Page 1

Series Digital Force Gauges

Models FGE-0.5X - 100X

Models FGV-0.5X - 100X

INSTRUCTION MANUINSTRUCTION MANU

INSTRUCTION MANU

INSTRUCTION MANUINSTRUCTION MANU

Congratulations on your purchase of a Shimpo FGE/V-X

series digital force gauge. We trust you will enjoy many

years of professional results from your Shimpo product.

Please read the entire instruction manual thoroughly

before initial set-up and operation; the information

contained herein will aid you in operating your Shimpo

digital force gauge safely and with excellent results.

If you have any questions regarding our product(s), call

your local Shimpo representative or contact Shimpo

Instruments directly for assistance.

ALAL

AL

ALAL

Inspection/Standard Accessories

If upon delivery shipping damage is detected, do not

operate the unit. Notify shipping carrier immediately

for damage claim instructions. Refer to nameplate and

record serial number for future reference. Items included

with the DART are:

• (1) Carrying case

• (1) Standard adapter set (hook, chisel, flat head,

notched head, cone head, extension rod)

• (1) Inch adapter (metric - English thread)

• (1) Hanger

• (1) RS-232C cable (FGV-X series only)

• (1) AC charger/adapter

Features and Benefits

Shimpo’s DART series digital force gauges offer many

features and benefits, including:

• 1,000 Hz update rate for capturing highest peaks

• Aluminum construction provides exceptional

durability

• An ergonomically designed digital instrument to

fit perfectly in the palm of your hand

• Single touch, measure force in lb, Kg and N (oz/gram

for 0.5X, 1X,2X) engineering units

• When gauge is placed on a test stand or if the

hanger is used, display may be reversed with push

buttons so that it can be read right side up.

• High accuracy ( ±0.2% F.S. ) is ideal for QC

inspection and process control

• RS-232C and Analog output (FGV-X series only)

• Inch adapter for converting our Metric thread to

an English thread. If your fixtures are English

threaded, please use this adapter.

Safety Precautions

Do not operate or store instrument in the

following places: explosive areas; near water, oil,

dust, or chemicals; areas where temperature is

above 104°F (40°C).

When not in use, place gauge back in its case to

prevent damage due to accidental drop etc. With

a little care you can have an instrument that will

provide service for many years.

Do not disassemble or repair unit while in

operation.

