Digital Force GaugeDigital Force Gauge

Digital Force Gauge

Digital Force GaugeDigital Force Gauge

Models DFS — 0.5, 1, 2, 5, 10, 20, 50, 100

DFS — 0.5R, 1R, 2R, 5R, 10R, 20R, 50R, 100R

ContentsContents

Contents

ContentsContents

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

Safety Precautions ....................................................2

Factory Settings ........................................................2

How to Change Units ...............................................3

How to Change Measuring Modes..........................3

Memory Modes......................................................... 4

Single (on-demand) Mode........................................4

Statistics.....................................................................4

Continuous Memory Mode......................................5

Standard Memory Mode .........................................5

Memory Back-up......................................................5

Comparator...............................................................5

How to Set Limits (HI/LO)......................................6

Parameter Setting.....................................................6

How to Select Parameters........................................7

Measuring Time & Peak Fast Mode.......................7

Setting Measuring Time & Peak Fast Mode..........8

Auto-Power-Off ........................................................8

Setting of Initial Conditions ....................................9

Output Selection .......................................................9

RS232C Output ......................................................10

Selecting Memory Mode ........................................ 11

Error Codes............................................................. 1 1

Low Battery Indication ..........................................11

External Control Input (TARE, HOLD) ..............12

External Input Selection ........................................13

Outputs(Analog, Comparator,

Digimatic, RS232C)........................................14, 15

Memory Data Output thru RS232C .....................16

Commands (External Control

Command thru RS232C).....................................17

Overload Output & Flow Control ........................18

Calibration ..............................................................19

Warranty .................................................................19

Specifications ..........................................................20

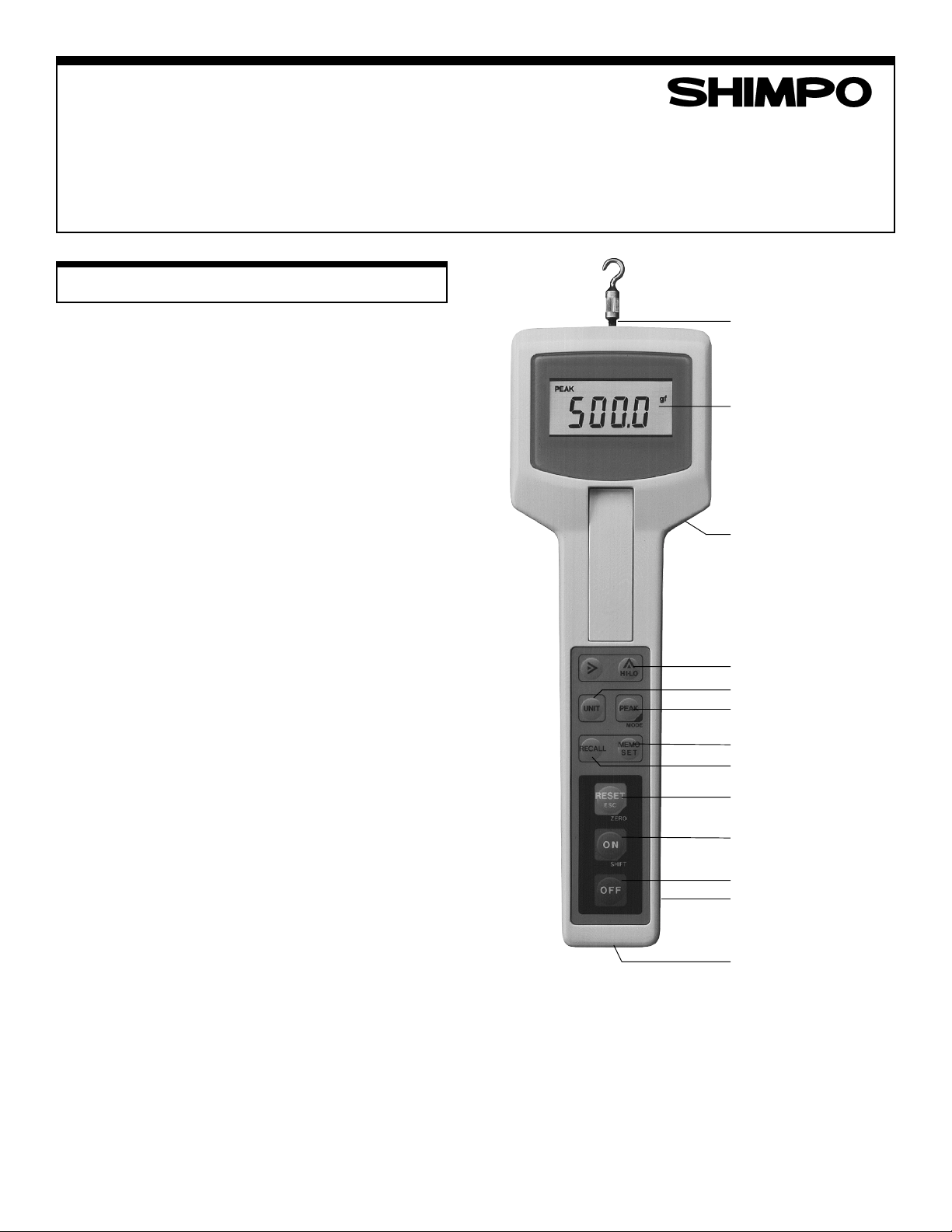

SHAFT

DISPLAY

AC ADAPTER

COMPARATOR

UNITS SELECTOR

PEAK MODE

MEMORY

MEMORY RECALL

RESET/TARE

POWER ON/SHIFT

POWER OFF

OVERLOAD OUTPUT

CONNECTOR

OUTPUT CONNECTER

1

Safety PSafety P

Safety P

Safety PSafety P

recautionsrecautions

recautions

recautionsrecautions

Factory SettingsFactory Settings

Factory Settings

Factory SettingsFactory Settings

1. Do not use any attachment that appears to be damaged.

2. Attachment must be properly installed. Hand tighten it.

Do not use wrenches or any other tools.

3. Do not exceed attachment capacity.

4. When installing gauge on a stand make sure to use all

necessary screws to secure unit.

5. Use eye protection devices when testing materials that

may shatter.

CautionCaution

Caution

CautionCaution

1. Do not use or store unit in extreme temperatures.

Note: Operating temperature is 0-45°C.

2. Do not use or store unit in oily, dusty or water splashing

areas.

3. If display shows stop test immediately and

release load. Over-load condition may damage the load

cell.

4. Do not apply force at an angle and avoid twisting the

shaft.

5. If gauge is not going to be used for a while, remove

batteries to avoid corrosion of battery terminals.

6. Use AC adapter that comes with the unit only. Any

other adapter will damage circuity.

7. Do not use any chemicals to clean outside case (including gasoline, alcohol e.t.c). Just use ordinary soapy

damp cloth.

8. Do not attempt to disassemble gauge. The warranty will

be voided.

Before UsingBefore Using

Before Using

Before UsingBefore Using

All DFS models come from the factory with the batteries not

installed. Before attempting to use the gauge install the four

AA batteries (provided) observing Figs. 1, 2 and 3 below.

Remove battery plate with a coin or appropriate screw driver.

Install 4-AA batteries as shown in Fig. 2 observing proper

polarity. Make sure lip engages properly before tighting the

battery plate screw.

Note: When the AC adapter is used, the batteries act as a

memory back up system only.

