Shimpo FGS-100E-H, FGS-100E-L Instruction Manual

Vertical Force Test Stand

FGS-100E-H/L

Operation Manual

Please read carefully before using this product.

Read carefully "Safety Precautions" and Handling Instructions.

Use appropriately as directed.

NIDEC-SHIMPO CORPORATION

Before Installation, Operation or Maintenance, be sure to read carefully this Operation Manual and use the equipment as

directed. Use the equipment after carefully reading all the caution items, safety information, and other discriminations.

In this User's Manual, the Safety Awareness Items are divided into three different categories: "Danger", "Warning" and

"Caution".

DANGER

WARNING

CAUTION

This symbol indicates if you ignore the contents mentioned and improperly operate, it

may lead to serious injury from a potential fire.

This symbol indicates a potential dangerous situation that could produce a serious

injury if improperly handled.

This symbol indicates a potential situation that could produce a minor injury or damage

to material if it is improperly handled. However, depending upon the situation, there

could be a possibility that it may cause more serious results.

Protection categories are explained and separated by the following symbols.

Proceed with Caution

Not Allowed -Prohibited

Mandatory- Must Follow

WARNING

Heavy! Take sufficient care while handling.

Ensure stand is placed on a flat, level,

Do not operate in areas where explosive

gases or vapors may be present.

stable surface that can support the unit.

Do not touch the running, inner parts.

Keep appendages and loose clothing

away from running, moving parts.

Do not attempt to inspect or perform maintenance on the unit with the

electrical cord connected to a power source.

1

CAUTION

If a loud noise is created from the unit

during operation, check the mounting

of the gauge or level of the stand. If

noise persists, contact the factory.

Hold power plug while removing the

power cord. Do not pull or put tension

on the cord. Doing so could result in

cord damage and electric shock.

Use only matching electrical sockets.

Do not alter the power connector in

order to fit an unmatched socket. Shock

or fire could result.

Mandatory

Do Not Use in Below Mentioned Locations.

- Where water, oil or chemicals may come in contact.

- Where there is ample amounts of dust.

- Where condensation may emerge.

Do not install in a high humidity

environment or near where water may

be present. Electric shock may occur if

water is encountered.

Do not scratch, damage, cut, over-turn,

pull, twist, or bundle the power supply

cord. The electric power cord may be

broken and may cause electric shock,

fire or accident.

Confirm that the power supply is the

same voltage rating as the displayed

voltage rating on the unit.

Take care that the Force Gauge Cable

is not caught in the moving parts. This

can be prevented by properly securing

the cable so that it cannot come into

contact with the moving parts.

- Where a fire or explosion may exist or occur.

Mount the Force Gauge to the Test

- Where vibration of machinery exists.

- Where temperatures will go outside

of 32

o

F to104 oF (0oC to 40oC).

Do not clean with flammable liquids such

as thinner and gasoline.

Stand with the Test Stand's power switch

in the off position.

Do Not adjust the limit knobs while the Test

Stand is moving.

Ensure that the green earth grounding

wire of the power cord is grounded.

Installation of Digital Force Gauge FGV Series

While installing the Digital Force Gauge FGV Series to the Test Stand FGV Function Setting

F06 Outer Parts Output Switchover Setting is to be performed by the Over Load Output (over)

Setting. If setting is performed using the Comparator Output, then with the Force Gauge Over

Load (Excess Load), the Stand does not Stop.

2

Index

1. Before Use

1.1. Force Gauge Installation

1.2.Inspection of Included Accessories

2. Specification

3. Product Diagram

4. Operation Panel Functions.

5. Preparation

5.1. Installation of Force Gauge.

5.2. Cable connection to the Force Gauge.

6. Operation.

6.1. Basic Movement

6.2. Speed unit change

6.3. Changing Mode

6.4. Movement Mode

6.4.1 Jogging Mode. (JOg)

6.4.2 Manual Mode. (MAU)

6.4.3 1 Cycle Mode. (SIg)

