SHIMPO TT User Manual

TT Torque Tool Tester

Operation Manual

1) Overloading the transducer does not only damage the transducer but

may break the transducer head and could result in injury!

2) Torque ranges of 25 N-m and higher must be fastened properly with 4

bolts and nuts to a secure work surface, either horizontally or vertically.

Failing to do so may result in damage to the transducer and could result

in injury to the operator. Ranges 10 N-m and lower do not require mounting and may be used with the included rubber feat as long as precaution

is taken and unit is secured to prevent slippage.

3) Ensure that the torque wrench’s driver has engaged the transducer

socket properly when operating. The transducer head may be damaged

if not engaged properly and could result in injury to the operator.

4) Please make sure that you have safety gear and safety precautions

in place when applying torque to the transducer or when calibrating

the transducer.

5) Do not use a charger other than the unit supplied with the TT torque

tester. Using the incorrect charger may result in damage to the Ni-MH

rechargeable batteries.

NIDEC-SHIMPO INSTRUMENTS

The TT Digital Torque Tool Tester is a simple operation test instrument for quickly checking torque tool performance. The TT Series

provides exceptional accuracy for measuring torque on various

products including torque wrenches, manual screwdrivers, electric screwdrivers, pneumatic screwdrivers and other torque controlled power tools.

The TT’s provide long operation life and power flexibility with the

ability to work from the internal rechargeable battery or included

AC adapter. The TT’s have four modes of operation: Track for live

readings, Peak which records the highest level over a test, First

Peak which records the first peak reading over the test and Track/

Peak which shows both the live readings as well as the peak reading recorded.

The backlit display provides an analog bar graph on screen to

allow the user to know where the resultant torque is currently positioned compared to the full scale range of the unit. CW/CCW

icons along with programmable pass/fail LED’s ( HI/OK/LO) assist

users with ensuring proper test set up along with enabling a quick

determination of the results.

Every tester comes standard with USB and RS-232 output. The

TT’s software enables the uploading of data and the additional

statistical analysis with its auto-calculation of the selected values.

These excellent features make the TT Torque Tool Testers a valuable and versatile addition to the production and quality control

departments.

SPECIFICATIONS

Accuracy: ± 0.5 % of full-scale.(Includes Creep, Non-linearity &

Temperature Shift at zero load)

Units of Measure: N-mm, N-cm, N-m, in-lb, ft-lb, kg-cm, kg-m

(depending on range)

Measure Modes: Track, Peak, First-Peak, Track/Peak

Tool Socket Size: Dual 3/8”, 20 mm female square.

Overload Protection: 120% of Full Scale

Max. Mounting Torque: 150% of Full Scale

Sampling Rate: 1000 Hz

Peak Capture Rate: 0.10 S

Display: 175 x 1.125˝ (44.4 x 28.6 mm) dot matrix backlit LCD

Operating Temperature: 60 - 95 ºF (15 to 35 ºC)

Storage Temperature: 5 - 149 ºF (-15 to 65 °C)

Humidity Limit: Maximum 70% rH.

Power: Rechargeable battery or 100 -240, 50-60 Hz universal AC

adapter/charger

Power Requirement: 500 mA 9 VDC

Charging Time: Approx. 14-16 Hours for Full Charge

Battery Operation: 12 Hours

Output: USB 8 data bits Baud rate: 38400

Communication Ports: Both RS232 & USB simultaneous output

Size: 4 x 8 x 2” (100 x 200 x 50 mm);

TT-25: 4 x 9.8 x 2.3” (100 x 250 x 58 mm)

Product Weight: 2.4 lb (0.9 kg); TT-25: 4.9 lb (2.22 kg)

Package Weight: 5.1 lb (2.3 kg); TT-25: 7.7 lb (3.49 kg)

Warranty: 1 year

Included Accessories: USB cable, charger adapter, cal. cert.,

rundown adapter, 1/4” male Hex to 3/8” square driver adapter.

Optional Accessories: RS-232 cable, Rundown adapter

springs, Rundown adapters. Note: Software available for free

download at www.shimpoinst.com.

INTRODUCTION

Thank you for selecting the Nided-Shimpo TT series torque tool

tester. With correct use and regular re-calibration, the TT tool tester will provide many years of accurate and reliable service.

The Series TT can accurately measure torque in both the ClockWise (CW) and Counter Clock-Wise (CCW) direction. The TT provides simple user operation and is accompanied with software

and accessories to simplify your torque testing needs.

Before Use

Upon receiving the unit, please check that no physical damage

has occurred to the packaging, plastic carrying case or the instrument itself. If any damage is evident, please notify Nidec-Shimpo

immediately.

Operation Overview

The most commonly used features, such as displaying torque,

peak hold, zeroing and changing of displayed units, can all be

done by pressing a single dedicated key identified on the front

panel. See the Basic Functions section. To access the menus,

simply press the Menu key to access the tester configurations.

See the Main Menu section.

POWERING THE FIRST TIME

The TT is supplied with a set of Nickel Metal Hydride 4xAAA rechargeable batteries. For safety reasons during transportation the

batteries are shipped discharged. To obtain maximum battery life

we recommend that you charge them with the supplied charger/

adaptor for at least 14-16 hours when you first receive the instrument.

Battery Indicator

If battery level shows empty, a “ battery empty” message will be

displayed and the tester will power down automatically.

Important: Only use the adaptor/charger supplied.

USING THE TT

Fitting Accessories

If power torque tools are used, the rundown adapter provided can

be inserted to the torque transducer head. For wrench and torque

screwdrivers, you may need a matching adapter.

