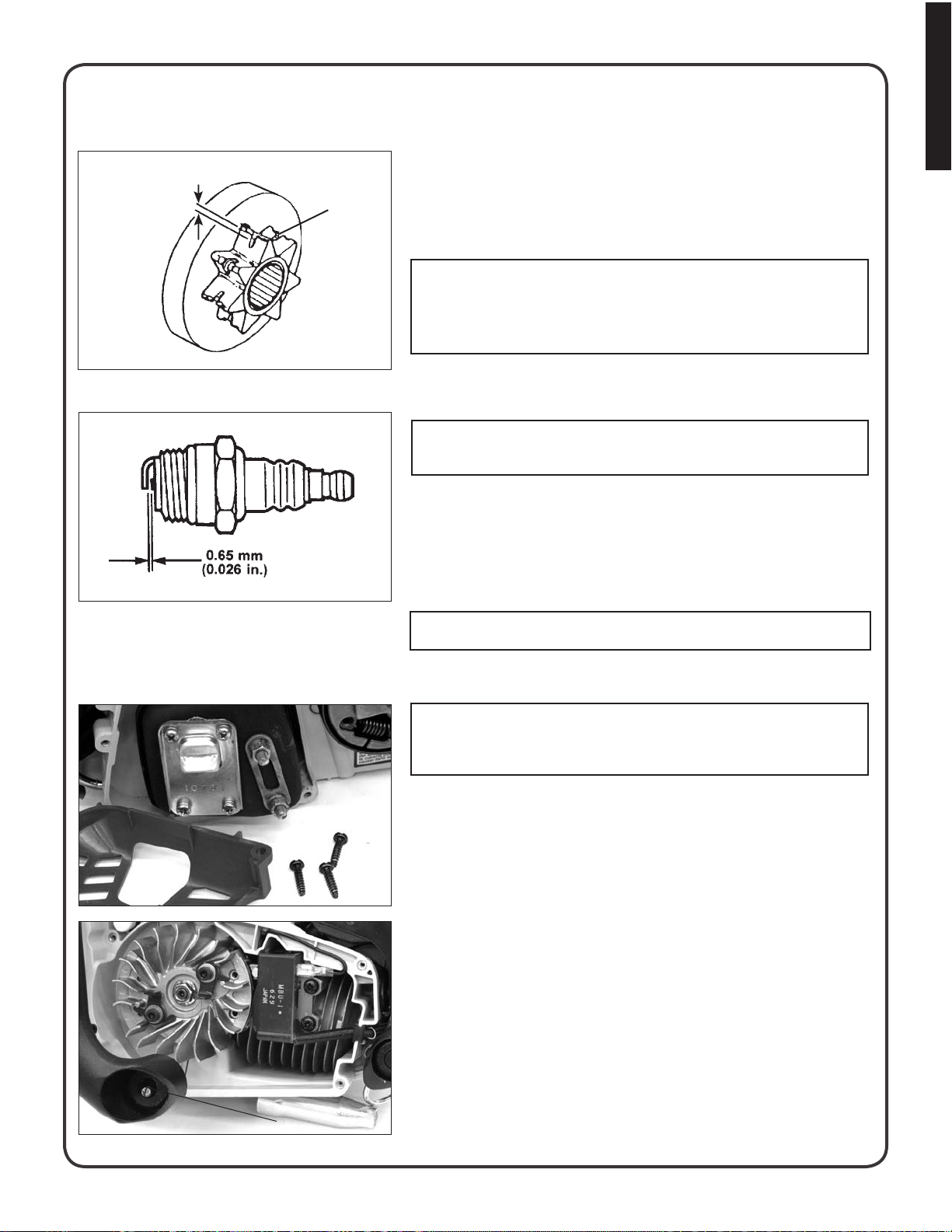

SPARK PLUG

Check periodically. ■

IMPORTANT: Use only NGK BPM-8Y spark plug (BPMR-8Y in

Canada) otherwise severe engine damage may occur.

Remove air cleaner cover.1.

Remove spark plug lead and spark plug.2.

Gap = 0.65 mm (0.026 in)3.

Replace if electrode is worn, or if the insulator is fouled by oil or 4.

other deposits

5.

Torque = 150 – 170 kg/cm (130 – 150 in. lb.)

IMPORTANT Do not over-torque

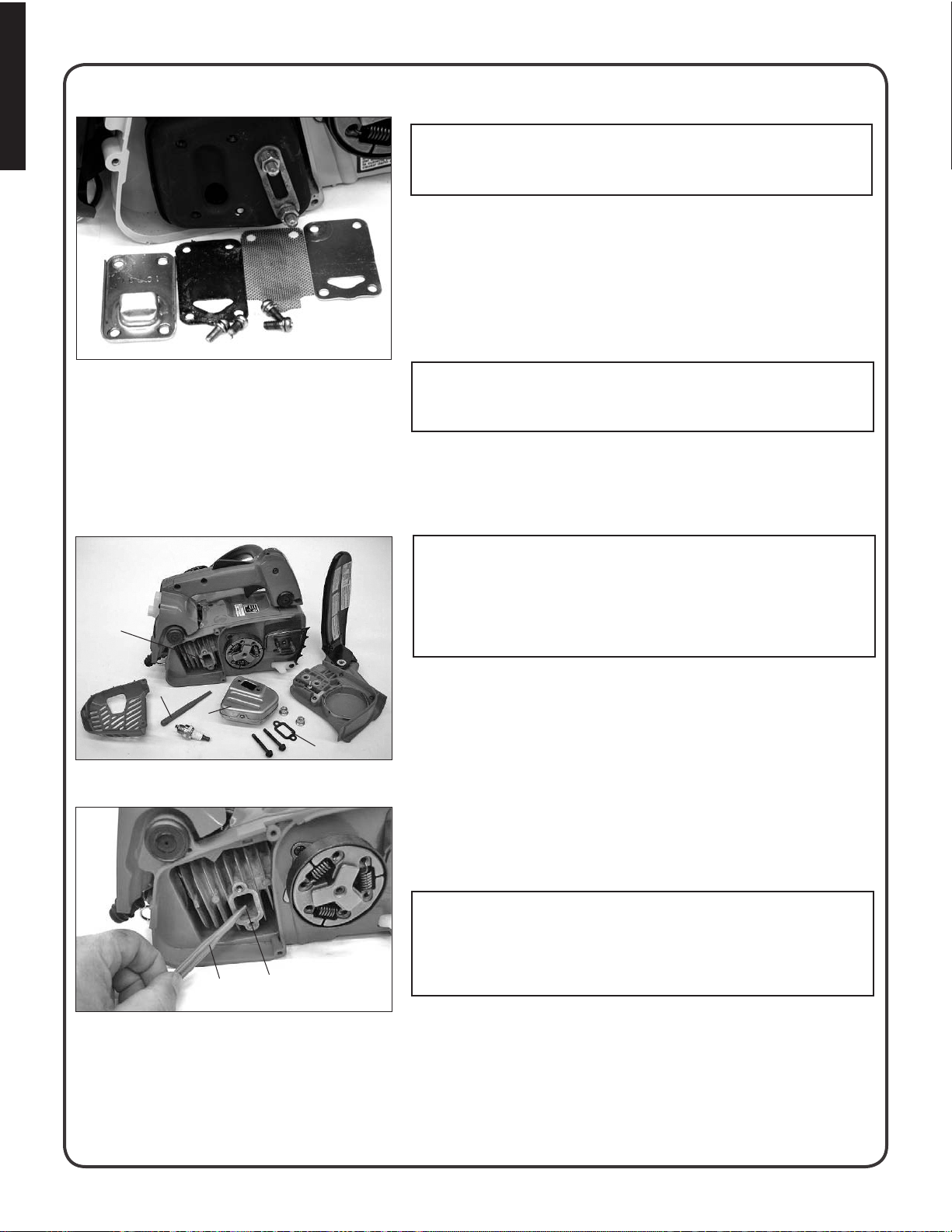

COOLING SYSTEM CLEANING

NOTE

See “Guide Bar and Saw Chain-Install/Remove Instructions for

sprocket guard removal/replacement instructions.

