Page 1

TNP Digital Torque Meter

Operation Manual

Do not attempt to repair or alter this instrument. Warranty will be voided

and damage to the unit may result.

Use and store within the stated temperature and humidity ranges, or

damage and failure may result.

Ensure during testing unit is properly used on a stable, level surface.

Do not test products that are filled with liquid as the TNP torque tester is

not protected from liquid spills.

Only use electrical charger supplied with unit.

The Series TNP Digital Torque Meter is a precision instrument for

measuring OPEN and CLOSE torque values for various applica-

The TNP Torque Meter is used in medical, pharmaceutical,

tions.

industrial quality control, R&D and countless other torque appli-

cations.

As a cap torque analyzer, the TNP repeatedly determines bottle

closure and breakaway torque. Its wide memory capacity is ca-

pable of storing 1,000 data points, including Average, Maximum

and Minimum values. A HI-GO-LO LED comparator feature can be

utilized for large batch testing to ensure overall product quality.

The TNP is a portable device powered with internal rechargeable

batteries or through provided universal AC adapter/charger.

Designed with a small footprint, it can easily be transferred be-

tween the shop floor and laboratory taking up little space when

operating. The TNP Torque Meter comes standard with USB con-

nection and cable for easy PC/Software interface. Combined with

the free “Digitorq” Software, statistical testing, graphing and anal-

ysis can be performed.

Each package includes the following:

• Operations Manual

• Software Installation Disk (Digitorq Software)

• Warranty Card

• USB A to USB B communication cable

• Universal AC adapter (100-240 VAC)

• Set of 30 mm chuck pins (4 pieces)

• TNP unit

SPECIFICATIONS

Measuring Range: TNP-0.5: 0-50.00 Ncm, 0-500.0 mNm,

0-5099 gcm, 0-4.425 lbin; TNP-2: 0-2.000 Nm, 0-200.0 Ncm,

0-20.39 kgcm, 0-17.70 lbin; TNP-5: 0-5.00 Nm, 0-500.0 Ncm,

0-50.99 kgcm, 0-44.25 lbin; TNP-10: 0-10.00 Nm, 0-1000 Ncm,

0-102.0 kgcm, 0-88.5 lbin

Test Sample Diameter Range: 0.39“ - 7.48” (10 - 190 mm)

Accuracy: ±0.5% / F.S.

Display: Main display: 4-digit LCD display, Character height 0.5”

(12 mm)

Comparator Display: HI - GO - LO (green and red LED indicator)

Display Update Time: Select from 0.125 second (8 times/second), 0.25 second (4 times/second), 0.5 second (2 times/second),

1 second (1 time/second). Peak display: 0.125 second

Measuring Mode: Opening Mode: Show max value when opening (peak display) Displays max counterclockwise torque; Closing

Mode: Show max value when closing (peak display) Displays max

clockwise torque; Average Mode: Real time display (average value

display) Displays torque in real time

Overload: 150% of full scale

Sampling Rate: 1000 Hz

Memory: 1000 data (max)

Data Output: USB1.1

Power: Built in nickel hydride battery (NiMH) or Auto-ranging AC

adapter (AC100 - 240V)

Battery Information: NiMH: 8 hours use after full charge. 16

hour max. recharge time.

Operating Environment: 32 - 104°F (0 - 40°C)

Dimensions: 12.60” x 8.94” x 4.96” (320 x 227x 126 mm)

Product Weight: TNP-0.5, -2, -5 = Approx. 17.6 lb (8 kg); TNP-

10 = 27.5 lb (12.5 kg)

Package Weight: TNP-0.5, -2, -5 = Approx. 19 lb (8.6 kg); TNP10 = 30.7 lb (13.9 kg)

Software: DigiTorque TNP Free Download from www.shimpoinst.

com

Included Accessories: USB cable, 120/240 VAC AC adapter,

30mm chuck pin (4pcs)

Certifications: CE

Warranty: 2 year

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Parts and Functions

Recall Key

Measuring mode indicators

Power key

Mode Key

Main Display

Parts Functions/Description

Power key

Turns the unit ON and OFF.

Recall data stored in OPEN and CLOSE modes.

