Shimpo DT-725, DT-725KIT-220V Instruction Manual

DT-725 Digital Stroboscope/Tachometer

Operation Manual

Do not operate or store instrument in the following places:

• Explosive areas

• Near water, oil, dust or chemicals

• Areas where temperature is above 104°F (40°C).

Do not look at the emitted light for long periods of time; it can be harmful

to the eyes.

Do not disassemble or repair unit while in operation.

The DT-725 portable, light weight stroboscope with rechargeable

battery possess many of the same features as the famous DT300 Series Stroboscopes, but are lighter in weight. Constructed of

strengthened high impact plastic, these rugged units are exceptionally reliable and withstand the same harsh conditions as more

expensive units. Employing its unique phase shifting feature, the DT725 “freezes” rotating or reciprocating machinery for visual inspection of covered gear teeth, shafts, oil/fuel/ink injector patterns, and

print media; all without stopping production.

These features make the DT-725 ideal for quality inspection and preventive maintenance of automated motion equipment. Units can be

ordered separately or as a convenient kit.

To mount the strobe on a tripod (or any other mounting surface), use

screw 1/4 - 20unc, length 8mm or shorter, for the tripod screw hole

on the bottom.

SPECIFICATIONS

Flashing Range: 40.0 - 12,500 fpm (flashes per minute)

Accuracy: ±0.02 % of reading

Resolution: 0.1 fpm: 40.0 - 4,999.9 fpm / 0.2 fpm: 5,000 - 7,999.9

fpm / 0.5 fpm: 8,000.0 - 9,999.5 fpm / 1 fpm: 10,000 - 12,5000 fpm

Phase Shift: Use +/- push buttons (360° in 6 seconds)

