Shimpo DT-2100 Instruction Manual

●Enables measurement of a rotating body at a distance using integral

laser beam

Handheld Digital Tachometer

with Dual Non-Contact, Contact Operation

DT-2100

Non-contact type

●Maximum of 1000 data point storage

●The organic light emitting display (OLED) allows enhanced viewing,

even in dark locations

●Selectable meter or graphic display modes

●High accuracy measurement capability of +/-0.006%

●PC communication through USB with available software

99265C

Instruction Manual

Thank you for purchasing Nidec-Shimpo's Handheld High-Performance Digital

Tachometer DT-2100. For instructions on how to use this product properly and

optimally for a long period of time, please be sure to read this manual thoroughly

before use.

Safety Requirements

Be sure to observe

Before operation, maintenance and inspection, please carefully read this instruction manual

and follow it for proper use. Start using only after you have read about the equipment’s func

tions, safety information and precautions.

This instruction manual provides three grades of safety warnings: "Danger", "Warning" and

"Caution". Each of them is an important description related to safety. Be sure to follow them.

Non-contact type digital tachometers are used to perform

measurement by applying the supplied reflection tape

to the rotating body of the object to be measured, and

projecting the laser beam (red) to the tape. In addition, they

can be used for contact type measurement by attaching the

supplied contact adapter.

■Inspection result certicate

We skip issuance of the inspection result certicate for this product. However, at the

time of factory shipment total shipment inspection has been completed, and we have

strictly conrmed that there is no error in measurement accuracy and operation.Your

understanding is appreciated.

Before operation, maintenance and inspection, please

carefully read this instruction manual and follow it for

proper use.

After carefully reading this manual, be sure to store it in a safe

and convenient place for easy reference.

-

・

・

・

!

Do not look into the laser beam

Do not point the laser beam at people

Do not allow usage by children

Warning

This indicates the possibility of re, severe injury,

Danger

!

Warning

!

Caution

!

●Limited Warranty

We are not responsible for damages resulting from negligence through failure to follow the

・

instructions set out in this manual.

We are not responsible for damages resulting from earthquake and/or re unrelated to us,

・

actions by third parties, or any other accidents, intentional or through customer negligence,

as well as from accidents caused by misuse or improper use under abnormal conditions.

For information regarding assurance provisions, please read the attached warranty certi

・

cate.

and even death if a user disregards the instruction

and operates the unit improperly.

This indicates the possibility of severe injuries if a

user operates the unit improperly.

This indicates the possibility of minor injury or

damage if a user operates the unit improperly.

www.nidec-shimpo.co.jp

Do not contact the laser beam irradiation port with a rotating body

If the unit comes into contact with a rotating body,

damage may result to the laser.

Do not measure using wet or oily

hands, or with loosely tted clothing.

If hands slip during measurement, ngers or part of the

hand may get caught in the rotating equipment.

!

Caution

Be careful around installed reective

tape.

-

The reection tape may come loose during high-speed

rotation.

INDEX

1. Part Names and Functions 2

2. Measurement Method 4

3. Measurement Display Description 6

4. Graph Display 8

5. Memory Function 9

5-1. Memory mode details 9

5-2.

Memory registration in the memory group

6. Various Settings 11

6-1. Contents selection 11

6-2. Memory data display 11

6-3. User settings 15

6-4. System settings 22

7. Battery Replacement 34

8. Dimensional Drawing 34

9. Specications 35

10

1

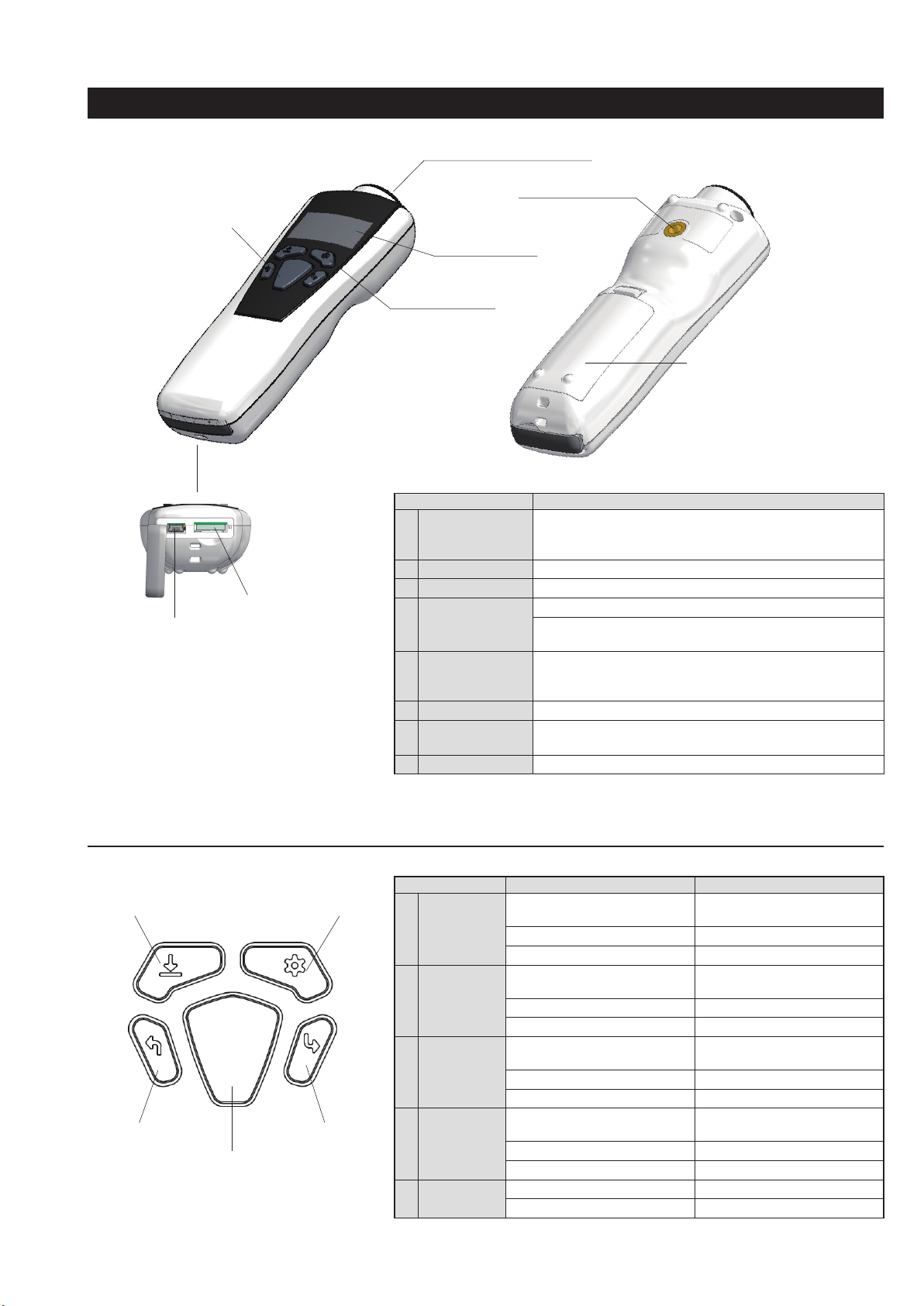

1. Part Names and Functions

(4) Power/Measurement key

(6) Connector

(5) USB connector

(1) Laser beam irradiation port

(7) Mounting Adapter

(2) Display screen

(3) Operation keys

Parts name Functions

(1) Laser beam

irradiation port

Apply the reection tape to the rotating body of the object to be

measured. Project the laser beam (red) to the tape and measure

the rotation speed.

