Page 1

NO.ELE-DE011101

DEG2000 Instruction Manual

Digital Electric Micrometer

Page 2

Contents

1. Introduction ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

2. Main Features ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

3. Main Modes・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

4. Names and Functions of Controls and Parts ・・・・・・・・・・・・・ 2

5. Specifications ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

6. Operation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 11

6.1 Description ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 11

6.2 Measuring ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 12

6.3 Automatic mastering ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 13

6.4 Setting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 14

7. I/O Description ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 16

7.1 Serial output ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 16

7. 2 External input・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 18

7.3 Judgment result output ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 19

8. Model Identification ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

9. Options ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

9.1 Instrument ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

9.2 Separately sold parts・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

10. Maintenance・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 33

11. Troubleshooting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 34

12. Cautions・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 34

13. Operation Flow ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 35

14. Work Sheet ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 45

Page 3

1. Introduction

The digital electric micrometer is a measuring instrument with a large easy-to-see

(three-color) digital display and an automatic mastering function. It can be operated by

external input and output signals and is thus suited for automatic measurement.

2. Main Features

(1) A large three-color main digital display provides the ease of seeing judgment and

measurement results.

(2) An eight-digit multifunctional alphanumeric display indicates the measurement

conditions and items.

(3) Control keys and external signals automate mastering.

(4) Judgment result output signals are provided as standard and are ideal for automatic

measurement.

(5) The standard serial communication function allows the output of data to the personal

computer and printer. The data can be stored, statistically processed, and input to a

spreadsheet program like Excel.

(6) Two electric micrometers can be connected for measurement by operational

processing. Tapers, ovals, and steps can be measured.

3. Main Modes

The instrument operates in the following four main modes:

(1) Measure mode

Measure: Measures a work.

Hold measured value: Holds the measured value, except when the

mastering result is NG.

(2) Set mode

Enters and changes the set value.

(3) Master mode

Master: Calibrates the instrument with the masters.

This instrument is a comparative measuring

instrument. Be sure to use it upon completion of the

mastering operation.

Adjust detector: Adjusts the detector.

Clear mastering data: Clears the mastering data.

(4) Change program mode

Changes from one program to another. When the instrument is started, the

program used last is launched.