Recall key

NOTE: in Average or Mean Mode, the Recall button has no function

Memory key for storing data in Open and Close Modes.

Note: In Mean mode the Mem key has no function. In this mode

Mem key

data cannot be stored in memory.

Mem combined with another key is used in secondary functions.

(Parameter and clear settings – see next section).

Selects mode of operation (CLOSE, MEAN, and OPEN)

Mode key

Serves as an exit function when in Memory recall.

Secondary function in parameter settings (see next section)

Zero/RST Key Memory Key

Comparator LED indicators

Tare or zero function for resetting and initializing values while in

Zero/RST key

Average or peak mode.

Secondary function in parameter settings (see next section)

Displays measured values and status indicators, which includes

Main Display

Measuring mode

indicators

Comparator LED

Indicators

Find Quality Products Online at: sales@GlobalTestSupply.com

units of measure, battery status and function status.

Red LED mode indicators. Informs which mode is selected “Open”,

“Mean” or “Close”.

Quick pass/fail visual indicators for all modes of measurement.

The LED indicator does not light when comparator feature is OFF.

2

www.GlobalTestSupply.com

Page 3

Main Display (Description)

1 minute warning

Battery Indicator

Direction Indicator

Units/Status Indicator

Main Display/ Setup Value

Extended Description

• Units/Status indicator – located on the upper part of the display this

shows the current units of measure selected for the torque meter. It also

serves as a sub display under function mode (F01, F02, F03, etc.)

Example: “OVR” indicates an overload condition the TNP went over its

rated capacity. “PWR”, the auto power off feature is set this indicator

serves as a 1 minute warning before the unit turns off.

Overload

before it turns off.

• Main display/Set up Values – shows the measured value in four digits

including decimal places. While under function mode, this displays the

options for each setting.

• Direction Indicator – indicates direction of applied torque based from F04

setting (Please see sign orientation information from function mode table).

By default, closing indicates a negative “-“values; Opening “no sign”.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

• Battery Indicator – shows the status of the TNP internal battery. “LO

BAT” appears on the display to indicate a low battery status. “BAT” is

shown when the TNP is charging. This indicator disappears when the

battery is fully charged or when the AC adapter is disconnected from the

TNP. It is important that the battery be cycled properly to achieve the

maximum life from it.

Secondary Functions

Parameter window settings: by using certain key combinations the parameter window can

be accessed.

Operation

key

Zero/RST

Power

Mem

Power

Operation How to operate

With Power off, press and hold the Zero/RST key

then power ON the torque meter. Continue

holding the ZERO/RST key until the display

shows “F01”, Pressing MODE changes the value

Function mode

of the selected function mode. Pressing the

“Zero/RST key” advances from one parameter

to the next. The lists of function are provided in

the next section. (See picture below for additional

description).

With Power off, press and hold the Mem key,

Clear memory

data

then power ON the torque meter. Continue

holding the Mem key until “nonE” appears on

the display.

This pic

Find Quality Products Online at: sales@GlobalTestSupply.com

ture indicates the torque meter is in Function Mode.

4

www.GlobalTestSupply.com

Page 5

If the display shows the normal operation of the torque meter, and no

F01 is seen on the display, the Zero/RST key was released earlier than

what is required. Turn off the torque meter and repeat the process.

Function Mode Table

FUNCTION Sub display

Options Initial setting

Changes units of measure

Measuring unit F01

TNP-0.5 :

mN-m, N-cm, g-cm, lb-in

TNP-2, 5, 10 :

TNP-0.5 : mN-m

TNP-2, 5, 10 : N-m

N-m, N-cm, Kg-cm, lb-in

Display-(update rate) F02 Switch 1, 2, 4, 8 times/second

2

Auto power OFF F03 10 minutes or on 10 minutes

Sign Orientation F04

Upper comparator

value (Hi limit)

Lower comparator

value (Lo limit)

HI

LO

-0000 CCW (Open "-");

0000 CCW(Open "+")

0000 – 9999: with decimal

point. (Setting the values to

zero disables this function) .

0000 – 9999: with decimal

point (Setting the values to

zero disables this function).

0000

0000

0000

How to change value on the function selected?