(2) Display screen

Operation keys 1 to 4

(3)

(4) Power/

Measurement key

Displays the measurement value.

Used to change setting or store memory data.

Press this key to turn the power ON.

The power will be turned OFF when no operation has been

performed for a certain period of time. (Auto off function)

(5) USB connector

Power can be supplied through the USB connector.

Also, connecting the unit to a PC enables communications using

using the available software. (Sold separately)

(6) Connector

(7) Mounting Adapter

For internal production usage only

Allows unit to be mounted with its x/x ? threaded connection on

tripod

Battery Compartment

(8)

Uses two AA dry cell batteries

(8) Battery Compartment

■Operation keys and power/measurement key details

Parts name Mode Function

Operation key 1

(1) Operation key 1

(4) Operation key 4

(5) Power/Measurement key

(2) Operation key 2

(3) Operation key 3

(1)

Operation key 2

(2)

Operation key 3

(3)

Operation key 4

(4)

Power/

(5)

Measurement key

2

・

Measurement mode (measurement

standby, during measurement)

・

Set mode Used to select the item.

・

Memory data display mode Used to select the item.

・

Measurement mode (measurement

standby, during measurement)

・

Set mode Used to select the item.

・

Memory data display mode Used to select the item.

・

Measurement mode (measurement

standby, during measurement)

・

Set mode Used as the enter key.

・

Memory data display mode Used as the enter key.

・

Measurement mode (measurement

standby, during measurement)

・

Set mode Used as the cancel key.

・

Memory data display mode Used as the cancel key.

・

When the power is OFF Used to turn the power ON.

・ zz

Measurement mode Used to perform measurement.

Used to store the memory data.

Used to display memory data,

and congure various settings.

Used to switch the measurement

display.

Used to return the measurement

display to the normal display.

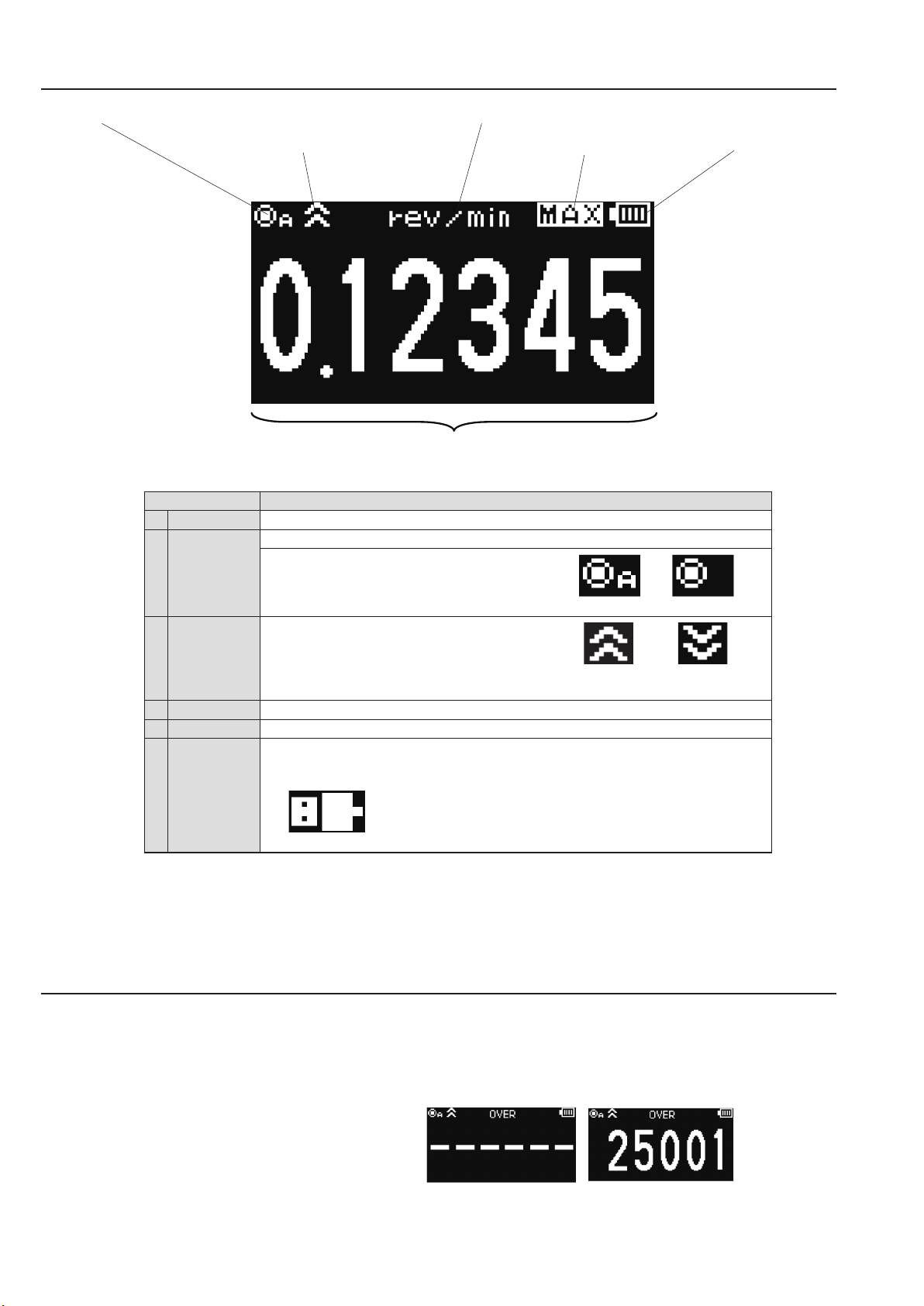

■Display screen details

(2) Rotation detection display

(3) Upper/lower limit judgment display

Key name

(1) Main display

Rotation

(2)

detection display

(4) Unit display

(5) Description display (6) Battery display

(1) Main display

Displays the measurement value.

Blinks during measurement.

"A" is displayed when the contact adapter has been

attached.

With contact Without contact

(3)

Upper/lower limit

judgment display

(4) Unit display

Description display

(5)

(6) Battery display

*For screen protection, the display becomes dark when no operation has been performed for 10 seconds.

Also, the display is turned OFF when no operation has been performed for 1 minute.

Displays judgment results of the display value

according to the comparator setting.

Displays the current set unit.

Displays description for the measurement value currently indicated.

Displays the remaining battery level.

Blinks when the remaining battery level becomes close to 0.

