Shimpo MFD-03, MFD-05, MFD-04, MFD-02, MFD-06 Instruction Manual

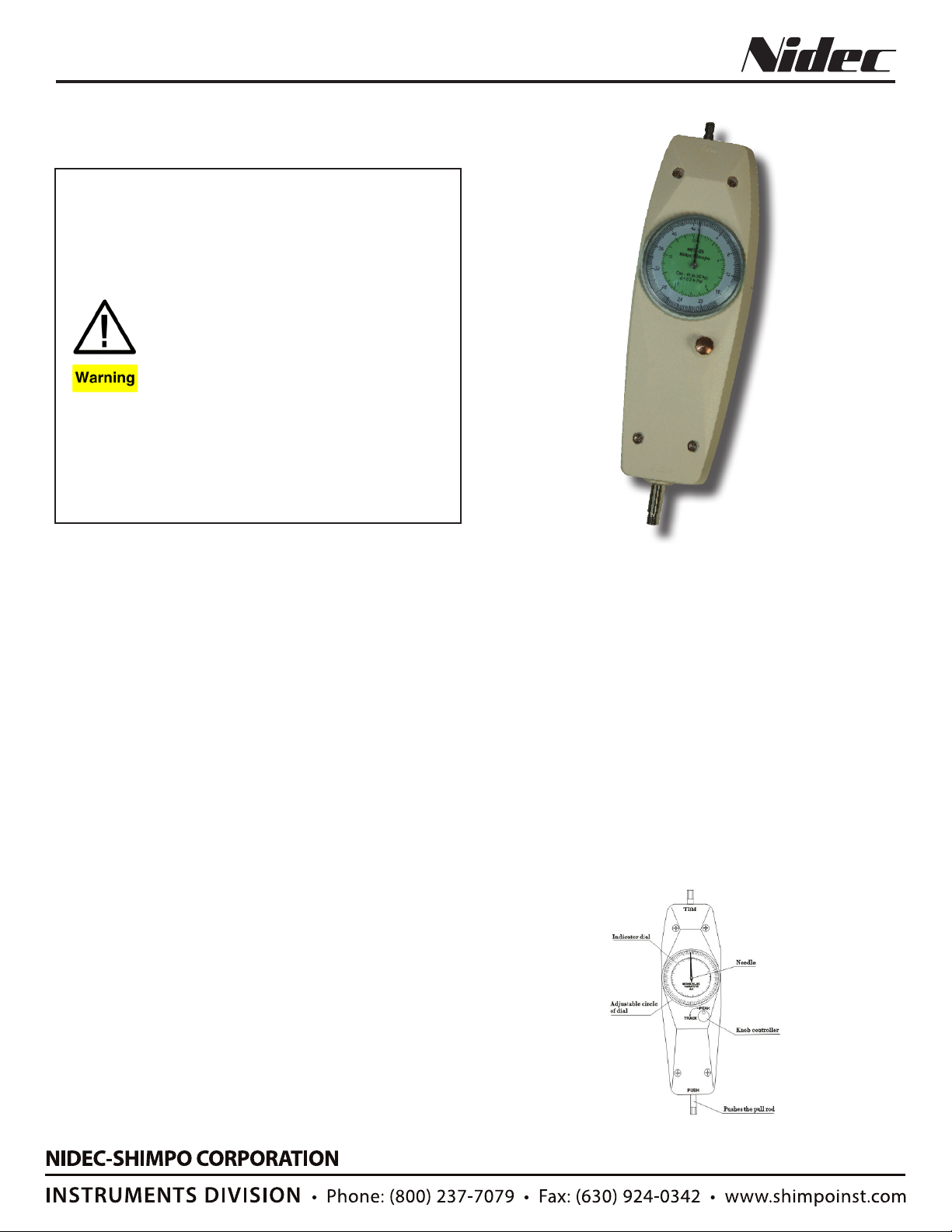

Series MFD Analog Force Gauge

Operation Manual

Do not operate or store instrument in the following

locations:

Explosive areas, near water, oil, dust or chemicals; areas where the temperatures can exceed 104°F

(40° C)

Take precaution to not drop the force gauge. Damage

to the sensor may occur.

