Page 1

TRC Series

DIGITAL TORQUE CHECKER Series

Operation Manual

Read the manual thoroughly prior to operation.

Use the instrument only after reading the complete manual.

Follow all safety precautions.

Page 2

Warning

Safety Precautions

Be sure to read the entire instruction manual thoroughly before initial set-up, operation and maintenance.

The instruction manual provides three grades of safety precautions: “Danger”, “Warning” and “Caution”.

Follow these precautions.

Danger” marking indicates possible death, severe injury or fire

if the user disregarded.

Danger

Warning

Caution

“Warning” marking indicates possibility of a serious injury

if the user does not follow the instruction.

Caution” marking indicates possibility of severe bodily or object damage

if operated improperly.

__The following marks indicate the sort of contents which are completed with.__

his mark indicates warning.

his mark indicates a prohibited operation.

his mark indicates Execute this warning.

Heavy! Pay close attention to location and conditions around TRC.

Dropping the TRC may cause damage or serious injury.

Page 3

Caution

Never exceed torque ratings.

May damage sensor and other parts.

May cause damage or injury.

Do not carry TRC by AC power cable.

cause electric shock, fire and/or injury.

Confirm the specified AC voltage.

Other then specified voltage may cause damage,

electric shock, fire and/or injury

Do not substitute AC adapter.

Use only

the adapter supplied with the

unit.

Use of other then specified ac adapter may cause

damage, electric shock, fire and/or injury.

Insert AC connector into outlet

securely.

May cause electric shock, fire and/or injury

Do not alter, repair or dispose of

TRC or batteries improperly.

cause damage, accidents and void warranty.

Do not use with AC power in an

area

where there is dust.

An electrical spark may cause fire.

To clean, gently wipe with a soft

cloth.

No volatile chemicals such as usage of

Benzene,

Thinner, or Alcohol are to be used to clean

TRC

Check operation of TRC and

calibrate

periodically.

Place TRC in a location

where

maintenance and check are

easy.

Fix object securely.

May

May cause damage or injury.

Do not damage AC cable.

May cause electric shock, fire and/or injury.

Do not use except with 115VAC.

May cause electric shock, fire and/or injury.

Do not insert plug into AC

outlet

if hands are wet or moisture

is

present.

May cause electric shock, fire and/or

injury.

Do not pull out the AC plug

by the

cable. Carefully pull on plug

May

only.

Pulling on cable may cause electric

shock.

A

void the following.

Di

rect sunshine, condensation, dust or caustic

ch

emicals, combustible gases, oils, water, salts.

Operate within 32-104°°°°F (0-

40°

°C)

C)

°°

C)C)

Outside specified temperature range

may alter

operation of TRC.

Humidity range 35 –––– 85%RH

(Not condensation)

Operation outside humidity range may alter

operation of TRC.

Page 4

Contents

1 Feature ................................................................................................................................................................................1

2 Confirmation of Product Packing ........................................................................................................................................1

3 Names and Functions of Components ................................................................................................................................ 2

3.1 Mainframe..................................................................................................................................................................2

3.2 Operation Panel .........................................................................................................................................................3

3.3 Main Display............................................................................................................................................................... 4

3.3.1 Main Display/Setup Values................................................................................................................................4

3.3.2 Unit/Status Indicators........................................................................................................................................4

3.3.3 Battery Indicator................................................................................................................................................5

4 Parameters..........................................................................................................................................................................5

4.1 Function Setting .........................................................................................................................................................5

4.1.1 Function Mode ..................................................................................................................................................5

4.1.2 Operation...........................................................................................................................................................5

4.2 High/Low Limit Setting for Comparator .....................................................................................................................8

4.2.1 Pattern No. Setting ............................................................................................................................................8

4.2.2 Operation...........................................................................................................................................................9

5 Measurement Mode .........................................................................................................................................................10

5.1 Peak Mode ...............................................................................................................................................................10

5.2 Mean Mode..............................................................................................................................................................10

6 Comparator Function ........................................................................................................................................................11

7 Measuring .........................................................................................................................................................................12

7.1 Measurement of Torque Wrenches .........................................................................................................................12

7.2 Measurement of Electric Screwdrivers/Torque Drivers ...........................................................................................12

7.3 Zero Adjustment....................................................................................................................................................... 13