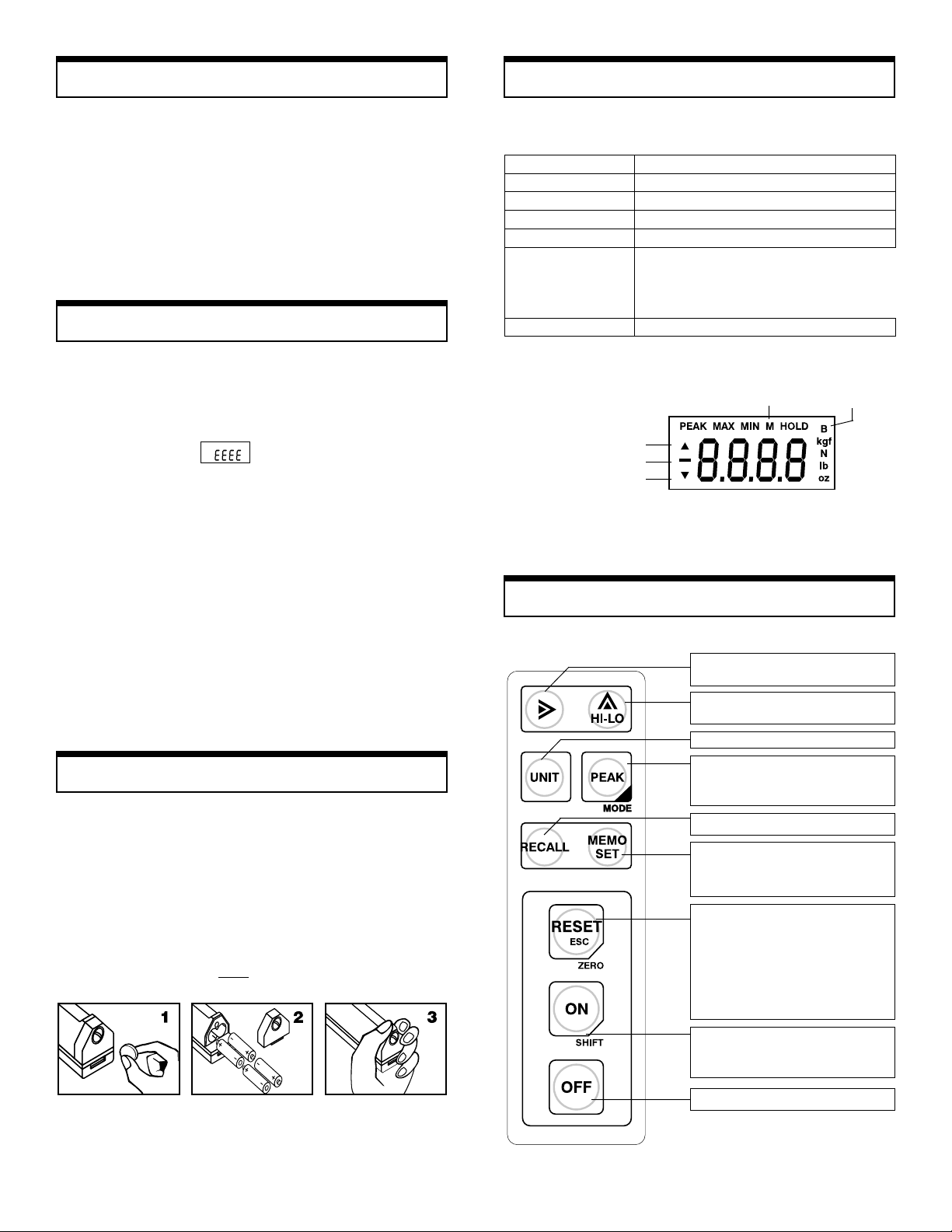

Each force Gauge comes from the factory with the settings

shown in the table 1 below

UNIT lb. or oz. (Depending on capacity)

MEASURING MODE Average

UPDATE TIME 0.125 seconds

AUTO POWER OFF 3 minutes

MEMORY MODE on demand mode (single data input)

OUTPUT RS232

INPUT Tare Function

Comparator indicator (over)

Comparator indicator (under)

Push Button FPush Button F

Push Button F

Push Button FPush Button F

(EIA)

Tension

Baud Rate:

Data Length:

Stop Bit:

Data End Code:

Software Flow Control:

Table 1

Memory Low battery

Fig. 1

unctionsunctions

unctions

unctionsunctions

Digit shift for comparator setting

Last Memory clear.

Comparator setting.

Comparator number check.

Unit

Measuring mode switch.

Statistics recall when in memory mode.

Shift + mode.

Memory recall

Memory store.

End key for for any setting.

Calibration.

Peak reset.

Prevent data entry.

Stop data output.

Prevent escape from

Memory recall.

Hold reset.

Tare (shift + zero)

4800 bps

8 bits

2 bits

None

Disabled

Power on

Shift key for

2nd function

Power off

2

RR

eady to Measureeady to Measure

R

eady to Measure

RR

eady to Measureeady to Measure

First press the ON switch to turn power ON. The display will

show momentarily all the indicators shown in Fig.1 and then

settle at lb (oz) and some arbitrary number with (usually but

not necessarily all zeros).

Assuming that the proper attachment is installed and the unit

is positioned as desired, press the ZERO and ON switches

simultaneously. The display should show all zeros, which

means that the gauge is “T ARED”.

How to Change UnitsHow to Change Units

How to Change Units

How to Change UnitsHow to Change Units

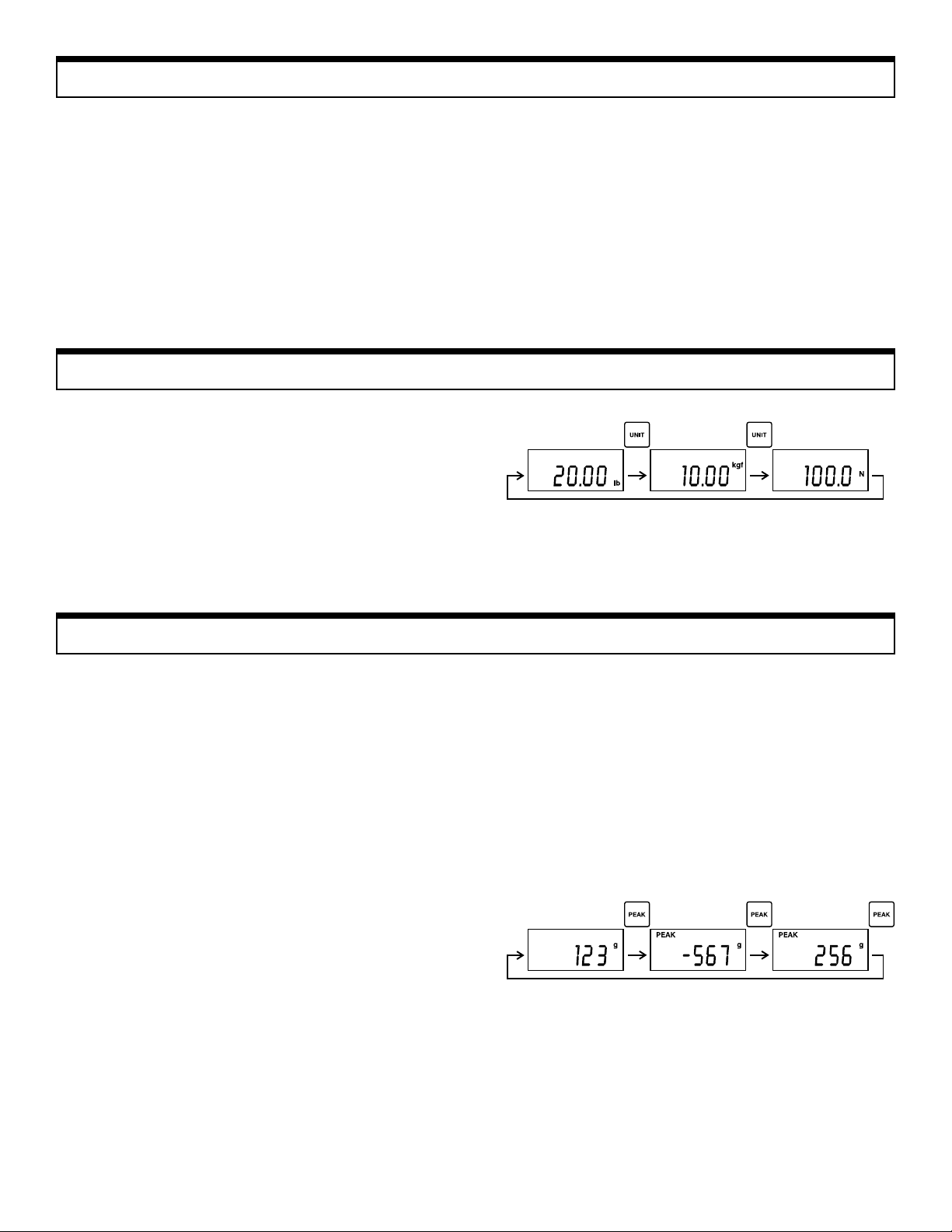

After the power is turned ON and gauge is “TARED”, by

pressing the UNIT switch the instrument will change from

lb(oz) to kg(g) to N and the cycle is repeated.

