Page 1

Page 2

Product Overview

Thank you for choosing the FGS-200PV motorized test stand. Read this manual

thoroughly prior to operation. This holds important information on the test stand

and its various functions. Keep this manual accessible for future reference.

The FGS-200PV is rated for 200 lbs capacity. Some of the key features of this

stand:

• USB communication (USB 1.1)

• Force vs. Distance Graph

• Force vs. Time Graph

• Multiple test sets (separated by sets)

• Programmable functions (Top Load Test, Standard Test, Break Test)

• Intuitive graphing functions (Graph capture, cross hair point check)

• Standard functions similar to previous test stand (Manual, Single, Jog,

Continuous, Program)

• Software is included with USB and FGS-FGV-200P communication cable

Compatibility

The FGS-200PV is compatible with the FGV-X/FGV-200HX force gauges

(excluding the FGV-500HX and FGV-1000HX models).

This test stand is also designed to work with the new FGV-XY series

Note: The test stand communicates to the force gauge via special DB9 cable

(FGS-FGV200P) The baud rate of the test stand is set at 19200 baud, it is

required that the Force gauge attached should have the same baud rate set for

proper communication.

See software section for PC interface requirements

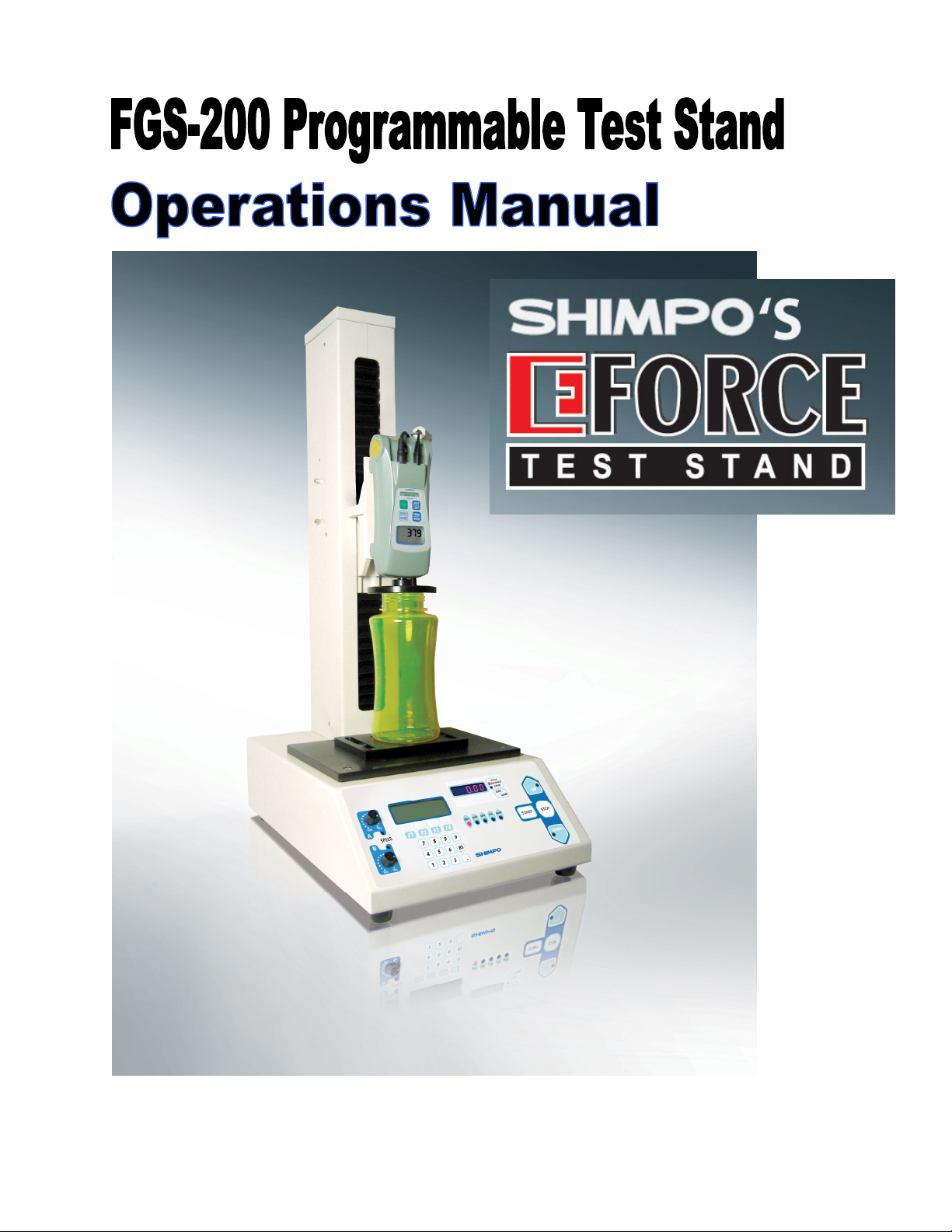

Description of Parts

There are two limit switches located on the side of the column. This limit

switches serves as mechanical stops for the force gauge bracket. This provides

a secondary safety stop in case of wrong entry on the program parameter.

To operate the limit switch, twist and push to slide in place.

Emergency Stop button located on the upper right section of the work table. This

is a master stop that will stop any movement and operation from the test stand.

It overrides all control functions from the test stand including software operation.

To reset simply turn counter clockwise and the button will release in place.

Page 3

.

Control Panel

Page 4

How to set up communication with the Test stand

1. Set the force gauge to 19200 Baud rate

2. Attach the force gauge to the mounting bracket

3. Attach the force gauge to the test stand using the FGS-FGV200P cable.

4. Important to follow the sequence of powering up the test stand

a. Turn on the Force gauge and allow initialization process

b. Turn on the force gauge, check if the model number of the attached

force gauge is reflected momentarily on the LCD.

c. Press Reset to reset to acknowledge the communication of the

force gauge.

Note: If the model number of the force gauge is not shown

a. Check the communication cable if it is firmly in place.

b. Verify if the force gauge is set to the right baud rate

c. Restart the power up procedure make sure that the force gauge is turned

on first before the test stand.

5. Choose the HOME position and press the ZERO/HOME button to accept

the new HOME position.

6. Using the function keys (F4) select the required MODE for testing. Each

time F4 or MOD button is pressed a corresponding LED indicator lights up

on the front display indicating the mode of the test stand. Pressing F4 or

MOD button after PROG, allows the user to go to the unit selection set

up. The following settings can be changed.

a. Distance – Millimeters or English units

b. Force – kg, lbs, N, oz, g (selection varies depending on the

attached force gauge).

Note: Pressing the F4 or MOD button after changes are made, scrolls

thru the available selection.

The Function keys changes selection depending on the window displayed.

Description of Different MODEs

1. MANU (Manual Mode) The simplest mode from the test stand. This

allows the user to reposition the force gauge bracket anywhere in the

column. Can be used for simple testing where one direction for test is

required.

Available Set up Options

a. Force limits can be entered to stop the test stand from moving.

Entering zero value disables the force limit function.

b. Speed is selected based from SPEED A or SPEED B. (Operation –

manual adjustments using the speed knobs).

Operation: The test stand moves based from the selected direction for test.

The test stand will continue to move towards the selected direction until

one of the conditions are met:

• One of the Limit switch has been activated

Page 5

• The STOP Button is pressed

• The set forece limit has been breached.

2. JOG (Jog Mode) Adjustment mode the test stand bracket will move based

on the activation of the UP and DOWN button. Unlike Manual Mode the

test stand bracket will stop as soon as the direction buttons are depressed

(momentary movement)

3. SING (Single Mode) Single operation for both direction. The test stand will

not only perform compression , but tension as well. The value for P1 and

P2 are based from which direction buttons is first pressed.

Available Set UP Options:

• Force Limits for both direction

• Dwell or hold time after the required distance or force had been

detected

• Tare function.

Operation: The test stand will perform one complete set of compression

and tenstion test.

Note: The test stand speed is manually adjsuted from the speed knobs

The test stand will move to the first selected direction then afterwards

move to the opposite direction.

