Page 1

PP

anel Mount Tanel Mount T

P

anel Mount T

PP

anel Mount Tanel Mount T

achometerachometer

achometer

achometerachometer

Model DTModel DT

Model DT

Model DTModel DT

FeaturesFeatures

Features

FeaturesFeatures

This microprocessor-controller digital tachometer can be

used in any direct rpm application where no special gears

or generators are required. Here are some of its outstanding features:

!

Mounts easily — no brackets or screws required.

!

Any AC line voltage between 85 and 264 (50/60 Hz)

can power the unit.

!

Parameters are easily set via front panel membrane

switches.

!

Parameter settings are stored in a nonvolatile

memory.

!

Pulses per revolution range is 1 - 9999.

!

Signal LED on front panel.

-5TP-5TP

-5TP

-5TP-5TP

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

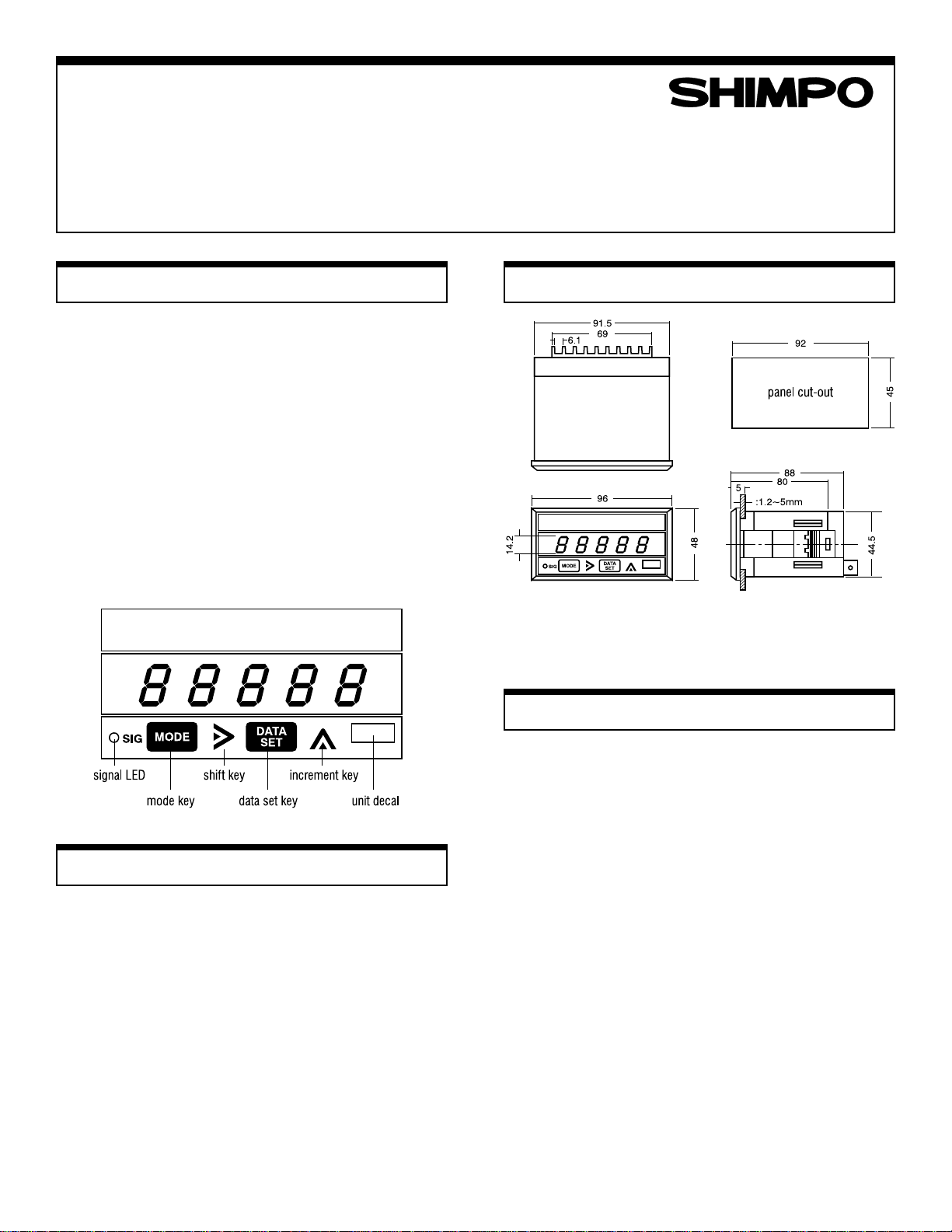

Dimensions (mm)Dimensions (mm)

Dimensions (mm)

Dimensions (mm)Dimensions (mm)

Operational POperational P

Operational P

Operational POperational P

!

