Page 1

Inverter Split system Air Conditioner

Shinco Service Manual

SERVICE MANUAL

R410A

Model:

KFR-25GWZ/BM

KFR-35GWZ/BM

KFR-50GWZ/BM

KFR-70GWZ/BM

- 1 -

Page 2

Shinco Service Manual

Table of contents

Part I

1. Introductions of Part Names and Functions

2. Outline Dimension of Indoor and Outdoor Units

3. Specification

4. Wiring Diagram

5. Refrigeration System Diagram

6. Refrigeration Piping Length and Height Difference Table

Additional Refrigerant Charge Table

Sensor Resistance Table

7.

8. Parts List and exploding view

Part II

1 Service warning

2. Frequency table

3. Method of Testing the System at a Fixed Frequency

4. Running mode

5. Protection

6. Lamp display

Annex

1. PCB diagram

2. Schematic diagram

- 2 -

Page 3

Shinco Service Manual

Part I

1. Introductions of Part Names and Functions

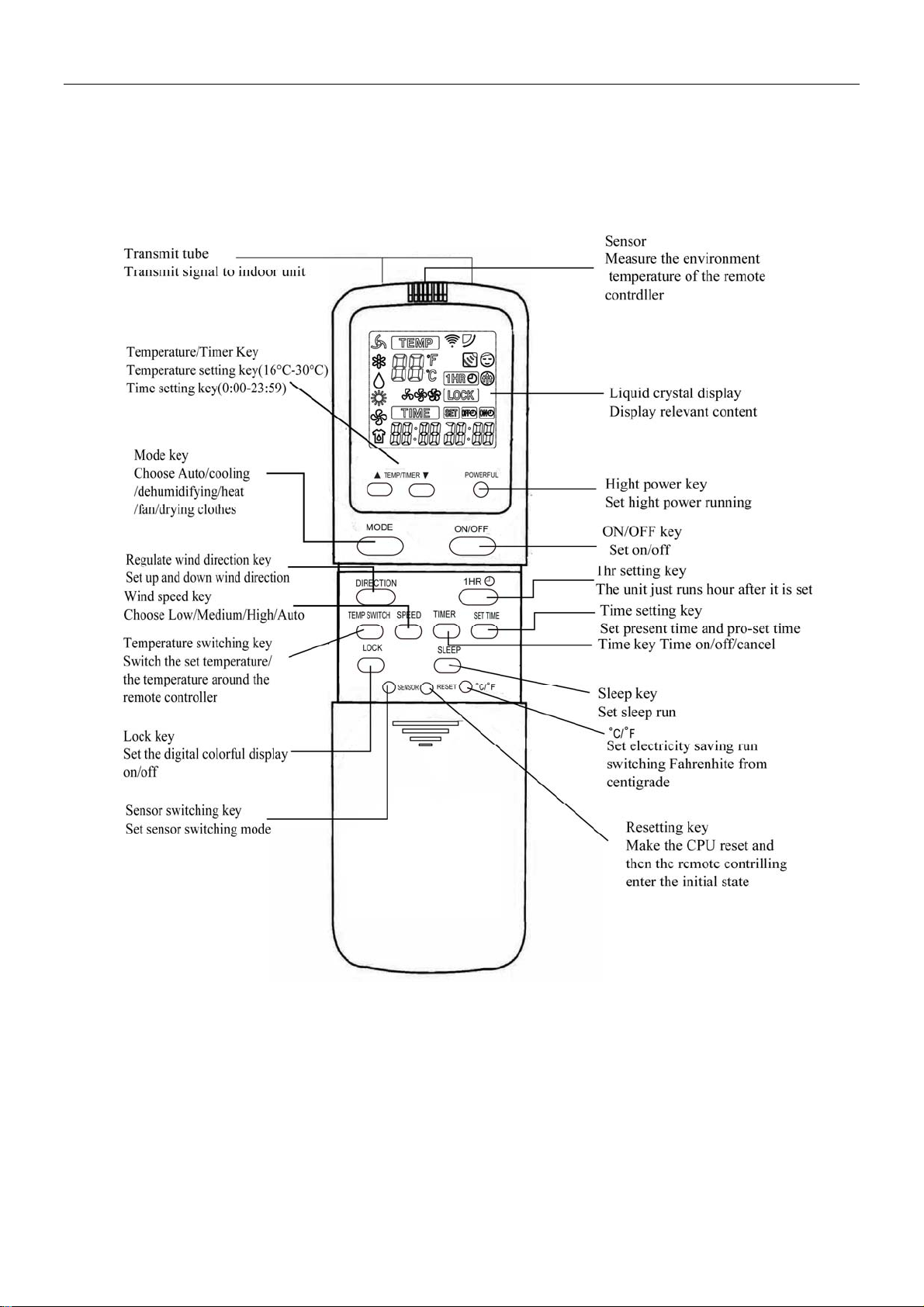

1.1 Remote controller

- 3 -

Page 4

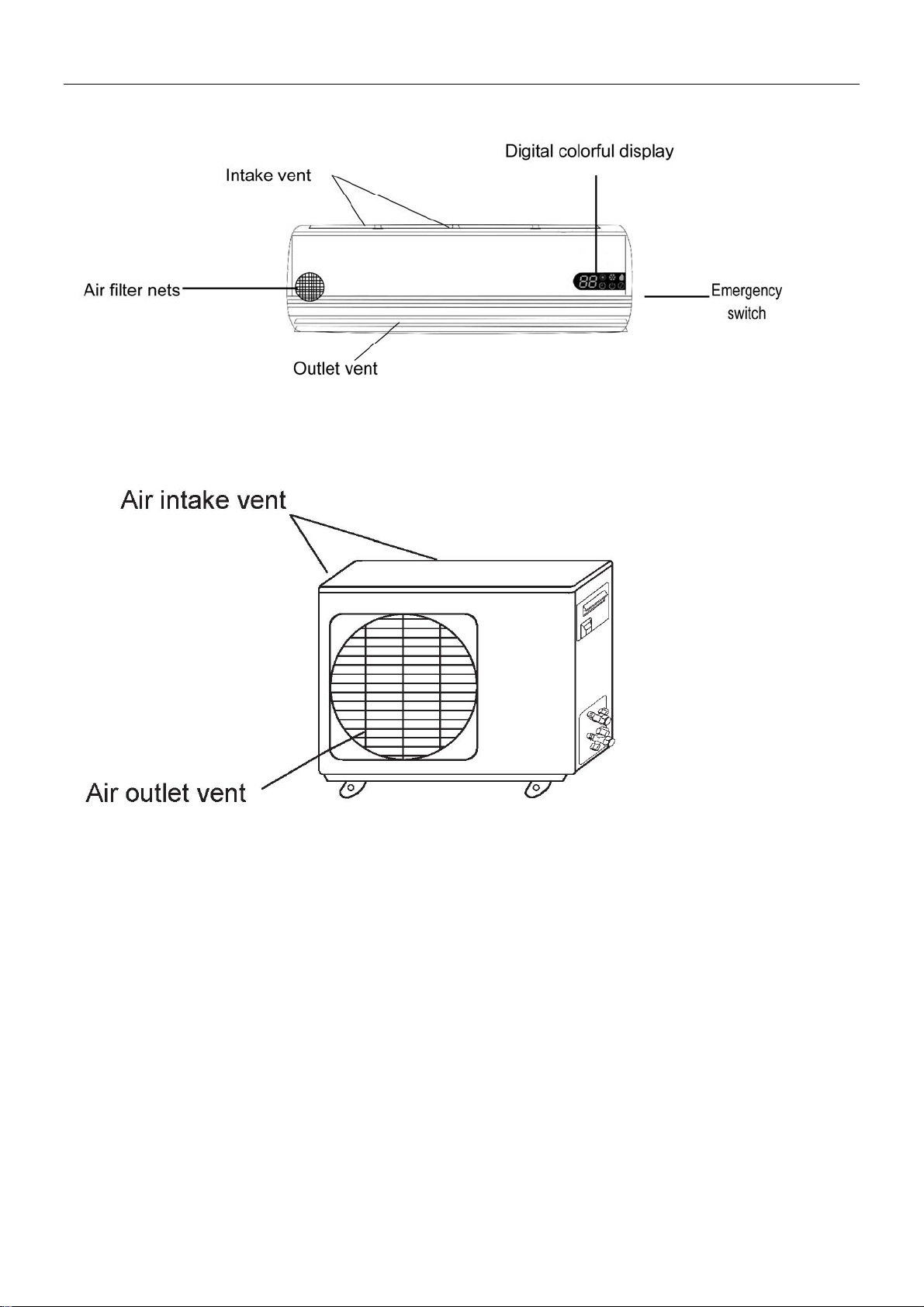

1.2 Indoor panel

1.3 Outdoor panel

Shinco Service Manual

- 4 -

Page 5

Shinco Service Manual

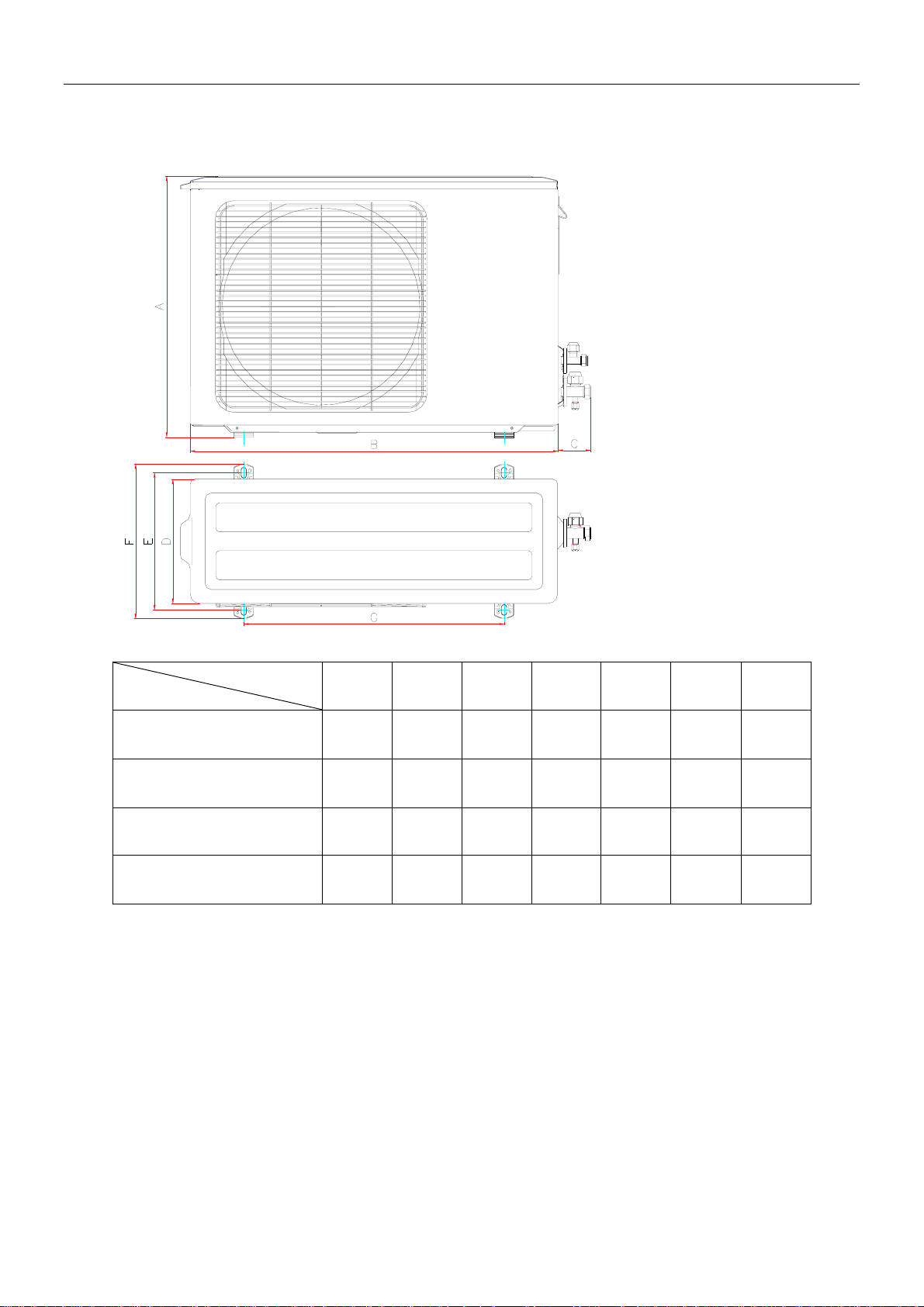

2. Outline Dimension of Indoor and Outdoor Units

2.1. Outdoor unit

MODEL

KFR-25GWZ/BM

SIZE mm

A B C D E F G

542 762 58 257 285 321 540

KFR-35GWZ/BM

542 762 58 257 285 321 540

KFR-50GWZ/BM

656 865 52 307 339.5 372 633

KFR-70GWZ/BM

840 950 60 352 388 425 582

- 5 -

Page 6

Shinco Service Manual

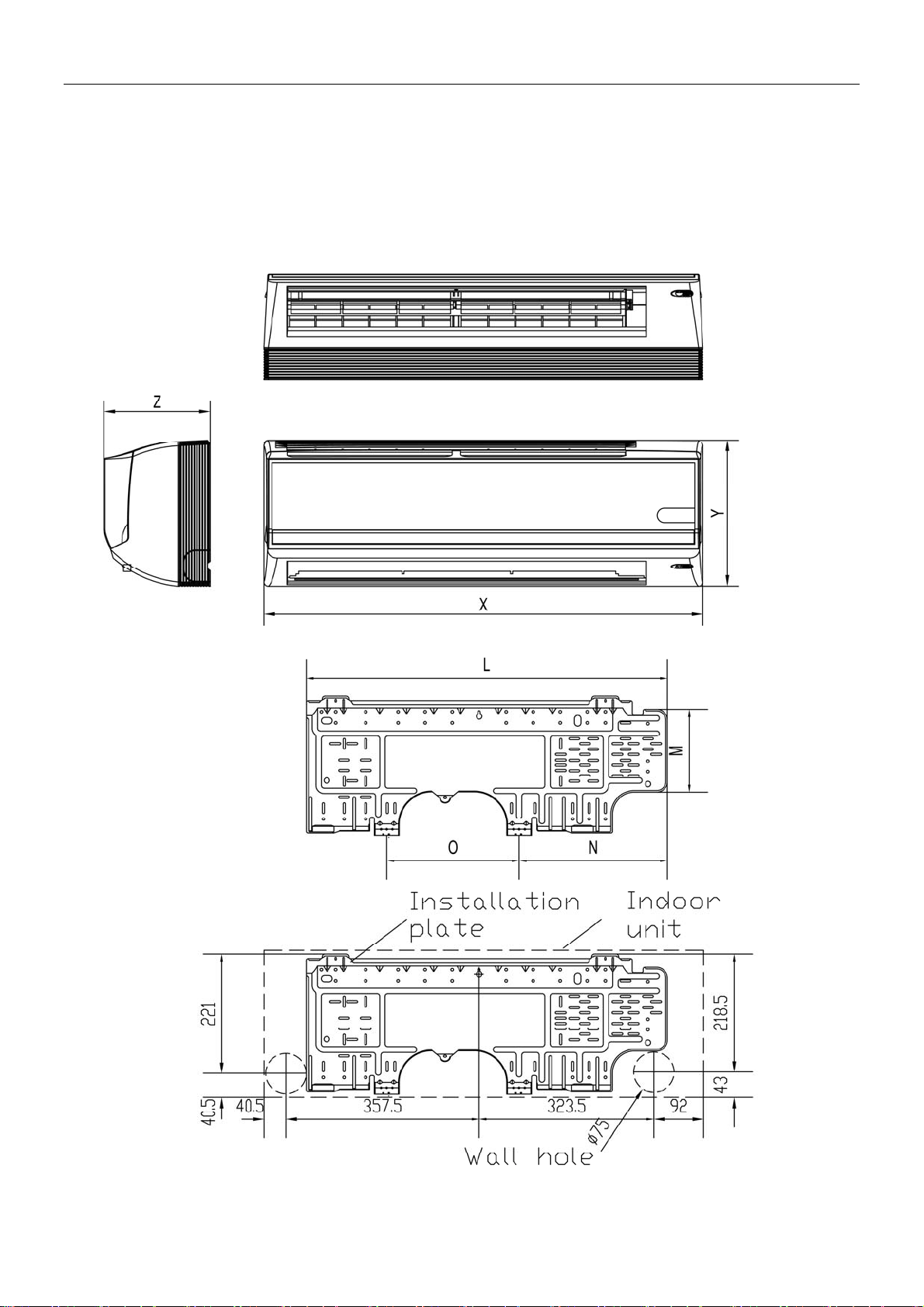

2.2 Indoor unit

Unit:mm

KFR-25GWZ/BM

KFR-35GWZ/BM

- 6 -

Page 7

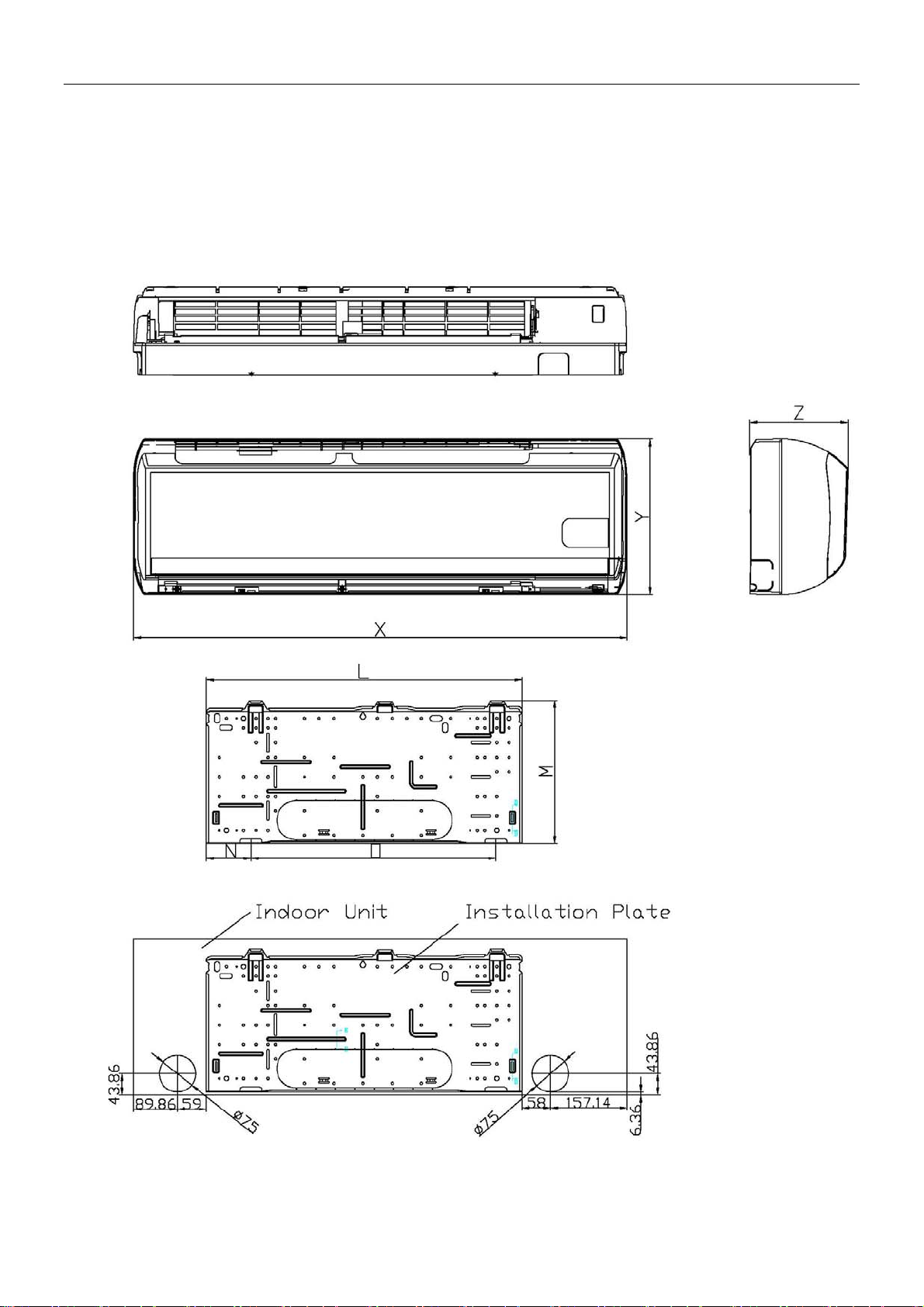

KFR-50GWZ/BM

Shinco Service Manual

- 7 -

Page 8

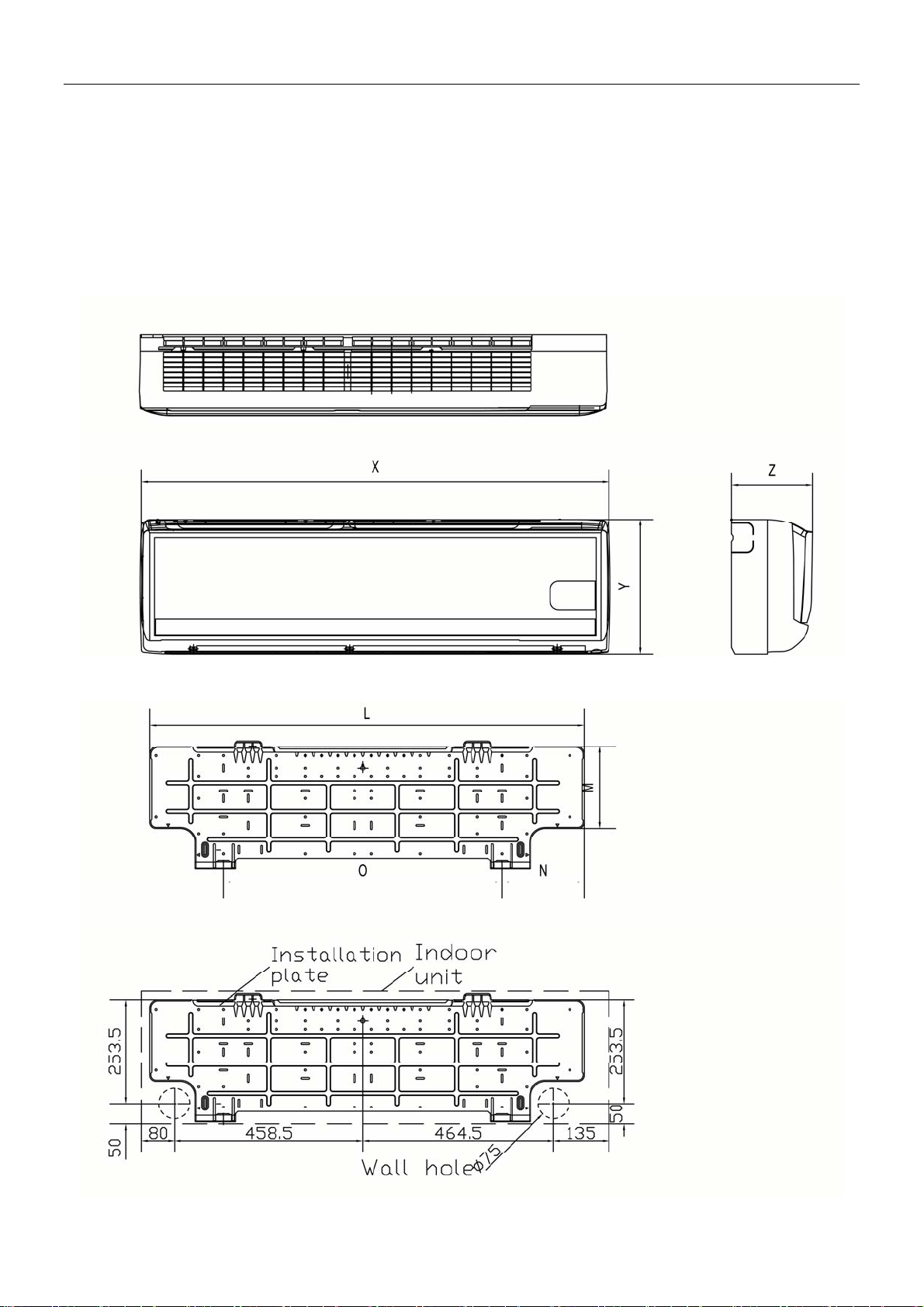

KFR-70GWZ/BM

Shinco Service Manual

- 8 -

Page 9

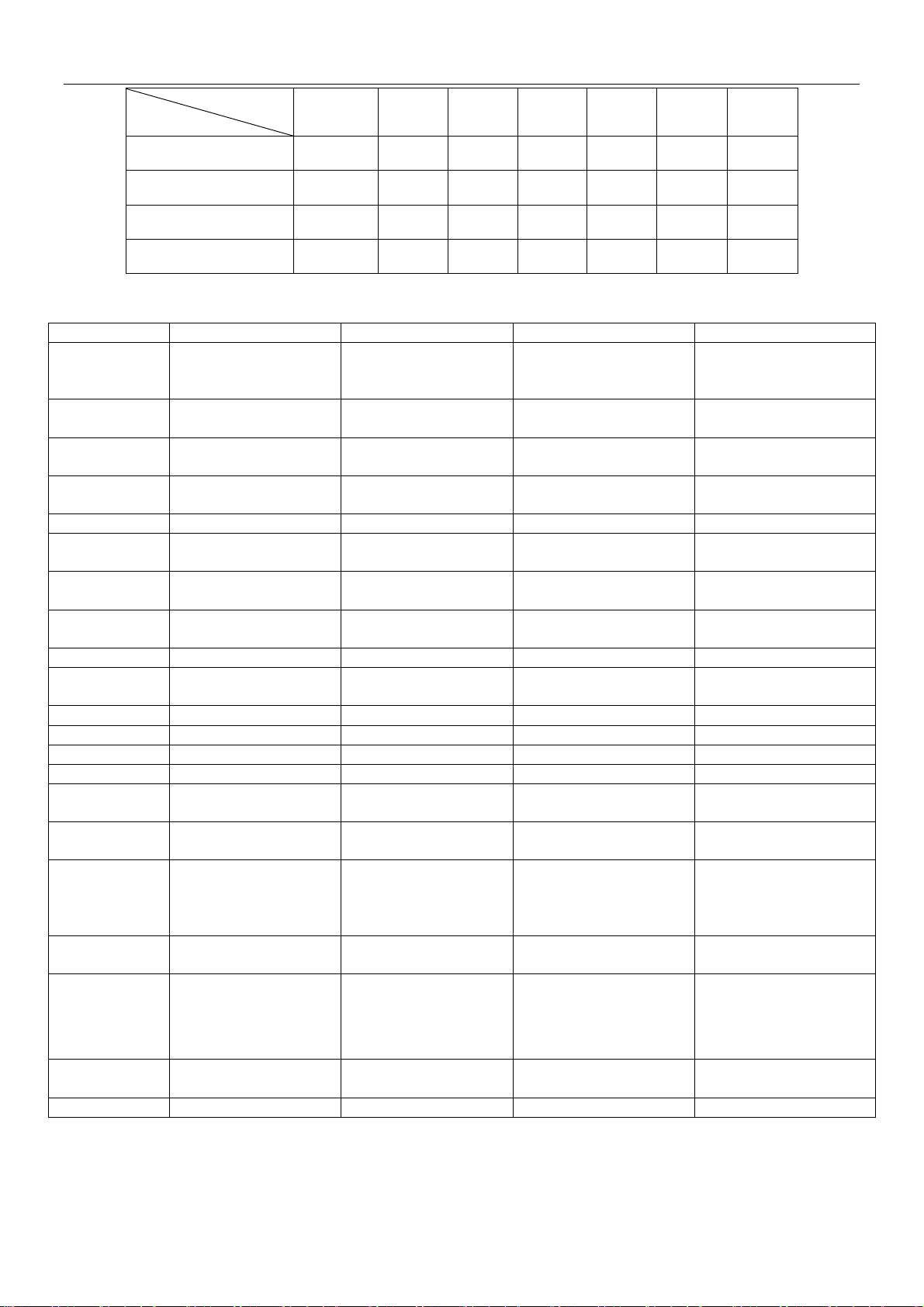

MODEL

SIZE mm

Shinco Service Manual

X Y Z L M N O

KFR-25GWZ/BM

KFR-35GWZ/BM

KFR-50GWZ/BM

KFR-70GWZ/BM

814 272 197 604 255 55 498

814 272 197 604 255 55 498

1013 323 198 648 295 57 502

1138 323 212 1055 312 180 679

3. Specification

Product type

Product

Number

Indoor

Outdoor bem25127610/W6 bem35127610/W6 bem50127603/W18 bem70127603/W13

Style

Compressor

Refrigerant R410A(pre-charged) R410A(pre-charged) R410A(pre-charged) R410A(pre-charged)

Cooling

Capacity

Heating

Capacity

Application

Area

Power Supply 230v/60Hz 230v/60Hz 230v/60Hz 230v/60Hz

Input Power

Input Current 3.4A(cool)/3.9A(heat) 4.9A(cool)/5.3A(heat) 7.6A(cool)/7.8A(heat) 10.4A(cool)/11.1A(heat)

SEER 13.8 13.6 14.5 13.3

HSPF 7.8 7.7 7.8 7.9

Sound Level 40dB(A)/54dB(A) 42dB(A)/55dB(A) 50dB(A)/58dB(A) 55dB(A)/62dB(A)

Dehumidify

Capacity(l/h)

Min Operating

Temp

Control System

Net

weight(Kg/lbs)

Dimensions(m

m/inches)

Line Set

Connection

Certificates ETL ETL ETL ETL

9000BTU 12000BTU 18000BTU 24000BTU

10400BTU 13650BTU 19100BTU 27000BTU

-7 -7 -7 -7

KFR-25GWZ/BM KFR-35GWZ/BM KFR-50GWZ/BM

bem25117610/G33 bem35117610/G33 bem50117603/G36 bem70117603/G37

Ductless mini split AC

system(heat pump)

Toshiba(rotary type DC

INVERTER)

10~18 ㎡ 16~24 ㎡

765W(cool)/880W(hea

t)

Ductless mini split AC

system(heat pump)

Toshiba(rotary type DC

INVERTER)

1075W(cool)/1160W(h

eat)

Ductless mini split AC

system(heat pump)

Panasonic(rotary type

DC INVERTER)

20~34 ㎡

1670W(cool)/1720W(he

at)

KFR-70GWZ/BM

Ductless mini split AC

system(heat pump)

Panasonic(rotary type

DC INVERTER)

32~47 ㎡

2400W(cool)/2550W(he

at)

0.85 1.5 1.7 2.1

Digital Multifunction

infrared Remote control

with indoor unit dynamic

digital LED display

11kg/24lbs(in),

40kg/88lbs(out)

814×192×272mm

3

2×7.6×

×

257×542mm

762

30

×

10.1×21.3inches(out)

10.7inches(in)

Digital Multifunction

infrared Remote control

with indoor unit dynamic

digital LCD display

11kg/24lbs(in),

43kg/95lbs(out)

814×192×272mm

32

×

7.6×10.7inches(in)

×

257×542mm

762

30

×

10.1×21.3inches(out)

Digital Multifunction

infrared Remote control

with indoor unit dynamic

digital LCD display

16kg/35lbs(in),51kg/112

lbs(out)

1013×198×323mm

39.9

865

34

×

7.8×12.7inches(in)

×

307×656mm

×12×

25.8inches(out)

Digital Multifunction

infrared Remote control

with indoor unit dynamic

digital LCD display

17kg/37lbs(in),68kg/150

lbs(out)

1138

44.8

950

37.4

×

212×323mm/

×

8.3×12.7inches(in)

×

352×840mm

×

13.8×33inches(out)

