Page 1

Model DT-205L

Handheld LCD Digital

Laser Tachometer

Congratulations on your purchase of a Shimpo DT-205L digital

laser tachometer! We trust you will enjoy many years of

professional results from your Shimpo tachometer.

Please read the entire instruction manual thoroughly before initial

set-up and operation; the information contained herein will aid

you in operating your Shimpo tachometer safely and with

excellent results.

If you have any questions regarding our product(s), call your

local Shimpo representative or contact Shimpo Instruments

directly for assistance.

Inspection/Standard Accessories

Instruction Manual

Features and Benefits

The Shimpo DT-205L is a battery-operated, microprocessorcontrolled, non-contact/contact tachometer that utilizes a laser

beam for movement detection. In the non-contact mode a laser

beam measures RPM when directed towards a shaft (or any other

rotating mechanism marked with a small piece of reflective tape).

The included 200L adapter allows for contact measurement via a

rubber tip cone attachment or the included 6” master linear wheel.

The DT-205L tachometer incorporates the latest microprocessor

and laser technology and offers:

• Multi-mode capability measures RPM, mPM, YPM, FPM,

IPM and total meters, yards, feet and inches

• Large memory capacity allows up to 13 measurements to

be stored in memory

• Single chip microprocessor ensures reliability and low

maintenance

• Safely measures RPM (non-contact mode) from up to 14

feet away

• Oversized 5-digit LCD display permits easy reading

• Long battery life (up to 40 hours of continuous use)

• Rugged die-cast aluminum housing provides exceptional

durability

• Extended measuring range (6 - 99,999 rpm) covers wide

range of applications

Important Safety Instructions

Do not point the laser beam into eyes as permanent

eye damage may occur! Shimpo Instruments does

not condone usage inconsistent with product's labeling

and warning.

If upon delivery shipping damage is detected, do not operate

tachometer. Notify shipping carrier immediately for damage

claim instructions. Refer to nameplate and record serial number

for future reference.

Items included with the DT-205L are:

• Carrying case

• Cone adapter

• 200L adapter

• 6” master wheel

• Reflective tape

• NIST certificate

When using the 6” master wheel, do not use the

extension shaft - the wheel may fly off the shaft and

cause damage.

Although the tachometer alone is able to achieve the

higher ranges listed in the Range and Accuracy table

on page 3, the master wheel has a maximum speed

limitation of 5,000 FPM (for safety reasons).

