SHIMPO Instruments PC-ANB-0R0C0, PC-ANB-00AC0, PC-ANB-0S0C0, PC-ANB-0RAC1, PC-ANB-000C0 User manual

...Page 1

SHIMPO INSTRUMENTS

COUNTER OWNERS MANUAL

SHIMPO INSTRUMENTS

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

1. ORDERING GUIDE

PC

Configure a model number in this format: PC-FRB-0-R-0-C5,

. ... Counter-timer. Includes screw

terminal connectors.

Signal Conditioner

2-Channel Counter

FRB.Basic 2-channel counter

Frequency (2 channels), rate (2 channels), total (up or down, 2 channels),

period (2 channels), stopwatch, time

interval, square root of rate, or 6-digit

remote display.

FRE.Extended 2-channel counter

Above plus rate and total simultane-

ously, custom curve linearization, arithmetic functions (A*B, A/B, A+B, A-B,

A/B-1), phase angle, duty cycle, up/

down counting, batch control.

Process Receiver & Totalizer Signal

ANB ......................... Basic analog input

Totalizes 4-20 mA, 0-1 mA or 0-10V

analog signals.

ANE ................... Extended analog input

Above plus custom curve linearization,

batch control, time based on rate.

Quadrature Input

QDBBasic quadrature for position.

QDEExtended quadrature for bidi-

rectional rate or position.

Power

0 . ................... 85-264 Vac, 90-300 Vdc

1 ... ..................... 10-48 Vdc, 12-30 Vac

Relay Output

0 ....................................................... None

R ...... Two 8A contact relays

S........... ..... Two 120 mA solid state relays

X ...... Four 8A contact relays

Y........... .... Four 120 mA solid state relays

Analog Output

0 ....................................................... None

A ........ ..Single 4-20 mA, 0-10V, -10/+10V

B ............. Dual 4-20 mA, 0-20 mA, 0-10 V

Communications

C0 .................................................... None

C1 .................................................. RS232

C2 ....... RS485 with dual RJ11 connectors

C5 ..................................................... USB

Options & Accessories

PM-232-RJDB

RJ11-to-DB9 RS232 cable. Connects

RS232 port of meter to RS232 COM port

of PC.

PM-232-USBDB

USB to DB9 adapter cable. Attaches to

PM-121-RJDB to connect RS232 port of

meter to USB port of PC.

PM-485-RJ1

6-wire data cable with RJ11 connectors, 1

ft. Used to daisy-chain meters via RS485.

PM-485-RJ7

6-wire data cable with RJ11 connectors, 7

ft. Used to daisy-chain meters via RS485.

PM-USB

USB-cable. Type A male to Type B male.

Connects USB port of meter with C5

communication option to USB port of PC.

PM-NEMA4X

NEMA-4X Polycarbonate wall mount, box

enclosure with 1/8 DIN opening

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

2. TABLE OF CONTENTS

1. ORDERING GUIDE ..................................................................................................... 2

2. TABLE OF CONTENTS ............................................................................................... 3

3. PRODUCT INTRODUCTION ....................................................................................... 4

4. RECEIVING & UNPACKING ....................................................................................... 5

5. SAFETY CONSIDERATIONS ...................................................................................... 5

6. CONNECTOR WIRING INFORMATION ..................................................................... 6

7. MECHANICAL ASSEMBLY ......................................................................................... 8

8. FRONT PANEL SETUP KEYS .................................................................................... 10

9. ENABLING & LOCKING OUT MENU ITEMS .............................................................. 12

10. DUAL CHANNEL PULSE OR AC INPUT SIGNAL CONDITIONER (FR) ................... 13

11. PROCESS RECEIVER & TOTALIZER SIGNAL CONDITIONER (VF) ........................ 31

12. QUADRATURE SIGNAL CONDITIONER (QD) .......................................................... 38

13. SERIAL INPUT METER / REMOTE DISPLAY (NO SIGNAL CONDITIONER) ............ 54

14. DUAL & QUAD RELAY OUTPUT OPTIONS .............................................................. 56

15. SINGLE & DUAL ANALOG OUTPUT OPTIONS ......................................................... 59

16. SERIAL COMMUNICATION OPTIONS ....................................................................... 61

17. EXCITATION OUTPUT & POWER SUPPLY ............................................................... 66

18. INSTRUMENT SETUP VIA PC .................................................................................... 67

19. CUSTOM CURVE LINEARIZATION ............................................................................ 70

20. METER CALIBRATION ............................................................................................... 71

21. SPECIFICATIONS ....................................................................................................... 72

22. GLOSSARY OF TERMS .............................................................................................. 75

23. WARRANTY ................................................................................................................ 80

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

3. PRODUCT INTRODUCTION

Our counters are a versatile, cost effective solution to a wide range of monitoring and control

applications including frequency, rate, total, period, time, phase, position, and flow. Setup can

be via front panel pushbuttons or a PC. Selective lockout of front panel keys protects against

accidental or unauthorized setup changes and simplifies meter use.

A dual-channel pulse or AC input signal conditioner board accommodates a wide range of

applications including rate/frequency, totalizing, timing, phase angle, power factor, and duty

cycle. Frequency and rate are determined by taking the inverse of period. Fast read rate is

ideal for peak or valley capture and allows quick response for control applications. Adaptive

digital filtering provides stable readings and control outputs while responding rapidly to actual

changes of the signal. A high stability quartz crystal and digital calibration assure accurate rate

and analog measurements.

A process receiver & totalizer signal conditioner board accepts 4-20 mA, 0-1 mA or 0-10V

analog signals for display of rate or position. Square root extraction is selectable for use with

differential pressure flow transducers.

A quadrature signal conditioner board provides accurate display of position, angle, or rate.

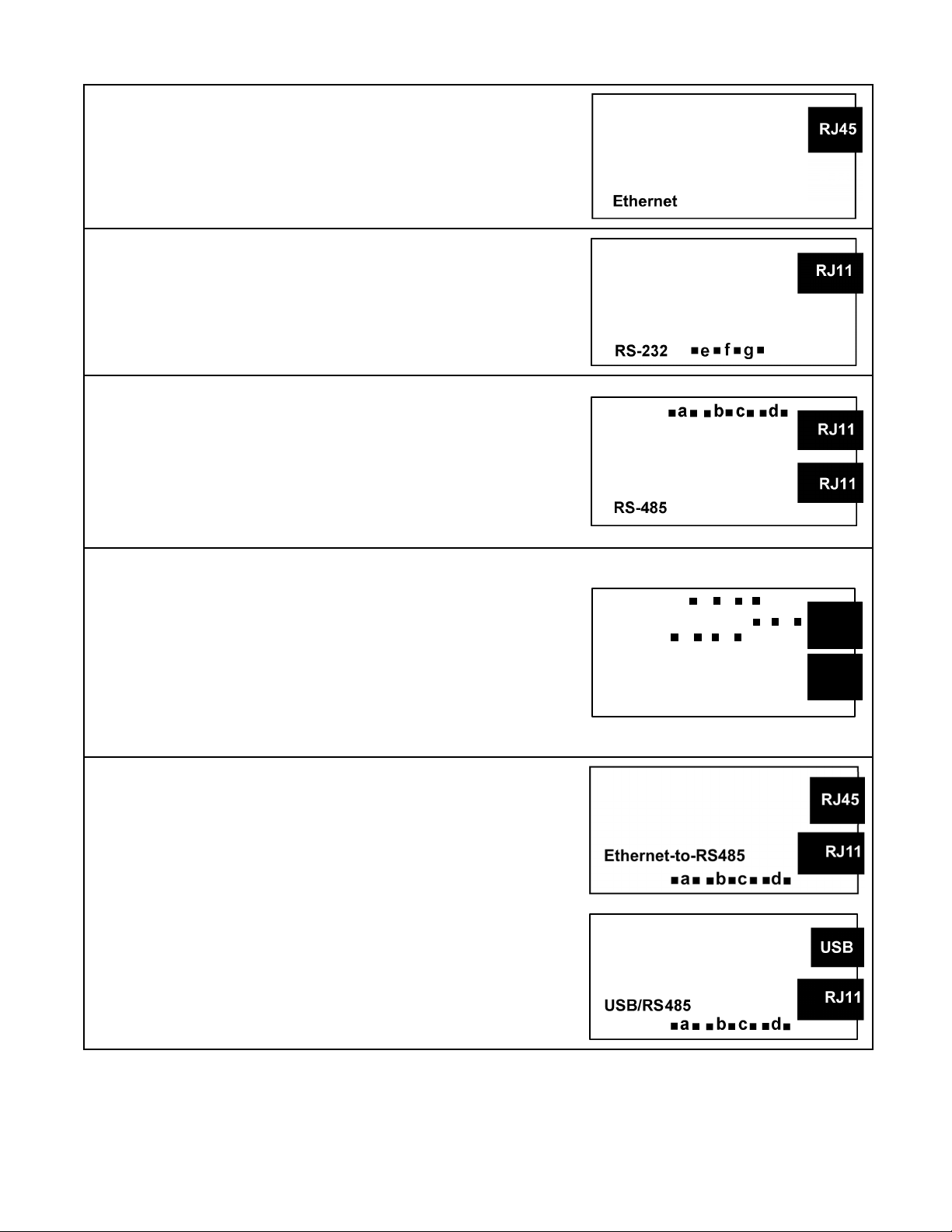

Ethernet USB, RS232, or RS485 (2-wire half-duplex or 4-wire full-duplex) serial communi-

cations options are available with the Modbus protocol or a simpler custom ASCII protocol.

Modbus operation includes RTU or ASCII modes, up to 247 digital addresses, and up to 32

devices per RS485 line without a repeater. Ethernet-to-RS485 and USB-to-RS485 converter

boards allow a meter to be interfaced to a PC and to multiple meters on an RS485 network

Meter programming can be via the meter’s front panel or a PC running Windows based

Instrument Setup Software. A serial interface option is required.

A standard switching power supply allows the meters to be powered worldwide from 85 to

264 Vac. An optional power supply operates from batteries or low voltage sources, such as 1232 Vac.

A built-in isolated excitation supply with jumper-selectable 5, 10 or 24 Vdc output levels is

standard and can eliminate the need for an external sensor power supply.

A dual or quad relay board is optional for alarm or control. The relays can be Form C 8A

mechanical relays or 2 or 4 Form A 120 mA solid state relays. The setpoints can be latching or

non-latching, be energized above or below the setpoint, or operate in a fail-safe mode.

A single or dual isolated analog output board is optional. With dual outputs, one of the

outputs can be assigned to the reading (such a rate), while other reading is assigned a nondisplayed item (such as total). The outputs can be 0-20 mA, 4-20 mA, 0-10V, or -10V to +10V.

Operation as a 6-digit serial input meter is achieved with a serial interface and no signal

conditioner board, allowing the unit to serve as the remote display of a computer, PLC or other

meter. With an optional dual or quad relay board, the unit can provide local alarm or On/Off

control. With an optional analog output board, it can also serve as a local isolated transmitter.

The meter case meets the 1/8 DIN size standard and is sealed to NEMA-4X (IP65) when

panel mounted. Mounting is from the front of the panel and requires less than 110 mm behind

the panel. All wiring is via removable plugs conforming to IEC950 safety standards. All output

options are isolated from meter and power grounds to 250 Vac.

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

4. RECEIVING & UPACKING

Your meter was carefully tested and inspected prior to shipment. Should the meter be

damaged in shipment, notify the freight carrier immediately. In the event the meter is not

configured as ordered or the unit is inoperable, return it to the place of purchase for repair or

replacement. Please include a detailed description of the problem.

5. SAFETY CONSIDERATIONS

Warning: Use of this equipment in a manner other than specified may impair the protection of the device and subject the user to a hazard. Visually inspect the unit for signs of

damage. If the unit is damaged, do not attempt to operate.

Caution:

• The unit must be connected to a Disconnect switch or a branch-circuit breaker, which must

be in a suitable location

• This unit must be powered with AC (mains) from 85-264 Vac with the high voltage power

supply option, or 10-48 Vdc (12-32 Vac) with the low voltage power supply option. Verify

that the proper power option is installed for the power to be used. This meter has no AC

(mains) switch. It will be in operation as soon as power is connected.

• The 85-264 Vac mains connector (P1 Pins 1-3) is colored Green to differentiate it from

other input and output connectors. The 12-32 Vac (10-48 Vdc) mains connector is colored

Black.

• Do not make signal wiring changes or connections when power is applied to the instrument.

Make signal connections before power is applied. If reconnection is required, disconnect

the AC (mains) power before such wiring is attempted.

• To prevent electrical or fire hazard, do not expose the instrument to excessive moisture.

• Do not operate the instrument in the presence of flammable gases or fumes; such an

environment constitutes a definite safety hazard. This meter is designed to be mounted in a

metal panel or a bench or wall mount style case. The spacing around the meter and the

ventilation must be sufficient to maintain the ambient temperature at less than 55°C.

• Verify the panel cutout dimensions, and mount according to instructions.

Symbols used

Caution (refer to accompanying documents)

Operating environment:

The meter is Class II (double insulated) equipment designed for use in Pollution degree 2.

Find Quality Products Online at: sales@GlobalTestSupply.com

Caution, risk of electric shock.

Equipment protected throughout by double

insulation or reinforced insulation.

www.GlobalTestSupply.com

6

Earth (ground) terminal.

Both direct and alternating current.

Page 6

6. CONNECTOR WIRING INFORMATION

CONNECTORS

Connectors for signal and power are U/L rated

screw-clamp terminal blocks that plug into mating

jacks on the circuit board. Communication connectors are a single RJ11 plug for RS232, a type B

jack for USB, dual RJ11 or RJ45 plugs for RS485,

or RJ45 for Ethernet. The functions of controls

inputs 1 and 2 are menu selectable. Control input

2 can be converted to a +5V, 50 mA power output.

