Page 1

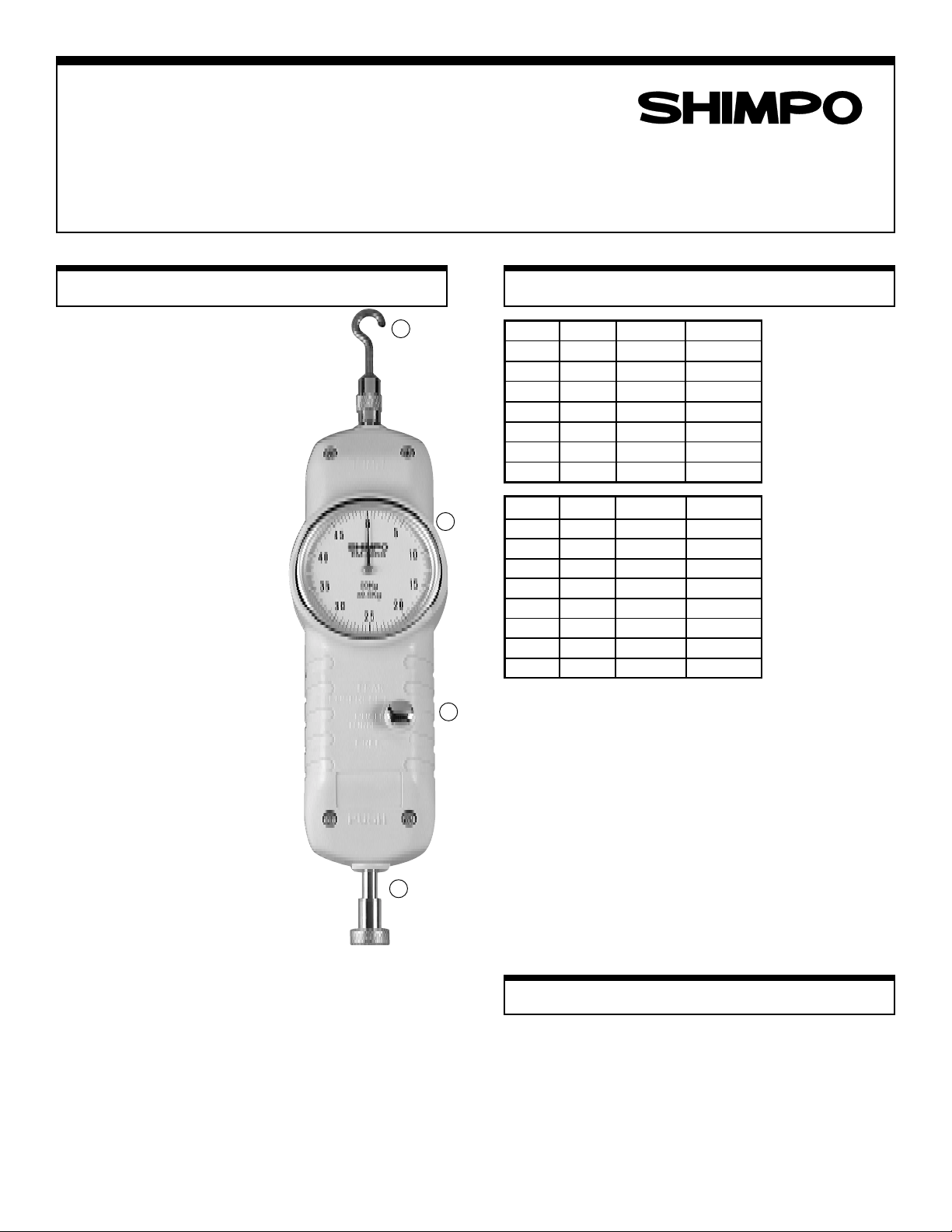

Mechanical Force Gauge

Series EM

Introduction

The EM mechanical force gauge is

a direct reading, dial type instrument designed for measuring

tension and compression forces.

All models are housed in a rugged,

ergonomically designed housing

which makes these instruments

ideal for material testing, manufacturing, quality control and laboratory environments.

1. T ension Sensing Rod (M6P1)

Measure tensile forces with the

small hook attachment.

2. Measure switch

Use this switch to select real

time or peak force.

3. T are Ring

Rotate tare ring to compensate

the attachment's weight.

4. Compression Sensing Rod

(M6P1)

Measure compressive forces

with following attachments: flat

head, conical head, chisel head

and notched head.