1

Page 2

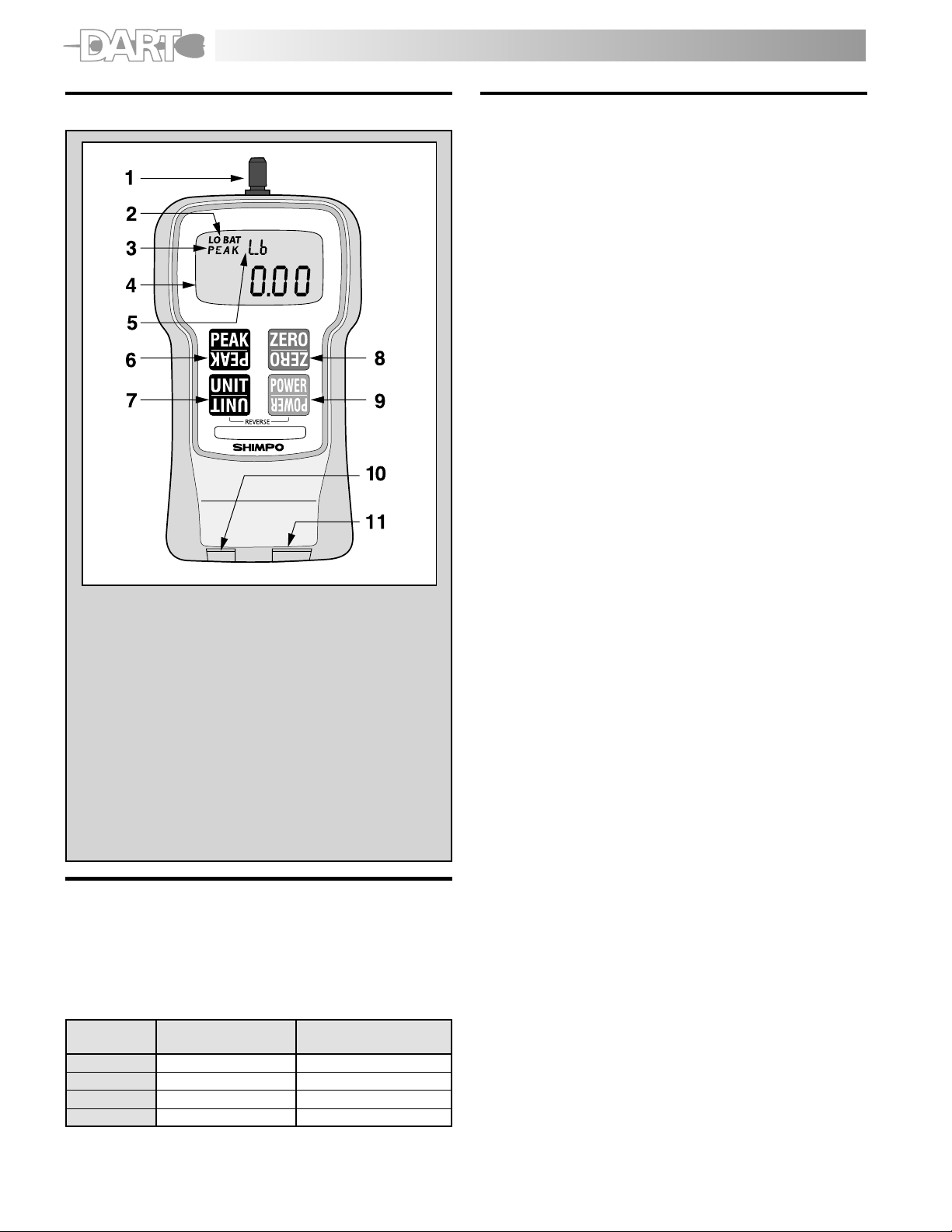

Physical Features

Operation

1. Charge the batteries for approximately 18 hours

before using the gauge (Batteries come discharged

from the factory). The BAT indicator is on when

batteries are charging, off when the batteries are

fully charged.

2. Hand tighten appropriate attachment to unit’s

measuring shaft (do not use a wrench or any other

device to tighten the attachment).

3. Press POWER and release. The unit will display model

name in small display and capacity in main display

and then will show some zeros with the last one or

two digits changing to some random numbers. Also

the unit of measurement (lb (oz), Kg (g) or N) will

appear above the digits and stay as long as the

instrument is on.

Change Display Units

To change the display units, just press UNIT and the units

will change every time the button is pressed.

lb ! oz (0.5X, 1X, 2X models only) ! N ! Kg (g) !

Reverse the Display

If unit is used with the hanger or mounted on a test stand

and the display must be reversed, follow this procedure:

NO. DESIGNATION

1. Sensor Shaft

2. Low Battery Indicator

3. Peak Indicator

4. Main Display

5. Small Display

6. Peak Button

7. Unit Button

8. Tare and Zero Button

9. Power (ON, OFF) switch

10. AC Adapter Port

11. Data Output Port

Factory Setting

The FGE/V-X will revert to factory setting when the gauge

is first powered on. Consult the “Function Setting”

section to customize these default settings.

The following chart reflects the default settings as

programmed by the factory:

FUNCTIONFUNCTION

FUNCTION

FUNCTIONFUNCTION

NUMBERNUMBER

NUMBER

NUMBERNUMBER

f01 Plus or Minus sign 0001 (plus for compression)

f02 Display update time 3 (3 times/sec)

f03 Auto power off 10 (min)

f04 Baud rate of RS-232C 2400 (bps)

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

DEFDEF

DEF

DEFDEF

AA

ULUL

T FT F

ACTORYACTORY

A

UL

T F

ACTORY

AA

ULUL

T FT F

ACTORYACTORY

SETSET

TINGTING

SET

TING

SETSET

TINGTING

1. Press POWER and hold it; display will go blank.

2. Press and hold UNIT.

3. Release POWER while you are still holding UNIT;

display is still blank.