Please see page 66.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

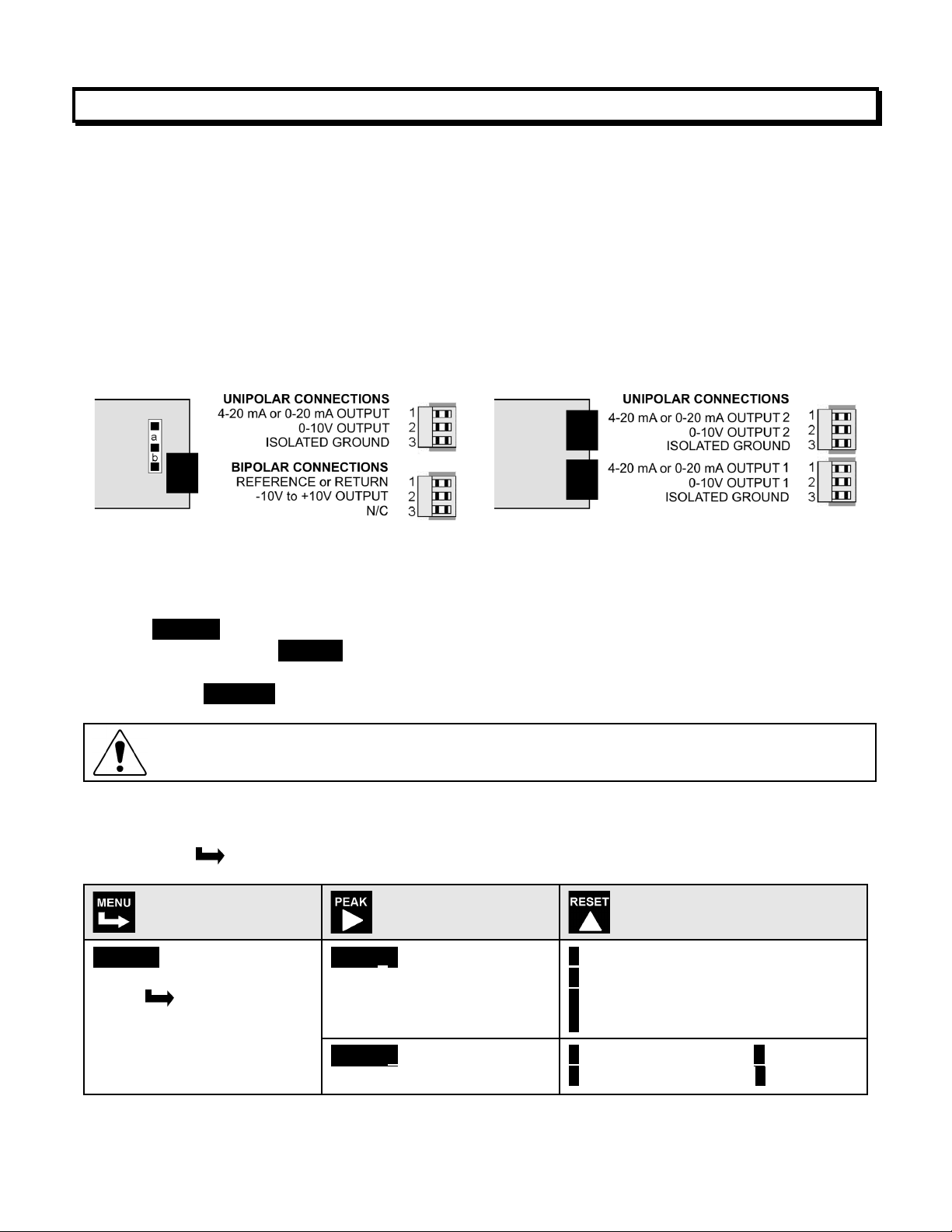

P3 - SERIAL OMMUNICATIONS

P4 –

DUAL ANALOG OUTPUT

unipolar connecti

ons.

uses two

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

7. MECHANICAL ASSEMBLY

Option Board

Main Board Plug

Rear Panel Jack

with tab release

Retaining tab

REMOVING THE REAR PANEL

First remove any connectors. Use one hand to press in the two sides of the rear of the

case, and the other hand to press down the two protruding tab releases at the top of the

rear panel (see figure below). This will unhook the rear panel from the case.

Retaining tab

with tab release

Retaining tab

Retaining tab

Rear Panel

REMOVING THE ELECTRONICS

With the rear panel removed, grasp the power supply board to the left and signal conditioner board to the right, then carefully slide the electronic assembly out through the rear of

the case.

INSTALLING NEW 0PTION BOARDS

Options boards plug into the main board at the front of the meter. These are plug-and-play

and may be installed in the field. They will be recognized by the software, which will

provide access to the menu items associated with that board. If necessary, remove rear

panel knockouts for new boards. Boards plug into connectors as follows:

Power supply

Relay board

Serial interface board

Analog output board

Signal conditioner board

P11

P12

P13

P14

P15

J1

J2

J3

J4

J4

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Note: Corresponding main board and option board connectors have the same number of

electrical lines. When an option board is correctly installed, the top and bottom edges of the

main board and option board are aligned.

REASSEMBLING YOUR METER

Slide the electronics assembly into the case until the display board is seated flush against

the front overlay. Insert the bottom tabs of the rear panel into the case, then carefully align

the board connectors with the openings in the rear panel. If necessary, remove any rear

panel knockouts for new option boards that may have been installed. Ensure that all option

boards are properly aligned with the molded board retaining pins on the inside of the rear

panel. Once the rear panel is in place, reinstall the input/output screw clamp terminal plugs.

PANEL MOUNTING

Ensure that the panel mounted gasket is in place against the back of the bezel. Turn the two

mounting screws counterclockwise until the space between the mounting pawl and the rear

of the gasket is greater than the panel thickness. Insert the meter in the panel cutout. Turn

the mounting screws clockwise until the meter is securely mounted in the panel. Do not

overtighten.

Dimensioned case drawings

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

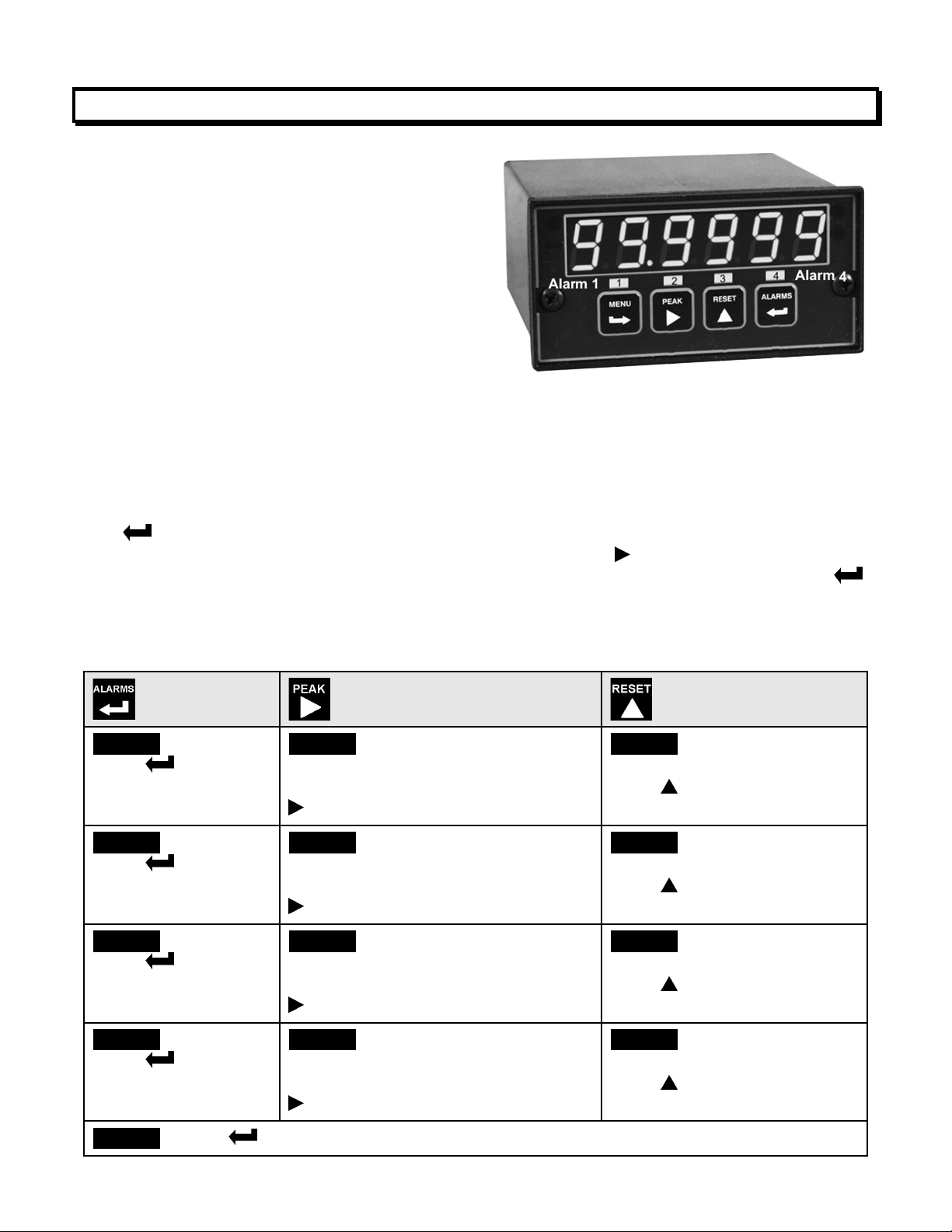

8. FRONT PANEL SETUP KEYS

Counter Front Panel

There are four front panel keys, which change function for the Run Mode and Menu Mode,

effectively becoming eight keys. The keys are labeled with alphanumeric captions (MENU,

PEAK, RESET, ALARMS) for the Run Mode and with symbols ( right arrow, right

triangle, up triangle, left arrow) for the Menu Mode.

FRONT PANEL LOCKOUT

The Menu Mode will not work with most meters shipped from the factory, since all menu

items have been disabled in software and a lockout jumper is in place. This jumper needs to

be removed for the Menu Mode to work, and values under _Loc 1 through _Loc 4 need to

be set to "0" via the front panel for these menu items to be available. See Section 9. The

paragraphs below assume that all lockout features have been removed.

MENU MODE KEY ACTION

In the Menu Mode, pressing a key momentarily advances to the next item. Holding down

the key advances through multiple menu items for fast menu navigation.

KEYS IN RUN MODE

MENU Key. Pressing MENU from the Run Mode enters the Menu Mode. Pressing

MENU repeatedly will step the meter through the various menu items (if these have not

been locked out) and then back to the Run Mode.

PEAK Key. Pressing PEAK causes the peak value of the input signal to be displayed.

The peak display blinks to differentiate it from the normal present value display.

Pressing PEAK again will return the display to the present value.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

RESET Key. Pressing RESET with PEAK resets peak and valley values. Pressing

RESET with ALARMS resets latched alarms. Pressing RESET with MENU performs a

meter reset (same as power on). Pressing and releasing RESET without pressing

another key changes the displayed item if the mode has multiple items. For Item 1, the

V LED is out. For Item 2, the V LED is on. For Item 3, the V LED is flashing.

ALARMS Key. Pressing ALARMS once displays the setpoint for Alarm 1. Pressing it

again displays the setpoint for Alarm 2. Pressing it again returns to the present value.

After 30 seconds, the meter automatically returns to the present value. Timing is

automatically reset whenever the ALARMS key is pressed.

KEYS IN MENU MODE

Right Arrow Key (MENU). Pressing steps the meter through all menu items that

have been enabled and then back to the Run Mode. With the dual-channel pulse input

signal conditioner board and no option boards, available menu items will be _InPut,

SEtuP, ConFiG, dSPYno, etc. Actual menu items will vary depending on the Input

selection and boards detected in the meter. If a change has been made to a menu item,

that change is saved to non-volatile memory when the key is pressed next, and

_StoreE is displayed briefly.

To return the meter to the run mode after StoreE has been displayed, you can press the

key repeatedly to step through all top-level menu selections until rESEt is displayed

briefly. As a shortcut, to return to the run mode after StoreE has been displayed, you

can press then simultaneously. Again, rESEt will be displayed briefly.

Right Triangle Key (Digit Select).

• Pressing from the InPut menu brings up all meter functions available with the

meter's signal conditioner. For the dual-channel pulse input signal conditioner, these

are _rAtE_, PEriod, _totAL, ti_Int, Stop_t, _PHASE, duty_C.

• Pressing from most menus selections sequentially selects digit positions 1 - 6, as

indicated by a flashing digit: 000000, 000000, 000000, 000000, 000000, 000000.

• Pressing from dEC.Pt1 brings up a decimal point display of type 11.1111. Pressing

from dEC.Pt2 brings up a decimal point display of type 22.2222.

Up Triangle Key (Value Select).

• Pressing from a selected meter function, such as _rAtE_, will select the a specific

operating mode within that function, such as A_OnLy. Always press the MENU key

to save your selection. Do not press the key to the right, or your selection will be

lost.

• Pressing for a flashing digit position or decimal point position will increment that

item. Pressing the MENU key will save any changes.

Left Arrow Key (Reverse Menu). Pressing has the same effect as pressing ,

except that menu items are brought up in reverse order. Pressing repeatedly will

backtrack to the previous menu items all the way to meter rESEt and return to the run

mode.

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

9. ENABLING & LOCKING OUT MENU ITEMS

Enabled / Disabled Menu Items

6 - Front panel reset (cold reset only)

For security reasons and ease of counter operation, any or all menu

items can be disabled or "locked out" so that they are no longer

accessible from the front panel. Each function to be disabled can be

set to "1" under menu headers Loc 1-4, while each function to be

enabled can be set to "0." Access to the menu headers Loc 1-4 can

in turn be locked out by installing a hardware jumper on the power

supply board. With the jumper installed, the operator only has

access to previously enabled menu items, not to the menu headers

Loc 1-4 and hence not to the menu items below. With the jumper

removed, the operator has access to menu headers Loc 1-4 and

hence to the menu items below.