Mufer Side

Remove air lter cover and remove spark plug lead. 1.

Remove two guide bar nuts and remove sprocket guard. 2.

Remove three mufer cover screws and remove mufer cover. 3.

Using a stiff bristle cleaning brush (do not use a metal brush), 4.

remove debris from cylinder ns in mufer area.

5.

Assemble components in reverse order

Starter Side

Remove air lter cover and remove spark plug lead.

1.

Remove plastic plug in side handle mount (D), and remove side 2.

handle mounting screw.

3.

Remove four starter cover screws and remove starter cover.

Using a stiff bristle cleaning brush (do not use a metal brush), 4.

remove debris from ywheel and ignition coil area.

5.

D

Assemble components in reverse order.

21

Page 22

English

Maintenance, continued

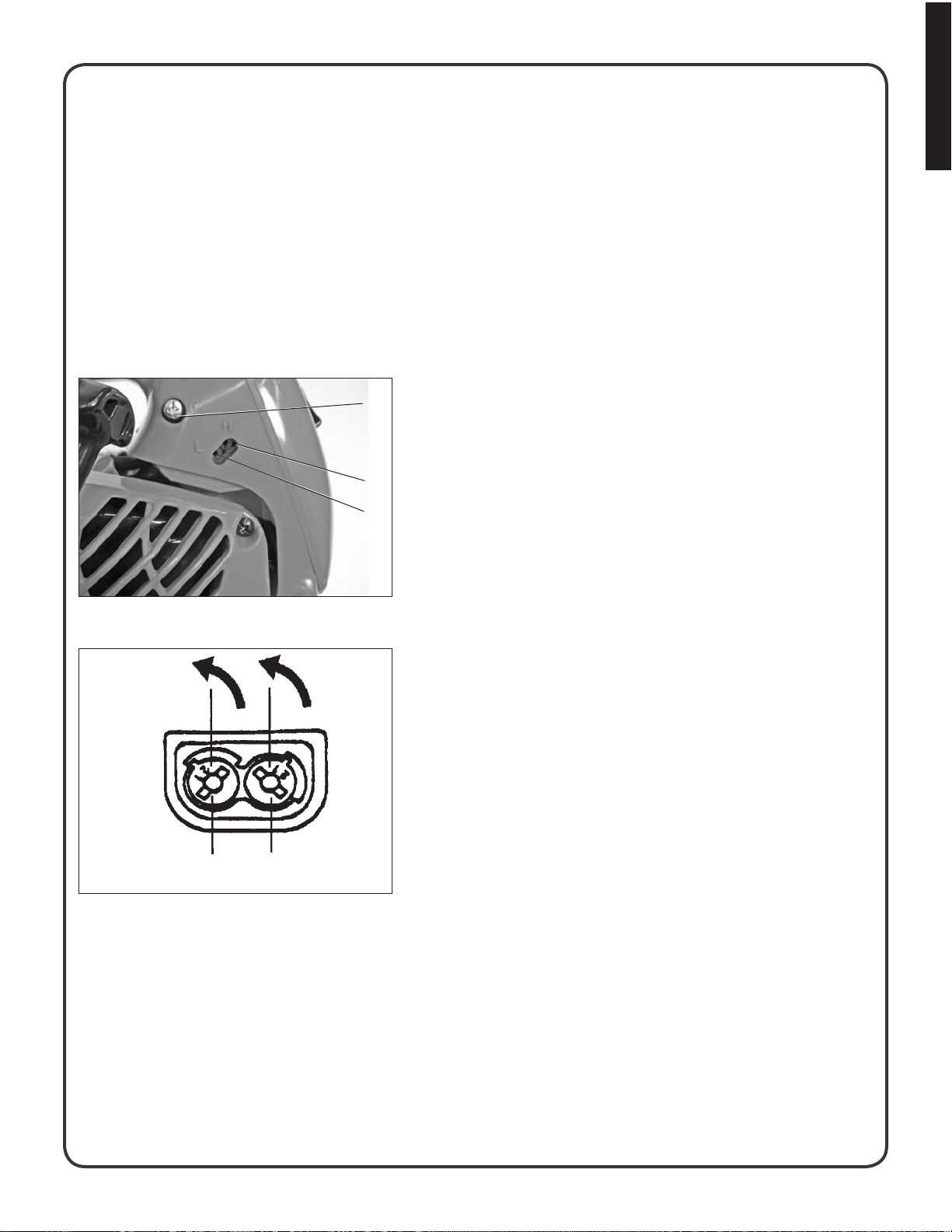

MUFFLER SPARK ARRESTER

IMPORTANT: Carbon deposits in mufer will cause a drop in engine

output and overheating. Spark arrester screen must be checked

periodically.

Remove air lter cover and remove spark plug lead. 1.

Remove two guide bar nuts and remove sprocket guard. 2.

Remove three mufer cover screws and remove mufer cover. 3.

Remove spark arrestor screen cover, gaskets, and screen from 4.

mufer body.

5.

Clean carbon deposits from mufer components.

Replace screen if it is cracked, plugged, or has holes burned through. 6.

NOTE: When cleaning carbon deposit, be careful not to damage the

catalytic element inside mufer.

Assemble components in reverse order. 7.

CYLINDER ExHAUST PORT

IMPORTANT :

cleaned of excess carbon every 3 months or 90 hours of operation in

order to maintain this engine within the emissions durability period.

Shindaiwa strongly recommends that you return your unit to your Shin-

D

C

A

B

daiwa dealer for this important maintenance service.

Exhaust Port Cleaning - Level 2

Tools required: Wood or plastic scraper, cross-head (Philips) screwdriver, 4 and 5 mm hex wrench

Parts Required: (as needed) mufer gasket

Remove spark plug lead from spark plug, and remove mufer

1.

cover (3 screws).

2.

Place piston at top dead center. Remove mufer ( A) and mufer

gasket (B ).

3.

Use a wood or plastic scraping tool (C) to clean deposits from cylinder exhaust port (D).

IMPORTANT

■

Never use a metal tool to scrape carbon from the exhaust port.

Do not scratch the cylinder or piston when cleaning the exhaust ■

C

D

port. Do not allow carbon particles to enter the cylinder.

