Page 1

ST-1000 Stroboscope Tachometer

Operation Manual

SHIMPO INSTRUMENTS

z

The Shimpo Series ST-1000 is a Stroboscope-Tachometer with

LED flash technology. This velocity analyzing and measuring device is ideal for rotational machine inspection. The stroboscope

is capable of flashing the light in a synchronous frequency to the

operating machinery, creating the illusion of viewing stopped or

slowed images. Utilizing this phenomenon of slowing or stopping

the motion with the adjusted rate of the ST-1000’s flashing light,

machine parts and processes may be inspected for defects. Plus,

the rotational speed of the machinery and systems may be recorded for further performance analysis.

The ST-1000 is adjustable in either coarse or fine step flash-rate

tuning. The backlit display shows the current flash rate, 10 userstored pre-set flash rates, as well as a low battery warning. The

backlit feature can be switched off to save battery life if desired.

The ergonomic, hand held device is made of sturdy ABS plastic

and comes with batteries and protective carrying case. The LED

technology extends operation due to the low energy requirement

of the light diodes compared with xenon stroboscopes. Typical

applications for using the ST-1000 is to inspect rotors, meshing

gears, vibration diagnostic equipment, textile equipment, printing

production lines, power tools, speaker acoustical analysis, fan

balancing and many more.

To Avoid Injury, do not point the light beam of the instrument or have it reflected into the eyes of people

or animals.

Do not leave the device close to water or any other

liquid to avoid damage.

-If not using this instrument for extended periods of

time, remove the batteries to prevent potential battery

leakage from causing product damage.

SPECIFICATIONS

Range: 60-40,000 Flash Rate Per Minute (RPM)

Accuracy: +/-0.05% FS

Lux Rating: 650 Lux @ 3000 RPM & 3.9 in (10 cm), 350 Lux @

3000 RPM & 7.9 (20 cm), 185 Lux @ 3000 RPM & 11.8 (30 cm)

Display: 5 digits with backlight. 40000 maximum reading

Resolution: <1000 RPM: 0.1 RPM; >1000 RPM: 1 RPM

Tuning: <1000 RPM: Coarse=10 RPM increments;

Fine= 0.1 RPM increments.

>1000 RPM: Coarse=100 RPM increments;

Fine= 1 RPM increments

Rate Storage: 10 stored user-defined flash rates.

Factory Defaults: 4000, 8000, 12000, 16000, 20000, 24000, 28000,

32000, 36000, 40000.

Power Supply: 4 AA batteries. Approx. 10 hours use with backlight on; 12 hours when off

Housing: ABS Plastic

Dimensions: 7.7 x 2.9 x 1.5” (195 x 73 x 38 mm)

Product Weight: Approx. 7 oz. (200 g)

Package Weight: Approx. 1.5 lb (680.4 g)

