CAUTIONS

�It is not safe to operate electrical equipment around water

if it is not grounded.

�Set Ball Mill on an even fl oor.

�Position idle shaft according to the size of the diameter of

Pot.

�Do not touch the rotating parts; drive shaft, idle shaft,

pulley, & etc. during operation.

�When the unit is switched to off and not in use, unplug the

unit from the power source.

�Do not wash POTMILL with water. Clear all dirt with

clothe when fi nishing operation.

�Do not damage the power supply cord. If the cord is

amaged, please contact the dealer to exchange.

The Ball Mill should be leveled. If it is not leveled,

the jar may fall of the ball mil during the

operation.

-The front left leg is an adjustable leg and can be

adjusted as follows,

1.Loosen hexagon nut with spanner (19mm).

2.Turn the adjustable leg and set the height.

3.Fasten the hexagon nut when the height is

horizontalized.

Allen wrench 4 mm 1 piece

TOOLS INCLUDED1

INSTALLATION2

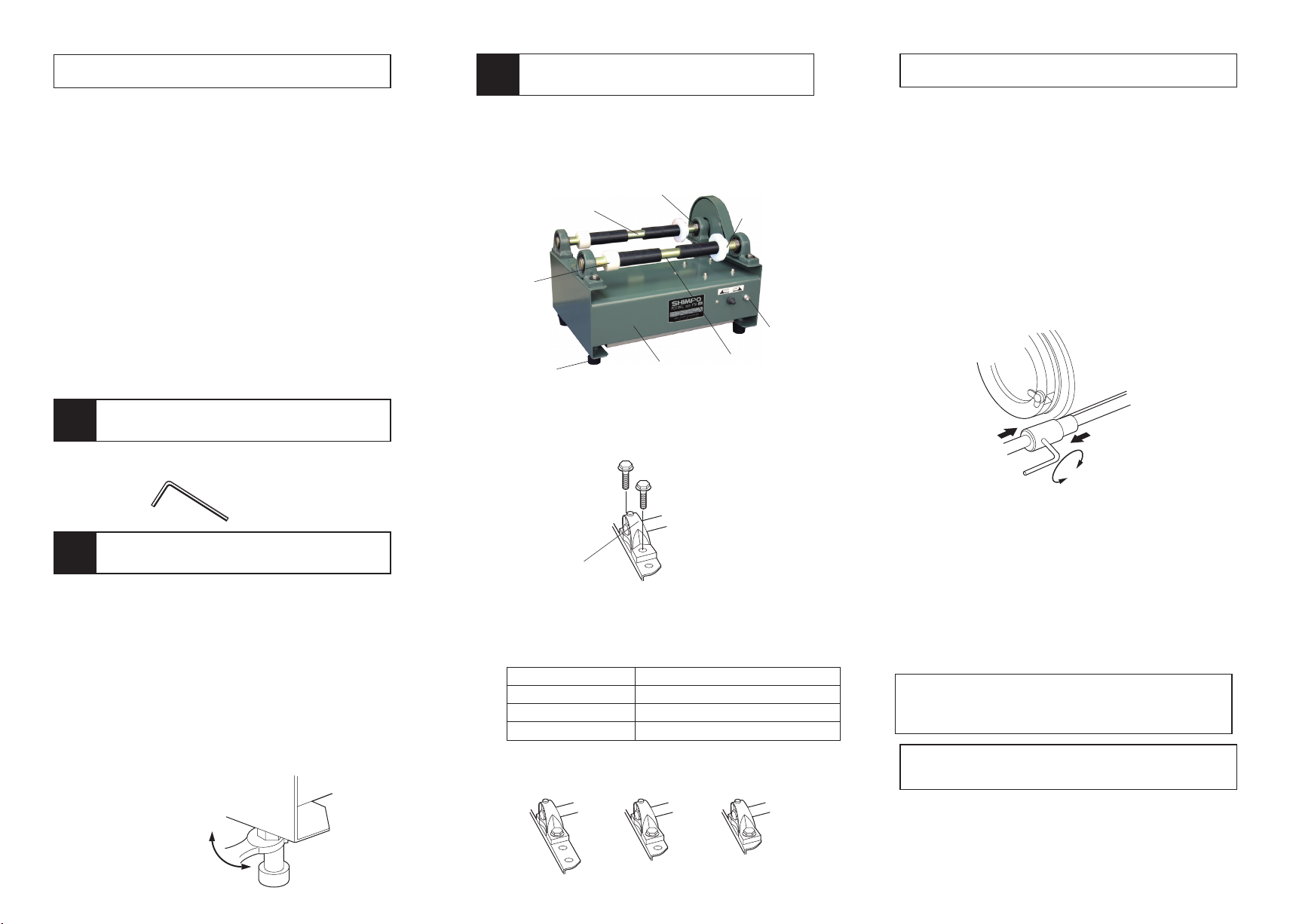

Adjust the drive shaft according to the size and diameter of

the jar by following these procedures.

1) With an open-end wrench (13mm), remove

4 hex. head bolts as shown in the Fig.

2) Adjust the drive shaft bars according to the size of the jar

being used. See the following table for sizes and distances

between the two shafts.

Jar size Distances between shafts

1 & 2 Liter A

2, 3 & 5 Liter B

5 & 10 Liter C

3.HOW TO ADJUST THE DRIVE

SHAFT

3

Place the jar on the rollers and adjust stopper.

1.Adjust the stoppers according to the size(s) of the jar

being used. With the allen wrench, loosen the set screws of