4. CONT (Continuous Mode) this is similar to Single mode with multiple

cycles.

Available Options

• Force Limits for both direction

• Dwell or hold time after the required distance or force had been

detected

• Tare function.

• Speed can be entered using the key pads

Operation: The test stand will perform repeated sets of compression and

tenstion test. Ideal for fatigue testing.

5. PROG ( Program Mode) There are 3 program modes set to the test stand

a. TOP – Top Load Test

b. STD – Standard Test

c. BREAK – Break Test

TOP Load test is designed for bottle testing where a required amount of force

is needed within a particular displacement.

Under this mode there are five optional test points, which can be programmed

for down or up direction.

Page 6

NOTE: Entering a zero value for distance on any of the test points disable

that particular test point.

Available Set up Options:

• Threshold – this value is used to determine if the compression plate

made contact with test sample. It is recommended that a max

value of 0.2% of FS be used as the threshold value for testing.

• Cycles – number of repetition for test that requires more than one

test to be performed on a particular cycle. Max cycle from the test

stand can be set to as high as 9,999 times.

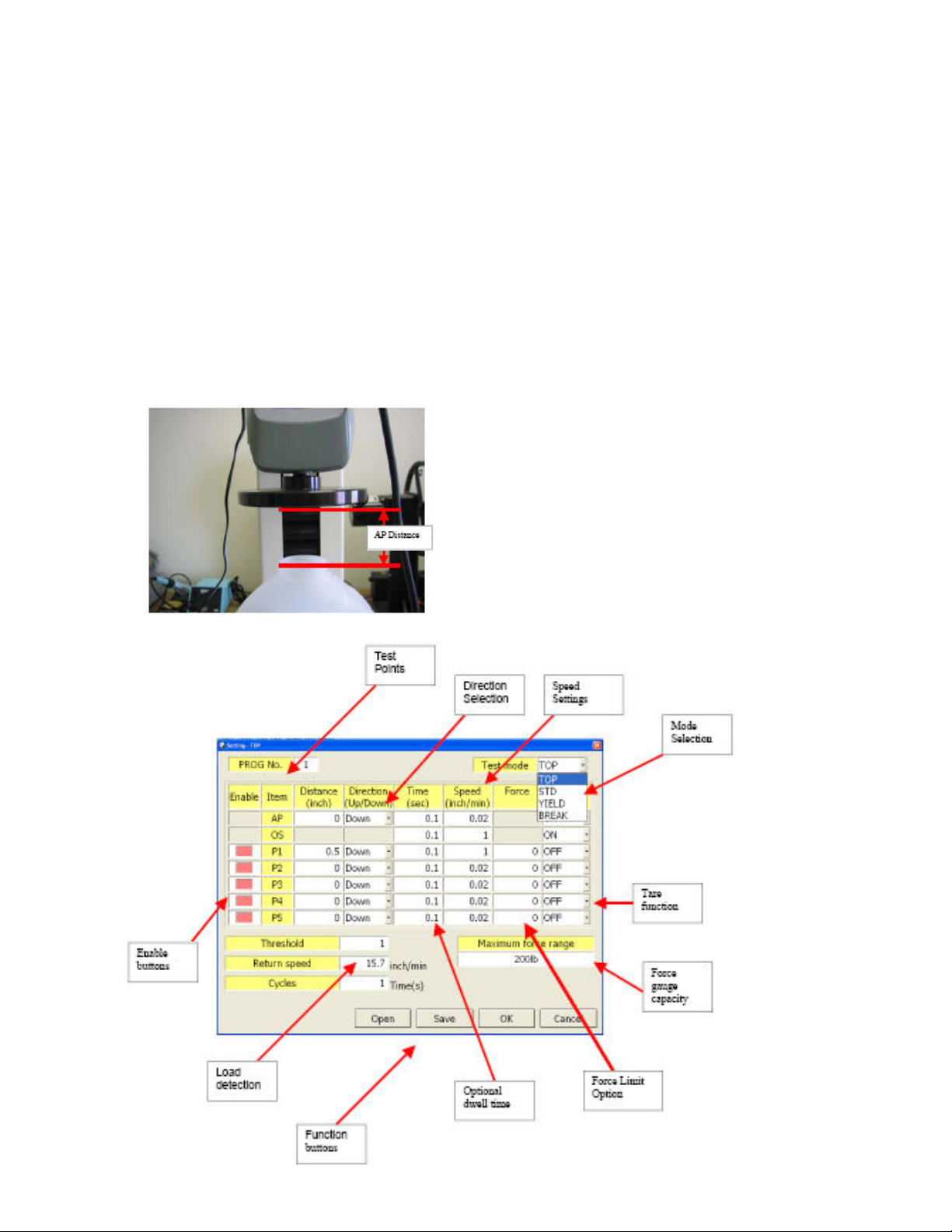

• AP (Approaching Point Distance) - Approaching distance from the

set HOME position. This function is very useful for testing samples

with different heights. Setting the value to “0” disables this function

and sets the threshold value as the main control for determining

where the test points starts (P1—P5).

• Force – force limits to prevent the force gauge bracket to move

forward or backwards once the set force has been detected.

• Direction – UP or Down direction for testing.

• Time – or Dwell time once the set distance has been reached.

STD or Standard Mode

This is the same as the regular test stand, allows users to have a preload value

to be set on the test stand to simulate real application conditions.

Similar to the TOP load test it has the same parameters and available options

with the absence of the threshold value which is replaced by PL or preload.

• Cycles – number of repetition for test that requires more than one test to

be performed on a particular cycle. Max cycle from the test stand can be

set to as high as 9,999 times.

• AP (Approaching Point Distance) - Approaching distance from the set

HOME position. This function is very useful for testing samples with

different heights. Setting the value to “0” disables this function and sets

the threshold value as the main control for determining where the test

points starts (P1—P5).

• Force – force limits to prevent the force gauge bracket to move forward or

backwards once the set force has been detected.

• Direction – UP or Down direction for testing.

• Time – or Dwell time once the set distance has been reached.

NOTE: In both test types if the value for distance is set to zero the program

ignores that test point.

Important to have the HOME position predetermined before entering parameter

settings.

Page 7

If the AP or Approaching distance is set wrong and the force gauge detects a

force prior to its completion. The test sand will terminate and end the program

and will stop.

