Page 1

OPERATION MANUAL

MFD

ANALOG FORCE GAUGE

Page 2

TABLE OF CONTENTS

1. Introduction …………………………………..1

2. Included Parts List ……………………………1

3. Gauge Outline .……………………… ……...2

4. Dimensions……………………. … … ……… .3

5. Specifications……………...…… … ………...4

6. Preparation Before Test………… … …….7

7. Testing...………………… ………… ………. .. 8

8. Attachments… ….… ………… …… ………..8

9. Maintenance……………………… …… …….9

Page 3

1. Introduction

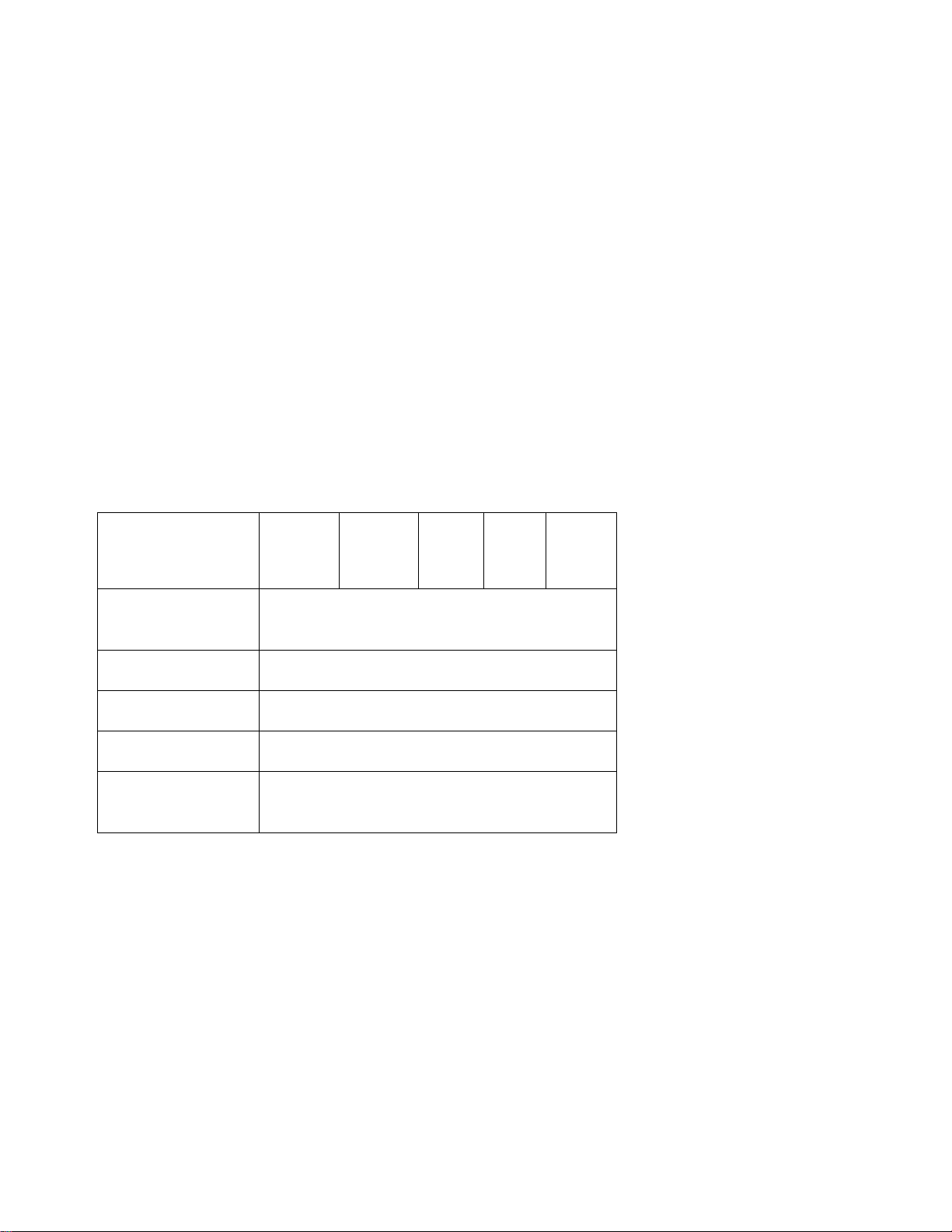

Model

MFD-

02

MFD-

03

MFD-

04

MFD-

05

MFD-

06

Push

Attachments

4

Pull Attachments

1

Extension Rod

1

User's Manual

1

Calibration

Certificate

1

The MFD Series Analog Force Gauge with compact size are easy to operate and

convenient to carry. They display the units of lb and kilogram at the same time. The