If the unit is used in a caustic environment, we

suggest you use a NEMA 4X enclosure.

!

Keep unit free of vibration and shock.

!

When installing unit, keep power and sensor wires

separate. Tie cable shield to terminal E (earth ground).

!

After inserting wires, tighten terminal screws securely.

recautionsrecautions

recautions

recautionsrecautions

InstallationInstallation

Installation

InstallationInstallation

Our 1/8 DIN case design eliminates the need for brackets

and screws for installation. With the tachometer in a level

position, insert it into the panel cutout. Gently push the

face of the unit until the front bezel locks into place. If the

tachometer case is loose, adjust the integral bracket with

the enclosed tool.

Page 2

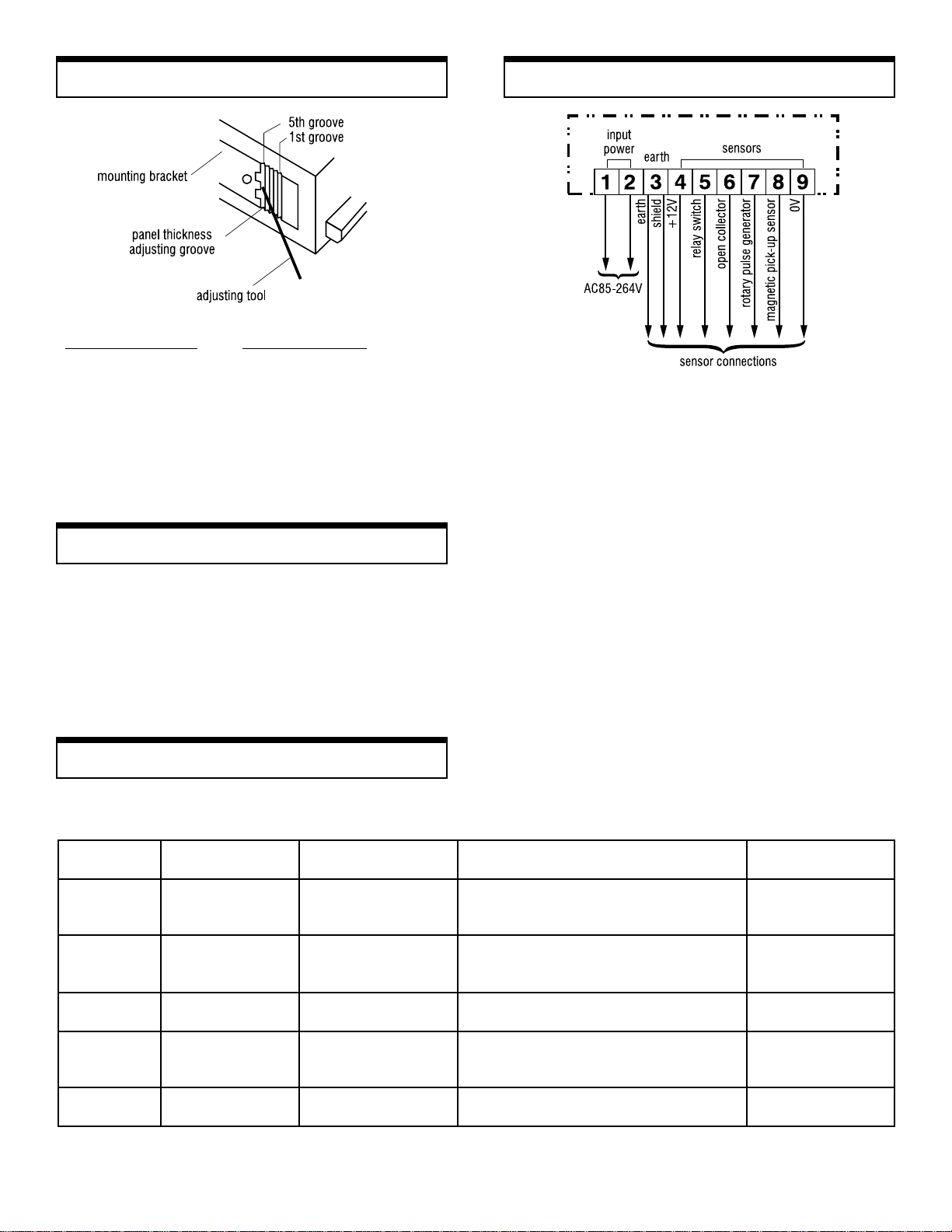

Mounting Bracket AMounting Bracket A

Mounting Bracket A

Mounting Bracket AMounting Bracket A

djustmentdjustment

djustment

djustmentdjustment

Panel Thickness

Thickness of Panel Adjusting Groove

1.2 – 1.6 mm 5th groove (factory setting)

1.8 – 2.5 mm 4th groove

2.8 – 3.6 mm 3rd groove

4.0 – 4.5 mm 2nd groove

5.0 mm 1st groove

RR

emoving Unitemoving Unit

R

emoving Unit

RR

emoving Unitemoving Unit

From the rear of the tachometer, alternately push the unit

from the left and right. This will free it for easy removal.

ConnectionsConnections

Connections

ConnectionsConnections

1&2 Line voltage input. AC voltage must be between 85

and 264 volts.

3 Earth ground. Connect all cable shielding to this

terminal.

4 12 VDC 50mA max. This sensor power supply is for

any sensor that requires external power

5 Switch closure input. To be used with a relay or

solenoid. The input frequency must be less than 20Hz.

6 For use with open collector sensors. Connect the

sensor's signal output wire. No need for an external

pull-up resistor.

7 Terminal to accept signals from rotary encoders or

pulse generators.

8 Standard input terminal for magnetic pick-ups and

proximity switches.

9 Signal ground or common.

SensorsSensors

Sensors

SensorsSensors

Shimpo offers a large selection of sensors to meet you application needs. The chart below shows

the optimum sensor to use when designing your system. Please call us for more information.