4. Press POWER once more and release it while still holding

UNIT. At this point you should see the display reversed.

5. Release UNIT; the display stays in that mode.

To go back to normal mode repeat steps 1 through 5.

Select Average or Peak

If you want to measure force in real time (average) the

display will show only the digits and units of the force

being measured. If you want to measure “peak” force:

1. Press PEAK; the word PEAK will appear in the upper

left corner of the display. (If you need a minus peak,

press PEAK again.)

2. The display will freeze after capturing the peak force.

3. Press ZERO to cancel previous peak and continue with

your tests.

If you want to go back to average mode press PEAK again.

The word PEAK will disappear from the display.

NOTE: It is very important that you measure forces

(tension or compression) that are in line with the

measuring shaft and not at any angle (see fig. 1). Failure

to observe this directive will damage the instrument. Also,

after the gauge is positioned and ready to take a

measurement (with the proper attachment in place) tare

the unit by pressing ZERO. To clear the display for another

measurement (in PEAK mode), press ZERO.

2

Page 3

Tension Measurement

To measure tensile force, use the hook attachment. The

display will show the force measured and a minus sign () will appear on the left of the display (to the left of the

digits).

NOTE: To display no sign (plus) for tensile force, consult

the “Function Setting” section.

Compression Measurement

To measure compression force, use the flat head

attachment. No sign will appear on the left of the display

during a compression measurement.

NOTE: To display minus sign (-) for compression force,

consult the “Function Setting” section.

Low Battery

When battery charge is low, LO BAT will appear on the

display indicating the batteries need to be charged.

Charging time of fully depleted batteries is approximately

18 hours when the unit is off. The adapter/charger

automatically shuts off when the battery is at full charge

to protect the battery.

Note: The adapter/charger can be used to power the unit

during battery charging, but will lengthen charging time.

External Device Communications

When operated with the appropriate output cable, the

FGV-X offers output capabilities.

