SHIMPO DRI User Manual

DRI-Digital Remote Indicator

with Remote Load Cell/Torque Sensor

Instruction Manual

Contents

Inspection / Standard Accessories 2

Features and Benefits 2

Important Safety Instructions 2

Set-Up 3

Power 3

Connection to Remote Sensors 3

Display and Keypad 4

Factory Settings 5

Operation 5-8

How to Tare and Zero the Display 5

Changing the Measuring Mode 5

Changing Units of Measure 6

Setting High and Low Limits 6

Changing Display Update Time 6

Changing Memory Modes 7

Recalling Statistics 8

Setting of Filter 8

Communication with External Devices 9-16

Output Selection 9-13

RS232 10-12

Digimatic 13

Analog 13

Comparator 13

Congratulations on your purchase of a Shimpo DRI (Digital

Remote Indicator). We trust you will enjoy many years of

professional results from your DRI when used in conjunction with

a Shimpo Remote Load Cell or Remote Torque Sensor for force

and/or torque measurement applications.

Please read the entire instruction manual thoroughly before initial

set-up and operation; the information contained herein will aid

you in operating your Shimpo DRI safely and with excellent results.

If you have any questions regarding our product(s), call your local

Shimpo representative or contact Shimpo directly for assistance.

External Control Input 14-15

Overload Output 16

Parameter Settings 17

Low Battery Indication 18

Auto Power Off 18

Calibration 18-19

Troubleshooting 19

Dimensions and Specifications 20

Warranty 20

Important Safety InstructionsInspection/Standard Accessories

If any damage is apparent, do not unpack the DRI. Notify the

shipping carrier immediately for damage claim instructions.

Refer to the nameplate to confirm model number ordered and

record serial number for future reference.

Items included with the DRI are:

• AC adapter

• (4) AA batteries

• DRI output connector

• Overload protection cable

• Plastic carrying case

Features and Benefits

The DRI offers many features and benefits, including:

• Enables easy set-up when changing applications and

reduces investment in gauges and/or torque sensors by

accepting multiple interchangeable load cells/torque

sensors

• Large memory capacity (100 samples plus statistics)

enables portable data collection for multi-location usage

• High sampling rate (1000 hz) allows peak force and tor que

points to be easily captured

• Handheld and test stand mountable - allows flexibility in

multiple test set-ups, applications and fixturing

• High and low set points permit measurement of br eakaway

torque in applications such as child safety cap testing

• External tare and hold control allows hands-free zeroing

using a keyboard or foot switch

Always wear eye protection when testing materials.

Never use a remote sensor that appears to be damaged

in conjunction with the DRI.

Confirm that the DRI is turned OFF when connecting

or disconnecting a remote sensor; failure to do so may

damage the DRI.

Attachments must be properly installed to the remote

sensors (hand-tighten only! Use only the Jacob’s Chuck

- provided with torque sensor - to tighten the torque

sensors. Do not use wrenches or other tools!).

Never exceed remote sensor capacity; if “OVR 1234”

appears on the display, STOP the test immediately to

avoid permanent sensor damage.

Never apply a force or load at an angle to the remote

sensor.

When installing the DRI on a test stand, confirm that

the indicator unit is thoroughly secured.

When not in use over an extended period of time,

remove batteries to avoid battery terminal corrosion.

Only use the provided AC adapter; usage of any other

adapter may damage circuitry.

Check the batteries periodically for corrosion when

using the unit under AC power; this will avoid damage

and ensure memory backup (refer to “Low Battery

Indication” section).

Do not use or store unit in extreme temperatures;

normal operating temperature is 32-113°F (0-45°C).

Do not use or store unit in oily, dusty, or excessively

wet areas.

Do not use any chemicals to clean the case; use a wet,

soapy cloth.

2

Set-Up

Power

Every DRI unit is shipped from the factory without the batteries (provided) installed. To install the batteries:

1. Remove the battery plate located at the bottom of the handle using a coin or appropriate screwdriver.

2. Install the (4) AA batteries, observing the proper polarity.

3. Reinsert the battery plate cover, making sure the lip engages properly before tightening.

NOTE: If AC adapter operation is preferred, refer to the “Display & Keypad” section of this manual for AC outlet location.

Connection/Disconnection of DRI to Load Cells (LC) or Torque Sensors (TS)

CAUTION: Always confirm that the DRI’s power is turned OFF when connecting or disconnecting an LC or TS.