The cylinder exhaust port must be inspected and

22

Inspect mufer gasket, and replace if damaged.4.

Install mufer gasket and mufer.5.

Install mufer cover and attach spark plug lead.6.

Replace the three mufer cover screws securely. If a torque 7.

wrench is available, torque the mufer cover screws to 10 - 20 kgf-

cm (1 - 2 N-m).

Page 23

Maintenance, continued

CARBUERATOR ADJUSTMENT

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel break-in before carburetor adjustments can be

made. During the break-in period your engine performance will increase and exhaust emissions will stabilize. Idle speed

can be adjusted as required.

BEFORE MAKING ADJUSTMENTS:

1.

The correct spark plug must be clean and properly gapped.

The air lter element must be clean and properly installed.2.

The mufer spark arrestor screen and exhaust port must be clear of carbon.3.

The standard bar and chain combination (refer to the section, Technical Data) must be installed to the power head, 4.

and properly tensioned.

LOW ALTITUDE ADJUSTMENT

Engines that have been adjusted to operate at high altitudes must be

readjusted to operate properly at altitudes below 1100 feet.

C

1.

Start engine and run for several minutes to reach operating

temperature.

2.

Stop engine.

A

B

Start engine and turn the high-speed needle (A) rich (CCW) until 3.

the engine runs between 13,500 and 14,500 RPM. Then turn the

low-speed needle (B) rich (CCW) until the engine does not hesitate when accelerated.

DO NOT REMOVE LIMITER CAPS!

4.

Idle Speed Adjustment.

Turn “idle” speed adjustment screw (C) CW until the saw chain

begins to move, then turn the screw CCW until saw chain stops

moving. Turn screw CCW an additional 1/4 turn.

5.

Accelerate to full throttle for 2-3 seconds to clear excess fuel from

engine then return to idle. Accelerate to full throttle to check for

smooth transition from idle to full throttle. If engine stops or stalls

after full warm-up return the unit to your authorized Shindaiwa

dealer for adjustment.

English

low

high

HIGH ALTITUDE ADJUSTMENT

High altitude adjustment may be required for proper operation of this

engine above 1100 feet.

1.

Start engine and run for several minutes to reach operating

temperature.

2.

Stop engine.

Start engine and turn the high speed needle (A) lean (CW) until 3.

the engine runs between 13,500 and 14,500 RPM. Then turn the

low speed needle lean (B) (CW) until the engine does not hesitate when accelerated.

DO NOT REMOVE LIMITER CAPS!

4.

Idle Speed Adjustment.

Turn “idle” speed adjustment screw (C) CW until the saw chain

begins to move, then turn the screw CCW until saw chain stops

moving. Turn screw CCW an additional 1/4 turn.

5.

Accelerate to full throttle for 2-3 seconds to clear excess fuel from

engine then return to idle. Accelerate to full throttle to check for

smooth transition from idle to full throttle. If engine stops or stalls

after full warm-up return the unit to your authorized Shindaiwa

dealer for adjustment.