To change the values of the function selected, use the Mode key button to scroll

through the options and the Zero/RST button to move to the next Mode.

Pressing the Mode button after setting the HI/LO limits exits out

of the function mode. You will need to reenter the settings to

change additional values.

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

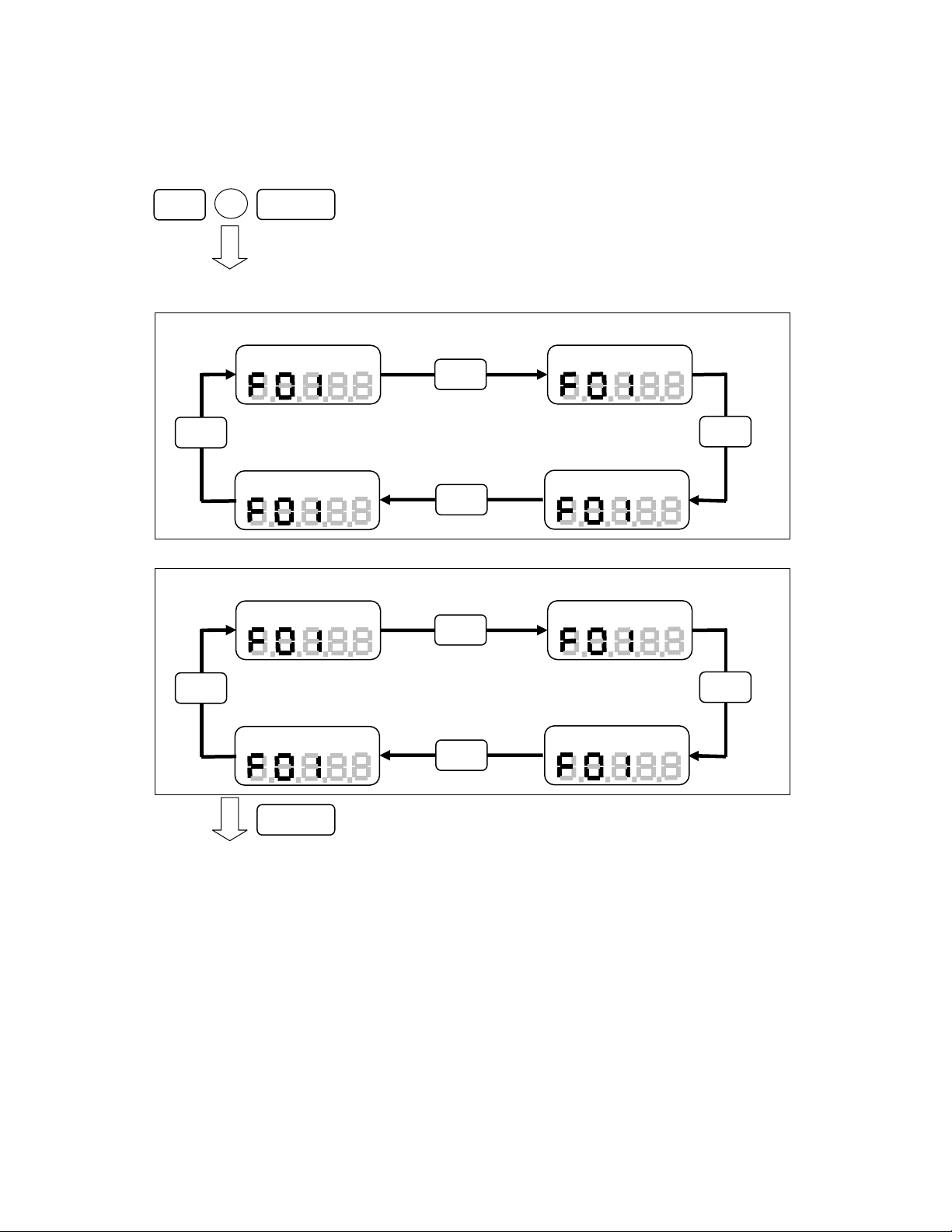

Operation diagram of how to access the Function Mode

Press and hold the Zero/RST key

Ncm

Kg

c

lb

i

Ncm

gcm

lbi

Turn OFF the TNP before starting

Power

Function Mode – Measurement unit

Zero/RST

TNP-2, 5, 10

Unit: N-m

Nm

Mode

Unit: lb-in

TNP-0.5

Unit: mN-m

mNm

Power on then release the Power button

but continue to hold Zero/RST key until display F01

Unit: N-c

Mode

m

Mode

Unit: Kg-cm

Mode

Unit: N-c

Mode

m

Mode

Unit: lb-in

Zero/RST

Mode

Pressing Zero/RST, it moves to the next function setting.