Instructions to connect a remote sensor (LC or TS) are as follows:

1. Remove the plastic cover from the DRI’s remote sensor port.

2. Align the arrows from the remote sensor’s plug with the arrows on the port of the DRI.

3. Push the plug straight onto the port until a “click” is heard.

4. Press the DRI’s ON button; the LCD will briefly display all indicators (see “Display & Keypad” section).

5. The DRI will briefly display what type of remote sensor is connected (“SEN” will be flashing on the small display). The abbreviations

on the main display are as follows. Please call Shimpo for information on additional sensors.

Load Cells (LC)

PART NUMBER MAIN DISPLAY

LC-50S 50L

LC-100S 100L

LC-200S 200L

LC-500S 500L

Instructions to disconnect a remote sensor (LC or TS) are as follows:

1. Press the DRI’s OFF button.

2. Press and hold the gray release button located towards the top of the remote sensor’s plug.

3. Pull the plug (not the cord) straight off the DRI’s port.

4. Connect another remote sensor (see instructions above) or replace the protective plastic cover on the exposed port of the DRI.

PART NUMBER MAIN DISPLAY

TS-3SD/TS-3J t50o

TS-10SD/TS-10J t10L

TS-20SD/TS-20J t20L

TS-50SD/TS-50J t50L

TS-100SD/TS-100J t100L

Torque Sensors (TS)