3 m connecting pipe 3 m connecting pipe 4 m connecting pipe 4 m connecting pipe

- 9 -

Page 10

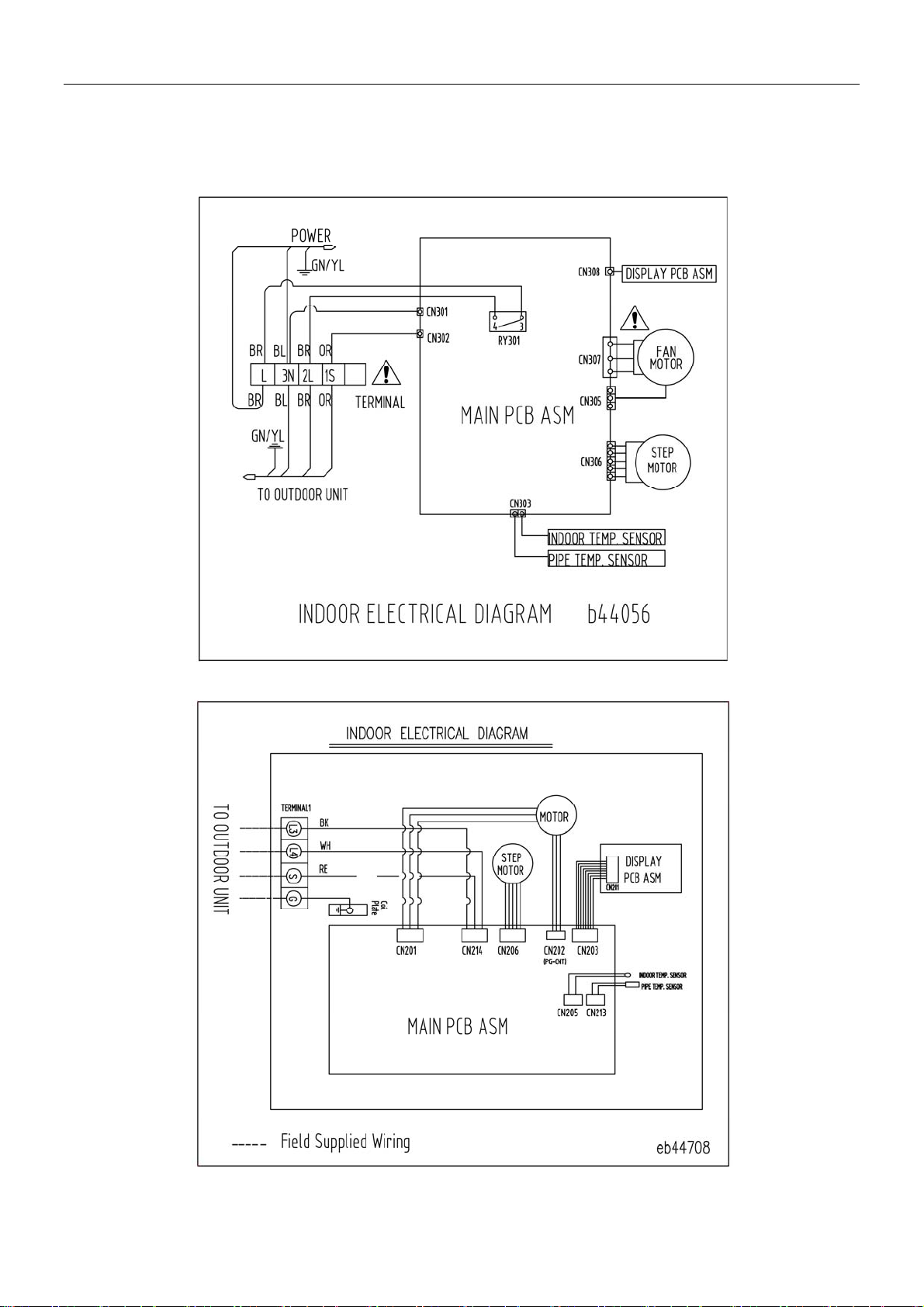

4. Wiring Diagram

4.1 Indoor unit Wiring diagram

KFR-25GWZ/BM

Shinco Service Manual

KFR-35GWZ/BM

- 10 -

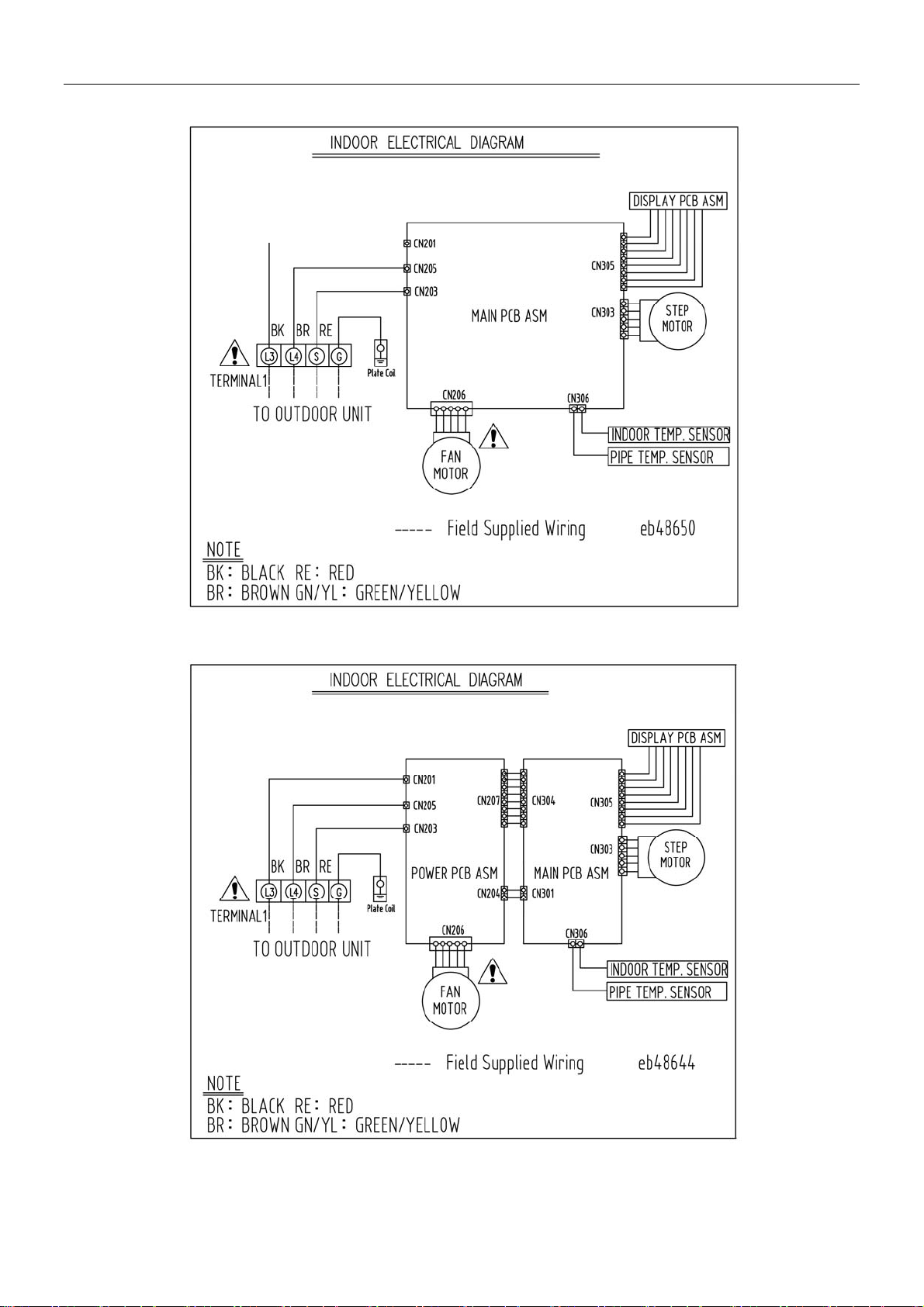

Page 11

KFR-50GWZ/BM

Shinco Service Manual

KFR-70GWZ/BM

- 11 -

Page 12

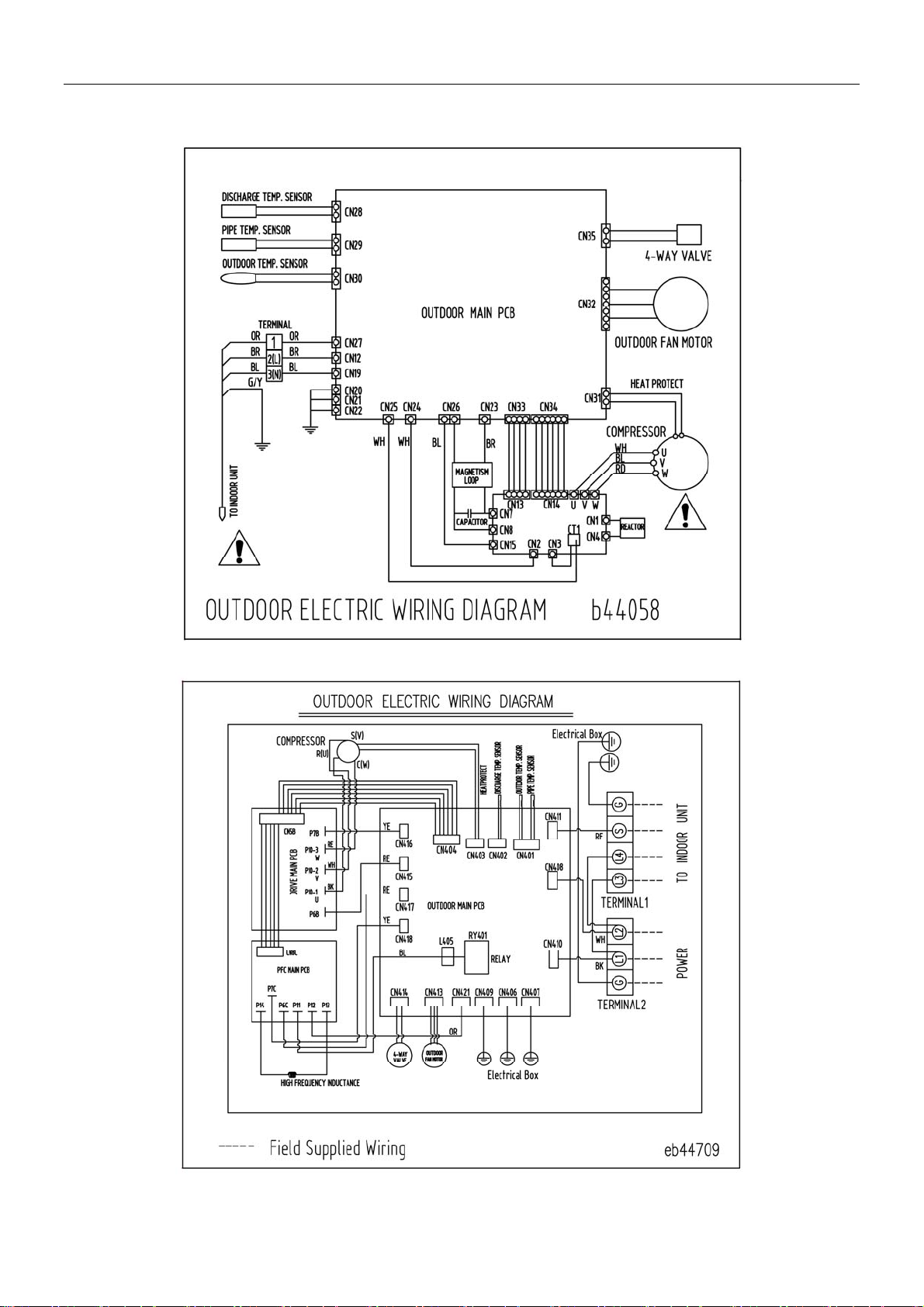

4.2 Outdoor unit Wiring diagram

KFR-25GWZ/BM

Shinco Service Manual

KFR-35GWZ/BM

- 12 -

Page 13

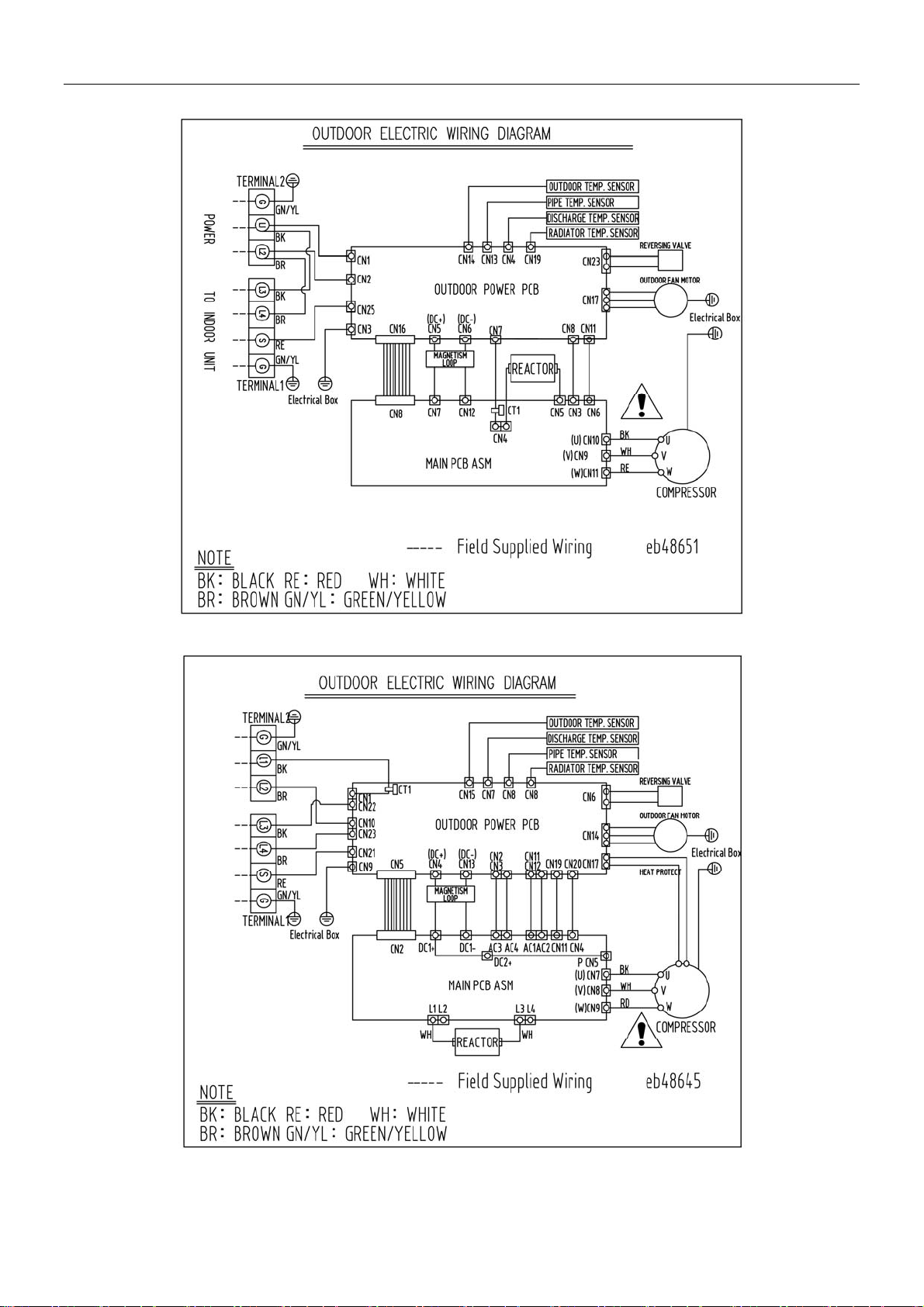

KFR-50GWZ/BM

Shinco Service Manual

KFR-70GWZ/BM

- 13 -

Page 14

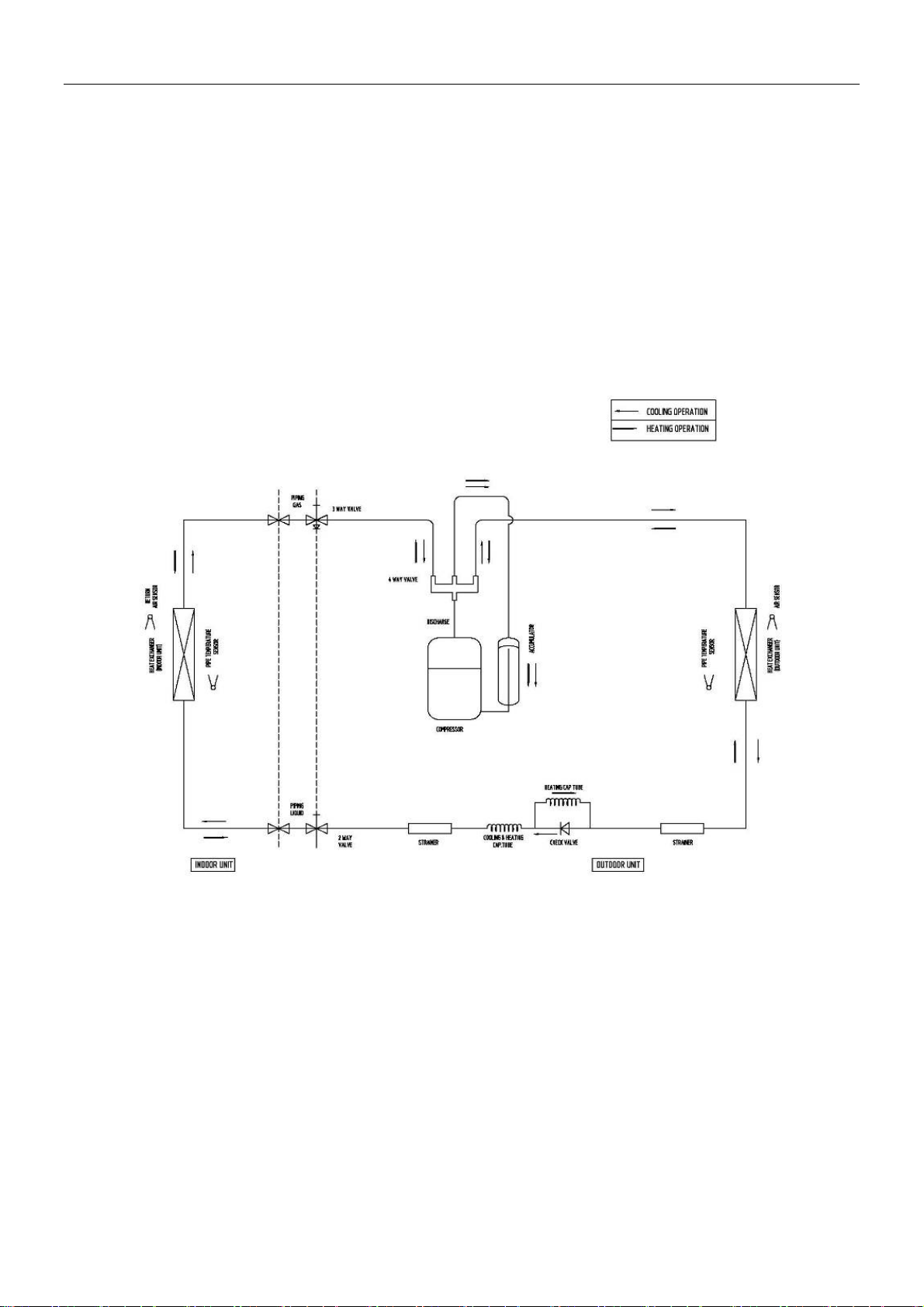

5. Refrigerant system diagram

Shinco Service Manual

- 14 -

Page 15

Shinco Service Manual

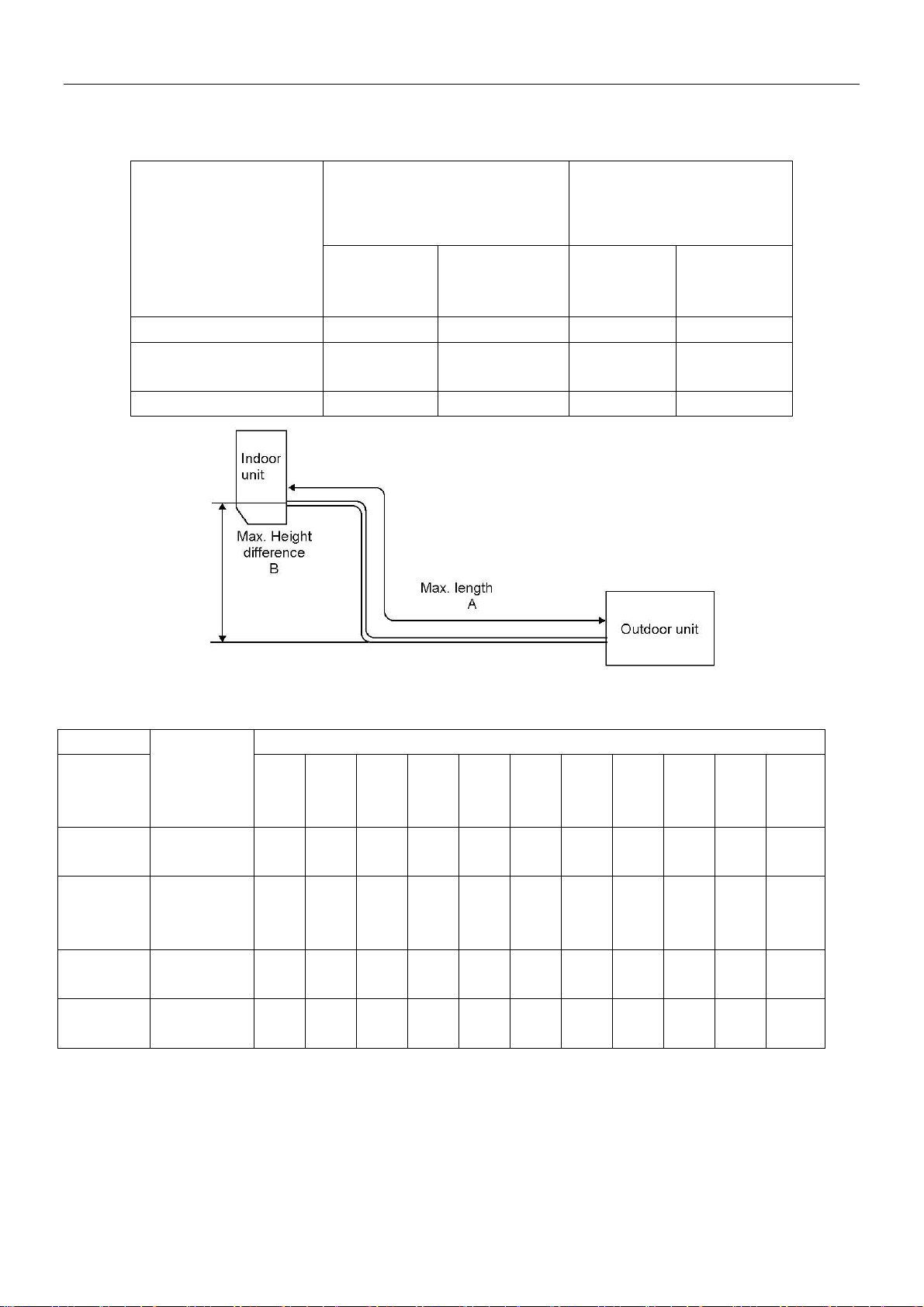

6. Max. refrigerant piping length and max. height difference

6.1 Piping length and height difference

REFRIGERANT PIPING:M PIPING SIZE O.D:mm MODEL

Max. length Max. Height