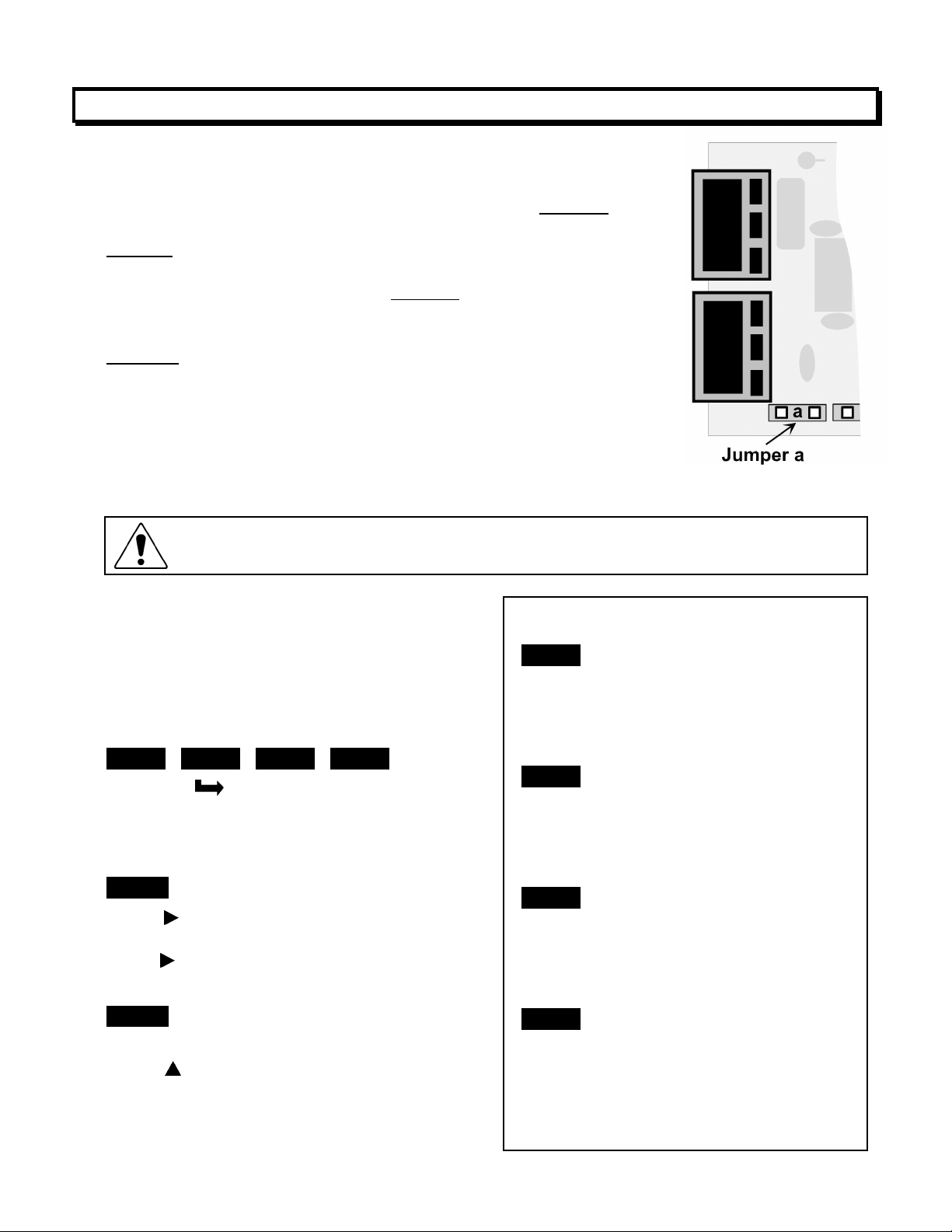

SETTING HARDWARE LOCKOUT JUMPER

To access the lockout jumper, remove the rear panel per Section 9

and locate jumper “a” in the lower portion of the power supply

board next to the input connectors (see figure at right).

The analog output is sourcing. Do not put an external voltage source in series

with it. Applying an external 24 Vdc source will burn out the analog output board.

SETTING SOFTWARE LOCKOUTS

When setting up the counter, it may be necessary to enable menu items by setting lockout

digits to “0”. Following setup, reset the digits

to "1" if you do not want the menu item to be

changed by an operator.

_Loc 1 _Loc 2 _Loc 3 _Loc 4

Press the MENU key until Loc 1, Loc 2,

Loc 3 or Loc 4 is displayed, as desired. Note:

lockout jumper “a” must be removed (see

above).

111111

Press to display the lockout status, consisting of 0’s and 1’s. The left digit will flash.

Press again to step to the next digit, which

will flash.

000000

123456

Press to set the flashing digit to "0" to

enable the menu item or to "1" to disable.

Press MENU to enter. See the table to the

right for list of menu items that can be

enabled or disabled.

_Loc 1

3 - Input type selection

4 - Setup, Config, Dspyno

5 - Gate time, timeout, batch setup

6 - Filter setup

_Loc 2

3 - Slope, decimal points

4 - Scale, offset, resolution, 2-coord.

5 - Alarm setup

6 - Alarm setpoint programming

_Loc 3

3 - Analog output setup & scaling

4 - Serial communications configuration

5 - Calibration

6 - Change displayed Item #

_Loc 4

3 - View peak value

4 - View alarm setpoints

5 - Front panel resets (peak & latched

alarms)

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

10. DUAL CHANNEL PULSE OR AC INPUT SIGNAL CONDITIONER

Frequency

Bias Resistor

Contact

The dual channel signal conditioner board is used for the frequency, rate, period, timing,

batch control, phase and duty cycle meter functions. The board needs to be configured via

jumpers for the input signal type and level. It is recognized by the meter software, which will

bring up the applicable menu items. The dual channel pulse input signal conditioner does

not require calibration, since the quartz crystal oscillator used for frequency and timing

applications is located on the counter main board.

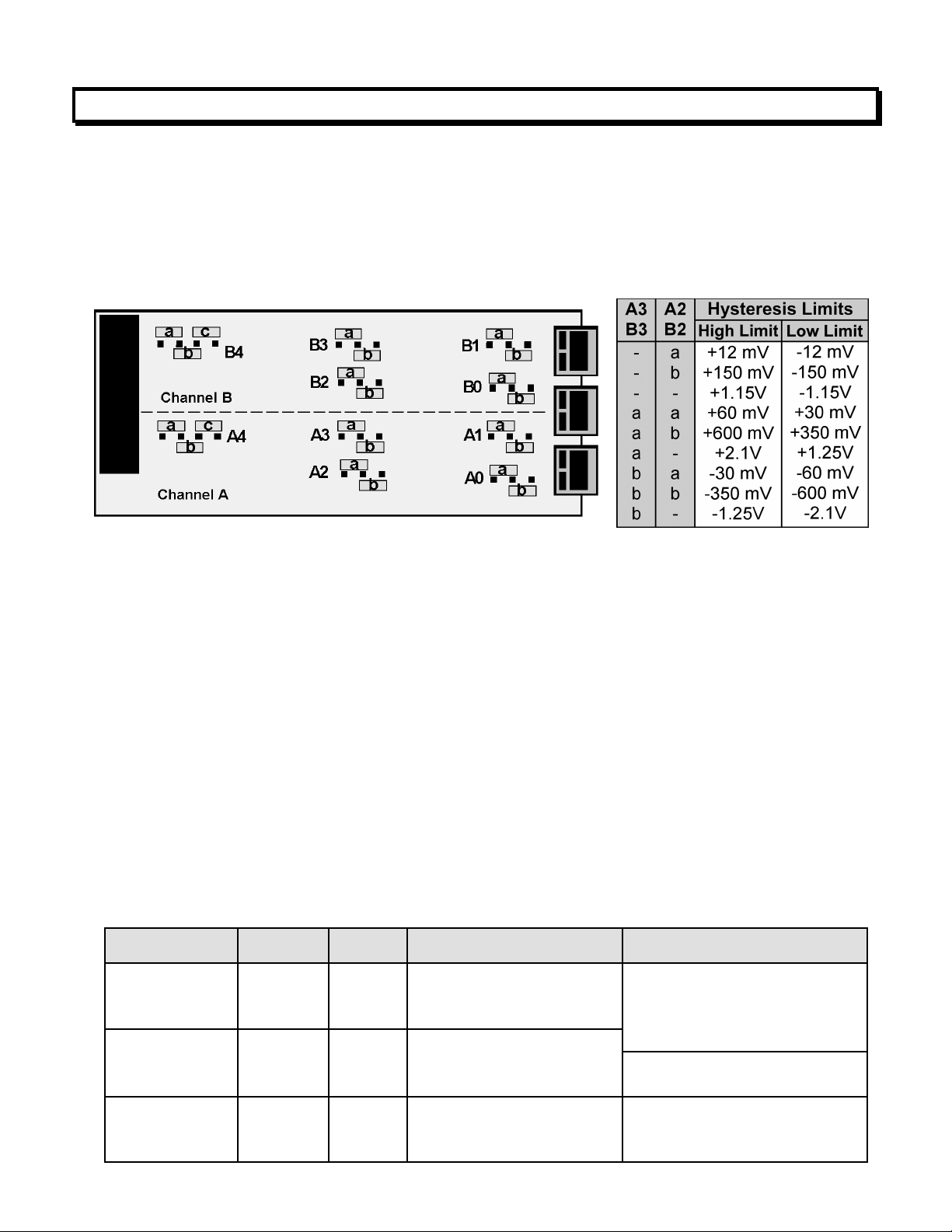

Jumper Settings for Expected Signal Levels

The jumper settings for Channel A (A2 & A3) and Channel B (B2 & B3) need to be set for

the expected signal voltage. Jumpers need to be set for both channels even if only one

channel is used.

A voltage input is recognized as a pulse when it exceeds a high hysteresis limit, and is

unrecognized as a pulse when it falls below a low hysteresis limit. Hysteresis is used to

avoid false counts due to electrical noise. The wider the hysteresis band, the better the

noise immunity. To count negative pulses, reverse the inputs to the counter.

Built-in pull-up or pull-down resistors are used to provide a +5V or -5V signal bias with open

collector devices or dry contact closures. They should not be used for other input types.

Debounce circuitry keeps the meter from counting extra pulses due to contact bounce.

High voltages Vin can be attenuated by a resistor R in series with the meter’s input resistance, which is 100 kΩ for non-biased signals greater than ±3V. This creates a voltage

divider, so that the sensed voltage is Vin x 100 kΩ / (R + 100 kΩ).

Function Group Jumper Jumper effect Input Resistance

Response

Debounce

A0 & B0 -

b

a

A1 & B1 -

a

b

A4 & B4 b

a, c

c

1 MHz max

30 kHz max

250 Hz max

No pull-up or pull-down

10 kΩ pull-up to +5V

10 kΩ pull-down to -5V

No debounce

3 msec

50 msec

14

1 MΩ for Vin within ±3V

100 kΩ for Vin outside ±3V

10 kΩ

10 kΩ

No effect on input

resistance

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

Common Jumper Settings

DISPLAY FREQUENCY IN Hz WITH 1 Hz RESOLUTION

Application:

cy from 1 Hz

date rate of 4/sec, and adaptive moving

Set Input to “Rate A Only.” Set

Config to display to 999999 counts. Set

play

sec +30 ms +1

quencies under 1 Hz are displayed as 0.

ilter for adaptive moving average with

scale

of 1

Input Type Vmax A0 & B0 A1 & B1 A2 & B2 A3 & B3 A4 & B4

Logic levels 250V - - - a b

NPN open collector +25V b a - a b

PNP open collector -15V b b - - b

Contact closures -15V, +25V a or b a - a a, c

Line frequency 250V b - - - a, c

Magnetic pickup, 2-wire

OVERVIEW OF OPERATING MODES

RATE & FREQUENCY MODES

Frequency in Hz is determined by timing an integral number of pulses over a user-specified

gate time from 0 to 199.99 sec and taking the inverse of average period. The typical display

update rate of the meter is gate time + 1 period + 30 ms Selecting a longer gate time

produces a more stable reading as more cycles are averaged, but slows down the update

rate. At very low frequencies, the update rate is controlled by the period. A time-out from 0

to 199.99 sec is also selectable. This is the time the meter waits for a signal to start or end a

conversion. If the signal is not received before the time-out ends, the meter reads zero. The

longer the time-out, the lower the minimum frequency the meter can display.

With a scale factor of 1 and a scale multiplier of 1, frequency is displayed in Hz with no

decimal point. Appling a scale multiplier from 10 to 100000 (in decade steps) and setting the

decimal point increases resolution from 0.1 to 0.00001 Hz. Decreasing the scale multiplier

from 1 to 0.00001 (in decade steps) and setting the decimal point allows display in kHz or

MHz. Note that the same 100 kHz frequency can be displayed as 100000 Hz or 100.000

kHz simply by moving the decimal point.

250V b - a - b

Display frequen

to 999999 Hz with no decimal, display up-

average filter for 6 readings.

Solution:

Gate Time to .22 sec so that the dis

update rate becomes .22

period. Set Timeout to 1 sec, so that fre-

Set F

a 1.6 sec time constant. Apply a

value of 1.00000 and a scale multiplier

for direct readout in Hz.

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

DISPLAY 0-50.00 RATE FROM 1-10 kHz INPUT, COORDINATES OF 2 POINTS METHOD

Application:

50.00 (with two

10 kHz input. Use

Set Input to “Rate A Only.”

Select “coordinates of 2 points” scaling

method under Setup. This is easier than

scale and offset. Set DecPt1 to two places.

Then enter the low input and desired low

reading, and high input and desired high

Application:

Display rate in GPM to two

decimal places from flow meter calibrated

Setup, select “coordinates of 2 points”

scaling method. Set DecPt1 to two places.

Then enter the low input and desired low

reading, and high input and desired high

reading, as shown. In this example, we

want to display 60.00 (GPM) from an input

Hz. Note that the meter’s native

rate measurements are in Hz. There will be

60 times more gallons per minute than per

Display 0decimal places) for 1coordinates of 2 points scaling method.

Solution:

reading, as shown.

DISPLAY RATE IN GPM FROM 36.67 PULSE/GALLON TURBINE FLOW METER

to 36.67 pulses/gallon.

Solution: Set Input to “Rate A Only. Un-

der

of 36.67

second.