Instruction Manual

Specifications

1

3

2

4

MODELS

MODELS CAPACITY

MODELSMODELS

EM-2

EM-2 2 lb 100 0.02 lb

EM-2EM-2

EM-5

EM-5 5 lb 100 0.05 lb

EM-5EM-5

EM-10

EM-10 10 lb 100 0.1 lb

EM-10EM-10

EM-20

EM-20 20 lb 100 0.2 lb

EM-20EM-20

EM-30

EM-30 30 lb 150 0.2 lb

EM-30EM-30

EM-50

EM-50 50 lb 100 0.5 lb

EM-50EM-50

EM-100

EM-100 100 lb 100 1 lb

EM-100EM-100

MODELS

MODELS CA PACITY

MODELSMODELS

EM-1kg

EM-1kg 1 kg 100 10 g

EM-1kgEM-1kg

EM-2kg

EM-2kg 2 kg 100 20 g

EM-2kgEM-2kg

EM-3kg

EM-3kg 3 kg 150 20 g

EM-3kgEM-3kg

EM-5kg

EM-5kg 5 kg 100 50 g

EM-5kgEM-5kg

EM-10kg

EM-10kg 10 kg 100 100 g

EM-10kgEM-10kg

EM-20kg

EM-20kg 20 kg 100 200 g

EM-20kgEM-20kg

EM-30kg

EM-30kg 30 kg 150 200 g

EM-30kgEM-30kg

EM-50kg

EM-50kg 50 kg 100 500 g

EM-50kgEM-50kg

CAPAC ITY DIAL DIV ISIONS

CAPACITYCAPACITY

CAPACITY DIAL DIV ISI ONS

CAPACITYCAPACI TY

DIAL DIV ISIONS RE SOLU TION

DIAL DIV ISIONSDIAL DIV ISIONS

DIAL DIV IS ION S RESOLUT ION

DIAL DIV IS ION SDIAL DIV IS ION S

RESOLU TION

RESOLU TIONRESOLU TION

RESOLU TION

RESOLU TIONRE SOLUTI ON

Overload capacity is 75kg for all models.

EM Models

Accuracy: ±0.2% full scale

Stroke: 10mm

Precautions

Do not exceed capacity of unit.

Accuracy may be affected if unit is exposed to high

humidity , dust or extreme shock.

Page 2

General Operation

Optional Accessories (cont'd)

1. Use "selector button" to select average (real time) or

peak mode.

2. Add proper attachment to push or pull measuring end.

3. Rotate tare ring to read"0". Adjustment should be

made under the same conditions as those used when

measuring actual load.

4. T o select average mode, push button down and turn

all the way counter clockwise.

5. T o select peak mode, turn button all the way clockwise. T o reset to zero, push button slightly.

Note: When in average mode you can still freeze the

indicator needle when desired measurement is reached

by turning selector all the way clockwise.

Dimensions

All dimensions in mm

Small Pin Grips

Theses special attachments are ideal

for gripping fine wires or filaments.

Choose between three ranges. Load

capacity is 22 pounds for each range.

0 - .5mm Diameter Pin Grip

.5 - 1mm Diameter Pin Grip

1 - 2mm Diameter Pin Grip

3mm Fine Point Grip

This narrow-faced grip is convenient

for testing fine and medium gauge

wire. It’s also handy for testing

electronic components in hard to

reach places. Load capacity is 30

pounds.

8mm Ribbon Grip

This grip is excellent for measuring

the tensile strength of ribbon, wire,

tape and paper. The load capacity is

60 pounds.

20mm Film Grip

Use this heavy duty, spring-loaded

film grip to check samples up to

10mm thick. The serrated jaw is

20mm wide.

Optional Accessories

Handle

Can be used with all models

Jacob’s Chuck Grip

Designed for testing low gauge wire

and rigid rods. Accepts diameters

from .5mm to 5mm. Load capacity is

110 pounds.

Flat Chuck Tensile Grip

Measure up to 110 pounds with this

heavy duty flat tensile grip. The

20mm square serrated faces can

accept materials to a maximum

thickness of 10mm.

Heavy Duty Wedge Grip

This self-clamping grip accepts

materials up to 10mm thick. The

retractable grooved jaw is 15mm

wide. Load capacity is 500 pounds.

SHIMPO INSTRUMENTSSHIMPO INSTRUMENTS

SHIMPO INSTRUMENTS 1701 Glenlake Avenue Itasca, IL 60143 USA (630) 924-7138 Fax (630) 924-0342

SHIMPO INSTRUMENTSSHIMPO INSTRUMENTS

Loading...

Loading...