Page 2

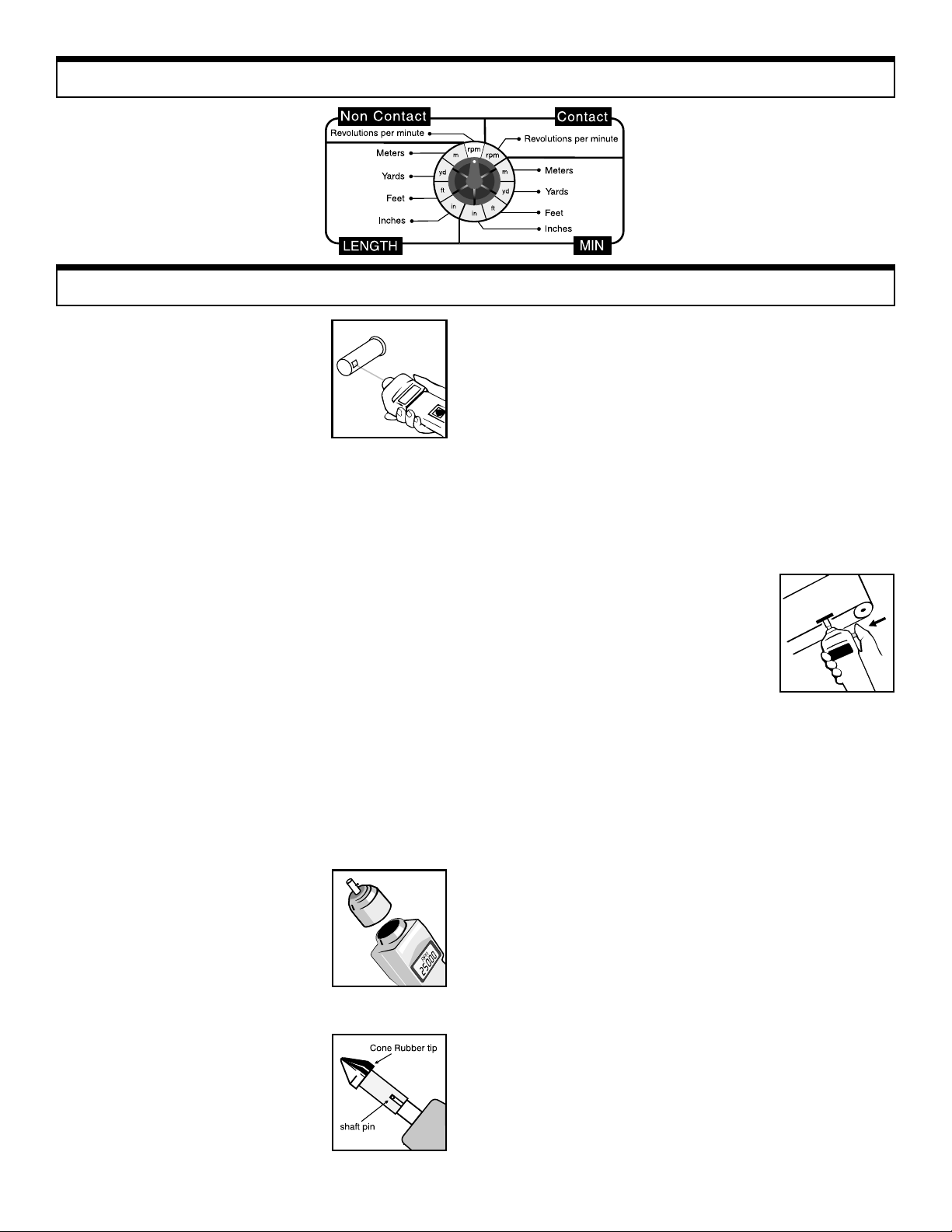

Display Panel

Operating Procedures

Non-Contact Measurement

1. Place a small piece of reflective tape

(included) on the shaft or moving

element (disc, pulley, etc.) whose

speed is to be measured. If the

element's surface is highly reflective

it may need to be painted a darker

color in order to ensure reliable results.

If the distance to the object is less than 5" (127 mm),

reflective tabs (optional) should be used instead of

reflective tape.

2. Aim the tachometer at the reflective tape from a distance

of 5" (127 mm) to 14' (4.3 m).

3. Press and hold the power switch for several seconds to

observe the display as it changes according to the speed of

the shaft or rotating element (as soon as the laser hits the

reflective tape, the unit will start to indicate the speed). If

the beam is “on target” the unit RPM will flash at the top

of the display . If RPM is not flashing then the beam is “off

target” (adjust aim).

4. After observation is completed, retain the reading by

releasing the power switch before removing the tachometer

from its position. The last reading is displayed for a period

of 5 minutes and can be extended any number of additional

5 minute increments by pressing the memory switch.

NOTE: When switching from the contact to the non-contact

mode, the unit RPM will show on the display and also 5 dashes

(-----). Press the power switch to cancel the dashes.

Contact Measurement

For both RPM measurements and nonRPM measurements, screw the 200L

adapter (included) into the front of the

tachometer.

NOTE: Do not use excessive torque when

mounting - hand tightening is sufficient

RPM Measur e ment

1. Place rubber cone tip on the shaft of

the 200L adapter. Make certain that

the pin on the shaft is properly

aligned with the slot on the cone’s

sleeve.

2. Bring cone into contact with the shaft. Apply only enough

pressure to avoid slippage.

3. Press and hold the power switch. During engagement the

display will reflect the proper RPM while the unit RPM

will be flashing above the display digits.

4. Release the power switch prior to removal of tachometer

from rotating object to capture the last reading.

5. After release of the power switch, the last reading (with a

non-flashing RPM unit) will remain on the display and in

memory for 5 minutes, and can be extended any number

of additional 5 minute periods by pressing the memory

switch.