23

Page 24

English

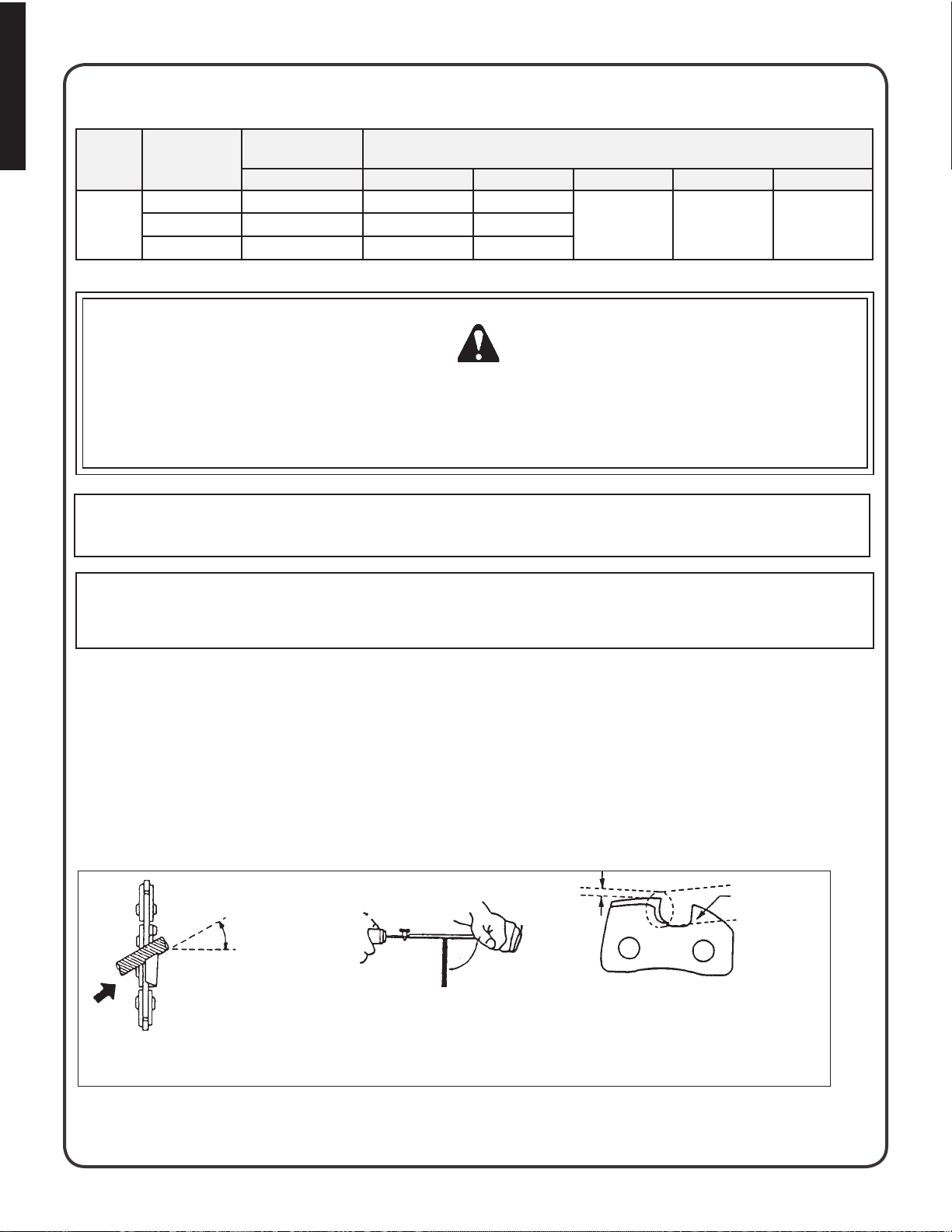

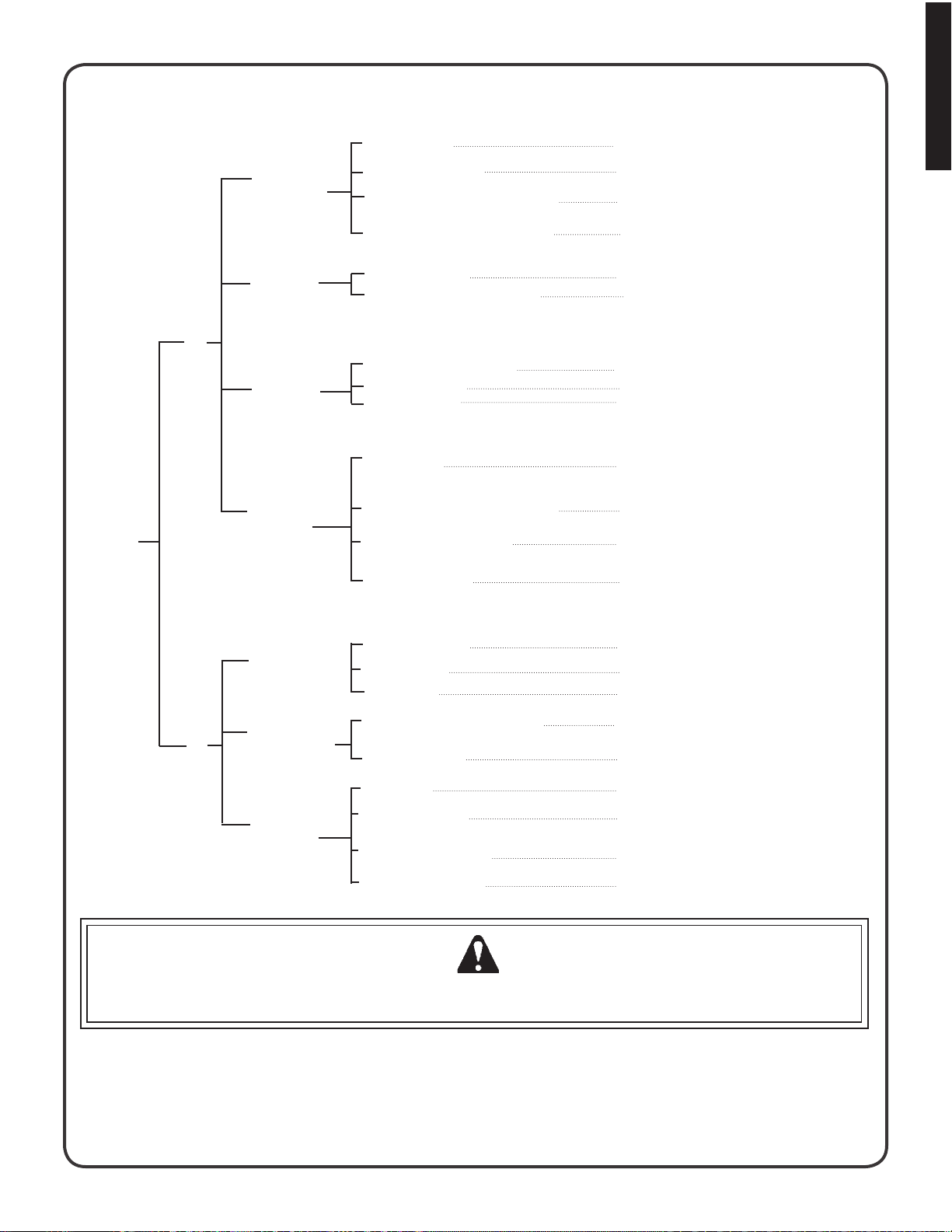

Ch a i n a n D gu i D e ba R Co m b i n a t i o n s

The following combinations may be used on 326T.

Model Bar Length Low Kickback

Guard Bar

Bar P/N Chain P/N Links Type Pitch Gauge

12” 120GPEA041 91VG-45 45

326T

16” 160GPEA041 91VG-57 57

*Reduced nose radius symmetrical bars (OREGON name — Double Guard)

WARNING DANGER

Use of replacement saw chain and/or guide bar other than that specied, or operation without the “tip guard” in place,

may cause severe kickback resulting in serious injury.

Only use saw chain designated as “LOW-KICKBACK” that meets the ANSI B175.1-2000 Standard and the guide bar

specied.

Low Kickback Saw Chain

91VG 3/8” .05014” 140GPEA041 91VG-52 52

IMPORTANT

Chain and guide bar gauge size must be identical. Use Bar/Chain combinations shown in table above.

IMPORTANT

If your kick guard is damaged or lost, contact your Shindaiwa dealer for a replacement.

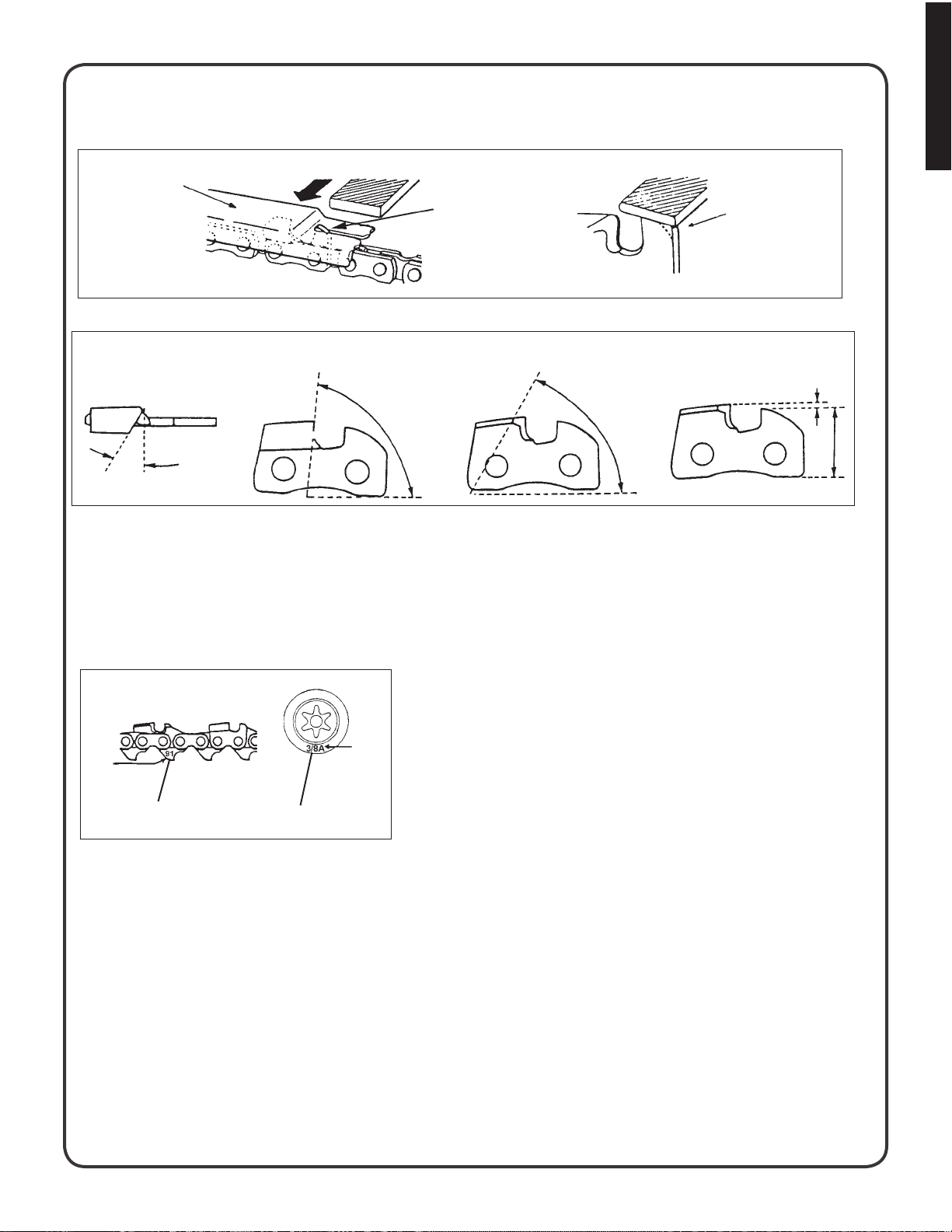

SETTING THE SAW CHAIN

For setting saw chains, round le (4 mm ø: 5/32”) and at le are used.