SENSOR FREQUENCY TYPE TERMINAL NUMBERS FREQUENCY OR RPM RANGE

RE1B–60C

RE1B–600C

RE1B–1000C

BI2–S12

DJ2–G

SE–G

RS220H

MCS–625

3030AN

MP–10

3070A*

Switch Closure Relay or Solenoid 5, 9, <20 Hz

* explosion proof

2

Rotary Pulse Generator

Proximity Switch

Proximity Switch

Proximity Gear Sensor

Retro Reflective Sensor

Magnetic Pick-up

3, 4, 7, 9,

3, 4, 7, 9,

3, 4, 7, 9,

4, 6, 9,

4, 8,

3, 4, 7, 9,

3, 4, 7, 9,

3, 4, 6, 9,

3, 8, 9,

3, 8, 9,

8, 9,

0–5000 rpm

0–3000 rpm

0–1800 rpm

0–2 KHz

0–1 KHZ

0–8KHz

0–500 Hz

0–250 Hz

Min. 5 I/s with 16 pitch gear .005" clearance

Min. 1 I/s with 12 pitch gear .005" clearance

OPERATION

TEMPERATURE

+14° F to +122° F

+14° F to +122° F

+14° F to +122° F

-13° F to +158° F

-4° F to +140° F

-4° F to +158° F

+14° F to +140° F

-22° F to +120° F

-100° F to +225° F

-40° F to +221° F

-100° F to +200° F

Page 3

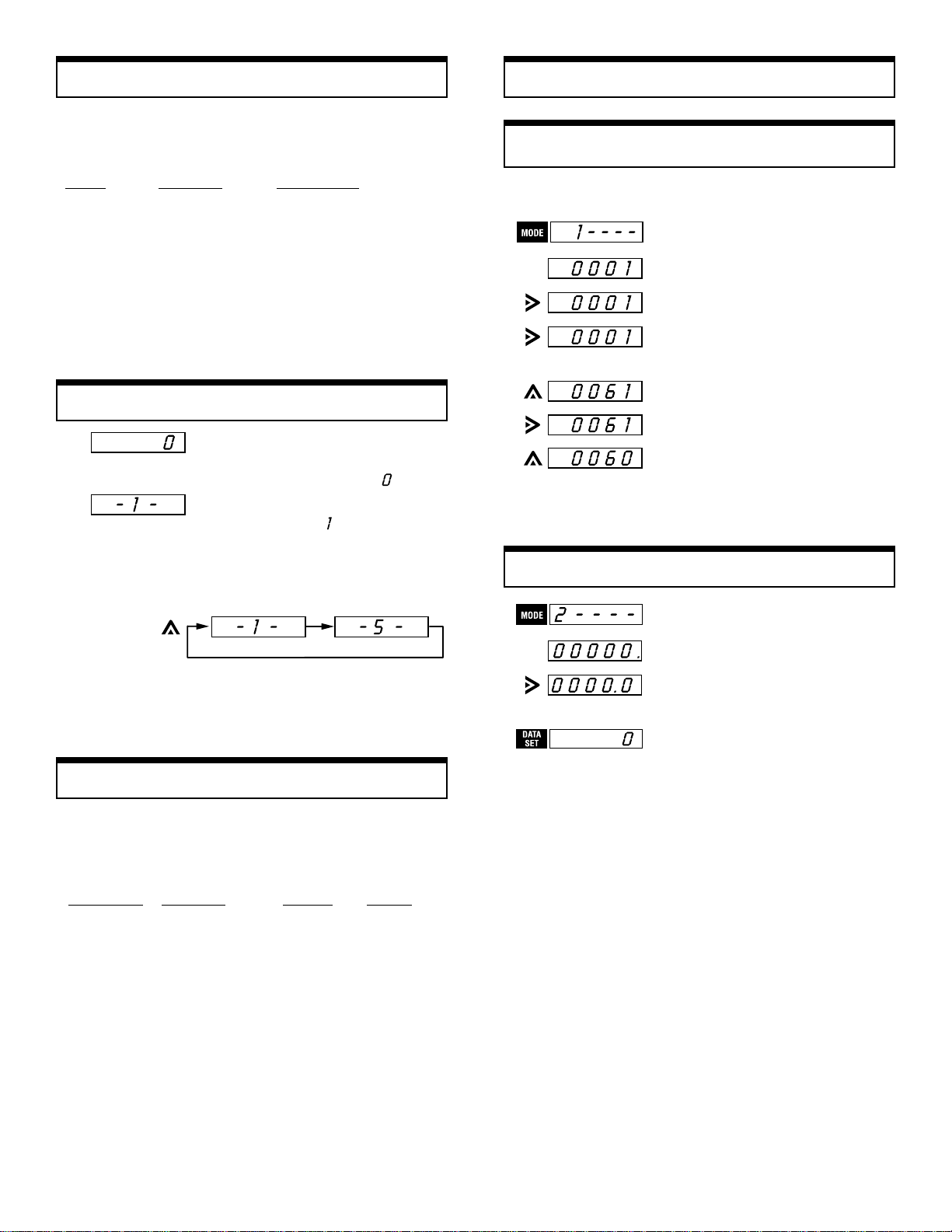

Mode SelectionsMode Selections

Mode Selections

Mode SelectionsMode Selections

The DT-5TP operates in two modes. Mode 1 is programmed

when setting up rpm applications, and mode 5 is for

diagnostic testing:

Mode Function Application

1 Rate Direct r pm

measurement measurements

Setting PSetting P

Setting P

Setting PSetting P

PP

arameter 1: Pulses per Rarameter 1: Pulses per R

P

arameter 1: Pulses per R

PP

arameter 1: Pulses per Rarameter 1: Pulses per R

Sensing GearSensing Gear

Sensing Gear

Sensing GearSensing Gear

Here is how to change the parameter from 1 to 60 pulses

per revolution ("p/r"):

arametersarameters

arameters

arametersarameters

1.Set unit to mode 1.

evolution ofevolution of

evolution of

evolution ofevolution of

5 Self test Diagnostic test of LED

display and input

circuitry

Setting ModesSetting Modes

Setting Modes

Setting ModesSetting Modes

1.Apply any voltage between 85–264

VAC (50/60Hz) to terminals 1 and

2. The display will show

2.Press mode and data set keys for at

least 5 seconds.

3.Press the increment key to select

the desired mode. The display will

shift between mode 1 and mode 5.