KFR-25GWZ/BM 15 5 9.52 6.35

KFR-35GWZ/BM

15 5 12.7 6.35

KFR-50GWZ/BM

KFR-70GWZ/BM 15 5 9.52 12.88

6.2 Additional refrigerant Charge (R410A:g)

Gas Liquid

difference

Model Refrigerant piping length(one way)

Outdoor

unit

5m 6m 7m 8m 9m 10m 11m 12m 13m 14m 15m

precharge

d(G)

KFR-25GW

840 0 20 40 60 80 100 120 140 160 180 200

Z/BM

KFR-35GW

1130 0 30 60 90 120 150 180 210 240 270 300

Z/BM

KFR-50GW

1300 0 30 60 90 120 150 180 210 240 270 300

Z/BM

KFR-70GW

1900 0 50 100 150 200 250 300 350 400 450 500

Z/BM

- 15 -

Page 16

Shinco Service Manual

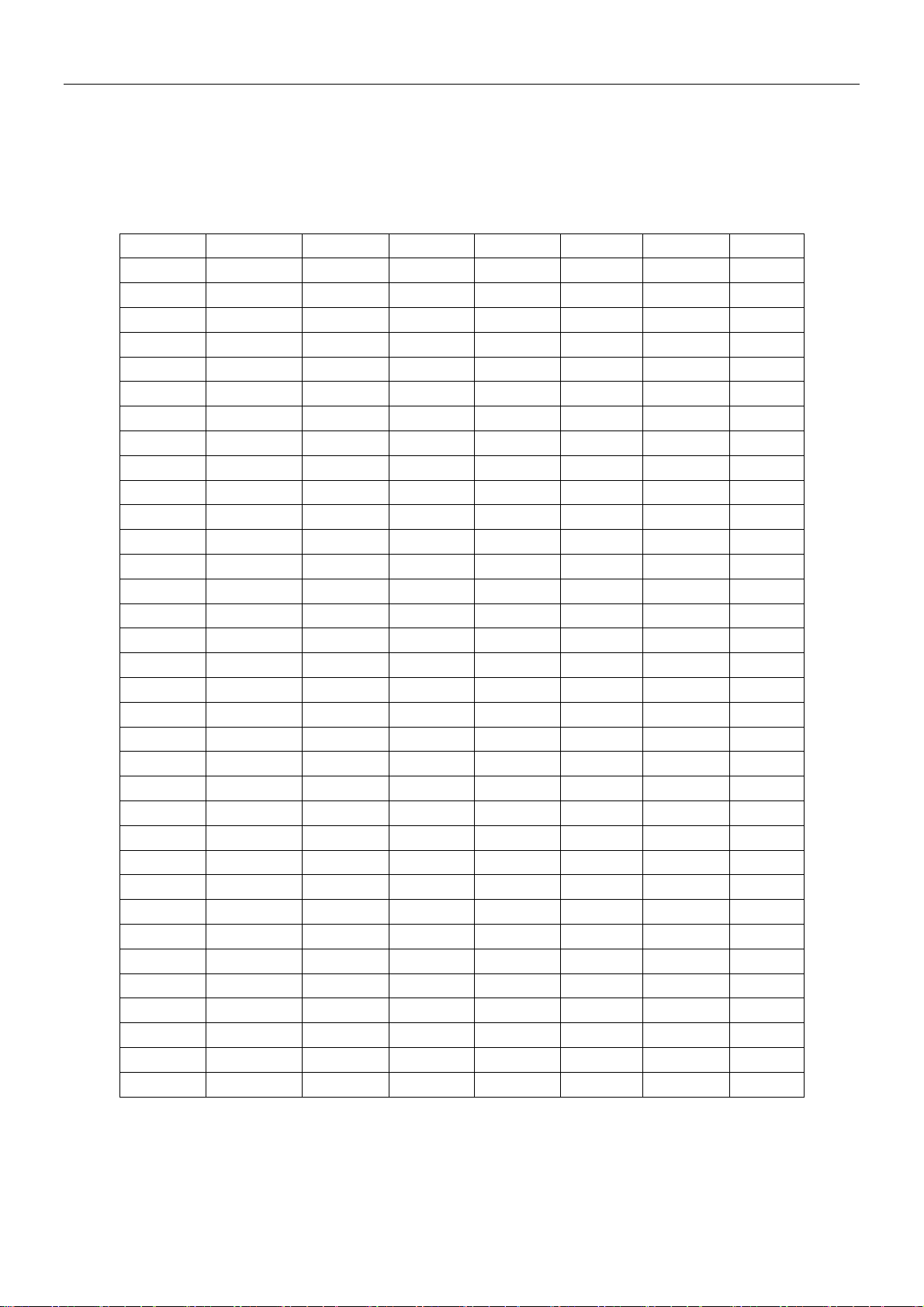

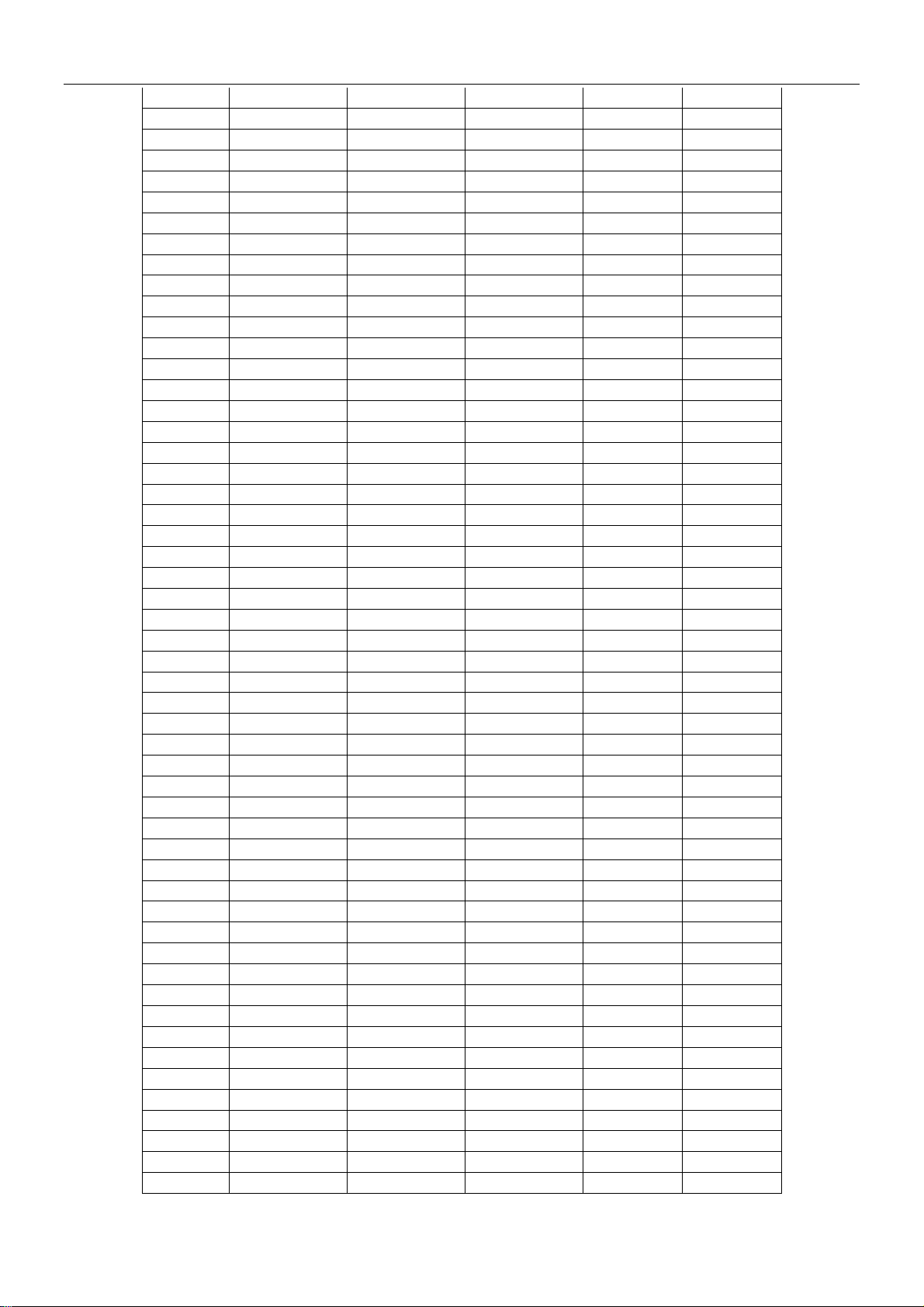

7. Sensor Resistance Table

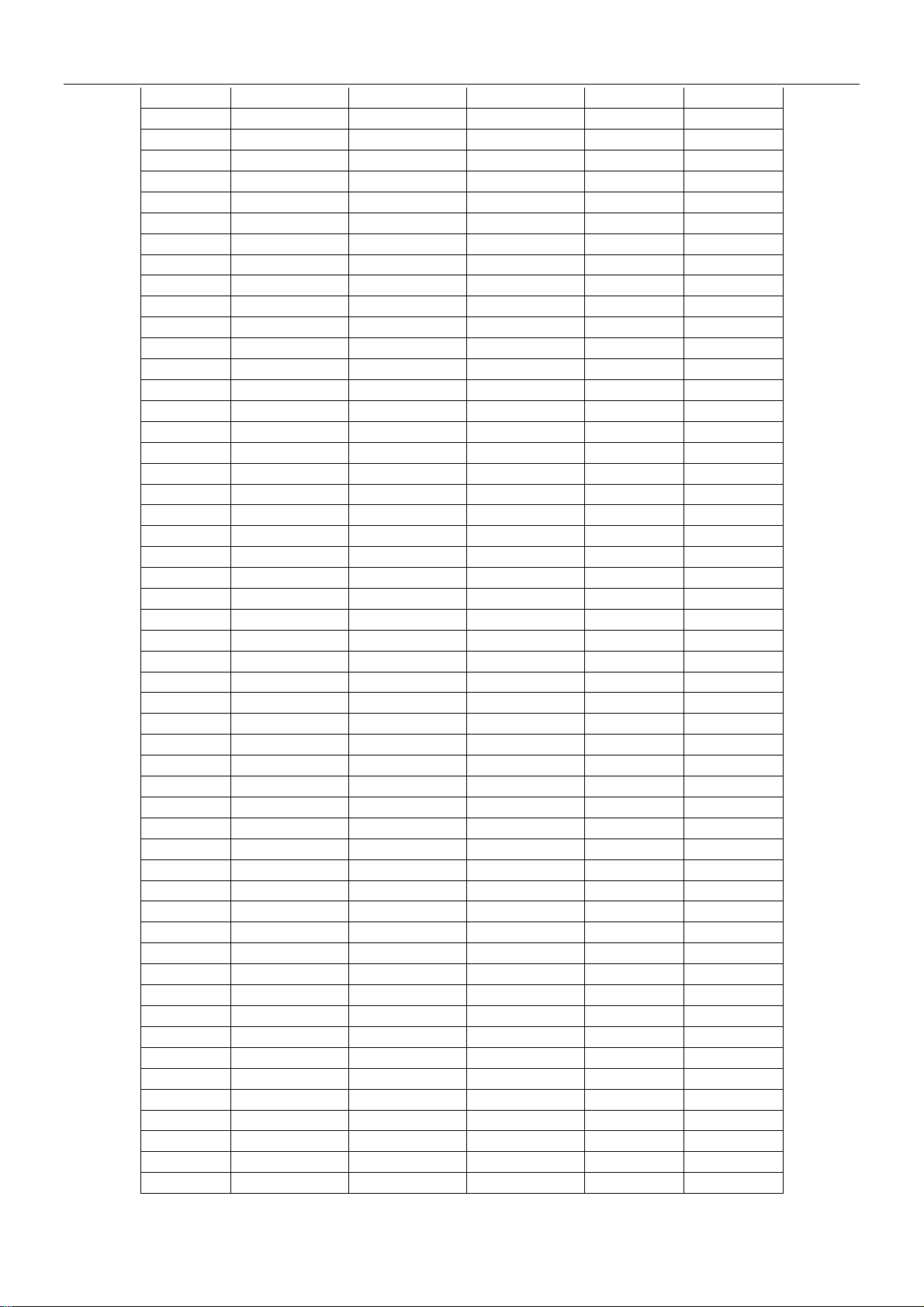

7.1 KFR-25GWZ/BM、KFR-35GWZ/BM Sensor Resistance Table

7.1.1 indoor air sensor、indoor pipe sensor、outdoor air sensor、outdoor pipe sensor

R-T datasheet 10K±0.5% ;3976K±0.5%,B(25/85)=3976K±0.5% R-T datasheet

Temp.(℃) R(KΩ) Temp.(℃) R(KΩ) Temp.(℃)R(KΩ) Temp.(℃) R(KΩ)