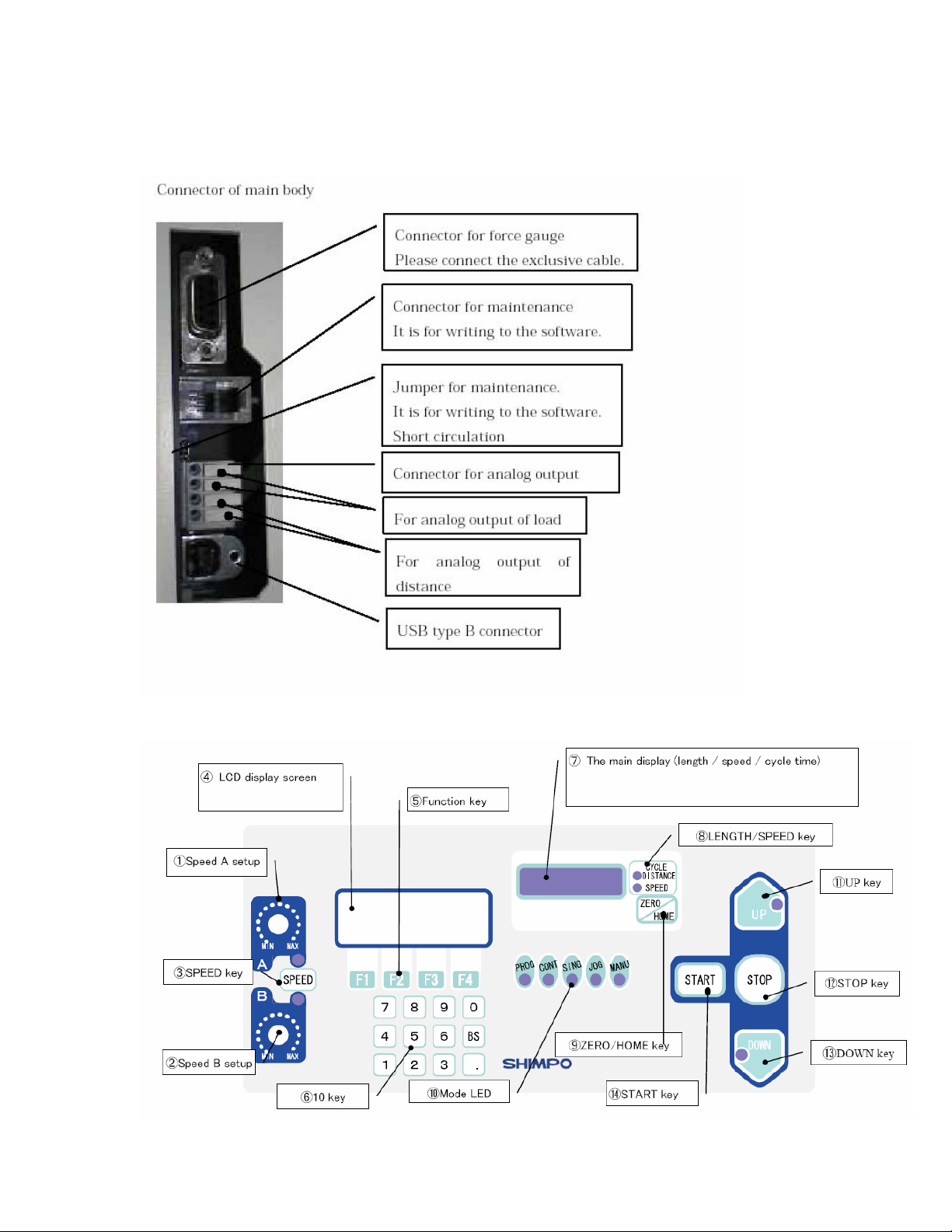

BREAK or Break Mode

The way the test stand determines the break point is to it detects the percent

drop from the Maximum peak value recorded.

MAXforce: 100g

Force

final_force is based on percentage of

MAXforce

Setting range : 0.5 – 100 %

MAXforce×final_force[%] = 100g x 10% = 10g

10g

100g – 10g = 90g, so after detect

90g

below 90g, test is finished. and

then, go back to start point

automatically.

100m

Tare ON/OFF

avairable.

From the diagram above the settings are as follows

Percent drop is set to 10 percent

Detected max value to be 100g

NOTE: Recommend not to set the percent drop less than 0.5%, this may trigger

false detection of the break point (Noise and vibration from the movement).

Distance

Operating Distance;

Page 8

Software for the FGS-200

System Requirements

• Minimum 512 RAM

• Windows 2000 (service pack 4) or Windows XP (service pack 2)

• 1 Gigabyte disk space

• USB 2.0 port

Materials

• FGS-FGV200P Communication Cable

• USB A to USB B Cable (6.6ft included in the test stand)

• Installation CD

Required programs:

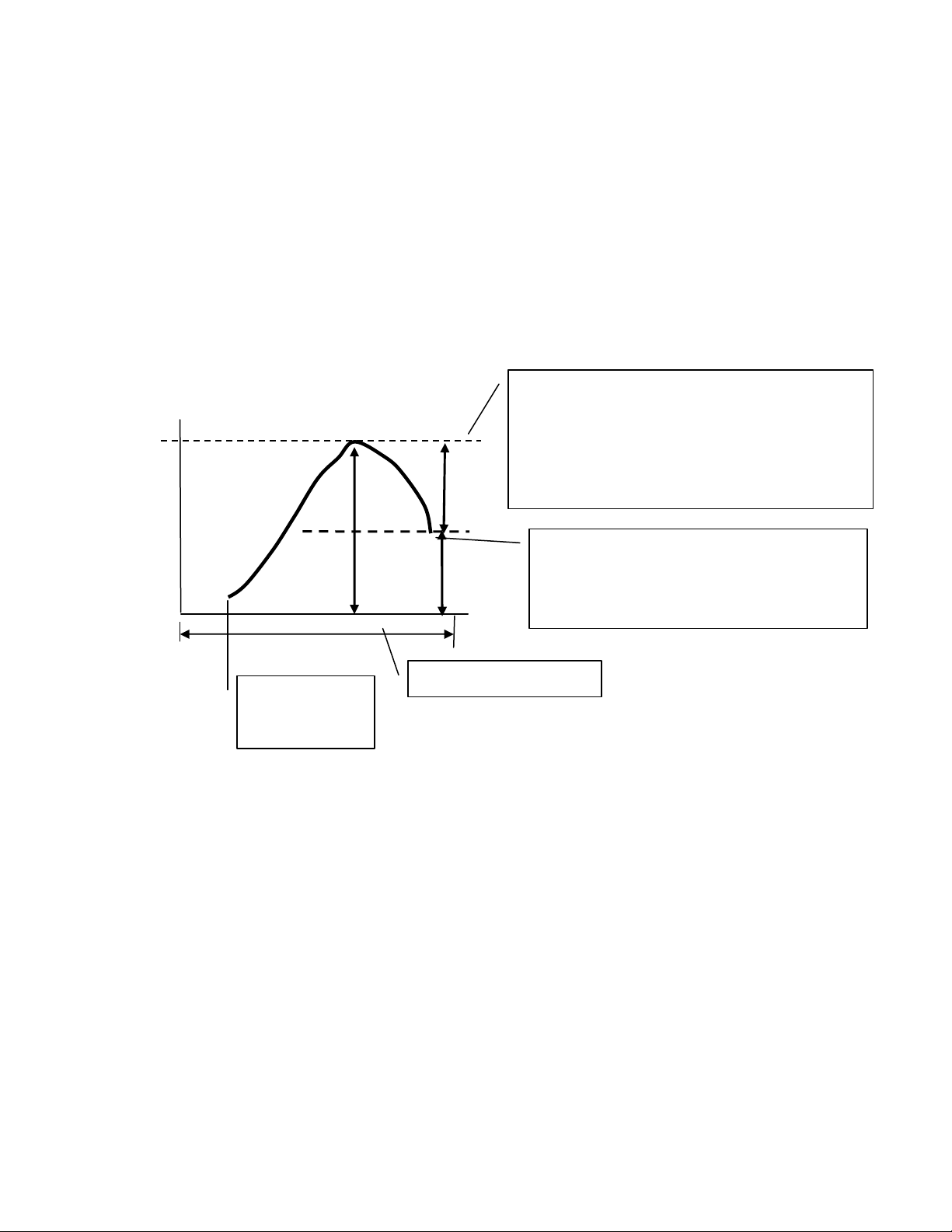

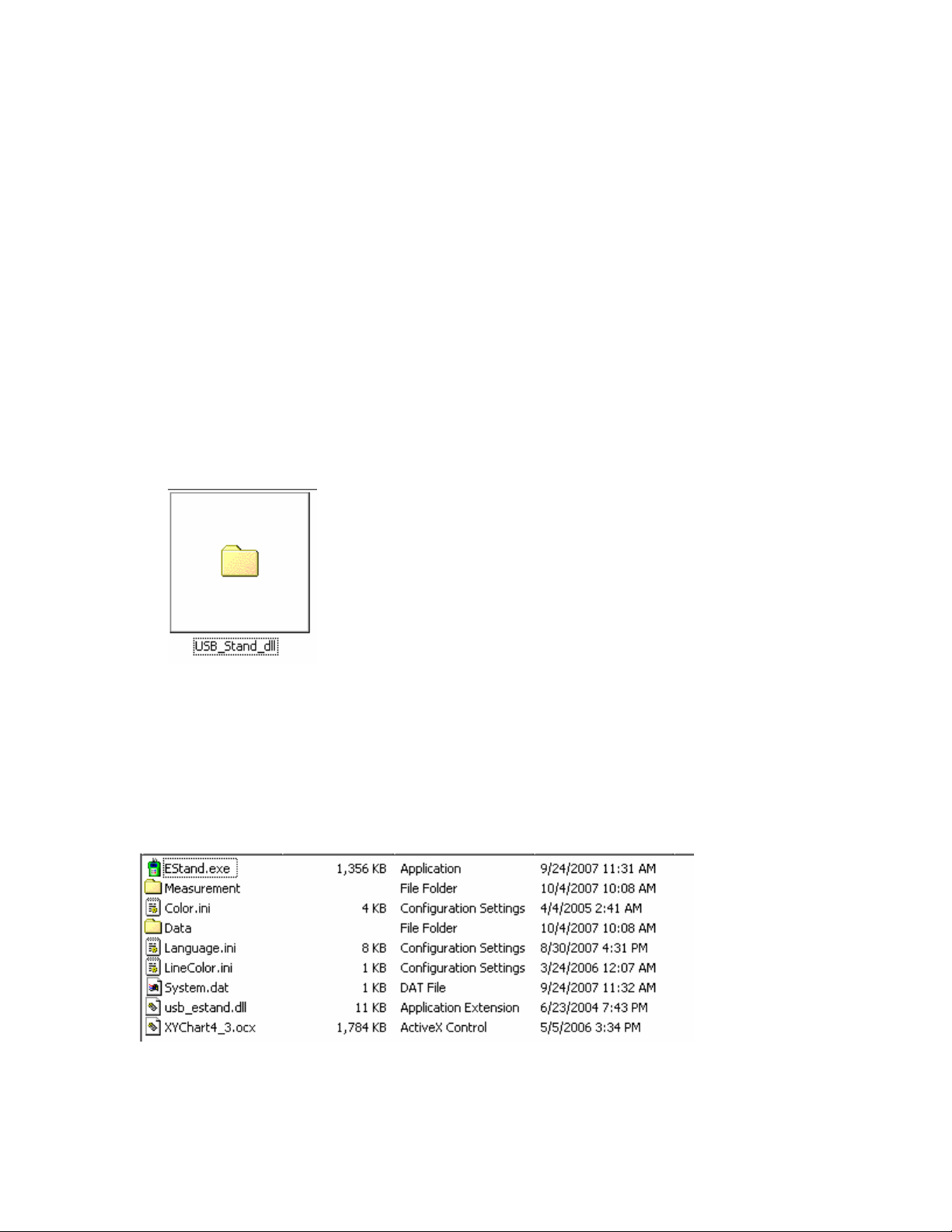

The installation CD should have the EStand_USB driver folder

Files in this folder

• Usb_estand.dll

• Usb_estand.inf

• Usb_estand.sys

Program folder should contain the following files.

How to install the USB drivers?

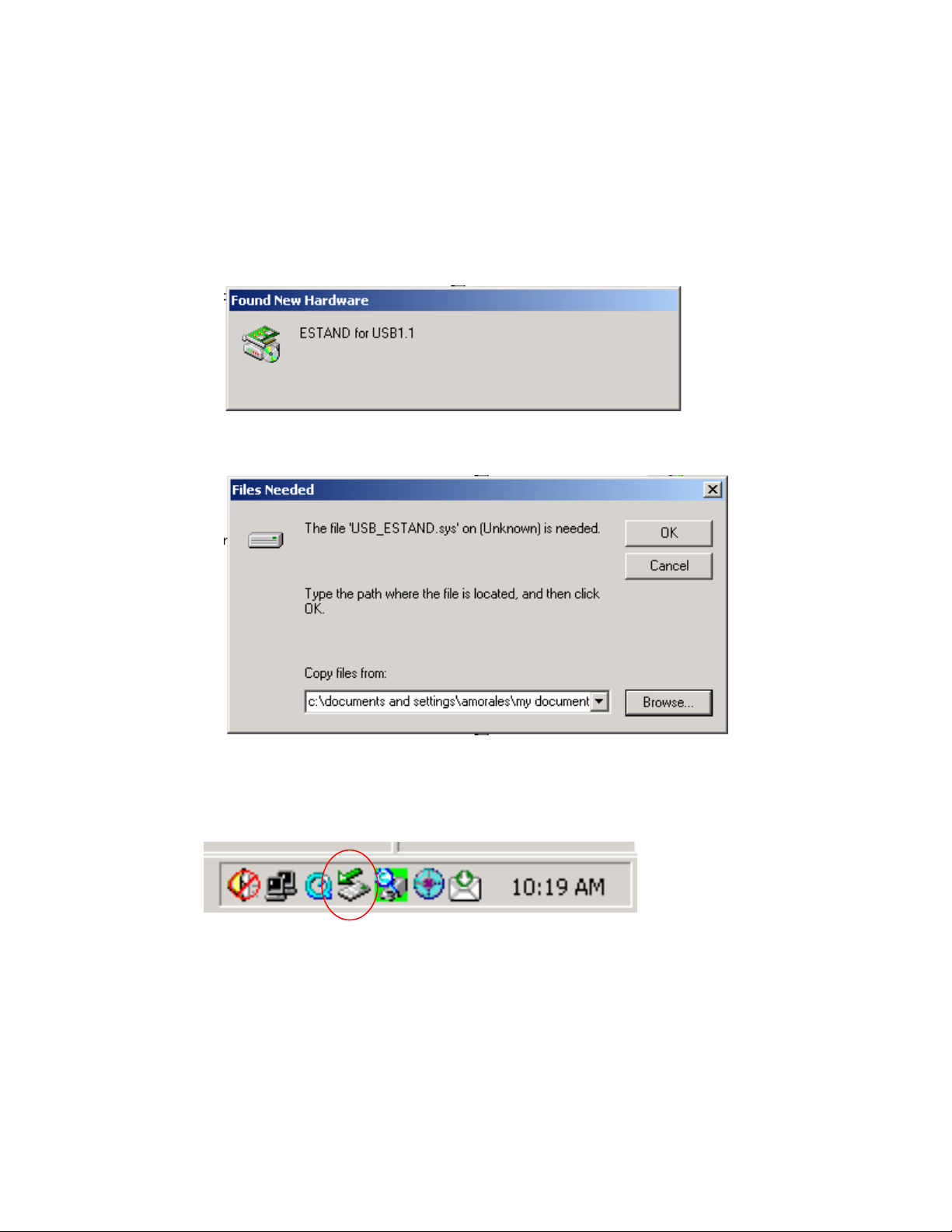

Page 9

There are two ways to install the USB drivers.

• Go the USB_Stand_dll folder and right click on the USB_estand.inf file.

Select install from the options available.

• Depending on the Operating system, you may need to install the USB

driver particularly on the USB port that will be used.

a. Plug in the USB cable and allow the computer to detect the new

hardware.

This will appear on the window after the USB connection is detected.

Please select cancel on this window and look for the icon for the USB

device located on the bottom of the screen.

