Page 1

Models FGS-50PXH

& FGS-50PXL

Programmable Motorized

Test Stand

Congratulations on your purchase of a Shimpo FGS-PXH or

FGS-50PXL motorized test stand. W e trust you will enjoy many

years of professional results from your Shimpo stand.

Please read the entire instruction manual thoroughly before initial

set-up and operation; the information contained herein will aid

you in operating your Shimpo stand safely and with excellent

results.

If you have any questions regarding our product(s), call your

local Shimpo representative or contact Shimpo directly for

assistance.

Features and Benefits

Shimpo's FGS test stands are designed for a variety of tensile

and compression force testing (up to 110 pounds) and feature:

• All steel construction guarantees durability and stability

for production, laboratory and quality contr ol applications

• Dual speed controls are optimally positioned to adjust test

and return travel rates of the drive assembly

• Drive assembly accepts an optional universal mounting

plate, enabling the interfacing of a large selection of force

gauge models (contact Shimpo for specific models)

• 4½ digit LED display indicates displacement or rate of

the drive assembly

• Analog output (labeled “Length Out”) is convenient for

data acquisition requirements

Inspection

If any shipping damage occurs, do not unpack test stand. Notify

shipping carrier immediately for damage claim instructions.

Refer to nameplate to con firm model number ordered and

record serial number for future reference. Items included with

test stand are:

• (3) M5 x 6 and (4) M4 x 8 screws

• (1) 5mm Allen wrench

Instruction Manual

Important Safety Instructions

• Position test stand on a level, heavy-duty and vibration

free table

• Confirm that the test stand case is properly grounded to

the AC line

• Keep hands, hair and jewelry away from stand when drive

assembly is in motion

• Operate the membrane keypad with care; do not use sharp

objects that may puncture the overlay

• Ensure that AC power is removed from test stand before

making any adjustments

• If LED indicates drive assembly has been overloaded,

immediately turn the power switch to the off position and

remove the overload condition (wait at least two minutes

before reapplying power to the test stand)

Set-Up

1. Plug in line cord and turn on power switch located on rear

of stand. All display segments and LEDs will execute a

power-up self test for two seconds. After the self test, the

4-digit display defaults to length which is displayed in

inches (0.00).

2. Metric units (mm) can be obtained by changing a dip

switch. The dip switches to control the measurement units

(switch #1) or the home position (switch #2) are located at

the top of the cutout for the cable ports in the side of the

stand (see page 2, display panel diagram, #27). It is possible

to raise and lower these switches using a small instrument

(such as a mini screwdriver). The stand must be reset

(turned off and on) whenever one of these switches is

changed.

NOTE: When dip switch #1 is in the up position, the stand will

display inches (0.00); when in the down position, it will display

millimeters (00.0). When dip switch #2 is in the down position

the upper manual limit switch is the home location. When in the

up position the lower manual limit switch is the home position.

Mounting Shimpo Force Gauges

With the 5mm Allen wrench, remove the mounting plate from

the test stand. For the FGE/FGV series use four M4 x 8 mounting

screws (supplied with stand) when mounting force gauge to

mounting plate. When mounting DFS series use three M5 x 6

screws (supplied with stand) to mount force gauge to mounting

plate. Reinsert mounting plate to test stand.

NOTE: Nearly all manufacturers' gauges are compatible with

the FGS-50PXH and FGS-50PXL when used in conjunction with

the optional UNI-Plate.