-30

-29

-28

-27

-26

-25

-24

-23

-22

-21

-20

-19

-18

-17

-16

-15

-14

-13

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

180.719

169.891

159.763

150.289

141.422

133.124

125.355

118.079

111.264

104.879

98.895

93.284

88.023

83.089

78.458

74.112

70.032

66.200

62.599

59.216

56.035

53.044

50.231

47.583

45.091

42.744

40.534

38.451

36.487

34.636

32.890

31.242

29.687

28.219

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

26.832

25.522

24.284

23.113

22.006

20.958

19.967

19.028

18.139

17.297

16.499

15.742

15.024

14.344

13.698

13.085

12.503

11.950

11.425

10.926

10.451

10.000

9.571

9.162

8.773

8.403

8.051

7.715

7.395

7.090

6.799

6.522

6.257

6.005

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

5.764

5.534

5.315

5.105

4.905

4.713

4.530

4.355

4.188

4.028

3.875

3.728

3.588

3.454

3.325

3.202

3.084

2.971

2.863

2.760

2.660

2.565

2.474

2.386

2.302

2.221

2.144

2.070

1.998

1.930

1.864

1.801

1.741

1.683

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

1.627

1.573

1.522

1.472

1.425

1.379

1.335

1.293

1.252

1.213

1.176

1.140

1.105

1.072

1.040

1.009

0.980

0.951

0.924

0.897

0.872

0.848

0.824

0.802

0.780

0.760

0.740

0.720

0.702

0.684

0.667

0.651

0.635

0.620

- 16 -

Page 17

Shinco Service Manual

7.1.2 outdoor discharge pipe R(0)=187.25K±6.3% ;B(0/100)=3979K±1% R-T datasheet

Temp.(℃) R(min) (KΩ) R(cent) (KΩ) R(max) (KΩ)

-20 488.35 526.61 565.60 -7.3% 7.4%

-19 461.94 497.84 534.41 -7.2% 7.3%

-18 437.15 470.87 505.17 -7.2% 7.3%

-17 413.89 445.57 477.76 -7.1% 7.2%

-16 392.05 421.83 462.06 -7.1% 9.5%

-15 371.54 399.54 427.94 -7.0% 7.1%

-14 352.27 378.61 405.31 -7.0% 7.1%

-13 334.16 358.96 384.06 -6.9% 7.0%

-12 317.13 340.48 364.10 -6.9% 6.9%

-11 301.11 323.11 345.34 -6.8% 6.9%

-10 286.03 306.77 327.71 -6.8% 6.8%

-9 271.83 291.40 311.13 -6.7% 6.8%

-8 258.46 276.92 295.52 -6.7% 6.7%

-7 245.86 263.29 280.83 -6.6% 6.7%

-6 233.98 250.44 266.99 -6.6% 6.6%

-5 222.78 238.33 253.96 -6.5% 6.6%

-4 212.20 226.91 241.67 -6.5% 6.5%

-3 202.22 216.13 230.07 -6.4% 6.4%

-2 192.79 205.95 219.13 -6.4% 6.4%

-1 183.88 196.34 208.80 -6.3% 6.3%

0 175.45 187.25 199.05 -6.3% 6.3%

1 167.33 178.66 190.00 -6.3% 6.3%

2 159.64 170.53 181.45 -6.4% 6.4%

3 152.37 162.84 173.34 -6.4% 6.4%

4 145.49 155.56 165.67 -6.5% 6.5%

5 138.97 148.66 158.39 -6.5% 6.5%

6 132.80 142.12 151.49 -6.6% 6.6%

7 126.95 135.92 144.94 -6.6% 6.6%

8 121.40 130.03 138.73 -6.6% 6.7%

9 116.13 124.45 132.83 -6.7% 6.7%

10 111.13 119.14 127.22 -6.7% 6.8%

11 106.38 114.10 121.89 -6.8% 6.8%

12 101.87 109.31 116.82 -6.8% 6.9%

13 97.585 104.75 112.00 -6.8% 6.9%

14 93.506 100.42 107.41 -6.9% 7.0%

15 89.625 96.289 103.04 -6.9% 7.0%

16 85.930 92.358 98.873 -7.0% 7.1%

17 82.411 88.612 94.902 -7.0% 7.1%

18 79.058 85.042 91.116 -7.0% 7.1%

19 75.861 81.637 87.503 -7.1% 7.2%

20 72.813 78.388 84.055 -7.1% 7.2%

21 69.904 75.287 80.768 -7.1% 7.3%

22 67.128 72.326 77.618 -7.2% 7.3%

23 64.477 69.498 74.612 -7.2% 7.4%

24 61.945 66.795 71.738 -7.3% 7.4%

25 59.525 64.210 68.990 -7.3% 7.4%

26 57.211 61.739 66.360 -7.3% 7.5%

27 54.998 59.373 63.843 -7.4% 7.5%

28 52.880 57.110 61.433 -7.4% 7.6%

29 50.853 54.942 59.124 -7.4% 7.6%

30 48.913 52.866 56.911 -7.5% 7.7%

ΔR(min) ΔR(max)

- 17 -

Page 18

Shinco Service Manual

31 47.054 50.876 54.791 -7.5% 7.7%

32 45.273 48.939 52.757 -7.5% 7.8%

33 43.565 47.140 50.806 -7.6% 7.8%

34 41.928 45.386 48.934 -7.6% 7.8%

35 40.358 43.703 47.137 -7.7% 7.9%

36 38.852 42.087 45.412 -7.7% 7.9%

37 37.408 40.536 43.755 -7.7% 7.9%

38 36.018 39.047 42.163 -7.8% 8.0%

39 34.685 37.616 40.632 -7.8% 8.0%

40 33.404 36.240 39.162 -7.8% 8.1%

41 32.174 34.919 37.747 -7.9% 8.1%

42 30.991 33.648 36.387 -7.9% 8.1%

43 29.855 32.426 35.078 -7.9% 8.2%

44 28.761 31.250 33.819 -8.0% 8.2%

45 27.710 30.119 32.606 -8.0% 8.3%

46 26.699 29.030 31.439 -8.0% 8.3%

47 25.725 27.982 30.315 -8.1% 8.3%

48 24.788 26.973 29.233 -8.1% 8.4%

49 23.887 26.001 28.190 -8.1% 8.4%

50 23.018 25.065 27.185 -8.2% 8.5%

51 22.182 24.163 26.217 -8.2% 8.5%

52 21.377 23.295 25.284 -8.2% 8.5%

53 20.601 22.457 24.384 -8.3% 8.6%

54 19.854 21.650 23.516 -8.3% 8.6%

55 19.133 20.873 22.680 -8.3% 8.7%

56 18.439 20.123 21.873 -8.4% 8.7%

57 17.770 19.399 21.094 -8.4% 8.7%

58 17.125 18.702 20.343 -8.4% 8.8%

59 16.503 18.029 19.618 -8.5% 8.8%

60 15.903 17.380 18.920 -8.5% 8.9%

61 15.324 16.754 18.245 -8.5% 8.9%

62 14.766 16.150 17.594 -8.6% 8.9%

63 14.228 15.568 16.965 -8.6% 9.0%

64 13.709 15.005 16.358 -8.6% 9.0%

65 13.209 14.463 15.772 -8.7% 9.1%

66 12.726 13.939 15.207 -8.7% 9.1%

67 12.260 13.433 14.681 -8.7% 9.3%

68 11.810 12.946 14.134 -8.8% 9.2%

69 11.376 12.475 13.650 -8.8% 9.4%

70 10.958 12.020 13.133 -8.8% 9.3%

71 10.554 11.581 12.658 -8.9% 9.3%

72 10.164 11.158 12.200 -8.9% 9.3%

73 9.7880 10.749 11.757 -8.9% 9.4%

74 9.4251 10.354 11.330 -9.0% 9.4%

75 9.0749 9.9733 10.917 -9.0% 9.5%

76 8.7370 9.6055 10.518 -9.0% 9.5%

77 8.4109 9.2505 10.134 -9.1% 9.6%

78 8.0962 8.9078 9.7618 -9.1% 9.6%

79 7.7926 8.5770 9.4028 -9.1% 9.6%

80 7.4997 8.2577 9.0562 -9.2% 9.7%

81 7.2170 7.9495 8.7215 -9.2% 9.7%

82 6.9443 7.6520 8.3983 -9.2% 9.8%

83 6.6812 7.3649 8.0883 -9.3% 9.8%

- 18 -

Page 19

Shinco Service Manual

84 6.4273 7.0878 7.7850 -9.3% 9.8%

85 6.1825 6.8204 7.4942 -9.4% 9.9%

86 5.9462 6.5623 7.2135 -9.4% 9.9%

87 5.7184 6.3133 6.9424 -9.4% 10.0%

88 5.4987 6.0731 6.6808 -9.5% 10.0%

89 5.2867 5.8413 6.4284 -9.5% 10.1%

90 5.0827 5.6177 6.1847 -9.5% 10.1%

91 4.8853 5.4018 5.9495 -9.6% 10.1%

92 4.6953 5.1939 5.7226 -9.6% 10.2%

93 4.5121 4.9932 5.5037 -9.6% 10.2%

94 4.3355 4.7997 5.2925 -9.7% 10.3%

95 4.1653 4.6131 5.0840 -9.7% 10.2%

96 4.0012 4.4331 4.8922 -9.7% 10.4%

97 3.8431 4.2596 4.7026 -9.8% 10.4%

98 3.6908 4.0924 4.5198 -9.8% 10.4%

99 3.5440 3.9312 4.3435 -9.8% 10.5%

100 3.4025 3.7759 4.1735 -9.9% 10.5%

101 3.2663 3.6262 4.0097 -9.9% 10.6%

102 3.1351 3.4819 3.8517 -10.0% 10.6%

103 3.0087 3.3429 3.6995 -10.0% 10.7%

104 2.8870 3.2090 3.5528 -10.0% 10.7%

105 2.7699 3.0801 3.4114 -10.1% 10.8%

106 2.6571 2.9559 3.2720 -10.1% 10.7%

107 2.5485 2.8363 3.1440 -10.1% 10.8%

108 2.4441 2.7211 3.0176 -10.2% 10.9%

109 2.3435 2.6103 2.8959 -10.2% 10.9%

110 2.2468 2.5036 2.7787 -10.3% 11.0%

111 2.1537 2.4009 2.6658 -10.3% 11.0%

112 2.0642 2.3021 2.5572 -10.3% 11.1%

113 1.9781 2.2070 2.4526 -10.4% 11.1%

114 1.8954 2.1155 2.3519 -10.4% 11.2%

115 1.8158 2.0276 2.2551 -10.4% 11.2%

116 1.7393 1.9430 2.1619 -10.5% 11.3%

117 1.6657 1.8616 2.0723 -10.5% 11.3%

118 1.5951 1.7834 1.9861 -10.6% 11.4%

119 1.5272 1.7082 1.9032 -10.6% 11.4%

120 1.4619 1.6359 1.8234 -10.6% 11.5%

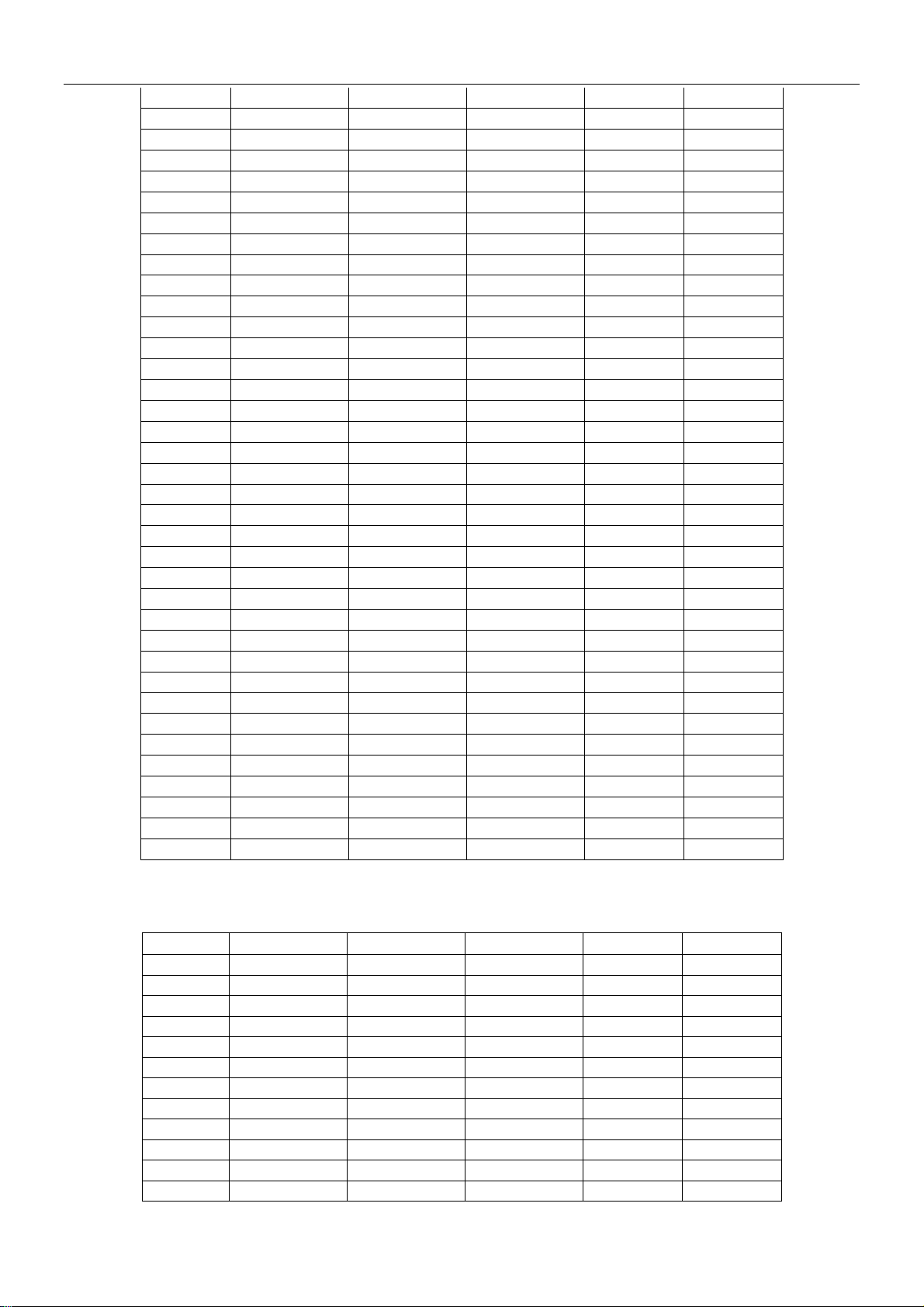

7.2 KFR-50GWZ/BM、KFR-70GWZ/BM Sensor Resistance Table

7.2.1 indoor air sensor R(25)=5K±2% ;B(25/50)=3950K±2% R-T datasheet

Temp.(℃) R(min) (KΩ) R(cent) (KΩ) R(max) (KΩ)

-20 44.23 47.70 51.40 -7.3% 7.8%

-19 41.82 45.05 48.49 -7.2% 7.6%

-18 39.55 42.56 45.76 -7.1% 7.5%

-17 37.43 40.23 43.20 -7.0% 7.4%

-16 35.43 38.03 40.80 -6.9% 7.3%

-15 33.54 35.97 38.54 -6.8% 7.1%

-14 31.77 34.04 36.43 -6.7% 7.0%

-13 30.11 32.22 34.44 -6.5% 6.9%

-12 28.54 30.50 32.57 -6.4% 6.8%

-11 27.06 28.89 30.82 -6.3% 6.7%

-10 25.66 27.37 29.17 -6.2% 6.6%

-9 24.35 25.94 27.61 -6.1% 6.4%

ΔR(min) ΔR(max)