the two stoppers (these can be found in the mid-section of

the two shafts). Move the stoppers on the same shafts so

that the stopper comes to the bottom of the pot and fi rmly

fasten the setscrew again. Move the rubber rollers to the

stoppers.

Note :

When fi nished with the adjustment of the shaft and

stoppers, turn the jar by hand to confirm smooth

turning on the ball mil.

HOW TO ADJSUT THE STOPPER

NOW THAT PREPARATION IS

COMPLETED, SWITCH ON TO OPERATE

THE BALL MILL MACHINE.

WHEN THE BALL MILL MACHINE IS NOT

IN USE, SWITCH OFF AND PULL OUT

PLUG.

Drive shaft

Adjustable foot

Idle shaft

Stopper

Breaker

Bearing B

Bearing A

Frame

Bearing B

B CA

looser

tighter

Ad justable foot

B E L T T E N SION A D J U S T M E N T

4

A N D R E PLAC E M E N T OF BE L T

H O W T O A D J U S T T H E

5

B E LT T E N SIO N

92871B

Check following points to decide whether to adjust or

replace belt.

1) Switch OFF and pull out plug. Remove belt cover

by removing 2 hex. head bolts (13mm) with a open

end wrench

2) Push belt in the bid section between pulleys to

measure loosens of belt.

Looseness is about 10 mm, tighten belt

Looseness is within 5 mm, loosen belt

Looseness is over 10 mm, tighten belt, or replace belt

with the new one.

With the open-end wrench 10mm, loosen 4 motor

fixing bolts and move motor toward the arrow

marked

Keep the looseness of belt between 0.5 mm and 1.0

mm when pushing belt in the mid. section between

pulleys.

6

1) With the screw driver, remove belt from larger

direction to increase the tension of the belt.

H O W T O R E PLAC E T H E B E L T

( u s e V-b e l t # M 3 2 )

pulley fi rst.

