Shimpo DT-501XD-FVT, DT-501XD, DT-501XD-CPT-FVC, DT-501XD-CPT, DT-501XD-TRT-FVC Instruction Manual

...

98211B

Digital Tachometer

Digital Tachometer/ Elapsed timecounter/ Time width meter/ Flowmeter

Standard input series Dierential input series

DT-501X/ DT-501F

Safety Requirements

Be sure to observe

Before operation, maintenance and inspection, please carefully read this instruction

manual and follow it for proper use. Please carefully read all information related to

this unit and safety, and precautions before use.

This instruction manual categorizes safety precautions as “DANGER”, “WARNING”,

and “CAUTION”. Each of them is an important description related to safety. Be sure

to observe.

Instruction Manual

Thank you for purchasing SHIMPO's Digital Tachometer DT-501X/

DT-501F. For instructions on how to use this product properly

and optimally for a long period of time, please be sure to read this

manual thoroughly before use.

When you purchase the product with optional equipment:

Please refer to the operation manual of the optional equipment.

Before operation, maintenance and inspection, please

carefully read this instruction manual and follow it

for proper use.

After reading, be sure to store this manual in a safe,

convenient place where operators can always refer to it easily.

!

CAUTION

Electric Shock.

Be sure to turn the power OFF when wiring as well as

inspecting the unit.

Failure to do so could result in electric shock.

DO NOT block the ventilation holes on the side of the main unit.

DO NOT put any foreign objects or materials inside the unit

through these holes.

Failure to follow this could result in abnormal heat generation

and/or malfunctions.

DO NOT touch the unit with wet (or sweaty) hands when

inspecting or for wiring.

Failure to do this could result in electric shock.

!

Precautions before use

Power

●Be sure to use the unit under the specied voltage (AC power

specications: 85 - 264VAC / DC power specications: 10.8 - 25.2VDC).

●Inverter power source cannot be used.

Input signal wire

●Connection wiring from sensors shall not be kept in the same or parallel conduit or

cable as the power source, power or high voltage cables. If you fail to separate the

wiring, noise may be superimposed on the signal wire, resulting in malfunctions.

●

Use shielded wire for input power connections with the shortest possible metal conduit.

Terminal

●

Check that the screws have not come loose due to vibrations after a certain period of time.

Operating environment

●Do not install the unit in the following places or conditions.

●●Places exposed to direct sunlight, or places where the ambient temperature

exceeds a range of 0 - 45ºC.

●●Places where the relative humidity percentage exceeds a range of 35 - 85%, or

places subject to condensation due to rapid change in humidity.

●●Places subject to corrosive and/or combustible gases.

●●Places subject to a large amount of dust, salinity, and/or ferric substance.

●●Places susceptible to noise (including static electricity).

Improper use by neglecting the following

!

!

!

DANGER

WARNING

CAUTION

precautions may result in the potential

for re, serious injuries, and/or death.

Improper use may result in serious injuries.

Improper use may result in minor injuries or

property damage.

●Limited Warranty

● We are not responsible for damages resulting from negligence through failure to

follow the instructions set out in this manual.

●

We are not responsible for damages resulting from earthquake and/or re unrelated

to us, actions by third parties, or any other accidents, intentional or through

customer negligence, as well as from accidents caused by misuse or improper use

under abnormal conditions.

● For information regarding assurance provisions, please read the attached warranty

certicate.

INDEX

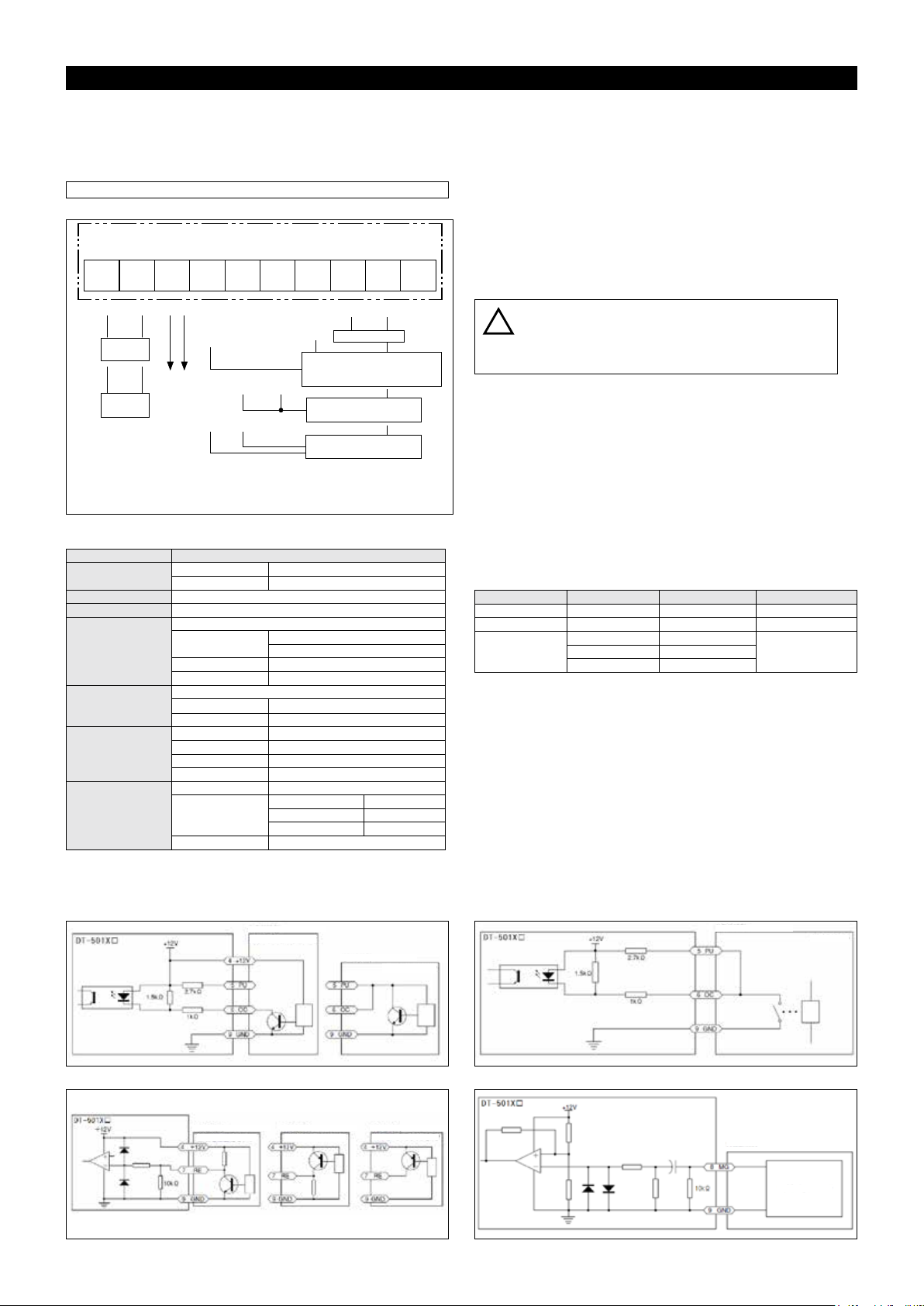

1. Installation to the Start of Operation

2. Unit Model

3. Specications

4. Component Part Names and Functions

5. External Dimensions

6. Installation to the Panel

7. Wiring to Power Source and Sensors (DT-501XA/DT-501XD)

8. Wiring to Power Source and Sensors (DT-501FA)

9. Basic Setting Procedure

10. Keys to be Used for Various Settings and Their Applications

11. Teaching Function Settings

12. About Mode

13.