Do not modify, disassemble or attempt to repair the

unit. Send to the factory for proper repair.

If upon delivery damage to the unit is detected, do not

operate the unit. Notify the shipping carrier immediately to obtain damage claim instructions.

Only measure forces that are in line with the measuring shaft. Do not attempt to take any measurements

(tension or compression) at any angle. Failure to keep

measurements in line will damage the instrument.

Do not exceed capacity of unit.

Accuracy may be affected if unit is exposed to high

humidity, dust or extreme shock.

The MFD Series Analog Force Gauge with compact size are easy

to operate and convenient to carry. They display the units of lb and

kilogram at the same time. The PEAK/TRACK knob allows the user

to easily switch between peak load testing or continuous load testing. The MFD’s are excellent products which are widely applied in

electric, electric appliance, hardware, automobile parts, lighter and

ignition system, light industry, mechanical, textile and a many more

for testing of compression or tension, insertion force, or destructive

analysis. Please read the manual carefully before using this instrument.

When vertically placed to use, especially when installing attachment,

do not apply load as needle will move from the dead weight result of

the attachment. Re-zero dial so zero [O] is aligned with needle. This

tares the attachment load for proper test results.

Note: If often exceeding max allowed capacity the internal operation

spring will gradually wear and lead to incorrect test performance.

Please do not overload to maintain life of the machine.

SPECIFICATIONS

Accuracy: ±1% F.S.

Display Analog: 2˝ in diameter (50 mm); rotatable 360˚ for taring

purposes

Live/Peak Mode: Selectable

Needle Update: Immediate

Threaded Insert: 4 on back for mounting inserts

Overload Capacity: 120% of range

Rod Travel: 10 mm (0.39 in)

Work Environment: No vibration

Product Weight: 1.25 lb (0.57 kg)

Package Weight: 2.2 lb (1 kg)

Warranty: 1 year

Included Accessories: Carrying case and attachments (flat

head, hook, chisel, notched head, cone head, extension rod),

mounting screws.