Caution: The gauge will default to lb (oz) (initial setting)

after power OFF regardless of what unit was previously

selected. To avoid above situation, see page 7.

The gauge is now ready to measure force according to the

factory settings shown in Table 1.

After measurements are finished, press the OFF switch to

turn unit off.

Note: The gauge will power off automatically in 3 minutes if

the OFF switch is not pressed. If the AC adapter is in use,

the AUTO-POWER-OFF function is inoperative.

Change of Measuring ModeChange of Measuring Mode

Change of Measuring Mode

Change of Measuring ModeChange of Measuring Mode

As was mentioned in previous pages the gauge is set from the

factory in the average mode. The sampling rates for the

average mode are 0.125, 0.25, 1 and 2 seconds (selectable).

In the PEAK mode if the sampling rate is set for 1/1000 sec.,

the actual peak force is captured. If another sampling rate is

chosen the maximum average force is captured. T o change

from average to peak mode press the PEAK switch once.

The display will show a negative sign in front of the digits.

This means that the gauge is ready to measure tension. If the

PEAK switch is pressed one more time the negative sign will

disappear and the gauge is ready to measure compression.

One more press of the PEAK switch will bring the unit back

to average mode.

The gauge is able to measure average, peak tension, and peak

compression in one operation. When in the average mode,

push on the shaft for a period of time and then pull the shaft

and release. When you press the PEAK switch the peak

tension appears on the display. One more push of the peak

switch and the display will show the peak compression. T o

cancel the peak value from the memory press the RESET

switch.

The gauge is set to go to the average mode when the power is

turned on. T o change this condition (go to peak on POWER

ON) see page 7.

3

Memory ModesMemory Modes

Memory Modes

Memory ModesMemory Modes

The memory of the DFS series operates in three distinct modes:

1. On-demand memory mode (single)

2. Continuous memory mode

3. Standard memory mode

ON-DEMAND MEMORY MODE (SINGLE)ON-DEMAND MEMORY MODE (SINGLE)

ON-DEMAND MEMORY MODE (SINGLE)

ON-DEMAND MEMORY MODE (SINGLE)ON-DEMAND MEMORY MODE (SINGLE)

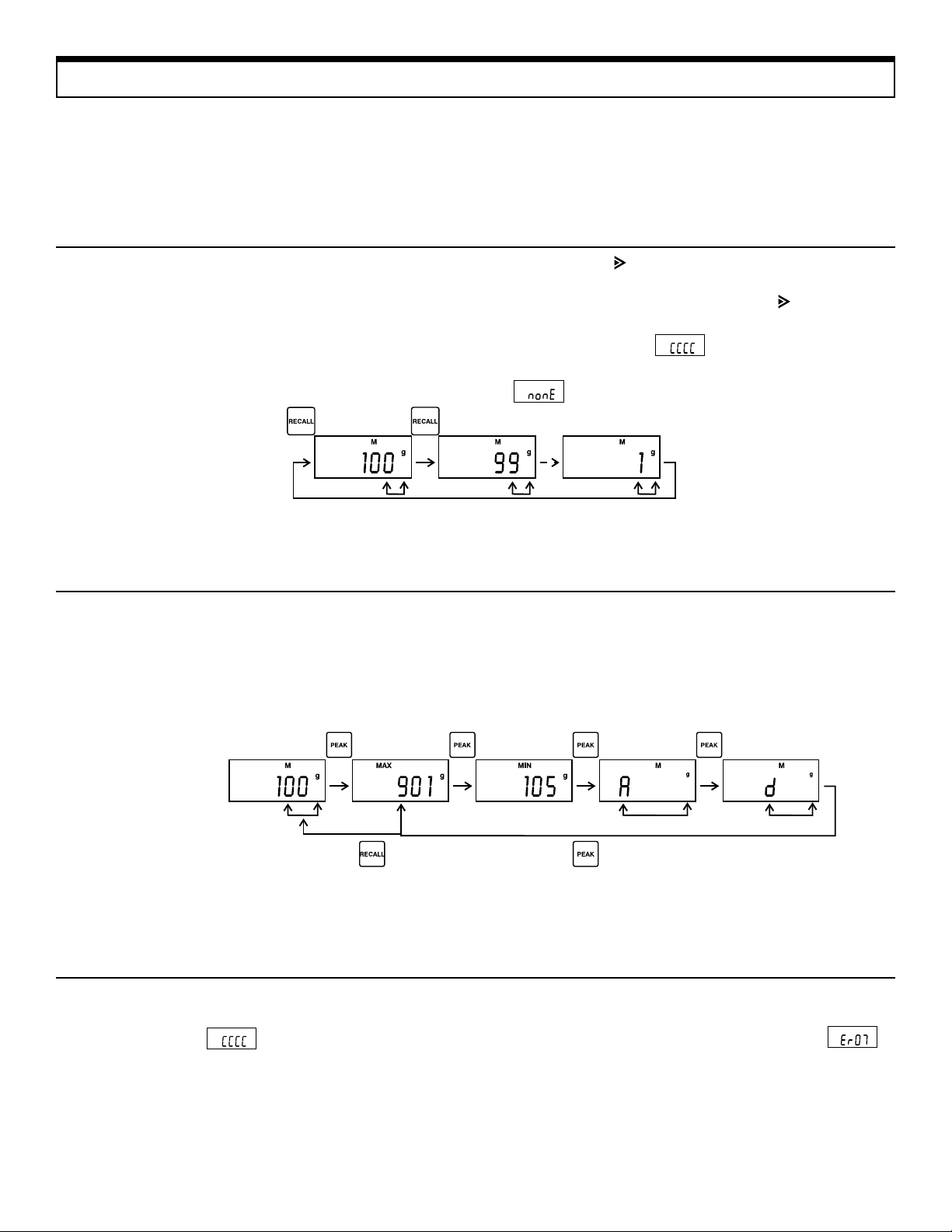

The unit comes from the factory set on the on-demand mode.

One hundred data can be stored in memory by pressing the

MEMO SET switch. If more than one hundred data are

forced into memory, the word FULL will appear on the

display. To recall the data in the memory press the RECALL

switch. The last data and memory position show up on the

display first. Any subsequent switch pressing will decrement

the data and memory position

By pressing the key, the last data in memory will be

erased. If unit is allowed to go OFF and then ON again, the

last data cannot be erased by pressing the key. To clear

the memory press RESET and ON switch at the same time.

The display will show momentarily and then go to

all zeros. If RECALL is pressed, the display will show

momentarily.