Rate in engineering units is displayed from measured frequency by applying an appropriate scale factor and setting the decimal point. The scale factor consists of a scale value

from 0.00000 to 9.99999 (fixed decimal point and settable digits) and a scale multiplier from

0.00001 to 100000 (in decade steps). When using the coordinates of 2 points method to

scale the meter, the low input and high input frequencies are entered in Hz.

• RATE A ONLY (A_OnLy) displays rate or frequency for Channel A. The latter utilizes

SCALE1, OFFSt1 and dECPt1. Channel B is not used.

• RATE A B (A__b__) displays rate or frequency for Channel A as Item #1 or for Channel

B as Item #2. The latter utilizes SCALE2, OFFSt2 and dECPt2.

• RATE A, TOTAL A (A_Atot) (Extended counter) displays Rate for Channel A as Item #1

and Total for Channel A as Item #2 since last reset. Total may count down from an offset

by entering a negative scale factor. Only used for non-linear inputs.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

• RATE A, TOTAL B (A_btot) (Extended counter) displays Rate for Channel A as Item #1

DISPLAY TOTAL IN GALLONS FROM 36.67 PULSE/GALLON TURBINE FLOW METER

Application:

Display total in gallons with

s of 2 points method.

This is the preferred scaling method. Set

gate time to its minimum of 0.01 sec for

smooth display updates. Set DecPt1 to two

places. Then enter low input and desired

low reading, and high input and desired

1.00 for 36.67

Application:

Display flow rate in GPM with

two decimal places and total gallons with

ter signal calibrated to 36.36 pulses/gallon,

ter, as

required for simultaneous rate and total.

Set Input to “Rate A A Total.” For flow rate

scale the display by entering Lo

In1, Lo rd1, Hi In1, Hi rd1 as shown. For

total in Gallons (Item #2), set DecPt2 to no

mals, and scale the display by entering

Lo In2, Lo rd2, Hi In2, Hi rd2 as shown.

Enter a Gate Time, such as 0.1 sec, which

used to slow down the display

and Total for Channel B as Item #2.

• RATES A+B, A-B, AxB, A/B, A/B-1 (Extended counter) display arithmetic combinations

of Rates A and B as Item #1, Rate A as Item #2, and Rate B as Item #3. With rates A and

B scaled to produce a ratio close to 1 and an offset of -1, the special combination A/B-1,

called “Draw,” can display percentage changes, such as elongation of material passing

between rollers. Channels A and B use DecPt1. The arithmetic combination uses DecPt2

and can be shifted by factors of 10 using a rESoLN (resolution) entry.

TOTAL MODES

two decimal places for flow meter calibrated to 36.67 pulses/gallon.

Solution: Set Input to “Total A Only.” Under Setup, select “Restore totals at poweron” and coordinate

high reading for display of

pulses, as shown.

DISPLAY SIMULTANEOUS RATE & TOTAL FROM 36.67 PULSE/GALLON FLOW METER

no decimal places from the same flow me-

applied to Channel A

Solution: Use an Extended coun

in GPM (Item #1), set DecPt1 to two decimals, and

deci

is only

update rate, not the actual totalizing rate.

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

DISPLAY TOTAL VOLUME BY ADDING TWO TURBINE FLOW METER CHANNELS

Application:

Display total liquid volume in

om 2 pipes

dispensing liquids into the same tank. Flow

quire the

Extended counter. Apply flow meter output

ter output B

to Channel B. Set Input to “Total A+B.” Set

dates. Select a positive trigger slope for A

and B. Set DecPt2, which applies to Grand

Total, and DecPt1, which applies to Totals

l places. Under

Setup, select the coordinates of 2 points

scaling method for A and B. To scale A,

enter 36.67 (pulses) for Hi In1 and 1.00

(gallons) for Hi Rd1. To scale B, enter

58.12 (pulses) for Hi In2 and 1.00 (gallons)

ill be Item

to view

gallons to two decimal places fr

meter A is calibrated to 36.67 pulses/gallon, flow meter B to 58.12 pulses/gallon.

Solution: Arithmetic operations re

A output to Channel A, flow me

Gate Time to 0.01 sec for fast display up-

A and B, both to two decima

for Hi Rd2. The normal display w

#1 (Grand Total). Press the key

Item #2 (Total A) and Item #3 (Total B).

TOTAL A ONLY (A_OnLy) displays the number of pulses applied to Channel A as Item #1. If

scientific notation is not selected, overflows beyond 999,999 are recorded in units of 1,000,000

as Item #2. For example, a total of 17,345,676 would be displayed as 345,675 in Item #1 and

17 in Item #2. This capability gives the counter 12-digit capability. Items #1-2 can also be

retrieved via serial communications.

• TOTAL A B (A__b__) displays Total A as Item #1 or Total B as Item #2.

• TOTALS A+B, A-B, AxB, A-B, A/B (Extended counter) display arithmetic combinations

of Totals A and B as Item #1, Total A as Item #2, and Total B as Item #3.

• TOTAL A-B UD (A-b_Ud) is the same as TOTAL A-B, except that counts are subtracted

on an ongoing basis, instead of subtracting totals. This avoids round-off errors with large

totals. Overflows are displayed as #2. (See Total A only)

• BURST (_burST) (Extended counter) displays the total number of signal bursts applied

to Channel B as Item #1. Gate time must be greater than the period of the lowest signal

frequency and less than the minimum time between bursts. Time-out should be set to 0.

• TOTAL A B U/D (A_bU/d) (Extended counter) displays Total A as Item #1, where the up

or down count direction is determined by an input on Channel B. If the menu item SLOPE

is set to 0 for Channel B, (digit 6), an input level on B below the jumper set Low

Threshold B causes the count to go up, and an input level above the jumper set High

Threshold causes the count to go down. If SLOPE for Channel B is set to 1, the opposite

occurs. The maximum frequency on A that can be counted is 250 kHz, or a minimum of 4

µs between pulses.

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

• TOTAL A B INHIBIT (A_bInH) (Extended counter) displays Total A as Item #1, where

Application:

flow

meter. Slow down filling at 54 gallons.

Cycle batches automatically with 20 sec

batch total & fill

Use an Extended counter with a

dual relay output board. Apply the flow

nels A & B. Set Input

to “Rate Batch.” Set Batch to count up to

tween batches. Make Item #2 the number

of batches. Set Gate Time to 20 sec. Set

an adaptive moving average filter, which

will apply to rate only, not totals. Set

DecPt1 and DecPt2 to two decimal places

for Items #1 and #3 (Batch Total and Rate).

Scale Item #1 (Batch Total) by entering a

Scale1 of 2.72702 (counts per pulse) and a

Setpoint1 of 55.00, which will serve as the

batch setpoint in gallons. Scale Item #3

ordinates of 2 points

method so that 36.67 pulses/sec will be

played as 60.00 GPM. Set Setpoint2 to

54.00 to activate Relay 2 to slow the fill

counting may be inhibited by a control input on Channel B. If the menu item SLOPE is set

to 0 for Channel B (digit 6), a low input level on B allows counting, and a high input level

inhibits counting. If the SLOPE for Channel B is set to 1, the opposite occurs. The

maximum frequency on A that can be counted is 1 MHz. Overflows are displayed as #2.

(See Total A only)

BATCH CONTROL MODE (_bAtCH)

BATCH CONTROL WITH A 36.67 PULSE/GALLON TURBINE FLOW METER

Fill 55 gallon tanks, measuring flow with a 36.67 pulses/gallon

between cycles. Display

rate to 2 places. Track number of batches.

Solution:

meter signal to Chan

Setpoint1. Use Gate Time as delay be-

(Rate) using the co

Batch control (Extended counter) uses the meter with a dual relay controller board to

control repetitive fill operations. Relay #1 is used as the batch relay. Relay #2 (or Setpoint

#2) can be assigned to another limit, such as pre-warn to slow filling near the setpoint, endof-process, or rate alarm. The same signal is applied to Channels A and B. When digit 6 of

bAtCH (Action after Meter Reset) is set to zero, the following applies:

dis

rate at 54.00 gallons.

• In batch control mode without external resets, the meter waits until the RESET key is

pushed. It then energizes Relay #1 and displays the changing Batch Total. When the

preset value is reached, Relay #1 de-energizes for the duration of the gate time setting.

Relay #1 then re-energizes, the Batch Total resets, and the fill cycle repeats.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

• In batch control mode with external resets, pushing the RESET key initiates cycling.

STOPWATCH TIMING, “ON” TIME OF A MACHINE WITH 0.00 HOUR RESOLUTION

Application:

Display daily “on” time of

a machine in hours with 2 decimals. For

Tie a relay across the AC input

to the machine so that the relay closes to

ground when power is applied. Apply the

relay output across both the A & B inputs

so that the voltage is 5V when the contacts

sed. Set

tive trigger slope for A and positive for B.

Under Config, set Display Mode to sec. Set

tes of 2 points scaling method for Item

ated

time). For Item #1, set DecPt1 to 2 places,

set Hi In1 to 3600 (sec) and Hi Rd1 to 1.00

(hrs). For Item #2, set DecPt2 to 0 places,

Grounding an external Gate input for a minimum of 3.33 ms then starts each new fill

cycle by energizing Relay #1 and resetting the Batch Total. Gate time is not used.

Three values are tracked and can be separately displayed by pressing the RESET key: Item

#1, the Batch Total; Item #2, the Grand Total of all batches or Number of Batches (selectable during setup); and Item #3, the Fill Rate.

• Item #1, Batch Total, is the total for that batch. It may be configured to count up from 0 to

a preset, or to count down from a preset to 0. The preset value is placed in SETPT1.

SCALE1 is positive whether counting up or down.

• Item #2, Grand Total, is the sum of previous Batch Totals and the current Batch Total. It

can overflow to exponential format.

• Item #2 (alternate), Number of Batches, is the current count of batches. SCALE1 does

not apply. dECPt1 is set to 1.

• Item #3, Fill Rate, is calculated with a fixed 20 ms (or 1 cycle min) gate time. It may be

displayed as Item #3.

PERIOD MODES

• PERIOD A ONLY (A_OnLy) displays period of Channel A as Item #1.

• PERIOD A B (A__b__) displays period of Ch A as Item #1 and of Ch B as Item #2.

• PERIODS A+B, A-B, AxB, A-B, A/B (Extended counter) display arithmetic combinations

of Periods A and B as Item #1, Period A as Item #2, and Period B as Item #3.

TIMING MODES

machine maintenance, also track accumulated hours since last reset.

Solution:

are open and 0V when they are clo

Input to “Stopwatch A to B.” Select nega-

Gate Time to 0.01 sec. Select the coordina

#1 (daily time) and Item #2 (accumul

set Hi In2 to 3600 and Hi Rd2 to 1 (hr).

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

STOPWATCH TIMING, CLOSING TIME OF A RELAY TO 0.001 MSEC RESOLUTION

Application:

Measure the closing time of a

To close the relay, apply the

tive voltage to the relay coil and

to meter Channel A. Wire the relay so that

ed across Channel B when the

watch A to B.” Select a positive trigger

slope for A and a negative trigger slope for

play Mode to sec.

Set Gate Time to 0.01 sec. Select the

points scaling method for

Item #1. Set DecPt1 to 3 places. Set Hi In1

to 1.00000 (sec) and Hi Rd1 to 999.999

relay in msec to 0.001 msec resolution.

Solution:

same posi

0V is appli

contacts are closed. Set Input to “Stop-

B. Under Config, set Dis

coordinates of 2

(msec). Ignore Item #2, which is not used.

• TIME INTERVAL A TO B (A_to_b) measures time between periodic inputs on Channels

A and B. Timing starts when a pulse is applied to Channel A (positive edge if slope A is 0,

negative edge if slope A is 1), and ends when a pulse is applied to Channel B (positive

edge if slope B is 0, negative edge if slope B is 1). Pulse width may be measured by tying

inputs A and B together and selecting a positive or negative edge to start (Slope A) and

the opposite polarity edge to stop (Slope B). If multiple start and stop pulses occur during

the gate time, the displayed value is the average of pulse widths. The value is updated at

the end of each gate time. With a scale factor of 1, one count is one microsecond. Use

Scale Value x Scale Multiplier to set other units of time. The display update rate is set by

Gate time.

• INVERSE TIME INTERVAL (__1/Ab) (Extended counter)

Takes the inverse of time interval for a reading in /second. For example, if the average

time interval for object to travel from point A to point B is 5 seconds, the inverse time

interval would be 0.2/sec. For the average speed of the objects, simply apply a scale

factor equal to the distance separating the two points, such as 7 (inches). Speed would

then be displayed as 7 x 0.2 = 1.4 (inches/sec). For a 6-digit reading, apply a scale

multiplier of 10,000 and move the decimal point.

• STOPWATCH A TO A (A_to_A) measures time between the same positive (or negative)

edge of start and stop pulses applied to Channel A. Single event times may be displayed

as Item #1 in decimal seconds, minutes or hours, or in HH:MM:SS clock format. Time is

reset to 0 when a new start pulse occurs. Accumulated total time may be displayed as

Item #2. With a scale factor of 1, one count is one microsecond. Use Scale Value x Scale

Multiplier to set other units of time. The display update rate is set by Gate time.

• STOPWATCH A TO B (A_to_B) measures time between a start pulse on Channel A and

a stop pulse on Channel B. Timing is the same as for A to A, except that positive or

negative edges may be selected separately for Channels A and B. This allows the pulse

width measurement of single pulses by tying Channels A and B together. One slope is

selected to start timing, and the opposite slope to stop timing.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

• INVERSE STOPWATCH TIME A TO A & A TO B (__1/AA & 1/AB) (Extended counter)

Application:

ence to 0.01º resolution between two AC

Use an Extended counter, as

required for phase angle measurement.

conditioner for maximum

sensitivity to catch zero voltage crossings

mize the effects of amplitude jitter.