3

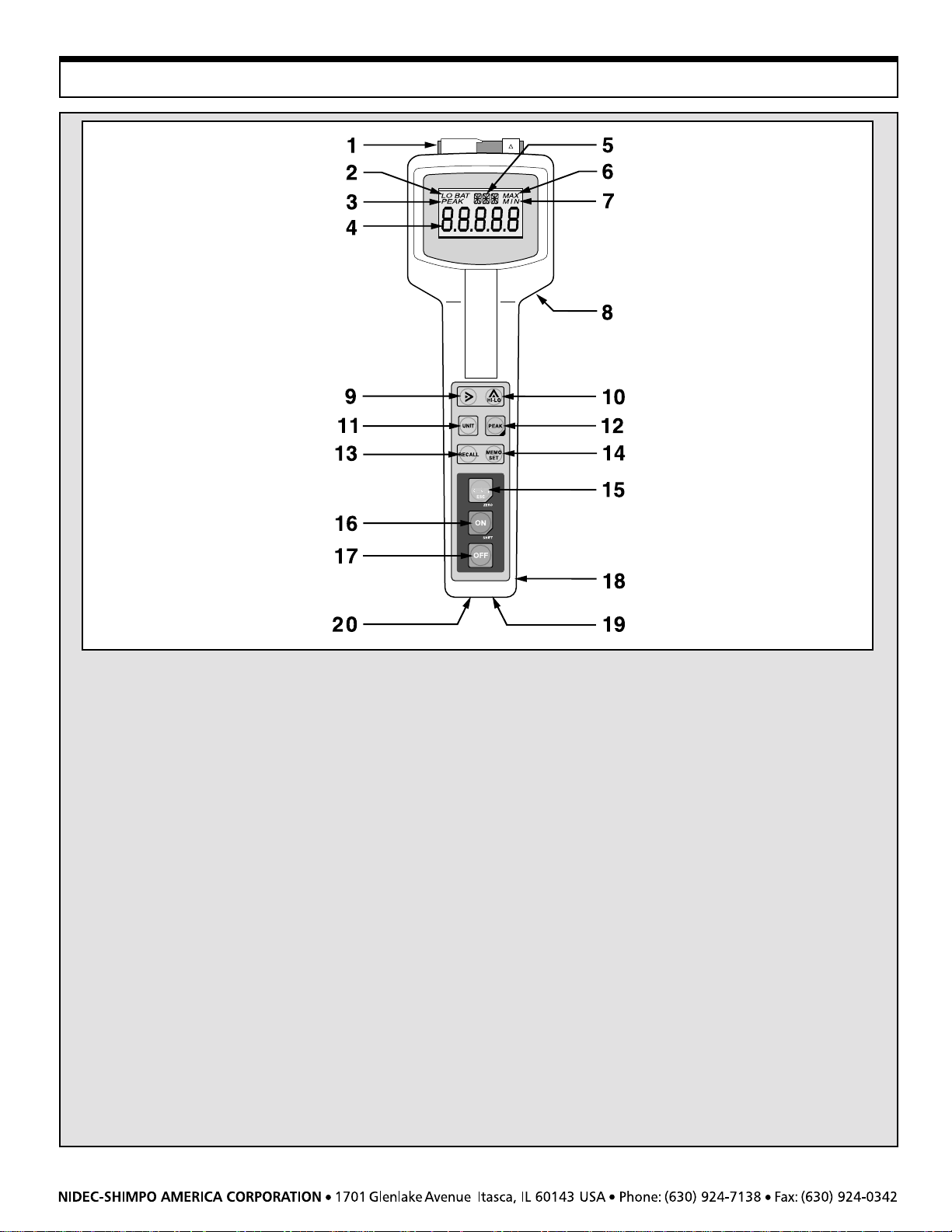

Display & Keypad

1. Remote Sensor Port

2. Low Battery Indicator

3. Peak Indicator (NOTE: Refer to “Changing the Measuring Mode” section for explanation)

4. Main Display

5. Small Display

6. Maximum Reading Indicator

7. Minimum Reading Indicator

8. AC Adapter Port

9. > Button

10. HI-LO Button

11. Unit Button

12. Peak Button (NOTE: Refer to “Changing the Measuring Mode” section for explanation)

13. Recall Button

14. Memo Set Button

15. Reset Button

16. On Button

17. Off Button

18. Overload Output Port

19. Data Output Port

20. Battery Compartment

4

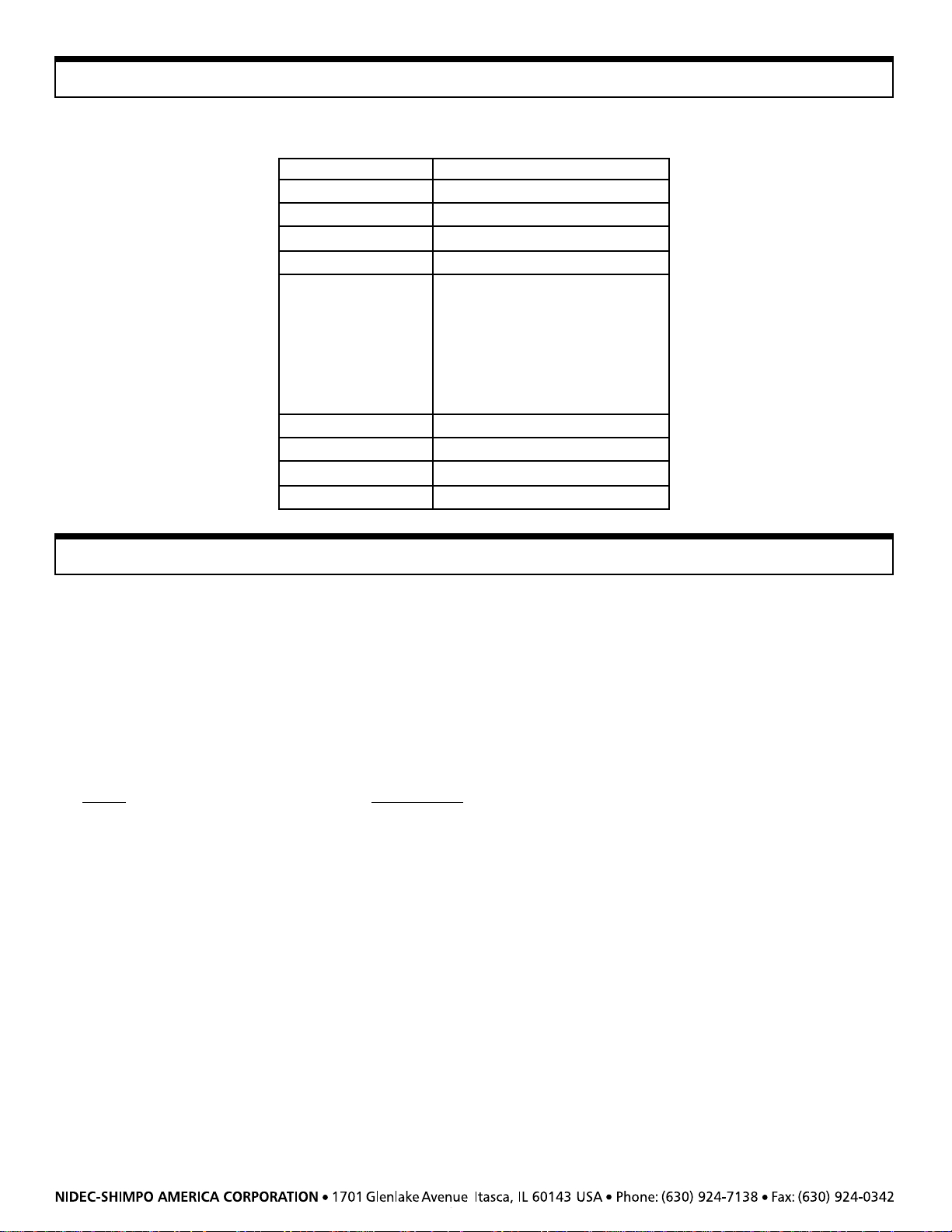

Factory Settings

Each time the power is turned OFF and ON there are some parameters that the DRI will default to. Consult the section on “Parameter