STST

AA

TISTICSTISTICS

ST

A

TISTICS

STST

AA

TISTICSTISTICS

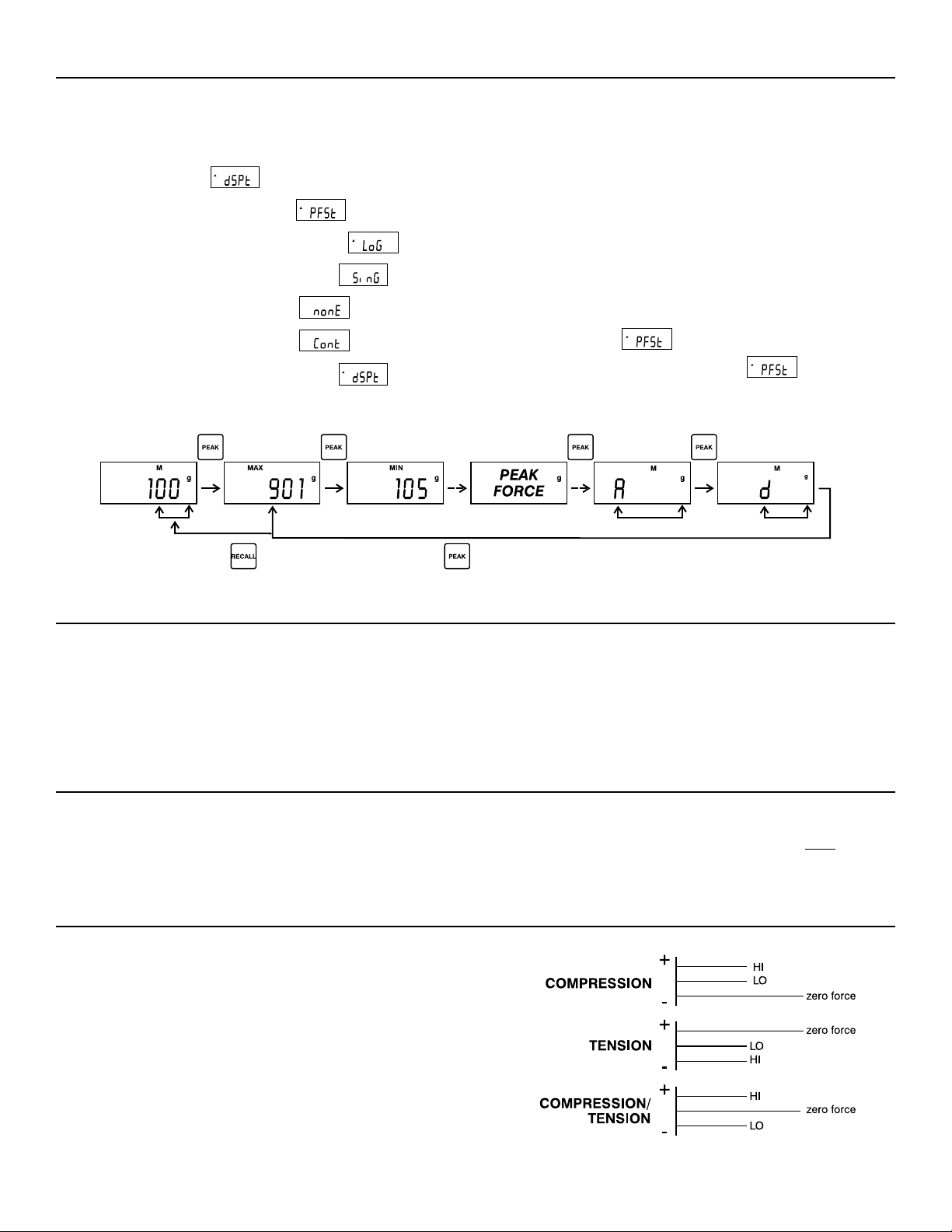

After the desired data has been stored in memory, set the

gauge in the RECALL mode and press the PEAK mode

switch. The last memory position will be displayed and also

the data in that position.

Subsequent manipulations of the peak switch will bring up

maximum, minimum, average data, and standard deviation.

See diagram below:

TO CLEAR MEMORYTO CLEAR MEMORY

TO CLEAR MEMORY

TO CLEAR MEMORYTO CLEAR MEMORY

T o clear memory from all data, press RECALL switch first

and then press simultaneously the ON and RESET switches.

The display will show momentarily and everything

will default to MEASURE (ready) state.

After standard deviation, by pressing peak again the unit goes

to maximum. T o escape from statistics press the RECALL

switch. T o escape from RECALL press the RESET(ESC)

switch.

Note: If the “UNIT” switch is pressed after a set of data has

entered the memory and new data is attempted to enter the

memory in different “units”, the display will show

which means that this action should be avoided. You cannot

change units during the process of entering data into memory.

4

CONTINUOUS MEMORY MODE CONTINUOUS MEMORY MODE

CONTINUOUS MEMORY MODE

CONTINUOUS MEMORY MODE CONTINUOUS MEMORY MODE

If the continuous memory mode must be used, do the

following to change from the ON-DEMAND mode to

continuous mode.

1. Press ON & PEAK at the same time.

Display will show .

2. Press PEAK. Display will show

3. Press PEAK 5 times. Display will show

4. Press MEMO SET . Display will show

5. Press PEAK. Display will show

6. Press PEAK. Display will show

You can enter 100 measurements at once in this mode.

While force is applied on the shaft, press MEMO SET.

The display will be changing according to force applied and

the letter M will be blinking on top of the numbers. When

100 measurements have entered the memory , the M letter

will disappear momentarily and the word FULL will appear

on the display momentarily and the letter M will reappear

solid. You can recall each measurement by pressing the

RECALL switch. T o clear the memory press RECALL, then

RESET and ON at the same time and the cycle can be

repeated.

Statistics can be performed in this mode as previously

described. If the is OFF, statistics can be performed

7. Press MEMO SET . Display will show

8. Press RESET . Now you are in the continuous memory

mode.

STST

ANDAND

ST

STST

Follow the same procedure as the one described above to

select the standard memory mode. The display will show

nonE. Proceed with steps 7 and 8 described above to stay in

the standard mode. In this mode the maximum and minimum

force (tension and compression) and last measurement are

MEMORY BACK UPMEMORY BACK UP

MEMORY BACK UP

MEMORY BACK UPMEMORY BACK UP

When power is off, memory back up is provided by the

batteries. If batteries are getting low, before a new set is

installed it is important to use the AC adapter and leave

ARD MEMORY MODEARD MEMORY MODE

AND

ARD MEMORY MODE

ANDAND

ARD MEMORY MODEARD MEMORY MODE

as described in previous pages. If the is ON, then the

PEAK force will show up between MIN and A (minimum

and average).

stored in memory in a selected period of time and can be

recalled later. If the selected period falls between a continuous compression and tension measurement, then the maximum compression and tension force will be stored and the

minimum will be zero for both.

power ON before removing old batteries otherwise data in

memory will be lost. When the AC adapter is used the

batteries are used as a memory back up system only.

COMPCOMP

COMP

COMPCOMP

T wo set points are available HI and LO.

Note: When the Digimatic output is selected, the comparator

output is not available. HI point is defined as follows:

HI < DATA (display)

OK or GO is defined as follows:

LO ≤ DATA ≤ HI

LO is defined as follows:

LO > DATA (display)

When setting the HI and LO limits, see adjacent diagrams.

ARAARA

ARA

ARAARA

TORTOR

TOR

TORTOR

5

How to Set LimitsHow to Set Limits

How to Set Limits

How to Set LimitsHow to Set Limits

Press to set upper limit. The arrow on the upper left corner

of the display will blink and the display will show previous

HI point (limit). Change setting by using the and

keys. After setting HI point, press MEMO SET to transfer

into memory. Unit is now ready to accept the lower point

(limit). Use the same procedure to accomplish LO point

setting. If it is attempted to set LO point higher than the HI

point the unit defaults to the beginning of the procedure.