Apply one AC signal to Channel A and one

180º.” The display will be in degrees. Set a

tes

per sec. Set both trigger slopes to positive.

tes of 2 points scaling method. Set Hi

In1 to 1.00000 (degrees) and Hi Rd1 to

1.00 (degrees). As an alternative, select

ffset scaling method. Then

simply select a scale value of 1.00000 and

Takes the inverse of stopwatch time for a reading in /second. For example, if the travel

time for an object to travel from point A to point B is 5 seconds, the inverse stopwatch

time interval would be 0.2/sec. For the speed of that object, simply multiply by a scale

factor equal to the distance separating the two points, such as 7 (inches). Speed would

then be displayed as 7 x 0.2 = 1.4 (inches/sec). For a 6-digit reading, apply a scale

multiplier of 10,000 and move the decimal point.

DUTY CYCLE MODE (duty_C) (Extended counter)

Measures ON or OFF period of periodic square waves as a percentage of total period

over a gate time which is selectable from 10 ms to 199.99 s. The same signal is applied

to Channels A and B. ON or OFF time is measured between positive and negative edges

of the signal, with averaging over multiple integral periods over the selected gate time.

Apply a scale factor of 1 for readings in percent. Apply a 10 or 100 multiplier and move

the decimal point by 1 or 2 positions for 0.1% or 0.01% resolution.

PHASE ANGLE MODE (PHASE) (Extended counter)

Measures the phase relationship in degrees between two signals with the same period

over a gate time which is selectable from 10 ms to 199.99 s, with averaging over multiple

integral periods over the selected gate time. The two signals are applied to Channels A

and B. For best accuracy, both signals should have the same amplitude. The amplitude

of sinusoidal signals should be larger that 1V, and the trigger level should be set at 12

mV (no jumper at A3 or B3, jumper a at A2 and B2).

PHASE ANGLE MEASUREMENT TO 0.01º RESOLUTION

signals centered around 0º.

Solution:

Jumper the signal

and mini

to Channel B. Set Input to “PHASE +/-

gate time of 0.22 sec for 4 display upda

Set two decimal places. Select the coordina

the scale and o

a multiplier of 100.

Measure phase angle differ-

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

POWER FACTOR MODE (PHASE) (Extended counter)

POWER FACTOR MEASUREMENT TO 0.001 RESOLUTION

Application:

Display power factor to 0.001

Use an Extended counter, as for

phase angle measurement. Jumper the

al conditioner for maximum sensitivity

mize the effects of amplitude jitter. Apply

AC signals to channels A and B. Set Input

180+”. Set gate time of 0.22

tes per sec. Set

SCALE and OFFSt are not

The power factor of an AC power system is the ratio of real power in watts (W) divided by

apparent power in volt-amperes (VA). For sinusoidal signals differing by a phase angle θ,

power factor will be cos(θ), which is how the meter computes power factor.

Power Factor readings can range from 1.000 to 0.000 with three decimal places and an

accuracy of 0.1% for sinusoidal signals at 50/60 Hz AC line frequency. Maximum

frequency is 1 kHz. While Power Factor is always positive, the meter artificially assigns a

minus sign to Power Factor for negative phase angles, and it sets Power Factor to 0 for

phase angles greater than 90°.

resolution between two AC voltage waveforms.

Solution:

sign

to catch zero voltage crossings and mini-

to “PHASE sec for 4 display upda

Config to 0200.

used.

Power Factor is stored in the custom curve section of the Extended counter and uses

"PHASE -180+" as the input type. Setting ConFiG to X1XX sets up for Phase Angle.

Setting ConFiG to X2XX enables Power Factor scaling. First set up the unit as a phase

meter and verify that it is working properly. You will need to set the jumpers on the signal

input board for the signal level to be applied to the A and B inputs.

The decimal point is set to xxx.xxx . Scale and Offset are disabled.

Power Factor is displayed as a value from -0 to -1 and +1 to +0, with a discontinuity at -1,

+1 corresponding to zero phase angle. As the display traverses the range from -0 to -1

and +1 to +0, an Output Control Value (OCV) is created that extends from 0 to +2.000

with a continuous positive slope and no discontinuity at zero phase angle.

The first half of OCV is created by assuming the absolute value of the display value from

-0 to -1, and hence becomes 0 to +1.000. The second half of OCV is created by

subtracting the displayed value +1 to 0 from 2.000, and hence becomes +1.000 to

+2.000. While never displayed, OCV is the source value for determining the analog

output, for setpoint comparisons, and for filtering purposes, as it eliminates the discontinuity observed at zero phase angle.

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Example of Using OCV of 0 to 2.000 for setting Analog Output

DUTY CYCLE MEASUREMENT TO 0.01% RESOLUTION

Application:

dic pulses as a % of total period with .01%

requires the Extended

counter. Apply the same signal to

Channels A & B. Set Input to “Duty Cycle

(A to B) / A.” The native counts will be in

rcent. For a positive “on” pulse, set

trigger slope to positive for A and negative

tes of 2 points

scaling method. Set Hi In1 to 1.00000

(percent) and Hi Rd1 to 1.00 (percent). As

an alternative, select the scale and offset

ing method. Then simply select a scale

4 mA output is desired for Power Factor of -0.4 (OCV = 0.400).

20 mA output is desired for Power Factor of +0.4 (OCV = 2.000 - 0.4 = 1.600).

Set up as follows: deC.Pt to 111.111, AnSEt to 21, An_Lo to +0.400 (4 mA point), An_Hi

to +1.600 (20 mA point), dEC.Pt as desired to 111.111, 1111.11 or 11111.1

Example of Using OCV of 0 to 2.000 for setting the Alarm Setpoints

It is desired to operate Relay1 when the Power Factor falls outside of ±0.75 display range

(or outside of 0.750 to 1.250 OCV range).

Set up as follows: ConFig to x1xx to take meter out of Power Factor, dEC.Pt to 111.111,

SEtPt1 to 1.000, AL_SEt to 00000, dEUtn1 to 0.250 to activate Relay1 above 1.250 and

below 0.750, dEC.Pt as desired to 111.111, 1111.11 or 11111.1 . Return meter to Power

Factor mode by setting ConFig to x2xx

Measure “on” period of perio-

resolution over a time interval of 100 sec.

Solution: Duty cycle

pe

for B. Select the coordina

scal

value of 1.00000 and a multiplier of 100.

1/RATE MODE FOR TIMING (Extended Counter)

An example of 1/Rate is the time it takes an item takes to travel through an oven at a

measured rate. Like Rate, 1/Rate can be scaled using Scale1 and Offset1. With no offset

and Scale1 set to 1, Rate A for the full analog input range will be displayed as 0-100000,

and 1/A will be displayed as 1000000/A. Both the A and 1/A readings are multiplied by

Scale1 and offset by Offset1. With Scale1 set to 1, A is displayed as 10000, and 1/A is

displayed as 100. With Scale1 set to 2, A is displayed as 20000, and 1/A is displayed as

200. If square root extraction is applied to rate, the rate display A is replaced by √Ā, and

1/A is replaced by 1/√Ā. 1/A does not apply to custom curves.

Scaling may also be done by using the coordinates of 2 points method, which automatically calculates scale and offset for the displayed value when the low and high input

signals and the corresponding desired low and high displayed values are entered.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

