Application Information

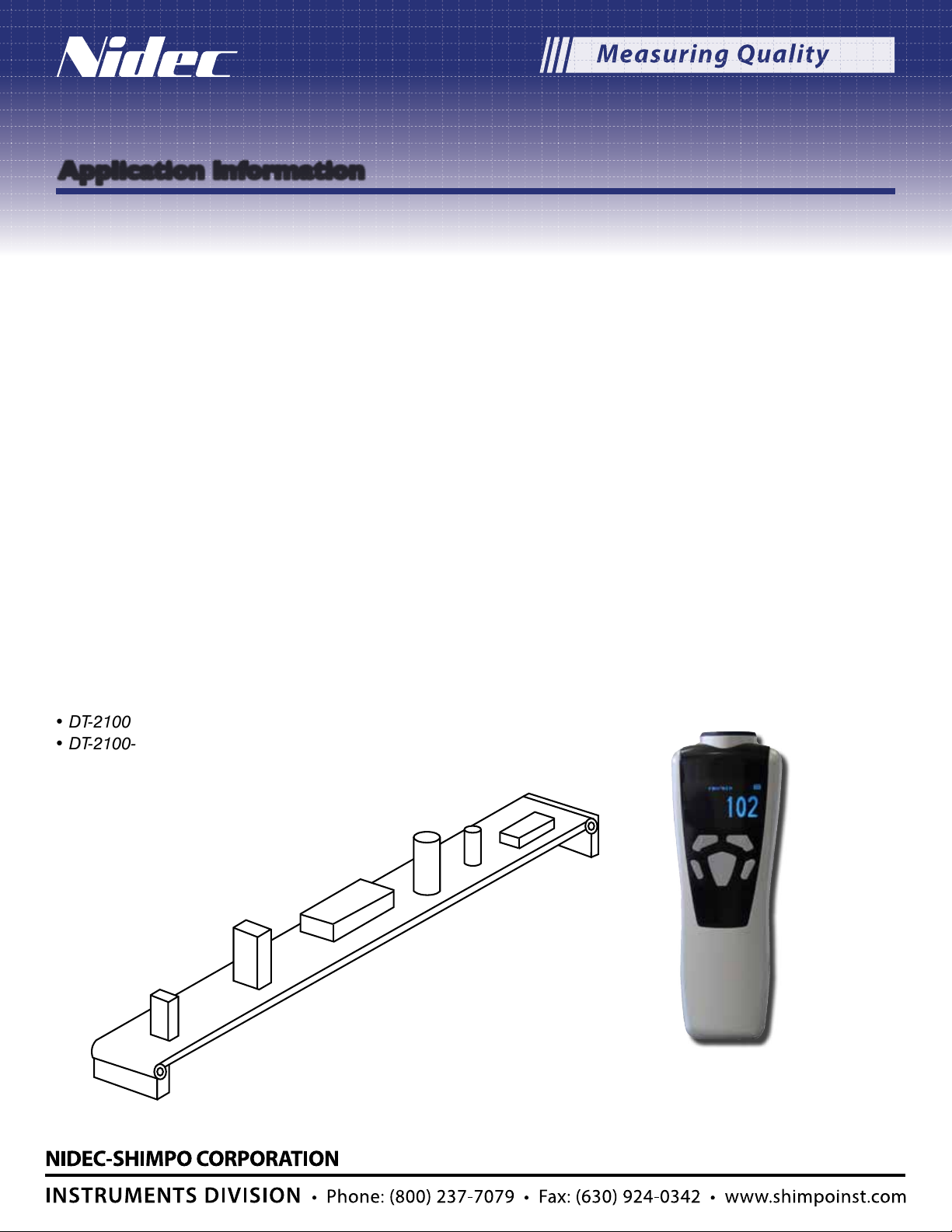

Assembly Line Conveyor Speed

A manufacturer of nutrition products who was experiencing a timing issue on the conveyor speed of their assembly line sought Shimpo in search of a solution. This factory ran production on a vast number of their organization’s products which varied in size and weight. Due to the large variation in the product mix, the weight

fluctuations produced varying conveyor belt speeds. The result was the disruption of subsequent stations further along the assembly line. To help analyze the issue, the first step was to measure and record the different

speeds associated with each product.

The instrument that was recommended was the DT-2100 Data Logging Laser Tachometer. The DT-2100’s

non-contact, laser design combined with threaded insert allowed the unit to be permanently mounted on a

nearby beam. Consistent line speed readings could be acquired from a safe distance. For their tests, they also

utilized the tachometer’s data logging software which provided live speed recordings of their test runs, plus

enabled them to further analyze the data after the tests were completed.

After gaining sufficient readings they were able to calculate the expected belt speeds produced from the corresponding product loads on the line. This provided them the corrective adjustments necessary on the motor

output to buffer out alterations in speed, producing a steady, efficient production run. After a relatively minimal

amount of time the customer was able to solve the speed variations and associated disruptions to their production line. The savings in efficiency paid for the equipment and test time in a matter of weeks.

Equipment Used

• DT-2100 Data-Logging Laser Tachometer

• DT-2100-OP-PCS PC Data-Logging Software for DT-2100 Tachometer

DT-2100 Data-Logging Laser Tachometer

Loading...

Loading...