When You Select Mode 1 (Digital Tachometer Mode) for Measurement

14.

When You Select Mode 2 (Elapsed Timecounter Mode) for Measurement

15.

When You Select Mode 3 (Time Width Meter Mode) for Measurement

16.

When You Select Mode 4 (Flowmeter Mode) for Measurement

17.

Setting Method of Functions (Excluding in the Test Mode, Common in Each Mode)

18. Comparator Function

19. Memory Function

20. Test Mode (Function to Check if the Unit is Operating Normally)

21. Error Display

22. Parameter List

23. Function List

24. Option -FVT/-FVC

25. Option -BCD

26. Option -TRT

27. Option -CPT

28. DT-501X / DT-501F series model list

2

2

3

3

4

4

5

6

6

6

7

8

8

10

12

14

16

17

18

19

19

20

21

23

25

27

27

28

1

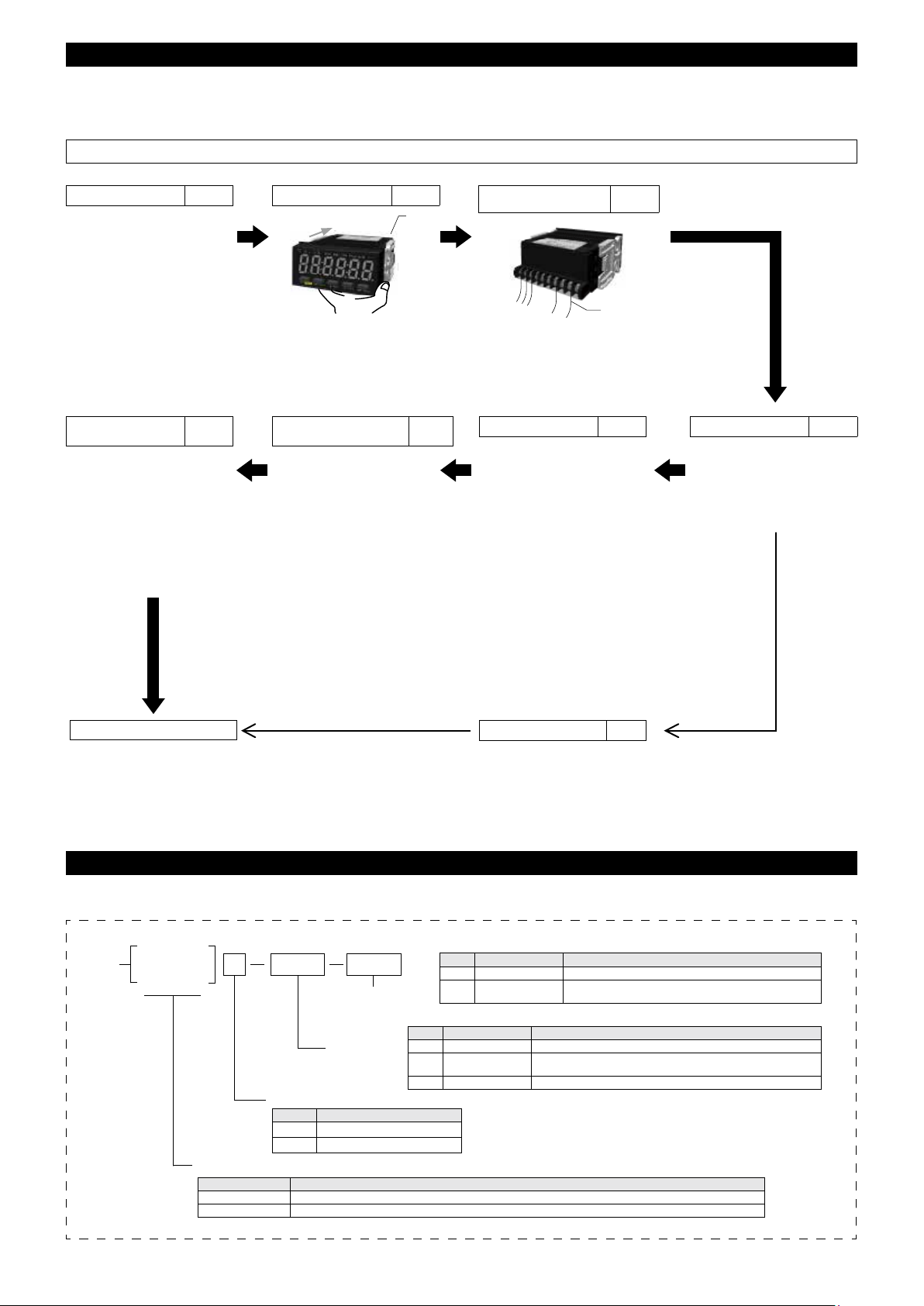

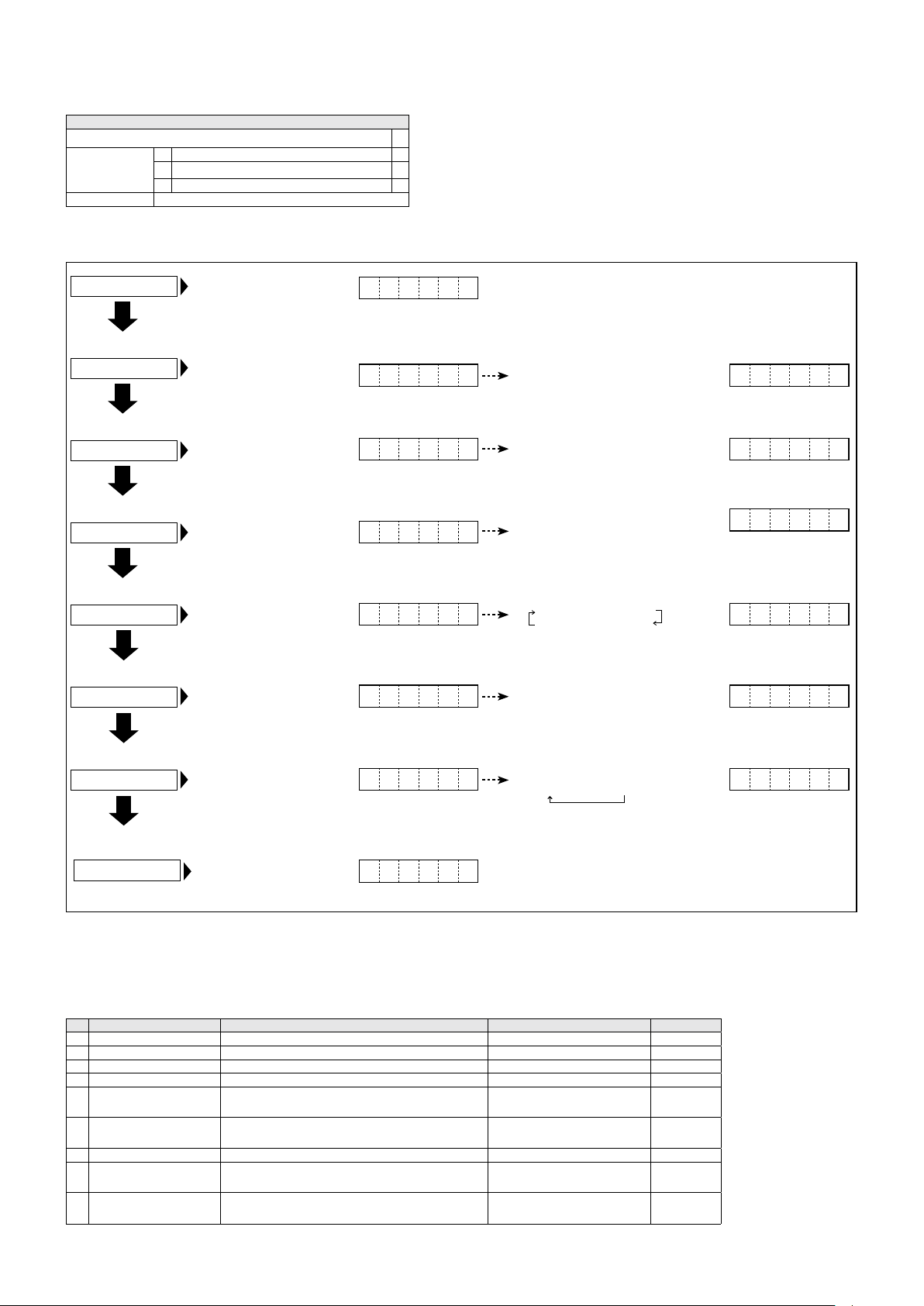

●1.

Installation to the Start of Operation

This unit is designed for use according to your measurement purposes.

Before use, follow the procedures below from installation to the start of operation.

Check before use

Check before use p.2 - 4

• Unit model

• Specications

• Component part names and

functions

• External dimensions

Memory function

settings

(1) Press the MEM key once to

display the MAX value.

(2) Press the MEM key again to

display the MIN value.

(3) Press the MEM key once again

to display the normal measurement

value.

*You can use the unit without

setting various functions.

p.17 - 19

Installation to the panel

View from

the front

(1)

Installation of waterproof gasket

(2) Fixation to the panel

(action conguration)

Function

settings

(1) Press and hold the SHIFT +

FUNC keys for 5 seconds or

more and start setting.

(2) Press the

item, and press the ENT key

to start changing the setting

value.

(3) Press the

another digit, and after

changing the value using the

s

nish the setting value change.

(4) After setting all functions, use

the SET key to nish setting.

key to select the

s

key to move to

t

key, use the ENT key to

p.4

Panel

p.8

p.

16 -17

Connection with the

power and sensor

View from

the back

(1) Connection with the power

(2) Connection with various sensors

p.5 - 6

Connecting wires

Parameter settings p.8 - 15

(1) Press and hold the SHIFT +

PAR keys for 5 seconds or

more and start setting.

(2) Press the

item, and press the ENT key

to start changing the setting

value.

(3) Press the key to move to

another digit, and after

changing the value using the

● key, use the ENT key to

nish the setting value change.

(3) After setting all parameters,

use the SET key to nish setting.

key to select the

s

t

(function)

Mode

(1) Press the SHIFT + MOD keys

and start setting.

(2) Use the

the SET key to nish setting.

settings p.8 - 15

key to set, and use

s

Start of operation

●2.

Unit Model

Please check the model number of the equipment purchased.

501X

DT

501F

Power

Symbol Power

A AC power (85 - 264VAC)

D DC power (10.8 - 25.2VDC)

Input type

Symbol Input type

501X Standard input : Supports the sensor input, including rotary encoders, and magnetic sensors

501F(AC Power only) Dierential input Supports the line driver output, including AC servo motors

Option #2

Option #1

Symbol Output Function

FVT

CPT Relay Output

TRT Transistor Output Open Collector Output. HH, H, LL, L GO and ZERO output.

Teaching function settings

●Parameter settings are not necessary.

Symbol Output Power Source

FVC

Analog Signal Output