Certification: CE

Warranty: 1 year

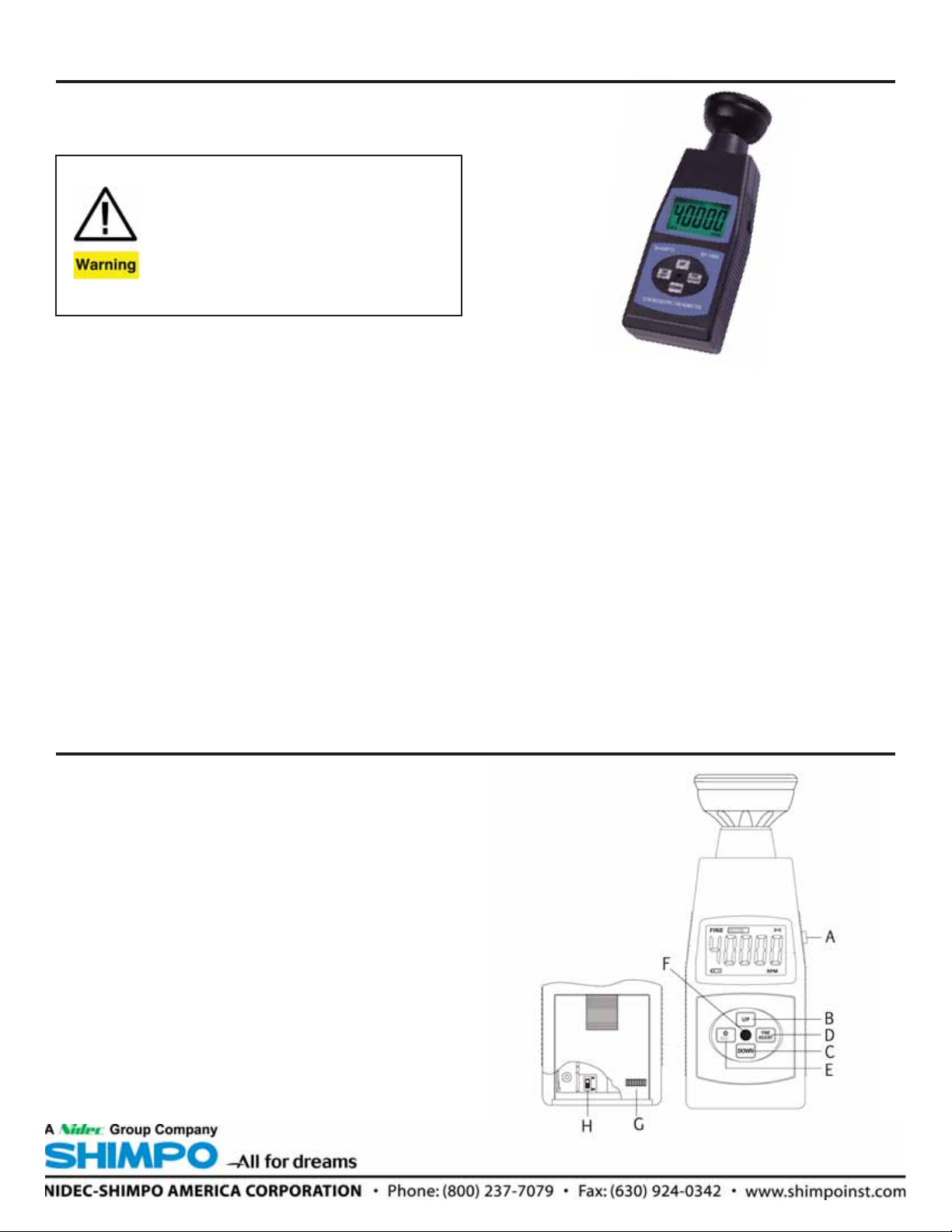

PRODUCT DIAGRAM

A. LED Flash Switch

B. Flash Rate Value Increase Button

C. Flash Rate Value Decrease Button

D. Coarse/Fine Tuning Button

E. Power/Stored Rate Retrieval Button

F. Flash Rate Storage Button

G. Battery Compartment Cover

H. Backlight ON/OFF Switch

Page 2

OPERATION

Power ON/OFF: Open the battery compartment cover on the back

of the unit and place the batteries in the battery holder properly.

Then press and hold the Power Switch . The display will turn

READ

on and show the initial lowest factory default flash rate of 4000

RPM. If a Pre-Stored rate has been stored during a previous use,

the last Pre-Stored rate will be shown. Coarse tuning is the default. Press and hold again to turn the instrument off.

READ

Turn on the LED’s with the LED Flash Switch (A). The LED’s will

remain flashing at the rate set on the display for as long as the

button is held. Once released, the LED’s will turn off.

To alter between Coarse and Fine tuning, select the (D) FINE ADJUST button to change from Coarse to Fine adjustment.

FINE

ADJUST

Press again to switch back to Coarse. When in Fine adjustment

mode, “FINE” icon will appear on the display. Adjust the flash

UP

speed with the & buttons (B & C). In coarse tuning each

single press of the & buttons the value of the flash speed

DOWN

UP

DOWN

will increase/decrease by 100 RPM when the range is greater than

1000 RPM or 10 RPM when less than 1000 RPM. In fine tuning

each single press of the or buttons increases/de-

UP

DOWN

creases the value by 1 RPM when greater than 1000 RPM, or 0.1

DOWN

RPM when less than 1000 RPM. Hold the or buttons to

UP

continue to increment continuously. Note: Once the maximum of

40000 or minimum of 60 RPM is met while adjusting the rate, the

device will automatically stop at those thresholds.