7.4 Measuring ................................................................................................................................................................ 13

7.5 Mounting Bracket.....................................................................................................................................................14

8 Memory Function..............................................................................................................................................................14

8.1 Saving Data in Memory ............................................................................................................................................ 14

8.2 Display Memory Data ............................................................................................................................................... 15

8.3 Clearing Stored Data (Latest Memory Data) ............................................................................................................ 16

8.4 Clearing Stored Data (Each Pattern No.) ..................................................................................................................16

8.5 Clearing Stored Data (All Memory Data).................................................................................................................. 16

9 DigiTorq_TRC.....................................................................................................................................................................17

9.1 Feature of DigiTorq_TRC ..........................................................................................................................................17

9.2 Download DigiTorq_TRC .......................................................................................................................................... 17

9.3 Battery Life and USB.................................................................................................................................................17

10 Support .............................................................................................................................................................................17

10.1 Repair and Calibration..............................................................................................................................................17

10.2 Warranty ..................................................................................................................................................................17

11 Specifications and Dimensions..........................................................................................................................................18

11.1 Specification .............................................................................................................................................................18

11.2 Dimensions............................................................................................................................................................... 19

Page 5

1 Feature

1. Mainframe (1)

3. AC adapter/charge

r (1)

4. USB cable (1)

2. Adapter for

torque

driver

6. Bolt M6x15 for

mounting bracket

(2)

7. Operation manual

8. Warranty card (1)

5. Mounting Bracket (1)

• Two measurement modes: Mean, Peak

• Peak hold & Auto reset of peak display

• Go/No Go judgment by comparator functions (LED indicator and Buzzer)

• Available 10 patterns of High/Low torque limits for judgment

• 300 data memories for each pattern (Total: 3,000 data)

• USB communication to PC (with “DigiTorq_TRC”operation software:)

• Selectable units: lb-in, N-m, N-cm, kg-cm

• Selectable Measurement periods: 1, 2, 4, or 8 times/sec

2 Confirmation of Product Packing

(1)