Unit: g-cm

Use the MODE key to change values of each function.

Use the Zero/RST key for moving to the next function

Mode

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

02

Function Mode – Display (update rate)

f04

f04

1time/sec 2times/sec

f02

Zero/RST

Function Mode – Auto power OFF

Disable auto power OFF

f03

Mode

f02

Mode

4times/sec

f02

Mode

8times/sec

f02

Mode

Pressing Zero/RST, it moves to the next function setting.

Set auto power OFF to

10 minutes

Mode

Mode

f03

Zero/RST

Function Mode – Sign Orientation

Open “+”

Zero/RST

Use the MODE key to change values of each function.

Use the Zero/RST key for moving to the next function

Pressing Zero/RST, it moves to the next function setting.

Open “-“

Mode

Mode

Pressing Zero/RST, it moves to the next function setting.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

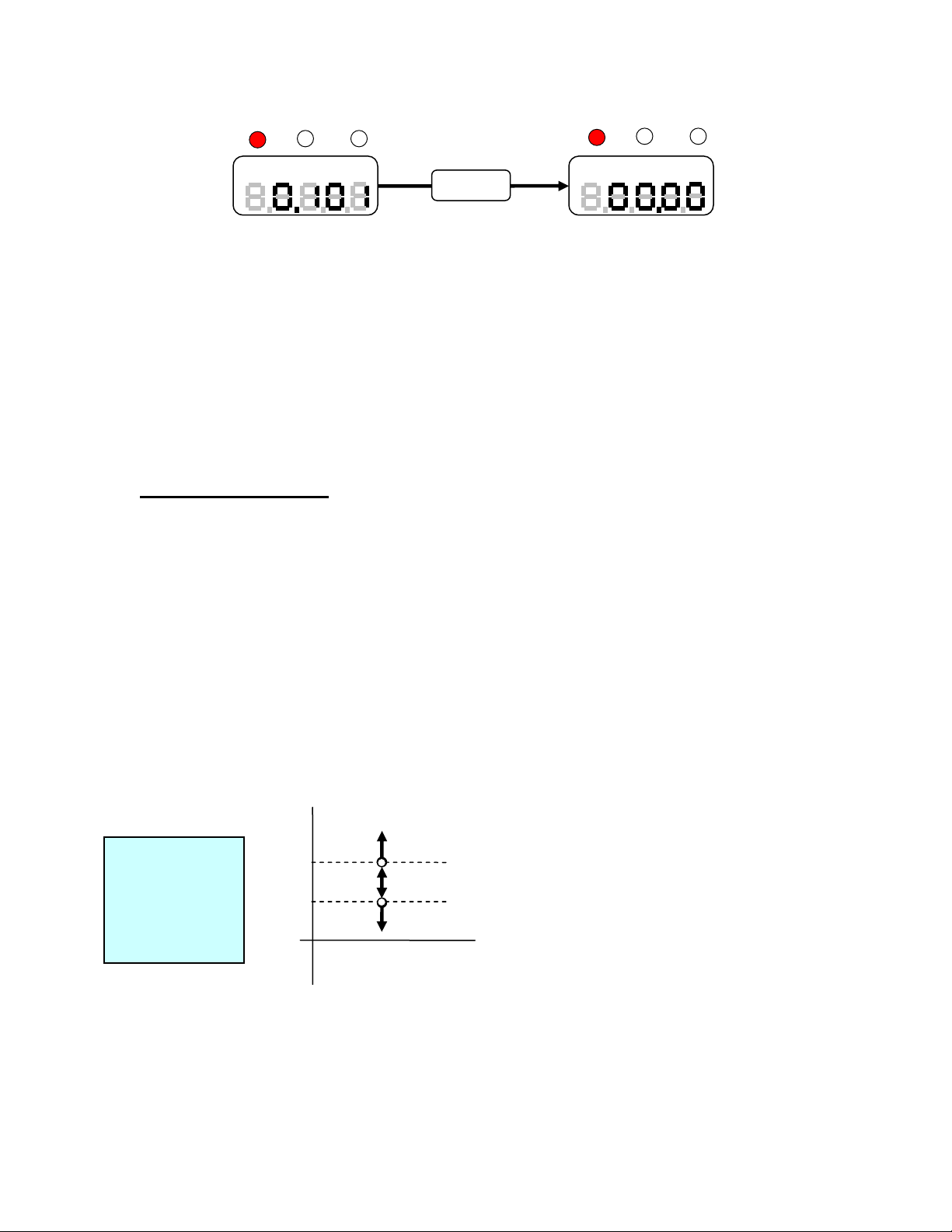

Function Mode – Upper comparator value (Hi Limit)

Present upper value

HI

Recall

HI

Recall

Plus 1 by pressing

Recall key

HI

HI

Move to the right

Move to right side one by one by pressing

Mem key.

Zero/RST

Function Mode – Lower comparator value (Lo Limit)

Present lower value

Pressing Zero/RST, it moves to the next function setting.

LO

Key operation is the same in entering the Hi limit value.

Recall

Mem Mem

Move to the right

HI

Press Mem key scrolls back to

the 1st digit position,

Zero/RST

Move to setting register/ standard display

Use the MODE key to change values of each function.

Use the Zero/RST key for moving to the next function

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Operation

Pretest Checklist:

Determine the size of the sample to be tested. Adjust the 4 jig on the testing

table accordingly. Center the sample and use the knob to secure the sample in

place (clockwise to tighten the jig to the sample material).

It is important to make sure that all the jigs are flush to the moving brackets.

Each one of these jigs has set pins which slides into place inside the grooved

brackets.

Measuring Modes

Measuring Modes available on the TNP: OPEN, CLOSE, MEAN

Select the measuring mode required for testing. Please check the settings below

on how to select the right mode for testing.

Open mode

Open