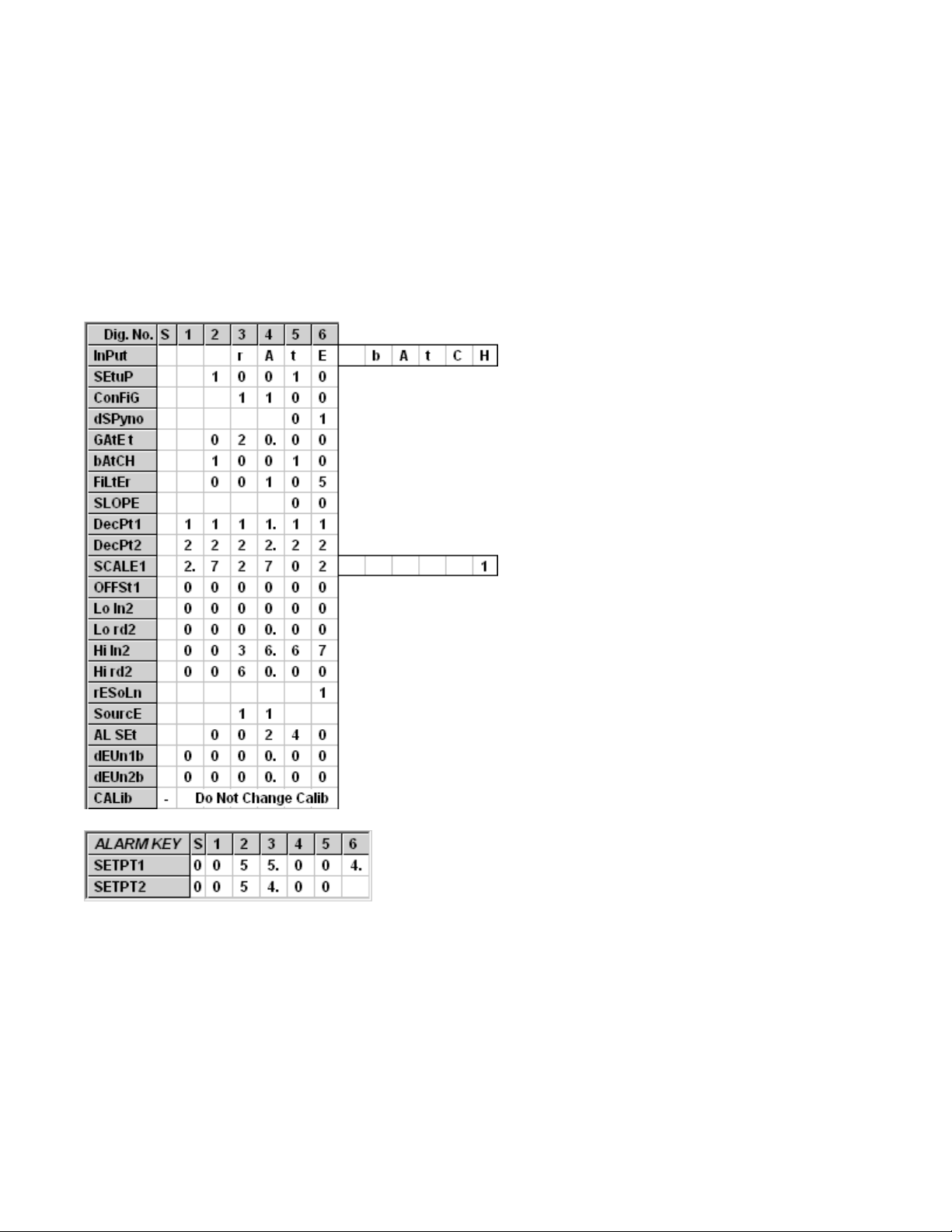

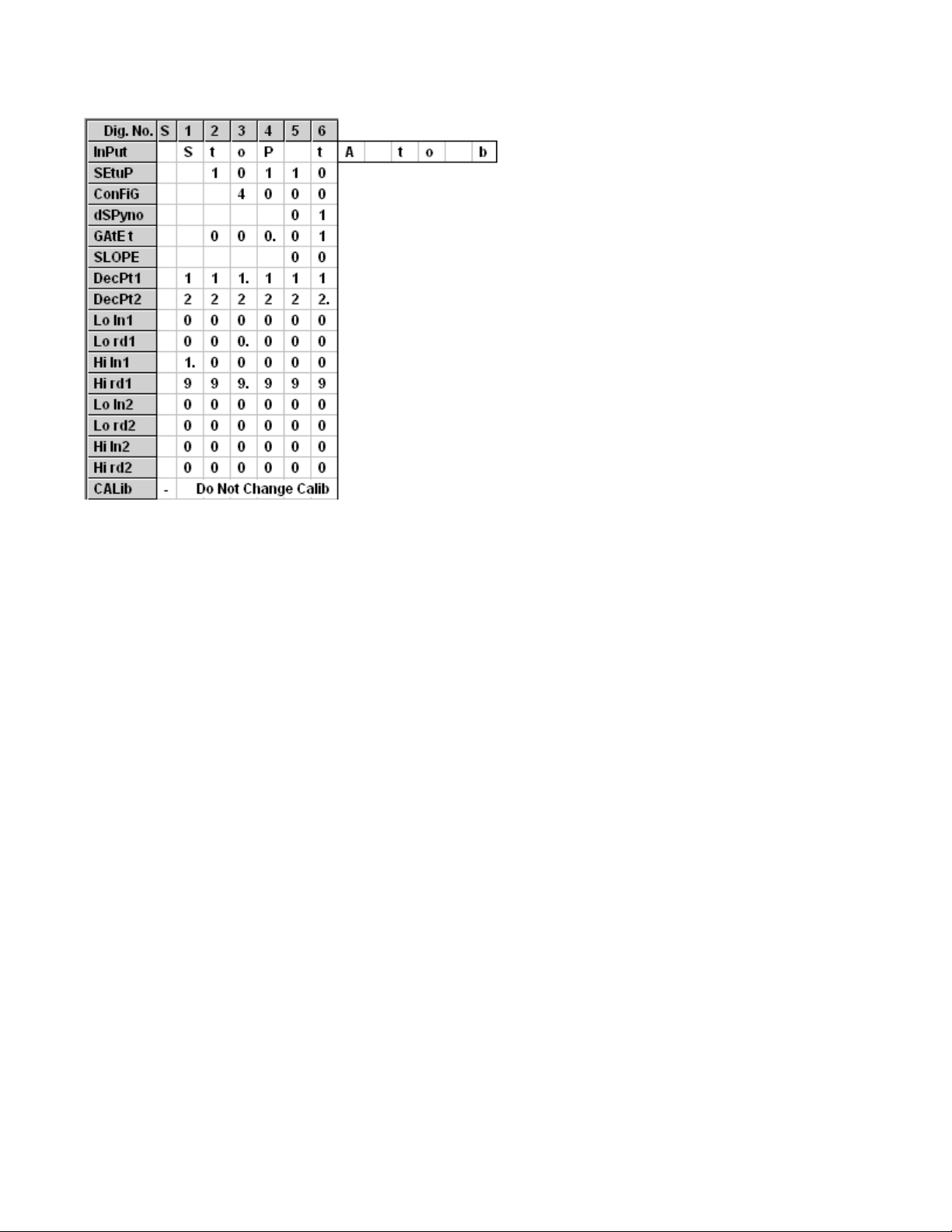

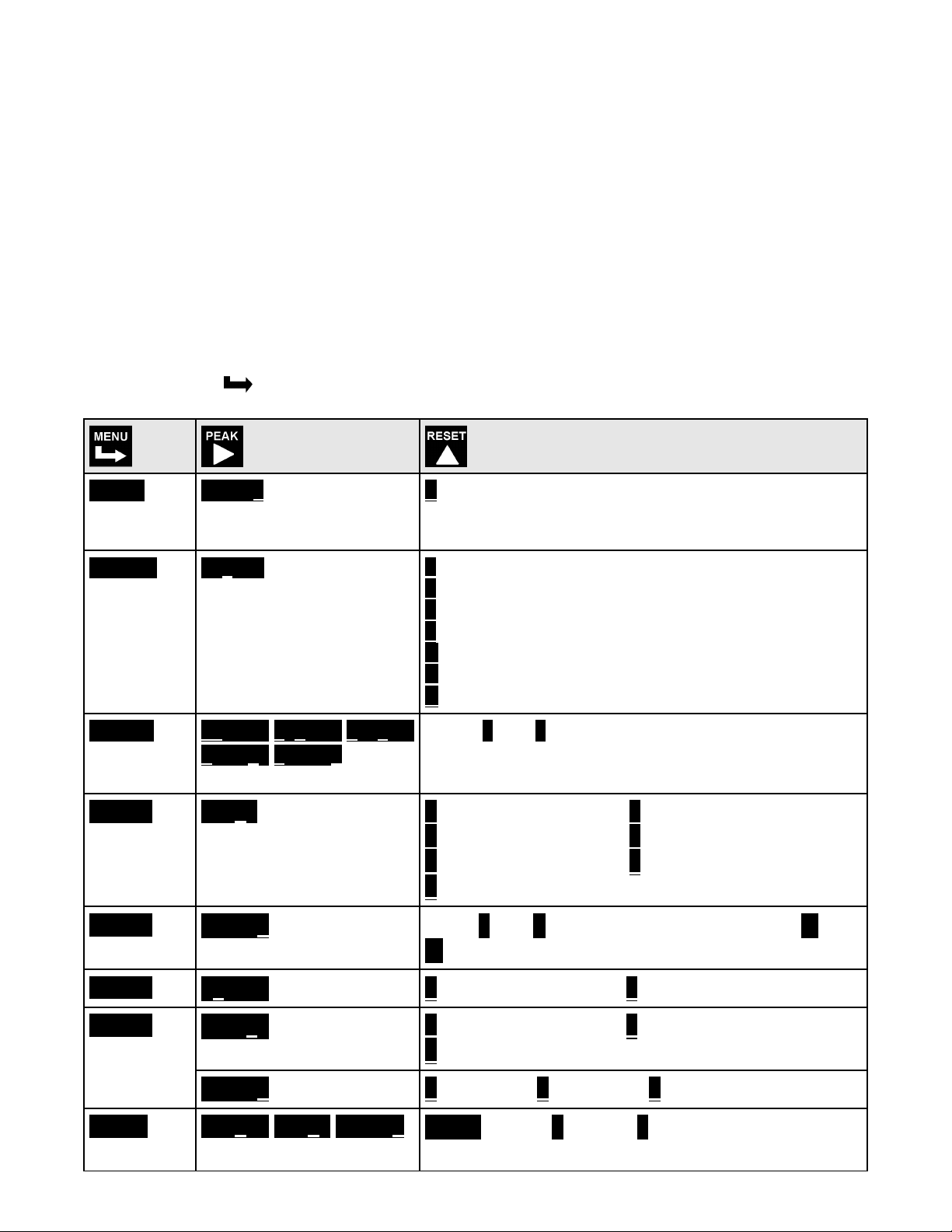

SETUP OF COUNTERS WITH DUAL CHANNEL PULSE SIGNAL CONDITIONER

_

InPut

rAtE

A__b__

A_OnLy

bAtCH

A_Atot

.

A_btot

.

b

b.

b.

Period

A__b__

A_OnLy

b

b.

b.

b.

If the MENU key does not work, see Section 9 “Enabling & Locking Out Menu Items.”

Menus are dynamic. Menu items will only appear if appropriate for previously made menu

selections. For example, Batch menu items will only appear if “Batch” was selected under

“Rate.” Extended counter items will only appear if “Extended” was selected under “Config.”

Input

Press

Menu

Press Digit

Select Key

__

Rate modes

Channel B (Item #2).

Basic

_

Grand total or number of batches (Item #2). Fill rate

(Item #3).

Channel A (Item #2).

Channel B (Item #2).

_A_+_

(Item #2). Rate B (Item #3).

_A_−−−−_b Difference of rates A and B (Item #1). Rate

A (Item #2). Rate B (Item #3).

_A_._

Extended meter only

(Item #2). Rate B (Item #3).

Press Value Select

Key

Rate for Channel A (Item #1). Rate for

Rate for Channel A only (Item #1).

Batch control mode. Batch total (Item #1).

Rate for Channel A (Item #1). Total for

Rate for Channel A (Item #1). Total for

Sum of rates A & B (Item #1). Rate A

Product of rates A and B (Item #1). Rate A

_A_/_

(Item #2). Rate B (Item #3).

_A/b−−−−1. Draw, rate A / rate B -1 (Item #1). Rate A

(Item #2). Rate B (Item #3).

Period modes

Channel B (Item #2).

Basic

_A_+_

A (Item #2). Period B (Item #3).

_A_-_

Period A (Item #2). Period B (Item #3).

_A_._

Period A (Item #2). Period B (Item #3).

_A_/_

Extended meter only

#1). Period A (Item #2). Period B (Item #3).

Rate A divided by rate B (Item #1). Rate A

Period Channel A (Item #1). Period for

Period for Channel A only (Item #1).

Sum of periods A and B (Item #1). Period

Difference of periods A and B (Item #1).

Product of periods A and B (Item #1).

Ratio, period A divided by period B (Item

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

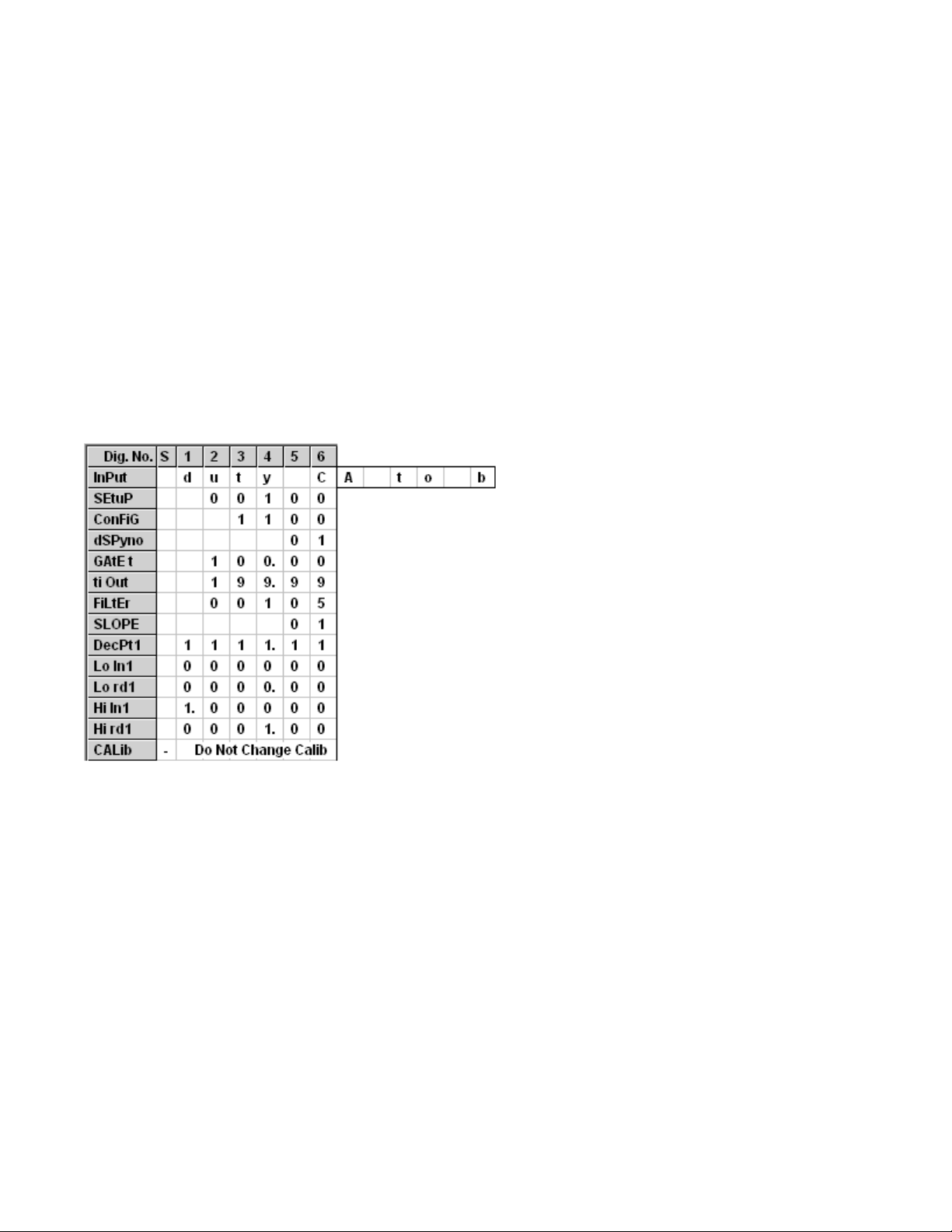

Press

_

InPut

totAL

.

A__b__

A_OnLy

A-b_Ud.

burSt

.

b_ArAt

.

A_bU/d

A_b_InH

b

b.

Difference of totals A and B (Item #1). Total

b.

b.

ti__Int.

A_to_b

1/Ab

StoP_t

A_to_A

A_to_b

Channels A &B, or accumulated total time (Item #2).

1/AA

1/Ab

Menu

Press Digit

Select Key

Press Value Select

Key

_

(continued)

Total modes

Channel B (Item #2).

Basic

Channel A minus counts on Channel B.

_

(Item #2).

Channel A (Item #2)

control via Channel B.

inhibit control via Channel B.

_A_+_

(item #2). Total B (Item #3).

Extended meter only

_A_-_

A (item #2). Total B (Item #3).

Total for Channel A (Item #1). Total for

Total for Channel A only (Item #1).

Running total (Item #1) of counts on

Count of bursts (Item #1). Burst frequency

Total for Channel B (Item #1). Rate for

Total for Channel A (Item #1) with up/down

Total for Channel A (Item #1) with count

Sum of totals A and B (Item #1). Total A

_A_._

(item #2). Total B (Item #3).

_A_/_

(item #2). Total B (Item #3).

Time interval mode

with pulse signals applied to Channels A & B.

Basic

__

Ext.

periodic events with pulse signals applied to A & B.

Stopwatch modes

on Channel A, or accumulated total time (Item #2).

Basic

__

for single events with pulse signals applied to A & A.

__

Extended

for single events with pulse signals applied to A & B.

Product of totals A and B (Item #1). Total A

Ratio of totals A and B (Item #1). Total A

Time interval (Item #1) for periodic events

Inverse of time interval (/sec) (Item #1) for

Single event time (Item #1) between pulses

Single event time (Item #1) with pulses on

Inverse of stopwatch time (/sec) (Item #1)

Inverse of stopwatch time (/sec) (Item #1)

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

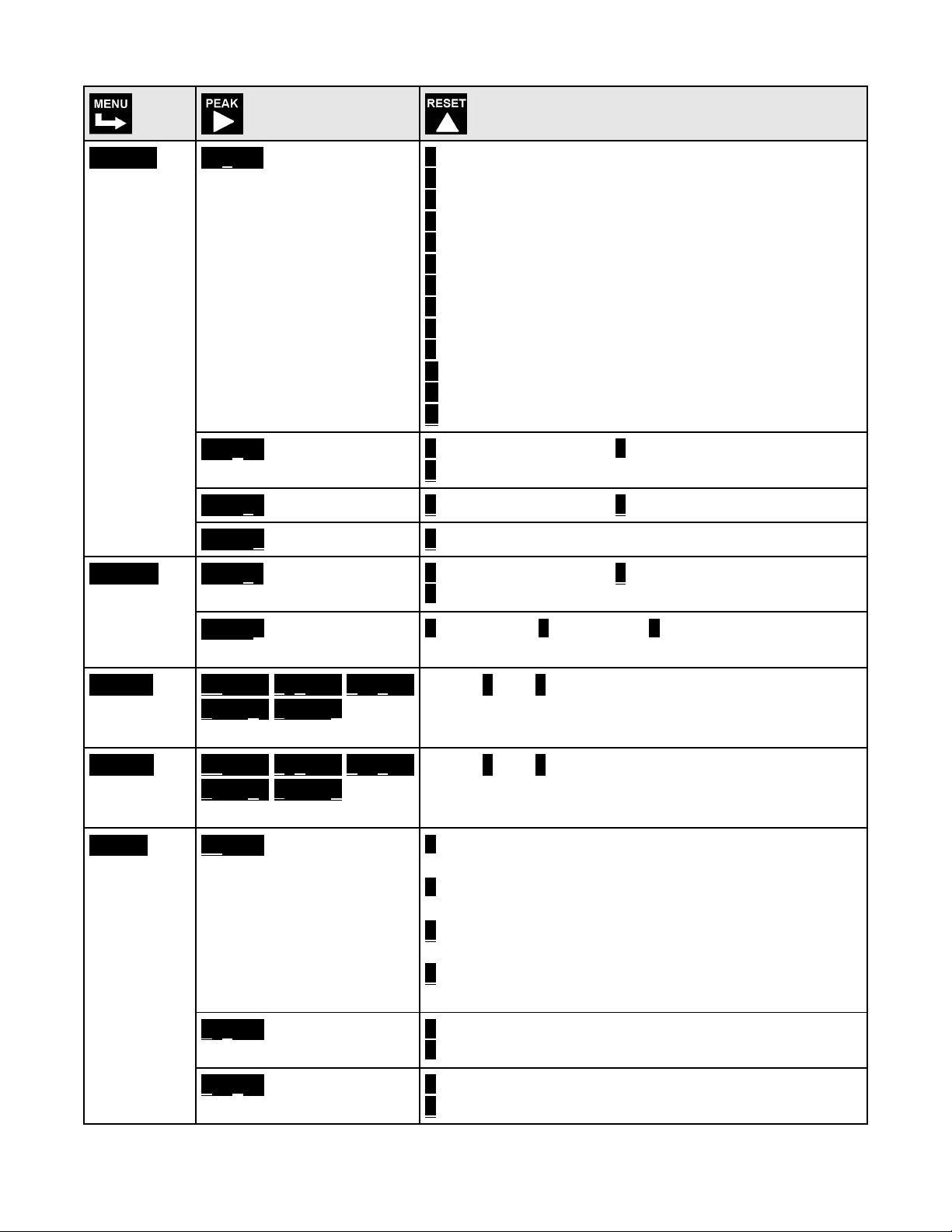

_

InPut

PHASE

0-360.