BCS Output

BCD

Analog Signal Output

Outputs voltage and current that correspond to displayed value

Open Collector, BCD Output

Simple interface with the sequencer

Outputs voltage and current that correspond to displayed value

Relay Changeover contact output. H output, L output, and GO

output, against the set value

P7

* HH : High set point 2 output

●●●●●H : High set point 1 output

●●●●● L : Low set point 1 output

●●●● LL : Low set point 2 output

Simple setting

2

●3.

Specications

Unit model DT-501X ● DT-501F

Action mode Digital tachometer mode Flowmeter mode Elapsed timecounter mode Time width meter mode

Display

Display 1

0 - 999999

6 digits

Display 2 -

0:00:00 - 9:59:59

(Hour:Minute:Second / base 60 display)

(Hour:Minute:Second / base 10 display)

0:00 - 999:99

0:00:00 - 0:59:59

(Hour:Minute:Second / base 60 display)

With zero suppression function

Decimal point position 0 to 5 digits after the decimal point(000000 ● 0.00000)

-

Number indicator Red 7 segment LED, Letter height 22mm, 6 digits, - display available

LED lamp 8 (SIG, LL, L, H, HH, MAX, MIN, TEA)

Operation key 5 ●SET/SHIFT ,MEM/TEACH , ● /PARA ,

/FUNC ,ENT/MODE●

●

Input range 0.0067Hz ● 100kHz 10ms - 3600s

Measurement accuracy ±0.008● ±1digit ±0.1● ±1digit

Filter

Note that you can switch between only 10kHz and 0.02kHz in a magnetic sensor, and its contact is only 0.02kHz.

Switches between 100kHz, 30kHz, 10kHz, and 0.02kHz using the parameter.

Display cycle 0.2, 0.5, 1, 2, 5, 10, 15, 30, 60 sec. (changeable in the parameter settings) Dependent on the input signal

Pre-scale function Parameter setting system using the front panel keys. The teaching (combination) of display values are also available.

Memory function

Comparator function

The maximum/minimum measurement values can be memorized and displayed in the indicator.

The settings of the high set point 1, low set point 1, high set point 2, and low set point 2, and judgment results can

be displayed on the LED lamp. The hysteresis setting of the high and low set point 1 values are also available.

(Switches the display using the MEM key)

Auto zero time 0.1 - 150 sec. 0.1 - 3600 sec.

Pre-arithmetic function Updates the displayed value according to the elapsed time after the pulse stops.

Teaching function

Performs scaling automatically by setting the display value with a certain signal input. (only in the tachometer and owmeter modes)

Insulation resistance 10MΩ or more (at DC500V Mega)

Voltage proof AC1500V or more 1min

Operating temperature 0 - 45ºC(No condensation)

Operating humidity 35 - 85%RH (No condensation)

Operating atmosphere No corrosive gas

Conforming standard RoHS

Protection function Front panel: IP66 (or equivalent), Rear terminal block: IP20

Casing material ABS resin

External dimensions ● 96 × ● 48 × ● 92 ● (DIN)

Weight

*There are the input specications in addition to the above specications. For details, refer to p.5 - 6.

●4.

Component Part Names and Functions

FVT● FVC● TRT● BDC options : + approx. 50g

Approx. 200g

CPT options : + approx. 100g

●Front

●●●●●●●●●●●● ● ●●●●●● ●

●

●●●●●●●●●●●●●● ●●

●Rear

●

●Side

№ Name Function

● SIG lamp Lights up when the sensor signal is input

● LL lamp Lights up when the low set point 2 is judged.

● L lamp Lights up when the low set point 1 is judged.

● H lamp Lights up when the high set point 1 is judged.

● HH lamp Lights up when the high set point 2 is judged.