Settings” to customize these default settings. The following chart reflects the default settings as programmed by the factory:

PARAMETER DEFAULT FACTORY SETTING

Display Update 0.125 seconds

Measuring Mode True Peak

Auto Power Off 3 Minutes

Measurement Unit English (Lb, Lb-I or oz-I)

Output RS232

Baud Rate - 4800

Data Length - 8 bits

Stop Pulse - 2 bits

Data End Code - CrLF

Software Flow Control - off

External Trigger Tare

Memory Mode Single

Analog Output Mode On

Filter Off

Operation

How to Tare and Zero the Display

After installing an attachment, it will be necessary to tare the DRI:

1. Press the RESET button while holding down the ON button to tare the display .

2. Press the RESET button by itself when the peak indicator is showing to zero the display . Repeat step 1 if the display does not return

to zero.

NOTE: The DRI can tare up to 50% of the remote sensor’s rated capacity.

Changing the Measuring Mode: True Peak Mode/Standard Mode

CAUTION: Depending on which of these two measuring modes is selected, the PEAK button performs two different functions! The DRI

will alway s display an average force when PEAK is not showing on the display. The average measurement is based upon the display

update rate chosen (see “Changing Display Update Time” section). When in the True Peak mode, pressing the PEAK button will allow

the display to scroll from average to peak “+” (compression or clockwise torque) to peak “-” (tension or counterclockwise torque). When

in the Standard mode, pressing the PEAK button will allow the display to scroll from average to maximum display reading “+” to

maximum display reading “-”. Despite showing PEAK on the display, these are not true peak readings; they are the highest average

displayed readings since the DRI was last “tared”.

Instructions to change the Measuring Mode are as follows:

1. Press the PEAK button while holding down the ON button. The small display will exhibit “dSP”.

3. Press the PEAK button; the small display will read “PfS” and the main display will show “on” (T rue Peak) or “oFF” (Standard).

3. Press the > button to toggle between “on” and “oFF”.

4. Press MEMO SET button to store the measuring mode and exit.

NOTE: By keeping the true peak mode “ON”, the DRI will always display the peak samples and not a maximum average.

5

Operation (continued)

Changing Units of Measure

By pressing the UNIT button, the DRI will scroll between English, Metric, and Newton units; once the DRI is turned OFF the unit will

default to the factory setting. Instructions to change the default unit of measure setting are as follows:

1. Press the PEAK button while holding down the ON button; the small display will indicate “dSP”.

2. Press the PEAK button three times; the main display will indicate “init” and the small display will reflect the current default setting.