When data exceeds these limits an arrow by the display

pointing upward or downward will indicate which limit is

PP

arameter Settingarameter Setting

P

arameter Setting

PP

arameter Settingarameter Setting

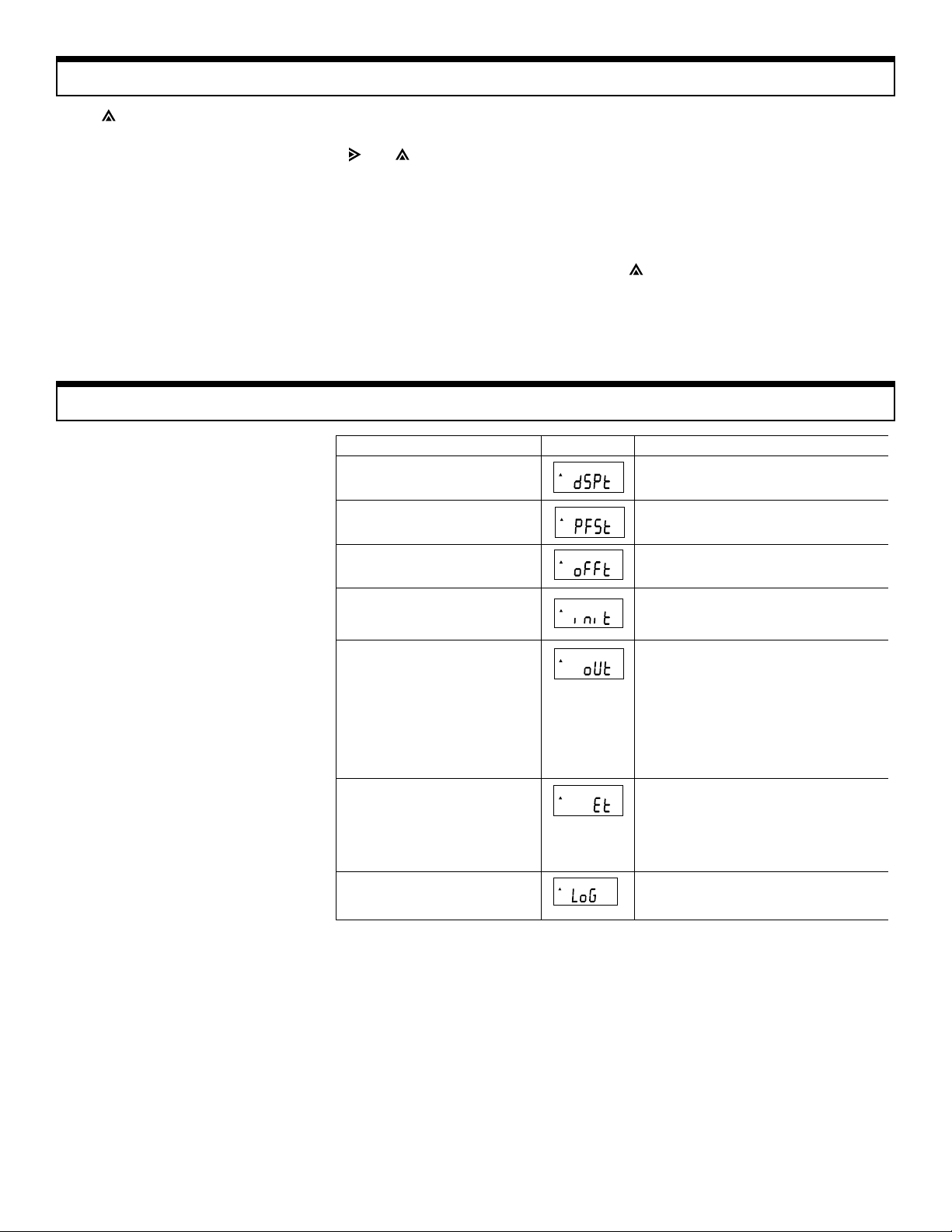

Many parameters can be set depending on operator’s requirements. See

typical parameters in the table below.

PARAMETER DESIGNATION

PARAMETER DESIGNATION DISPLAY

PARAMETER DESIGNATIONPARAMETER DESIGNATION

DISPLAY UPDATE (Measuring time)

DISPLAY UPDATE (Measuring time) 0.125, 0.25, 1, 2, sec. (select one)

DISPLAY UPDATE (Measuring time)DISPLAY UPDATE (Measuring time)

PEAK FAST MODE (1000 sample/sec)

PEAK FAST MODE (1000 sample/sec) ON, OFF (Select one)

PEAK FAST MODE (1000 sample/sec)PEAK FAST MODE (1000 sample/sec)

AUTO POWER OFF

AUTO POWER OFF NONE, 3 minutes (select one)

AUTO POWER OFFAUTO POWER OFF

exceeded. There are three OC NPN transistors that turn on

respectively if the corresponding set points are reached, HI,

GO and LO. These outputs can be used as alarms or indicators for the limits set. T o erase any or both of the set points,

just set them to zero. Erase HI point first.

Set the HI point to zero and press MEMO SET. Then set LO

point to zero and press MEMO SET . This is the only way

they can be erased from the memory. To check set points at

any time press the switch. The gauge comes from the

factory with both HI and LO points set to zero.

DISPLAY TYPICAL VALUE

DISPLAYDISPLAY

TYPICAL VALUE

TYPICAL VALUETYPICAL VALUE

INITIAL CONDITIONS

INITIAL CONDITIONS

INITIAL CONDITIONSINITIAL CONDITIONS

"Unit" when powered up.

"Unit" when powered up.

"Unit" when powered up."Unit" when powered up.

Measuring mode when powered up.

Measuring mode when powered up.

Measuring mode when powered up.Measuring mode when powered up.

OUTPUT

OUTPUT • None

OUTPUTOUTPUT

EXTERNAL

EXTERNAL

EXTERNALEXTERNAL

Control input

Control input

Control inputControl input

MEMORY MODE

MEMORY MODE • Single (on-demand)

MEMORY MODEMEMORY MODE

unit: kg(g), N, lb(oz)

display: average, peak tension, peak compression

• RS232C

Baud rate: 1200, 2400, 4800, 9600 (choose)

Data length: 7 or 8 bits

Stop pulse: 1 or 2 bits

Parity: none, even, odd

Data end code: CR, CR + LF

Software flow control: ON or OFF

• Digimatic

• None

• Tare

• Hold

Trigger: Edge, level

Trigger timing: contact close enable

contact open enable

• Continuous

• None (standard)

6

How THow T

How T

How THow T

1. Press ON and PEAK switches simultaneously . The gauge will display .

2. Press PEAK. The displaywill show . By pressing the PEAK switch the display will show the following sequence:

3. If you choose , press the MEMO SET switch. The action will get you in the memory field (single, none or continuous).

4. Press PEAK to display and choose any of the three modes.

o Select Po Select P

o Select P

o Select Po Select P

Note: If you press the RESET switch while you are in the memory field, the unit will default to step 2 .

arametersarameters

arameters

arametersarameters

5. Press MEMO SET to enter your selection, like → . After selection is made press RESET.

Measuring Time and PMeasuring Time and P

Measuring Time and P

Measuring Time and PMeasuring Time and P

Measuring time: Select one of the four time periods 0.125,

0.25, 1, or 2 seconds. When the peak fast mode is OFF, the

gauge will average the data for the selected period at the

1000/sec. rate. When the peak fast mode is ON, the gauge

will capture the maximum peak value from all data for the

selected time period at the 1000/sec. rate.

The table at right shows the

response time of the various

models. Due to mechanical

limitations the table shows

the 90% response time (see

graph 1).

MODEL

MODEL RESPONSE TIME

MODELMODEL

DFS-0.5, 1

DFS-0.5, 1 35 ms

DFS-0.5, 1DFS-0.5, 1

DFS-2

DFS-2 12 ms

DFS-2DFS-2

DFS-5, 10

DFS-5, 10 8 ms

DFS-5, 10DFS-5, 10

DFS-20, 50, 100

DFS-20, 50, 100 6 ms

DFS-20, 50, 100DFS-20, 50, 100

eak Fast Modeeak Fast Mode

eak Fast Mode

eak Fast Modeeak Fast Mode

Response times are shown with small attachments.

If heavier attachments are used the response time will be

slower.

RESPONSE TIME

RESPONSE TIMERESPONSE TIME

Graph 1

7

Setting Measuring Time and PSetting Measuring Time and P

Setting Measuring Time and P

Setting Measuring Time and PSetting Measuring Time and P

eak Fast Modeeak Fast Mode

eak Fast Mode

eak Fast Modeeak Fast Mode

See flow chart below. Press ON and PEAK switches simultaneously . The display will show dSPt

AA

uto - Puto - P

A

uto - P

AA

uto - Puto - P

ower - Offower - Off

ower - Off

ower - Offower - Off

Set measuring time and PEAK fast mode as the diagram

below indicates.