-

180+

.

duty_C

A_to_b

SEtuP

0

_00

0

0

0

0

Press

Menu

Press Digit

Select Key

Press Value Select

Key

(continued)

Phase angle modes

_

Extended

Duty cycle mode

_00000 Stored totals

Ext.

Setup

000 Leading zeros

_00000 Scaling method 1

_00000 Scaling method 2

_00000

Operation of rear connector control inputs 1 & 2.

True = 0V or tied to

digital ground).

False = 5V or open).

_

Span from 0° to 360°. Select for phase

angles centered around 180° (Item #1).

Span from -180° to +180°. Select for phase

angles centered around 0° (Item #1).

On or Off period of square waves as a

percentage of total period (Item #1).

Zero totals at power-on.

1 Restore totals at power-on.

Blank leading zeros.

1 Display leading zeros.

Input scale factor 1 and offset 1.

1 Use coordinates of 2 points method.

Input scale factor 2 and offset 2.

1 Use coordinates of 2 points method.

1 = Meter Reset*, 2 = Function Reset*

1 1 = Meter Reset*, 2 = Meter Hold*

2 1 = Meter Reset*, 2 = Peak or Valley Display*

3 1 = Meter Reset*, 2 = External Gate*

4 1 = Function Reset*, 2 = Meter Hold*

5 1 = Valley Only Display**, 2=Peak Only Display**

6 1 = Function Reset*, 2 = External Gate*

7 1 = Meter Hold**, Peak or Valley Display**

8 1 = Reset Total A**, 2 = Reset Total B**

9 1 = Force Alarm1, 2 = Force Alarm2

A 1 = Meter Reset*, 2 = Display Blank*

B 1 = Function Reset*, 2 = Display Blank*

C 1 = Meter Hold*, 2 = Display Blank*

D 1 = Peak or Valley Display**, 2 = Display Blank**

E 1 = Display Blank, 2 = External Gate*

F 1 = Display Item #2, 2 = Display Item #3

With 1 and 2 at 5V or open, Display Item #1.

------------------------------------------------------------------* 1 & 2 both at 0V = Meter Reset (can restore

totals).

** 1 & 2 both at 0V for selections 5, 7, 8, D =

Function Reset* (erases all totals).

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

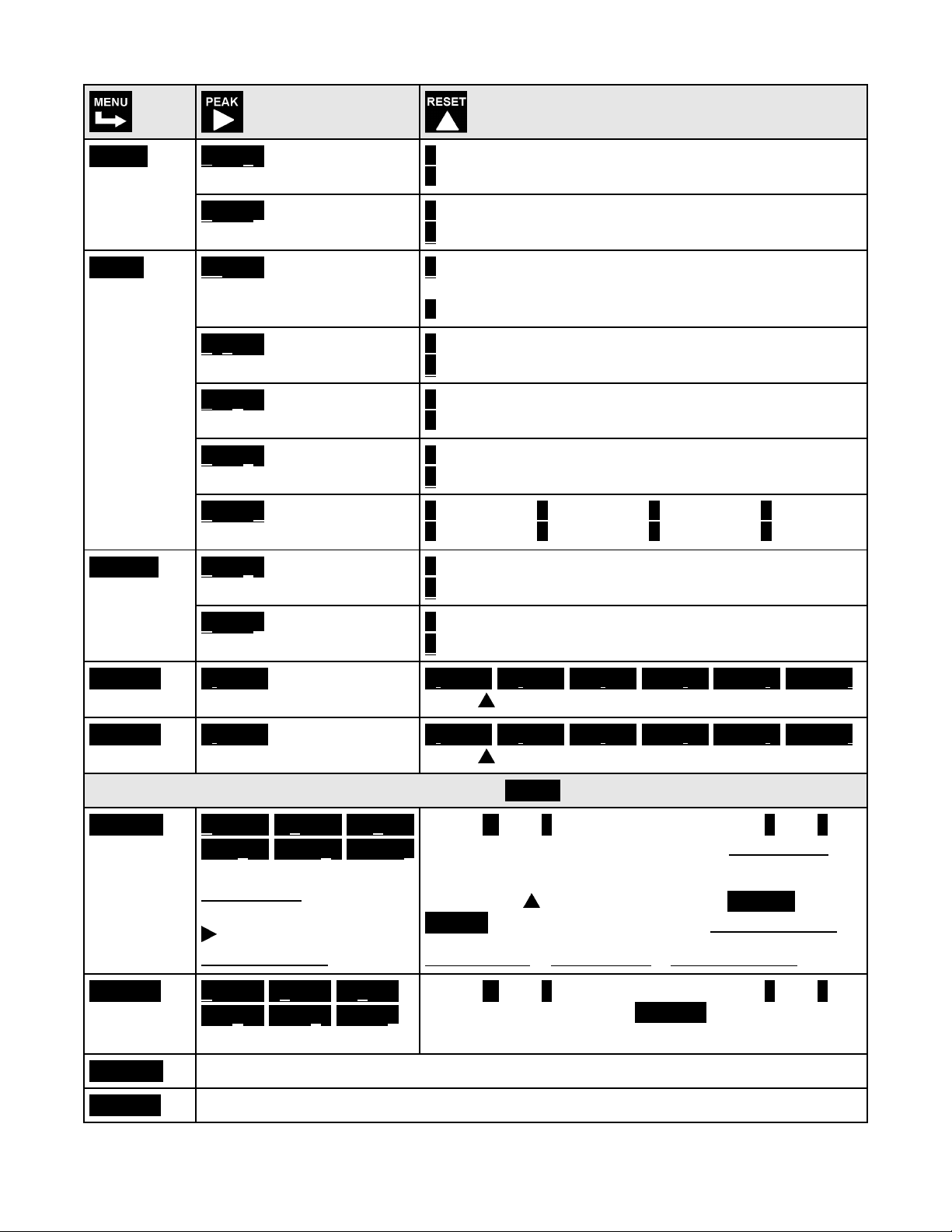

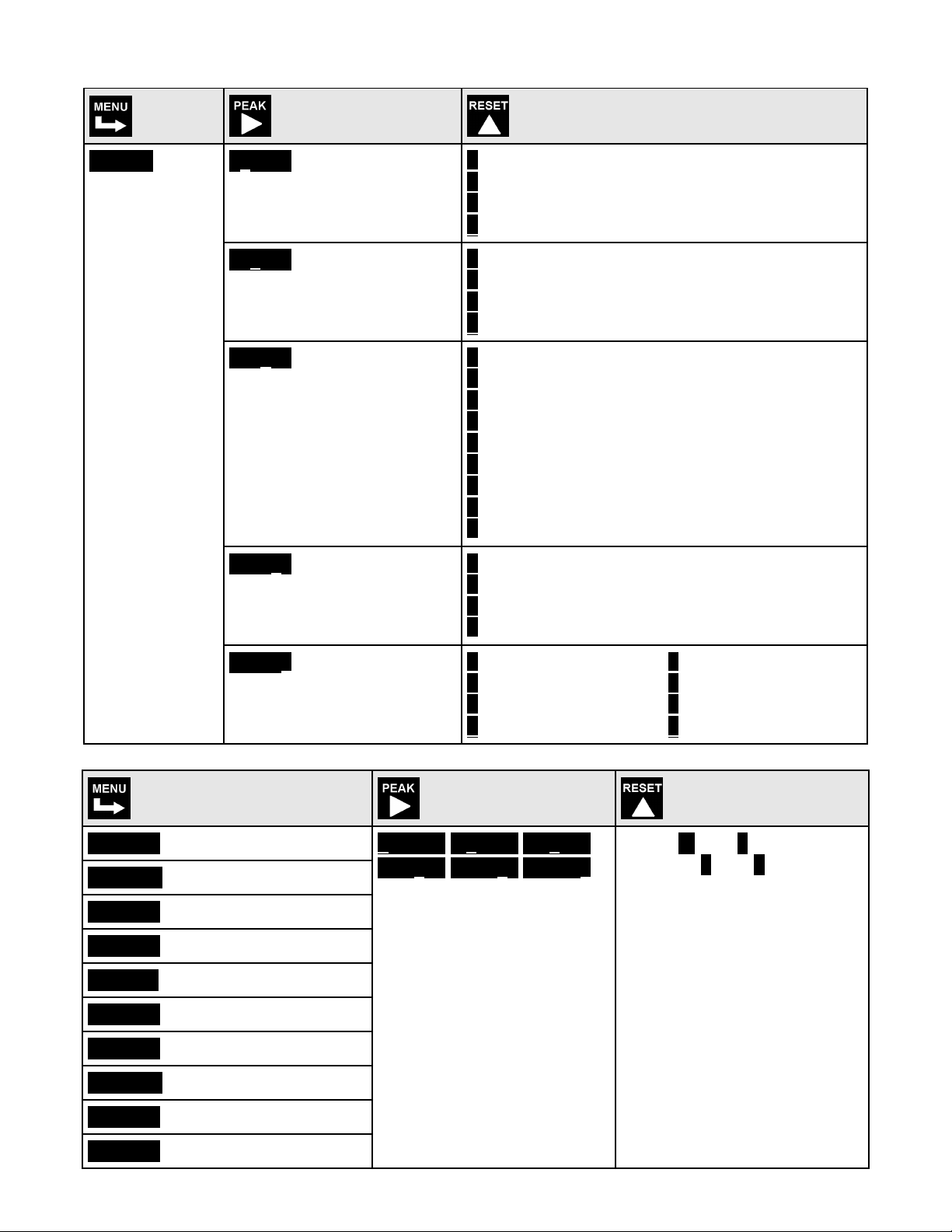

ConFiG

0

0

1

0

1

0

dSPyno

0

1

1

3

GAtE

t

.

ti_Out

.

bAtCH

0

0

0

Press

Menu

Press Digit Select

Key

Press Value Select

Key

Configuration

Display #

__0000

Display mode

__0000 Counter mode

__0000 Square root

__0000 Not applicable

____01

PEAK key action

Normal, overload to exponential format

1 Normal, overload to 999999

2 1 right-hand dummy zero

3 2 right-hand dummy zeros

4 Time display in seconds (not in µsec)

5 Time display in HH.MM.SS format (not in µsec)

6 Remote display (H, K, L commands)

7 Single-value remote display

8 Show 1st string value, slaved to another meter

9 Show 2nd string value, slaved to another meter

A Show 3rd string value, slaved to another meter

B Show 4th string value, slaved to another meter

C Custom Start, Stop, Skip, Show

Basic counter

Extended counter

2 Extended counter, custom curve linearization

Linear rate input.

Square root rate input.

Set to 0.

Display Peak 1 Display Valley

2 Peak (1st push), Valley (2nd push)

_

Gate time*

Time-out*

Batch setup

____0

Item to display

after Meter Reset*

_000.00 _000.00 _000.00

_000.00 _000.00

Select digit to flash.

_000.00 _000.00 _000.00

_000.00 _000.00

Select digit to flash.

_00000

Handling of extra pulses

that overshoot beyond

batch Preset.

_00000

Count direction

Item #1* 2 Item #2*

Item #3*

Select 0 thru 9 for flashing digit to set gate time* in

seconds. Decimal point location is fixed for 10 ms

resolution.

Select 0 thru 9 for flashing digit to set time-out* in

seconds. Decimal point location is fixed for 10 ms

resolution.

Do not count extra pulses in batch total or grand

total. Only add preset values to grand total.

1 Count extra pulses in batch total but not in grand

total.

2 Do not count extra pulses in batch total, but do

count them in grand total.

3 Count extra pulses in batch total and in grand

total.

Reset batch to 0 and count up to Setpoint 1.

1 Reset batch to Setpoint 1 and count down.

_00000

Batch triggering

Use internal gate time as delay between batches

1 Use External Input B to trigger each new batch.

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

Press

bAtCH

0

0

FiLtEr

0

0

0

0

0

0

.

SLOPE

0

0

0

dEC.Pt1

dEC.Pt2

2

SEtuP

SCALE1

0

-

9

OFFSt1

.

0

-

9

SCALE2

OFFSt2

.

Menu

Press Digit Select

Key

Press Value Select

Key

(continued)

Filtering

Triggering

_00000

Definition of Item #2

_00000

Action after Meter Reset

_00000

Filter type

_00000

Peak & Valley filtering

_00000

Display filtering

_00000

Adaptive filter threshold

_0000

Filter time constant

____00

Trigger slope, Channel A

Make Item #2 the Grand Total of all batches.

1 Make Item #2 the Total Number of batches.

Display “rEAdy.” RESET key starts batching.

1 Start batching upon Meter Reset.

Adaptive moving average filter. Restarts filter for

high actual changes in signal.

1 Conventional moving average filter without reset.

Peak* or Valley* value from unfiltered signal.

1 Peak* or Valley* value from filtered signal.

Display value of unfiltered signal.

1 Display value of filtered signal.

Set adaptive filter for normal noise.