To keep correct position and correct angle, use the le holder. ■

Round le and at le are available from your Shindaiwa Dealer. -

File cutters as below. ■

Type : 91VG

30°

Keep this angle

90°

1/5

Depth gauge

24

PUSH FILE AS SHOWN

HOLD FILE HOLDER LEVEL

ONE FIFTH OF FILE DIAMETER REMAINS

To sharpen other type chain, follow chain manufacturer’s instructions

ABOVE CUTTER EDGE

Page 25

Place the depth gauge tool rmly on guide bar so that depth gauge protrudes. Then le top of depth gauge with ■

at le until at with top of the gauge tool.

-

Be sure to round off the front edge of the depth gauge.

Depth gauge tool

Properly led cutters are shown below. ■

Remove

until at

with tool

Round off

the edge

English

Top plate angle

30°

Side plate angle

80°

Top plate cutting angle

60°

Depth gauge

0.64 mm (0.025 in.)

When setting of the chain is nished, soak it in oil and wash away lings completely before using. ■

When chain has been led on the bar, supply sufcient oil to it, rotate the chain slowly to wash away the lings ■

before using again.

■

If the chain saw is operated with lings clogged in the groove, the saw chain and the guide bar will be damaged

prematurely

■

If the saw chain becomes soiled with resin, for instance, clean it with kerosene and soak it in oil.

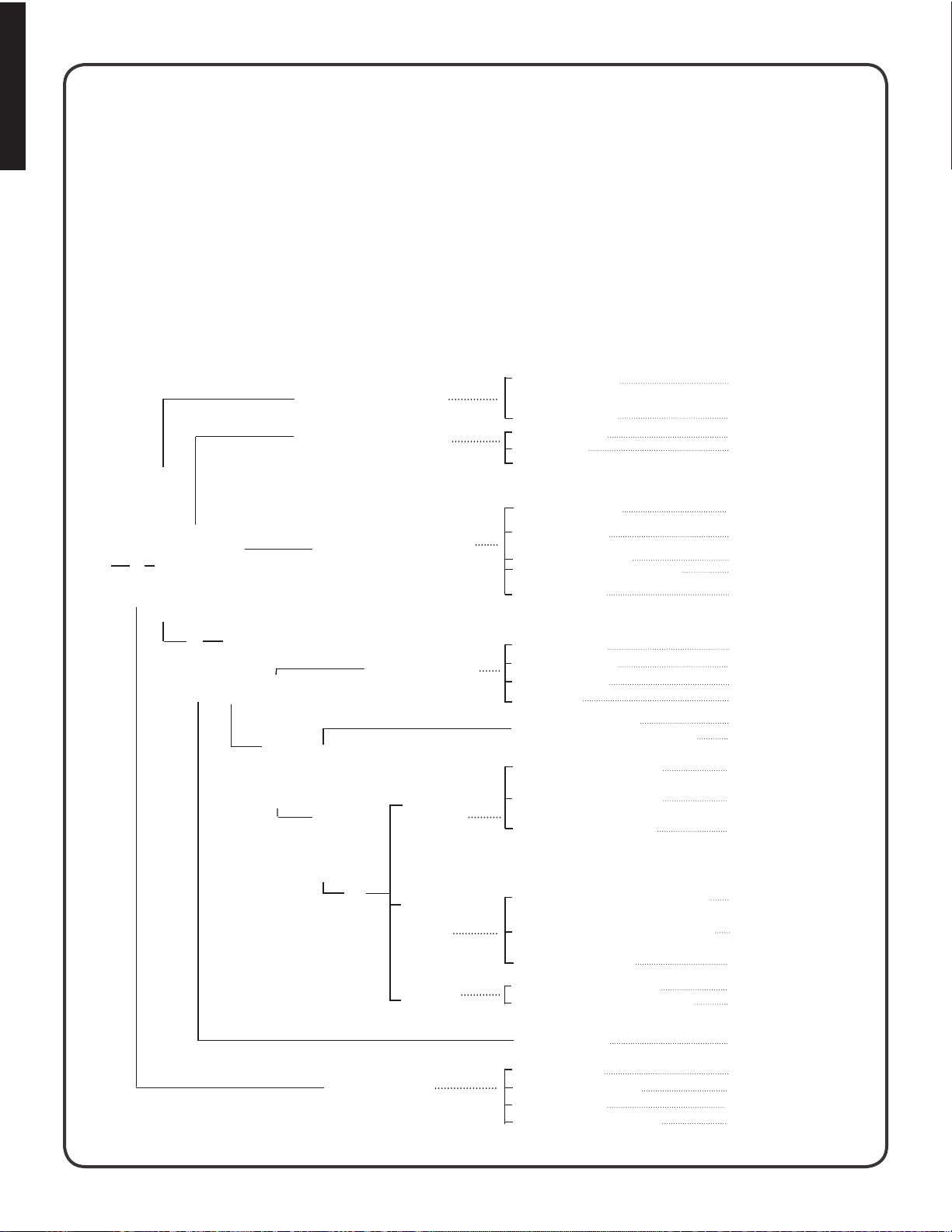

(DRIVE LINK)

(SPROCKET)

CHAIN TYPE AND SPROCKET PITCH

Saw chain should be used with corresponding pitched sprocket. To

identify chain type and pitch of sprocket, check as follows.

Sprocket

Number

indicates

Chain type

Pitch

91

A

B

3/8A

Chain type number (A) is stamped on drive link. ■

Sprocket pitch (B) is stamped on clutch drum. ■

Parallel

Inspect and adjust every part of the chain saw. ■

Completely clean every part, and repair, if necessary. ■

Apply thin coating of oil on metal parts to prevent corrosion. -

Drain fuel tank, pull starter slowly a few times to drain fuel from carburetor. -

Pour a small amount of clean two-stroke oil into spark plug hole, pull starter 2 to 3 times, then leave the piston at TOP ■

DEAD CENTER.

■

Store in a dry area, free from dust.

st o R a g e af t e R us e

25

Page 26

English

tR o u b l e s h o o t i n g

Poor performance of the engine and/or cutting mechanism can normally be prevented by carefully following these

instructions.

Poor performance can easily be corrected even by a beginner.

When the engine does not function properly check the following three (3) points rst.