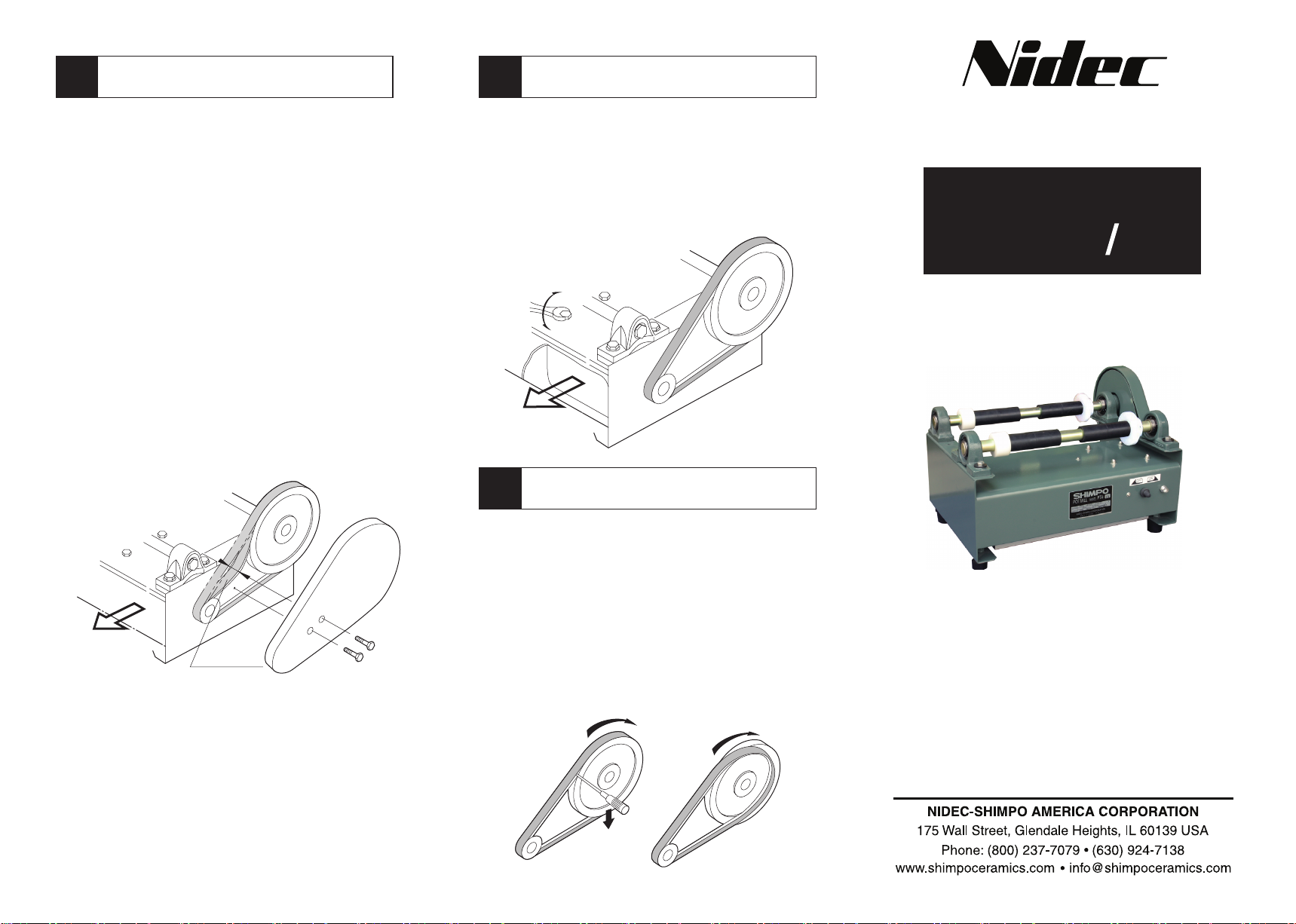

BALLMILL

MODEL

PTA-01,02

INSTRUCTION MANUAL

0.5cm~1cm

■ABOUT THE BREAKER

If jar (s) is/are too heavy, the breaker will activate

automatically. If this happens, turn off the power supply

and remove the jar, then push the breaker all the way.

2) Assemble belt in reverse sequence starting to

place new belt #M32 from the smaller pulley

fi rst. Adjust to keep the looseness between 0.5

- 1.0 mm Measure the looseness by pushing the

belt in the middle of the two pulleys.

21

Manufactured by

NIDEC-SHIMPO AMERICACORPORATION

1 Tereda,Kohtari,Nagaokakyo-city,Kyoto,Japan

Phone:(075)958-3608 Fax:(075)958-3647

1701 Glenlake Ave

Itasca, IL 60143

800-237-7079

www.shimpoceramics.com

Loading...

Loading...