4.Press mode key to activate mode 1

or mode 5.

will then appear.

(factory setting)

2.Press mode key.

3.Press shift key to select the

desired digit.

4.Press the increment key 6 times.

5.Press shift key.

6.Press the increment key 9 times.

.

Parameter 1 is now set for 60p/r.

PP

arameter 2: Decimal Parameter 2: Decimal P

P

arameter 2: Decimal P

PP

arameter 2: Decimal Parameter 2: Decimal P

1.Press mode key.

2.Press shift key to select position

of decimal point.

ointoint

oint

ointoint

Mode 1: RMode 1: R

Mode 1: R

Mode 1: RMode 1: R

The DT-5TP can directly measure any rotational rate

speed. The two parameters listed below may need to be

changed during system set-up.

Parameter Function Setting Range

1 Pulses per 1p/r 1–9999

2 Decimal point none 0–4th place

ate Measurementate Measurement

ate Measurement

ate Measurementate Measurement

Factory

revolution of

sensing system

Parameter settings are now complete.

Press data set key to begin counting.

3

Page 4

Mode 5: Self TMode 5: Self T

Mode 5: Self T

Mode 5: Self TMode 5: Self T

estest

est

estest

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

This mode lets you check the LED display and input

circuitry.

1. After disconnecting sensor, press

mode and data set keys for five

seconds.

2.Press increment key until

display

shows mode 5.

3.Press mode key to test display

segments and decimal points.

4.Press mode key. The display will

show

will flash.

5. Press the data set key. The unit

is

now ready for counting.

and the signal

Model DT-5TP

Mode Rate Measurement

Display Range 0.0000–9.9999

0.000–99.999

0.00–999.99

0.0–9999.9

0–99999

Measuring range 10–99999 rpm (at 1p/r), 0.2–30000 rpm

Display period 1 sec. (1 p/r input 60 rpm or over)

Display Red LED (0.56" or 14.2 mm high)

Time base Controlled by a 4.194304 MHz crystal

Accuracy ±0.008% ± 1 digit

Measuring system CPU controlled

Input no. of p/r 1–9999 (programmable)

Input signal

characteristics

Input signal amplitude Sine wave (0.3–30 VP–P)

Input impedance Approx. 10 k ohms

Voltage output 12 VDC ±5% (50 mA max) to power sensors

Ambient temperature 32°–113° F (0°–45° C)

Power consumption 1W

Voltage requirements 85–264 VAC (50/60Hz)

Dimensions 3.46"L x 1.88"H x 3.78"W (88L x 48H x 96W

Weight 0.55 lbs (250g)

(at 60p/r)

1–6 sec. (1 p/r input 10–60 rpm)

Sine wave–max frequency 10 KHz

Square wave–max frequency 30 KHz

Open collector–max frequency 30 KHz

Contact closure–max frequency 20 Hz

Square wave LO: 0–1.5 V, HI 4–30 V

mm), includes bezel, fit 1/8 DIN cutout

Error CodesError Codes

Error Codes

Error CodesError Codes

Display Type of Error What to Do

EE-02 Internal memory Press data set key. Interrupt power at terminals 1 and 2.

EE-03 Memory recall 1. Press data set key.

2a. Press increment key. Display should show

2b. Press data set key. Display should show

2c. Press shift key. Display should show

2d. Press mode key. Display should show

and reset to . If display goes to or and

locks up, turn power off and on again and repeat above steps.

SHIMPO INSTRUMENTS 1701 Glenlake Avenue Itasca, IL 60143 USA (630) 924-7138 Fax (630) 924-0342

Page 5

PP

anel Mount Tanel Mount T

P

anel Mount T

PP

anel Mount Tanel Mount T

achometerachometer

achometer

achometerachometer

Model DTModel DT

Model DT

Model DTModel DT

FeaturesFeatures

Features

FeaturesFeatures

This microprocessor-controller digital tachometer can be

used in any direct rpm application where no special gears

or generators are required. Here are some of its outstanding features:

!

Mounts easily — no brackets or screws required.

!

Any DC line voltage between 9 and 35 VDC can

power the unit.

!

Parameters are easily set via front panel membrane

switches.

!

Parameter settings are stored in a nonvolatile

memory.

!

Pulses per revolution range is 1 - 9999.

!

Signal LED on front panel.