b. Double click on the Icon for the USB device

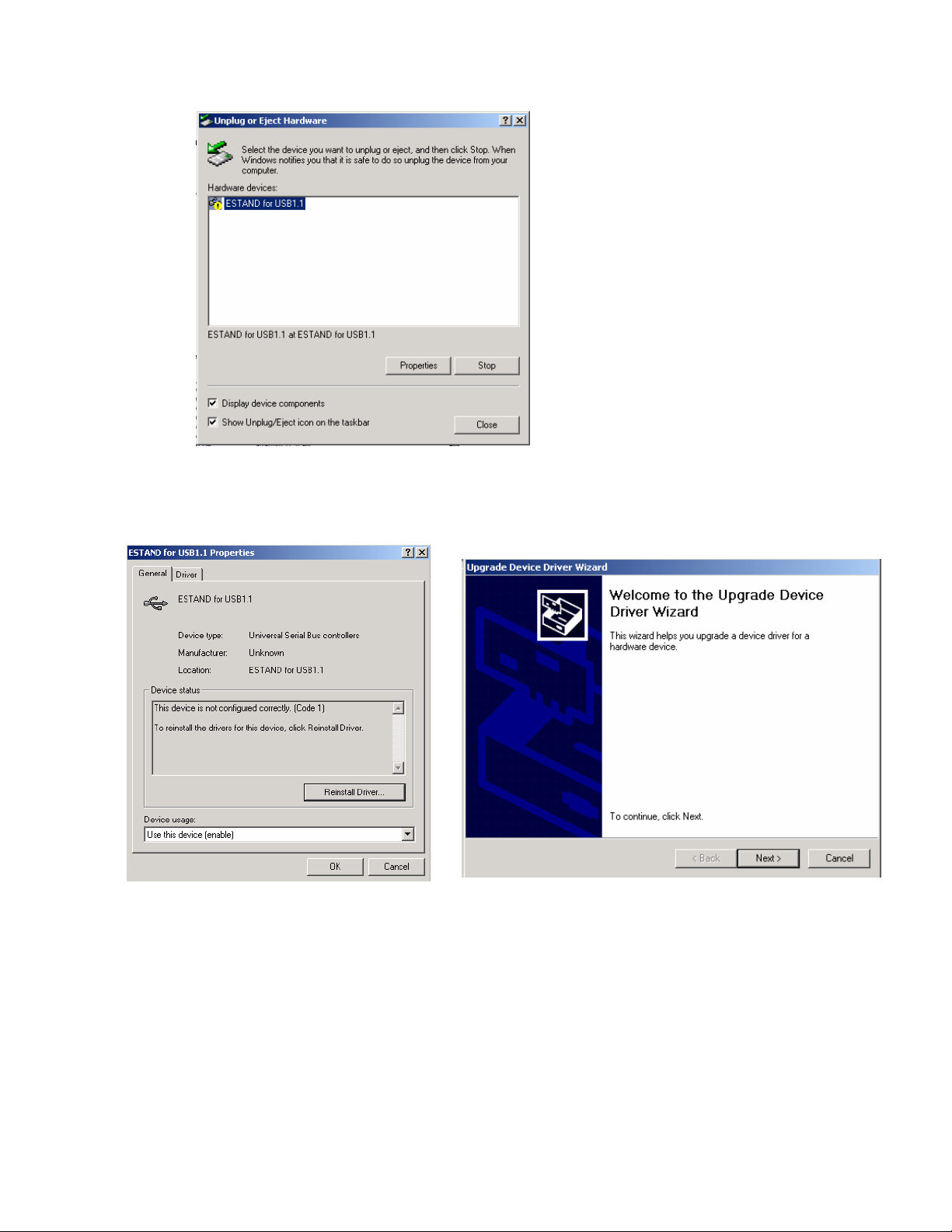

Page 10

This window will appear on the screen. The yellow mark indicates that the USB

device is not recognized.

c. Select properties

d. Select Reinstall Driver, and follow the Driver Wizard

e. Select Next to proceed. From the location of the device driver

select specific location as the option as shown on the next page.

Page 11

f. Select Next and Have a disk button, browse to the location of the

USB driver folder

Page 12

g. Select the usb_estand.inf file then open. This will install the driver

to the particular port where the test stand is connected.

Browse the location of the USB_stand dll folder.

Page 13

Select finish to exit and complete the installation for the USB driver.

To test the communication, go back to the software folder.

(Make sure that the icon for the test stand is extracted together with

the other files on the zip. This will prevent OCX and runtime error from

occurring).

Open the folder and select EStand.exe icon to open the program

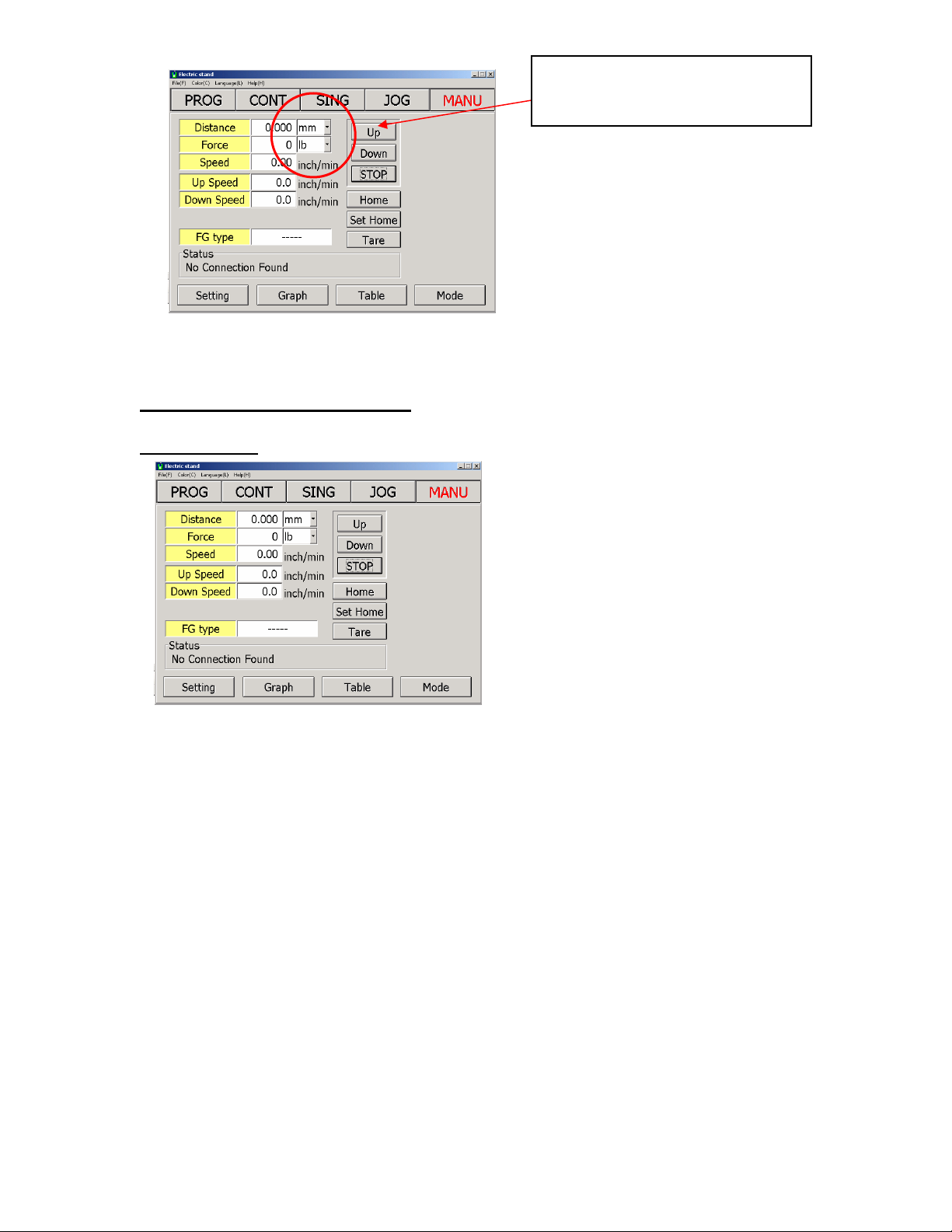

Page 14

The initial screen will appear within 5 seconds with the force gauge

type information.

If the program will not communicate an offline error will appear and the

force gauge information will not be reflected on the main screen.

• When this happens check the cable both the USB and the FGSFGV200P cable going towards the test stand.

• Sequence of powering up the devices are not correct. Turn off

the test stand and the force gauge.

o Turn on the force gauge

o Turn on the test stand

o Open the software

Note: If an OCX or runtime error appears, please check the Windows version

installed on the PC, this may need to be updated to service pack 4 for Windows

2000 and Service Pack 2 for Windows XP.