● MAX amp Lights up when the maximum value is displayed

● MIN lamp Lights up when the minimum value is displayed

● TEA lamp Lights up when the teaching function is set

● PEAK lamp Not used

● BTM lamp Not used

● Unit label space Space for attaching the supplied unit labels

● Main display Displays the measurement value

● SET/SHIFT key

● MEM/TEACH key

●

● ●(UP)/PARA key

●●(NEXT)/FUNC key

● ENT/MODE key

Finishes the setting in various setting modes

Pressing this key with other keys switches to various setting modes

Switches to the memory display

Pressing this key with the SET key goes to the teaching setting mode

Changes the selected items in various setting modes, or numerical values

Pressing this key with the SET key switches to the parameter setting mode

Changes the selected digit in various setting modes

Pressing this key with the SET key switches to the function setting mode

Selects the changed item(s) in various setting modes

Pressing this key with the SET key switches to the mode setting mode

● Terminal block

● Rear panel

● Terminal block cover

21

Mounting adapter

Unit label

ℓ

cm

21

● PS

● ● kHz rpm

●:●:●

●:●●●

h

sec min rps Hz h:m:s sec min rps Hz

●

m●●

mm

●● h

●● s

10

m

●

min

●

min

h

ℓ

min

ℓ

r

●s

km

h

m:s:●

min

mm

min

ℓ

●

cm

h

min

mm sℓ

m

km

min

h

● PS

● ● kHz rpm

●

m

h

10

s

●

h

ℓ

min

r

min

mm

min

FVT

CPT

TRT

FVC

TRC

BCD

RMT

DRT

SDT

SDC

●

3

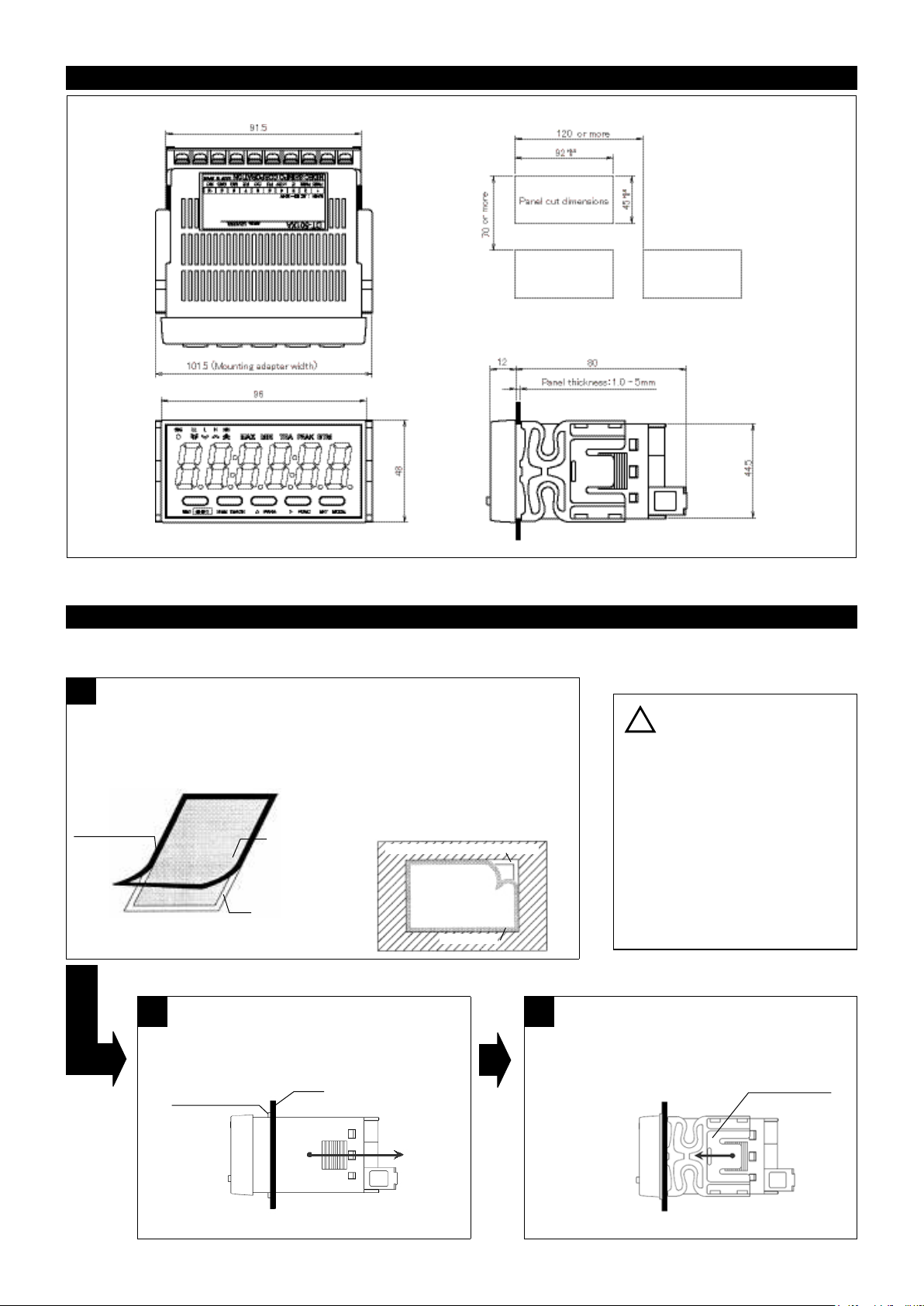

●5.

External Dimensions

●6.

Installation to the Panel

Mount this unit to the panel according to the following procedures.

Check that the mounting panel is thick enough (1.0 - 5mm) before mounting operation.

Attach the provided waterproof gasket to the panel surface.

1

* If waterproong is not necessary, skip this step.

(1)

Remove the external frame with the cutting

lines(backing paper + waterproof gasket)

from the gasket sheet.

(Adhesive paste is applied on the both

of the waterproof gasket.)

sides

External frame

(backing paper +

waterproof gasket)

Backing paper

(side with cutting lines)

Backing paper

(side without cutting lines)

(2) Attach the provided waterproof gasket to

the edges of the unit attachment panel and

opening, aligning with its left and right sides,

and then peel o the backing paper.

*

At this time, be sure not to displace or wrinkle

the waterproof gasket. Also, do not expand the

waterproof gasket vertically and/or horizontally

past the attachment panel’s edges.

Adhesive part of the waterproof gasket

Unit attachment opening

Backing paper

●mm●

CAUTION

!

About waterproong

● Front panel: IP66 (or equivalent)

● Rear terminal block: IP20 (non-waterproof )

Do not install the unit in the following

places or conditions.

(1) Places regularly subject directly to water

(2) Places subject to oil splashes and/or

medical supplies

(3) Places subject to water splashes on the

rear or side face(s).

* The front panel is IP66 (or equivalent)

waterproofed, but if water is splashed on

the unit, be sure to wipe it o the unit as

soon as possible.

Place the unit horizontally, and insert the gasket into

2

the opening of the panel surface.

Push the unit until the waterproof gasket (adhesive part)

securely reaches the panel surface of the unit.

Waterproof gasket

Panel

Attach the mounting adapter to the unit.

3

Slide the mounting adapter until it lightly touches the

panel surface.

Mounting adapter

4

●7.

Wiring to Power Source and Sensors (DT-501XA/DT-501XD)

Note)

In order to prevent electric shock, be sure to turn the power OFF. Be sure to use the unit under the rated voltage (AC power specifications:

85 - 264VAC / DC power specifications: 10.8 - 25.2VDC). The inverter output (output to connect a motor) cannot be used as power. Connection

wiring from sensors shall not be kept in the same or parallel conduit or cable as the power source, power or high voltage cables. If you fail to

separate the wiring, noise may be superimposed on the signal wire, resulting in malfunctions. Use shielded wire for input power connections

with the shortest possible metal conduit.