-5TP (VDC)-5TP (VDC)

-5TP (VDC)

-5TP (VDC)-5TP (VDC)

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

Dimensions (mm)Dimensions (mm)

Dimensions (mm)

Dimensions (mm)Dimensions (mm)

Operational POperational P

Operational P

Operational POperational P

!

If the unit is used in a caustic environment, we

suggest you use a NEMA 4X enclosure.

!

Keep unit free of vibration and shock.

!

When installing unit, keep power and sensor wires

separate. Tie cable shield to terminal E (earth ground).

!

After inserting wires, tighten terminal screws securely.

recautionsrecautions

recautions

recautionsrecautions

InstallationInstallation

Installation

InstallationInstallation

Our 1/8 DIN case design eliminates the need for brackets

and screws for installation. With the tachometer in a level

position, insert it into the panel cutout. Gently push the

face of the unit until the front bezel locks into place. If the

tachometer case is loose, adjust the integral bracket with

the enclosed tool.

Page 6

Mounting Bracket AMounting Bracket A

Mounting Bracket A

Mounting Bracket AMounting Bracket A

djustmentdjustment

djustment

djustmentdjustment

Panel Thickness

Thickness of Panel Adjusting Groove

1.2 – 1.6 mm 5th groove (factory setting)

1.8 – 2.5 mm 4th groove

2.8 – 3.6 mm 3rd groove

4.0 – 4.5 mm 2nd groove

5.0 mm 1st groove

RR

emoving Unitemoving Unit

R

emoving Unit

RR

emoving Unitemoving Unit

From the rear of the tachometer, alternately push the unit

from the left and right. This will free it for easy removal.

ConnectionsConnections

Connections

ConnectionsConnections

1&2 DC input terminals. Power required: 9–35 VDC, 1W.

3 Earth ground. Connect all cable shielding to this

terminal.

4 12 VDC 50mA max. This sensor power supply is for

any sensor that requires external power

5 Switch closure input. To be used with a relay or

solenoid. The input frequency must be less than 20Hz.

6 For use with open collector sensors. Connect the

sensor's signal output wire. No need for an external

pull-up resistor.

7 Terminal to accept signals from rotary encoders or

pulse generators.

8 Standard input terminal for magnetic pick-ups and

proximity switches.

9 Signal ground or common.

SensorsSensors

Sensors

SensorsSensors

Shimpo offers a large selection of sensors to meet you application needs. The chart below shows

the optimum sensor to use when designing your system. Please call us for more information.

ROSNESEPYTYCNEUQERFSREBMUNLANIMRETEGNARMPRROYCNEUQERF

C06B1ER

C006B1ER

C0001B1ER

21S2IB

G2JD

GES

H022SR

526SCM

NA0303

01PM

*A0703

hctiwS

erusolC

* explosion proof

2

esluPyratoR

rotareneG

hctiwSytimixorP

hctiwSytimixorP

raeGytimixorP

rosneS

evitcelfeRorteR

rosneS

pu-kciPcitengaM

dioneloSroyaleR,9,5zH02<

,9,7,4,3

,9,7,4,3

,9,7,4,3

,9,6,4

,8,4

,9,7,4,3

,9,7,4,3

,9,6,4,3

,9,8,3

,9,8,3

,9,8

mpr00050

mpr00030

mpr00810

zHK20

ZHK10

zHK80

zH0050

zH0520

NOITAREPO

ERUTAREPMET

F°221+otF°41+

F°221+otF°41+

F°221+otF°41+

F°851+otF°31F°041+otF°4F°851+otF°4-

F°041+otF°41+

F°021+otF°22-

ecnaraelc"500.raeghctip61htiws/I5.niM

ecnaraelc"500.raeghctip21htiws/I1.niM

F°522+otF°001-

F°122+otF°04-

F°002+otF°001-

Page 7

Mode SelectionsMode Selections

Mode Selections

Mode SelectionsMode Selections

The DT-5TP operates in two modes. Mode 1 is programmed

when setting up rpm applications, and mode 5 is for

diagnostic testing:

Mode Function Application

1 Rate Direct r pm

measurement measurements

Setting PSetting P

Setting P

Setting PSetting P

PP

arameter 1: Pulses per Rarameter 1: Pulses per R

P

arameter 1: Pulses per R

PP

arameter 1: Pulses per Rarameter 1: Pulses per R

Sensing GearSensing Gear

Sensing Gear

Sensing GearSensing Gear

Here is how to change the parameter from 1 to 60 pulses

per revolution ("p/r"):

arametersarameters

arameters

arametersarameters

1.Set unit to mode 1.

evolution ofevolution of

evolution of

evolution ofevolution of

5 Self test Diagnostic test of LED

display and input

circuitry

Setting ModesSetting Modes

Setting Modes

Setting ModesSetting Modes

1.Apply any voltage between 9–35

VDC to terminals 1 and 2.