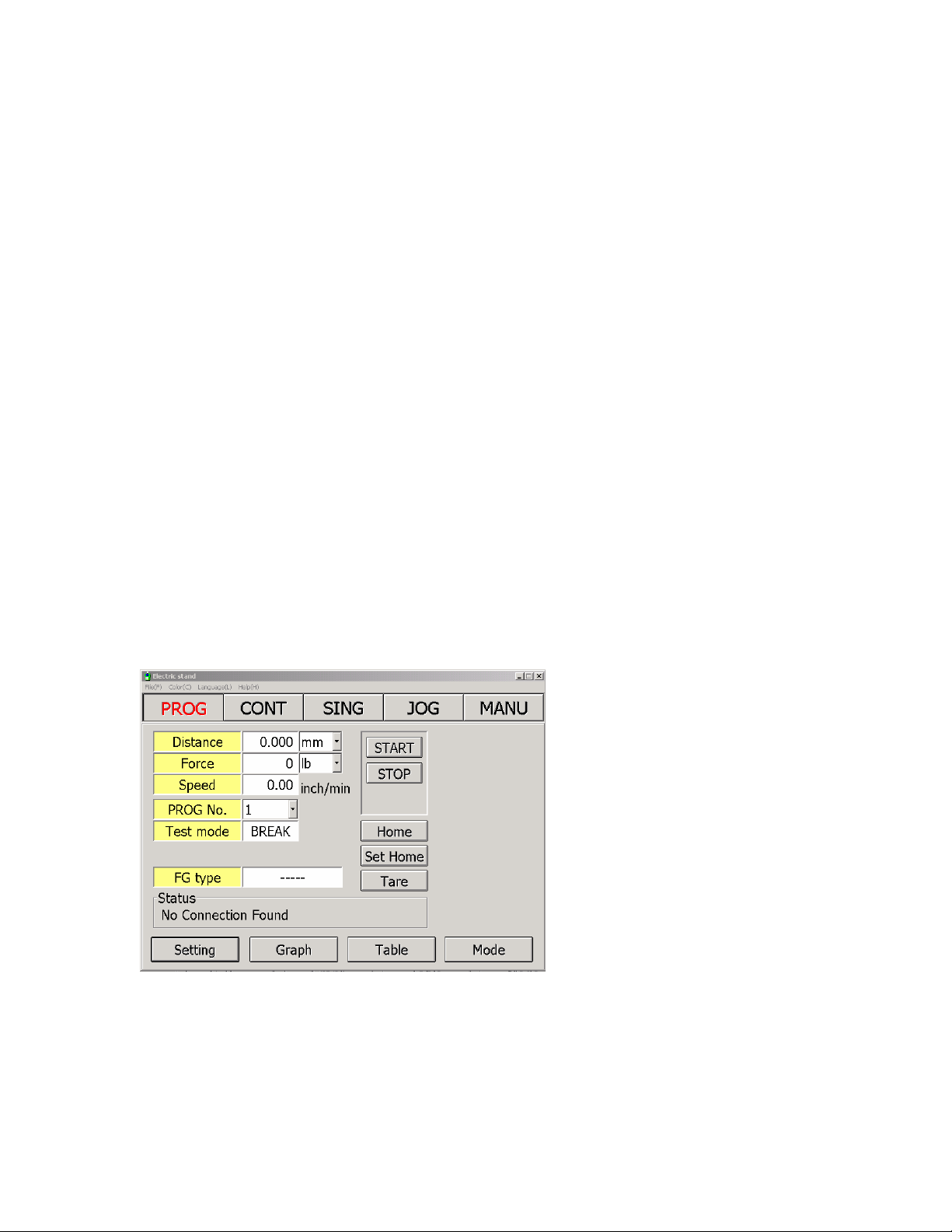

Description of the Software

Initial window

Initial Window holds information on the software version and controller version. It

also works as a test for proper communication from the test stand to the PC.

Main Window

The main window is a software replica of the test stand front panel.

It holds information pertaining to the condition and mode of the test stand.

Page 15

Modes

Available Menu on the Main Window

• File - exits out the program

• Color Scheme - changes the color of the window and its peripherals

• Language – this will be a future update to reflect different language on the

main window. Current version English only

• Modes buttons are located on top of the window, selected mode is

highlighted in red (Screen above indicates that the software is in

Continuous mode).

• Status indicator and Status message indicates condition of

the set up

• Start and Stop button are available (depending on mode

selected)

• Tare function for zeroing out the force gauge and

initializing the test

• Set Home button for changing the position of the reference

point or HOME position.

• HOME button for immediate return to reference point.

Page 16

Operating State

How to select the units for force and distance?

From the main window the units can be selected and changed. Force and

distance fields contain drop down windows for units of measure available. For

distance the fixed units are millimeters or Inches.

For Force, units vary depending on the model number of the force gauge. For

small force capacity (FGV-0.5X – FGV-2X) the available units are (Oz, g, lbs, N)

For models higher than 2 lbs (Kg, N, Lbs)

NOTE: Each the units are changed the previously saved data on the test

windows are erased. Only the existing values are converted to the selected

units.

Page 17

Drop down selection box for

force and speed

1

Description of Different Modes

Manual Mode

Speed can be adjusted from the main window. Enter value on the UP and Down

entry box.

Manual Mode or simple UP/ Down Test has the following settings

Page 18

• Tension Limit force – sets the maximum amount of force allowed for pull

or tension test. Values entered have units based from the selected units

of measure from the main Window.

• Compression Limit force – sets the maximum allowed compression or

push force.

Setting zero values on the tension and compression limit force disables this

function.

If the limits are reached the test stand will stop operation.

The UP and Down buttons allows the test stand to move in the selected direction.

It will continue to move until one or more of the following situation occurs.

• Limit Switch Activated (HI or Low).

• Stop condition is requested

• Set Limit force detected.

A warning message will appear if the entered value is set beyond what the

attached gauge can measure. Caution is required to prevent damaged on the

force gauge.