Mean mode

Mean Close

Nm Nm Nm

Mode

Open

Mean Close

Mode

Mode

Close mode

Open

Mean Close

Pressing the Mode key toggles through the mode available from the TNP, LED

indicators are provided to display current selected mode.

OPEN and CLOSE modes are PEAK Values captured by the TNP, these values

are not real time values, and are retained on the display until one of the following

occurs, the Zero/RST key is pressed or a higher peak value is detected (which in

this case, replaces the current value detected).

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Open

Nm

Mean Close

Open

Mean Close

Nm

Zero/RST

Resetting the Peak values to Zero

MEAN is real time value based on the average data captured in 1000 samples

per second.

The maximum display update for all modes is 8 times/second.

This update rate can be adjusted by changing F02 from function mode

(See section - Values available 1, 2, 4, 8 times/second).

Comparator Function

This compares the measured value to the upper and lower limits entered under

function mode for HI and LO limits.

If both HI and LO limits are set to “0000” this feature is not available

(deactivated).

The following conditions are valid under comparator mode:

• HI>LO

• HI=LO (HI Red LED indicator will be lit on the Comparator LED indicators).

Utilizing this feature makes it an ideal tool for quality assurance checks.

Example: HI is set to 100 and LO is set to 50. Based from the conditions met

the corresponding LED will light up (HI (Red LED), GO (Green LED), LO (Red

LED)).

Test 1 = 105 HI

Red LED

Test 2 = 45 LO

Red LED

Test 3 =65, GO

Green LED

100 Upper limit value

50

0

HI:ON

OK:ON

Lower limit value

LO:ON

From the previous example any values greater than 100 will light up the HI red

LED.

Any values lower than 50 will light up the LO red LED.

Values measured in between these values (100<X<50) will give a GO green LED

indicator.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

How to change the HI and LO values from the TNP torque meter?

• To set the HI and LO limits from the TNP torque meter access the function

mode. (See Diagram How to Access the Function).

• Power off the torque meter

• Press and hold the Zero/RST key then power on the torque meter.