4

4

4

5

6

6

8

8

8

9

9

10

11

11

12

12

13

6.4.4 Continue Mode. (CON)

6.5. Speed

7. Display Error

8. Outer Dimensions.

9. Trouble Shooting.

14

15

16

17

18

3

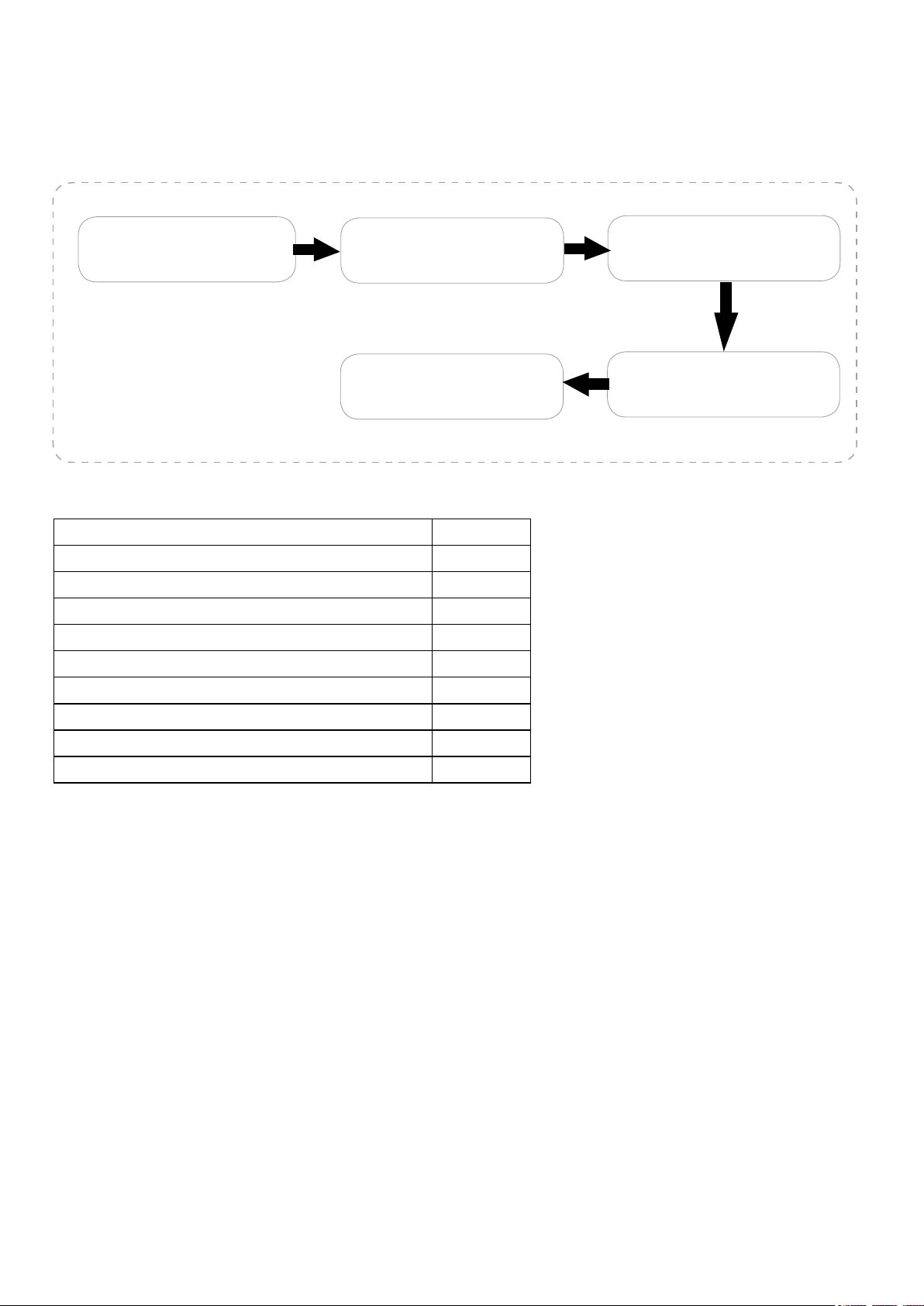

1. Before Use

1.1. Force Gauge Installation

This Shimpo Instruments FGS-100E Test Stand is to be installed with a Shimpo Instruments Digital Force Gauge Series FGV

and is able to perform all types of Load Tests. Related to its execution from installation to measurement, utilize the following

procedure. If encountering issues, check the Trouble Shooting section of this manual.

Confirmation before Use.

1.2.Inspection of Included Accessories

Name of Product.

FGV Connecting Cable (2m).

Power Supply Cable

Cable Clip

Socket Bolt (M4 x 8) for Installing Gauge to Sta

Socket Bolt (M6 x 12) for Test Jig Installation.

Allen Key Spanner for M6t.

Allen Key Spanner for M4

Operation Manual

Guarantee

Installation of Force Gauge

Trouble Shooting.

Quantity.

1

1

1

4

2

1

1

1

1

Connection.

Issues

Measurement Mode Separate

Operation Method.