Page 2

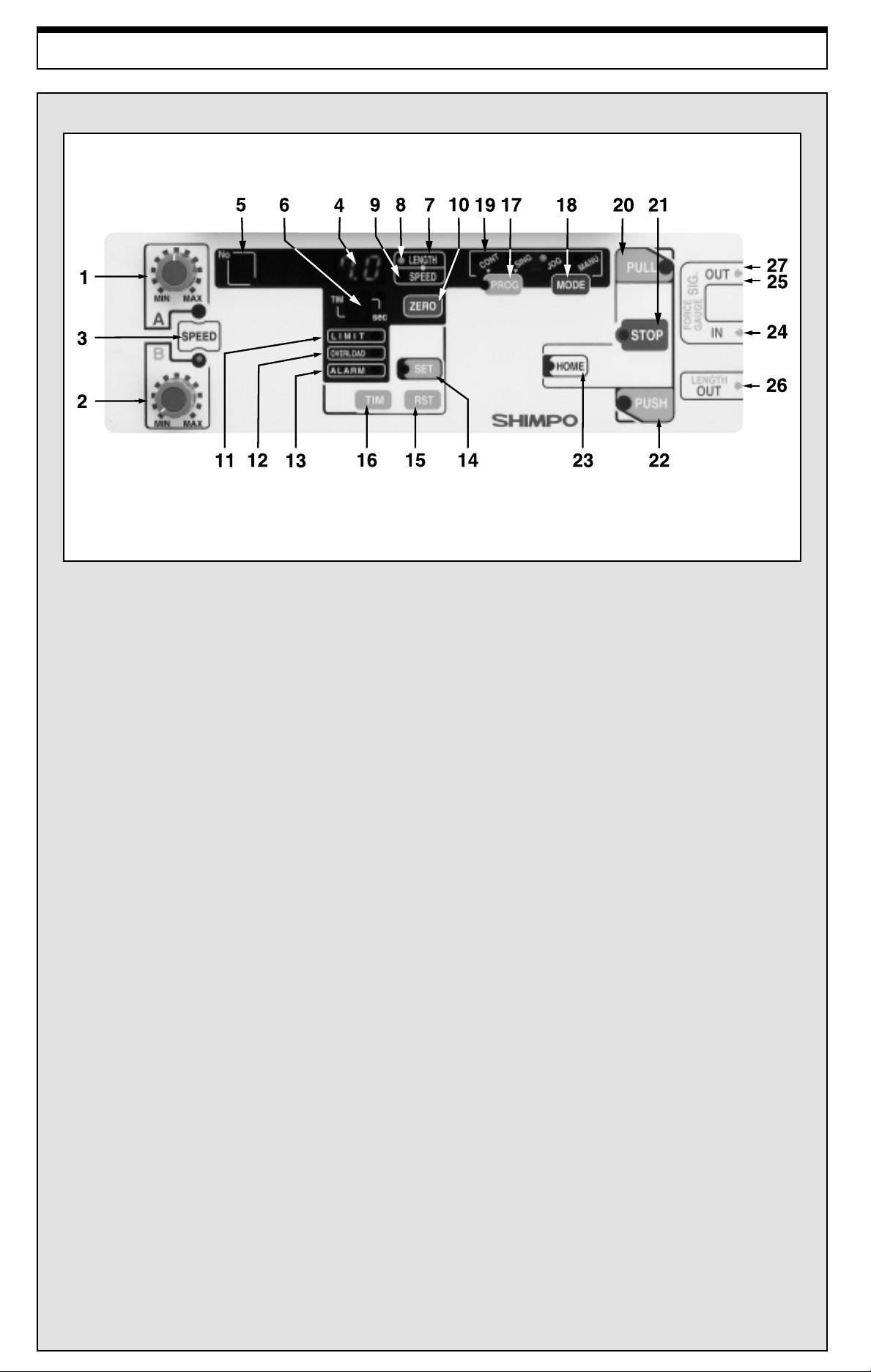

Display Panel

1. Speed A control knob: Changes the A speed of the force gauge plate

2. Speed B control knob: Changes the B speed of the force gauge plate

3. Speed select switch: Selects which speed control knob (A or B) is active

4. Movement distance/speed/cycle count display: Indicates movement distance/speed/number of cycles performed

5. Programmed point display: Displays program point (0-9)

6. Stop time display: Displays stop time when operating a program or cycle

7. Movement distance/speed/cycle count switch: Selects whether distance/speed/number of cycles performed is displayed

8. LED distance indicator: Indicates if distance is being displayed

9. LED speed indicator: Indicates if speed is being displayed

10. Zero switch: Resets distance measurement to zero

11. Limit switch LED: Indicates if one of the manual limit switches has been tripped

12. Overload LED: Indicates if the force gauge has been overloaded

13. Motor alarm LED: Indicates if the stand’ s motor has been overloaded

14. Program setting switch: Set program points

15. Setting reset switch: Clear and/or cancel a set point

16. Time set switch: Selects stop time for a program or cycle

17. Program switch: Selects a single program or a cycle program

18. Mode switch: Selects standard, jog, single cycle, or continuous cycle operation

19. Movement display LED: Displays type of mode or program operation

20. Pull switch: Begins movement in “pull” direction

21. Stop switch: Stops movement

22. Push switch: Begins movement in “push” direction

23. Home switch: Returns gauge to either the upper or lower manual limit switch

24. Force gauge input connector: Permits communication between digital gauges and the test stand

25. Force gauge output connector: Permits transfer of data from FGV series to computer when FGV is connected to the stand