Also, the following mark is displayed when the power is supplied through the USB cable.

When the USB cable is connected

■OVER display

When the measured value exceeds the display range, "

Also, when it exceeds the measurement range, "OVER" is indicated in the unit display, and it blinks.

- - - - - -

" is displayed.

When the upper When the lower

limit is reached limit is reached

●Display range OVER ●

* When "OVER" is indicated, the measurement accuracy is

not guaranteed.

Measurement range OVER

3

2. Measurement Method

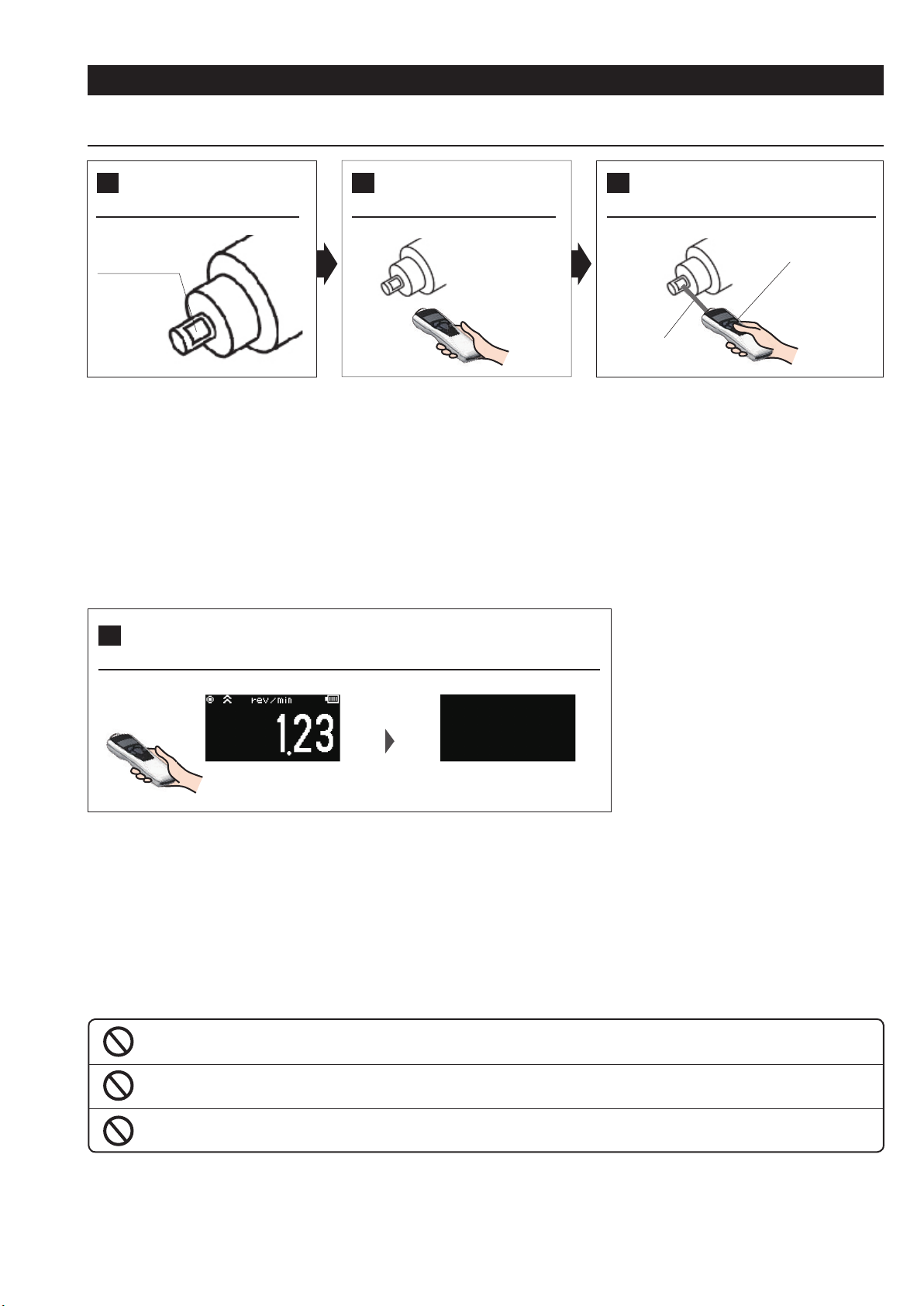

■Non-contact measurement

Apply the re ection tape to

1

the object to be measured

Re ection tape

Apply the supplied reflection tape to

the rotating body of the object to be

measured.

●Do not apply to a rotating body smaller than

the re ection tape.

●If the rotating body is glossy, apply black tape,

or paint it black and apply the reflection

tape.

●Before applying the re ection tape, wipe off

water/oil on the attachment surface of the

rotating body, and apply the tape without

any irregularities.

Point the laser beam irradiation

2

port to the object to be measured

Point the laser beam irradiation port

to the reflection tape applied to the

rotating body.

●Keep a distance of 50 to 4000 mm (2 in.

to 13 ft.) between the reflection tape and

irradiation port.

Press the power/measurement key

3

to start measurement

Power/Measurement key

Laser beam

Press the power/measurement key, and start

measurement.

●When the rotating body is static, the value "0" is

displayed.

●When the rotating body rotates, the actual measurement

data is displayed every display update cycle.

Power OFF when no operation has been performed for a certain

4

period of time (Auto off function)

Left unoperated

Final measurement

value held

After measurement ends, the power is turned OFF when no operation has been performed for a certain period of time.

●The period of time until the power goes OFF can be set in "Auto off" in the system settings.

●When performing communication using the optional USB cable, the auto off function is disabled.

* When the speed and distance units are selected in the unit setting, be sure to select "3. SET_SYSTEM" in contents selection, and set the distance

value per pulse in the "9. DIST/PULS" setting.

Power OFF

■Precautions on measurement and handling

Never look into the laser beam.

Failure to follow this could result in injury to the eyes.

Do not point the laser beam at people.

Do not allow usage by children.