1

Page 6

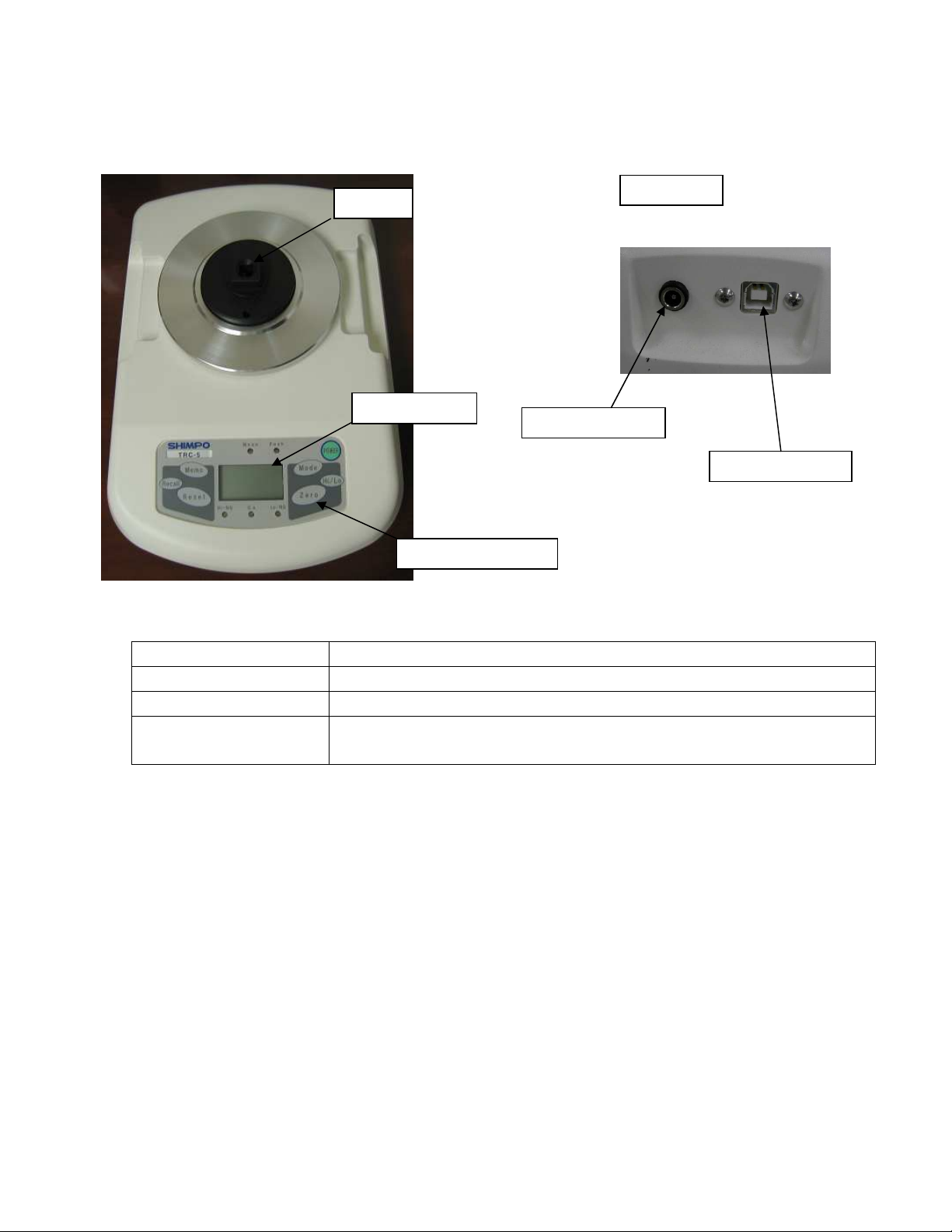

3 Names and Functions of Components

USB connector

LCD display

Socket

Operation Panel

Back side

DC power input

3.1 Mainframe

Socket Insert torque wrench or torque driver adapter

Operation Panel LCD display, Keys, LED indicators

USB Connector USB communication (B type)

DC Power Input

Insert AC adapter/charger when AC power supply is used or battery is being

charged.