Is the engine compression adequate?

■

Is fuel system in good condition and is enough fuel being supplied? ■

Is electrical system in good condition and is spark plug operating normally? ■

When there is serious trouble with the unit, do not try to repair it yourself but have your distributor or dealer do it for you.

For detailed TROUBLESHOOTING refer to tables 1 and 2. Locate the problem on the following charts and repair as

necessary.

Table 1

Engine cranks

There is fuel in the tank

Engine does not start (or, is difcult to start)

Fuel is not reaching carbuerator

Fuel is not reaching cylinder

No spark at high tension cord end

Fuel is reaching cylinder

Fuel is reaching carburetor

There is spark at high

tension cord end

No spark at plug

Fuel does not

keep running

Fuel strainer clogged

Fuel pipe clogged

Suction insufcient

Strainer clogged

Carburetor out of order

C.D.I. module defective

Ignition coil defective

Wire connection defective

High-tension cord connection defective

Switch is grounded

Insulator cracked

Spark gap incorrect

Covered with carbon

Fouled with fuel

Starting procedures incorrect

Low and high speed needle setting too lean

Metering lever spring too strong

Fuel pump diaphragm defective

Fuel passage clogged with dust

Clean.

Clean.

Make sufcient.

Clean.

Disassemble and check.

Remove and replace.

Remove and replace.

Reconnect.

Repair as necessary.

Switch on.

Replace plug.

Adjust.

Clean or replace.

Clean or replace.

Start correctly.

Readjust.

Readjust.

Replace.

Disassemble and clean.

26

There is spark at plug

Acceleration and

low speed function defective

Starting procedures correct

Carburetor

overow

Engine does not crank

Fuel leaking from xing surfaces of carburetor

Air valve, fuel tank cap does not work normally

Fuel pump does not operate

Fuel inlet needle clogged with dust

Metering spring not placed in dent of lever

Mufer sticky with fuel

Bearing damaged

Piston and/or cylinder deized

Crankshaft worn

Crankshaft contacting crankcase

Retighten all screws.

Replace or Clean.

Check impulse drilling.

Clean.

Correct.

Fuel mixture is too rich

Disassemble and replace.

Disassemble and replace.

Disassemble and replace.

Disassemble and replace.

Page 27

Table 2

English

Engine

overheated

Firing function

defective

Carburetor

Ouput (engine speed) insufcient

defective

Other

troubles

Improper fuel used

Spark plug defective (worn)

As cooling ns clogged, air does not pass well

Excessive deposits in combustion chamber

Plug damaged or fouled

Combustion poor due to defective wiring

High-speed needle setting incorrect

Carburetor overow

Air cleaner clogged

Compression insufcient (piston ring stuck or

worn out)

Cylinder chromium plating peeled or worn out

Exhaust port clogged with carbon

Throttle is not fully open

Use fuel with correct mixing ratio. Never use

gasoline of poor quality.

Replace.

Clean ns.

Disassemble and remove carbon.

Replace or clean.

Check wiring.

Readjust.

Refer to Table 1.

Clean as necessary.

Disassemble, check and replace if

necessary.

Replace cylinder

Clean as necessary.

Readjust.

Engine keeps running, but chain does not cut clean

Output (engine speed) sufcient

Chain does not cut

clean

Chain stops

(Clutch slips)

Chain poorly

lubricated

Chain tension incorrect

Chain wrongly set

Depth incorrect

Chain saw pressed against tree too rmly

Clutch shoe worn out

No oil in tank

Oil delivery incorrect

Oil contaminated with dust

Oil viscosity inappropriate

Adjust.

Set correctly.

Readjust.

Press lightly.

Replace.

Rell.

Adjust.

Rinse tank and ll with new oil..

Use oil with correct viscosity for summer or winter.

WARNING DANGER

Fuel vapors are extremely ammable and may cause re and/or explosion. Never test for ignition spark by

grounding spark plug near cylinder plug hole, otherwise serious personal injury may result.

27

Page 28

English

Co R R e C t us e o f Ch a i n bR a k e

The installation of a chain brake may be mandatory by law or as stipulated by insurance regulations in your area of opera-

tion. You should inquire through local government ofces, your employer or your local dealer to ensure that your chain saw

conforms to the required safety standard. Shindaiwa chain brakes have been designed and tested to comply with international safety standards as follows.

■

ANSI Standard B175.1-2000 Safety Requirement for chain saws

CSA Standard Z 62.1 CHAIN SAWS ■

WARNING DANGER

ANSI Standard B175.1-2000 stipulates that the brake shall stop the chain in 0.15 seconds maximum (.12 sec avg)

at full throttle. It is the responsibility of the Owner/Operator to ensure that the brake is serviced, adjusted and tested

strictly in accordance with the instructions as detailed herein in order to ensure that the brake performance is maintained in compliance with the Standard B175.1-2000.

Kickback Motion:

When the bar nose hits another tree, etc.

Improper thrust cutting.

INSTALLATION

Shindaiwa recommends that the chain brake should be serviced by an authorized Shindaiwa servicing dealer. ■

OPERATION

Set the lever in the released position before starting to cut. ■

If the brake is tripped by kick back reaction, the chain will stop. Immediately release the throttle to avoid possible dam- ■

age to the engine or clutch.

Do not attempt to operate the engine with the brake engaged.

■

Function:

When the lever is pushed forward, chain

brake instantly works to stop the chain

Release:

When the lever is fully pulled toward the

operator, brake is released.

TESTING THE BRAKE

Start the engine on a solid level surface and run at a fast idle until warm. ■

Hold the saw rmly by the handles and accelerate the engine to a fast idle. ■

Slowly operate the chain brake lever while holding the saw rmly on the ground. When the brake lever trips, the chain ■

should stop. Immediately release the throttle trigger.

IMPORTANT: Do not allow the saw to tip forward in order to avoid damage to the chain.

If the chain does not stop, immediately return the saw to your authorized Shindaiwa dealer for repair.

28

Page 29

Wa R R a n t y st a t e m e n t

Shindaiwa Corporation

EPA PHASE 2 / CALIFORNIA TIER III EMISSION

CONTROL WARRANTY STATEMENT - WARRANTY RIGHTS AND OBLIGATIONS

The Environmental Protection Agency (EPA) and the California Air

Resources Board (C.A.R.B.) and Shindaiwa Inc. are pleased to

explain the emission control system warranty on your EPA Phase 2

/ C.A.R.B. Tier III model year 2007 and later small off road engine

(SORE). New small off road engines must be designed, built and

equipped to meet stringent EPA and C.A.R.B. anti-smog standards.

Shindaiwa Inc. warrants the emission control system on your small

off road engine for the periods of time listed below provided there has

been no abuse, neglect or improper maintenance of your small off

road engine.

Your emission control system may include parts such as: carburetor/

fuel injected system, ignition system, catalytic converter, fuel tank,

fuel lines, fuel caps, valves, canisters, lters vapor hoses, clamps

connectors, and other associated components. For certain handheld products with engines less than or equal to 80cc displacement,

the fuel tank is subject to the C.A.R.B. evaporative emission control

warranty requirements of this section. Contact Shindaiwa Inc. for the

models covered under the C.A.R.B. evaporative emission regulations.