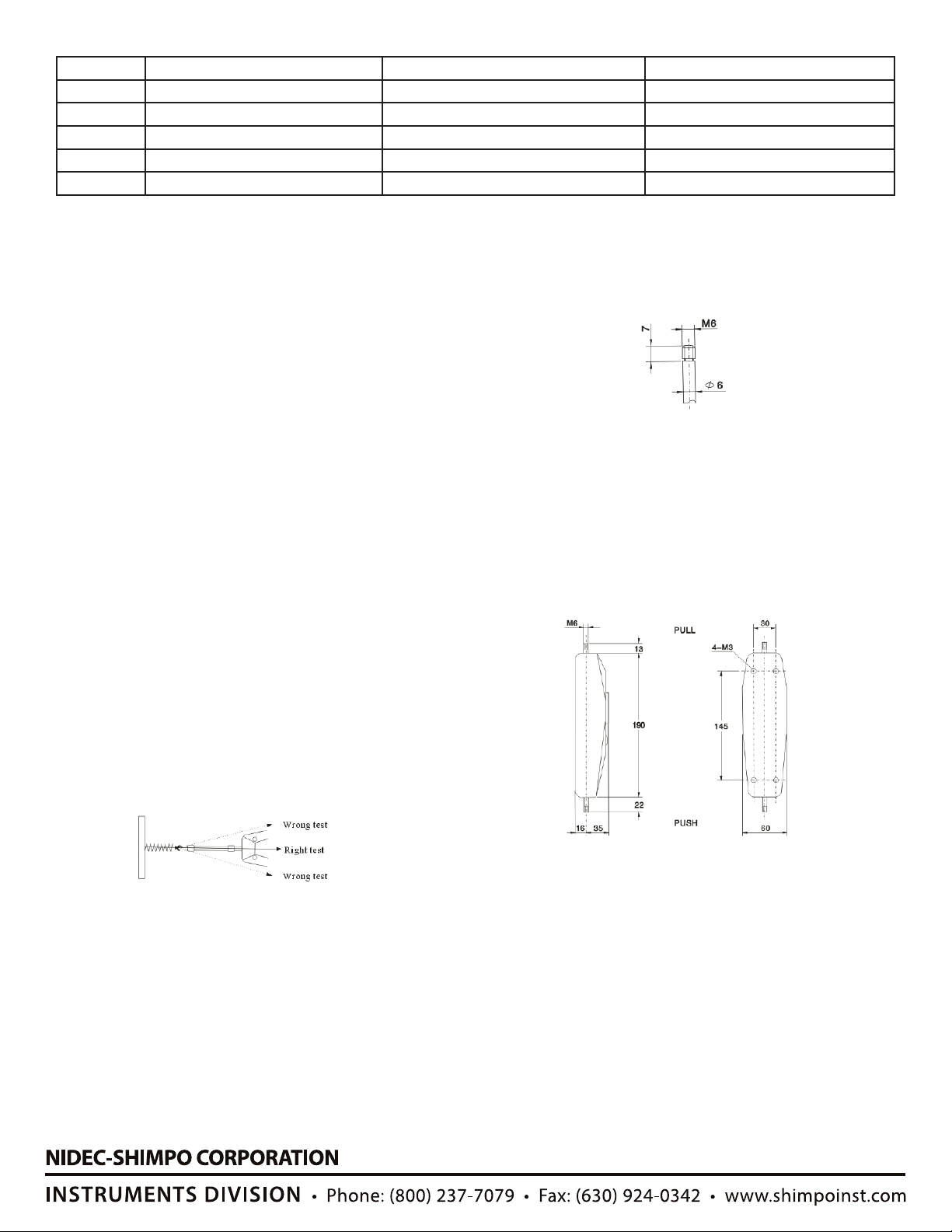

Model Range Capacity Resolution Min. Load

MFD-02 4.5 lb (2 kg) 0.02 lb (0.02 kg) 0.45 Ib (0.2 kg)

MFD-03 11 lb (5 kg) 0.05 lb (0.05 kg) 1 Ib (0.5 kg)

MFD-04 22 lb (10 kg) 0.1 lb (0.1 kg) 2.2 Ib (1.1 kg)

MFD-05 45 lb (20 kg) 0.2 lb (0.2 kg) 4.5 Ib (2.2 kg)

MFD-06 110 lb (50 kg) 0.5 lb (0.5 kg) 11 Ib (5.5 kg)

OPERATION

Preparation Before Test

Choose appropriate attachment and install it on the gauge before

test.

(1) Pull Test: Choose pull attachment and install it on the connector

marked [PULL].

(2) Push Test: Choose push attachment and install it on the connector marked [PUSH].

(3) Use of Extension Rod: When it isn’t possible to reach item under

test, add extension rod with attachment.

Note: When operating, tested object and gauge must be on the

same straight line. If not properly aligned, correct load values are

not possible and damage to gauge may occur.

(4) Confirm operation method by the location of the knob controller:

Changing from [PEAK] or [TRACK]: Lightly press knob inward, then

turn it to align dot on knob (•) with either [TRACK] or [PEAK] text on

the gauge.

Note: After testing, place the dot (•) in the [PEAK] location. If knob

is left in the place of [TRACK] for an extended period, the life of the

inner springs will shorten.

(5) Adjustments of indicator dial: Confirm needle aims at zero [O]

on dial. If not, turn adjustable outer circle of dial until needle aligns

with zero [O] on

gauge face.

Attachments

In order for the gauge to produce a stable value, please utilize included attachments. If your company wants to utilize its own attachments, please refer to size of attachment connector.

Maintenance

(1)Do not apply loads exceeding the max test range of gauge to

avoid damaging instrument..

(2)Do not put or use gauge in low or high temperature and humidity

locations. Please store and use it in the specified environment.

(3)If there is something wrong with gauge, please contact the original sales department you purchased from.

DIMENSIONS

Testing

(1) Please tightly hold gauge by hands or appropriate stands to perform test. When testing, please place tested object and gauge on

the same straight line. If they are not aligned, test will not be accurate.

(2) Change of load mode testing

(a) When knob controller is in [TRACK] mode, the needle moves in

accordance with changes in force.

(b) When knob controller is in [PEAK] mode, the needle records

Max. value of load and remains at that maximum force until pressing

inward on the controller knob. Once knob is pushed, the needle returns to zero position as long as the tested force is removed.

Loading...

Loading...