2

Page 7

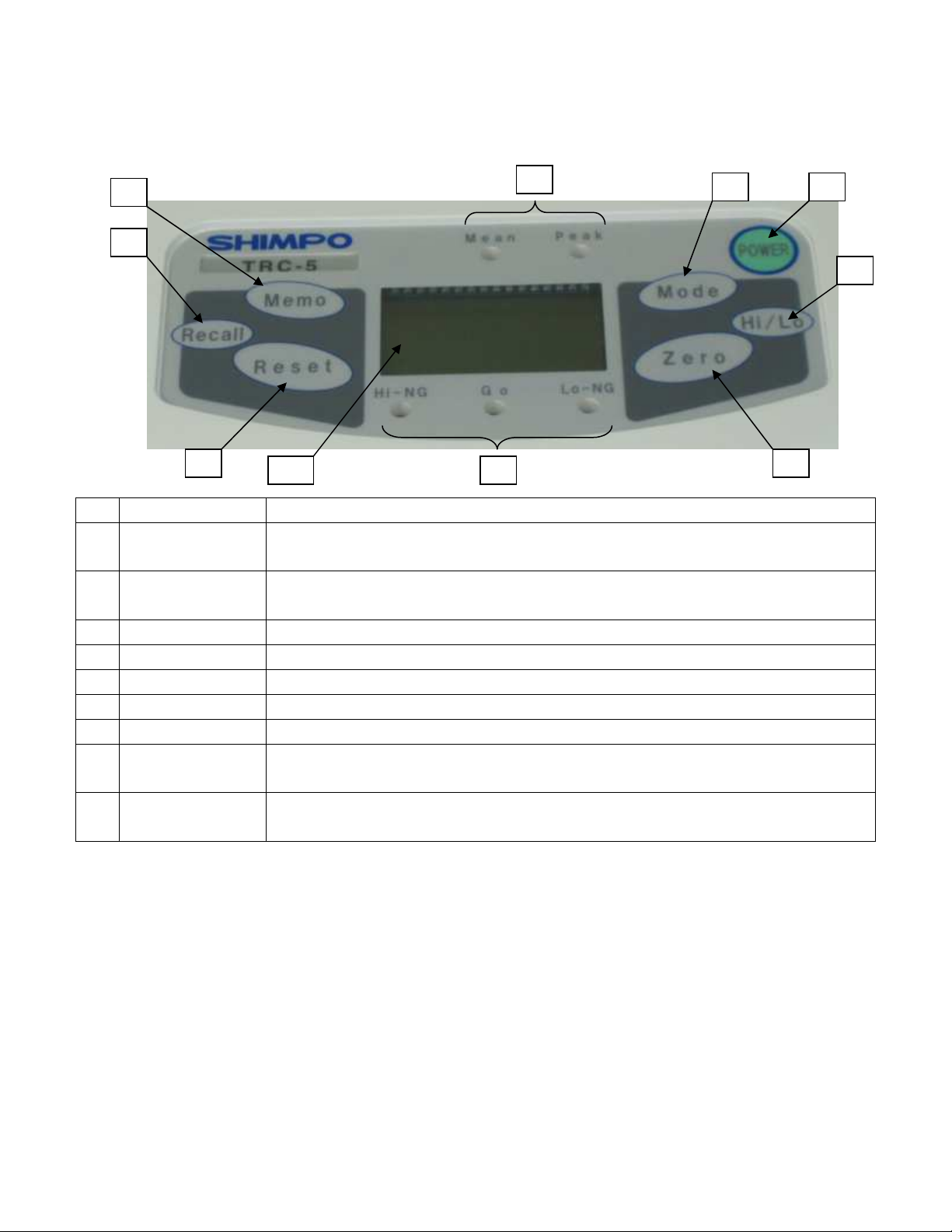

3.2 Operation Panel

2

3

4

5

6

7

8

9

10

1

1 POWER key Power the unit on or off.

2 Memo key

3 Recall key

4 Reset key Peak reset function in “Peak” mode.

5 Mode key Select “Mean” or “Peak” mode of operation

6 Hi/Lo key Sets the high/low limit values.

7 Zero key Sets Zero in “Mean” and “Peak” mode.

8 Mode LED’s Indicates which mode is selected: “Mean” or “Peak”.

9 Comparator LED’s

10 Main display

When in Peak mode, data is stored.

Note: In “Mean” mode, Memo key has no function.

Recall the peak data stored in “Peak” mode.

Note: In “Mean” mode, Recall key has no function.

When the high/low limit values are enabled, the LED indicates: Hi-NG or Go or Lo-NG

is ON. When the high/low limit values are disabled, all LED’s are off.

Displays measured values and status indicators. Includes units of measure, battery

status and function status.

3

Page 8

3.3 Main Display

3.3.1 Main Display/Setup Values

Main display shows four digits including decimal point.

The + sign means CW direction torque, the – sign means CCW direction torque in Mean mode.

IMPORTANT NOTE: In the case of Peak mode selection, the sign is always +.

3.3.2 Unit/Status Indicators

Located on the upper part of display, this shows the unit of measure selected.

It also serves as a sub display under function mode or status. The example display is shown in below.

lb-in unit N-m unit

lbI

Nm

Overload

OVR

1 minute warning

before it turns off

PWR

4

Page 9

3.3.3 Battery Indicator

Next page

Displayed according to battery status.

“LO BAT” blinking: “BAT”:

Battery diminished. Charging by AC adapter/charger.

Connect AC adapter/charger for charge.

LO

lbI

4 Parameters

4.1 Function Setting

4.1.1 Function Modes

Function modes are as follows.

Item Sub Display Setting Contents Initial setting

Auto reset F01 OFF/1/2/5 sec OFF

Unit of torque F02 lb-in/N-m/N-cm/kg-cm lb-in

Display update time F03 1/2/4/8 [times/sec] 4

Auto power off F04 OFF/10 [minutes] 10

Unit No. F05 0-99 0

BAT

lbI

4.1.2 Operation

With power off, press and hold Zero key then press POWER key.

Hold Zero key until the display shows “F01”.

Power

++++

Zero

5

Page 10

4.1.3

<Auto Reset

Selection

>

Save and exit

4.1.4

<Units of measure selection

>

Save and exit

Next page

The Auto Reset function automatically resets Peak after each setting period.

The Peak Reset function operates the same as pressing Reset key.

(Current setting is displayed first.)

Auto reset OFF

F01

Mode

F01

Mode

Mode

5 sec 2 sec

Hi/Lo

The torque units are selectable: lb-in, N-m, N-cm and kg-cm.

lb-in

lbI

Mode

1 sec

F01

F01

N-m

Nm

Mode

(Current setting is displayed

Memo

first.)