This option can be selected. If the auto-power-off option is

selected, the power will be turned off automatically after 3

minutes if no switches are activated during that time and if no

force change occurs during the 3 minute period. Force

change must be less than 0.1% of gauge’s capacity to be

defined as no change.

The auto-power-off will not work if

a) not selected

b) unit is in the continuous memory mode and data are

entering memory

c) AC adapter is in use

d) Unit is in calibration mode

Here is how to set up or cancel the auto-power-off option.

8

Setting of Initial ConditionsSetting of Initial Conditions

Setting of Initial Conditions

Setting of Initial ConditionsSetting of Initial Conditions

The gauge comes from the factory with the “unit” set in lbs

and the “measuring mode” in average. The “unit” condition

can be changed to N or Kgs by depressing the “unit” push

button. If a unit is selected other than lbs., when the power is

turned off and on again the gauge defaults back to initial

setting which is lbs.

The same holds true if the gauge is set at the auto-power-off

condition.

T o opt out of this condition follow the diagram below.

See page 7 to get to and follow diagram as shown.

Output SelectionOutput Selection

Output Selection

Output SelectionOutput Selection

The operator has the option in selecting:

a) RS232C

b) Digimatic

c) None

See page 7 and set the display on the

See flow chart below to select any of the outputs above.

9

RS232C outputRS232C output

RS232C output

RS232C outputRS232C output

If the RS232C output is selected, more parameters must be

chosen. See flow chart below:

When you have entered the RS232C output field and you

don’t want to change the factory settings, just press RESET

and you will exit this field.

10

Choosing Memory ModeChoosing Memory Mode

Choosing Memory Mode

Choosing Memory ModeChoosing Memory Mode

See page 7 to get to . Choose one of the memory

modes according to the diagram shown below:

Error CodesError Codes

Error Codes

Error CodesError Codes

If any of the error codes show up in the display,

turn power off and then on. If the error code

remains, see table below:

DISPLAY

DISPLAY CONDITION

DISPLAYDISPLAY

CONDITION ACTION

CONDITIONCONDITION

2

E PROM

reading error

Temperature

compensation error

Calibration error Unit needs repair and recalibration

D/A converter error Analog output will not tare. When tare is pressed

RS232C

communications error

Memory unit error This occurs if "units" are changed during

Overload condition or

load cell damaged

ACTION

ACTIONACTION

Press RESET.

Unit should go to factory settings

Bad temperature compensating ckt.

Send unit for repair. Unit may be used if

temperature is not a problem. Press RESET.

the voltage will not go to zero.

All else is OK. Repair is needed. Press RESET.

Check connections and all RS232C parameters

memory data entering. Some data in lbs, then

some in kgs, etc. Change units or clear memory

• Use proper load

• Repair unit by changing load cell

Low Battery IndicationLow Battery Indication

Low Battery Indication

Low Battery IndicationLow Battery Indication

When the letter B shows on the display , it means that the

batteries have to be changed. Note: Memory back up is

accomplished thru the batteries. Before changing batteries,

in order not to lose data in memory , plug in AC adapter and

turn gauge on.

11

External Control InputExternal Control Input

External Control Input

External Control InputExternal Control Input

TARE and data display HOLD can be externally controlled.

The Digimatic output shares the same wires as the external

control input. Make sure to use the RS232C output or no

Input: 5VDC, 0.3mA

Pulse width: >25ms

External TExternal T

External T

External TExternal T

To tare, short pins 5 and 10 for at least 25 ms.

External HOLDExternal HOLD

External HOLD

External HOLDExternal HOLD

AREARE

ARE

AREARE

output when the external control input function is used.

The external input cable looks like the one below:

} Comparator wires

Input (white)

gnd (BLACK)

Choose edge or level trigger and also OPEN or CLOSED

condition.

1. Level trigger: OPEN

Display holds present value when switch opens.

2. Level trigger: CLOSED

Display holds present value when switch closes.

3. Edge trigger: OPEN

Display holds present value after switch opens until it is reset.

4. Edge trigger: CLOSED

Display holds present value after switch closes unitl it is reset.

HOLD cannot be released from an external source in the

edge trigger mode. To release it press RESET. Level mode

can be released externally .

12

External Input SelectionExternal Input Selection

External Input Selection

External Input SelectionExternal Input Selection

From page 7 go to

When in HOLD mode, select trigger mode as follows:

13

OutputOutput

Output

OutputOutput

There are four outputs available:

1. RS232C

2. Digimatic

3. Analog

4. Comparator

Connector

I. Analog OutputI. Analog Output

I. Analog Output

I. Analog OutputI. Analog Output

The analog output is not derived from the CPU but is

generated from the load cell and amplifier. It is very linear

and has a high response time. When in TARE mode, the

analog output goes to zero volts.

Specifications

Voltage: -1VDC ~ 0 ~ +1VDC

Load Impedance: 2K or higher

Response Time: 35mS (DFS-0.5/1)

12mS (DFS-2)

8mS (DFS-5/10)

6mS (DFS-20/50/100)

1. RXD

2. TXD

3. CTS

4.

RTS

5. REQ

6. READY

7. CLK

8. DATA

9. (0±1V), Always present

10. GND

Digimatic*

RS232 (selectable)

5. Ext. Input

6. HI

7. GO

8. LO

Ext. Input*

Comparator

Output*

*Digimatic, External input and

Comparator output share wires.

Comparator OutputComparator Output

Comparator Output

Comparator OutputComparator Output

The comparator output shares wires with Digimatic and

External input, therefore when Digimatic is selected, the

comparator output is not available.

6

0C output

28 VDC, 7mA (max)

14

HI (yellow)

GO (green)

LO (red)

GND (black or blue)

TRIGGER INPUT (white or brown)

Comparator cable

Digimatic OutputDigimatic Output

Digimatic Output

Digimatic OutputDigimatic Output

Connect cable between gauge and Mitutoyo Model

DP-1HS printer. Select Digimatic output according

to previous instructions described on page 9. Press

RECALL to display DATA in memory . Then press

MEMO key . All data in memory will be outputed into

the printer. During the transfer of DATA from unit to

printer the doUt word on the display will be blinking.

When all data have been transferred, the unit returns

to measuring mode and the display stops blinking.

If the printer DATA key is pressed, only one measurement at

a time is transferred into the printer. STATISTICS from the

gauge will not be outputed because the printer has its own

capability of performing all the statistical functions.

RS232 CommunicationsRS232 Communications

RS232 Communications

RS232 CommunicationsRS232 Communications

All communications between the gauge and the PC are

possible with only one exception, the PC cannot turn the

gauge ON and OFF.