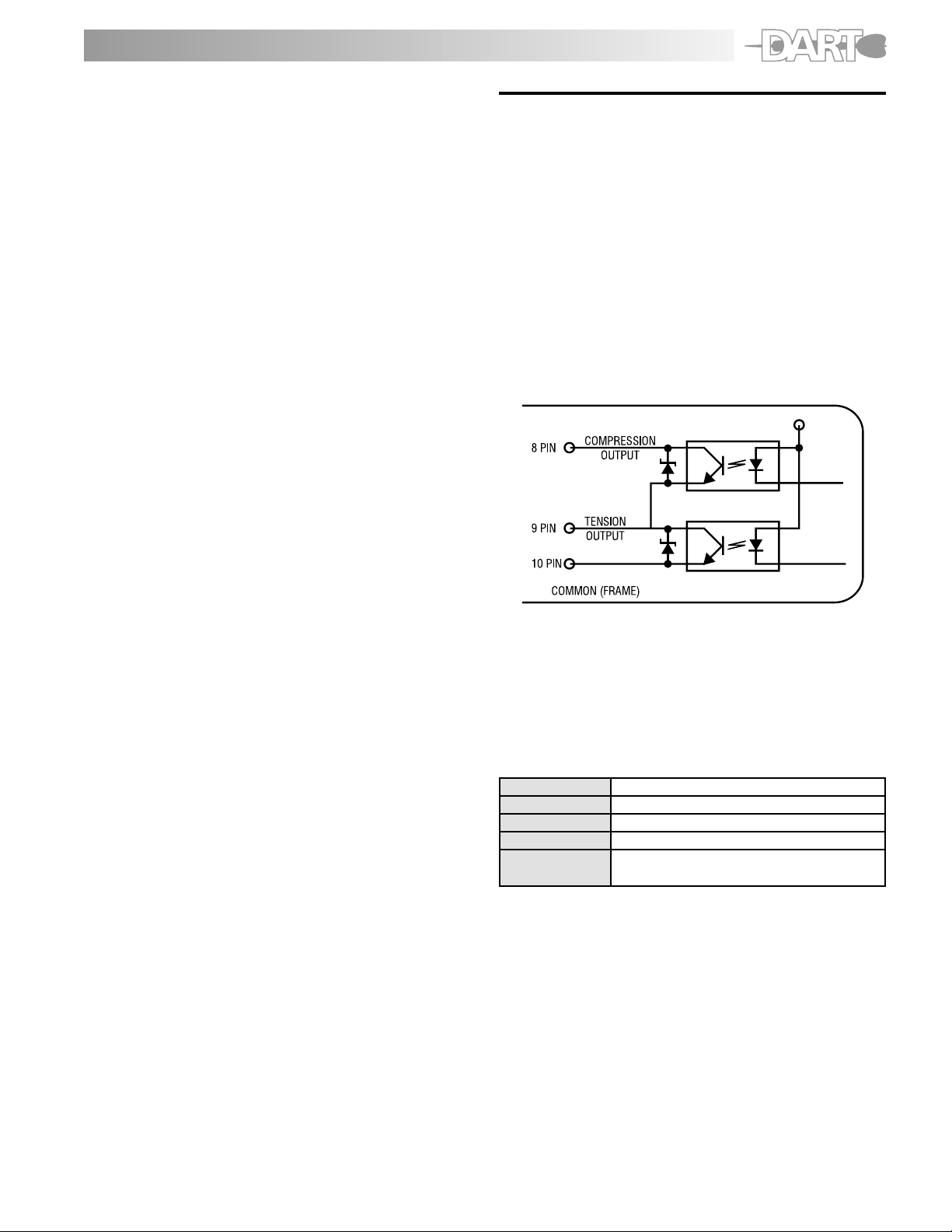

Overload

Even though each model is able to withstand an overload

of 200% of its rated capacity, caution should be exercised

that this does not happen, otherwise the sensor will be

damaged. To protect the gauge and/or the sample under

test when a motorized stand or some other device is

used in conjunction with the gauge, two overload output

OC NPN transistors are available to be used to disconnect

power when the overload condition reaches 120% of

the gauge’s rated capacity. One transistor is for tension

and the other for compression. See figure 2.

Auto Power Off

If the gauge is on and there is no activity for 10 minutes,

the unit automatically powers off to conserve battery

charge. PWR appears above the display digits to notify

that there is 1 minute before power off. If the adapter/

charger is powering the gauge, auto power off function

becomes inactive.

NOTE: To modify the auto power off function, consult

the “Function Setting” section.

Tracking Function

A tracking function has been introduced to check and

compensate for temperature drift. When measuring very

minute forces (a few ounces or grams) and at a very

slow rate, you may want to turn off the tracking function.

To turn the tracking function off, follow the steps below:

1. Turn POWER off.

2. Press PEAK and UNIT switches simultaneously and

hold, then press and release POWER (If tracking

function was on, the display will show TRK OFF

momentarily)

3. Release PEAK and UNIT.

The tracking function is now off. Repeat above steps to

turn it on. The gauge will display TRK SET when turned

on. It is a good idea to have this function on at all the

times unless it is absolutely necessary to cancel it.

Fig. 2

Analog Output

An analog output signal is available for recording

purposes. The amplitude of this signal is ± 1 VDC. The

voltage is positive when compression testing is performed

and negative for tension. The signal characteristics are

as follows:

AmplitudeAmplitude

Amplitude ± 1 VDC

AmplitudeAmplitude

Generated byGenerated by

Generated by 12-bit D/A converter

Generated byGenerated by

Signal updateSignal update

Signal update 100 times/sec (update every 10 msec)

Signal updateSignal update

Load impedanceLoad impedance

Load impedance 10 KW minimum

Load impedanceLoad impedance

Connector pinsConnector pins

Connector pins Pin #1 signal output (analog)

Connector pinsConnector pins

Pin #2 GND (analog)

(see Fig.3 & Table 1)

NOTE: When the zero switch is pressed to tare the gauge

the analog output goes to 0V automatically.

3

Page 4

RS-232C Port

An important feature of the FGV-X family of gauges is

the RS232C communications port. Data and commands

can be linked to a PC or any other device responding to

RS232C signals for storage or further analysis. Table 1

(below) describes the function of each pin of the

connector (HR12-10RC-10SDL) shown in Fig. 3.