Ncm

Mode

Memo

Mode

kgc

Mode

Kg-cm N-cm

Hi/Lo

6

Page 11

4.1.5

<Display Update Time S

etting

>

Save and exit

4.1.6

<Auto Power Off Setting>

Save and exit

Next page

Display update time is selectable from 1/2/4 or 8 times/sec.

1 time/sec

F03

Mode

F03

Mode

Mode

8 times/sec 4 times/sec

Hi/Lo

If the TRC is on battery power and there is no activity for 10 minutes, the TRC automatically

powers off to conserve battery power. This option may be disabled. Auto Off is disabled when

connected to AC adapter/charger.

Auto Off time defaults to 10 minutes

. No other time is available.

(Current setting is displayed first.)

2 times/sec

F03

Mode

Memo

F03

(Current setting is displayed first.)

Disable

F04

Mode

Enable 10 minutes

F04

Memo

Mode

Hi/Lo

7

Page 12

4.1.7

<Unit No. Setting>

Current unit No.

LSD(Last Significant Digit) blinking

Save and exit

F05

Go to Auto Reset Setting

The ID No. can be individually applied.

Mode

MSD(Most Significant Digit)blinking

F05

Recall

F03

Press Mode to increment, return to 0 when 9

Press Recall to go to MSD setting

Recall

Press Mode to increment, return to 0 when 9

Mode

F05

Hi/Lo

4.2 Comparator settings for High/Low Limits

(Current setting is displayed first.)

Memo

4.2.1 Pattern No. Setting

The TRC can store up to 10 patterns of High/Low torque limits.

This section describes how to set the pattern No.

The pattern No. is from 0 to 9.

When a torque unit of measure is displayed, the Comparator function may be disabled.

Disabled comparator

lbI

Hi/Lo

-0-

Hi/Lo

Hi/Lo

Pattern No.

-1-

-9-

Hi/Lo

Hi/Lo

-2-

8

Page 13

4.2.2 Operation

To s

ave

Hi/LO limit

setting

s,

go to

M

easurement mode

.

(Section 5)

<High Limit Setting> Hi

-

NG LED on

Measurement Mode

Move

1 digit to the

right

Press Reset, move to digit

on right

.

<Low Limit Setting> Lo

-

NG LED on

Start setting

MSD: Most Significant Digit

Select the pattern number according to above Section 4.2.1. Pattern No. Setting.

Low limit data

Reset

Move 1 digit to right

-1-

Hi/Lo

1-L

Press and hold Hi/Lo until the display shows “1-L”.

Reset

1-L

Return to MSD when LSD is displayed.

MSD blinking & setting

1-L

Press Memo to increment.

Returns to “0” after 9 is

displayed.

LSD: Least Significant Digit

(Current setting is displayed first.)

Memo

1-L

1-L

Reset

Mode

(Current setting is displayed first.)

High limit data

1-H

Mode

Note: Low limit value must be smaller than High limit value. If the setting data is

incorrect, all digits will be blinking. Turn TRC off and reset limits.

Key operation is the same as Low limit setting above.

9

Page 14

5 Measurement Modes

Mean Peak

Mean Peak

Mean Peak

Mean Peak

Peak, Mean Measurement modes are available on the TRC:

To select the measuring mode required for testing, follow the settings below.

Mean Mode

Peak Mode

5.1 Peak Mode

The Peak value displayed on the TRC is measured at 1,000 times per second. (1000Hz)

The Peak value is reset by pressing the Reset key or activating the Auto reset function (refer to 4.1.3

Auto Reset Setting).

Set zero by pressing Zero key.

5.2 Mean Mode

The mean mode is the real time value based on the average data captured in 1,000 samples per second.

(1000Hz)

F03 Display Update time Average

1 1 time/sec Displays the average of 1,000 measuring data by 1msec sampling

2 2 times/sec Displays the average of 500 measuring data by 1msec sampling

4 4 times/sec Displays the average of 250 measuring data by 1msec sampling

8 8 times/sec Displays the average of 125 measuring data by 1msec sampling

lbI

lbI

lbI

Mode

Mode

lbI

Zero

Press and hold Zero key

until the display shows

“0”

10

Page 15

6 Comparator Function

• This function compares the High/Low limits and measured data (Mean Mode) or peak data (Peak

Mode) or memory data. The result is displayed by Comparator LED indicators.