Rate & Length Measurement

1. Attach the 6” master wheel and select

the desired function using the selector

switch located just below the display .

2. Press and hold the power switch;

while the wheel is turning and the

tachometer is measuring the selected

function, the function will be indicated above the digits

and will be flashing.

3. Release the power switch before disengaging the

tachometer in order to capture the last reading.

4. After release of the power switch, the last, maximum, and

minimum readings will be stored in memory for 5 minutes

and can be extended any number of additional 5 minute

periods by pressing the memory switch.

NOTE: The memory will clear in 5 minutes after the release of

the power switch.

For steps 1-4 described above, it was assumed that the selector

switch was in the rate mode region. If the selector switch is

moved from the rate mode to the count mode (length), the display

will show the selected function (m, ft, yd, or in) and also 5 dashes

(-----). Press the power switch to cancel the dashes and start

measuring the same way as was described above. Once in the

counting mode, the measurement can be stopped at any time and

the last reading will be retained for 5 minutes. There is no

maximum or minimum reading when in the count (length) mode.

2

Page 3

Memory Recall

Range and Accuracy

Non-Contact Mode

The following readings are stored in memory for 5 minutes after

release of the power switch:

• Last reading

• Maximum reading

• Minimum reading

These readings can be recalled by pressing the memory switch.

Ten extra readings can also be captured, stored, then recalled

using the memory switch - simply press the memory switch each

time a reading needs to be stored while the tachometer is in use.

Contact Mode (Rate Functions)

When the rate functions are selected (mPM, YPM, FPM and

IPM), the memory store and recall functions are accomplished

exactly as noted above.

Contact Mode (Length Functions)

When the counting functions are selected, the memory store and

recall functions are accomplished in the same manner as the non-

contact mode, the only exception being the maximum and

minimum readings (they do not exist).

To clear the memory completely (for all functions), press the

memory switch for approximately 6 seconds until the display

shows CCCCC, then release the switch.

Place selector switch in the proper position. Using the 200L

adapter and 6” master wheel, the following industrial units of

measurement are achieved:

MODEL DT-205L

R: REVOLUTIONS SINGLE RANGE ACCURACY RESOLUTION

Non-Contact RPM 6 - 8,300 ± 1

(rev./min.)

Contact R PM (r ev./min.) 0.8 - 9,999.9 ±0.6% 0.1

F: FEET SINGLE RANGE ACCURACY RESOLUTION

F/M (feet/min.) 0.4 - 9,999.9 ± 0.6 0.1

FT (feet) 0.10 - 999.99 0.01

Y: YARDS SINGLE RANGE ACCURACY RESOLUTION

Y/M (yards/min.) 0.13 - 999.99 ± 0.06 0.01

YRd (length) 0.02 - 999.99 0.01

I: INCHES SINGLE RANGE ACCURACY RESOLUTION

I/M (inches/min.) 5 - 99,999 ±0.006% of reading ±1digit

IN (length) 1.0 - 9,999.9 0.1

m: METERS SINGLE RANGE ACCURACY RESOLUTION

m/M (meters/min.) 0.11 - 999.99 ± 0.06 0.01

m (length) 0.02 - 999.99 0.01

8,300 - 25,000 ± 2 1

25,000 - 99,999 ±0.006% of reading ±1digit

(or ±6 RPM max.)

10,000 - 25,000 ±0.006% of reading ±1digit 1

(or ±2 RPM max.)

10,000 - 12,500 ± 1 1

1,000.0 - 9,999.9 0.1

10,000 - 99,999 1

1,000.0 - 4,167.0 ± 0.3 0.1

1,000.0 - 9,999.9 0.1

10,000 - 99,999 1

(or ±6 RPM max.)

10,000 - 99,999 1

1,000.0 - 3,810.0 ± 0.3 0.1

1,000.0 - 9,999.9 0.1

10,000 - 99,999 1

1

Battery Replacement

Low battery voltage is indicated by flashing LOW BAT on the

display. Remove end cover by using a coin or appropriate

screwdriver and replace both batteries. Please ensure proper

polarity.