The display will show

2.Press mode and data set keys for at

least 5 seconds.

3.Press the increment key to select

the desired mode. The display will

shift between mode 1 and mode 5.

4.Press mode key to activate mode 1

or mode 5.

.

will then appear.

(factory setting)

2.Press mode key.

3.Press shift key to select the

desired digit.

4.Press the increment key 6 times.

5.Press shift key.

6.Press the increment key 9 times.

Parameter 1 is now set for 60p/r.

PP

arameter 2: Decimal Parameter 2: Decimal P

P

arameter 2: Decimal P

PP

arameter 2: Decimal Parameter 2: Decimal P

1.Press mode key.

2.Press shift key to select position

of decimal point.

ointoint

oint

ointoint

Mode 1: RMode 1: R

Mode 1: R

Mode 1: RMode 1: R

The DT-5TP can directly measure any rotational rate

speed. The two parameters listed below may need to be

changed during system set-up.

Parameter Function Setting Range

1 Pulses per 1p/r 1–9999

2 Decimal point none 0–4th place

ate Measurementate Measurement

ate Measurement

ate Measurementate Measurement

Factory

revolution of

sensing system

Parameter settings are now complete.

Press data set key to begin counting.

3

Page 8

Mode 5: Self TMode 5: Self T

Mode 5: Self T

Mode 5: Self TMode 5: Self T

estest

est

estest

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

This mode lets you check the LED display and input

circuitry.

1. After disconnecting sensor, press

mode and data set keys for five

seconds.

2.Press increment key until

display

shows mode 5.

3.Press mode key to test display

segments and decimal points.

4.Press mode key. The display will

show

will flash.

5. Press the data set key. The unit

is

now ready for counting.

and the signal

Model DT-5TP (VDC)

Mode Rate Measurement

Display Range 0.0000–9.9999

0.000–99.999

0.00–999.99

0.0–9999.9

0–99999

Measuring range 10–99999 rpm (at 1p/r), 0.2–30000 rpm

Display period 1 sec. (1 p/r input 60 rpm or over)

Display Red LED (0.56" or 14.2 mm high)

Time base Controlled by a 4.194304 MHz crystal

Accuracy ±0.008% ± 1 digit

Measuring system CPU controlled

Input no. of p/r 1–9999 (programmable)

Input signal

characteristics

Input signal amplitude Sine wave (0.3–30 VP–P)

Input impedance Approx. 10 k ohms

Voltage output 12 VDC ±5% (50 mA max) to power sensors

Ambient temperature 32°–113° F (0°–45° C)

Power consumption 1W

Voltage requirements 9–35 VDC

Dimensions 3.46"L x 1.88"H x 3.78"W (88L x 48H x 96W

Weight 0.55 lbs (250g)

(at 60p/r)

1–6 sec. (1 p/r input 10–60 rpm)

Sine wave–max frequency 10 KHz

Square wave–max frequency 30 KHz

Open collector–max frequency 30 KHz

Contact closure–max frequency 20 Hz

Square wave LO: 0–1.5 V, HI 4–30 V

mm), includes bezel, fit 1/8 DIN cutout

Error CodesError Codes

Error Codes

Error CodesError Codes

Display Type of Error What to Do

EE-02 Internal memory Press data set key. Interrupt power at terminals 1 and 2.

EE-03 Memory recall 1. Press data set key.

2a. Press increment key. Display should show

2b. Press data set key. Display should show

2c. Press shift key. Display should show

2d. Press mode key. Display should show

and reset to . If display goes to or and

locks up, turn power off and on again and repeat above steps.

SHIMPO INSTRUMENTS 1701 Glenlake Avenue Itasca, IL 60143 USA (630) 924-7138 Fax (630) 924-0342

Loading...

Loading...