For DT-501XA/DT-501XD

• Terminal block connection diagram

Sensor

Power 1 Power 2 Earth

power output

+12V

Pull-up

Open

collector

Voltage

input

Magnetic

sensor input

0V

1 2 3 4 5 6 7 8 9 10

NC

● Wiring requirements

●●Use M3 crimp-style terminals with a width of 7 mm or

less to connect wires to the terminal block.

● After wire connection to the terminal block is completed,

be sure to attach the provided terminal block cover.

PWR1 PWR2 E PU

AC power

85 - 264V

DC power

10.8 - 25.2V

-

+

* Model

AC power specications: DT-501XA

DC power specications: DT-501XD

+12V

Shield wire

Earth

OC

MG

RE

V

oltage output sensor

NPN open collector sensor

(Adjacent switch, gear sensor, rotary encoder)

DC 2-wire sensor

NPN open collector sensor

●adjacent switch●

GND

Magnetic sensor

Relay switch

CAUTION

!

Be sure to connect the power wires to the 1st and 2nd terminals.

Incorrect connection could result in damage and/or burns to the unit.

• Input specications • Connection list with sensors

Item Description

Power

AC (DT-501XA) 85 - 264VAC(50/60Hz)

DC (DT-501XD) 10.8 - 25.2VDC

Consumption power 10VA

Sensor power output DC+12V Max.100mA

Open collector (NPN) input

Open collector input

LO input

Load capacity 12mA or more

0 - 3V

HI input Leakage current 0.5mA or less

Maximum frequency

(Minimum pulse width 5micro second●

100kHz

For no-voltage contact. Short-circuit ● and ● to use.

Contact input

Contact capacity Voltage 12V, Current 15mA or more

Maximum frequency

(Minimum pulse width 25micro second●

20Hz

LO input 0 - 1.5V

Voltage input

HI input 4.0 - 30V

Input resistance

Maximum frequency

10kΩ

30kHz

(Minimum pulse width 17micro second●

Input resistance 10k Ω

1Hz ● 100Hz 0.3 ● 30Vp-p

Magnetic sensor input

Input voltage

● 1kHz 1.5 ● 30Vp-p

● 10kHz 6 ● 30Vp-p

Note) Magnetic sensors cannot be used in the time wide meter mode (mode 3).

Maximum frequency

(Minimum pulse width 50micro second●

10kHz

The table below shows the sensors and connection terminal No. to be applied

according to the input signal type.Check using the connection diagram on

the left.

Input signal type Sensor

Contact signal Relay switch ● 5-6-9

Open collector Adjacent switch SE-P12-1 4-6-9

Adjacent switch SE-P12

Square wave

Gear sensor SE-G2

Note 1)

Connect sensor wires to the specied terminals, and be sure to leave theother

terminals empty. More than one sensor cannot be connected simultaneously.

Note 2)

When one sensor is connected to more than one tachometer, supply the power

for the sensor from one of them.

Our product model

Connection terminal

4-7-9Rotary encoder RE-1-●F

• Input circuit

Open collector sensor

Voltage output sensor

Example of external connection

NPN open collector sensor

Example of external connection

Example of external connection Example of external connection Example of external connection

NPN voltage output sensor

PNP voltage output sensor

DC 2-wire sensor

PNP open collector sensor

Relay switch

Magnetic sensor

5

Example of external connection

Example of external connection

Relay switch

Magnetic sensor

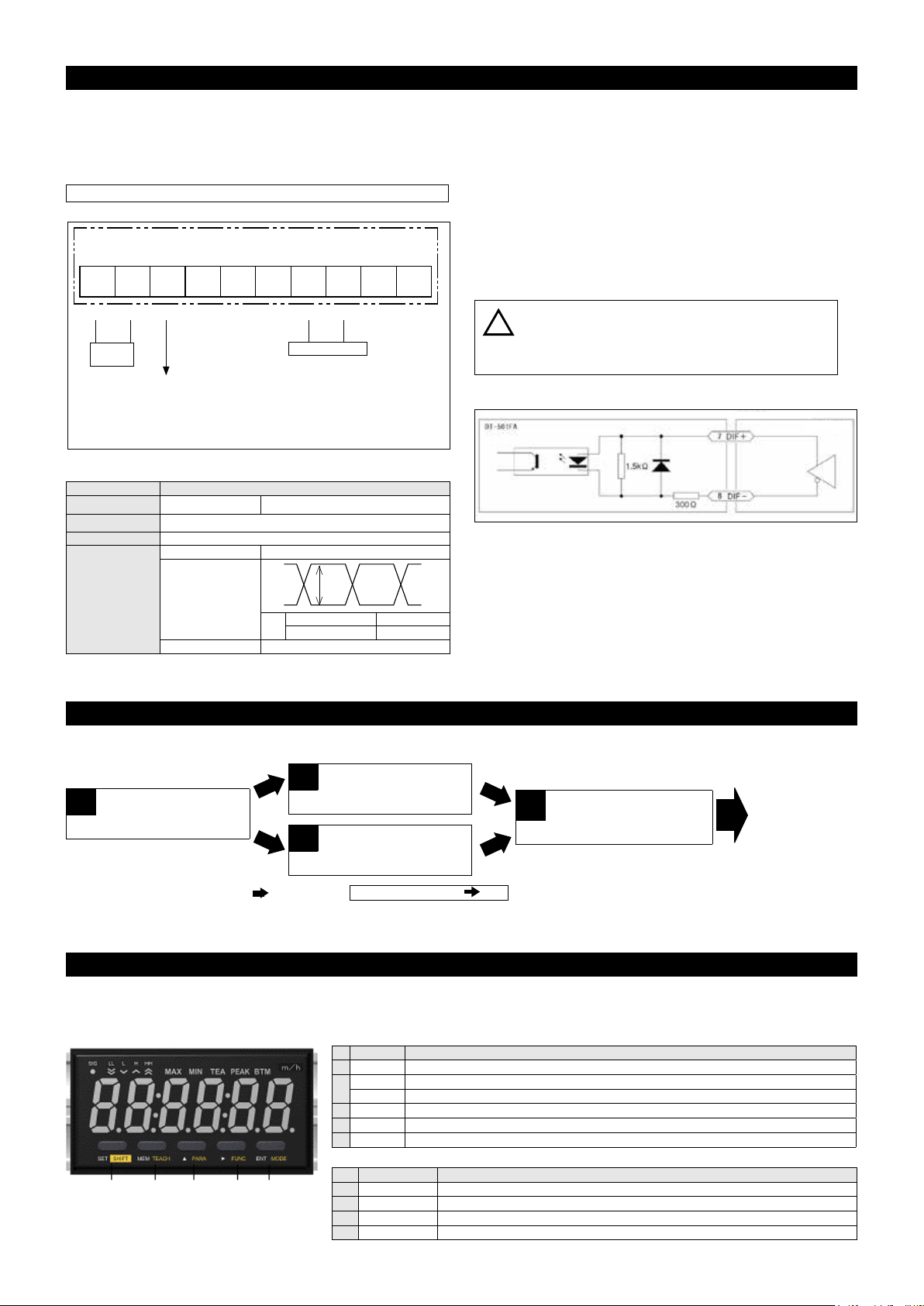

●8.