- 19 -

Page 20

Shinco Service Manual

-8 23.11 24.59 26.15 -6.0% 6.3%

-7 21.94 23.33 24.78 -5.9% 6.2%

-6 20.84 22.13 23.48 -5.8% 6.1%

-5 19.79 21.00 22.26 -5.7% 6.0%

-4 18.81 19.94 21.11 -5.6% 5.9%

-3 17.88 18.93 20.03 -5.5% 5.8%

-2 17.00 17.98 19.00 -5.5% 5.7%

-1 16.17 17.09 18.04 -5.4% 5.6%

0 15.39 16.24 17.13 -5.3% 5.5%

1 14.64 15.44 16.27 -5.2% 5.3%

2 13.94 14.69 15.46 -5.1% 5.2%

3 13.28 13.97 14.69 -5.0% 5.1%

4 12.65 13.30 13.96 -4.9% 5.0%

5 12.05 12.66 13.28 -4.8% 4.9%

6 11.49 12.05 12.63 -4.7% 4.8%

7 10.95 11.48 12.02 -4.6% 4.7%

8 10.44 10.93 11.44 -4.5% 4.6%

9 9.961 10.42 10.89 -4.4% 4.5%

10 9.504 9.934 10.37 -4.3% 4.4%

11 9.071 9.472 9.881 -4.2% 4.3%

12 8.660 9.034 9.416 -4.1% 4.2%

13 8.270 8.619 8.974 -4.1% 4.1%

14 7.899 8.225 8.556 -4.0% 4.0%

15 7.547 7.851 8.159 -3.9% 3.9%

16 7.212 7.496 7.783 -3.8% 3.8%

17 6.894 7.159 7.427 -3.7% 3.7%

18 6.592 6.839 7.088 -3.6% 3.6%

19 6.305 6.534 6.767 -3.5% 3.6%

20 6.031 6.245 6.462 -3.4% 3.5%

21 5.771 5.971 6.172 -3.3% 3.4%

22 5.524 5.710 5.897 -3.3% 3.3%

23 5.288 5.461 5.635 -3.2% 3.2%

24 5.064 5.225 5.386 -3.1% 3.1%

25 4.850 5.000 5.150 -3.0% 3.0%

26 4.638 4.786 4.934 -3.1% 3.1%

27 4.437 4.582 4.728 -3.2% 3.2%

28 4.245 4.388 4.532 -3.3% 3.3%

29 4.063 4.203 4.344 -3.3% 3.4%

30 3.890 4.027 4.166 -3.4% 3.4%

31 3.724 3.859 3.996 -3.5% 3.5%

32 3.567 3.699 3.833 -3.6% 3.6%

33 3.417 3.547 3.679 -3.7% 3.7%

34 3.274 3.401 3.531 -3.7% 3.8%

35 3.138 3.263 3.389 -3.8% 3.9%

36 3.008 3.130 3.255 -3.9% 4.0%

37 2.884 3.004 3.126 -4.0% 4.1%

38 2.766 2.883 3.003 -4.1% 4.1%

39 2.654 2.768 2.885 -4.1% 4.2%

40 2.546 2.658 2.773 -4.2% 4.3%

41 2.444 2.553 2.665 -4.3% 4.4%

42 2.346 2.453 2.563 -4.4% 4.5%

43 2.252 2.357 2.464 -4.4% 4.6%

44 2.163 2.265 2.370 -4.5% 4.6%

- 20 -

Page 21

Shinco Service Manual

45 2.077 2.178 2.280 -4.6% 4.7%

46 1.996 2.094 2.194 -4.7% 4.8%

47 1.918 2.014 2.112 -4.7% 4.9%

48 1.843 1.937 2.033 -4.8% 5.0%

49 1.772 1.863 1.958 -4.9% 5.1%

50 1.704 1.793 1.885 -5.0% 5.1%

51 1.639 1.726 1.816 -5.0% 5.2%

52 1.577 1.662 1.749 -5.1% 5.3%

53 1.517 1.600 1.686 -5.2% 5.4%

54 1.460 1.541 1.625 -5.3% 5.5%

55 1.405 1.484 1.566 -5.3% 5.5%

56 1.353 1.430 1.510 -5.4% 5.6%

57 1.303 1.378 1.456 -5.5% 5.7%

58 1.255 1.328 1.405 -5.5% 5.8%

59 1.209 1.280 1.355 -5.6% 5.8%

60 1.164 1.235 1.308 -5.7% 5.9%

61 1.122 1.191 1.262 -5.7% 6.0%

62 1.082 1.148 1.218 -5.8% 6.1%

63 1.043 1.108 1.176 -5.9% 6.2%

64 1.006 1.069 1.136 -5.9% 6.2%

65 0.9698 1.032 1.097 -6.0% 6.3%

66 0.9355 0.9960 1.060 -6.1% 6.4%

67 0.9025 0.9616 1.024 -6.1% 6.5%

68 0.8709 0.9286 0.9892 -6.2% 6.5%

69 0.8406 0.8969 0.9561 -6.3% 6.6%

70 0.8115 0.8664 0.9243 -6.3% 6.7%

71 0.7835 0.8372 0.8936 -6.4% 6.7%

72 0.7567 0.8090 0.8642 -6.5% 6.8%

73 0.7309 0.7819 0.8359 -6.5% 6.9%

74 0.7061 0.7559 0.8086 -6.6% 7.0%

75 0.6822 0.7309 0.7824 -6.7% 7.0%

76 0.6593 0.7068 0.7571 -6.7% 7.1%

77 0.6373 0.6837 0.7328 -6.8% 7.2%

78 0.6161 0.6614 0.7094 -6.8% 7.3%

79 0.5958 0.6400 0.6868 -6.9% 7.3%

80 0.5762 0.6193 0.6651 -7.0% 7.4%

81 0.5573 0.5995 0.6442 -7.0% 7.5%

82 0.5392 0.5804 0.6241 -7.1% 7.5%

83 0.5218 0.5619 0.6047 -7.1% 7.6%

84 0.5050 0.5442 0.5859 -7.2% 7.7%

85 0.4888 0.5271 0.5679 -7.3% 7.7%

86 0.4732 0.5106 0.5505 -7.3% 7.8%

87 0.4582 0.4948 0.5337 -7.4% 7.9%

88 0.4438 0.4795 0.5176 -7.4% 7.9%

89 0.4299 0.4647 0.5020 -7.5% 8.0%

90 0.4165 0.4505 0.4869 -7.6% 8.1%

91 0.4036 0.4368 0.4724 -7.6% 8.1%

92 0.3911 0.4236 0.4584 -7.7% 8.2%

93 0.3791 0.4109 0.4449 -7.7% 8.3%

94 0.3676 0.3986 0.4318 -7.8% 8.3%

95 0.3564 0.3867 0.4192 -7.8% 8.4%

96 0.3456 0.3753 0.4071 -7.9% 8.5%

97 0.3353 0.3642 0.3953 -8.0% 8.5%

- 21 -

Page 22

Shinco Service Manual

98 0.3253 0.3536 0.3840 -8.0% 8.6%

99 0.3156 0.3433 0.3730 -8.1% 8.7%

100 0.3063 0.3333 0.3624 -8.1% 8.7%

101 0.2973 0.3237 0.3522 -8.2% 8.8%

102 0.2886 0.3144 0.3423 -8.2% 8.9%

103 0.2802 0.3055 0.3327 -8.3% 8.9%

104 0.2721 0.2968 0.3235 -8.3% 9.0%

105 0.2643 0.2885 0.3146 -8.4% 9.0%

106 0.2568 0.2804 0.3059 -8.4% 9.1%

107 0.2495 0.2726 0.2976 -8.5% 9.2%

108 0.2424 0.2650 0.2895 -8.5% 9.2%

109 0.2356 0.2577 0.2817 -8.6% 9.3%

110 0.2290 0.2507 0.2741 -8.6% 9.4%

111 0.2227 0.2438 0.2668 -8.7% 9.4%

112 0.2165 0.2372 0.2597 -8.7% 9.5%

113 0.2106 0.2309 0.2529 -8.8% 9.5%

114 0.2048 0.2247 0.2462 -8.8% 9.6%

115 0.1993 0.2187 0.2398 -8.9% 9.7%

116 0.1939 0.2129 0.2336 -8.9% 9.7%

117 0.1887 0.2073 0.2276 -9.0% 9.8%

118 0.1837 0.2019 0.2217 -9.0% 9.8%

119 0.1788 0.1966 0.2161 -9.1% 9.9%

120 0.1741 0.1916 0.2106 -9.1% 9.9%

121 0.1695 0.1866 0.2053 -9.2% 10.0%

122 0.1651 0.1819 0.2002 -9.2% 10.1%

123 0.1608 0.1772 0.1952 -9.3% 10.1%

124 0.1567 0.1728 0.1903 -9.3% 10.2%

125 0.1527 0.1684 0.1857 -9.4% 10.2%

126 0.1488 0.1642 0.1811 -9.4% 10.3%

127 0.1450 0.1602 0.1767 -9.5% 10.3%

128 0.1414 0.1562 0.1725 -9.5% 10.4%

129 0.1379 0.1524 0.1683 -9.5% 10.4%

130 0.1344 0.1487 0.1643 -9.6% 10.5%

131 0.1311 0.1451 0.1604 -9.6% 10.6%

132 0.1279 0.1416 0.1566 -9.7% 10.6%

133 0.1248 0.1382 0.1530 -9.7% 10.7%

134 0.1218 0.1349 0.1494 -9.8% 10.7%

135 0.1188 0.1318 0.1459 -9.8% 10.8%

136 0.1160 0.1287 0.1426 -9.8% 10.8%

137 0.1132 0.1257 0.1393 -9.9% 10.9%

138 0.1106 0.1228 0.1362 -9.9% 10.9%

139 0.1080 0.1199 0.1331 -10.0% 11.0%

140 0.1055 0.1172 0.1301 -10.0% 11.0%

141 0.1030 0.1145 0.1272 -10.1% 11.1%

142 0.1007 0.1120 0.1244 -10.1% 11.1%

143 0.0984 0.1095 0.1217 -10.1% 11.2%

144 0.0961 0.1070 0.1190 -10.2% 11.2%

145 0.0940 0.1047 0.1165 -10.2% 11.3%

146 0.0919 0.1024 0.1140 -10.3% 11.3%

147 0.0898 0.1001 0.1115 -10.3% 11.4%

148 0.0878 0.0980 0.1092 -10.3% 11.4%

149 0.0859 0.0959 0.1069 -10.4% 11.5%

150 0.0840 0.0938 0.1046 -10.4% 11.5%

- 22 -

Page 23

Shinco Service Manual

151 0.0822 0.0918 0.1025 -10.5% 11.6%

152 0.0805 0.0899 0.1003 -10.5% 11.6%

153 0.0787 0.0880 0.0983 -10.5% 11.7%

154 0.0771 0.0862 0.0963 -10.6% 11.7%

155 0.0755 0.0844 0.0943 -10.6% 11.8%

156 0.0739 0.0827 0.0924 -10.6% 11.8%

157 0.0724 0.0810 0.0906 -10.7% 11.9%

158 0.0709 0.0794 0.0888 -10.7% 11.9%

159 0.0694 0.0778 0.0871 -10.7% 11.9%

160 0.0680 0.0762 0.0854 -10.8% 12.0%

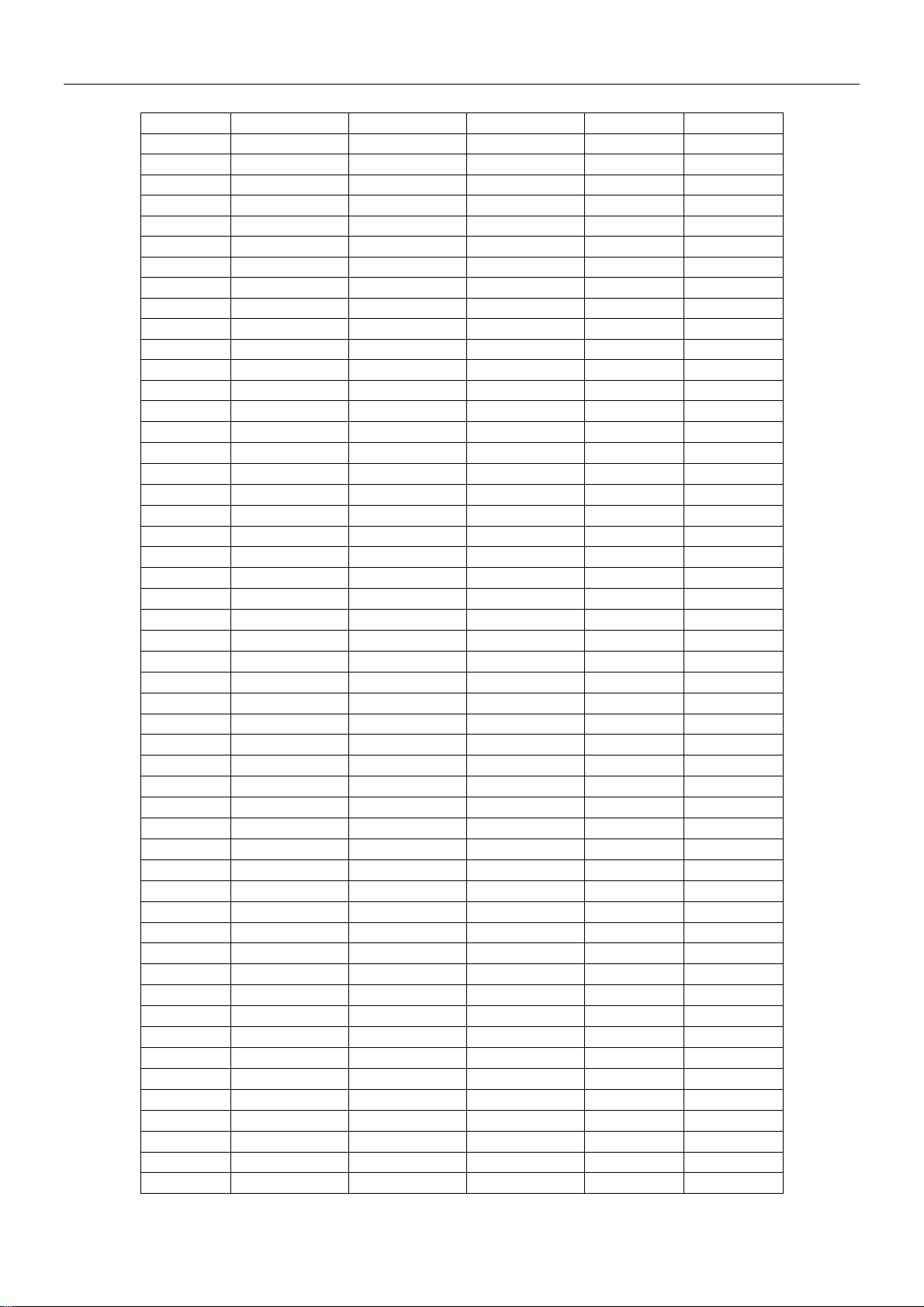

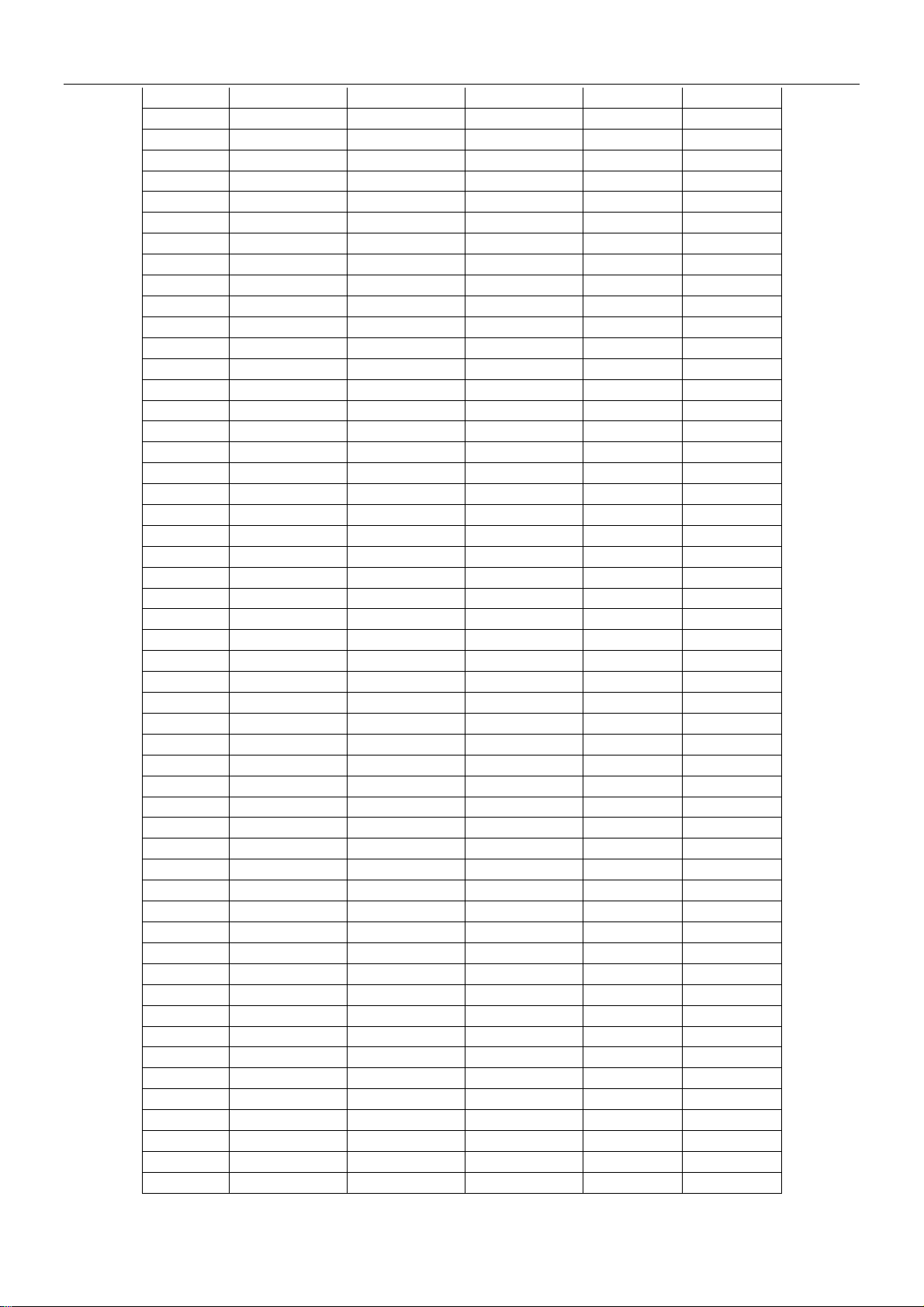

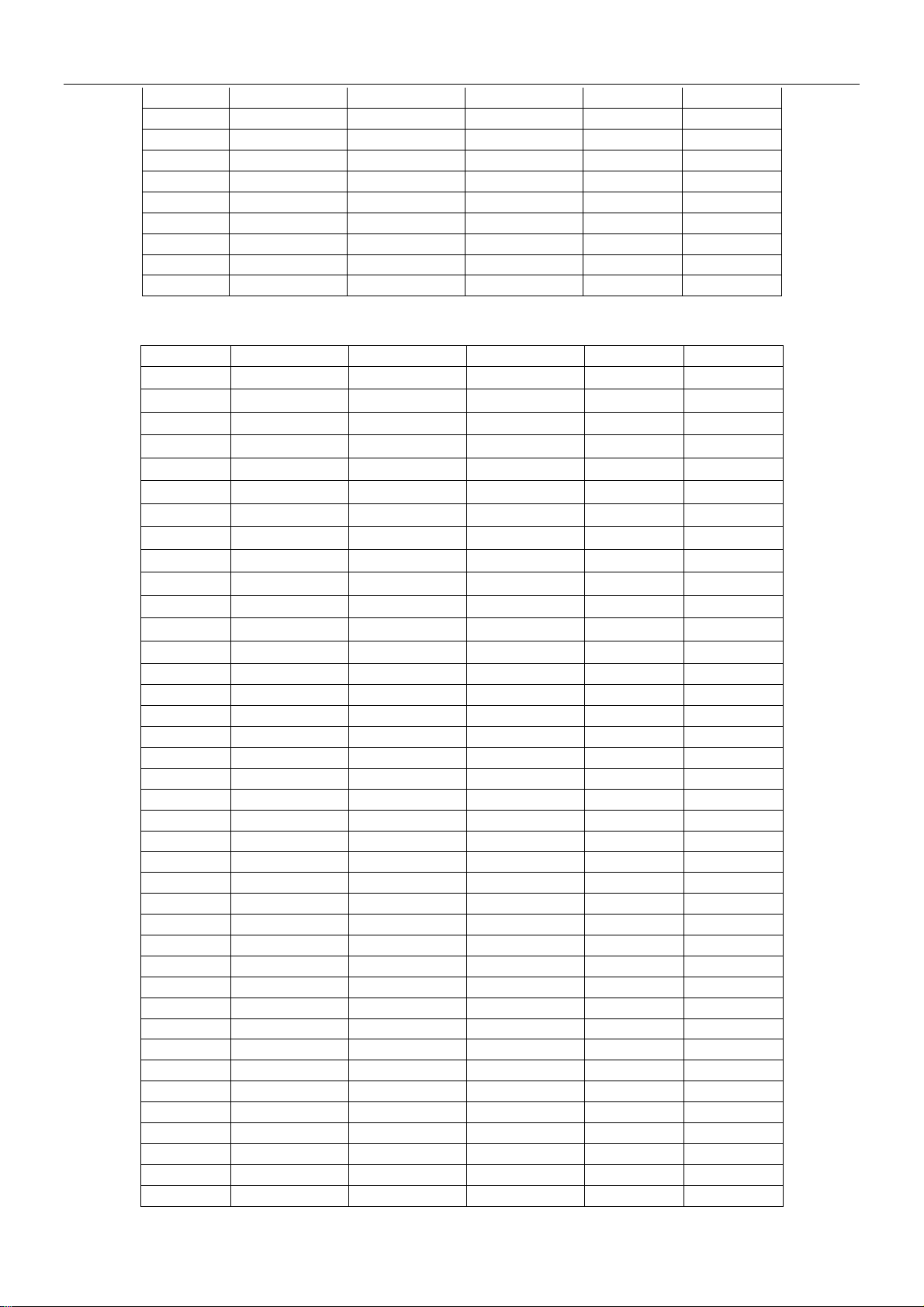

7.2.2 indoor pipe sensor R(0)=188.1K±4% ;B(0/50)3877K±3% R-T datasheet

Temp.(℃) R(min) (KΩ) R(cent) (KΩ) R(max) (KΩ)

-20

-19

-18

-17

-16

-15

-14

-13

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

510.22 548.83 589.42

482.84 518.50 555.89

457.10 490.02 524.47

432.88 463.28 495.02

410.09 438.16 467.39

388.64 414.55 441.47

368.44 392.35 417.14

349.41 371.47 394.30

331.47 351.83 372.84

314.56 333.34 352.67

298.61 315.93 333.72

283.56 299.53 315.89

269.36 284.07 299.11

255.95 269.50 283.32

243.28 255.77 268.46

231.32 242.81 254.46

220.01 230.58 241.27

209.31 219.03 228.84

199.20 208.13 217.11

189.63 197.83 206.06

180.58 188.10 195.62

171.49 178.90 186.34

162.91 170.20 177.54

154.80 161.98 169.21

147.14 154.19 161.32

139.91 146.82 153.83

133.06 139.85 146.74

126.59 133.24 140.01

120.47 126.98 133.62

114.68 121.05 127.57

109.20 115.42 121.81

104.00 110.09 116.35

99.085 105.03 111.16

94.425 100.23 106.23

90.008 95.680 101.55

85.822 91.355 97.091

81.851 87.249 92.855

78.085 83.349 88.825

74.511 79.643 84.992

- 23 -

ΔR(min) ΔR(max)