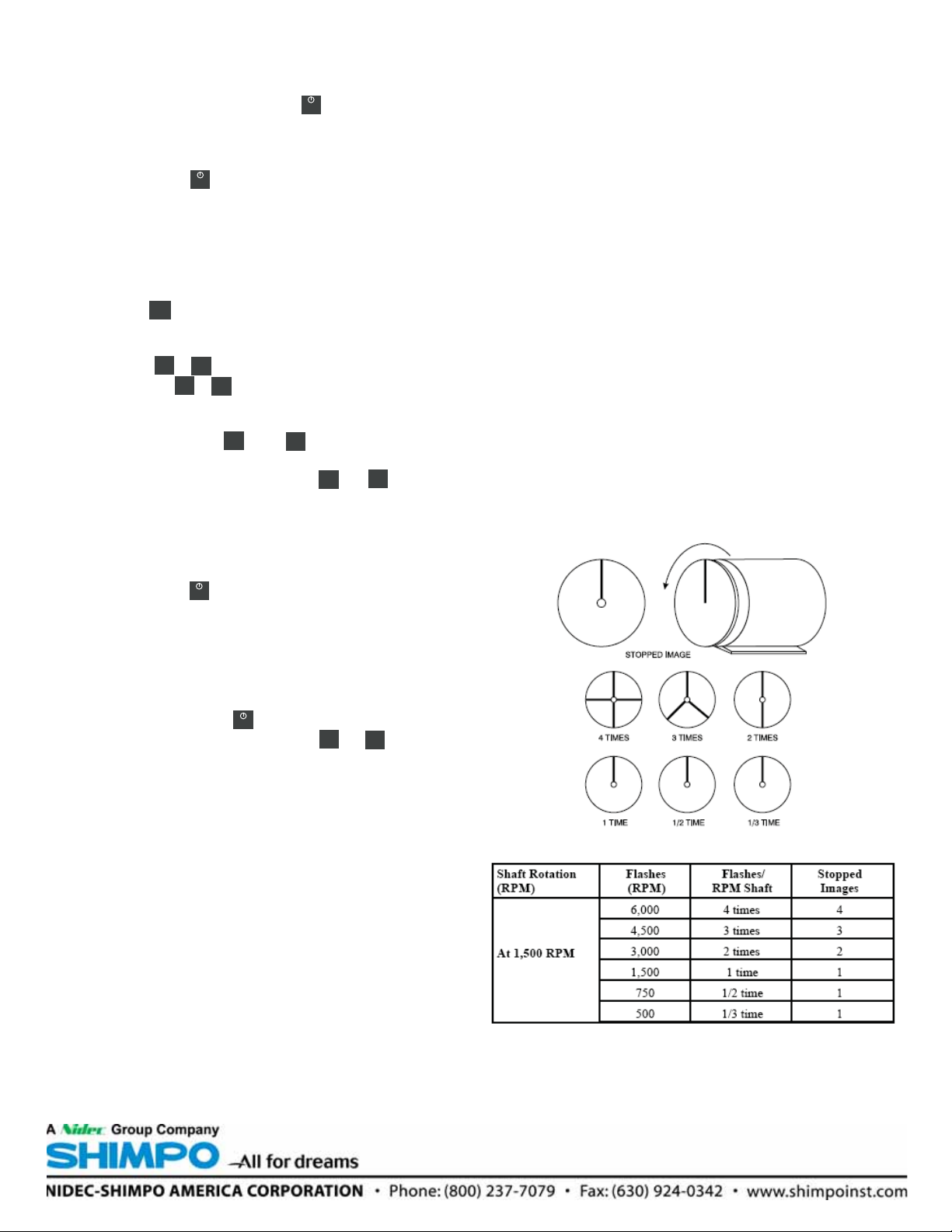

If the surface being viewed is uneven or contains asymmetric

texts, images or marks, the persistence of a pattern will become

obvious when the texts, images etc begin to slow down and become static. When the image or device moving appears static,

view the RPM on the display. This is the speed to record of the

system being viewed.

To utilize the ST-1000 as a T achometer and measure the true revolutions per minute (RPM):

1. Mark the object to be measured by either visually noting an

inherent distinguishing character, such as a label, scratch,

etc., or physically mark the object with a pen, tape or similar.

2. Turn on Power

3. Adjust RPM on display to highest setting

4. Push LED Flash Switch

5. Adjust the Flash Rate Value (RPM) downward

6. The true revolutions per minute (RPM) can be noted once the

action appears frozen and the first single image of the mark

appears (see chart and diagram below for further explanation)

7. To verify the revolution (RPM) reading, adjust the rate to half

the rate found in #6. If the image is again static after dividing

the rate in half, the RPM found in #6 is confirmed.

To retrieve and utilize the 10 Pre-Set flash rates (RPM’s), push the

Power/READ button . Each press of the button will cycle to

READ

the next successive Pre-Set value.

To save new Pre-Set Flash Rates into storage, adjust the speed

to the desired setting, then press the Pre-Set rate storage button

(F) in the center of the button panel. That rate setting will now be

stored into position 1 (4000) of the factory presets. To store values

in locations 2-10, press the button to view a factory Pre-Set

rate. Adjust to a new desired rate with the & adjustment

READ

UP

DOWN

buttons. Then, press the Flash Rate storage button (F) to override

the selected Pre-Set Storage rate position. Repeat to adjust the

remaining Pre-Set rate storage locations. The next time the unit is

turned on, the last rate stored will be displayed and ready for use.

To measure rotation speed, direct the light source onto the rotating surface of an object, observe the light spot and adjust the

flash rate. If the flashing frequency is adjusted to the same rotation speed of the object, the target object will appear to be static

or motionless when in actuality the equipment is still moving.

With a slight adjustment of the flash rate, movement can also be

viewed in an apparent slow motion. The operator can study the

process in action in either a slowed or static state to review for

proper performance.

Loading...

Loading...