• If both High and Low limits are set to 0, the Comparator function is deactivated. Refer to 4.2.2

Operation.

• The buzzer sounds and the “Go” LED illuminates when the displayed data is between the High and

Low limits.

- In Peak mode, the buzzer sounds when the peak value is fixed.

- In Mean mode, the buzzer sounds every 1 sec.

Note: When the displayed value is less than 1% of the torque rating, the buzzer does not activate.

• Comparison is used with all completed data.

<Example of comparator function>

High limit = 100, Low limit = 50

Measurement of CW direction

+

100 High limit

50

0

Hi-NG: ON

Go: ON

Low limit

L0-NG: ON

-

Measurement of CCW direction

+

0

Lo-NG: ON

50

Go: ON

100 High limit

Hi-NG: ON

Low limit

-

11

Page 16

7 Measuring

Socket

for torque

wrench

Attachment for driver

Adapter for driver

7.1 Torque Wrench – torque measurement

To measure torque, insert the torque wrench square drive into the TRC socket attachment.

7.2 Electric Screwdrivers/Torque Driver - torque measurement

To measure torque, insert the adapter into the attachment of the TRC as

shown below.

Torque wrench

Driver

The torque driver adapter is designed to measure in only the CW (tightening) direction.

Note:

12

Page 17

The adapter is a consumable product.

Loosen (CCW direction)

Tighten (CW direction)

Replace the adapter when it is impossible to perform a repeatable measurement.

7.3 Zero Adjustment

In “Mean” mode, press the Zero key when the display does not display “0” and no torque is applied.

In “Peak" mode, press the Zero key when the display does not display “0” if the automatic peak reset

function is not activated.

7.4 Measuring

The measured torque data is displayed with a given torque test.

When the TRC is in “Peak” mode, press Reset key to reset the Peak function before the next torque test.

NOTE: Peak reset cannot operate while torque is applied.

Spring shrinks

Spring returns

13

Page 18

7.5 Set Mounting Bracket

M6 tap (2)

Hole x2 (Ø7mm)

Bolts M6x15 (2)

for

mounting

10.63” (270mm)

Return to measuring mode after 1 sec

Secure the TRC to a work bench or other suitable surface by using the mounting bracket accessory if the

TRC moves during measurements.

Procedure to mount the mounting bracket:

1. Prepare the mounting bracket (1) and bolts M6x15 (2) of accessories.

2. Set the mounting bracket to the bottom of the unit by the bolts as shown below.

3. Set the unit to worktable using two holes (diameter 7mm).

Bottom of TRC

8 Memory Function

8.1 Saving Data in Memory

Measuring torque data can be stored in the unit by pressing Memo key.

The feature is only available in Peak mode.

The unit is able to store 300 data for each pattern of High/Low limits.

Pattern No. 1

-1-

Memo

Mounting

Saving data

“003” is the 3rd data.

003

Peak reset

after 1sec

-1-

If the stored data of this pattern is already 300,

the display is “FULL” and the data can not store.

-1-

14

Page 19

8.2 Display Memory Data

Minimum

Maximum

Return to test mode

Memory number

Latest memory data ind

icates

Memory number

Return to

Select Peak mode, press the Recall key and the TRC display will indicate the number of data stored in the

memory.

The Memory data is displayed from the last number stored.

Measuring mode

Pattern No.1

-1-

Recall

300

Recall

Average

Recall

AVE

MAX

last memory

data stored

stored

001

Recall

Operation same as

Memory data 300

Recall

Memory number

decrement

299

Recall

Recall

MIN

Recall

300

Mode

-1-

15

Page 20

8.3 Clearing Stored Data (Latest Memory Data)

Indicating target

+

C

lear display

Indicating about 1 sec

Return to test mode

+

Power off

Clear display

Indicating about 1 sec

Return to test mode

When the latest memory data is displayed, press and hold the Zero key until “Clr” is shown in the display.

Latest memory data indicates

Press and hold until clear display

Clear display

Zero

300

New latest memory data

299

Indicating about 1 sec

In case of latest memory number = 001:

Memory No. =001

001

Zero

Clear display

Indicating about 1 sec

8.4 Clearing Stored Data (Each Pattern No.)

When the pattern No. is displayed, press and hold the Memo key and the Zero key until “Clr” is shown in

display.

pattern No.