26. Distance output connector: Permits connection for analog output voltage for distance/displacement measurement

27. English to Metric and home position dip switches (within communications cutout)

Page 3

Operation

Drive Assembly Control

Speed controls A & B can easily be adjusted and assigned to control

the test and return travel rates of the force gauge. The position of

the LED (A or B) determines which control is active.

The upper and lower travel limits can be adjusted by loosening

the thumb limit screws and sliding them to the desired position.

NOTE: Don’t forget to hand tighten the limit screws when the

desired position is reached.

Operating Procedures

The FGS-50PXH and FGS-50PXL feature two types of operation:

• Mode Operation

• Program Operation

Mode Operation

By pressing the “mode” button the LED will change between

four basic types of operation:

1. MANU - Stand moves in either the “push” or “pull” direction

(depending on the button depressed) and will continue to move

in direction selected until “stop” is pushed or until one of the

two manual switches are tripped.

2. JOG - Moves in either the “push” or “pull” direction as long as

the corresponding button is being depressed.

3. SING - Performs single cycles between the upper and lower

manual switches. The length of pause time (1-5 seconds) c an

be selected by depressing the “tim” button. The speed for the

“pull” direction will always be setting “A” and the “push”

dir ec t io n setting “B ” ( th e stand switches automatically). The

stand can run either compression or tension cycles, depending

on which direction the stand is in itially directed. The total

number of cycles run can be obtained by depressing the “length/

speed” button until there is no LED showing.

4. CONT - Same as the SING mode, except that the stand will

continuously cycle between the upper and lower manual

switches.

Program Operation

Before initiating the program mode it is best to adjust the speed

settings until each are at satisfactory levels.

The program will begin from the "home" position. The factory

setting for the home position is the upper manual limit switch.

NOTE: When dip switch #2 is in the down position the upper

manual limit switch is the home location. When in the up

position, the lower manual limit switch is the home position.

By pressing the “prog” button the LED will move between the

two types of program operation:

1. SING - The stand will run a single program.

2. CONT - The stand will continuously cycle through the

program.

The test stand is programmed as follows:

1. Press "home". This will be the starting position of the

program.

2. After selecting one of the two programs, press the “set”

button. The LED number in the far upper left corner of

the display will show a flashing “0” followed by a flashing

"-----".

3. Using the “push” and “pull” buttons, move the stand into

position.

4. Select speed “A” or “B” using the “speed” button.

5. Select the amount of stop time (in seconds) by pressing

the “tim” button. The LED will scroll through 1,2,3,4,5,P

(“P” stands for pause; the program will pause at this

position until either “push” or “pull” are pressed to resume

the rest of the program).

6. Press the “set” button again to store this first point. The

LED number in the upper left corner of the display will

change to the next digit.

7. To set the next point simply repeat steps 2-5. The LED in

the upper left corner of the display can display numbers 0-9,

up to ten potential set points.

8. When all points have been programmed, press the “set”

button again to store the program.

9. Press either the "push" or "pull" button to begin the program.

10. To cancel a set point, press the “rst” button while in the

“set” mode; press “rst” once more to move the next

programmed point into position.

11. If “stop” is pressed while the program is at one of its stop

positions, the entire program is canceled.

12. T o erase the whole program you must scroll through each

set point and erase them individually.

Input & Output Ports

Three communication/data ports are located on the right side of

the test stand. Use these ports along with the appropriate cable(s)

(optional) to download information from a compatible force gauge

and upload information to a compatible data acquisition device.

PORT 1: FGC.V.X Input Port

DFS Series (Requires DFS-CTRLCABLE) - Receives

overload information from a DFS series gauge. If an overload

condition exists, the drive assembly will stop, thus preventing

permanent load cell damage. As an added feature, the test stand

will stop at force setpoints when the "hi" and "lo" limits are

programmed on the DFS.