• Continue to hold on the Zero/RST key until the main display shows F01

• Press the Zero/RST key until the main display shows HI limit

• Using the Recall key we can increment the highlighted digit from 0-9.

• Press the Mem key to move from left to right or to the next digit.

• Entering values that are invalid the display will blink momentarily indicating

wrong values entered to the HI and LO limits. (HI>LO, HI=LO).

After entering the LO limit value and pressing the Zero/RST button the

torque tester will go back to normal operation.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

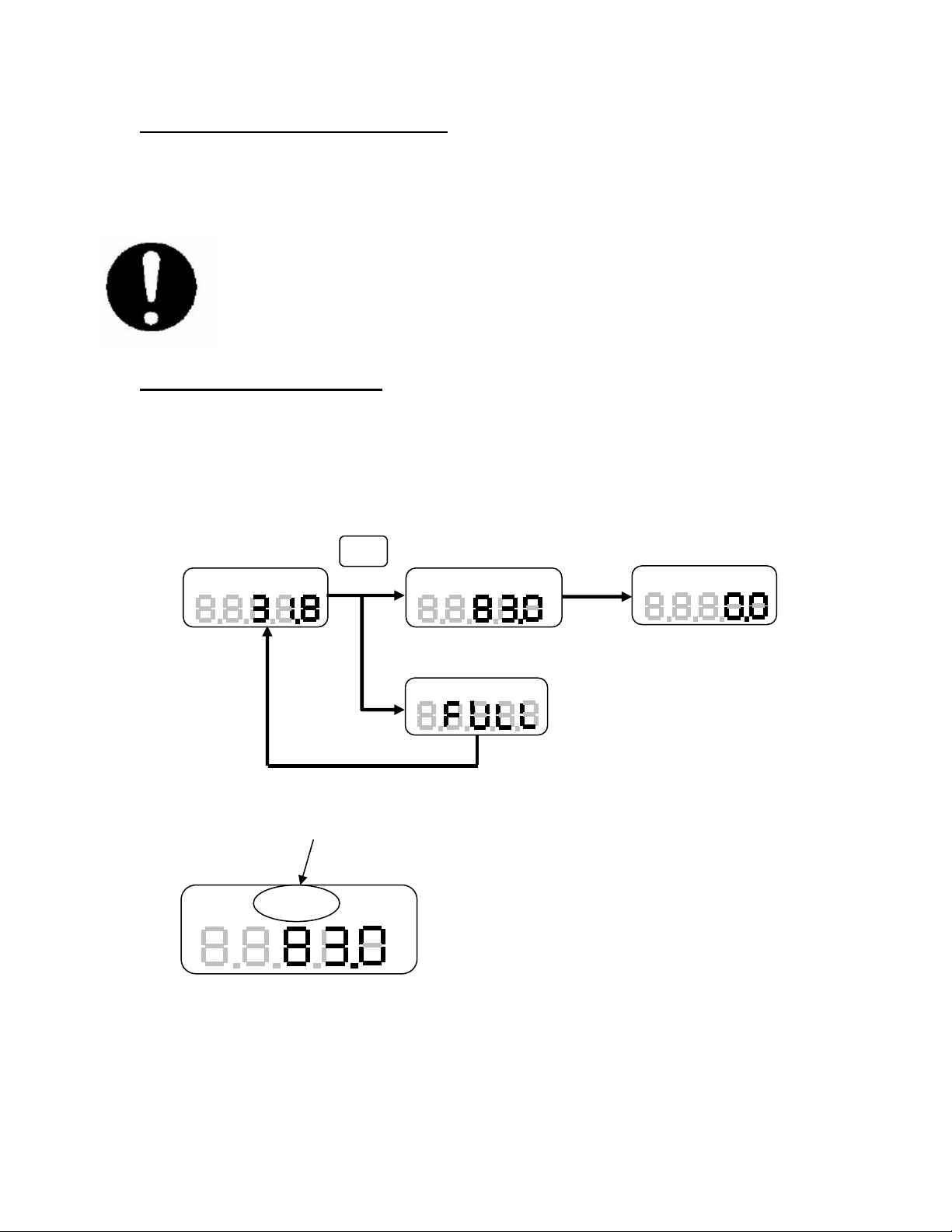

Zero adjustment / Tare the TNP

Taring or zeroing the value of the TNP initialize the torque meter to zero.