2 RXD

3 TXD

4 CTS

5 RTS*

7 GND

*RTS is always a "space"

(+5 to +10VDC)

BAUD RATE

BAUD RATE 1200, 2400, 4800, 9600

BAUD RATEBAUD RATE

DATA

DATA 8 bits

DATADATA

STOP BITS

STOP BITS 1, 2

STOP BITSSTOP BITS

PARITY

PARITY none, even, odd

PARITYPARITY

DATA END CODE

DATA END CODE CR, CR + LF

DATA END CODEDATA END CODE

SOFTWARE FLOW CONTROL

SOFTWARE FLOW CONTROL (X ON, XOFF)

SOFTWARE FLOW CONTROLSOFTWARE FLOW CONTROL

HARDWARE FLOW CONTROL

HARDWARE FLOW CONTROL CTS (clear to send signal)

HARDWARE FLOW CONTROLHARDWARE FLOW CONTROL

15

Memory DMemory D

Memory D

Memory DMemory D

AA

TT

A output thru RS232CA output thru RS232C

A

T

A output thru RS232C

AA

TT

A output thru RS232CA output thru RS232C

Data can be transferred from the memory in all three

modes. Press RECALL to display memory DATA

and then press MEMO SET

ON-DEMAND CONTINUOUS STANDARD

ST ATISTICS ST ATISTICS Units lbs

Max 98.8

Units lb Units lb Max - 0.0

DATA 100 DATA 100 MIN

MAX MAX MIN

MIN MIN LAST

AVG. PKC **END**

DEV PKT

HLMT AVG

LLMT DEV

HLMT

LLMT

DATA

1 XXXX

2 XXXX DATA

3 XXXX 1 XXXX

2 XXXX

RS232CRS232C

RS232C

RS232CRS232C

Output DATA format from gauge

2 3 4 5 6 7 8 9 10 11 12 13

1

S T A T I S T I C S CR LF

CR LF

U N I T S g f CR LF

D A T A 1 0 0 CR LF

M A X — 1 0 0 0 CR LF

M I N — 1 0 CR LF

P K C 0 CR LF

P K T — 1 1 0 0 CR LF

A V G — 9 1 2 CR LF

D E V 8 . 2 CR LF

H L M T — 1 0 0 0 CR LF

L L M T — 9 0 0 CR LF

CR LF

D A T A — 9 1 5 CR LF

1

2 L — 8 9 5 CR LF

9 9 H — 1 0 0 5 CR LF

1 0 0 9 9 0 CR LF

* * E N D * *

External control command

ASCII Capital Characters

COMMAND FUNCTION DACOMMAND FUNCTION DA

COMMAND FUNCTION DA

COMMAND FUNCTION DACOMMAND FUNCTION DA

UNTG Change units to g or kg

UNTN Change units to N

UNTL Change units to lb or oz

DSPN Change mode to average

DSPT Change mode to peak tension

DSPC Change mode to peak compression

PKCL Peak clear reset

MEMS Display value stored in memory

CPST Upper and lower limit set ±dddd±dddd

MEMC Last data in memory clear

MEMD Memory data output

MEMZ Clear all data in memory

MEMN Memory location recall

Z Tare

UPD Display update 1, 2, 3, 4

APF Auto - power - off 0, 3

EXS External input setting Z, H, N

HLD Hold trigger mode E, L O, C

LOG Memory mode setting S, C, N

PKF Peak fast mode 0, 1

D Output displayed data

DATN Output average mode data

DATT Output tension peak data

DATC Output compression peak data

LIST Gauge's present state

TT

AA

T

A

TT

AA

16

RS232CRS232C

RS232C

RS232CRS232C

External control command

ASCII Capital Characters

! UNTG, UNTN, UNTL - Change UNITS to Kg, N, lb

UNTG CR... Kg(g)

UNTN CR... N

UNTL CR... lb (oz)

! DSPN, DSPT, DSPC - Change to average, peak tension,

peak compression mode.

DSPN CR... Change to average mode

DSPT CR... Change to peak tension mode

DSPC CR... Change to peak compression

! PKCL _____________________ Peak Clear

PKCL CR.... Peak reset. Same as reset from the gauge. If

edge trigger is selected for HOLD, the PC can release the

HOLD using this particular command.

! MEMS, MEMC, MEMD, MEMZ, MEMN

(five control memory commands).

MEMS CR.... with this command if gauge is set in the ON-

DEMAND (single) mode, it sends back to the computer the

word SING. If gauge is set in the continuous or standard

mode then when this command is sent and the gauge’s

memory starts, it sends back to PC the word ST A. If memory

stops, the word STP is sent back to the PC.

! APF ____________________ Auto-Power-Off

APF " CR, " = 0: none

3: 3 minutes

! EXS ________________________External Input Setting

EXS " CR " = Z: TARE

H: HOLD

N: NONE

! HLD _________________ HOLD Trigger Mode

HLD " CR " = E: Edge

L: Level

O: Open Contact

C: Closed Contact

! LoG __________________ Memory Mode Setting

LoG " CR " = S: Single

= C: Continuous

= N: Standard

! PKF __________________ PEAK Fast Mode

PKF " CR " =O:OFF

=1:ON

MEMC CR.... Last DATA in memory to clear

MEMD CR ....Memory DATA recall

MEMZ CR ... Clear all DATA in memory

MEMN CR ....Memory location recall

! CPST _________________________Comparator Setting

CPST 0 0000 0 0000 CR

SIGN UPPER SIGN LOWER

LIMIT LIMIT

Example: CPST 1234-0123 CR

SPACE need 4-digit # (fill with zeros)

! Z _________________________________ TARE

Z CR .... T o TARE. Works the same way as if it were done

thru the gauge i.e SHIFT + ZERO.

! UPD __________________________ Display Update

Time

UPD " CR, " = 1: 0.125 sec.

2: 0.25 sec.

3: 1 sec.

4: 2 sec.

! D, DATN, DATT, DATC _________ Data output request

(4 commands)

D CR .... Output displayed DATA

DATN CR .... Output average mode DATA

DATT CR .... Output tension PEAK DATA

DATC CR .... Output compression PEAK DATA

! LIST ____________ Gauge’s present state

LIST CR (Command from PC)

MDL DFS-0.5

Units g

DSPM Normal

DSPT 0.125 sec

PKFST ON

OFFT 3 min

232C 4800 B8 S2

232C PN CR LF X OFF

Typical

gauge

response

CP ON

HLMT 200.0

LLMT 100.0

ET HOLD

ET LEVEL CLOSE

LOG NONE

17

RSRS

RS

RSRS

-232C-232C

-232C

-232C-232C

! Gauge Response

OK .... Command accepted

ERRO ....Did not recognize command*

ERR1 .... Command cannot be processed*

ERR2 .... Wrong nomenclature, i.e N,S,C*

ERR3 .... Communications error*

IN HOLD ... When in HOLD, certain commands

cannot be processed.

IN MEMORY.. When in continuous memory mode or

standard mode (active), certain

commands can be processed.

*Check command and resend

UNITS CHANGE DISABLE .... This output is transmitted

to PC when someone is trying to change UNITS while

memory is accepting DATA.

! Flow Control

Flow control can be accomplished by CTS input and software.

1. Control by CTS

When CTS is a “space” (5 ~ 10VDC), communica

tions are enabled. When CTS is a “mark”

(-5 ~ -10VDC), communications are disabled.

2. Software flow control

If software flow control is selected, communications

flow control can be accomplished thru RS232C by

sending XON or XOFF. XON (enable: ASCII

position D1#H11). XOFF (disable: ASCII

position D3#H13). If “disabled” is over 5 seconds,

Er06 is displayed momentarily , unit defaults to

measure mode and communications stop.

! Over-load output

When load exceeds approximately 120% of gauge's capacity

an open collector transistor turns ON (there are two OC NPN

transistors, one for tension and one for compression). The

output of these transistors can be used as an alarm or to stop

a process, thus protecting the gauge or the sample (material)

under test.

OVERLOAD

OUTPUT

CONNECTOR

TENSION

COMPRESSION

COM

Both transistors can handle up to 28VDC, 5 mA.

! Statistics

Statistics for up to 100 measurements can be performed using

the following formulas:

18

Note: For above calculations only absolute values are used

even though algebraic signs may appear on the display .

CalibrationCalibration

Calibration

CalibrationCalibration

The DFS series is an easy series to calibrate. At the same

time certain caution should be excersised not to lose the

calibration data in the process.

! Before proceeding with calibration

a) Secure a stand or some kind of fixture.

b) Secure calibration weight

c) Calibration weight has to be precise,

full scale and in Kg/g only.

d) Avoid vibration totally.

Note: If the analog output is used, steps 1 thru 15 must be

used. If the analog output is not used, steps 1 thru 11 must be

used. When steps 1 thru 11 are used, the analog zero maybe

slightly off.

Calibration ProcedureCalibration Procedure

Calibration Procedure

Calibration ProcedureCalibration Procedure

1. Turn power off. Use hook attachment and mount unit on

a stand or fixture up-side-down.

2. Press MEMO SET first and hold, then press ON and hold

for approximately 4 seconds till display shows CAL.