-1-

Memo

Zero

-1-

8.5 Clearing Stored Data (All Memory Data)

Power off. Press and hold the Memo key and power on. Continue to hold the Memo key until “All Clr” is

shown in the display.

Memo

Indicating No data

Return to

Test mode

Indicating about 1 sec

-1-

POWER

16

ALL

-1-

Page 21

9 DigiTorq_TRC

When you connect the TRC to a PC with the USB cable, your PC is able to obtain test data from the TRC.

Installation of the DigiTorq_TRC application software is required.

9.1 Feature of DigiTorq_TRC

DigiTorq_TRC is an add-in software for MS Excel ®*

The measurement data and the memory data of the unit can be directly sent to an

Excel spreadsheet where graphing and data analysis is easy.

*Excel is a registered trademark of Microsoft Corp.

9.2 Download DigiTorq_TRC

The DigiTorq_TRC is available for free at the following web address:

http://www/shimpoinst.com/software.php

The manual is included with the software download, and is available separately.

9.3 Battery Life and USB

Leaving the USB cable connected to the TRC will drain battery power at a faster rate. Only connect the

TRC USB cable when communicating or use the AC adapter/charger.

10 Support

10.1 Repair and Calibration

Please contact your Shimpo dealer for information regarding the repair and calibration of your TRC.

10.2 Warranty

Nidec-Shimpo Corp. warrants, to the original purchaser of new products only, that this product shall be

free from defects on workmanship and materials under normal use and proper maintenance for one

year from the date of original purchase. See warranty card.

17

Page 22

11 Specifications and Dimensions

11.1 Specification

TRC Series Digital Torque Checker

TRC Models TRC-2 TRC-5 TRC-10

Measuring Units N-m, N-cm, lb-in, kg-cm

0.020-2.000 N-m 0.050-5.000 N-m 0.10-10.00 N-m

Measuring Range

Main Display 4-digit LCD display, Character height 12mm

Display

Buzzer Available (Result of comparator, completing to measure, etc.)

Accuracy +/- 0.5% Full Scale

Measuring

Display Update Time

Sampling Rate 100 times/sec (10msec)

Memory

Data Output USB1.1

PC Software

Standard Accessories

Power

Dimensions DxHxW inch(mm) 12.60”x3.82”x8.66” (320x97x220mm)

Shipping Weight 18lb (8kg)

Operation Environment

Battery Type/ Battery Life Ni-MH / 8 hours after full charge

Battery Recharger Time Maximum 16 hours

Sub Display 3-digit LCD display, Character height 7mm

Mode Display Mean, Peak (red LED indicators)

Comparator Display Hi-NG, Go, Lo-NG (green and red indicator)

Mean Mode Measuring real time torque

Peak Mode Measuring peak torque

Memory data number Total 3,000 data (300 data/ each pattern [Total 10 patterns])

Statistical Process Average value, Maximum value, Minimum value

Battery Built in nickel metal hydride battery (NiMHd)

AC adapter/charger 100-240VAC input/ 9VDC 300mA

2.0-200.0 N-cm 5.0-500.0 N-cm 10-1000 N-cm

0.18-17.7 lb-in 0.45-44.25 lb-in 0.89-88.50 lb-in

0.21-20.39 kg-cm 0.51- 50.99 kg-cm 0.1-102.0 kg-cm

Select from 0.125sec (8 times/sec), 0.25sec (4 times/sec),

0.5sec (2 times/sec), 1 sec (1 time/sec).

DigiTorq_TRC(free download from web site: www.shimpoinst.com)

Torque adapter for driver, AC adapter/charger, USB cable, Mounting

bracket, bolts for mounting bracket (2 pcs)

32-104° F (0 – 40° C)/ 35-85% RH (non condensation)

18

Page 23

11.2 Dimensions

When Spring

4.37” (111mm)

0.25”(6.35mm) Hexagon

12.20” (310mm)

8.66” (220mm)

0.35” (9.5mm)

10.63” (270mm)

Operation Panel

Socket

2-Ø0.28”

(2-Ø7mm)

1.97”

(50mm)

Mounting Bracket (Accessory)

Mounting bracket

□

Wrench

Attachment

Driver

Attachment

Max. Length

12.60” (320mm)

Ø1.18” (30mm)

Adapter for Driver

19

Loading...

Loading...