4

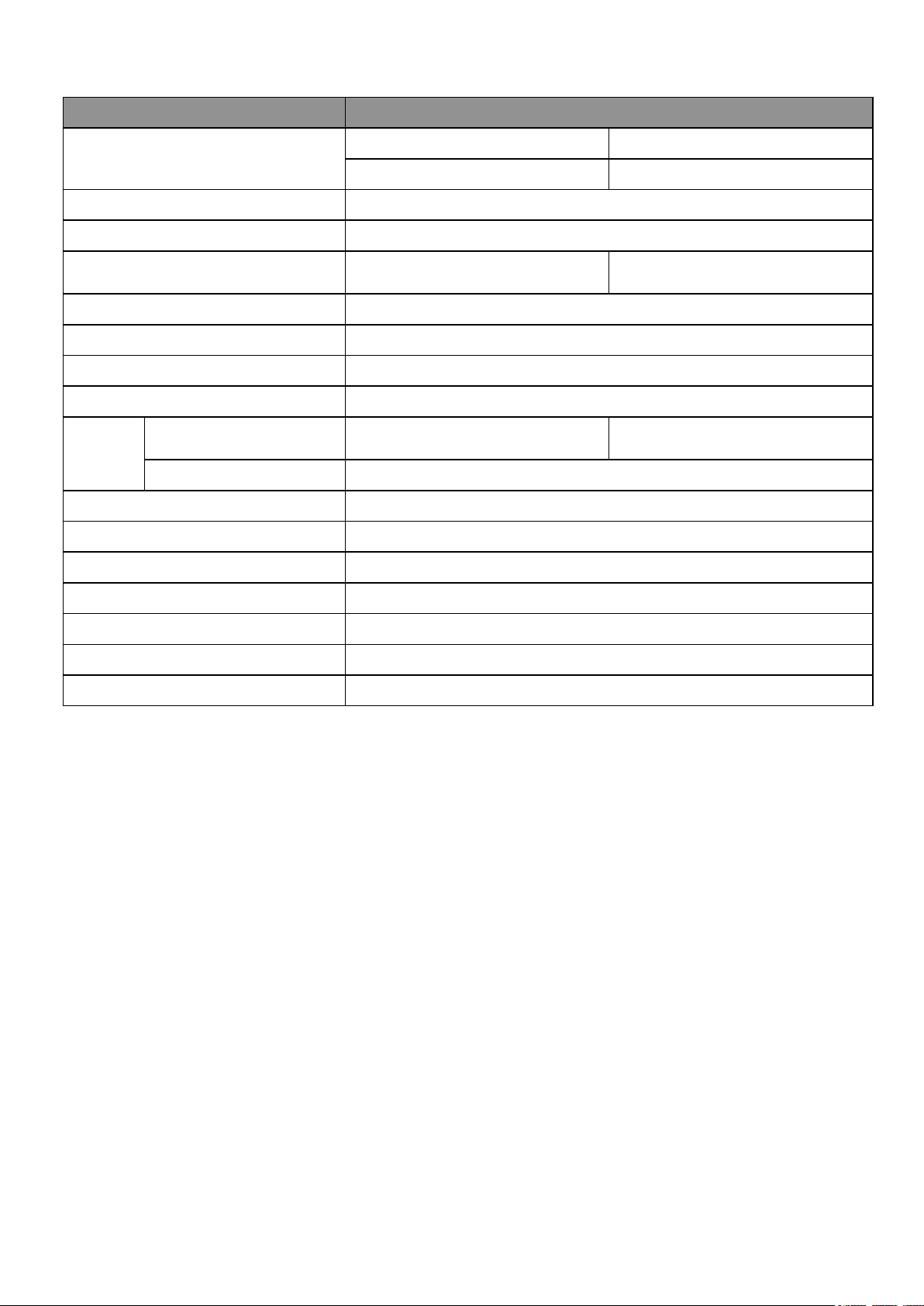

2. Specifications

Series FGS-100E

Display

Model

FGS-100E-L FGS-100E-H

Low Speed Specifications High Speed Specifications

Measuring Load 500N(50kgf) (112.4 lbf)

Load Resistance 500N(50kgf) (112.4 lbf)

Forwarding Speed 6-180mm/min(0.23-7.00in/min)

20-600mm/min(0.78-23.60in/

min)

Speed Settings Set the Speed through Operation panel.

Speed Accuracy ±5%

Stroke 400mm (15.75in)

Display Parts LCD 3 Digits indicates movement speed, Operation Mode.

Movement Speed 6-180mm/min(0.23-7.00in/min)

20-600mm/min(0.78-23.60in/

min)

Operation Mode Manual (MAU), Jogging (JOG), 1 Cycle (SIG), Continuous (CON).

Input Over Load Input Stops by FGV Over Load Signal

Measurement Table 93×150mm(3.66×5.91in)

Temperature Range 0 - 45°(No Condensation) 32 to 113° F

Power Supply AC100 - 230V±10%

Weight Approx.20kg(40.1lbs)

Outer Dimensions 220×680×358mm (8.7×26.8×14.1in)

Corresponding Force Gauge FGE-0.5 - 100 FGV-0.5 - 100

5

Loading...

Loading...