FGV Series (Requires FGV-CTRLCABLE) - When interfacing

to a FGV series force gauge, the test stand will receive overload

and measuring data. If an overload condition exists, the drive

assembly will stop, thus preventing permanent load cell damage.

NOTE: The force gauge must be turned on (display showing)

for the overload protection feature to work.

PORT 2: FGC.V Output Port

(Requires FGV-RS232 cable) - Transmits RS232C data to an

external device when a FGV series force gauge is mounted to

the stand (this port is not needed for the DFS series).

PORT 3: Length Output Port

(Requires FGV-ANALOG cable) - Transmits an analog output

voltage proportional to the length meter display . The relationship

between output and display is 10mV/mm. Since the length meter

data is generated by the test stand, this port can be used with any

force gauge mounted to the stand.

NOTE: If the LED display shows rate (mm/min), the voltage

output will still reflect length meter data.

Page 4

Troubleshooting

The stand does not turn on:

• Check all electrical components (power source, power cord, fuse, power switch, emergency cut-off switch)

The mounting plate (force gauge) does not move:

• Check manual limit switches and adjust accordingly

• Check to see if the full travel range has already been achieved

• Check to be sure you are in the correct operating mode

The stand will not accept my program:

• The mounting plate (force gauge) must be at the home position

Dimensions & Specifications

KEY:

mm

(in)

Model FGS-50PXH FGS-50PXL

Capacity 110 lb (50 kg)

Stroke 5.5" (140 mm)

Travel Speed Adjustable: 1.57-15.74"/min Adjustable: 0.39-3.93"/min

Display Four digit LED, 0.41" high (10.5 mm).

Power 120 VAC, 60 Hz

Weight 40 lb (18 kg)

OPTIONAL ACCESSORIES UNI-Plate, FGV-CTRLCABLE, FGV-RS232, FGV-ANALOG,

NOTE: The display ranges for length and rate are larger than what’s listed in the specifications. This is due to a

mechanical backlash which may occur if the drive assembly is subjected to excessive changes in direction.

(Horizontal - Standard) (Horizontal - Low Speed)

(40-400 mm/min) (10-100 mm/min)

Reads in inches (0.01 resolution) or millimeters (0.1 resolution)

DFS-CTRLCABLE, DFS-RS232 and DFS-ANALOG

Warranty

LIMITED EXPRESS WARRANTY: Shimpo Instruments warrants, to the original purchaser of new products only, that this product shall be free from defects in

workmanship and materials under normal use and proper maintenance for one year from the date of original purchase. This warranty shall not be effective if the product

has been subject to overload, misuse, negligence, or accident, or if the product has been repaired or altered outside of Shimpo Instruments’s authorized control in any

respect which in Shimpo Instruments’s judgment, adversely affects its condition or operation.

DISCLAIMER OF ALL OTHER WARRANTIES: The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY , and Shimpo Instruments hereby

disclaims all other warranties, expressed, statutory or implied, applicable to the product, including, but not limited to all implied warranties of merchantability and fitness.

LIMITATION OF REMEDY: Under this warranty , Shimpo Instruments’ SOLE OBLIGATION SHALL BE TO REPAIR OR REPLACE the defective product or part, at

Shimpo Instruments’ option. Shimpo Instruments reserves the right to satisfy warranty obligation in full by reimbursing Buyer for all payments made to Shimpo Instruments,

whereupon, title shall pass to Shimpo Instruments upon acceptance of return goods. To obtain warranty service, Purchaser must obtain Shimpo Instruments’ s authorization

before returning the product, properly repackaged, freight pre-paid to Shimpo Instruments.

INDEMNIFICATION & LIMITATION OF DAMAGES: Buyer agrees to indemnify and hold Shimpo Instruments harmless from and against all claims and damages

imposed upon or incurred arising, directly or indirectly, from Buyer’ s failure to perform or satisfy any of the terms described herein. In no event shall Shimpo Instruments

be liable for injuries of any nature involving the product, including incidental or consequential damages to person or property, any economic loss or loss of use.

MERGER CLAUSE: Any statements made by the Seller’s representative do not constitute warranties except to the extent that they also appear in writing. This writing

constitutes the entire and final expression of the parties’ agreement.

Loading...

Loading...