4

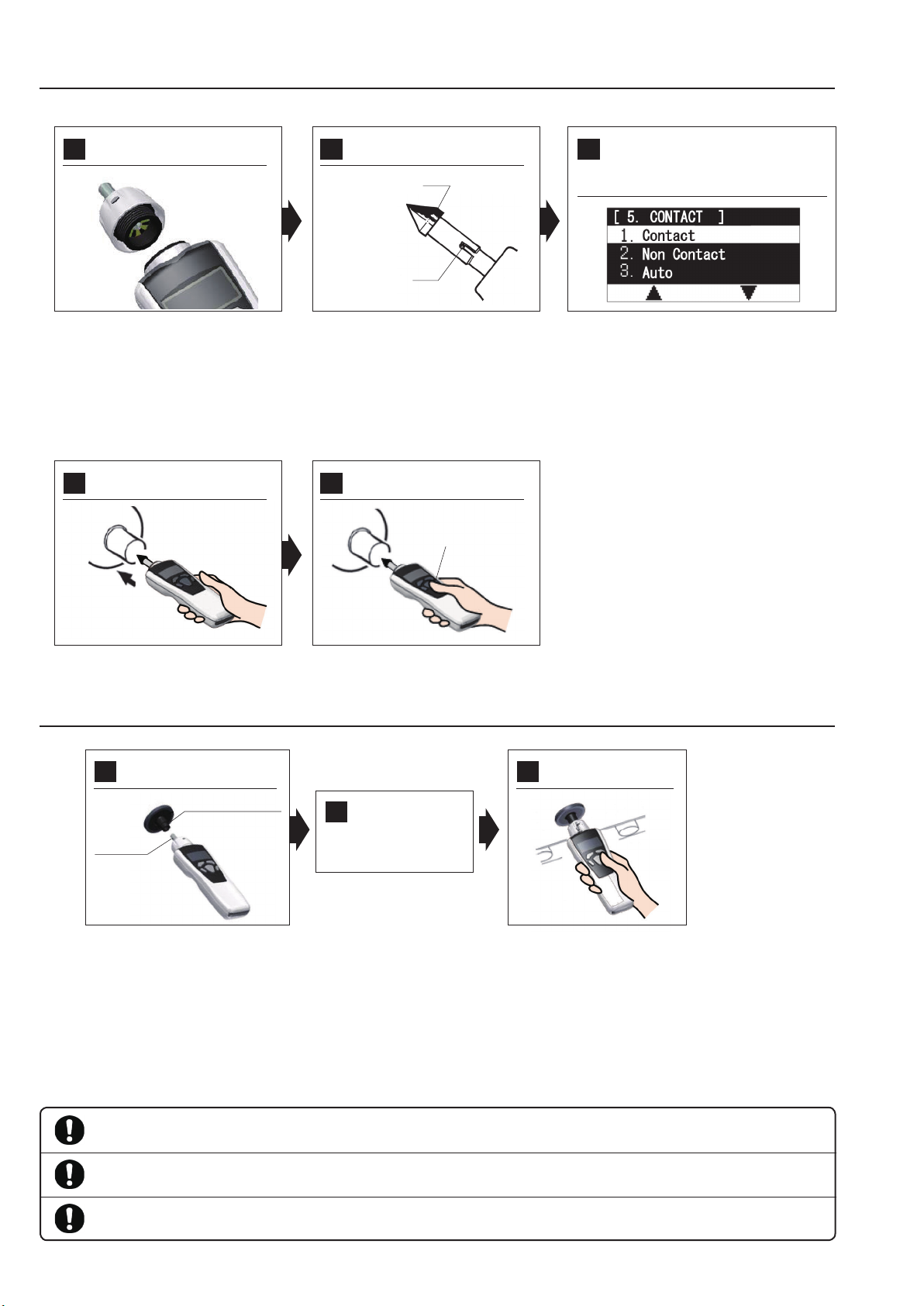

■Contact measurement

Attaching the optional contact adapter enables measurement in the contact mode.

Attach the contact

1

adapter

Put the contact on the

4

object to be measured

Select the appropriate

2

contact tting and attach.

Contact (conical)

Measurement

shaft pin

For rotation speed measurement, attach

the conical or funnel contact.

● When the object to be measured has a

concave shaft, attach the conical contact.

●When the object to be measured has a

conical shaft, attach the funnel contact.

* When attaching the contact, securely fit

the measurement shaft pin into the contact

groove.

Press the power/measurement

5

key, and start measurement

Power/Measurement key

In the "5. CONTACT" setting of "3. SET_

3

SYSTEM" in contents selection, change

to "1. Contact" or "4. Contact (Low)"*.

* Select "4. Contact (Low)" when using the optional

contact adapter for low speed.

Carefully put the contact on the center of the

rotating body of the object to be measured.

Press the power/measurement key, and

start measurement.

■When using the speed measurement wheel

Attach the speed measurement

1 3

wheel to the measurement shaft

Speed measurement wheel

Put the speed

2

measurement

wheel on the object

Measurement

shaft pin

Note) When attaching the wheel, securely t the

measurement shaft pin into the wheel groove.

*The auto off function works similarly as in the case of non-contact measurement.

* When performing the non-contact measurement again after contact measurement ends, be sure to select "3. SET_SYSTEM" in

contents selection, and set to "1. Contact" in the "5. CONTACT" setting.

* When using the speed measurement wheel, in the "8. DIAMETER" setting of "3. SET_SYSTEM" in contents selection, set the

diameter value of the peripheral speed foil. When using the supplied speed measurement wheel (circumference of 6 inches),

use it with the default value (diameter value of 48.5104 mm).

to be measured

Carefully put the speed

measurement wheel on the object

to be measured (belt part, etc.).

Press the power/measurement

key, and start measurement

Refer to the above (rotation speed

measurement)

■Precautions on measurement and handling

Before measurement, securely t the contact adapter to the contact. Also, during measurement, carefully put the contact on the rotating body of the

object to be measured.

When attaching the speed measurement wheel for measurement, align it along the object to be measured, and do not push the wheel with excessive

force. Also, for safety measurement, use with a speed of 300m/min (500cm/s, 18000m/h, ~18km/h, 197inch/s) or less.

When measuring a high-speed rotating body using the conical or funnel contact over a long period of time, note that the convex and concave portions

of the contact may produce high heat.