Wiring to Power Source and Sensors (DT-501FA)

Note)

In order to prevent electric shock, be sure to turn the power OFF. Be sure to use the unit under the rated voltage (AC power specifications:

85 - 264VAC). The inverter output (output to connect a motor) cannot be used as power. Connection wiring from sensors shall not be kept

in the same or parallel conduit or cable as the power source, power or high voltage cables. If you fail to separate the wiring, noise may be

superimposed on the signal wire, resulting in malfunctions. Use shielded wire for input power connections with the shortest possible metal

conduit.

For DT-501FA

• Terminal block connection diagram

Sensor

Power 1

Power 2 Ear th

power output

+12V

No connection No connection

Dierential

input +

Dierential

input -

0V

1 2 3 4 5 6 7 8 9 10

No connection

● Wiring requirements

● Use M3 crimp-style terminals with a width of 7 mm or

less to connect wires to the terminal block.

● After wire connection to the terminal block is completed,

be sure to attach the provided terminal block cover.

PWR1 PWR2 E NC NC

Earth

AC power

85 - 264V

* Model

AC power specications: DT-501FA

DIF+

DIF-

Dierential output

NC

GND+12V

• Terminal block connection diagram

Item

Power AC (501FA) 85 - 264VAC(50/60Hz)

Consumption power

Sensor power output

Dierential input

●9.

Basic Setting Procedure

10VA

DC+12V Max.100mA

Connection to Dierential line driver AM26LS31 etc.

Dierential input

voltage

Maximum frequency

Description

DIF+

DIF

V

DIF-

Maximum voltage±5.5V(15mA)

DIF

V

Minimum voltage

(Minimum pulse width 5micro second●

100kHz

±3.0V

Conduct settings as indicated below based on the intended use.

CAUTION

!

Be sure to connect the power wires to the 1st and 2nd terminals.

Incorrect connection could result in damage and/or burns to the unit.

• Line driver input circuit

Example of external connection

Line driver

Parameter settings

2

Mode (function) settings

1

Refer to p.8 - 15.

Refer to p.8 - 15.

Teaching function settings

2

Function (action configuration)

3

settings

Refer to p.16 - 17.

Refer to p.7.

Conduct the comparator function p.17 and memory function settings p.18, if necessary.

This unit requires no complicated calculation, and implements the teaching function which enables optional

changes of display values and error compensation. (excluding the elapsed timecounter and time wide meter modes)

10.

Keys to be Used for Various Settings and Their Applications

The front panel keys to be used for mode, parameter, and function settings, as well as various settings

(teaching function / high and low set point 1 value setting / memory function) are described below.

• Operation during the normal measurement display / memory display

№ Name Function

●

SHIFT key

MEM key

●

TEACH key Pressing and holding this key with the SHIFT key for 5 seconds switches to the teaching setting mode

●

PARA key

●

FUNC key

●

MODE key

Pressing this key with other keys switches to various setting modes

Switches to the memory display

Pressing and holding this key with the SHIFT key for 5 seconds switches to the parameter setting mode

Pressing and holding with the SHIFT key for 5 seconds switches to the function setting mode

Pressing and holding this key with the SHIFT key for 5 seconds switches to the parameter setting mode

• Operation in the various setting modes

№ Name Function

● ● ● ● ●

● SET key Setting completion key in various setting modes

●

(UP) key Changes the selected items in various setting modes, or numerical values

s

●

●(NEXT) key Changes the selected digit in various setting modes

t

● ENT key Selects the changed item in various setting modes

Measurement start

6

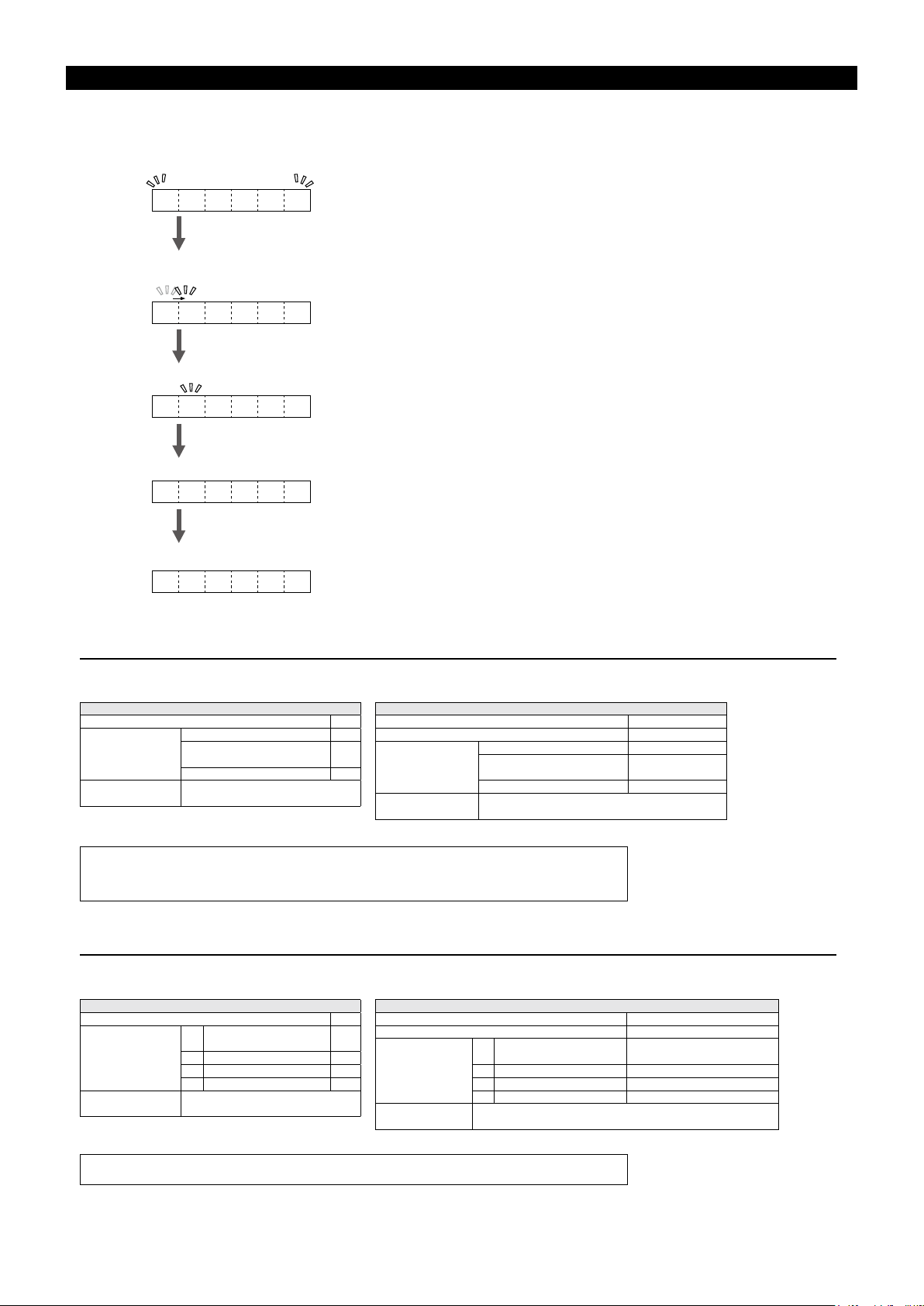

●11.

Teaching Function Settings

When you can check (measure) the actual revolution speed, the following simple method (teaching function) can be used.