3. Press MEMO SET . Display will go to hex data. W ait

approximately 10 minutes for the unit to warm up.

4 . Zero position calibration

Press MEMO SET with no load. Down arrow will blink

and after 6 seconds it will go on solid and display will

show a hexadecimal number between 7E0 and 8C0 which

has no particular meaning to the operator.

→

5. Hang calibration weight. Press MEMO SET . Upper arrow

will blink and after 6 seconds it will go on solid. The

display will show a hexadecimal number depending on

the particular model under calibration. This number has

no meaning to the operator.

6. Now SP AN calibration is complete. Turn power of f.

7. Take unit out from stand or fixture and place it in a

horizontal position.

8. Press MEMO SET first and hold, then press ON and hold

for approximately 4 seconds. The display will

show CAL.

9. Press MEMO SET and wait approximately 30 seconds.

10.Press MEMO SET again. Arrow will blink and then go

solid.

11.Calibration is now complete. Turn power off. DO NOT

press MEMO SET before turning power off, otherwise

you will have to start with step 2 again.

12.Keep unit in horizontal position and press RECALL and

ON simultaneously and hold for approximately 4 seconds

till display shows .

13.Press MEMO SET . The unit will display along

with a hexadecimal number depending on the output

residual analog voltage.

14.Measure analog output voltage and adjust to zero using

the and switches. If switch is pressed, the

output voltage increases. If the switch is pressed, the

output voltage decreases.

15.Press MEMO SET and then turn power off.

Note: After step 12, be careful not to touch the ON key .

If the ON key is touched accidentally , the display will go

to some hexadecimal number. To default press ON key

twice.

The display will show the number as in step 13 above.

See diagram below .

→

SHIMPO ONE-SHIMPO ONE-

SHIMPO ONE-

SHIMPO ONE-SHIMPO ONE-

LIMITED EXPRESLIMITED EXPRES

LIMITED EXPRES

LIMITED EXPRESLIMITED EXPRES

that this product shall be free from defects in workmanship and materials under normal use and proper maintenance for one year from the date of original purchase. This warranty shall not be effective if the product has been

subject to overload, misuse, negligence, or accident, or if the product has been repaired or altered outside of

Shimpo Instruments’s authorized control in any respect which in Shimpo Instruments’s judgment, adversely

affects its condition or operation.

DISCLDISCL

DISCL

DISCLDISCL

WARRANTY, and Shimpo Instr uments hereby disclaims all other warranties, expressed, statutory or implied,

applicable to the product, including, but not limited to all implied warranties of merchantability and fitness.

LIMITLIMIT

LIMIT

LIMITLIMIT

OR REPLACE the defective product or part, at Shimpo Instruments’s option. Shimpo Instruments reserves the

right to satisfy warranty obligation in full by reimbursing Buyer for all payments made to Shimpo Instruments,

S WS W

ARRARR

ANTYANTY

S W

ARR

ANTY

S WS W

ARRARR

ANTYANTY

AIMER OF ALL OTHER WAIMER OF ALL OTHER W

AIMER OF ALL OTHER W

AIMER OF ALL OTHER WAIMER OF ALL OTHER W

AA

TION OF REMEDTION OF REMED

A

TION OF REMED

AA

TION OF REMEDTION OF REMED

YY

::

Y

: Under this warranty, Shimpo Instruments’s SOLE OBLIGATION SHALL BE TO REPAIR

YY

::

::

: Shimpo Instruments warrants, to the original purchaser of new products only,

::

ARRARR

ANTIES:ANTIES:

ARR

ANTIES: The foregoing warranty constitutes the SOLE AND EXCLUSIVE

ARRARR

ANTIES:ANTIES:

TYPICAL

EXAMPLE

YEAR WYEAR W

YEAR W

YEAR WYEAR W

whereupon, title shall pass to Shimpo Instruments upon acceptance of return goods. To obtain warranty service, Purchaser must obtain Shimpo Instruments’s authorization before returning the product, properly repackaged, freight pre-paid to Shimpo Instruments.

INDEMNIFICAINDEMNIFICA

INDEMNIFICA

INDEMNIFICAINDEMNIFICA

harmless from and against all claims and damages imposed upon or incurred arising, directly or indirectly, from

Buyer’s failure to perform or satisfy any of the terms described herein. In no event shall Shimpo Instruments be

liable for injuries of any nature involving the product, including incidental or consequential damages to person or

property, any economic loss or loss of use.

MERGER CLMERGER CL

MERGER CL

MERGER CLMERGER CL

extent that they also appear in writing. This writing constitutes the entire and final expression of the parties’

agreement.

ARRANTYARRANTY

ARRANTY

ARRANTYARRANTY

TION & LIMITTION & LIMIT

TION & LIMIT

TION & LIMITTION & LIMIT

AA

USE:USE:

A

USE: Any statements made by the Seller’s representative do not constitute warranties except to the

AA

USE:USE:

AA

TION OF DAMAGES:TION OF DAMAGES:

A

TION OF DAMAGES: Buyer agrees to indemnify and hold Shimpo Instruments

AA

TION OF DAMAGES:TION OF DAMAGES:

19

0

R

I

S

n

m

s

o

A

b

SpecificationsSpecifications

Specifications

SpecificationsSpecifications

MODELS DFS-0.5

CAPACITY

RESOLUTION

ACCURACY ±0.2% FS + 1/2 digit at 23°C

DISPLAY 4-Digit LCD, 11.5 mm High with various indicators including Low Battery

MEASURING MODE Average, Peak Compression, Peak Tension (selectable)

DISPLAY UPDATE 125 ms, 250 ms, 1 sec, 2 sec (selectable)

SAMPLING RATE Average Mode: 125 ms, 250 ms, 1 sec, 2 sec Peak Mode: 1 ms, 125

TEMPERATURE COEFFICIENT Zero: ±0.02% FS/°C (max.), Span:±0.015% of reading/°C (max.)

OUTPUTS

OVERLOAD CAPACITY 200% of FS

COMPARATOR OUTPUT

(Set Points)

OVERLOAD OUTPUT Two open collector NPN transistors one for Tension and one for Compre

TARE & HOLD CONTROL Relay contact (selectable)

MEMORY Holds 100 samples plus statistics (MAX, MIN, AVG, and Standard Deviati

POWER 4 - AA Alkaline batteries. Last approx. 20hrs. in continuous operation or

AUTO POWER SHUT-OFF Selectable (3 minutes if there is no activity)

OPERATING TEMP RANGE 32 - 113°F (0 - 45°C)

DIMENSIONS/WEIGHT 3"W x 1.77"H x 9.72"L (76 x 45 x 247)mm /1.2 lbs. (550 g)

ACCESSORIES (Included)

ACCESSORIES (Available) Test stands, RS232C cable, Digimatic, analog and comparator output ca

DFS-0.5R

8 oz

200 g

2 N

1. RS232C 2. Digimatic: (works with Mitutoyo's printer model DP-1H

3. Analog: (±1VDC with load impedance of 2K or higher and tare functio

Three open collector NPN transistors for HI, GO, and LO (28VDC, 7 ma

Batteries, carrying case, overload output cable, AC adapter, 6 adapters (f

extension rod)

DFS-1

DFS-1R

16 oz

500 g

5 N

0.01 oz 0.001 lb

0.1 g 1 g 0.001 Kg

0.001 N 0.01 N

DFS-2

DFS-2R

2 lb

1000 g

10 N

DFS-5

DFS-5R

5 lb

2 Kg

20 N

DFS-1

DFS-10

10 lb

5 Kg

50 N

*

*DFS – 0.5 to DFS – 10 models

SHIMPO INSTRUMENTSSHIMPO INSTRUMENTS

20

SHIMPO INSTRUMENTS 1701 Glenlake Ave. Itasca, IL 60143 USA (630) 924-7138 Fax (630) 924-0342

SHIMPO INSTRUMENTSSHIMPO INSTRUMENTS

Loading...

Loading...