PIN#PIN#

PIN# DESCRIPTION

PIN#PIN#

11

1 Analog signal output

11

22

2 Analog GND

22

33

3 Receive data (input)

33

44

4 Digital GND

44

55

5 Communication enable

55

66

6 Transmit data (output)

66

77

7 No connection

77

88

8 Compression overload output

88

99

9 Tension overload output

99

1010

10 Frame GND

1010

Table 1

Figure 3

(HR12-10RC-10SDL), HIROSE

RS232C Output SpecificationsRS232C Output Specifications

RS232C Output Specifications

RS232C Output SpecificationsRS232C Output Specifications

Baud rateBaud rate

Baud rate 2400, 4800, 9600, 19200 bps (selectable)

Baud rateBaud rate

Data lengthData length

Data length 8 bits

Data lengthData length

PP

arityarity

P

arity None

PP

arityarity

Stop bitStop bit

Stop bit One

Stop bitStop bit

Commands/Responses

The FGV-X series of force gauges has the ability to

recognize and respond to various commands from

outside peripherals. If for instance the gauge receives a

legitimate command from a PC, it will respond by sending

back the same code indicating to the PC that the

command was recognized. If for example the command

is a request for average data output, it will send the

data and the code NA etc. If the gauge recognizes an

error while it is receiving a command, an error symbol is

transmitted back to the PC indicating the exact nature

of the error.

Commands to FGV-X Gauge

AAcr Tare

ABcr Stop output

ACcr Change to peak mode

ADcr Change to average mode

AEcr Peak reset

AFcr Change units to Kg (g)

AGcr Change units to N

AHcr Change units to lb (oz)

BAcr Data output request (single reading)

BBcr Continuous data output request (10 times/sec)

BB1cr Continuous data output request (20 times/sec)

BB2cr Continuous data output request (50 times/sec)

BB3cr Continuous data output request (100 times sec)

BCcr Model name confirmation request

BDcr Units confirmation request

BEcr Peak data output request

BFcr Minus Peak data output request

cr (cr: carrige return)

Response from FGV-X gauge

NA""""""cr Average data output

NB""""""cr Peak data output

4-digit number with decimal point

sign (+ or –)

NE""cr Model number

02 = FGV-0.5X

03 = FGV-1X

04 = FGV-2X

05 = FGV-5X

06 = FGV-10X

07 = FGV-20X

08 = FGV-50X

09 = FGV-100X

NH"cr Unit

0 = N

1 = Kg (g)

2 = lb (oz)

Error Symbols

OBcr Command error

OEcr Parity error

OFcr Format error

OGcr Summing error

OHcr Overrun error

4

Page 5

Function Setting

The FGE/V-X will default to certain parameters when power is turned OFF and ON. To access the function setting:

1. Press and hold the ZERO button.

2. Press and release the POWER button.

3. Each time the PEAK button is pressed, the FGE/V-X will scroll through each of the functions.

4. Press the ZERO button to exit.

OFF

Press and hold ZE RO butt on. Pr ess and r el ea se the PO WE R button. -> See Fi g. 3

Plus or minus si gn

Displ ay update time

**

F01

0001

PEAK

F02

UNIT

-0001

Minus Plus

UNIT

3

PEAK

Auto power off

PEAK

Baud rate of

RS232C

PEAK

Plus or minus si gn

**Note: In function 2 , the num b ers sign ify as follows.

1; 1 time/sec, 2; 2 times/sec, 3; 3 times/sec, 5; 5 times/sec, 10; 10 times/sec, 20; 20 times/sec

F03

10

F04

2400

UNIT

UNIT

UNIT UNIT

F01

UNIT

F02

5

UNIT

F03

OFF

UNIT UNITUNITUNIT

F04

4800

F02

F03

F04

9600

F01

0001

10

10

UNIT

UNIT

F02

F04

19200

UNIT

20

F02

F04

2400

UNIT UNIT

1

F02

2

UNIT

F02

3

ZERO

Data was memorized

Data was memoried.