The teaching function requires no complicated calculation.

● The teaching function is supported only in mode 1 and mode 4. Mode 2 and mode 3 have no teaching function.

● Setting method

1 0

SHIFT + MEM keys

5 seconds elapsed

Teaching function setting mode

TEA

When you press the SHIFT + MEM keys simultaneously during the

normal measurement display, the main display blinks.

●●●●●●●●●●●●●●●●●●●●●●●●(TEA lamp lights up)

The measurement value which was displayed before is displayed in the main display. In

the initial status, the digit on the left blinks. Because the value in the blinking digit can be

0 0 0 0 1 0

●

Use the

key

to select the digit

TEA

0 1 0 0 1 0

key to

Use the ●

select the value

TEA

0 1 0 0 1 0

Use the SET key to

nish the setting

Returns to the normal measurement display

changed, use the

Every time you press the

digit”, and “decimal point”, then back to “1st digit”.

After selecting the digit you want to change, use the

When you select the decimal point, use the

When the numerical value setting is complete, press the SET key to finish the

teaching setting.

The teaching setting result is reflected, and the display returns to the normal measurement

display.

key to select the digit in which you want to change the value.

t

key, the digit blinks in the order of “1st digit”, “2nd digit”, ... “6th

t

key to change the value (0 - 9).

s

key to change the decimal point position.

s

0 1 0 0 1 0

● Teaching function details

• Mode 1

The teaching function can be used to automatically change the value of parameter items (P2, P3), and calculate

the present measurement value from the teaching setting value as below.

External input pulse (Hz) A

Parameter setting

value

Display calculation

formula

When the input revolution speed is outside the input revolution speed range, “EE-2” is displayed, and the teaching function cannot be used.

During normal display

P1●Pulse count per revolution B

P2●Setting revolution speed

(detection section)

P3●Value to be displayed D

{ (A/B) * 60 } * (D/C)

Input pulse (Hz) in the teaching setting A

Teaching function setting value F

C

Parameter setting

value

Display calculation

formula

When the teaching function is executed

P1●Pulse count per revolution B

P2●Setting revolution speed

(detection section)

P3●Value to be displayed D = F

{ (A/B) * 60 } * (D/C)

C = A * 60(Hz)/ B

Input revolution speed range : 1rpm ● Input revolution speed* ● 99999rpm

●●●●●●●●●●●●●●●●●●●●●●

* The P2 calculation value is maintained by rounding o fractions after the decimal point.

●

Depending on input and teaching setting values, the teaching setting value for the input at the time might not be displayed.

*Input revolution speed = A × 60(Hz) / B

• Mode 4

The teaching function can be used to automatically change the value of parameter items (P3, P4), and calculate

the present measurement value from the teaching setting value as below.

External input pulse (Hz) A

Parameter setting

value

Display calculation

formula

When the input frequency is outside the input frequency range, “EE-2” is displayed, and the teaching function cannot be used.

Input frequency range●: 1Hz

*

The P3 scaling value maintains values after decimal point up to 7 digits inside. Note that because the number of digits

after decimal point that can be maintained in the parameter setting is up to 5, values in 5 digits or more after decimal

point will be rounded o when you enter the value in the parameter setting.

* If the P3 calculation value exceeds 999999, the P3 value will be forced to be “999999”.

Mode 4 Display value calculation

Number of blades per

P1

revolution

P2 Capacity per sensor blade C

P3 Scaling D

P4 Decimal point display

●A * B● * C * D

●●●A●●●

Input pulse (Hz) in the teaching setting A

Teaching function setting value F

B

Parameter setting

value

E

Display calculation

formula

99999Hz

Mode 4 Display value calculation

Number of blade per

P1

revolution

P2 Capacity per sensor blade C

P3 Scaling D = F/ (A * B * C )

P4 Decimal point display Decimal point position of E = F

●A * B● * C * D

B

7

●12.

About Mode

DT-501X/DT-501F have ve modes (functions) which can be selected according to the measurement purpose.

Mode

No.

99 Test Mode Executes the self diagnosis p.19

* The mode 1 (digital tachometer mode) is set in the factory setting.

Mode description Details

1 Digital Tachometer Mode* Digital tachometer / used as speedmeter●Displays the proportional value to the input p.8 - 9

2 Elapsed Timecounter Mode Used as the elapsed time display in a certain period●Displays the inversely proportional value to the input p.10 - 11

3 Time Width Meter Mode Measures time for the period when the signal is ON (or OFF) and displays it p.12 - 13

4 Flowmeter Mode Displays the instantaneous ow amount p.14 - 15

for the setting method

For the lists of parameters and functions to be set in each mode, refer to pages 20 and 21.

Page No.

Setting Method

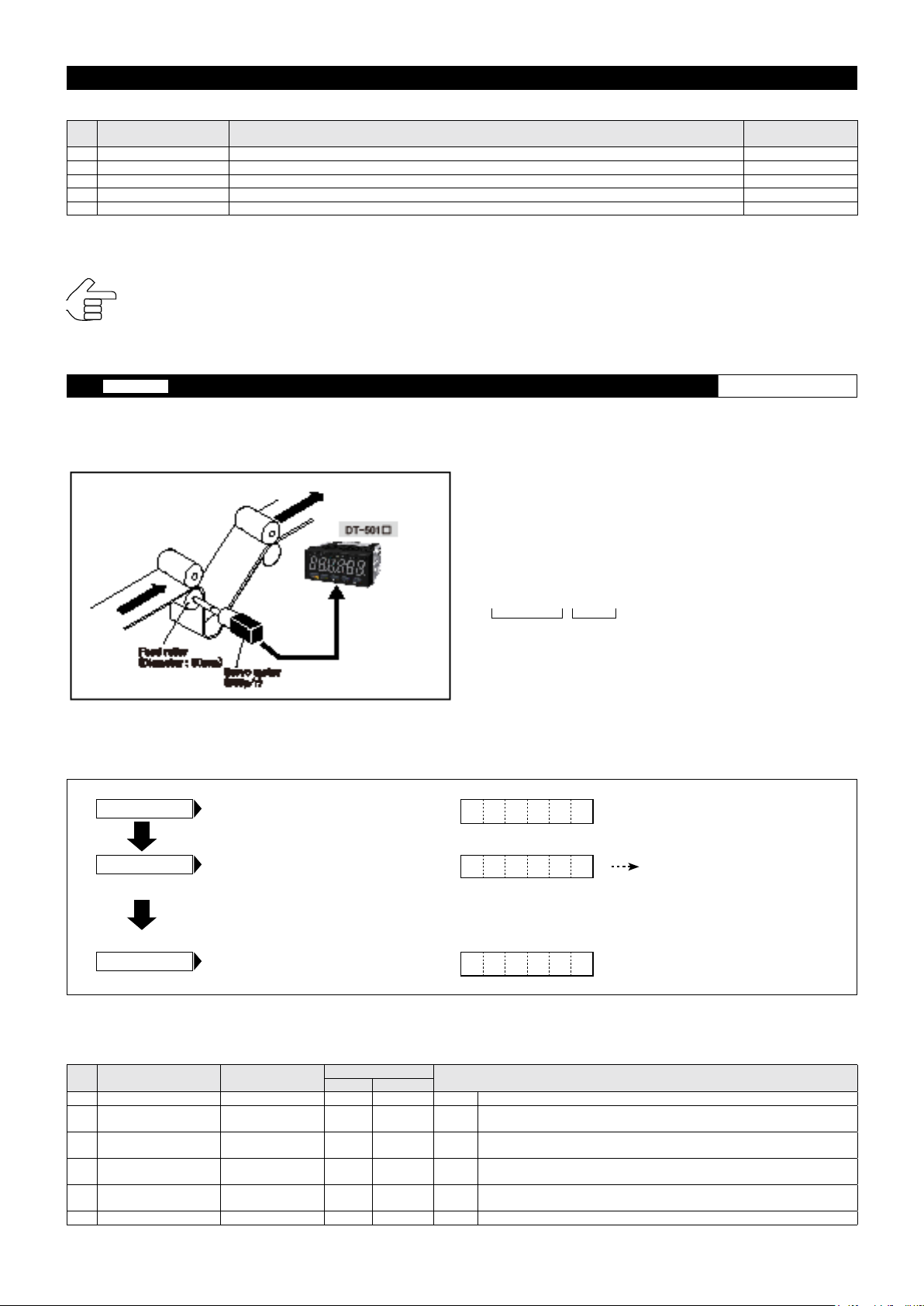

13.