Display Update Time: Ext. mode : varies with flashing rate

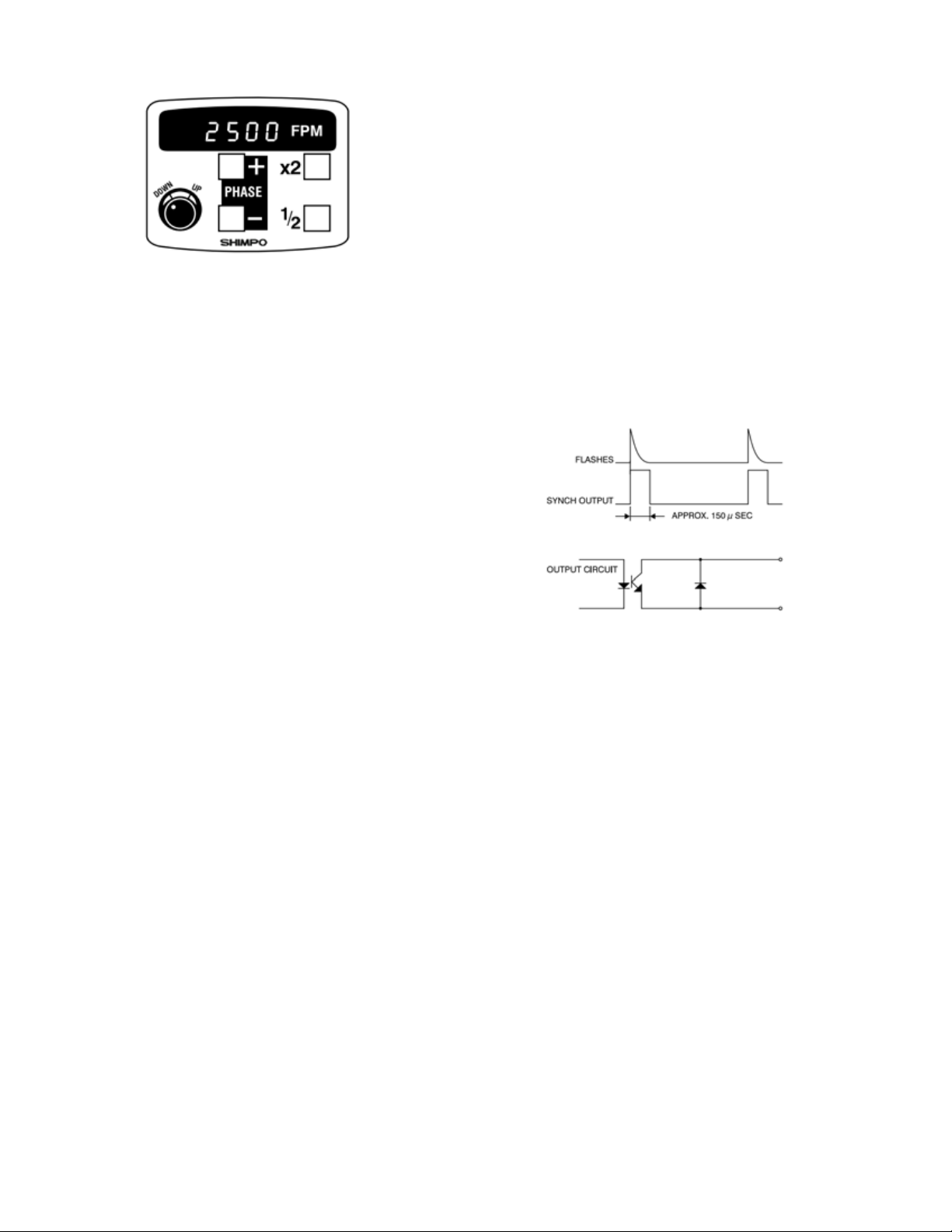

Output Signal: NPN open collector (24 VDC max., 50 mA), 150

μsec typical

Rate Multiplier/Divider: Multiply by 2, divide by 2

External Trigger Input Signal:

a) 12 - 24 VDC thru a 3-wire NPN output sensor (requires external

power

b) 12 VDC thru a 2-wire proximity sensor (leakage current 1 mA

max., load current 8 mA min.)

c) Switch or relay contact

Display: 5 digits, 0.3” (8 mm) high, LED

Flashtube Power/Life: Xenon, 10 W max. (100 million flashes)

Flash Duration: 10 - 15 μsec

Low Battery Indicator: Flashing LED

Battery Life: 1 - 2 hours depending on flash rate

Power Requirement: 115 VAC or 220 VAC ±10 % 60/50 Hz /

Internal battery pack

Operating Temperature: 32 - 104°F ( 0 - 40°C )

Product Weight: 2.75 lbs (1.25 kg)

Package Weight: 4.45 lbs (2.02 kg)

Dimensions: 7.28” L x 4.72” W x 4.72” H (185 mm x 120 mm x

120 mm)

Warranty: 2 year

Included Accessories: AC adapter

FEATURES

External Triggering

1. Connect wires according to connector pin designation: Tip: signal Sleeve: Gnd

2. Pull power trigger switch and lock it. When the ext. phone jack

is inserted in unit, the strobe automatically switches from the internal mode to the external.

3. The strobe will flash every time the sensor puts out a pulse. See

specifications table for input signal requirements.

4. If the input signal frequency exceeds upper or lower

limits, the alarm mark will be displayed and the strobe

will stop flashing.

Setter: The setter changes the flashing rate. Turn CW to increase

the rate, turn CCW to decrease rate.

x2 Switch: Pressing “x2” will double and display the flashing rate.

1/2 Switch: Pressing the “1/2” will divide flashing rate by two and

display it.

Plus (+) Switch: When object appears to be standing still, pressing “+” will give the illusion that the object is moving towards the

opposite direction of rotation. This action increases the rate slighly (phase shift) and is used to place the object in desired position.

Minus (–) Switch: When object appears to be standing still, pressing “–” will give the illusion that the object is moving towards the

rotating direction. This action decreases the rate slightly (phase

shif) and is used for the same reason as above.

Input and Output Connectors: Phonejack (3.5 mm); Tip: Signal;

Sleeve: GND

Power switch with lock option

OPERATION

Internal Triggering

1. Charge battery for approx. 15 hrs. before using strobe for the

first time.

Synchronous Output Signal

The Synchronous output signal appears on the tip of the output

phonejack. See table for more information.

2. Aim light beam at object under observation. The best distance

between the strobe and moving object is approximately 2 ft.

3. Measure rpm by turning setter. Turn setter to adjust the flashing

rate to the rotational speed of the object. To reach the desired rate

faster, use the 1/2 or x2 switches.

2

Loading...

Loading...