-7.0% 7.4%

-6.9% 7.2%

-6.7% 7.0%

-6.6% 6.9%

-6.4% 6.7%

-6.2% 6.5%

-6.1% 6.3%

-5.9% 6.1%

-5.8% 6.0%

-5.6% 5.8%

-5.5% 5.6%

-5.3% 5.5%

-5.2% 5.3%

-5.0% 5.1%

-4.9% 5.0%

-4.7% 4.8%

-4.6% 4.6%

-4.4% 4.5%

-4.3% 4.3%

-4.1% 4.2%

-4.0% 4.0%

-4.1% 4.2%

-4.3% 4.3%

-4.4% 4.5%

-4.6% 4.6%

-4.7% 4.8%

-4.9% 4.9%

-5.0% 5.1%

-5.1% 5.2%

-5.3% 5.4%

-5.4% 5.5%

-5.5% 5.7%

-5.7% 5.8%

-5.8% 6.0%

-5.9% 6.1%

-6.1% 6.3%

-6.2% 6.4%

-6.3% 6.6%

-6.4% 6.7%

Page 24

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

Shinco Service Manual

71.119 76.120 81.343

67.899 72.772 77.870

64.840 69.587 74.562

61.935 66.558 71.412

59.175 63.676 68.411

56.551 60.934 65.550

54.057 58.323 62.824

51.685 55.836 60.225

49.429 53.469 57.746

47.282 51.213 55.381

45.239 49.063 53.125

43.295 47.014 50.971

41.443 45.061 48.916

39.679 43.198 46.953

37.999 41.421 45.078

36.398 39.726 43.288

34.872 38.108 41.576

33.418 36.563 39.941

32.031 35.089 38.378

30.708 33.681 36.883

29.445 32.336 35.454

28.241 31.051 34.086

27.091 29.823 32.778

25.994 28.649 31.526

24.946 27.527 30.327

23.945 26.454 29.180

22.988 25.428 28.081

22.075 24.446 27.029

21.201 23.507 26.021

20.367 22.607 25.055

19.568 21.747 24.129

18.805 20.923 23.241

18.075 20.133 22.391

17.376 19.378 21.575

16.708 18.653 20.792

16.068 17.959 20.041

15.455 17.294 19.321

14.869 16.657 18.630

14.307 16.045 17.966

13.769 15.459 17.329

13.253 14.897 16.717

12.759 14.357 16.130

12.286 13.840 15.565

11.832 13.343 15.023

11.396 12.866 14.502

10.979 12.408 14.001

10.578 11.969 13.520

10.194 11.546 13.057

9.8257 11.141 12.612

9.4720 10.751 12.184

9.1324 10.377 11.772

8.8064 10.017 11.376

8.4934 9.6711 10.995

-6.6% 6.9%

-6.7% 7.0%

-6.8% 7.1%

-6.9% 7.3%

-7.1% 7.4%

-7.2% 7.6%

-7.3% 7.7%

-7.4% 7.9%

-7.6% 8.0%

-7.7% 8.1%

-7.8% 8.3%

-7.9% 8.4%

-8.0% 8.6%

-8.1% 8.7%

-8.3% 8.8%

-8.4% 9.0%

-8.5% 9.1%

-8.6% 9.2%

-8.7% 9.4%

-8.8% 9.5%

-8.9% 9.6%

-9.0% 9.8%

-9.2% 9.9%

-9.3% 10.0%

-9.4% 10.2%

-9.5% 10.3%

-9.6% 10.4%

-9.7% 10.6%

-9.8% 10.7%

-9.9% 10.8%

-10.0% 11.0%

-10.1% 11.1%

-10.2% 11.2%

-10.3% 11.3%

-10.4% 11.5%

-10.5% 11.6%

-10.6% 11.7%

-10.7% 11.8%

-10.8% 12.0%

-10.9% 12.1%

-11.0% 12.2%

-11.1% 12.3%

-11.2% 12.5%

-11.3% 12.6%

-11.4% 12.7%

-11.5% 12.8%

-11.6% 13.0%

-11.7% 13.1%

-11.8% 13.2%

-11.9% 13.3%

-12.0% 13.4%

-12.1% 13.6%

-12.2% 13.7%

- 24 -

Page 25

Shinco Service Manual

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

8.1928 9.3386 10.628

7.9040 9.0189 10.275

7.6266 8.7114 9.9346

7.3600 8.4156 9.6072

7.1038 8.1310 9.2920

6.8575 7.8572 8.9883

6.6208 7.5938 8.6958

6.3932 7.3401 8.4139

6.1742 7.0960 8.1423

5.9637 6.8609 7.8805

5.7611 6.6346 7.6282

5.5662 6.4165 7.3849

5.3787 6.2065 7.1504

5.1981 6.0042 6.9241

5.0224 5.8092 6.7060

4.8571 5.6214 6.4955

4.6960 5.4403 6.2924

4.5409 5.2657 6.0965

4.3915 5.0974 5.9073

4.2475 4.9351 5.7248

4.1088 4.7786 5.5486

3.9752 4.6276 5.3785

3.8464 4.4820 5.2142

3.7222 4.3414 5.0556

3.6025 4.2058 4.9023

3.4871 4.0750 4.7543

3.3759 3.9487 4.61

3.2685 3.8267 4.4731

3.1650 3.7090 4.3395

3.0651 3.5953 4.2105

2.9688 3.4855 4.0857

2.8758 3.3795 3.9650

2.7860 3.2770 3.8484

2.6994 3.1781 3.7356

2.6158 3.0824 3.6265

2.5350 2.9900 3.5210

2.4571 2.9007 3.4189

2.3818 2.8143 3.3202

2.3090 2.7309 3.2246

2.2388 2.6502 3.1321

2.1709 2.5721 3.0426

2.1053 2.4966 2.9560

2.0419 2.4236 2.8721

1.9807 2.3530 2.7909

1.9215 2.2847 2.7122

1.8642 2.2186 2.6361

1.8089 2.1546 2.5623

1.7554 2.0927 2.4909

1.7036 2.0328 2.4216

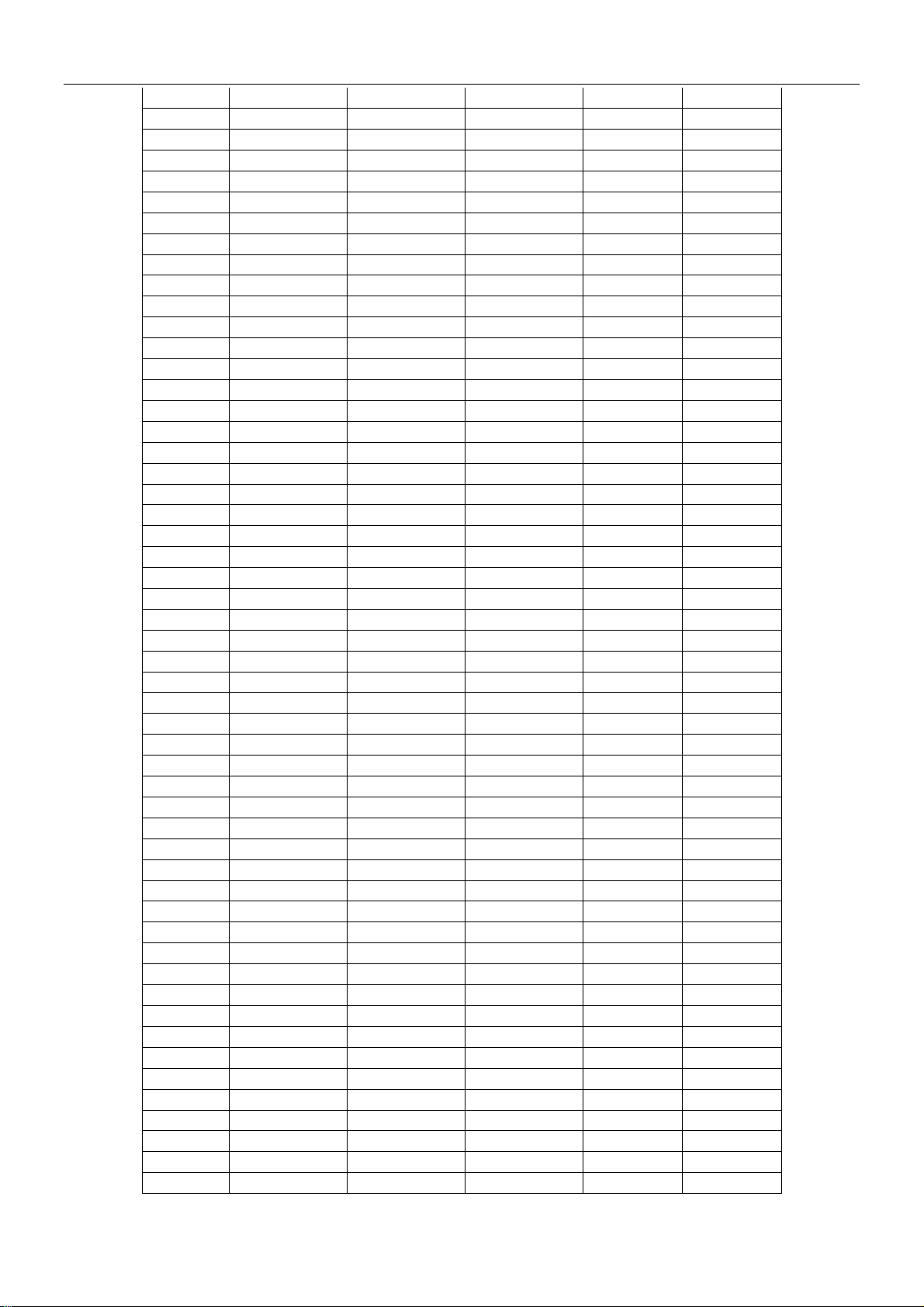

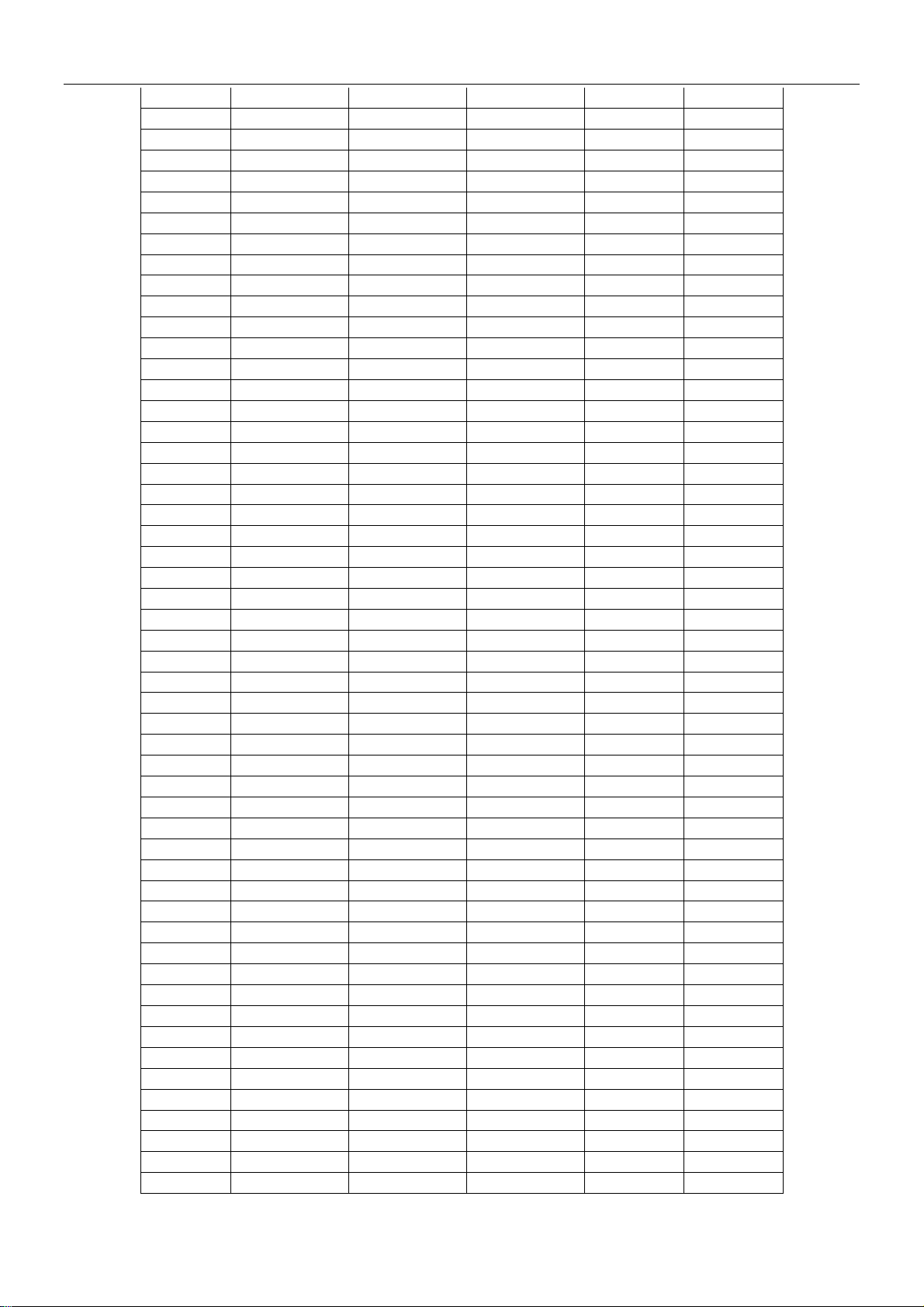

7.2.3 outdoor air sensor and outdoor pipe sensor

R(0)=15K±2% ;B(0/100)=3450K±2% R-T datasheet

Temp.(℃) R(min) (KΩ) R(cent) (KΩ) R(max) (KΩ)

- 25 -

-12.3% 13.8%

-12.4% 13.9%

-12.5% 14.0%

-12.5% 14.2%

-12.6% 14.3%

-12.7% 14.4%

-12.8% 14.5%

-12.9% 14.6%

-13.0% 14.7%

-13.1% 14.9%

-13.2% 15.0%

-13.3% 15.1%

-13.3% 15.2%

-13.4% 15.3%

-13.5% 15.4%

-13.6% 15.5%

-13.7% 15.7%

-13.8% 15.8%

-13.8% 15.9%

-13.9% 16.0%

-14.0% 16.1%

-14.1% 16.2%

-14.2% 16.3%

-14.3% 16.5%

-14.3% 16.6%

-14.4% 16.7%

-14.5% 16.8%

-14.6% 16.9%

-14.7% 17.0%

-14.7% 17.1%

-14.8% 17.2%

-14.9% 17.3%

-15.0% 17.4%

-15.1% 17.5%

-15.1% 17.7%

-15.2% 17.8%

-15.3% 17.9%

-15.4% 18.0%

-15.4% 18.1%

-15.5% 18.2%

-15.6% 18.3%

-15.7% 18.4%

-15.7% 18.5%

-15.8% 18.6%

-15.9% 18.7%

-16.0% 18.8%

-16.0% 18.9%

-16.1% 19.0%

-16.2% 19.1%

ΔR(min) ΔR(max)

Page 26

Shinco Service Manual

-40 106.800 113.500 120.500 -5.90% 6.17%

-39 101.000 107.200 113.700 -5.78% 6.06%

-38 95.600 101.300 107.400 -5.63% 6.02%

-37 90.430 95.760 101.400 -5.57% 5.89%

-36 85.610 90.550 95.740 -5.46% 5.73%

-35 81.070 85.660 90.470 -5.36% 5.62%

-34 76.800 81.060 85.510 -5.26% 5.49%

-33 72.780 76.730 80.860 -5.15% 5.38%

-32 68.990 72.650 76.480 -5.04% 5.27%

-31 65.420 68.820 72.370 -4.94% 5.16%

-30 62.060 65.210 68.500 -4.83% 5.05%

-29 58.890 61.810 64.860 -4.72% 4.93%

-28 55.890 58.610 61.430 -4.64% 4.81%

-27 53.070 55.590 58.210 -4.53% 4.71%

-26 50.410 52.750 55.170 -4.44% 4.59%

-25 47.890 50.060 52.310 -4.33% 4.49%

-24 45.520 47.530 49.610 -4.23% 4.38%

-23 43.270 45.140 47.070 -4.14% 4.28%

-22 41.150 42.890 44.670 -4.06% 4.15%

-21 39.150 40.760 42.410 -3.95% 4.05%

-20 37.260 38.740 40.280 -3.82% 3.98%

-19 35.460 36.840 38.260 -3.75% 3.85%

-18 33.770 35.050 36.360 -3.65% 3.74%

-17 32.160 33.350 34.560 -3.57% 3.63%

-16 30.640 31.740 32.860 -3.47% 3.53%

-15 29.200 30.220 31.260 -3.38% 3.44%

-14 27.840 28.780 29.740 -3.27% 3.34%

-13 26.550 27.420 28.310 -3.17% 3.25%

-12 25.330 26.130 26.950 -3.06% 3.14%

-11 24.170 24.910 25.670 -2.97% 3.05%

-10 23.070 23.75 24.450 -2.86% 2.95%

-9 22.020 22.66 23.300 -2.82% 2.82%

-8 21.030 21.62 22.210 -2.73% 2.73%

-7 20.090 20.63 21.180 -2.62% 2.67%

-6 19.200 19.7 20.200 -2.54% 2.54%

-5 18.350 18.81 19.270 -2.45% 2.45%

-4 17.540 17.97 18.390 -2.39% 2.34%

-3 16.780 17.17 17.560 -2.27% 2.27%

-2 16.050 16.41 16.770 -2.19% 2.19%

-1 15.360 15.69 16.010 -2.10% 2.04%

0 14.700 15 15.300 -2.00% 2.00%

1 14.050 14.35 14.650 -2.09% 2.09%

2 13.430 13.73 14.030 -2.18% 2.18%

3 12.840 13.14 13.440 -2.28% 2.28%

4 12.280 12.58 12.880 -2.38% 2.38%

5 11.750 12.05 12.340 -2.49% 2.41%

6 11.250 11.54 11.830 -2.51% 2.51%

7 10.770 11.05 11.340 -2.53% 2.62%

8 10.310 10.59 10.880 -2.64% 2.74%

9 9.876 10.16 10.440 -2.80% 2.76%

10 9.461 9.738 10.020 -2.84% 2.90%

11 9.067 9.340 9.617 -2.92% 2.97%

12 8.691 8.960 9.234 -3.00% 3.06%

13 8.333 8.598 8.868 -3.08% 3.14%

- 26 -

Page 27

Shinco Service Manual

14 7.9920 8.253 8.519 -3.16% 3.22%

15 7.667 7.924 8.186 -3.24% 3.31%

16 7.357 7.609 7.867 -3.31% 3.39%

17 7.061 7.309 7.563 -3.39% 3.48%

18 6.778 7.023 7.273 -3.49% 3.56%

19 6.509 6.749 6.995 -3.56% 3.64%

20 6.252 6.487 6.729 -3.62% 3.73%

21 6.006 6.238 6.475 -3.72% 3.80%

22 5.772 5.999 6.232 -3.78% 3.88%

23 5.548 5.770 5.999 -3.85% 3.97%

24 5.334 5.552 5.777 -3.93% 4.05%

25 5.130 5.343 5.564 -3.99% 4.14%

26 4.934 5.144 5.360 -4.08% 4.20%

27 4.747 4.952 5.165 -4.14% 4.30%

28 4.568 4.769 4.978 -4.21% 4.38%

29 4.397 4.594 4.798 -4.29% 4.44%

30 4.233 4.426 4.627 -4.36% 4.54%

31 4.077 4.266 4.462 -4.43% 4.59%

32 3.927 4.112 4.304 -4.50% 4.67%

33 3.783 3.964 4.153 -4.57% 4.77%

34 3.645 3.823 4.007 -4.66% 4.81%

35 3.513 3.687 3.868 -4.72% 4.91%

36 3.387 3.557 3.734 -4.78% 4.98%

37 3.266 3.432 3.606 -4.84% 5.07%

38 3.150 3.313 3.483 -4.92% 5.13%

39 3.038 3.198 3.364 -5.00% 5.19%

40 2.932 3.088 3.250 -5.05% 5.25%

41 2.829 2.982 3.141 -5.13% 5.33%

42 2.731 2.880 3.036 -5.17% 5.42%

43 2.636 2.782 2.935 -5.25% 5.50%

44 2.546 2.689 2.838 -5.32% 5.54%

45 2.459 2.599 2.745 -5.39% 5.62%

46 2.375 2.512 2.655 -5.45% 5.69%

47 2.295 2.429 2.569 -5.52% 5.76%

48 2.218 2.349 2.486 -5.58% 5.83%

49 2.1440 2.2720 2.4060 -5.63% 5.90%

50 2.0720 2.1970 2.3290 -5.69% 6.01%

51 2.0040 2.1260 2.2550 -5.74% 6.07%

52 1.9380 2.0580 2.1840 -5.83% 6.12%

53 1.8750 1.9920 2.1150 -5.87% 6.17%

54 1.8140 1.9280 2.0490 -5.91% 6.28%

55 1.7550 1.8670 1.9850 -6.00% 6.32%

56 1.6980 1.8080 1.9240 -6.08% 6.42%

57 1.6440 1.7510 1.8650 -6.11% 6.51%

58 1.5920 1.6960 1.8070 -6.13% 6.54%

59 1.5410 1.6440 1.7520 -6.27% 6.57%

60 1.4930 1.5930 1.6990 -6.28% 6.65%

61 1.4460 1.5440 1.6480 -6.35% 6.74%

62 1.4010 1.4970 1.5990 -6.41% 6.81%

63 1.3570 1.4510 1.5510 -6.48% 6.89%

64 1.3150 1.4070 1.5050 -6.54% 6.97%

65 1.2750 1.3650 1.4600 -6.59% 6.96%

66 1.2360 1.3240 1.4170 -6.65% 7.02%

- 27 -

Page 28

Shinco Service Manual

67 1.1980 1.2840 1.3760 -6.70% 7.17%

68 1.1620 1.2460 1.3360 -6.74% 7.22%

69 1.1270 1.2090 1.2970 -6.78% 7.28%

70 1.0930 1.1740 1.2600 -6.90% 7.33%

71 1.0600 1.1390 1.2240 -6.94% 7.46%

72 1.0290 1.1060 1.1890 -6.96% 7.50%

73 0.9985 1.0740 1.1550 -7.03% 7.54%

74 0.9691 1.0430 1.1220 -7.09% 7.57%

75 0.9407 1.0130 1.0910 -7.14% 7.70%

76 0.9133 0.9841 1.0600 -7.19% 7.71%

77 0.8868 0.9561 1.0300 -7.25% 7.73%

78 0.8612 0.9290 1.0020 -7.30% 7.86%

79 0.8364 0.9028 0.9741 -7.35% 7.90%

80 0.8124 0.8773 0.9473 -7.40% 7.98%

81 0.7893 0.8529 0.9213 -7.46% 8.02%

82 0.7669 0.8292 0.8962 -7.51% 8.08%

83 0.7452 0.8062 0.8718 -7.57% 8.14%

84 0.7242 0.7839 0.8482 -7.62% 8.20%

85 0.7039 0.7624 0.8254 -7.67% 8.26%

86 0.6842 0.7415 0.8032 -7.73% 8.32%

87 0.6652 0.7213 0.7817 -7.78% 8.37%

88 0.6468 0.7017 0.7609 -7.82% 8.44%

89 0.6290 0.6827 0.7407 -7.87% 8.50%

90 0.6117 0.6643 0.7212 -7.92% 8.57%

91 0.5949 0.6465 0.7022 -7.98% 8.62%

92 0.5787 0.6292 0.6838 -8.03% 8.68%

93 0.5630 0.6124 0.6660 -8.07% 8.75%

94 0.5478 0.5962 0.6486 -8.12% 8.79%

95 0.5330 0.5804 0.6318 -8.17% 8.86%

96 0.5187 0.5651 0.6155 -8.21% 8.92%

97 0.5048 0.5503 0.5997 -8.27% 8.98%

98 0.4913 0.5359 0.5843 -8.32% 9.03%

99 0.4783 0.5219 0.5694 -8.35% 9.10%

100 0.4656 0.5084 0.5549 -8.42% 9.15%

101 0.4533 0.4952 0.5408 -8.46% 9.21%

102 0.4414 0.4824 0.5271 -8.50% 9.27%

103 0.4298 0.4700 0.5138 -8.55% 9.32%

104 0.4186 0.4580 0.5009 -8.60% 9.37%

105 0.4077 0.4463 0.4883 -8.65% 9.41%

106 0.3971 0.4349 0.4761 -8.69% 9.47%

107 0.3868 0.4238 0.4643 -8.73% 9.56%

108 0.3768 0.4131 0.4527 -8.79% 9.59%

109 0.3671 0.4027 0.4415 -8.84% 9.63%

110 0.3576 0.3925 0.4306 -8.89% 9.71%

111 0.3485 0.3826 0.4200 -8.91% 9.78%

112 0.3396 0.3731 0.4097 -8.98% 9.81%

113 0.3309 0.3637 0.3997 -9.02% 9.90%

114 0.3225 0.3547 0.3899 -9.08% 9.92%

115 0.3143 0.3458 0.3804 -9.11% 10.01%

116 0.3063 0.3373 0.3711 -9.19% 10.02%

117 0.2986 0.3289 0.3621 -9.21% 10.09%

118 0.2911 0.3208 0.3533 -9.26% 10.13%

- 28 -

Page 29

Shinco Service Manual

119 0.2838 0.3129 0.3448 -9.30% 10.19%

120 0.2767 0.3052 0.3365 -9.34% 10.26%

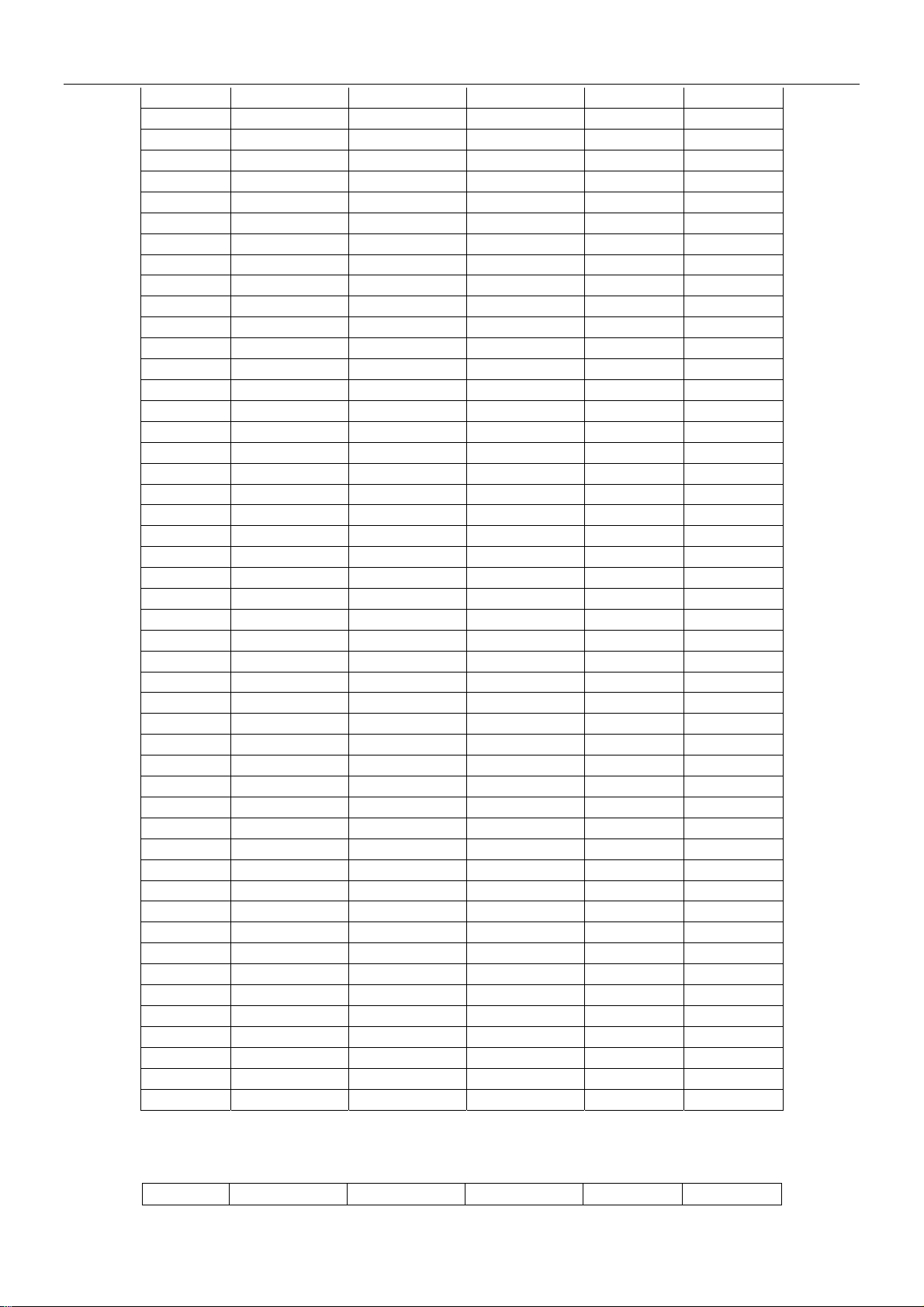

7.2.4 outdoor discharge pipe R(0)=187.25K±6.3% ;B(0/100)=3979K±1% R-T datasheet

Temp.(℃) R(min) (KΩ) R(cent) (KΩ) R(max) (KΩ)