When You Select Mode 1 (Digital Tachometer Mode) for Measurement

Digital tachometer mode

Set each setting item for mode and parameter according to the following procedures.

(For the setting method of functions, refer to pages 16 and 17.)

● Setting example (for measuring the peripheral speed of the roller)

As in the gure on the left, the rotary encoder is connected to the feed

roller via coupling in the paper manufacturing process. To display the

peripheral speed (m/min.) of the feed roller in DT-501under the following

conditions:

[Conditions]

● Servo motor (pulse input)

● Diameter of the feed roller

● Peripheral speed of the roller diameter of 90mm ●

●0.09m×3.14)×500rpm ● 141.3m/min

Circumference

●●●●

of the roller

Revolution

speed*

*Suppose that the revolution speed

in the detection section is 500rpm

because the revolution speed is not

instructed.

● Setting method

(1) Mode

• When you select mode 1 (digital tachometer mode) for measurement (The digital tachometer mode is set in the factory setting.)

Normal display

The main display shows “0”.

0

Mode setting

Finish setting

Note) If you change the mode settings, each parameter and function setting value will return to the factory default setting value.

Press and hold the SHIFT + MODE keys

for 5 seconds or more.

The main display shows the current set

mode No. after blinking.

* When you are setting for the rst time after the

purchase of this unit, mode 1(digital tachometer

mode) in the factory default setting is displayed.

Press the SET key.

The display goes to mode 1 (digital tachometer

mode).

- 0 1 -

0

The numerical value does not

need to be changed and you can

proceed to the next step.

* Every time you press the

the mode No. switches.

s

(2) Parameter

•

Parameter setting items in mode 1 (digital tachometer mode) nd numerical values to be set according to the above example

No. Setting item Setting range

Pulse count per revolution

P1

Revolution speed in the

P2

detection section

Value to be displayed

P3

(with decimal point)

P4 Display cycle

P5 Auto zero time 0.1 - 150 sec. _ _ 006.0 6.0 sec. 6 sec. Measure using the default setting value as no special instruction is provided.

P6 Input lter 10/30/100/0.02kHz _ 10_ 10kHz 30kHz As the rotary encoder is used as a sensor, select "30".

* For the description about the parameter functions, refer to page 20.

1 - 9999p/r _ _ 0001 1p/r 600p/r Enter the pulse count of the rotary encoder.

1 - 99999rpm _01000 1000rpm 500rpm Enter some numerical value as the revolution speed is not instructed.

0.00001 - 999999 001000 1000 141.3 Refer to the above "Setting example".

0.2/0.5/1.0/2.0/

5.0/10/15/30/60 sec.

Default setting value

Display Description

_ 1.0 _ 1 sec. 1 sec. Measure using the default setting value as no special instruction is provided.

Numerical value to be set according to the above example

8

key,

● Mode 1 (digital tachometer mode) Display value calculation equation

Mode 1 Display value calculation

External input pulse (Hz) A

P1 Pulse count per revolution B

Parameter setting

Equation ●(A/B)

P2

P3 Value to be displayed D

Revolution speed in the detection section(rpm)

*

*

60)

(D/C)

C

• Start setting according to the setting example on the previous page.

Parameter setting

Press and hold the SHIFT +

PARA keys for 5 seconds or

more to switch to the parameter

setting mode.

0 1 - P 0 1

Parameter 1 setting

Parameter 2 setting

Parameter 3 setting

Parameter 4 setting

Parameter 5 setting

Parameter 6 setting

Press the ENT key and start

setting parameters. (The main

display shows t

merical value of each parameter.)

Every time you press the key, the

display switches to the next pa

rameter.

Every time you press the ●

key, the display switches to the

next parameter.

he current set nu

s

0 0 0 1

--

-

0 1 0 0 0

-

-

0 0 1 0 0 0

2. 0-

-

0 1 0. 0

--

0 1 0. 0

Use the key to move to another digit

t

s

Use the key to change the numerical value

to “600”.

Use the ENT key to nish setting.

Use the

key to move to another digit

t

Use the key to change the numerical value

s

to “500”.

Use the ENT key to nish setting.

t

key to move to another digit

Use the

s

Use the key to change the numerical value

to “141.3”.

Use the ENT key to nish setting.

(Use the

use the key to change its position.)

Every time you press the ● key, the

display switches as below.

Select "1.0" and use the ENT key to

nish setting.

Use the key to move to another digit

Use the key to change the numerical value

to “6.0”.

Use the ENT key to nish setting.

(Use the

use the key to change its position.)

Every time you press the key, the display

switches as below.

Select "30" and use the ENT key to

nish setting.

key to select the decimal point, and

t

s

0.2 > 0.5 >1.0 >2.0 >5.0

60●<●30●<●15●<●10

t

s

key to select the decimal point, and

t

s

s

●10 > 30 >100 > 0.02

●●●●●●●●●●●●

--

-

-

--

-

0 6 0 0

5 0 0

1 4 1. 3

1. 0-

6. 0

3 0

---

Press the SET key.

Finish setting

*If you enter a value outside the setting range, all the input values will blink, which indicates the setting is disabled.

●When this occurs, you cannot switch to other displays until you enter a value within the setting range.

The display goes to mode 1

(digital tachometer mode).

0. 0

(3) Function (For the setting method, refer to pages 16 and 17.)

• Function setting item in mode 1 (digital tachometer mode)

No. Setting item Setting range Input range Default value

F1 High set point 1 value Sets the high set point 1 value 000000 - 999999 0

F2 Low set point 1 value Sets the high set point 1 value 000000 - 999999 0

F3 High set point 2 value Sets the high set point 2 value 000000 - 999999 0

F4 Low set point 2 value Sets the low set point 2 value 000000 - 999999 0

Hysteresis of the high and

F5

low set point 1 values

Judgment output timer at

F6

startup

F7 Minimum revolution speed Sets the revolution speed to be displayed as zero 000000 - 999999 0

Frequency of the moving

F8

average

F9 Pre-arithmetic function

* For the description of functions, refer to pages 21 and 22.

Sets the hysteresis of the high and low set point 1

values

Sets the time when the comparator judgment is output

at startup

Used when variation of the revolution speed is large

and a stable display cannot be attained

Promptly performs the deceleration display when the

signal is lost

0 - 99 0

0 - 99 sec. 0 sec.

0(disabled)/1(3 times)/2(10 times) 0(disabled)

0(disabled)/1(enabled) 0(disabled)

9

Loading...

Loading...