3. Each time the UNIT button is pressed, the small display will scroll between English, Metric, and Newton units.

4. Press the MEMO SET button to store the default unit setting and exit.

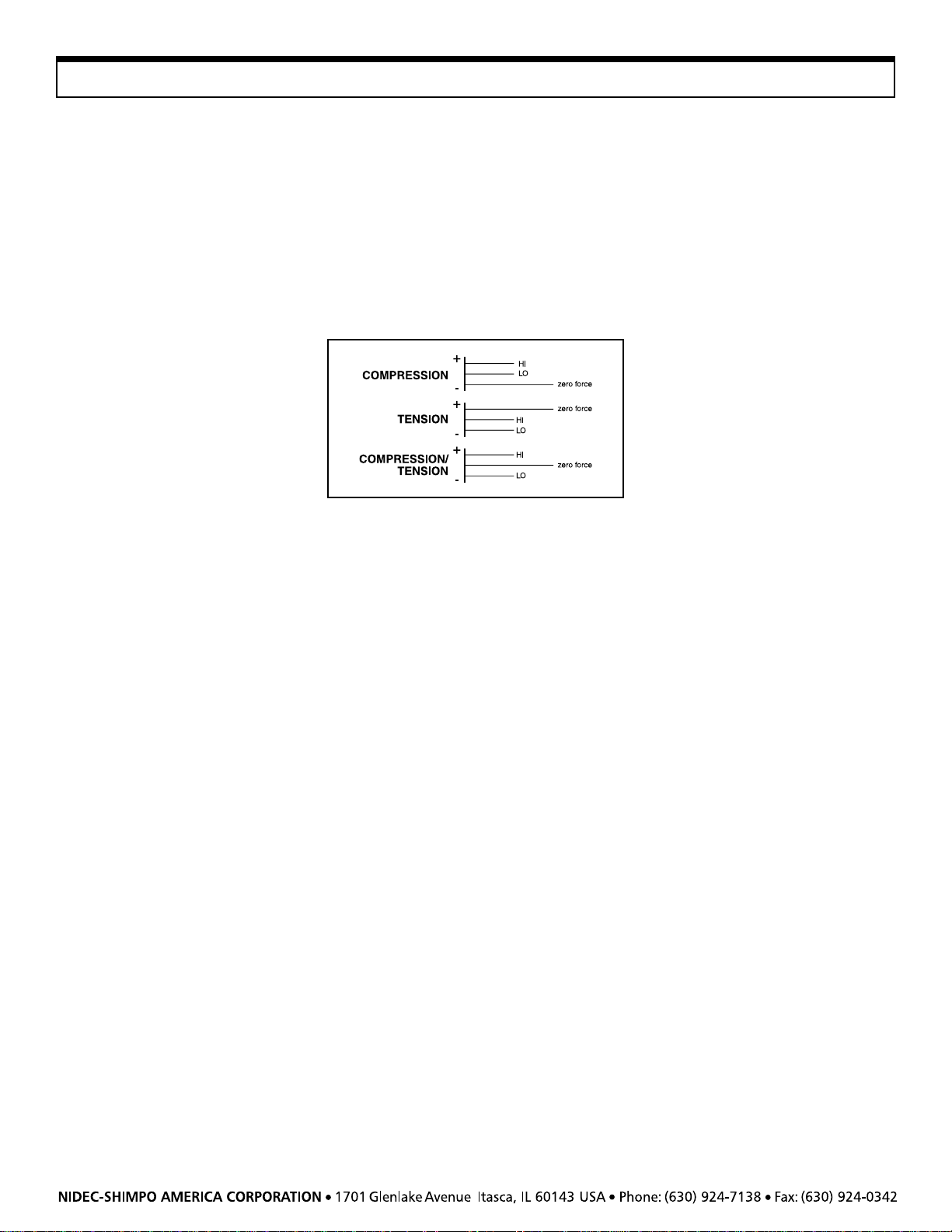

Setting High and Low Limits

It is possible to program high and low limits for applications requiring tolerances. Use the diagram below as a guide for setting the limits.

Instructions to set the high and low limits are as follows:

1. Press the HI-LO button; “∆HI” will be flashing on the small display and whatever limit is already programmed will be displayed.

2. Press the > button; the entire display will be flashing.

3. Press the HI-LO button to toggle between “+” (compression or clockwise torque) and “-” (tension or counter-clockwise torque).

4. Press the > button to scroll across each digit position.

5. Press the HI-LO button to select the numerical value of each digit position.

6. Once the high limit has been programmed, press the MEMO SET button; “∇LO” will be flashing on the small display and whatever

limit is already programmed will appear on the main display.

7. To program the low limit, repeat steps 2-5.

8. Once the low limit has been programmed, press the MEMO SET button to store the set points and exit from this function.

The unit of measure will be displayed when the measurement is within the set points. Small “arrows” (

display when the measurement is above or below the set points.

The unit of measure will never be displayed if the low limit is set higher than the high limit. This is because it is impossible for the

measurement to fall between the setpoints.

Set points can be referenced by pressing the HI-LO button: the first time the button is pressed the display will show the high limit, the

second time will show the low limit, and the third time will exit.

To cancel the high and low limits, both settings must be set to zero.

NOTE: A comparator output is available for “go – no go” testing (refer to “Comparator Output” section).

or ∇) will appear on the small

∆

Changing Display Update Time

The display update time works with the sampling rate (1000 hz) to provide an average reading. All samples taken within the selected

update time are averaged (based on 1000 samples/sec) and displayed.

To change display update time:

1. Press the PEAK button while holding down the ON button. The small display will exhibit “dSP” and the main display will reflect

the current setting.

2. Each time the > button is pressed, the main display will scroll through “0.125”, “0.25”, “0.5”, “1.0” and “2.0” (these correspond

with the amount of time in seconds that the display will update).

3. Press the MEMO SET button to store the desired display update time and exit.

6

Loading...

Loading...