-20 488.35 526.61 565.60 -7.3% 7.4%

-19 461.94 497.84 534.41 -7.2% 7.3%

-18 437.15 470.87 505.17 -7.2% 7.3%

-17 413.89 445.57 477.76 -7.1% 7.2%

-16 392.05 421.83 462.06 -7.1% 9.5%

-15 371.54 399.54 427.94 -7.0% 7.1%

-14 352.27 378.61 405.31 -7.0% 7.1%

-13 334.16 358.96 384.06 -6.9% 7.0%

-12 317.13 340.48 364.10 -6.9% 6.9%

-11 301.11 323.11 345.34 -6.8% 6.9%

-10 286.03 306.77 327.71 -6.8% 6.8%

-9 271.83 291.40 311.13 -6.7% 6.8%

-8 258.46 276.92 295.52 -6.7% 6.7%

-7 245.86 263.29 280.83 -6.6% 6.7%

-6 233.98 250.44 266.99 -6.6% 6.6%

-5 222.78 238.33 253.96 -6.5% 6.6%

-4 212.20 226.91 241.67 -6.5% 6.5%

-3 202.22 216.13 230.07 -6.4% 6.4%

-2 192.79 205.95 219.13 -6.4% 6.4%

-1 183.88 196.34 208.80 -6.3% 6.3%

0 175.45 187.25 199.05 -6.3% 6.3%

1 167.33 178.66 190.00 -6.3% 6.3%

2 159.64 170.53 181.45 -6.4% 6.4%

3 152.37 162.84 173.34 -6.4% 6.4%

4 145.49 155.56 165.67 -6.5% 6.5%

5 138.97 148.66 158.39 -6.5% 6.5%

6 132.80 142.12 151.49 -6.6% 6.6%

7 126.95 135.92 144.94 -6.6% 6.6%

8 121.40 130.03 138.73 -6.6% 6.7%

9 116.13 124.45 132.83 -6.7% 6.7%

10 111.13 119.14 127.22 -6.7% 6.8%

11 106.38 114.10 121.89 -6.8% 6.8%

12 101.87 109.31 116.82 -6.8% 6.9%

13 97.585 104.75 112.00 -6.8% 6.9%

14 93.506 100.42 107.41 -6.9% 7.0%

15 89.625 96.289 103.04 -6.9% 7.0%

16 85.930 92.358 98.873 -7.0% 7.1%

17 82.411 88.612 94.902 -7.0% 7.1%

18 79.058 85.042 91.116 -7.0% 7.1%

19 75.861 81.637 87.503 -7.1% 7.2%

20 72.813 78.388 84.055 -7.1% 7.2%

21 69.904 75.287 80.768 -7.1% 7.3%

22 67.128 72.326 77.618 -7.2% 7.3%

23 64.477 69.498 74.612 -7.2% 7.4%

24 61.945 66.795 71.738 -7.3% 7.4%

25 59.525 64.210 68.990 -7.3% 7.4%

26 57.211 61.739 66.360 -7.3% 7.5%

27 54.998 59.373 63.843 -7.4% 7.5%

ΔR(min) ΔR(max)

- 29 -

Page 30

Shinco Service Manual

28 52.880 57.110 61.433 -7.4% 7.6%

29 50.853 54.942 59.124 -7.4% 7.6%

30 48.913 52.866 56.911 -7.5% 7.7%

31 47.054 50.876 54.791 -7.5% 7.7%

32 45.273 48.939 52.757 -7.5% 7.8%

33 43.565 47.140 50.806 -7.6% 7.8%

34 41.928 45.386 48.934 -7.6% 7.8%

35 40.358 43.703 47.137 -7.7% 7.9%

36 38.852 42.087 45.412 -7.7% 7.9%

37 37.408 40.536 43.755 -7.7% 7.9%

38 36.018 39.047 42.163 -7.8% 8.0%

39 34.685 37.616 40.632 -7.8% 8.0%

40 33.404 36.240 39.162 -7.8% 8.1%

41 32.174 34.919 37.747 -7.9% 8.1%

42 30.991 33.648 36.387 -7.9% 8.1%

43 29.855 32.426 35.078 -7.9% 8.2%

44 28.761 31.250 33.819 -8.0% 8.2%

45 27.710 30.119 32.606 -8.0% 8.3%

46 26.699 29.030 31.439 -8.0% 8.3%

47 25.725 27.982 30.315 -8.1% 8.3%

48 24.788 26.973 29.233 -8.1% 8.4%

49 23.887 26.001 28.190 -8.1% 8.4%

50 23.018 25.065 27.185 -8.2% 8.5%

51 22.182 24.163 26.217 -8.2% 8.5%

52 21.377 23.295 25.284 -8.2% 8.5%

53 20.601 22.457 24.384 -8.3% 8.6%

54 19.854 21.650 23.516 -8.3% 8.6%

55 19.133 20.873 22.680 -8.3% 8.7%

56 18.439 20.123 21.873 -8.4% 8.7%

57 17.770 19.399 21.094 -8.4% 8.7%

58 17.125 18.702 20.343 -8.4% 8.8%

59 16.503 18.029 19.618 -8.5% 8.8%

60 15.903 17.380 18.920 -8.5% 8.9%

61 15.324 16.754 18.245 -8.5% 8.9%

62 14.766 16.150 17.594 -8.6% 8.9%

63 14.228 15.568 16.965 -8.6% 9.0%

64 13.709 15.005 16.358 -8.6% 9.0%

65 13.209 14.463 15.772 -8.7% 9.1%

66 12.726 13.939 15.207 -8.7% 9.1%

67 12.260 13.433 14.681 -8.7% 9.3%

68 11.810 12.946 14.134 -8.8% 9.2%

69 11.376 12.475 13.650 -8.8% 9.4%

70 10.958 12.020 13.133 -8.8% 9.3%

71 10.554 11.581 12.658 -8.9% 9.3%

72 10.164 11.158 12.200 -8.9% 9.3%

73 9.7880 10.749 11.757 -8.9% 9.4%

74 9.4251 10.354 11.330 -9.0% 9.4%

75 9.0749 9.9733 10.917 -9.0% 9.5%

76 8.7370 9.6055 10.518 -9.0% 9.5%

77 8.4109 9.2505 10.134 -9.1% 9.6%

78 8.0962 8.9078 9.7618 -9.1% 9.6%

79 7.7926 8.5770 9.4028 -9.1% 9.6%

80 7.4997 8.2577 9.0562 -9.2% 9.7%

- 30 -

Page 31

Shinco Service Manual

81 7.2170 7.9495 8.7215 -9.2% 9.7%

82 6.9443 7.6520 8.3983 -9.2% 9.8%

83 6.6812 7.3649 8.0883 -9.3% 9.8%

84 6.4273 7.0878 7.7850 -9.3% 9.8%

85 6.1825 6.8204 7.4942 -9.4% 9.9%

86 5.9462 6.5623 7.2135 -9.4% 9.9%

87 5.7184 6.3133 6.9424 -9.4% 10.0%

88 5.4987 6.0731 6.6808 -9.5% 10.0%

89 5.2867 5.8413 6.4284 -9.5% 10.1%

90 5.0827 5.6177 6.1847 -9.5% 10.1%

91 4.8853 5.4018 5.9495 -9.6% 10.1%

92 4.6953 5.1939 5.7226 -9.6% 10.2%

93 4.5121 4.9932 5.5037 -9.6% 10.2%

94 4.3355 4.7997 5.2925 -9.7% 10.3%

95 4.1653 4.6131 5.0840 -9.7% 10.2%

96 4.0012 4.4331 4.8922 -9.7% 10.4%

97 3.8431 4.2596 4.7026 -9.8% 10.4%

98 3.6908 4.0924 4.5198 -9.8% 10.4%

99 3.5440 3.9312 4.3435 -9.8% 10.5%

100 3.4025 3.7759 4.1735 -9.9% 10.5%

101 3.2663 3.6262 4.0097 -9.9% 10.6%

102 3.1351 3.4819 3.8517 -10.0% 10.6%

103 3.0087 3.3429 3.6995 -10.0% 10.7%

104 2.8870 3.2090 3.5528 -10.0% 10.7%

105 2.7699 3.0801 3.4114 -10.1% 10.8%

106 2.6571 2.9559 3.2720 -10.1% 10.7%

107 2.5485 2.8363 3.1440 -10.1% 10.8%

108 2.4441 2.7211 3.0176 -10.2% 10.9%

109 2.3435 2.6103 2.8959 -10.2% 10.9%

110 2.2468 2.5036 2.7787 -10.3% 11.0%

111 2.1537 2.4009 2.6658 -10.3% 11.0%

112 2.0642 2.3021 2.5572 -10.3% 11.1%

113 1.9781 2.2070 2.4526 -10.4% 11.1%

114 1.8954 2.1155 2.3519 -10.4% 11.2%

115 1.8158 2.0276 2.2551 -10.4% 11.2%

116 1.7393 1.9430 2.1619 -10.5% 11.3%

117 1.6657 1.8616 2.0723 -10.5% 11.3%

118 1.5951 1.7834 1.9861 -10.6% 11.4%

119 1.5272 1.7082 1.9032 -10.6% 11.4%

120 1.4619 1.6359 1.8234 -10.6% 11.5%

- 31 -

Page 32

Shinco Service Manual

8. Parts List and exploding view

Exploding view and part list of KFR-25GWZ/BM

Indoor unit

No. Part Name Quantity BOM code

1 Wall Mounted Board 1 e18503

2 Chassis Assembly 1 e535123

3 Cross Fan 1 e19294

4 Left Axial Cover 1 e19257

5 Evaporator Pipe 1 e20747

6 Evaporator 1 eQ00138

7 Frame Assembly 1 e19297

8 Frame 1

9 PVC 1 eb38637

10 Filter 1 7 include 10

11 Display board Assembly 1 e50543

- 32 -

7 include 8

Page 33

12 Indoor 1 eb35153

13 Air Sensor 1 eb11665

14 Pipe sensor 1 eb11666

15 Motor Cover 1 e19258

16 Indoor Motor 1 eb38560

17 Step Motor 1 eb60073

18 Copper Pipe Clip 1 e19256

19 Electric Controlling box Up Cover 1 e19296

20 Indoor Controlling Board 1 e50582

21 Electric Controlling box soleplate 1 e19295

22 Electric Controlling box 1 e18499

23 Remote Controller 1 eb85093

Outdoor unit

Shinco Service Manual

No. Part Name Quantity BOM code

1 Front Frame Assembly 1 e30640/e30641

2 Chassis Assembly 1 e30851/e30852

- 33 -

Page 34

Shinco Service Manual

3 Axial Fan 1 eb38658

4 Motor Bracket 1 e30206

5 Outdoor Air Sensor 1 eb11667

6 Condenser 1 eQ00136

7 Top Cover 1 e14335/e14336

8 4-way valve winding 1 eb40103

9 4-way valve 1 eb40090

10 discharge sensor 1 eb11664

11 pipe sensor 1 eb11667

12 Capillary assembly 1 e20603

13 middle clipboard 1 e15607

14 outdoor motor 1 eb61530

15 compressor 1 eb15582

16 valve board 1 e14339/e14340

17 high pressure valve 1 eb40092

18 low pressure valve 1 eb40093

19 electric controlling box cover 1 e30745

20 electric controlling box 1 e30639

21 Fin 1 e30702

22 outdoor driver board 1 e52138

23 Outdoor terminal block 1 eb35154/eb35153

24 outdoor PFC board 1 e52137

25 Right Side Panel 1 e30644/e30645

26 big handle 1 e14219

- 34 -

Page 35

Shinco Service Manual

Exploding view and part list of KFR-35GWZ/BM

Indoor unit

No. Part Name Quantity BOM code

1 Wall Mounted Board 1 e18503

2 Chassis Assembly 1 e535123

3 Cross Fan 1 e19294

4 Left Axial Cover 1 e19257

5 Evaporator Pipe 1 e20748

6 Evaporator 1 eQ00138

7 Frame Assembly 1 e19297

8 Frame 1

7 include 8

9 PVC 1 eb38637

10 Filter 1 7 include 10

11 Display board Assembly 1 e50543

- 35 -

Page 36

Shinco Service Manual

12 Indoor terminal block 1 eb35153

13 Air Sensor 1 eb11665

14 Pipe sensor 1 eb11666

15 Motor Cover 1 e19258

16 Indoor Motor 1 eb38560

17 Step Motor 1 eb60073

18 Copper Pipe Clip 1 e19256

Electric Controlling box Up

19

Cover 1 e19296

20 Indoor Controlling Board 1 e52125

Electric Controlling box

21

soleplate 1 e19295

22 Electric Controlling box 1 e18499

23 Remote Controller 1 eb85093

Outdoor unit

- 36 -

Page 37

Shinco Service Manual

No. Part Name Quantity BOM code

1 Chassis Assembly 1 e30640/e30641

2 Front Frame Assembly 1 e14598/e14599

3 Axial Fan 1 eb38658

4 Motor Bracket 1 e30308

5 Outdoor Air Sensor 1 eb11667

6 Condenser 1 eQ00137

7 Top Cover 1 e14335/e14336

8 4-way valve winding 1 eb40103

9 4-way valve 1 eb40094

10 discharge sensor 1 eb11664

11 pipe sensor 1 eb11667

12 Capillary assembly 1 e20617

13 middle clipboard 1 e15607

14 outdoor motor 1 eb61530

15 compressor 1 eb15599

16 valve board 1 e14339/e14340

17 high pressure valve 1 eb40092

18 low pressure valve 1 eb40096

19 electric controlling box cover 1 e30745

20 electric controlling box 1 e30639

21 Fin 1 e30702

22 outdoor driver board 1 e52138

23 Outdoor terminal block 1 eb35154/eb35153

24 outdoor PFC board 1 e52137

25 Right Side Panel 1 e30644/e30645

26 big handle 1 e19306

- 37 -

Page 38

Shinco Service Manual

8.3 Exploding view and part list of KFR-50GWZ/BM

Indoor unit

No. Part Name Quantity BOM code

1 Wall Mounted Board 1 e17978

2 Chassis Assembly 1 e19341

3 Cross Fan 1 eb38669

4 Left Axial Cover 1 e17980

5 Evaporator Pipe 1 e20509

6 Evaporator 1 eQ00139

7 Frame Assembly 1 e19340

8 Frame 1

7 include 8

9 PVC 1 e19383

- 38 -

Page 39

Shinco Service Manual

10 Filter 1 e17989

11 Display board Assembly 1 e50543

12 Indoor terminal block 1 eb35153

13 Air Sensor 1 eb10007

14 Motor Cover 1 e17982

15 Indoor Motor 1 eb38668

16 Step Motor 1 eb38162

17

18 Copper Pipe Clip 1 e17987

19 Electric Controlling box 1 e30706

20 Electric Controlling box soleplate 1 e19343

21 Indoor Controlling Board 1 e50613

22 Electric Controlling box top Cover 1 e30707

23 Remote Controller 1 eb85093

Outdoor unit

Flume 1 e19342

- 39 -

Page 40

Shinco Service Manual

No. Part Name Quantity BOM code

1 Chassis Assembly 1 e30708/e30709

2 Front Frame Assembly 1 e30741/e30742

3 Axial Fan 1 eb38670

5 Motor Bracket 1 e30684

6 Outdoor Air Sensor 1 eb10011

7 Condenser 1 eQ00140

8 Top Cover 1 e30680/e30681

9 4-way valve winding 1 eb40103

10 4-way valve 1 eb40094

11 discharge sensor 1 eb11664

12 pipe sensor 1 eb11660

13 Capillary assembly 1 e22179

14 middle clipboard 1 e30679

4 outdoor motor 1 eb61531

23 compressor 1 eb15656

24 valve board 1 e30749/e30750

26 high pressure valve 1 eb40092

25 low pressure valve 1 eb40137

15 electric controlling box cover 1 e30683

16 electric controlling box 1 e30682

17 High-frequency inductance 1 eb38674

18 outdoor driver board 1 e50615

19 Outdoor terminal block 1 eb35154

20 outdoor power board 1 e50614

22 Right Side Panel 1 e30710/e30711

21 big handle 1 e19306

- 40 -

Page 41

Shinco Service Manual

Exploding view and part list of KFR-70GWZ/BM

Indoor unit

No. Part Name Quantity BOM code

1 Wall Mounted Board 1 e18416

2 Air outlet vent assembly 1 e535126

3 Chassis Assembly 1 e19326

4 Cross Fan 1 eb38667

5 indoor connect pipe 1/2 1 e20442/e18771

6 Evaporator 1 eQ00141

7 Part Name 1 e19328

8 PVC 1 e19384

- 41 -

Page 42

Shinco Service Manual

9 Remote Controller 1 eb85093

10 Display board Assembly 1 e50543

11 Air Sensor 1 eb10007

12 Indoor Controlling Board 1 e50610

13 Indoor power Board 1 e50609

14 Electric Controlling box top Cover 1 e19325

15 Electric Controlling box 1 e19324

16 Indoor terminal block 1 e35153

17 Indoor Motor 1 eb61535

18 Indoor Motor cover 1 e19339

19 Step Motor 1 eb38229

Outdoor unit

- 42 -

Page 43

Shinco Service Manual

No. Part Name Quantity BOM code

1 Chassis Assembly 1 e30478/e30479

2 Front Frame Assembly 1 e30693/e30694

3 Axial Fan 1 eb38666

4 Outdoor motor 1 eb61532

5 Motor Bracket 1 e30512

6 middle clipboard 1 e19166

7 outdoor air sensor 1 eb10011

8 Condenser 1 eQ00142

9 Top Cover 1 e15838/e15839

10 outdoor pipe sensor 1 eb11660

11 High-frequency inductance 1 eb38676

12 outdoor power board 1 e50611

13 outdoor driver board 1 e50612

14 electric controlling box cover 1 e30252

15 electric controlling box 1 e30697

16 Outdoor terminal block 1 eb35156

17 Capillary assembly 1 e22092

18 4-way valve 1 eb40741

19 4-way valve winding 1 eb40742

20 big handle 1 e14219

21 valve board 1 e15831/e15832

22 low pressure valve 1 e40719

23 high pressure valve 1 e40718

24 compressor 1 eb15630

25 indoor to outdoor connect pipe 2 e21093/e21094

26 Right Side Panel 1 e30695/e30696

27 Right Frame Panel 1 e15835/e30494

- 43 -

Page 44

Part II

1. Service warning

Part I General Warnings

1、The service person should wear safety belt if working more than 2.5m above the ground.

2、If working above ground level, measures should be adopted to prevent the outdoor unit or tools

from falling and causing injuries or damage.

3、Check the customers power supply before testing the unit.

4、The power supply should be switched OFF when disassembling the casing and electrical

components.

5、Take care to prevent a frost bite injury when charging with refrigerant.

6、Do not over pressurize the Freon cylinder. The over exposure, high temperature or dropping the

Shinco Service Manual

cylinder should be avoided, otherwise, it could cause an explosion.

7、If there is need to pressure test the system, Dry Nitrogen should be used.

Part II Warnings of repair operation

1、 The high capacity electrolytic capacitor is used in the electric control cabinet of the outdoor unit.

Even if the power plug is unplugged; this capacitor will retain a residual charge for a certain time. In

order to avoid electric shock, please do not touch the control board as soon as the power is switched

OFF. If it is necessary to change the control board of the outdoor unit, please switch OFF the power

supply first. After the light emitting diode of outdoor control board extinguishes or the power is

switched OFF for >30 sec’s, let the high capacity capacitor discharges fully. The replacement can

only be conducted after checking the high capacity capacitor has discharged fully with an electrical

meter.

2、 After making use of self-diagnosis of faults on the site, switch the snap switch to “demonstrate”,

re-electrify the air-conditioner so that the system can erase the stored fault information of former

self-diagnosis. Switch the snap switch to “ON” again, prepare for re-starting the air-conditioner.

Because the LS-LT1508V model air-conditioner has not been fitted with an E

device of fault information), the fault information will be automatically erased after switching OFF

the power.

2

PROM (storage

3、 For diagnosis of the system fault, first it is suggested to check whether the electrical wiring is

reliable and correct. After eliminating this cause, continue to seek other causes.

- 44 -

Page 45

2. Frequency table

F0 F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Shinco Service Manual

KFR-25GWZ/BM

COOLING

KFR-25GWZ/BM

HEATING

KFR-35GWZ/BM

COOLING

KFR-35GWZ/BM

HEATING

KFR-50GWZ/BM

COOLING

KFR-50GWZ/BM

HEATING

KFR-70GWZ/BM

COOLING

KFR-70GWZ/BM

HEATING

0 30 35 40 45 52 55 58 66 69 73

0 30 35 40 45 52 55 59 66 69 73

0 30 36 42 48 54 61 66 72 78 84

0 30 36 42 48 54 61 66 72 78 84

0 30 36 43 49 56 64 72 77 82 87

0 30 36 43 49 58 67 77 81 84 87

0 30 34 39 44 48 52 57 62 67 72

0 30 35 40 46 51 56 62 67 73 78

3. Method of Testing the System at a Fixed Frequency

Cooling

Capacity(MIDDLE

FREQUENCY)

1. Start the air conditioner

2.Operate remote controller as following

Mode : Cool mode

Set temp. : 18℃

indoor fan : high

Press ‘powerful’ button 5 times with 10 seconds.

Cooling rated capacity Heating Capacity(MIDDLE

FREQUENCY)

Mode : Cool mode

Set temp. : 16℃

indoor fan : high

Mode : heat mode

Set temp. : 28℃

indoor fan : high

Heat rated capacity

Mode : heat mode

Set temp. : 30℃

indoor fan : high

- 45 -

Page 46

Shinco Service Manual

4. Running mode

4.1. Defrosting

1. Entry condition:

Defrosting starts when meeting one of the following conditions

a. The temperature of outdoor heat exchanger remains consecutively lower than 3°c for more than

temperature remains consecutively

b. The temperature of outdoor heat exchanger remains consecutively lower than 3°c for more than

temperature remains consecutively

c. The temperature of outdoor heat exchanger remains consecutively lower than 3°c for more than

temperature remains consecutively

2. .Ending condition of defrosting

If one of following conditions is satisfied, end the defrosting and turn into heating mode:

a. The defrost time has reached to 10 minutes.

b. When the temperature of outdoor heat exchanger rises up to

3.Defrosting Actions:

Max. 10 minutes

20s 20 s

ON 10s 10S

Compressor. OFF

ON ON

4 way valve OFF

ON ON

Outdoor fan OFF

ON

-6°c for more than 3 minutes

-4°c for more than 3 minutes

-3°c for more than 3 minutes

15°C.