Where a warrantable condition exists, Shindaiwa Inc. or its authorized

service representative will repair your small off road engine at no cost

to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE:

The 2007 and later small off road engines are warranted for two years

for certain emission related parts. If any emission-related part on your

engine is defective, the part will be repaired or replaced by Shindaiwa

Inc. or its authorized service representative.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off road engine owner, you are responsible for

■

the performance of the required maintenance listed in your

Operator’s Manual. Shindaiwa Inc. recommends that you retain all

receipts covering maintenance on your small off road engine, but

Shindaiwa Inc. cannot deny warranty solely for the lack of receipts

or for your failure to ensure the performance of all scheduled

maintenance.

As the small off road engine owner, you should however be aware

■

that Shindaiwa Inc. may deny you warranty coverage if your small

off road engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modications.

You are responsible for presenting your small off road engine to

Shindaiwa Inc.’s authorized service center as soon as a problem

exists. The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you can contact Shindaiwa Inc. at 800-521-7733 or

www.shindaiwa.com

EPA PHASE 2 / CALIFORNIA TIER III EMISSIONS DEFECT

WARRANTY ExPLANATION

This is additional detailed information about the EPA PHASE 2/

CALIFORNIA TIER III EMISSIONS DEFECT WARRANTY for your

small off road engine.

WHAT DOES THIS WARRANTY COVER?

Shindaiwa Inc. warrants that your unit was designed, built and

equipped to conform with applicable EPA and California emissions

standards and that your unit is free from defects in material and

workmanship that would cause it to fail to conform with applicable

requirements within two (2) years. The warranty period begins on

the date the product is delivered to a retail purchaser. This is your

emission control system DEFECTS WARRANTY.

HOW WILL A COVERED PART BE CORRECTED?

If there is a defect in a part covered by this warranty, Shindaiwa Inc.’s

authorized service dealer will correct the defect.

You will not have to pay anything to have the part adjusted, repaired or

replaced. This includes any labor and diagnosis for warranted repairs

performed by the dealer. In addition, engine parts not expressly

covered under this warranty but whose failure is a result of a failure of

a covered part will be warranted.

Emissions System repairs covered under this warranty should be

completed in a reasonable time, not to exceed 30 days.

IMPORTANT

If the diagnosis reveals no defect, the emission defect warranty does

not apply.

WHAT PARTS ARE COVERED BY THE EPA PHASE 2/CALIFORNIA

TIER III 2007 & LATER SMALL OFF ROAD ENGINE EMISSIONS

DEFECT WARRANTY?

Any emission related part not scheduled for, “required

■

maintenance” (See Operator’s Manual, “SERVICE

MAINTENANCE SCHEDULE”) will be repaired or replaced

within the warranty period. The repaired or replaced part will be

warranted for the remaining Emissions Defect warranty period.

Any emission related part scheduled for replacement during

■

“required maintenance” (See Operator’s Manual, “SERVICE

MAINTENANCE SCHEDULE”) is warranted for the period of time

prior to the rst scheduled replacement point for that part. Any

such part repaired or replaced under warranty shall be warranted

for the remainder of the period prior to the rst scheduled

replacement point for that part.

Any Shindaiwa Inc. approved replacement part may be used in the

■

performance of any warranty maintenance or repairs on emissionrelated parts, and must be provided without charge if the part is

still under warranty.

Any replacement part that is equivalent in performance and

■

durability may be used in non-warranty maintenance or repairs,

and shall not reduce the warranty obligations of Shindaiwa Inc.

The owner is responsible for the performance of the required

■

maintenance described in the operator’s manual.

SPECIFIC EMISSION RELATED WARRANTED PARTS:

Choke

Carburetor (complete assembly or replaceable components)

Fuel Injection Assembly or replaceable components

Air Filter

Electronic Ignition System

Spark Plug

Catalytic Converter / Mufer Assembly

Fuel Tank (CARB only)

WHAT IS NOT COVERED BY THE EPA PHASE 2/CALIFORNIA

TIER III 2007 & LATER SMALL OFF ROAD ENGINE EMISSIONS

DEFECT WARRANTY?

Any failure caused by abuse, neglect, improper maintenance.

■

Any failure caused by unapproved modications, use of ■

unapproved add-on parts/modied parts or unapproved

accessories.

English

29

Page 30

NOTES

Shindaiwa Inc.

11975 S.W. Herman Rd.

Tualatin, Oregon 97062 USA

Telephone: 503 692-3070

Fax: 503 692-6696

www.shindaiwa.com

Shindaiwa Corporation

Head Ofce:

6-2-11, Ozuka-Nishi

Asaminami-Ku, Hiroshima

731-3167, Japan

Telephone: 81-82-849-2220

Fax: 81-82-849-2481

©2008 Shindaiwa, Inc.

Part Number 82085

Revision 8/08

Shindaiwa is a registered trademark of Shindaiwa, Inc.

Specications subject to change without notice.

Page 31

MANUAL DEL PROPIETARIO Y USUARIO DE SHINDAIWA

326T MOTOSIERRA

¡ADVERTENCIA!

Lea detenidamente este manual y familiarícese con su contenido.

Esta máquina está diseñada para cortar madera y viga. Utilícela únicamente para el propósito designado.

Número de parte 82085 Revisión 8/08

Page 32

Español

Re g l a s Pa R a l a OP e R a c i ó n se g u R a

A. Precaución De Seguridad Para El Contragolpe Para Los Usuarios De La Sierra De Cadena

ADVERTENCIA!

EL CONTRAGOLPE se puede producir cuando la nariz

o la punta de la barra de guía toca un objeto, o cuando

la madera obstruye y comprime la sierra de cadena al

cortar

En algunos casos, el contacto con la punta puede producir una REACCION de contramarcha rapidísima haciendo saltar la barra de guía hacia arriba y de vuelta

hacia el operador. Si se comprime la sierra de cadena a

lo largo de la parte superior de la barra de guía puede

empujaria rápidamenta hacia atrás hacia el operador.

Cualquiera de estas reacciones puede hacer que se

pierda el control de la sierra, lo que puede resultar en

graves daños personale.

El dispositivo Kick Guard® no está instala en la espada

cuando se compra una sierra de cadena Shindaiwa. El

protector Kick Guard® puede usarse en la mayoría de

las operaciones de corte, y se recomienda especialmente

para principiantes, propietarios de casas o personas que

vayan a usar la sierra de cadena por primera vez.

No confíe exclusivamente sobre los dispositivos de seguridad incorporó en su vio. Como un usuario de motosierra, usted debería tomar varios pasos para guardar sus

empleos de recorte libres del accidente o la herida.

1.

Si se sabe básicamente lo que es el contragolpe,

se puede reducir o eliminar el elemento de sorpresa. Las sorpresas repentinas contribuyen a los

accidentes.

Agarre la sierra rmemente y mantengala asi con 2.

ambas manos. Cuando el motor está funcionando,

use la mano derecha sobre el mango trasero y la

mano izquierda sobre el mango delantero. Agarrela

rmemente, con los pulgares y los dedos rodeando

los mangos de la sierra de cadena. Si agarra la sierra

rmemente se ayuda a reducir el contragolpe y a mantener el control de está. No la suelte.