1 Set adaptive filter for presence of high transients.

No filter 1 0.1 sec 2 0.2 sec 3 0.4 sec

4 0.8 sec 5 1.6 sec 6 3.2 sec 7 6.4 sec

Positive slope

1 Negative slope

Decimal pt1

Decimal pt2

____0

Trigger slope, Channel B

1.11111

Decimal point flashes.

2.22222

Decimal point flashes.

Positive slope

1 Negative slope

1.11111 11.1111 111.111 1111.11 11111.1 111111.

Press to shift the decimal point.

2.22222 22.2222 222.222 2222.22 22222.2 222222.

Press to shift the decimal point.

Scale and Offset scaling method if selected under

Scale

Factor 1

Offset 1

.00000 0.00000 0.00000

0.00000 0.00000 0.00000

Select digit to flash for

Scale Value. When right

digit has been set, press

one more time for the

Scale Multiplier.

00000 000000 000000

000000 000000 000000

Select digit to flash.

Select

other flashing digits. This will set the Scale Value*

from -9.99999 to 9.99999 with a fixed decimal point.

Then press to select a value from 0.00001 to

100000 in decade steps to set the Scale Multiplier.

Scale Factor = Scale Value x Scale Multiplier

Select

other flashing digits. Use dEC.Pt1 to set the decimal

point.

Scale Factor 2. Same setup process as for Scale Factor 1.

thru 9 for flashing first digit and 0 thru 9 for

thru 9 for flashing first digit and 0 thru 9 for

Offset 2. Same setup process as for Offset 1.

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Press

SEtuP

In1.

0

-

9

Lo_

rd1

0

-

9

In1.

0

-

9

rd1.

0

-

9

In2.

0

-

9

Lo_ rd2

0

-

9

In2.

0

-

9

rd2.

0

-

9

A-b_Ud

.

A_bU/d

PrESEt

0

-

9

ConFiG

rd0_In.

0

-

9

Menu

Press Digit Select

Key

Press Value Select

Key

Coordinates of 2 points scaling method if selected under

.Lo_

Low signal

input 1.

Reading at

Lo In1.

.Hi_

High signal

input 1.

.Hi_

Reading at

Hi In1.

.Lo_

Low signal

input 2.

Reading at

Lo In2.

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Move decimal point location

when flashing.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Decimal point is fixed by

dEC.Pt1.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Move decimal point location

when flashing.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Decimal point is fixed by

dEC.Pt1.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Move decimal point location

when flashing.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Decimal point is fixed by

dEC.Pt1.

.Hi_

High signal

input 1.

.Hi_

Reading at

Hi In1.

Preset function. Displayed for Total modes

Preset*

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

00000 000000 000000

000000 000000 000000

Select digit to flash.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Move decimal point location

when flashing.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Decimal point is fixed by

dEC.Pt1.

Select

or

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. dEC.Pt1 is used. When the

meter counts up and reaches the Preset, it reverts to

Offset1. When the meter counts down and reaches

Offset1, it reverts to Preset. Set to 0 for no Preset.

Special curve offset for square root or custom curve linearization if selected under

.

00000 000000 000000

000000 000000 000000

Select digit to flash.

Select

thru 9 for flashing first digit and 0 thru 9 for

other flashing digits. Decimal point is fixed by

dEC.Pt1.

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

_

InPut

rESoLn

.

CALib

SourcE

AL SEt

. AL S34

dEUn1H

dEUn2H

dEUn1b

dEUn2b

dEUn3H

DEUn4H

DEUn3b

An_SEt

An_Lo

An_Hi

SEt

An_Lo1

An_Hi1

An_Lo2

An_Hi2

SEr

SEr

SEr

3

_SEr

serial communications

Loc

1

_Loc

2

_Loc

3

_Loc

4

Scale multiplier for combinations of two channels (e.g., AxB, A/B) if selected under

Resolution

Flashing 6-digit number

in decade steps from

0.00001 to 100000

Press to select. This is a multiplier R to avoid

overflow or underflow of arithmetic combinations of

Channels A and B.

Quartz crystal time base calibration

_

Time base calibration. Do not change. See Calibration section of manual.

Option dependent menu items

DEUn4b Menu items related to alarm setup These will only appear if a relay board is

detected. If so, please see Section 14.

or An_

Menu items

related to analog output. These will only appear if a single or dual analog output board is

detected. If so, please see Section 15.

_

_1 _

_2 _

_

_4 Menu items related to

. These will

only appear if an RS232 or RS485 I/O board is detected. If so, please see Section 16.

Menu lockout items

_

_

_

_

_

Menu items used to enable or lock out (hide) other menu

items. Loc menu items may be locked out by a hardware jumper. Please see Section 9.

* See Glossary for explanation of item.

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

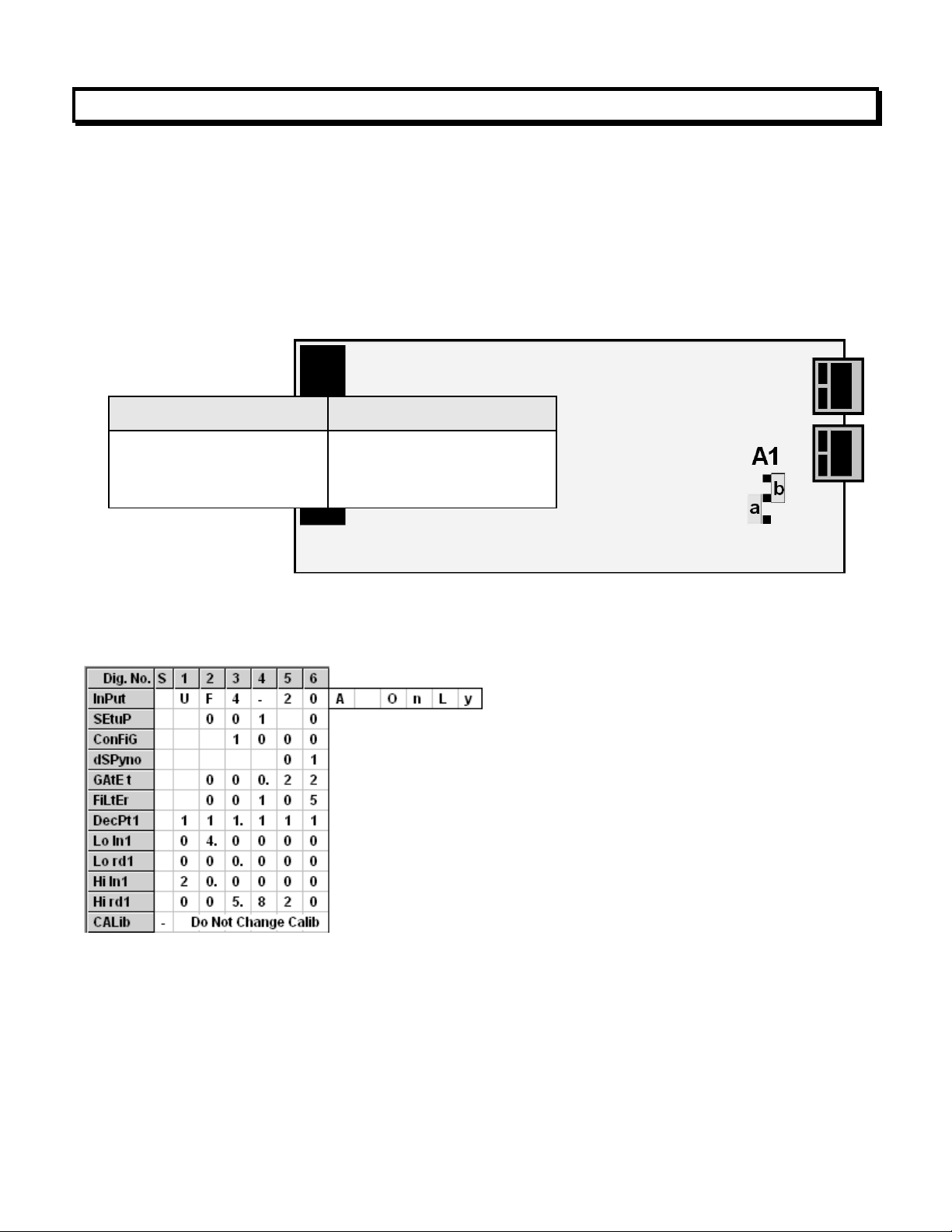

11. PROCESS RECEIVER & TOTALIZER SIGNAL CONDITIONER

Input Range

Jumper Position A1

RATE FROM A 4

-

20 mA OUTPUT FLOW METER

Application:

20 mA flow meter where

der Setup, select the coordinates of 2 points

play of 999999 and filtering. Set the decimal

to

20.0000 and Hi Rd1 to 5.820. Set Gate Time

aging at a display update rate of 4/sec. Also

set a 1.6 sec adaptive moving average filter

This signal conditioner board converts 0-1 mA, 4-20 mA or 0-10 V analog process signals to

a frequency signal, which is then read by the counter main board and processed

mathematically for display of rate, total (time x rate), time based on rate, or batch control.

The board needs to be configured via jumpers for the input signal range. The meter

software recognizes the board and brings up the applicable menu items for it.

Please see further manual pages for the following features: relay output, analog output,

serial communications, and transducer excitation output.

JUMPER SETTINGS

0-10V

0-1 mA

4-20 mA

OPERATING MODES

None

a

b

Display rate in GPM to 3 decimal places from a 44 mA = 0 GPM and 20 mA = 5.820 GPM.

Solution: Set Input to “VF420 A only.” Un-

scaling method. Under Config, select a dis-

point to 3 places. For scaling, set Hi In1

to 0.22 sec, which will provide noise aver-

to process the equivalent of 6 readings.

RATE MODE (Basic Counter)

Rate A accepts 0-1 mA, 4-20 mA or 0-10 V analog signals, as set by jumpers, for display in

engineering units. Scaling is normally done using the coordinates of 2 points method, with

entry of low and high input signals, and the low and high values to be displayed. Scaling can

also be done by entering scale and offset. With 0-1 mA or 0-10 V, the full analog input range

is displayed as 0-100000 with Scale1 at 1 and Offset1 at 0. With 4-20 mA, set an “rd0_in”

offset to 04.000. With 1-5V, set the “rd0_in” offset to 01.000

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Measurements are averaged over a gate time, which is programmable from 10 ms to 199.99

TOTAL FROM A 4

-

20 mA OUTPUT FLOW METER

Application:

Solution:

Set Input to “VF420 A A Total,”

which displays Rate as Item #1 & Total as

Item #2. Under dSPyno, select Item #2 to be

displayed after meter reset. Set Gate Time to

dates with

ing. Set DecPt1 to 3 places for

Rate and DecPt2 to 2 places for Total. Under

tes of 2 points

scaling method for Rate. Set Hi In1 to

20.0000 and Hi Rd1 to 5.820. You will need

Total is

calculated as the product of displayed rate

Since our rate is in

units per minute, we have to divide by 60,

mal places.

Enter 1.66667 for Scale2 and a multiplier of

You may also enter a Cutoff such as

0.010 GPM, below which zero offset errors

sec. Selecting a long gate time provides a slower display update rate but superior noise

filtering. Moving average filtering is also available. Square root extraction is selectable un

ConFiG for use with differential pressure flow transducers. Custom curve linearization is

available with the Extended counter.

RATE & TOTAL MODE (Basic Counter)

Display Total from a 4-20 mA flow

meter where 4 mA = 0 and 20 mA = 5.820 GPM.

0.1 sec to provide fast display up

noise averag

Setup, select the coordina

to use scale & offset to scale Total.

and time in seconds.

then multiply by 0.1 for two deci

0.001.

and negative values will not be totalized.

Rate A, Total A allows rate to be displayed as Item #1 and total as Item #2. Scale2 and

Offset2 apply to total. Total is calculated as the product of displayed rate and time in

seconds. Since rate may be displayed in units per second, units per minute, units per hour

or other units, the total must be scaled appropriately. If rate is in units per minute, multiply

the total by 1/60. This is achieved by setting Scale2 to a scale factor of 1.66666 and a

multiplier of 0.01. If rate is in units per hour, multiply the total by 1/3600. This is achieved by

setting Scale2 to a scale factor of 2.77778 and a multiplier of 0.0001. If square root extraction or custom curve linearization have been selected, totalizing will be of the linearized rate

readings.

BATCH CONTROL MODE (_bAtCH) (Extended Counter)

Batch control uses the meter with a dual relay controller board to control repetitive fill

operations. Relay #1 (or Setpoint #1) is used as the batch relay. Relay #2 (or Setpoint #2)

can be assigned to another limit, such as pre-warn to slow filling near the setpoint, end-ofprocess, or rate alarm.

• In batch control mode the meter displaying “Ready”, the meter waits until the RESET

key is pushed, it then energizes Relay #1 and displays the changing Batch Total starting

at “Offset2”. When the setpoint 1 value is reached, Relay #1 de-energizes for the

duration of the “time out” setting. Relay #1 then re-energizes, the Batch Total resets, and

the fill cycle repeats.

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

• In batch control mode with “external gate”, the meter waits a the end of every cycle

Application:

Fill 55 gallon tanks. Use a

20 mA flow meter where 4 mA = 0 and 20

mA = 39.20 GPM. Slow down filling at 54

gallons. Cycle batches automatically with 20

sec between cycles. Display batch total & fill

ber of

Use an Extended counter with

a dual relay output board. Set Input to “Rate

Batch.” Set Batch to count up to ALARM1, to

use Gate Time as delay between batches,

and to make Item #2 the number of batches.

ime to 20 sec. Set DecPt1 and

DecPt 2 to two decimal places for Items #1

and #3 (Batch Total and Rate). Scale Item

ordinates of 2 points

played

as 39.20 GPM. Scale Item #1 (Batch Total)

tiplier of 0.01. That is because totalizing

ings in gallons every second.

Since our rate is in GPM, we have to divide

to serve as

the batch setpoint in gallons. Set Setpoint2

.00 to activate Relay 2 to slow the fill

until an external gate input is grounded for a minimum of 3.33 ms. This starts a new fill