4.2. Fan-only mode

The outdoor unit doesn’t operation, only the indoor fan runs. The fan speed can be set on HIGH MID LOW, and the

louver can be regulated by remote controller.

4.3. Cooling mode

40 minutes, and the

80 minutes, and the

120 minutes, and the

4.3.1 Compressor frequency controlling

a. Frequency control when starting

Temperature difference= Room temperature (RT)-Set temperature (ST)

RT-ST

b. Frequency control during operation

The frequency will change according to the RT-ST, and details see following fig.

- 46 -

Page 47

Shinco Service Manual

A-—E: rise the present frequency one class (for example, from F3 to F4)

F: Frequency keep unchanged

G:lower the present frequency on class( for example, from F4 to F3), and the

maximum frequency is F3 in G area.

H:The compressor stops.

c. Frequency will change due to outdoor temperature, details see following fig.

4.3.2 Indoor heat exchanger anti-frozen

When indoor air sensor temperature is less than 3℃, the frequency will lower down to protect

indoor heat exchanger. When indoor air sensor temperature is higher than 6℃ for more than 10 minutes,

the air conditioner will return to former mode.

When indoor air sensor temperature is less than -1℃,the compressor will stop to protect indoor

heat exchanger. When indoor air sensor temperature is higher than 6℃ for more than 10 minutes, the

air conditioner will return to former mode.

4.3.3 Outdoor heat exchanger anti-overheated

When condenser temperature is higher than 54℃, the compressor frequency will be

lowered down to protect the heat exchanger , and the outdoor fan runs in high speed. When condenser

temperature lower down to 52℃, the compressor frequency rise up, and when the condenser temperature

lower to 50℃ and keep for 5 minutes, and compressor frequency will rise to former value.

- 47 -

Page 48

Shinco Service Manual

When condenser temperature is higher than 60℃, the compressor will stop, and hen the condenser

temperature lower to 50℃ and keep for 5 minutes, and compressor frequency will rise to former value

4.4. Dehumidifying mode

4.4.1 Temperature set and motor control in dehumidifying mode

The compressor and outdoor fan run in dehumidifying mode similar as cooling mode,

and the temperature can be set.

The indoor motor speed need to be set in low speed.

4.4.2 Compressor frequency on dehumidifying mode

The maximum frequency in dehumidifying mode is F3,and the frequency changes as following

fig.

4.4.3 The louver control in dehumidifying mode

The Louver control in dehumidifying mode is same as cooling mode.

4.4.4 Protection

The Indoor heat exchanger anti-frozen and Outdoor heat exchanger anti-overheat is same as

cooling mode.

4.5. Heating mode

4.5.1 Compressor frequency controlling

a. Frequency control when starting

Temperature difference= Room temperature (RT)-Set temperature (ST)

RT-ST

- 48 -

Page 49

Shinco Service Manual

b. Frequency control during operation

The frequency will change according to the RT-ST, and details see following fig.

A-—E: rise the present frequency one class (for example, from F3 to F4)

F: Frequency keep unchanged

G:Lower the present frequency on class (for example, from F4 to F3), and the

maximum frequency is F3 in G area.

H:The compressor stops.

c. Frequency will change due to outdoor temperature, details see following fig.

- 49 -

Page 50

Shinco Service Manual

4.5.2 Indoor heat exchanger anti-overheated

When indoor exchanger temperature is higher than 50℃, the compressor frequency

will be lowered down to protect the heat exchanger. When indoor exchanger temperature lower down

to 46℃, the compressor frequency rise up, and when the

℃ and keep for 5 minutes, and compressor frequency will rise to former value.

indoor exchanger temperature lower to 44

When condenser temperature is higher than 54℃, the compressor will stop, and hen the condenser

temperature lower to 44℃ and keep for 5 minutes, and compressor frequency will rise to former value

4.6 Emergency Operation

The set temperature is 24 , and the fan speed is AUTO during emergency operation.℃

Press emergency switch within 5 s during stand-by mode, and the air conditioner starts emergency mode if

there is DU sound from indoor unit.

Press emergency switch during operation mode, and the air conditioner can be turned off.

Note: During emergency mode, the air conditioner will turn to the mode set by remote controller after

receiving signal from remote controller.

4.7 Sleeping operation

Cooling mode: Press sleep button, the fan speed lower down one class automatically ( HI-ME-LO-VL). The

set temperature rise one degree, and rise one degree again one hour later, then keep it.

Heating mode: Press sleep button, the fan speed lower down one class automatically (HI-ME-LO-VL). The set

temperature lower one degree, and lower one degree again one hour later, then keep it.

Note: During sleep mode, if change the set temperature, the a ctual set temperature is new set temperature

plus lowered or rised temperature.

4.8 Auto restart:

The air conditioner will restart with set mode automatically after power on again, and this can be canceled by

user, and to cancel this mode follow the following instructions:

1. Press ON/OFF button 6 times within 7 s, and the AUTO restart mode can be cancelled.

2. Press ON/OFF button 6 times within 7s, and the AUTO restart mode can be set again.

- 50 -

Page 51

Shinco Service Manual

4.9 Refrigerant charge mode

Entry condition:

Press the emergency switch over 5 seconds, there will be three “DU” sound in the indoor unit, and start

the unit with the remote controller.

Actions

1. On cooling mode, the indoor fan speed is low

2. Cancel the mode

Turn off the air conditioner with remote controller

:

the frequency is fixed on F6,

:

5. Protection

5.1 Compressor protection

5.1.1 High pipe discharge temperature protection

When discharge pipe temperature is higher than T3, the compressor frequency will

be lowered, when discharge pipe temperature lower to T1, the frequency will rise, and the

frequency will be limited one class than former one. When the discharge pipe temperature

lower to T2 and keep for 10 minutes, the frequency will return to former one.

When discharge pipe temperature is higher than T4, the compressor stop and the

outdoor motor stop 15s later. When discharge pipe temperature lower to T1 and the unit

restart after 3 minutes.

T1 T2 T3 T4

KFR-25GWZ/BM

KFR-35GWZ/BM

KFR-50GWZ/BM

KFR-70GWZ/BM

90 95 105 110

5.1.2 Sensor protection

There is thermal sensor on compressor, and the compressor will stop when the temperature is too

high, and the outdoor motor will stop 15s later. When the temperature return normal value, the

compressor will restart 3 minutes later.

5.1.3 Compressor relay start protection

The compressor will restart 3 minutes after stop.

5.2 Current protection

When outdoor current is higher than I1, the compressor frequency will be limited and prohibited to rise. When the

current is higher than I2, and the compressor frequency will lower until the current is lower than I1.

When outdoor current is lower than I3, the compressor will stop.

The detailed current value see below table:

- 51 -

Page 52

Shinco Service Manual

KFR-25GWZ/BM

MODE I1 I2 I3

COOLING AND DEHUMIDIFYING 7.1 8.3 10.3

HEATING 6.3 7.5 9.5

KFR-35GWZ/BM

MODE I1 I2 I3

COOLIGN AND DEHUMIDIFYING 8.1 9.6 11.6

HEATING 10.5 12 14

KFR-50GWZ/BM

MODE I1 I2 I3

COOLING AND DEHUMIDIFYING 8.5 10.5 12.5

HEATING 8.5 10.5 12.5

KFR-70GWZ/BM

MODE I1 I2 I3

COOLIGN AND DEHUMIDIFYING 12 16 18

HEATING 14 19 21

5.3 Low voltage protection

The compressor frequency changes as following fig. during low voltage:

When voltage value lower than 190V and keep for 10s, the low voltage protection start,

and when voltage value rise to 195V and keep for 10s, the low voltage proteccion finish.

When voltage value lower than 158V, the unit turn off, when voltage rise to 162V, keep

for 10s, the unit restart.

- 52 -

Page 53

Shinco Service Manual

6、Display lamp

6.1 Indoor display

5 6 7

1 2 3 4

1 Dual-Digital lamp; 2 Timer Lamp; 3 Operation lamp; 4 Protection Lamp; 5 cooling mode; 6 dehumidify mode;

7 heating mode 。

6.2 Fault code display

KFR-25GWZ/BM、KFR-35GWZ/BM

Item FAULT CODE CHECK POINT COUNT MEASURE

CHECK IF THE INDOOR UNIT MATCH OUTDOOR UINT CHANGE WRONG UNIT。

1、 CHECKTHE VALUE OF SENSOR

2、 OUTDOOR POWER BOARD IS FAULT(CHECK

CAPICATOR)

CHANGE SENSOR

CHANGE POWER BOARD

1

2

INDOOR UNIT DON’T MATCH

OUTDOOR UNIT

OUTDOOR DISCHARGE PIPE

SENSOR FAULT

EP

E0

- 53 -

Page 54

Shinco Service Manual

1.CHECK IF THE CONNECTING WIRING IS CONNECT

WELL

2.TEST THE VOLTAGE VALUE BETWEEN L4 AND S,

IF IT ‘S CHANGE REGULARLY,THE SINGAL

TRANSFERING BETWEEN INDOOR AND OUTDOOR UNIT

1.FIX THE WIRING AGAIN。

2.CHANGE RELATE PCB BOARD

IS GOOD,

WHEN IT‘S NO CHANGE

3

COMMUNICATION FAULT

BETWEEN INDOOR UNIT AND

OUTDOOR UNIT

E4

IF VALUE IS BELOW 14V, THE INDOOR PCB BOARD

IS FAULT,CHANGE IT.

IF VALUE IS OVER 14V,THE OUTDOOR PCB IS FAULTY

3)CHECK IF THERE IS LED FLASHING ON THE

OUTDOOR PCB

IF THERE IS NO FLASHING,CHECK VOLTAGE VALUE

FROM POWER BOARD TO PFC BOARD, BETWEEN ACL AND

CAN ON PFC BOARD

IF IT’S NOT 220V, CHANGE POWER BOARD

IF IT’S 220V,CHANGE PFC BOARD

4

5

6

7

8

COMPRESSOR DRIVER BOARD

IS

OURDOOR AIR SENSOR IS

FAULTY

OUTDOOR PIPE SENSOR IS

FAULT

INDOOR AIR SENSOR IS

FAULTY

INDOOR PIPE SENSOR IS

FAULTY

EA

E6

E1

E2

CHECK OUTDOOR DRIVER BOARD CHANGE DRIVER BOARD

1、 CHECK THE SENDOR VALUE

2、 POWER BOARD IS FAULT

3、 CHECK THE SENSOR VALUE

4、 INDOOR BOARD IS FAULT

CHANGE SENSOR

CHANGE POWER BAORD。

CHANGE SENDOR

CHANGE INDOOR BOARD

9 POWER BOARD IS FAULT E8 OUTDOOR POWER BOARD IS FAULT CHANGE THE POWER BOARD

10 POWER BOARD IS FAULT E9 OUTDOOR POWER BOARD IS FAULT CHANGE THE POWER BOARD

DRIVER BOARD IS FAULT DRIVER BOARD IS FAULT

11 DRIVER BOARD IS FAULT E5

12

OUDOOR COMMUNICATION

FAULTY

EC

- 54 -

CHECK IF WIRINGS BETWEEN POWER BOARD AND

DRIVER BOARD ARE CONNECTED WELL

FIX THE WIRING BETWEEN POWER BOARD AND

DRIVER BOARD

Page 55

Shinco Service Manual

13 INDOOR MOTOR IS FAULT E3

1、INDOOR MOTOR OR INDOOR MOTOR CAPACITOR IS

FAULT

2、INNER WIRING DON’T CONNECT WELL

3、INDOOR PCB IS FAULT

4、INDOOR MOTOR IS BLOCKED

1、CHANGE MOTOR OR CAPACITOR

2、FIX THE WIRINGS

3、CHANGE INDOOR PCB

4、REMOVE THE BLOCKING

14 INDOOR PCB BAORD IS FAULTY EE INDOOR PCB BAORD IS FAULTY INDOOR PCB BAORD IS FAULTY

1

OUTDOOR DISCHARGE TEMP IS

TOO HIGH

P1

2 DRIVER BOARD PROTECTION P7

1、 CHECK IF THE OUTLET IS BLOCKED OR THE

CONDENSOR IS DIRTY

2、 CHECK THE OUTDOOR MOTOR WORK NORMALLY

3、CHECK IF THE REFRIGERANT IS CHARGED TOO MUCH

1、 CHECK IF THE REFRIGERANT IS CHARGED TOO

MUCH

2、 CHECK IF THE COMPRESSOR IS BLOCKED

1、REMOVE OBSTACLE AROUND OUTDOOR UNIT OR

WASH THE CONDENSER

2、CHANGE OUTDOOR MOTOR OR MOTOR CAPACITOR

3、REGULATE THE QUANTITY OF REFRIGERANT

1、REGULATE THE QUANTITY OF REFRIGERANT

2、CHANGE COMPRESSOR

3、CHANGE IPM MOLD

3、 IPM MOLD IS FAULT

3 THE VOLTAGE IS NOT STABLE P3 CHECK THE POWER SUPPLY RESTART THE AIR CONDITIONER

4

ELECTRIC CURRENT IS TOO

HIGH

P2

1、CHECK IF THE REFRIGERANT IS CHARGED TOO MUCH

2、CHECK IF THE VOLTAGE IS TOO LOW, POWER

WRINGIS TOO THIN OR TOO LONG OR CONTACT

BADLY

3、 CHECK IF THE OUTLET IS BLOCKED OR THE

CONDENSOR IS DIRTY

1、REGULATE THE QUANTITY OF REFRIGERANT

2、UPDATING POWER SUPPLY, CHANG POWER WIRING

3、 REMOVE OBSTACLE AROUND OUTDOOR UNIT OR

WASH THE CONDENSER

4、CHANGE OUTDOOR MOTOR OR MOTOR CAPACITOR

4、 CHECK THE OUTDOOR MOTOR WORK NORMALLY

5 OCR TRIPED P4

1.COMPRESSOR OCR IS OPEN CURCUIT

2. CHECK IF THE OCR TEMPERATURE IS TOO HIGH

AND OCR TRIPED

1、 CHANGE OCR OR COMPRESSOR

2、TURN OFF THE AIR CONDITIONER, AND RESTART

IT 2 HOUR LATER

3、IF AIR CONDITIONER IS ON AND OFF

REGULARLY, CHECK OUTDOOR MOTOR OR MOTOR

CAPACITOR, THE OUTLET IS BLOCKED OR THE

CONDENSOR IS DIRTY

6

INDOOR PIPE TEMP. IS TOO

HIGH WHEN HEATING

P5

1、CHECK INDOOR MOTOR WORK NORMALLY

2、CHECK FILTER NET OR EVAPERATOR IS DIETY

1、CHANGE OUTDOOR MOTOR OR MOTOR CAPACITOR。

2、 WASH THE FILETE NET OR EVAPERATOR

7 OUTDOOR PIPE TEMP. ID TOO P6 1、CHECK IF THE REFRIGERANT IS CHARGED TOO MUCH 1、REGULATE THE QUANTITY OF REFRIGERANT

- 55 -

Page 56

Shinco Service Manual

HIGH 2、CHECK IF THE VOLTAGE IS TOO LOW, POWER

WRINGIS TOO THIN OR TOO LONG OR CONTACT

BADLY

3、CHECK IF THE OUTLET IS BLOCKED OR THE

2、UPDATING POWER SUPPLY, CHANG POWER WIRING

3、REMOVE OBSTACLE AROUND OUTDOOR UNIT OR

WASH THE CONDENSER

CONDENSOR IS DIRTY

8 DRIVER BOARD IS FAULT P0 DRIVER BOARD IS FAULT CHANGE DRIVER BAORD

- 56 -

Page 57

Shinco Service Manual

KFR-50GWZ/BM、KFR-70GWZ/BM

Item FAULT CODE CHECK POINT COUNT MEASURE

1

E1

INDOOR AIR SENSOR IS FAULTY

2

3

4

INDOOR PIPE SENSOR IS FAULTY

INDOOR IN-PHASE MOTOR IS FAULT

COMMUNICATION FAULT BETWEEN

E2

E3

E4

INDOOR UNIT AND OUTDOOR UNIT

5

6 OUTDOOR SENSOR IS FAULT E6

7 INDOOR MOTOR FAULTY E7

8 COMMUNICATION SIGNAL IS

DRIVER BOARD IS FAULT )

NOT GOOD

E5

E8

1、CHECK THE SENSOR VALUE

2、INDOOR BOARD IS FAULT

-----------------------

1、CHECK IF THE CONNECTING WIRING IS CONNECT WELL

2、TEST THE VOLTAGE VALUE BETWEEN L4 AND S, IF IT ‘S

CHANGE REGULARLY,THE SINGAL TRANSFERING BETWEEN

INDOOR AND OUTDOOR UNIT IS GOOD,

WHEN IT’S NO CHANGE

IF VALUE IS BELOW 14V, THE INDOOR PCB BOARD IS FAULT,

CHANGE IT.

IF VALUE IS OVER 14V,THE OUTDOOR PCB IS FAULTY

3、CHECK IF THERE IS LED FLASHING ON THE OUTDOOR PCB

IF THERE IS NO FLASHING,CHECK VOLTAGE VALUE FROM

POWER BOARD TO PFC BOARD, BETWEEN ACL AND CAN ON PFC

BOARD

IF IT’S NOT 220V, CHANGE POWER BOARD

IF IT’S 220V,CHANGE PFC BOARD

DRIVER BOARD IS FAULT DRIVER BOARD IS FAULT

1、CHECK THE SENDOR VALUE

2、POWER BOARD IS FAULT

----------------------

CHECK IF THE COMMUNICATION WIRING IS CONNECTED WELL.

CHECK IF POWER BOARD OR DRIVER BOARD IS FAULT

CHANGE SENDOR

CHANGE INDOOR BOARD

-----------------------

1、FIX THE WIRING AGAIN。

2、CHANGE RELATE PCB BOARD

CHANGE SENSOR

CHANGE POWER BAORD。

-----------------------

FIX THE COMMUNICATION WELL

CHANGE THE PCB BOARD

- 57 -

Page 58

Shinco Service Manual

9

10

11

12 IPDU IS FAULT P3 ----------------------- -----------------------

13

DRIVER BOARD IS FAULT

OCR TRIPED

POWER BOARD IS FAULT

INDOOR UNIT DON’T MATCH

P0

P1

P2

P4

DRIVER BOARD IS FAULT DRIVER BOARD IS FAULT

1、COMPRESSOR OCR IS OPEN CURCUIT

2、 CHECK IF THE OCR TEMPERATURE IS TOO HIGH AND OCR

TRIPED

OUTDOOR POWER BOARD IS FAULT CHANGE THE POWER BOARD

CHECK IF THE INDOOR UNIT MATCH OUTDOOR UINT CHANGE WRONG UNIT。

1、CHANGE OCR OR COMPRESSOR

2、TURN OFF THE AIR CONDITIONER, AND RESTART

IT 2 HOUR LATER

3、IF AIR CONDITIONER IS ON AND OFF

REGULARLY, CHECK OUTDOOR MOTOR OR MOTOR

CAPACITOR, THE OUTLET IS BLOCKED OR THE

CONDENSOR IS DIRTY

OUTDOOR UNIT

14

15

16 PFC FAULTY P7 OUTDOOR PFC BOARD IS FAULT CHANGE PFC BOARD

17 INDOOR MOTOR FEEDBACK

ELECTRIC CURRENT IS TOO HIGH

THE VOLTAGE IS NOT STABLE

FAULTY

P5

P6

P8 ----------------------- -----------------------

1、CHECK IF THE REFRIGERANT IS CHARGED TOO MUCH

2、CHECK IF THE VOLTAGE IS TOO LOW, POWER WRINGIS TOO

THIN OR TOO LONG OR CONTACT BADLY

3、 CHECK IF THE OUTLET IS BLOCKED OR THE CONDENSOR

IS DIRTY

4、CHECK THE OUTDOOR MOTOR WORK NORMALLY

CHECK THE POWER SUPPLY

1、REGULATE THE QUANTITY OF REFRIGERANT

2、UPDATING POWER SUPPLY, CHANG POWER WIRING

3、REMOVE OBSTACLE AROUND OUTDOOR UNIT OR

WASH THE CONDENDSOR

4、CHANGE OUTDOOR MOTOR OR MOTOR CAPACITOR

RESTART THE AIR CONDITIONER

Note: The fault code doesn’t display directly, and it will display as following instruction:

Press the ON/OFF button 6 times within 7 seconds, there will be three DU sound on indoor unit, and the indoor unit will display

the fault code.

- 58 -

Page 59

Annex

PCB diagram

KFR-25GWZ/BM、KFR-35GWZ/BM

1、 Indoor PCB

Shinco Service Manual

- 59 -

Page 60

2、 Outdoor power board

Shinco Service Manual

- 60 -

Page 61

3、 Outdoor diver board

Shinco Service Manual

- 61 -

Page 62

4、 Outdoor PFC board

Shinco Service Manual

- 62 -

Page 63

KFR-50GWZ/BM

1、 Indoor PCB

Shinco Service Manual

- 63 -

Page 64

2、Outdoor power board

Shinco Service Manual

- 64 -

Page 65

3、outdoor driver board

Shinco Service Manual

- 65 -

Page 66

KFR-70GWZ/BM

1、 Indoor power board

Shinco Service Manual

- 66 -

Page 67

2、Indoor driver board

Shinco Service Manual

- 67 -

Page 68

3、 outdoor power board

Shinco Service Manual

- 68 -

Page 69

4、outdoor driver board

Shinco Service Manual

- 69 -

Page 70

Schematic

KFR-25GWZ/BM、KFR-35GWZ/BM

1、 Indoor PCB

Shinco Service Manual

- 70 -

Page 71

2、 Outdoor power board

Shinco Service Manual

- 71 -

Page 72

3、Outdoor diver board

Shinco Service Manual

- 72 -

Page 73

4、Outdoor PFC board

Shinco Service Manual

- 73 -

Page 74

KFR-50GWZ/BM

1、 Indoor PCB

Shinco Service Manual

- 74 -

Page 75

2、 outdoor power board

Shinco Service Manual

- 75 -

Page 76

3、 outdoor driver board

Shinco Service Manual

- 76 -

Page 77

KFR-70GWZ/BM

1、 Indoor power board

Shinco Service Manual

- 77 -

Page 78

2、Indoor driver board

Shinco Service Manual

- 78 -

Page 79

3、 outdoor power board

Shinco Service Manual

- 79 -

Page 80

4、outdoor driver board