5

Page 6

Calibration

1. A secure calibration stand to mount a force gauge

upside-dawn.

2. The appropriate calibration weight for your force

gauge. (Metric only!)

9. Press ZERO to zero calibrate. Wait approx. 17

seconds. The display will change to show PEK after

blinking SCN. Do not press any other switches or

move the sensing shaft during calibration.

MODELMODEL

MODEL

MODELMODEL

FGE/V-0.5X 02 200 g

FGE/V-1X 03 500g

FGE/V-2X 04 1Kg

FGE/V-5X 05 2Kg

FGE/v-10X 06 5Kg

FGE/V-20X 07 10Kg

FGE/v-50X 08 20Kg

FGE/V-100X 09 50Kg

3. Turn POWER off.

4. Mount the force gauge upside down on the

calibration stand.

5. Attach the fixture on the sensing shaft of the force

gauge, carefully threading it finger tight.

6. Press and hold the UNIT, PEAK and ZERO switches.

7. Press and release the POWER switch (while continuing

to press UNIT, PEAK and ZERO) until the smaller

characters at the top of area of the display show

CAL. Release the UNIT, PEAK and ZERO switches. The

force gauge is now in calibration mode.

CODECODE

CODE

CODECODE

WEIGHTWEIGHT

WEIGHT

WEIGHTWEIGHT

CAL

-00-

8. Press the UNIT switch. The display will show ZER after

blinking SCN for 10 seconds. The force gauge is now

ready for zero point calibration.

“SCN”

88888

10. Hang the calibration weight on the hook and

stabilize; the larger characters on the display will

change. The force gauge is now ready for full-scale

calibration.

11. Press the PEAK switch to begin full scale calibration.

Display blink SCN. Do not press any other keys or

touch the weight during calibration. After approx.

17 seconds the display blinks END, then after approx.

5 seconds the display blinks OK.

“SCN”

88888

12. If calibration was successful, the display will show

OK momentarily (see above picture.). Press the UNIT

switch, then automatically power off.

13. If calibration was unsuccessful, the display will show

ERR. Remove the calibration weight, then press UNIT

switch. Repeat the procedure 6-9.

“End”

88888

PEK

88888

“oK”

88888

Err

88888

“SCN”

-00-

6

ZER

88888

Page 7

Troubleshooting

The following are general checkpoints; please call your local Shimpo representative or contact Shimpo Instruments

directly for further assistance.

The force gauge does not come on:

• Check all electrical components (power source, charged battery or AC adaptor connected)

The stand does recognize the RS232 output/input:

• Check all connections between the test stand and the force gauge and/or computer

Error codes are displayed:

• Turn unit off, then back on. If error codes are still displayed, see table below:

Small display

Small display Condition

Small displaySmal l display

Condition Action

ConditionCondition

Action

ActionAction

OVM

OVP

OV+

OV-

ERR

- 3 -

ERR

- 4 -

Dimensions

Minus side overload condition - possible load cell damage

Remove exces si ve load; i f the display doe s not return to normal operati on,

send unit in for repair

Plus side overload condition - possible load cell damage

The loa d exceeds 120% of its ca pacity Remove excess ive load

EEPROM reading error

Turn off, then turn on again. If the display does not return to normal operation,

send unit in for repair.

EEPROM wr iting error

7

Page 8

Specifications

FGE-X and FGV-X DART SERIES SPECIFICATIONS

FGE-FGE-

X ModelX Model

FGE-

X Model

FGE-FGE-

X ModelX Model

FGVFGV

--

X ModelX Model

FGV

-

X Model

FGVFGV

--

X ModelX Model

CapacityCapacity

Capacity 0.5 lb (8 oz) 1 lb (16 oz) 2 lb (32 oz) 5 lb 10 lb 20 lb 50 lb 100 lb

CapacityCapacity

RR

esolutionesolution

R

esolution 0.001 lb (0.01 oz) 0.001 lb (0.01 oz) 0.001 lb (0.01 oz) 0.001 lb 0.01 lb 0.01 lb 0.01 lb 0.1 lb

RR

esolutionesolution

AccuracyAccuracy

Accuracy ±0.2% f.s.