Page 19

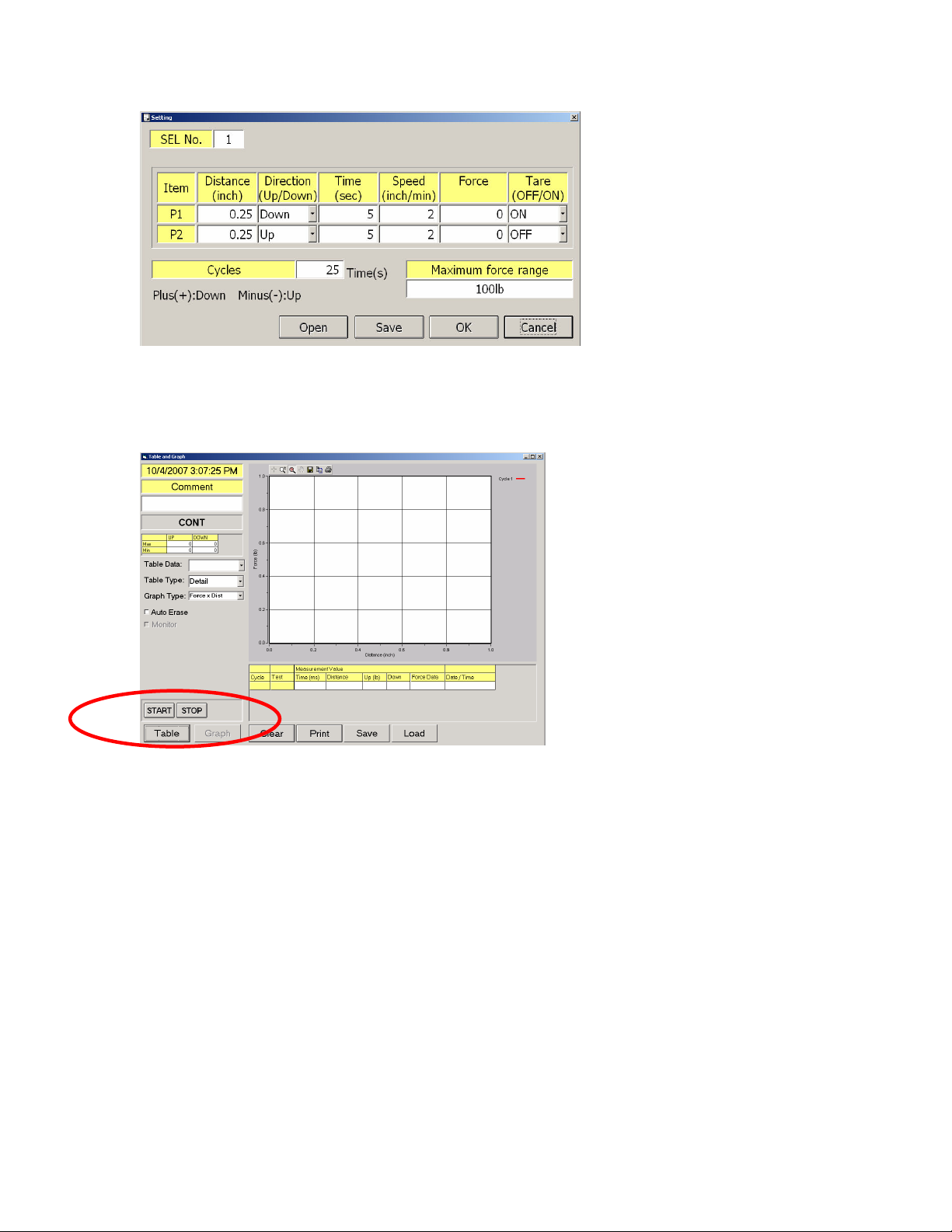

The graph has an extension of the control features of the main window. Data

can be observe as the test progresses.

Comments can be entered to easily identify results.

Table Data

Separates the values based on the number of cycles.

• Table Type, has two formats point by point data or a summarize data

where max min and average values are reflected.

• Time Stamping is available on all graph window.

• A small summary table is also available for immediate review of each

cycle

• Table button sets the graph in a table format without the graph options.

• Clear button acts as a master reset for the mode. It erases all previously

saved data.

• Print prints the current screen for easy portability

• Save records the data set and the settings for the current test

• Load, loads previously saved data.

Graph Type: Allows the following graph types to be displayed on screen

• Force vs. Distance

• Force vs. Time

Page 20

Note all saved data on the table can be retrieved using Microsoft Excel (.csv file

extension.

Jog Mode

Jog mode or simply fine adjustment allows operation of test stand from the front

panel. The force gauge bracket moves depending on the length of time the UP or

down buttons are pressed from the test stand front panel.

Single Mode

This test performs one complete set for both compression and tension test.

Speeds for UP and Down Direction are entered from the main window.

NOTE: Point 1 and point 2 is determined based from, which direction is first

selected.

Force gauge bracket goes back to initial position after the test is completed.

Page 21

Settings window for single mode allows additional functions such as

Tare function both for P1 and P2,

P1 and P2 hold time or dwell time

Graphing function similar to Manual Mode, where the data are separated into

cycles

Continuous Mode

Continuous mode can be used for fatigue testing of small plastic materials

It allows distance to be entered for 2 points (P1 and P2).

Directions can also be defined based on the application.

Time can be set to hold the position after the set distance is reached.

In addition to this function cycles can be entered to perform multiple cycles on

one test. Limitation on the number of cycles is based from the availability of

computer resources (RAM and disk space).

Page 22

There are five available settings that can be stored in the program. Each one is

assigned by number.

This features allows easy access for comparing results by switching programs

back and forth Cuts down set up time where experimental results are

compared.

Note: The reference point has to be established correctly prior to using the

program selection. If each test set up has different home position, the settings

has to be adjusted to accommodate this change.

Page 23

P1 and P2 are determined based on the direction.

Standard function such as force limit which is Force in Continuous can be found.

Speed of the test is set from the setting window unlike the previous two programs

where the adjustments are entered on the main window.

Start and Stop replaced the UP and Down buttons from Manual and Single

Programs.

Note: The test stand is rated for 9999 cycles, but the PC software may perform

less depending on the availability of resources from the host PC.

Tare function should also be observed when activated on P2. The force gauge is

designed to shift zero when requested to tare values under load.

Example

The force gauge is showing a compressed reading of 5 lbs when a request of

tare is sent. The force gauge will show zero while on load (0.2% of FS) but after

the test is completed and it goes back to home the force gauge will indicate -5 to

compensate for the zero shifts.

Page 24

Recommend to tare the force gauge prior to the test to minimize additional forces

added on the data table.

A legend for each graph is set to identity force curves.

Limited to 24 colors, then the software recycles the color to be used.

Program Mode

Main feature of the test stand, it has 3 different types

STD-Standard

TOP – Top Load Test

BREAK – Break Test

TOP Mode

Indicates the existing setting on the program

Enable buttons

Page 25

Test mode drop down window allows selection of test type

Enable buttons are also located on the setting window,

Red means enabled.

Threshold value can be entered which will determine the location of the top

portion of the test sample.

Note: if AP distance is set to wrong the program will terminate and exit out of the

program.

Zero values on distance will be ignored by the program even if there are time and

speed values entered.

Page 26

Standard Mode (STD)

STD or standard Testing works the same as a regular test stand with the addition

of the preload function.

The ideas is to have a preload value set to the test sample then start the test

from that initial condition.

Example springs with nominal force when attached to the end product being

tested for additional force

Non-Vibration rubber testing simulating conditions on a motor mount where initial

compression or shear force is present on actual application.

Cushion testing on the seals of a pneumatic cylinder.

The main window for Standard Mode is similar to TOP mode.

5 program settings can be stored on the program.

Page 27

Enable buttons

Standard mode is similar to TOP mode with the additional feature of allowing the

user to return to initial position after test and the preload function where force can

be entered to simulate actual conditions.

Pre-load setting

Return to Start point Option

Monitor function (available in program mode with 1 cycle)

Page 28

This function allows examination of results for long periods of time. It records

data and graph the max value on a particular date. This function helps in

quantifying the consistency of the end products.

Useful for auditing quality results over a period of time.

Note: If more than one test is performed in a day, it will only record the last

one and used that as the basis for the graph value.