Power Up

To power up the tester press the ON/OFF key. A short self-test

runs during which the display will show the capacity in Newtons.

The TT re-zeroes itself during the self-test routine.

After the self-test, providing no load has been applied to the instrument, the display will show all zeroes.

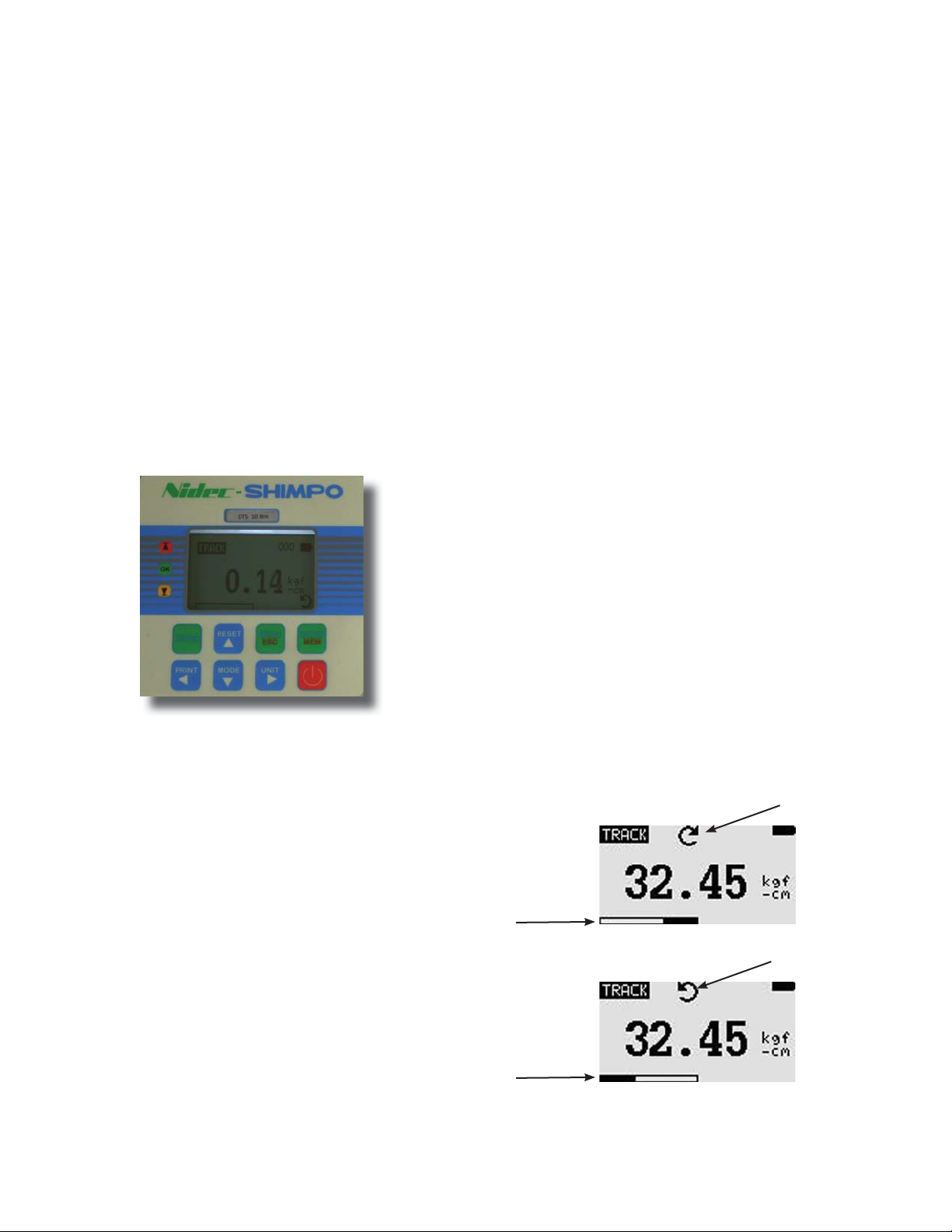

Figure 1: TT Keypad

ZERO: Resets the displayed value to zero

POWER: Turns unit on/off

UNIT: Home screen changes engineering units.

In Menus, moves cursor to the right position

MODE: Home screen, scrolls through 4 modes of

operation. In menus, moves cursor down in the list or

decreases a value

RESET: Home screen, resets the maximum

values. In menus, moves cursor up in the menu list or

increases a value

*

Do not overload

the load sensor. This will cause irreparable

damage. Torques greater than 120% of full-scale will produce an

audible beep and OL symbol will blink on the display until the load

is released and the RESET key is pressed.

To power down the tester press the ON/OFF key.

*All the current settings are saved when the tester is turned off. The

tester will function in the same mode when powered up again.

Basic Functions

Clock-Wise(CW) torque is displayed by the right pointing arrow

symbol (see image below). Counter Clock-Wise torque is displayed by the left pointing arrow symbol (see image below).

Clockwise

Symbol

Load Indicator

Bar for

Clockwise

Counter-Clockwise

Symbol

ENTER/MEM: Home screen, enters data into memory

storage In menus, enters into sub-menus, makes

selections and enters values.

MENU/ESC: Home screen, enters into menus

In menus and sub-menus, returns one level

PRINT: Home screen, sends current reading to PC

In Menus, moves cursor to the left position

2

Load Indicator

Bar for

Counter-

Clockwise

Figure 2: Display of Clockwise & Counter-Clockwise

Loading...

Loading...