PEAK/TRACK knob allows the user to easily switch between peak load testing or

continuous load testing. The MFD’s are excellent products which are widely applied

in electric, electric appliance, hardware, automobile parts, lighter and ignition system,

light industry, mechanical, textile and a many more for testing of compression or

tension, insertion force, or destructive analysis. Please read the manual carefully

before using this instrument.

2. Included Parts List

(b) When vertically placed to use, especially when installing attachment, do not apply load as

needle will move from the dead weight result of the attachment. Re-zero dial so zero [O] is

aligned with needle. This tares the attachment load for proper test results.

Note:

If often exceeding max allowed capacity the internal operation spring will gradually wear and

lead to incorrect test performance. Please do not overload to maintain life of the machine.

Page 4

3.Gauge Outline

Page 5

4. Dimensions (mm)

Page 6

5. Specifications

Model

MFD- 02

MFD- 03

MFD- 04

MFD- 05

MFD- 06

Max load

4.5 Ib

2 kg

10 Ib

5 kg

22 Ib

10 kg

45 Ib

20 kg

110 Ib

50 kg

Min load

0.45 Ib

0.2 kg

1 Ib

0.5 kg

2.2 Ib

1.1 kg

4.5 Ib

2.2 kg

11 Ib

5.5 kg

Load Graduation

0.02 Ib

0.02 kg

0.05 Ib

0.05 kg

0.1 Ib

0.1 kg

0.2 Ib

0.2 kg

0.5 Ib

0.5 kg

Rod Travel

10 mm (0.39 in)

Working

Temperature

20土10 °C

Storage

Temperature

-27 ~+70℃

Relative

Humidity

15%~80%RH

Work

Environment

No vibration

6. Preparation Before Test

Choose appropriate attachment and install it on the gauge before test.

(1) Pull test

Choose pull attachment and install it on the connector marked [PULL].

(2) Push test

Choose push attachment and install it on the connector marked [PUSH].

(3) Use of extension rod.

When it isn't possible reach item under test, add extension rod with attachment.

Page 7

NOTE: When operating, tested object and gauge must be on the same straight line. If not

properly aligned, correct load values are not possible and damage to gauge may occur.

(4) Confirm operation method knob controller.

(a) Changing from [PEAK] or [TRACK]

Lightly press knob inward. At the same time, turn it to left to make dot on knob (●) align with

[TRACK].

(b) Changing from [TRACK] to [PEAK]

Turn knob to right. The knob springs and dot (●) is in the place of [TRACK].

(C) Note after testing

Put the dot (●) in the [PEAK] location. If knob is left in the place of [TRACK] for an extended

period, the life of the inner springs will shorten.

(5) Adjustments of indicator dial

(a) Confirm needle aims at zero [O] on dial. If not, please turn adjustable circle of dial until needle aligns

with zero [O].

7. Testing

(1) Please tightly hold gauge by hands or appropriate stands to perform test. When testing,

please place tested object and gauge on the same straight line. If they are not aligned, test will

not be accurate.

(2) Change of load mode testing

(a) When knob controller is in [TRACK] mode, the needle moves in accordance with changes in

force.

(b) When knob controller is in [PEAK] mode, the needle records Max. value of load and remains

at that maximum force until pressing inward on the controller knob. Once knob is pushed, the

needle returns to zero position as long as the tested force is removed.

Page 8

8. Attachments

In order for the gauge to produce a stable value, please utilize included attachments. If your

company wants to utilize its own attachments, please refer to size of attachment connector.

9. Maintenance

(1)Do not apply loads exceeding the max test range of gauge to avoid damaging instrument..

(2)Do not put or use gauge in low or high temperature and humidity locations. Please store and

use it in the specified environment.

(3)If there is something wrong with gauge, please contact the original sales department you

purchased from.

Loading...

Loading...