AccuracyAccuracy

DisplayDisplay

Display 4-Digit LCD, 12mm high. Reversible by the push of a button. Minus sign for tension.

DisplayDisplay

Display UpdateDisplay Update

Display Update 0.05, 0.1, 0.2, 0.3, 0.5, 1 sec

Display UpdateDisplay Update

Sampling RSampling R

Sampling R

Sampling RSampling R

OverloadOverload

Overload 200% of f.s.

OverloadOverload

PP

P

PP

Output (FGVOutput (FGV

Output (FGV

Output (FGVOutput (FGV

Auto PAuto P

Auto P

Auto PAuto P

BatterBatter

Batter

BatterBatter

RR

R

RR

TT

emperatureemperature

T

emperature 32° - 104°F (0° - 40°C)

TT

emperatureemperature

DimensionsDimensions

Dimensions 5.1” L x 2.9” W x 1.5” H (130 mm x 75 mm x 38 mm)

DimensionsDimensions

WW

W

WW

Standard AccessoriesStandard Accessories

Standard Accessories AC adapter/charger, carrying case, hook, chisel, flat head, notched head, hanger, cone head, extension rod, inch adapter,

Standard AccessoriesStandard Accessories

ApprovalsApprovals

Approvals CE approved

ApprovalsApprovals

ateate

ate 1000 times per second

ateate

owerower

ower Rechargeable Ni-Cad battery or AC through adapter/charger

owerower

only)only)

only) Analog: ±1VDC (through a 12 bit D/A converter)

only)only)

ower Shut-Offower Shut-Off

ower Shut-Off Yes (not active if adapter/charge is in use)

ower Shut-Offower Shut-Off

y Chargey Charge

y Charge 12 hours (when fully charged)

y Chargey Charge

echarge Timeecharge Time

echarge Time Approximately 18 hours when fully discharged

echarge Timeecharge Time

eighteight

eight 1 lb (450 g)

eighteight

FGE-0.5XFGE-0.5X

FGE-0.5X

FGE-0.5XFGE-0.5X

FGVFGV

-0.5X-0.5X

FGV

-0.5X

FGVFGV

-0.5X-0.5X

200.0 g 500.0 g 1,000 g 2.000 Kg 5.000 Kg 10.00 Kg 20.00 Kg 50.00 Kg

2.000 N 5.000 N 10.00 N 20.00 N 50.00 N 100.0 N 200.0 N 500.0 N

0.1 g 0.1 g 1 g 0.001 kg 0.001 kg 0.01 kg 0.01 kg 0.01 kg

0.001 N 0.001 N 0.01 N 0.01 N 0.01 N 0.1 N 0.1 N 0.1 N

RS232C: Baud rate (19200, 9600, 4800, 2400 bps selectable), commands control

FGV-232CABLE (FGV series only)

FGE-1XFGE-1X

FGE-1X

FGE-1XFGE-1X

FGVFGV

-1X-1X

FGV

-1X

FGVFGV

-1X-1X

FGE-2XFGE-2X

FGE-2X

FGE-2XFGE-2X

FGVFGV

-2X-2X

FGV

-2X

FGVFGV

-2X-2X

FGE-5XFGE-5X

FGE-5X

FGE-5XFGE-5X

FGVFGV

-5X-5X

FGV

-5X

FGVFGV

-5X-5X

FGE-10XFGE-10X

FGE-10X

FGE-10XFGE-10X

FGVFGV

-10X-10X

FGV

-10X

FGVFGV

-10X-10X

FGE-20XFGE-20X

FGE-20X

FGE-20XFGE-20X

FGVFGV

-20X-20X

FGV

-20X

FGVFGV

-20X-20X

FGE-50XFGE-50X

FGE-50X

FGE-50XFGE-50X

FGVFGV

-50X-50X

FGV

-50X

FGVFGV

-50X-50X

FGE-100XFGE-100X

FGE-100X

FGE-100XFGE-100X

FGVFGV

FGV

FGVFGV

-100X-100X

-100X

-100X-100X

8

Loading...

Loading...