Asegurese que el area en donde está cortando no 3.

tenga obstrucciones. No deje que la nariz de la barra

de quia se ponga en contacto con un leno, una rama

o cualquier otra obstruccion contra la que se pueda

golpear mientras se opera la sierra

4.

Corte a velocidades del motor altas.

No trate de alcanzar mas alia de lo que es posible 5.

alcanzar ni corte mas arriba de la altura del hombro.

Siga las instrucciones del fabricante para la aladura 6.

y el mantenimiento de la sierra de cadena.

7.

Use solamente las barras y cadenas de repuesto

especicadas por el fabricante, o su equivalente.

B. Otras Precauciones De Seguridad

¡No opere una sierra de cadena con una sola mano! 1.

Si se opera con una mano, el operador, los ayudantes, los espectadoes o cualquera combinación

de estas personas pueden sufrir daños graves. La

sierra de cadena está hecha para ser usada con las

dos manos.

2.

No opere una sierra de cadena cuando esté

fatigado.

3.

Use calzado de seguridad, ropa ceñida, guantes protectores y dispositivos de protección para los ojos,

los oídos y la cabeza. Lleve una cubierta protectora

para contener el cabello largo.

4.

Tenga cuidado cuando maneje el combustible.

Mueva la sierra de cadena a por lo menos 3 metros (10 pies) del punto de abastecimiento antes de

hacer arrancar el motor.

5.

No permita que otras personas estén cerca de la

sierra de cadena cuando la haga arrancar o corte

con élla. Mantenga a los espectadores y a los animales fuera del área de trabajo.

6.

No empiece a cortar hasta que tenga un área de trabajo despejada, una base segura para pisar y haya

planeado un camino de retirada del árbol que va a

caer.

7.

Mantenga todas las partes de su cuerpo lejos de la

sierra de cadena cuando el motor está funcionando.

8.

Antes de hacer arrancar el motor, asegúrese que la

cadena de la sierra no esté en contacto con ninguna

cosa.

9.

Transporte la sierra de cadena con el motor

detenido, con la barra de guía y la cadena de la

sierra hacia atrás y con el silenciador alejado de su

cuerpo.

10.

No opere una sierra de cadena que está dañada,

adjustada incorrectamente o que no está montada

completa y rmemente. Asegúrese que la cadena

de la sierra deja de moverse cuando se suelta el

gatillo del control de la aceleración.

SP_2

Page 33

Apague el motor antes de dejar la sierra de cadena en 11.

alguna parte.

12.

Tenga mucho cuidado cuando corte matorrales de

tamaño pequeño y árboles jóvenes, porque el material más ligero se puede coger en la cadena de la sierra

y serlanzado contra Ud. o lo puede hacer perder el

equilibrio.

13.

Cuando corte una rama que está bajo tensión, esté

alerta por si salta hacia átras, para que no lo golpee

cuando se libera la tensión en las bras de madera.

14.

Mantenga los mangos secos, limpios y sin aceite o

mezcla de combustible.

15.

Opere la sierra de cadena solamente en áreas bien

ventiladas.

16.

No opere la sierra de cadena en un árbol, a menos

que haya sido entrenado especialmente para hacerlo.

ADVERTENCIA PELIGRO

Todo el servicio de la sierra de cadena, a excepción de 17.

los artículos enumerados en las instrucciones de mantenimiento del manual del Instruccione, debe ser efectuado

por personal de servicio para la sierra de cadena competente. (Por Ejemplo, si se usan herramientas inadecuadas para remover el volante, o si se usa una herramienta

ínadecuada para sostenerlo mientras se remueve el

embrague, se puede producir un dano estructural en éste

lo que subsecuentemente puede hacer que éste se rompa.

Cuando transporte su sierra de cadena, use la funda 18.

de la guía de la barra apropiada.

Los silenciadoes del amortiguador de chispas aprobados 19.

de acuerdo al Standard SAE J335b, son estándar en las

sierras de cadena Shindaiwa para reducir la posibilidad

de incendios forestales. No opere la sierra de cadena

con un silenciador suelto o defectuoso. No remueva la

rejilla del amortiguador de chispas.

Español

Durante la operación, el silenciador o el silenciador catalítico y la tapa circundante se calientan. ■

No cuelgue nunca la sierra por un cable con el motor en marcha. ■

Use siempre la sierra por el lado derShindaiwa del cuerpo - No la use NUNCA por el lado izquierdo. ■

Lleve siempre ropa de seguridad apropiada para protegerse la parte inferior del cuerpo contra la cadena alada y ■

el silenciador caliente de la sierra.

■

Mantenga siempre limpia de residuos inamables el área de escape durante el transporte o almacenamiento, ya

que de lo contrario se pueden producir lesiones personales graves o daños materiales importantes.

ADVERTENCIA PELIGRO

Usar componentes de repuesto inadecuados o remover los dispositivos de seguridad son las lesiones graves o ■

fatales.

SP_3

Page 34

Español

STOP

cO n t e n t s

Reglas Para la Operación Segura ............................................................................................................................. SP_2

Símbolos internacionales

Datos Técnicos

Datos Emisiones......................................................................................................................................................... SP_6

Descripción

control de emisiones ................................................................................................................................................. SP_6

Nomenclatura de las Partes

Etiqueta

Combustible y lubricante

Instruccións para el Corte

Mantenimiento y cuidado

Combinaciones de la Cadena y Guía de la Barra

Almacenamiento

Identicación de Problemas

Uso Correcto del Freno de la Cadena

Declaratión de la Garantía

.......................................................................................................................................................................SP_8

........................................................................................................................................................... SP_5

................................................................................................................................................................. SP_6

....................................................................................................................................................... SP_25

.......................................................................................................................................... SP_4

......................................................................................................................................SP_7

......................................................................................................................................... SP_12

....................................................................................................................................... SP_16

........................................................................................................................................SP_19

.................................................................................................. SP_24

.................................................................................................................................... SP_26

....................................................................................................................SP_28

...................................................................................................................................... SP_29

Forma

de los

simbolos

sí m b O l O s i n t e R n a c i O n a l e s

Simbolo descripción/

aplicación

LEA CUIDADOSAMENTE EL

INSTRUCCIONES

Utilice siempre protecciones en

las orejas, ojos y cabeza.

Funcionamiento del freno de

sierra

Parada de emergencia

Control del estrangulador

“arranque en frio” posición

(Estrangulador Cierra)

Forma

de los

simbolos

L

H

Simbolo descripción/

aplicación

Llene de aceite para sierra

Bomba de aceite

Ajuste del lubricador de sierra

Ajuste del carburador - Mezcla

de baja velocidad

Ajuste del carburador - Mezcla

de alta velocidad

SP_4

Mezclas de gasolina y aceite

T

Ajuste del carburador -

Velocidad de ralenti

Page 35

Da t O s té c n i c O s

Model 326T

Long. x Ancho x alturo 277 x 245 x 214 mm (10.9 x 9.7 x 8.4 inch)

Pesa

Motor tipo Cilindro simple, de dos carreras, engrado por aire

Combustible propoción de la