5

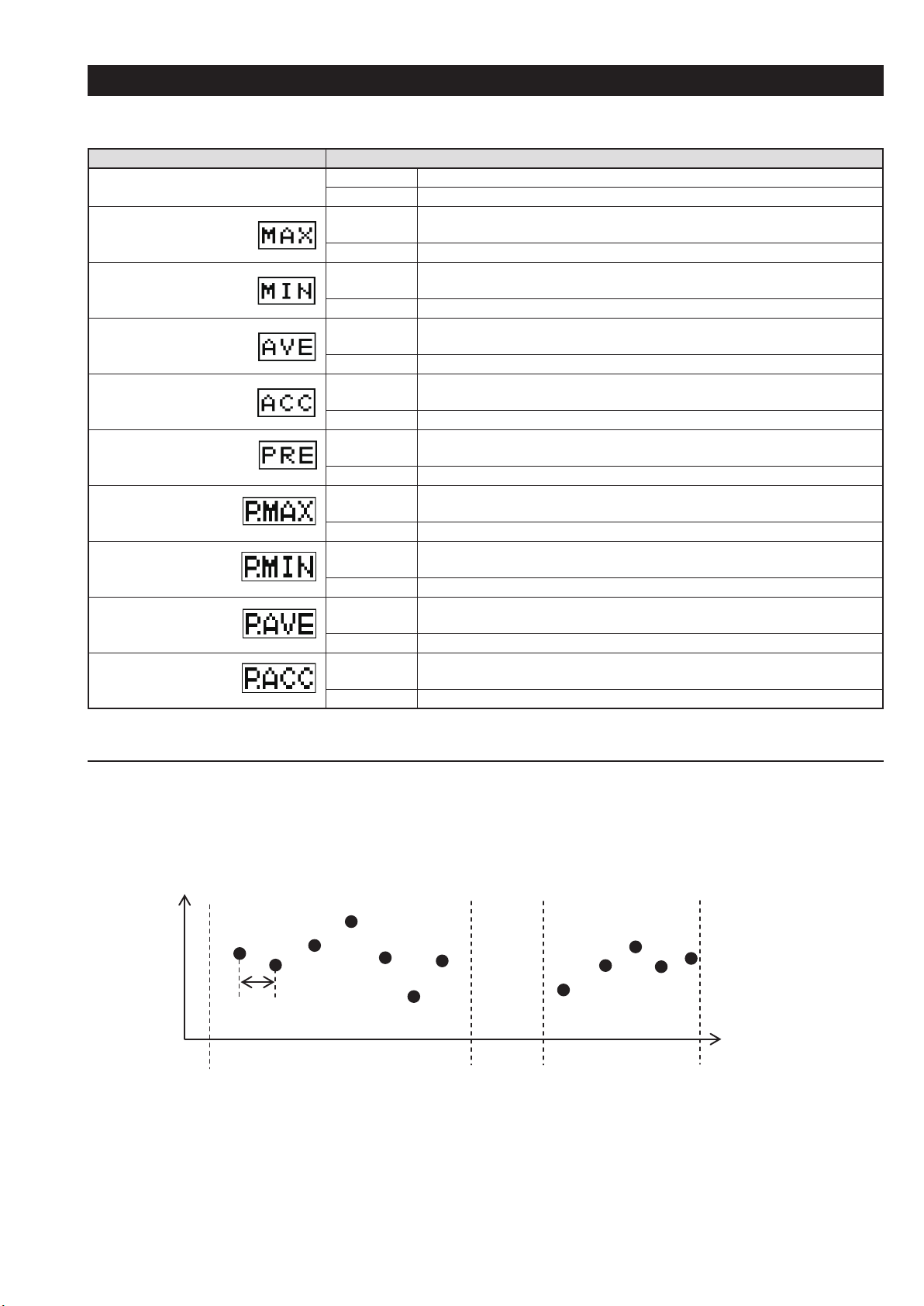

Rotation speed

3. Measurement Display Description

Press the operation key 3 in the measurement mode. The measurement value description to be displayed is switched.

The types of the measurement value to be displayed are as follows:

Display Description

Normal Description Displays the measurement value corresponding to the selected unit.

Display update Updates every display update cycle.

Maximum value

(Inactive during distance

and manual measurement)

Minimum value

(Inactive during distance

and manual measurement)

Average value

(Inactive during distance

and manual measurement)

Acceleration rate

(Inactive during distance

and manual measurement)

Prescale Description

Prescale maximum value

(Inactive during distance

and manual measurement)

Prescale minimum value

(Inactive during distance

and manual measurement)

Prescale average value

(Inactive during distance

and manual measurement)

Prescale acceleration rate

(Inactive during distance

and manual measurement)

Description Displays the maximum value from measurement start to end. This value is reset when

the next measurement starts.

Display update Updates every display update cycle.

Description Displays the minimum value from measurement start to end.

next measurement starts, or the auto zero function is performed.

Display update Updates every display update cycle.

Description Displays the average value within the "GRAPH_TIME" specied in the system

settings.

Display update Updates every "GRAPH_TIME".

Description Displays the acceleration rate within the "GRAPH_TIME" specied in the system

settings.

Display update Updates every "GRAPH_TIME".

Displays the measurement value when "PRESCALE" is enabled. This feature is selected in

the system settings. When "PRESCALE" is not specied, this is not displayed.

Display update Updates every display update cycle.

Description Displays the maximum value among the measurement values when "PRESCALE" is

enabled. This value is reset when the next measurement starts.

Display update Updates every display update cycle.

Description Displays the minimum value among the measurement values when "PRESCALE" is

enabled. This value is reset when the next measurement starts.

Display update Updates every display update cycle.

Description Displays the average value within the "GRAPH_TIME" specied in the system

settings, among the measurement values when "PRESCALE" is enabled.

Display update Updates every "GRAPH_TIME".

Description Displays the acceleration rate within the "GRAPH_TIME" specied in the system

settings, among the measurement values when "PRESCALE" is enabled.

Display update Updates every "GRAPH_TIME".

