Shimpo FGS-100E-H, FGS-100E-L Cement Viscosity Test Application Information

Application Information

Cement Viscosity Test

Shimpo test equipment has a wide variety of uses in a multitude of quality control testing applications. Uniformity is especially critical in manufacturing materials for products in the construction industry due to the numerous

quality standards.

Recently, a cement manufacturing company wanted a streamlined process to spot check their ingredients along

the production line in one of their facilities. It was found that compression tests were a more reliable method of

determining the quality of the cement ingredients over conventional viscosity tests. Chosen were a FGS-100EH

Motorized Force Test Stand combined with a FGV-50XY Digital Force Gauge with 50 lb (20 kg) capacity. The

manufacturer created a custom machined ball to connect to the force gauge which would create the proper

forces when positioned into the sample material. To initiate the test, a sample cup of their cement mixture was

placed on the force test stand base. Using the complimentary Shimpo software, the peak measurements were

collected and measured against their pre-determined standards to determine a pass or fail status.

Implementing this testing process which utilizes the repetitive control of the Shimpo test stand with the precision of the digital force gauge and its associated data acquisition software, they have been able to evaluate the

quality of their ingredients prior to final mixing. This ability to more efficiently and accurately check their product

has allowed their operators to make adjustments in real time to their mixtures resulting in a significant decrease

in defective product, saving the company time and reducing costs while eliminating the potential for customer

complaints.

Equipment Used

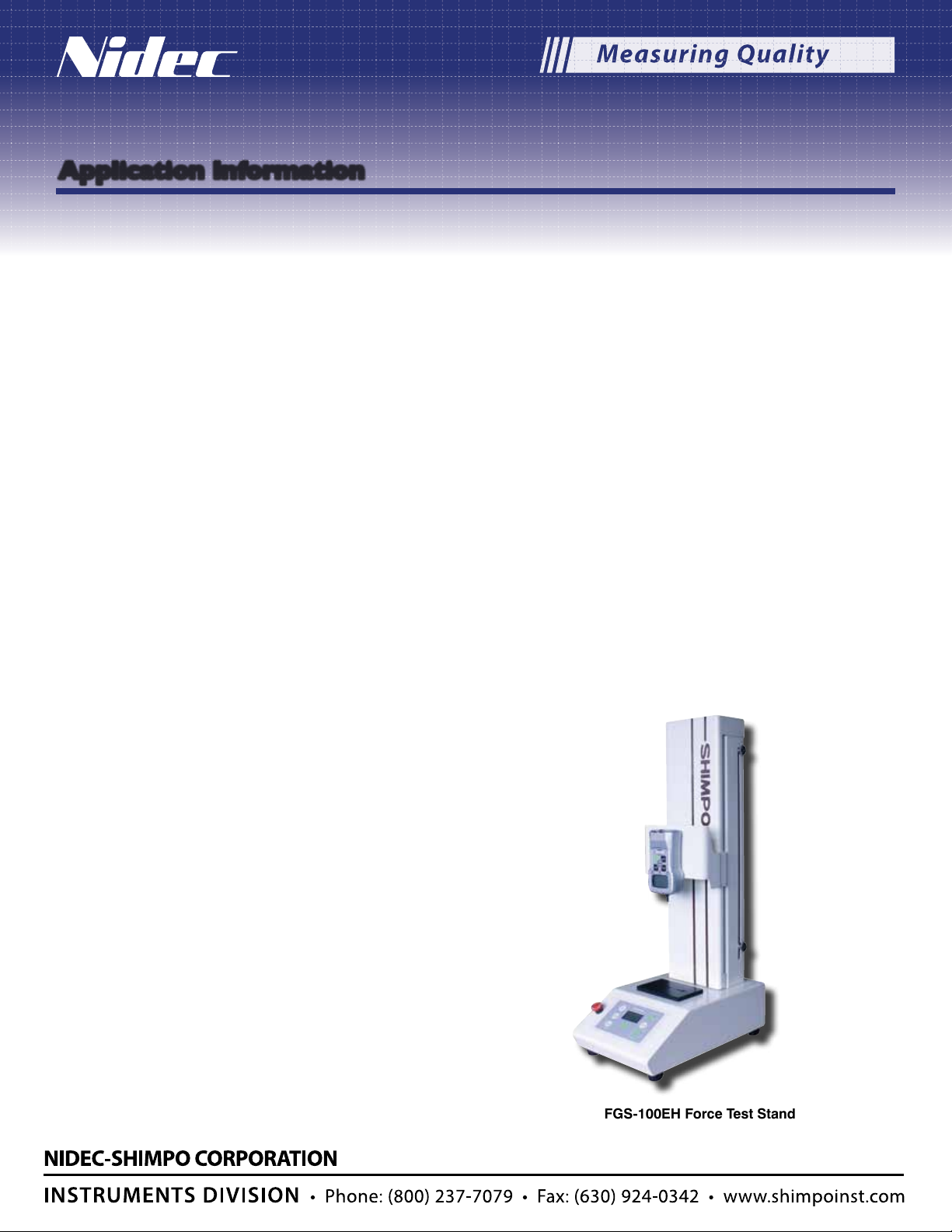

• FGS-100EH Motorized Force Test Stands

• FGV-50XY Digital Force gauge 50 lb (20 kg)

FGS-100EH Force Test Stand

with FGV-50XY Digital Force Gauge