NOTE: When using the 6” master wheel, accuracy can be

affected as much as 0.3% of reading

Although the tachometer alone is able to achieve the

above ranges, the master wheel has maximum speed

limitation of 5,000 FPM (for safety reasons)

3

Page 4

Troubleshooting

The following are general checkpoints; please call your local Shimpo representative or contact Shimpo Instruments directly for further

assistance.

No laser beam is evident:

• Confirm that power switch is functioning

• Confirm that batteries are functioning and that polarity is correct

Inaccurate measurement results:

• If the surface being measured is highly reflective, it may need to be painted a darker color in order to ensure reliable results

• Beam may not be hitting the reflective tape, or taped area may be too small

• Measuring distance may be too short (unit must be at least 5” from intended mark)

Dimensions and Specifications

MODEL DT-205L

Display Range 6 to 99,999 rpm

Accuracy ±1 rpm: 6 to 8,300 rpm

±0.006% of reading ±1 digit (or ±6 rpm max.): 25,000 to 99,999 rpm

Display 5 digit 0.47" (12mm) high LCD

Measuring Units RPM (on contact using adapter, included)

For YPM, mPM, FPM, IPM and Length: YRD, m, FT and IN

Measuring Distance 14' (4.2 m) maximum

Memory System 13 readings are stored in memory and retained for 5 minutes

Detection Laser diode

System Control Single chip C-MOS microprocessor

Over Range Indicator Flashing numerals

Update Time 1 second (typical)

Batteries Included Size: 2 AA 1.5V

Low Voltage Indicator Flashing “LO BA T” display

Operating Tempera t u re 32° to 1 13°F (0° to 45°C)

Construction Die-cast aluminum housing

Weight 0.8 lb (365g)

Dimensions 6.6"L x 2.4"W x 1.8"H (167 mm x 60 mm x 46 mm)

Warranty 1 year

STANDARD ACCESSORIES Reflective tape, cone adapter, carrying case,

±2 rpm: 8,300 to 25,000 rpm

use 6” cir. wheel with 200L adapter

(last, max., min. and 10 extra measurements)

Life: Approx. 40 hrs

master wheel (6" cir.) and 200L adapter

Warranty

LIMITED EXPRESS WARRANTY: Shimpo Instruments warrants, to the original purchaser of new products only, that this product shall be free from defects in

workmanship and materials under normal use and proper maintenance for one year from the date of original purchase. This warranty shall not be effective if the product

has been subject to overload, misuse, negligence, or accident, or if the product has been repaired or altered outside of Shimpo Instruments’s authorized control in any

respect which in Shimpo Instruments’s judgment, adversely affects its condition or operation.

DISCLAIMER OF ALL OTHER WARRANTIES: The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and Shimpo Instruments hereby

disclaims all other warranties, expressed, statutory or implied, applicable to the product, including, but not limited to all implied warranties of merchantability and fitness.

LIMITATION OF REMEDY: Under this warranty, Shimpo Instruments’ SOLE OBLIGATION SHALL BE TO REPAIR OR REPLACE the defective product or part, at

Shimpo Instruments’ option. Shimpo Instruments reserves the right to satisfy warranty obligation in full by reimbursing Buyer for all payments made to Shimpo Instruments,

whereupon, title shall pass to Shimpo Instruments upon acceptance of return goods. T o obtain warranty service, Purchaser must obtain Shimpo Instruments’s authorization

before returning the product, properly repackaged, freight pre-paid to Shimpo Instruments.

INDEMNIFICATION & LIMITATION OF DAMAGES: Buyer agrees to indemnify and hold Shimpo Instruments harmless from and against all claims and damages

imposed upon or incurred arising, directly or indirectly, from Buyer’s failure to perform or satisfy any of the terms described herein. In no event shall Shimpo Instruments

be liable for injuries of any nature involving the product, including incidental or consequential damages to person or property, any economic loss or loss of use.

MERGER CLAUSE: Any statements made by the Seller’s representative do not constitute warranties except to the extent that they also appear in writing. This writing

constitutes the entire and final expression of the parties’ agreement.

Loading...

Loading...