This value is reset when the

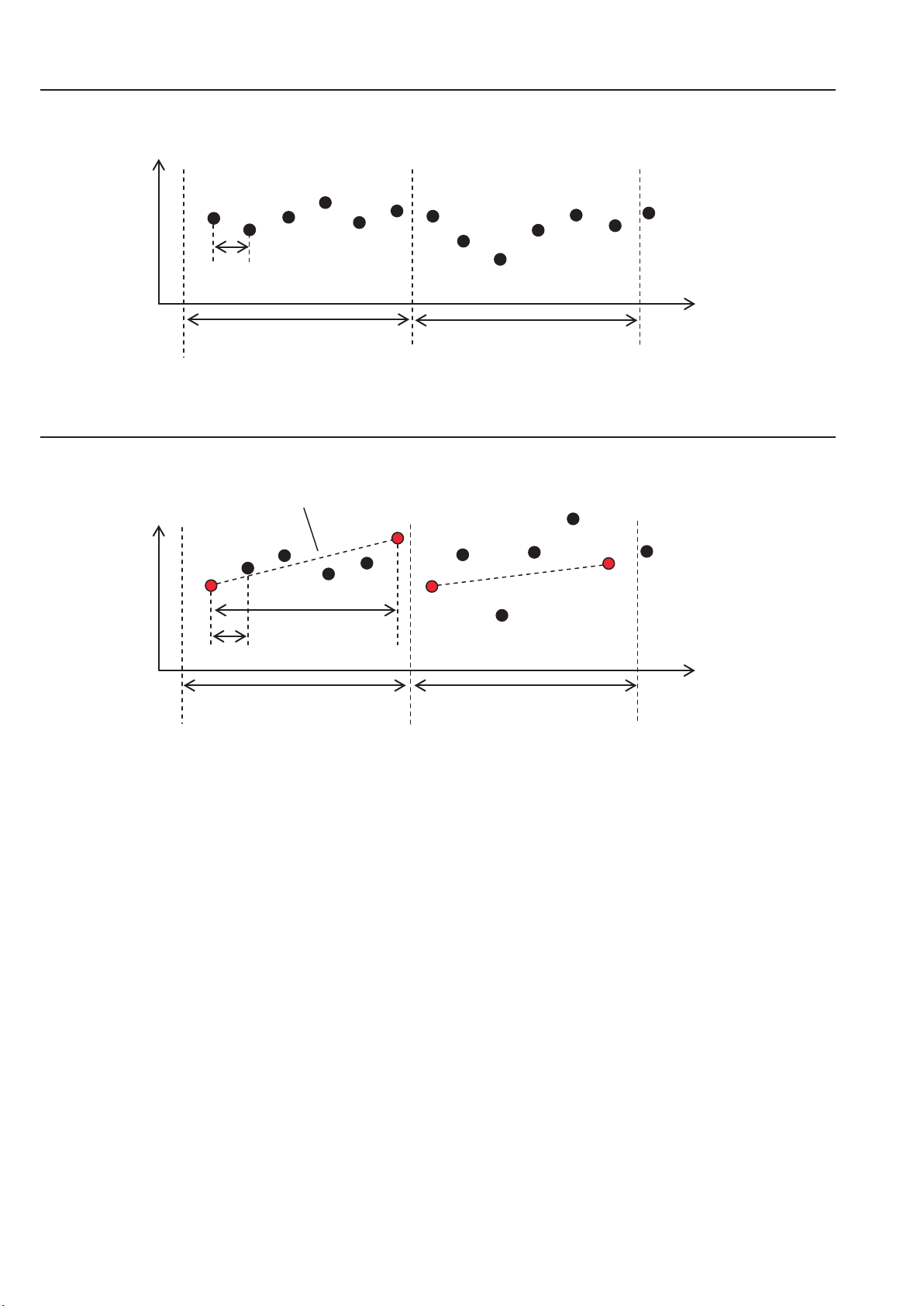

■About calculation of the maximum value (MAX) and minimum value (MIN)

・

As shown in the gure below, the instrument sets the measurement value when measurement starts with initial values of MAX0 and MIN0.

It then compares them to new measurement values every sampling cycle.

New updated maximum and minimum values are created and displayed if they exceed (for MAX0) or are below (for MIN0).

(Updates in the order of MAX

・

The maximum and minimum values are reset when measurement starts.

Measurement

start

→ MAX1 → MAX2)

0

MAX0

MIN0

MAX

1

MIN

Sampling cycle*1

1

MAX

2

MAX2

MAX

MAX0

1

MIN0

MIN2

Time

Measurement

end

Measurement

start

Measurement

end

6

■About calculation of the average value (AVE)

Rotation speed

The average value is displayed by averaging the measurement values in the corresponding cycle every average value update cycle.

4

1

3

2

6

5

7

8

11

10

9

Sampling cycle*1

Average value update cycle*2

Average calculation of the

measurement display values 1 to 6

Average calculation of the

measurement display values 7 to 12

■About calculation of the acceleration rate (ACC)

The acceleration rate is calculated based on v0 and v1 in the corresponding cycle every acceleration rate update cycle.

Rotation speed

Gradient = Acceleration rate

v

0

Acceleration rate

calculation time

Sampling cycle*1

Acceleration rate update cycle*2

v

1

MIN

MAX

12

Time

Time

Acceleration rate =(v1 - v0)/Acceleration rate calculation time

*1 The sampling cycle is "DISP_CYCLE" in the system settings.

*2 The average value update cycle and acceleration rate update cycle are "3-2 Graph time" in the system settings.

*The acceleration rate is displayed up to 5 digits, and when the speed is decreased, it is displayed as a negative value.

*Minus value of the acceleration value cannot be displayed in the graph.

7

4. Graph Display

Using the "4. GRAPH_DISP" setting of "2. SET_USER" in contents selection enables the graph to be indicated on the display.

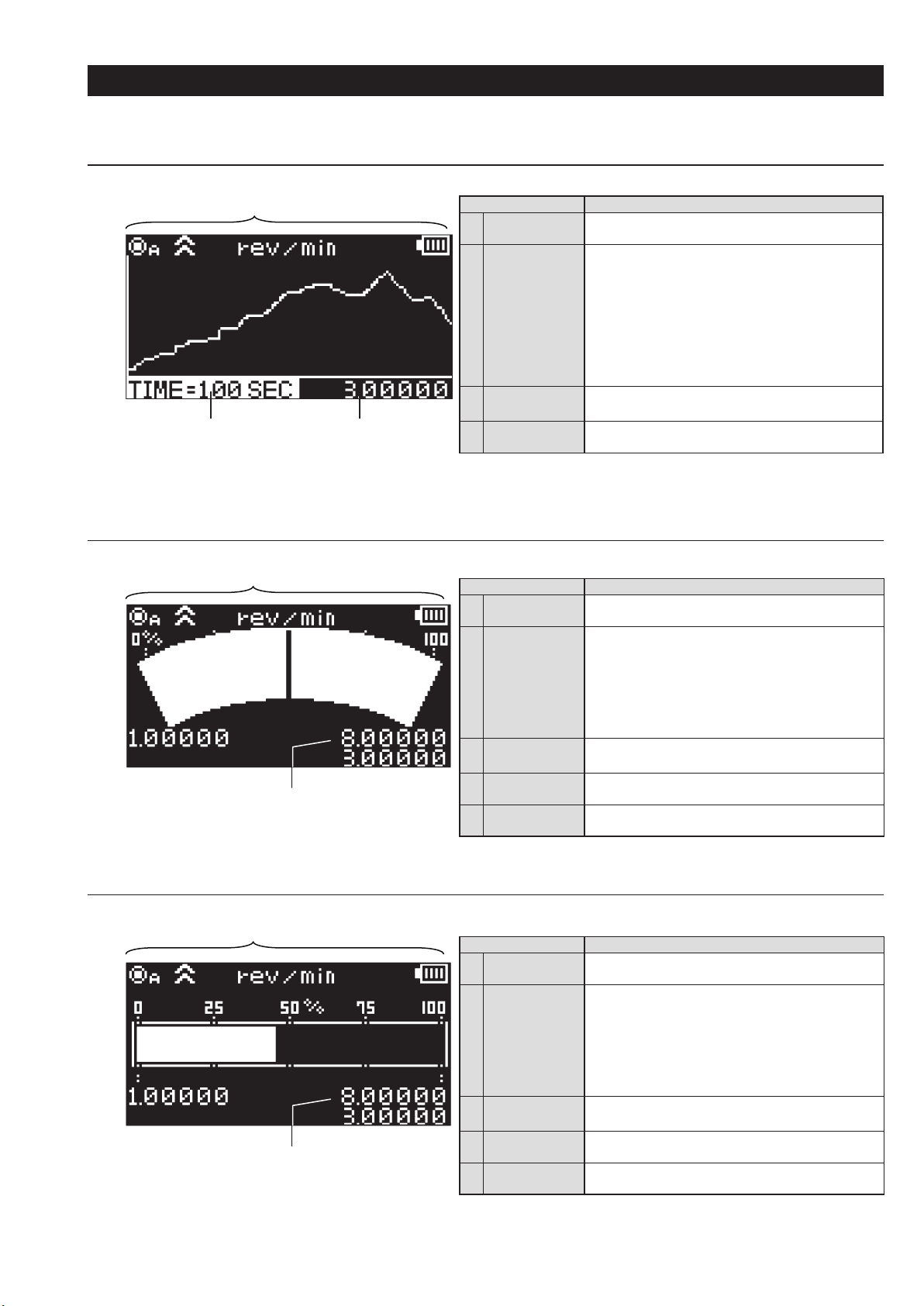

(1) Graph_1 (Line graph)