This function is performed by pressing Zero/RST button on the front panel. In

OPEN and CLOSE modes this zeros out the Peak values measured.

It is essential that the TNP be zeroed out before performing another

test. This ensures that the TNP is properly initialized and no

additional values are added to the measurement.

Saving Data in Memory

Data can be stored in the TNP meter by pressing the Mem key. This feature is

only available in OPEN and CLOSE measuring modes.

NOTE: In MEAN or Average mode the Mem key has no function.

“Open”or“Close”

measuring mode

Memory identification/Number

Memory registration

Mem

Nm

When the number of data points > 1000

After 1 sec, digits will return to original display.

001

Taking a closer look at display the upper sub-display indicates the

memory identification or data number.

001

Nm

After 1sec, the peak value displayed will

automatically reset to zero; ready for

another test.

Nm

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

How to recall stored Memory

Select Open or Close Mode, press the Recall key and the display will indicate the

number of data stored in memory.

Press Recall key second time to access the following information.

• AVERAGE Value

• MAX Value

• MIN Value

• Stored data (Data order of recall is based from the last data stored in

memory)

Displays Max Values after pressing Recall

To access the stored measured value use the Recall key to scroll thru the values.

(This will be after the MIN value is displayed). The display will flash two sets of

numbers, the first number indicates the memory ID and the second number is the

value stored on that memory ID.

NOTE: The order of values is from the last data stored to the first data stored. To

review previous values shown, scroll through the values using the Recall key.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Picture above indicates the memory ID followed by the stored data. Pressing the

Nm

Nm

(1sec interval)

Nm Nm

(1sec interval)

mode button anytime exits out of the memory window. Below is a flowchart of

how the recall function works.

Recall

Recall

Power

key

Recall

Last memory number, data display

Available Zero/RST key on main

display

CNT

Alternating

display

Recall

Average value

AVE

Minimum value

Test number displayed

CNT

Alternating

display

Recall

Recall

Maximum value

MAX

Recall

MIN

Recall

CNT

Alternating display:

(1sec.interval)

Shows last memory data

Returns to

measuring mode

Mode

Nm

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Clearing Stored Data

There are two types of memory clear available on the TNP torque meter.

• Single memory clear

• Clear all memory

Single Memory Clear

Single clear refers to erasing the stored data manually from the torque tester. The

erase process starts from the most recent to the very first data stored.

Clearing data that is within the set cannot be accomplished by a

single memory clear. The TNP does not allow the user to select the

memory to be deleted. (jump out of sequence).

How does it work?

First select from Open or Close Modes (Mean or average mode data cannot be

stored).

Press the Recall key to access memory, the first display you see will indicate the

number of data stored in the torque tester and the last value saved.

Example from the picture above shows 3 data is saved (003) and the last value is

12.6. Pressing the Zero/RST button, the last data is eliminated (CLr will appear

on the screen). Pressing the Zero/RST button again deletes the next data stored

in the TNP torque meter.

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Here is a flowchart of how the single clear works.

002

Last memory number

Zero/RST

Clear

003

(Appear 1 sec.)

When there is one last data, the last data is cleared by pressing Zero/RST

key. After that, “nonE” is displayed at main display for 2 seconds, then the

display returns to measuring mode as shown below:

Last memory number

001

Zero/RST

No data

Back to standard

measuring mode

(Appear about 2 second)

After all the data are erased pressing the Zero/RST button returns the display to

normal measuring condition.

Clear all Memory

Clear all Memory or erasing all stored data in memory is possible by doing the

following.

• Power off the TNP torque meter

• Press the Mem key and continue to hold this key while powering the

torque tester. The TNP will initialize itself. You will see the model capacity

displayed on the front panel then followed by the message “nonE”. This

indicates that all data stored in memory have been erased or cleared.

Display shows no data

“Power”(off),

press “Mem” (hold “Mem” key),

press “Power” (on)

(Appear about 2 seconds)

Back to standard

measuring mode

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

DIMENSIONS

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...