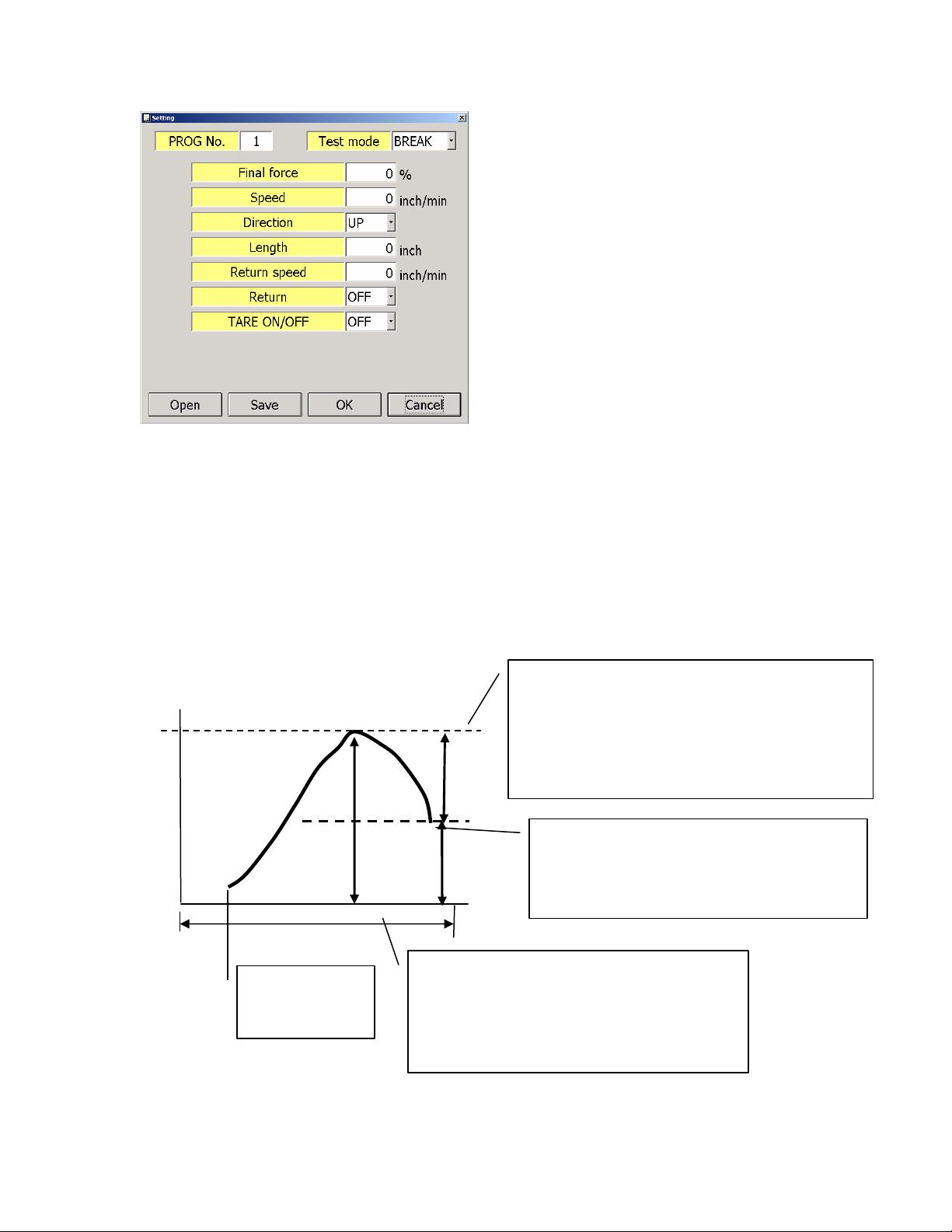

Break Mode

Break mode is defined in the FGS-200 program as a percent drop from the

highest recorded max value on the test.

The percent drop can be adjusted based on the application and requirements of

the end user.

It is however advised to keep this value higher and with considerations on the

speed settings. Even though the test stand can detect the percent drop, if the

speed is higher the program may overshoot.

Values lower than 1% are prone to false activation due to possible vibration o

noise on the set up.

Break is designed for one cycle test, an optional continuance of the test if no

break is detected is possible by turning off the return position option.

Page 29

Break setting option include a length option

Priority of the test stand is Force, if no break or percent drop is detected on a

certain length the test stand stops or return to initial position.

Additional adjustments can then be made to increase the pull or decrease the

compression distance of the test sample.

Force

MAXforce: 100g

100m

Tare ON/OFF

avairable.

10g

90g

Distance

Operating Distance;

.

final_force is based on percentage of

MAXforce

Setting range : 0.5 – 100 %

MAXforce×final_force[%] = 100g x 10% = 10g

100g – 10g = 90g, so after detect

below 90g, test is finished. and

then, go back to start point

automatically.

Page 30

FGS-200PV

SPECIFICATIONS

Capacity 100 kgf (200 lbs.)

Reduction Ratio 1:20

Precision Ball Screw Pitch 4mm / 1 Rotation

Stroke 400 mm (15.7 inch)

Travel Speed 0.6 mm/min (0.02 inch/min) - 400 mm/min (15.7 inch/min)

Drive Systeem Servo Motor (Trapezoidal thread (pitch 4mm / 1 rotation)

Speed Setting Selectable Speed Knobs (Speed A and Speed B)

Display 5 digit LED

Cycle (max) 1 - 9,999 times

Analog Signal Output 5 mV/ mm max +/- 2 V (400 mm)

Emergency Switch Push/Twist and release emergency stop button

Operating Modes

MANU MANUAL - Operates to selectable force limits

JOG JOG - Operates while direction key is pressed

SING SINGLE - Operates one cycle between upper and lower force limits

CONT CONTINUOUS - Cycles test between upper and lower force limits.

PROG PROGRAM - Specific Program Tests (each can store 5 programs on each type)

TOP: Top Load test with threshold option

STD: Standard test with preload option

BREAK: Break point test with force drop detection

Communication Feature USB 1.1 communication from Test stand to PC

Force Gauge Compatibility FGV-X and DFS models (Made after 1991)

Communication Software Windows based program, virtual front panel compatible with Windows XP/2000

Alarm Overload protection for test stand motor (stops motor when overload condition occurs).

Work Space 200 mm (7.87 inch) X 280 mm (11.02 inch)

Operating Temperature 0 - 45 degrees Celcius (Non-condensing)

Power Supply 120 V AC

Weight 23 Kg

Page 31

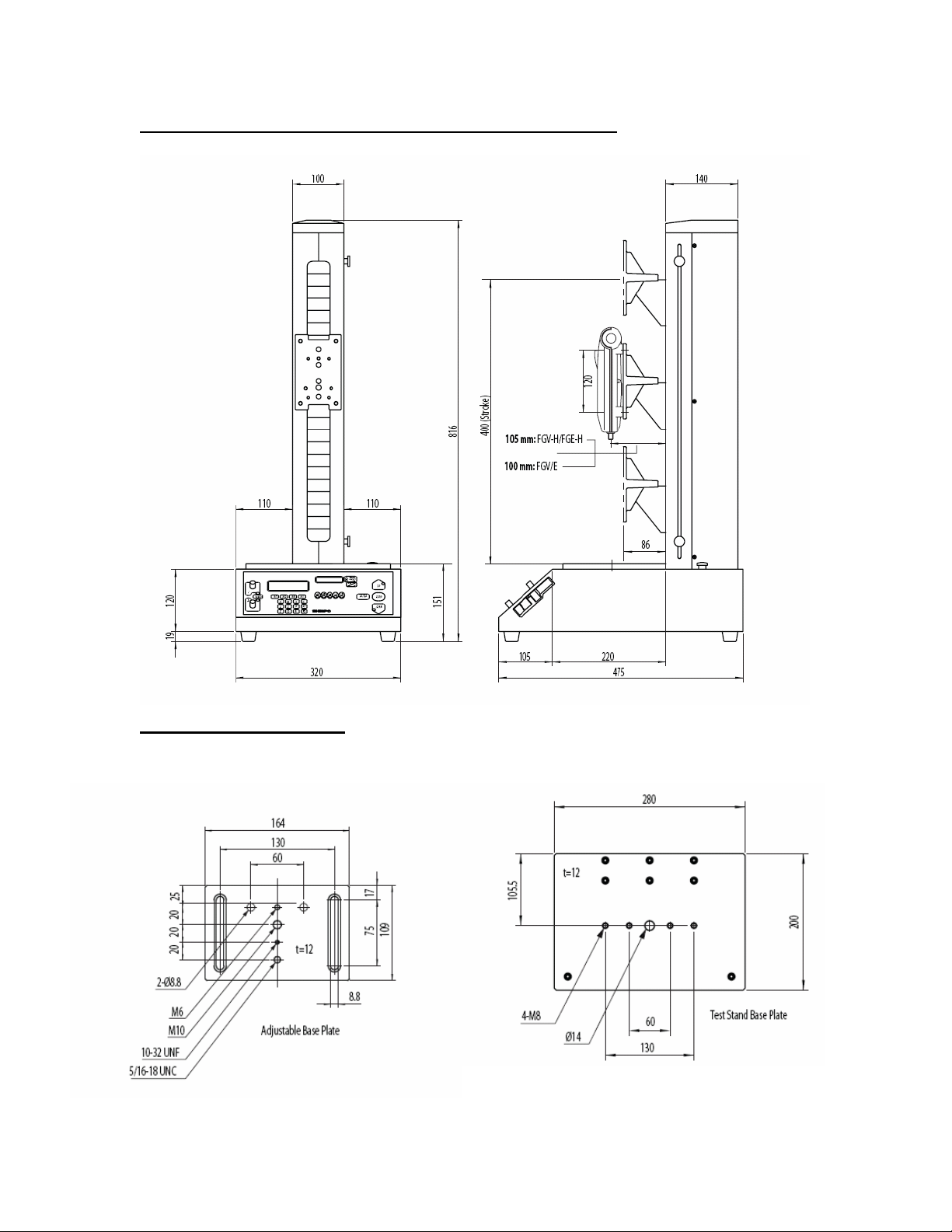

Drawings and Dimensions (All measurements in mm)

Base Plate Dimensions

Loading...

Loading...