(1) Various status display

(2) Line graph display

4) Graph time display (3) Measurement value display

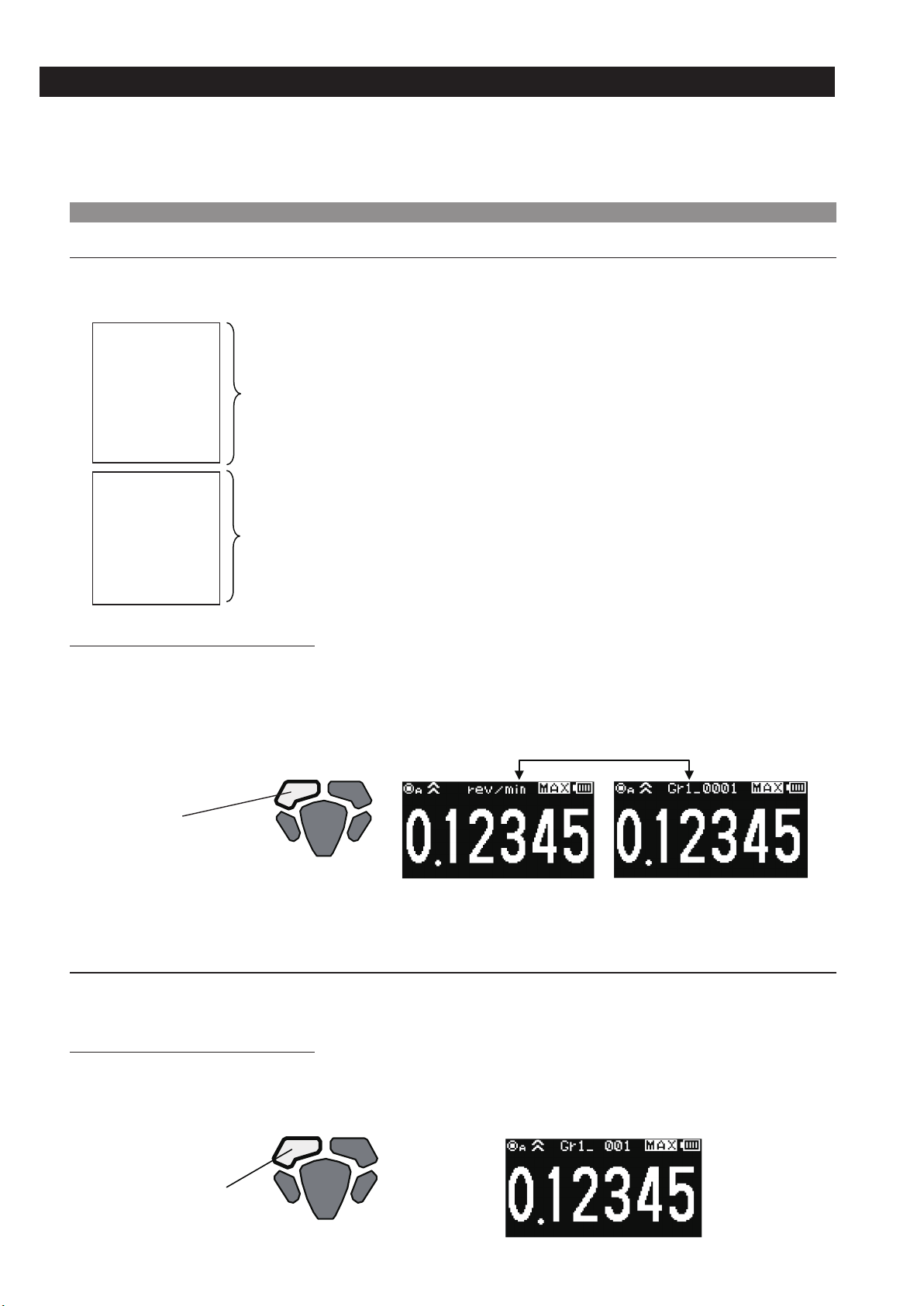

(2) Graph_2 (Gauge Mode)

(1) Various status display

(2) Needle graph display

(5) Graph minimum

value display

(4) Graph maximum

value display

(3) Measurement

value display

Parts name Operation

Various status

(1)

display

(2) Line graph display

(3) Measurement

value display

Graph time

(4)

display

Update cycle: Every display update cycle

*

Parts name Operation

Various status

(1)

display

(2) Gauge Display

(3) Measurement

value display

Graph maximum

(4)

value display

Graph minimum

(5)

value display

Update cycle: Every display update cycle

*

Same as in the normal display

Displays the line graph for the measurement value.

Depending on selection one of the below will equal the

graph values:

Maximum value on the vertical axis:

Graph maximum value setting

Minimum value on the vertical axis:

Graph minimum value setting

Horizontal axis: Graph time setting value

Graph ow: Graph ow setting value

Displays the current measurement value

Can switch among MAX, MIN, AVE, and ACC

Displays the graph time setting value

Same as in the normal display

Displays the needle graph for the measurement value.

Depending on selection one of the below will equal the

gauge values:

Graph maximum value:

Graph maximum value setting

Graph minimum value:

Graph minimum value setting

Displays the current measurement value

Can switch among MAX, MIN, AVE, and ACC

Displays the graph maximum value setting

Displays the graph minimum value setting

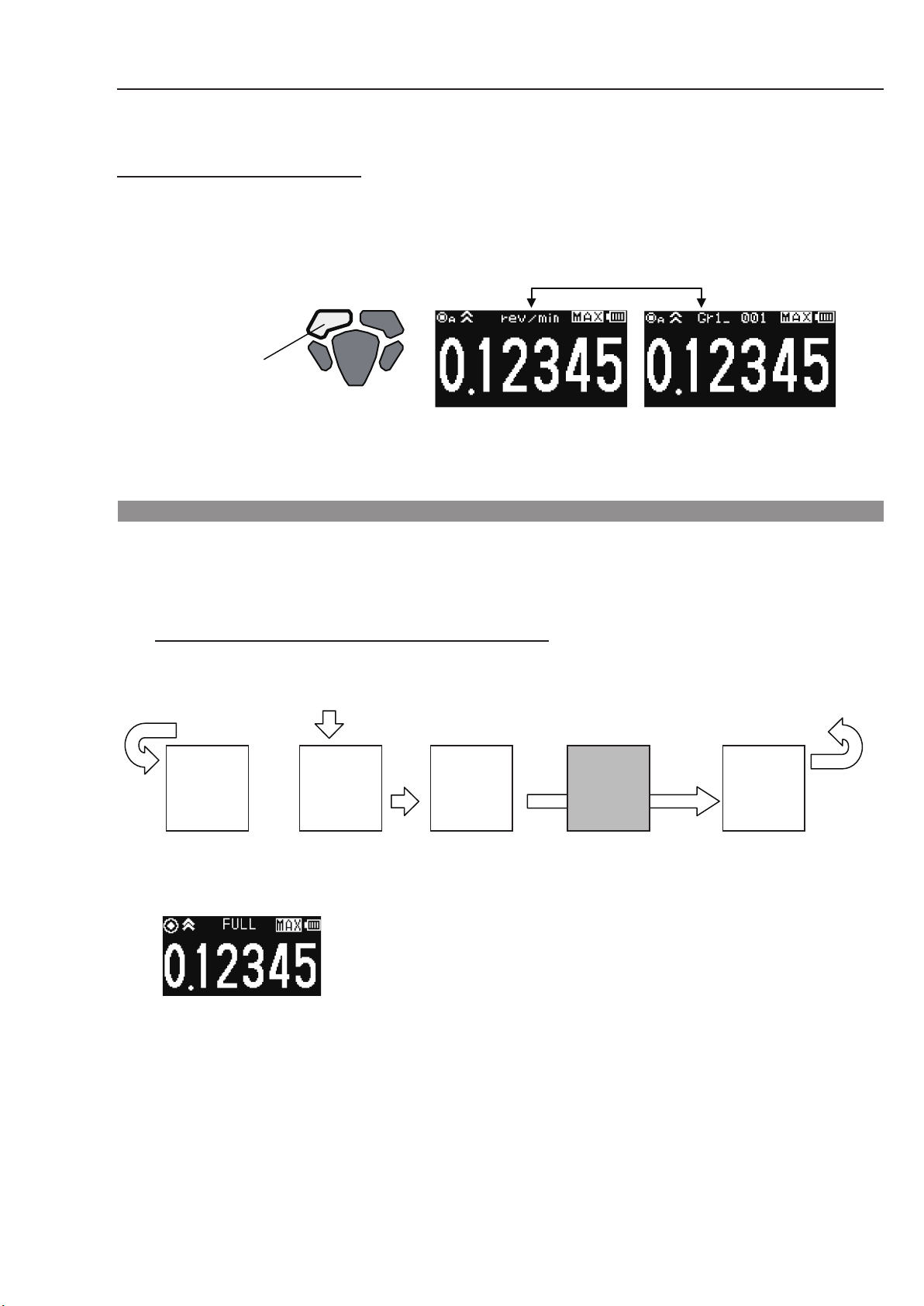

(3) Graph_3 (Bar graph)

(1) Various status display

(2) Bar graph display

(5) Graph minimum

value display

(4) Graph maximum

value display

(3) Measurement

value display

Parts name Operation

Various status

(1)

display

(2) Bar graph display

(3) Measurement

value display

Graph maximum

(4)

value display

Graph minimum

(5)

value display

Update cycle: Every display update cycle

*

Same as in the normal display

Displays the bar graph for the measurement value.

Depending on selection one of the below will equal the

gauge values:

Graph maximum value:

Graph maximum value setting

Graph minimum value:

Graph minimum value setting

Displays the current measurement value

Can switch among MAX, MIN, AVE, and ACC

Displays the graph maximum value setting

Displays the graph minimum value setting

8

5. Memory Function

The measurement value can be registered and stored in the memory during measurement.

The stored data can be displayed in contents selection "1. DATA".

Registration contents and methods depend on the memory mode.

Set the memory mode in the "2. MEMORY_MODE" of "2. SET_USER" in contents selection.

5-1 Memory mode details

(1) Continuous memory mode

In the continuous memory mode, the measurement value continues to be registered in the memory every display update cycle.

・

The number of memory sets that can be registered in the continuous memory is up to 1000.

・

For the continuous memory, the value description to be registered in the memory depends on the measurement display description.

・

Normal display

・

MAX display

・

MIN display

・

AVE display

・

ACC display

・

PRE display

・

P.MAX display

・

P.MIN display

・

P.AVE display

・

P.ACC display

・

Registers the measurement value every display update cycle

Registers the measurement value every display update cycle after prescale calculation

●Memory registration operation

Press the Operation key 1 once during measurement to start memory registration. Press it again to end memory registration.

・

When turning measurement OFF, or switching to the contents selection mode during memory registration, memory registration ends at

・

that moment.

The unit and "Gr ○ _ □□□□" are alternately displayed in the unit display part during memory registration.

・

(○ shows the number of memory groups, and □ shows the number of memory points currently registered: 0001 to 1000)

Displayed alternately every second during memory registration

Operation key 1:

Memory registration start/end

*The continuous memory mode can be used only when one of the units from "rev/min" to "miles/h" is selected in the unit setting.

(2) Each memory mode

In the each memory mode, only one set of the measurement value currently displayed is registered in the memory.

・

The number of data points that can be registered in the each memory is up to 100.

・

●Memory registration operation

Press the operation key 1 once during measurement to register the display value at that moment in the memory.

・

"Gr ○ _ □□□□" is displayed for 1 second in the unit display part during memory registration.

・

(○ shows the number of memory groups, and □ shows the number of memory sets currently registered: 001 to 100)

Displayed for 1 second during memory registration

Operation key 1:

Performs memory registration

9

(3) Statistics memory mode

In the statistics memory mode, only the statistics data for the measurement value every display update cycle from memory registration start

・

to end is registered in the memory.

The number of data points that can be registered in the statistics memory is up to 100.

・

●Memory registration operation

Press the operation key 1 once during measurement to start memory registration, and press it again to end memory registration.

・

When turning measurement OFF, or switching to the contents selection mode during memory registration, memory registration ends at that

・

moment.

The unit and "Gr ○ _ □□□□" are alternately displayed in the unit display part during memory registration.

・

(○ shows the number of memory groups, and □ shows the number of memory sets currently registered: 001 to 100)

Displayed alternately every second during memory registration

Operation key 1:

Memory registration start/end

* In the statistics memory mode, the statistics data in a single registration is calculated from the measurement value for up to 100 times of

display update. When the display update frequency exceeds 100 in a single registration, memory registration automatically ends.

*The statistics memory mode can be used only when one of the units from "rev/min" to "miles/h" is selected in the unit setting.

5-2. Memory registration in the memory group

Start memory registration from the start memory group (that has been set in "3. START_MEM" of "2. SET_USER" in contents selection).

・

When the number of memory groups reaches the number of memory sets in each group (that has been set in "4. MEM_GROUP" of "3. SET_

・

SYSTEM" in contents selection), the memory group switches to the next one.

When the number of memory sets exceeds the total number of memory sets for all memory groups, "FULL" is displayed in the unit display

・

part. In this case, additional memory cannot be registered.

Example: When the start memory group is set to memory group 2

(1) Start memory registration from

the start memory group

Group 1 Group 2 Group 3 Group 5Group 4

(2) Go to the next memory group

when the number of memory

sets exceeds the specied

number

(5) Displays "FULL" when the number of memory sets exceeds the specified number for all

memory groups, and ends memory registration ("FULL" is displayed until the operation key 1 is

pressed)

After that, even if you press the operation key 1 and try to start memory registration, "FULL" is

displayed for 1 second, and registration is disabled.

(3) Go to the next memory

group when the number

of memory sets is 0

(4) Return to memory group 1

when the number of memory

sets exceeds the specied

number in group 5

10

Loading...

Loading...