1

Page 4

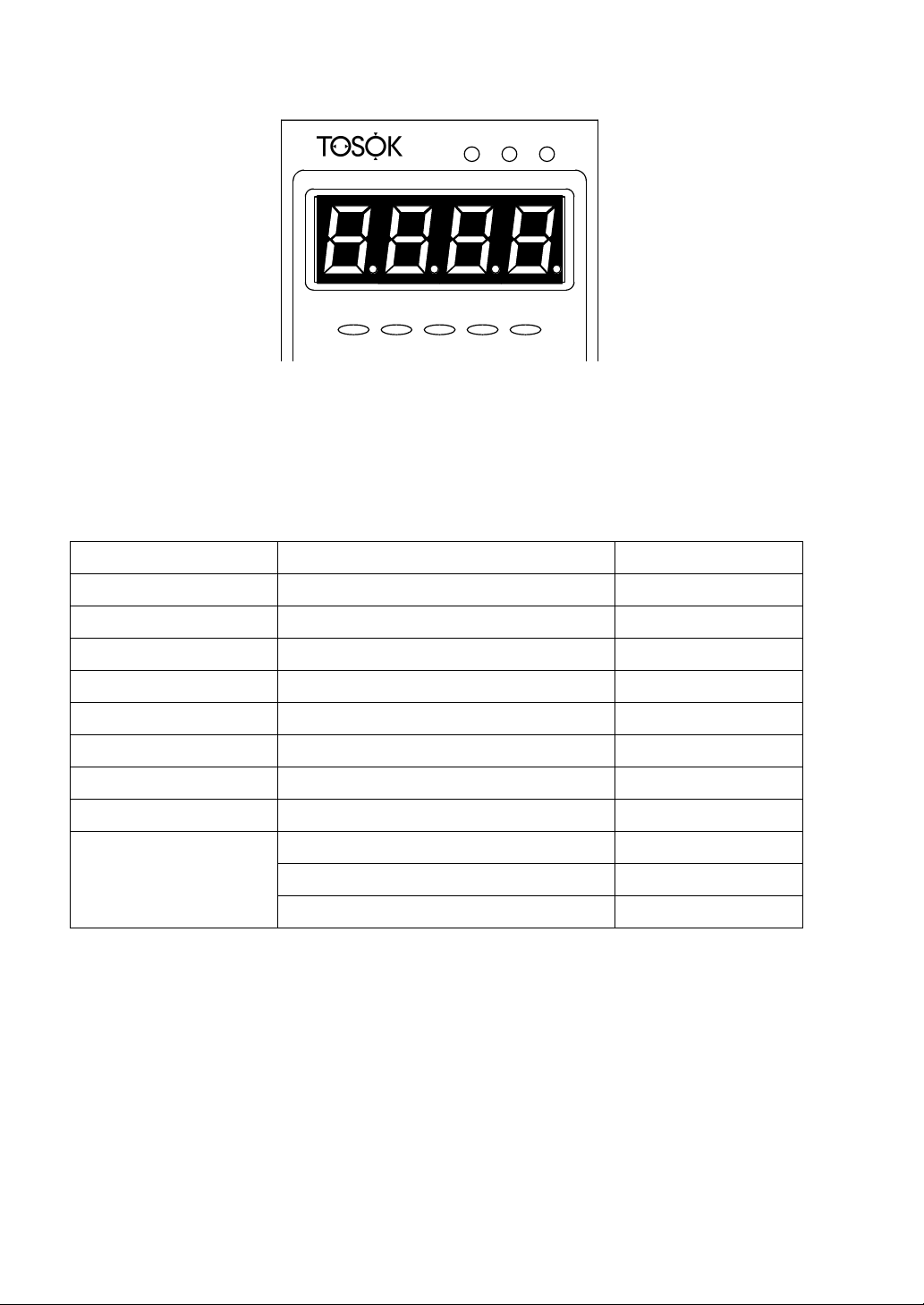

4. Names and Functions of Controls and Parts

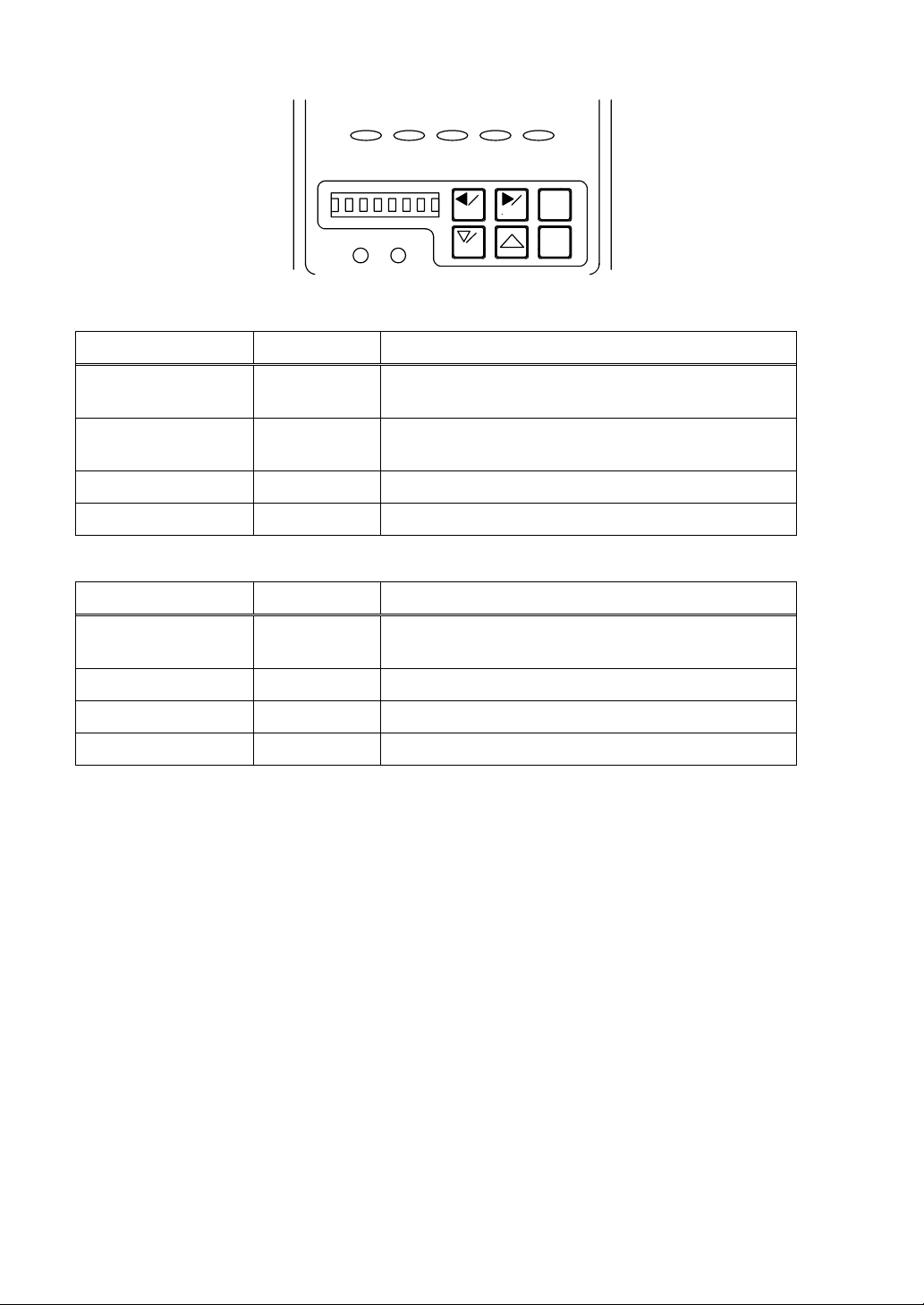

1

◯

Item and judgment LEDs

-NG-

OK

OK +OK +NG

➀

12

3

Indicate the judgment result and measurement under way (as shown on the main

display), among other things. The conditions of Items 1 to 3 are indicated by LEDs 1 to

3, respectively. The lighting colors of the LEDs and the conditions indicated by them are

shown in Table 1.

Table 1. LED colors and conditions indicated.

Color Condition Mode

Green (light and dark) Judgment result OK; Main display item Measure

Green (light) Judgment result OK; Other item Measure

Green (dark) and blank Judgment result OK; Main display item Hold measured value

Green (dark) Judgment result OK; Other item Hold measured value

Red (light and dark) Judgment result NG; Main display item Measure

Red (light) Judgment result NG; Other item Measure

Red (dark) and blank Judgment result NG; Main display item Hold measured value

Red (dark) Judgment result NG; Other item Hold measured value

Orange (light)

Set value of item being entered Set

Instrument being calibrated with master Master

Detector being adjusted Adjust detector

2

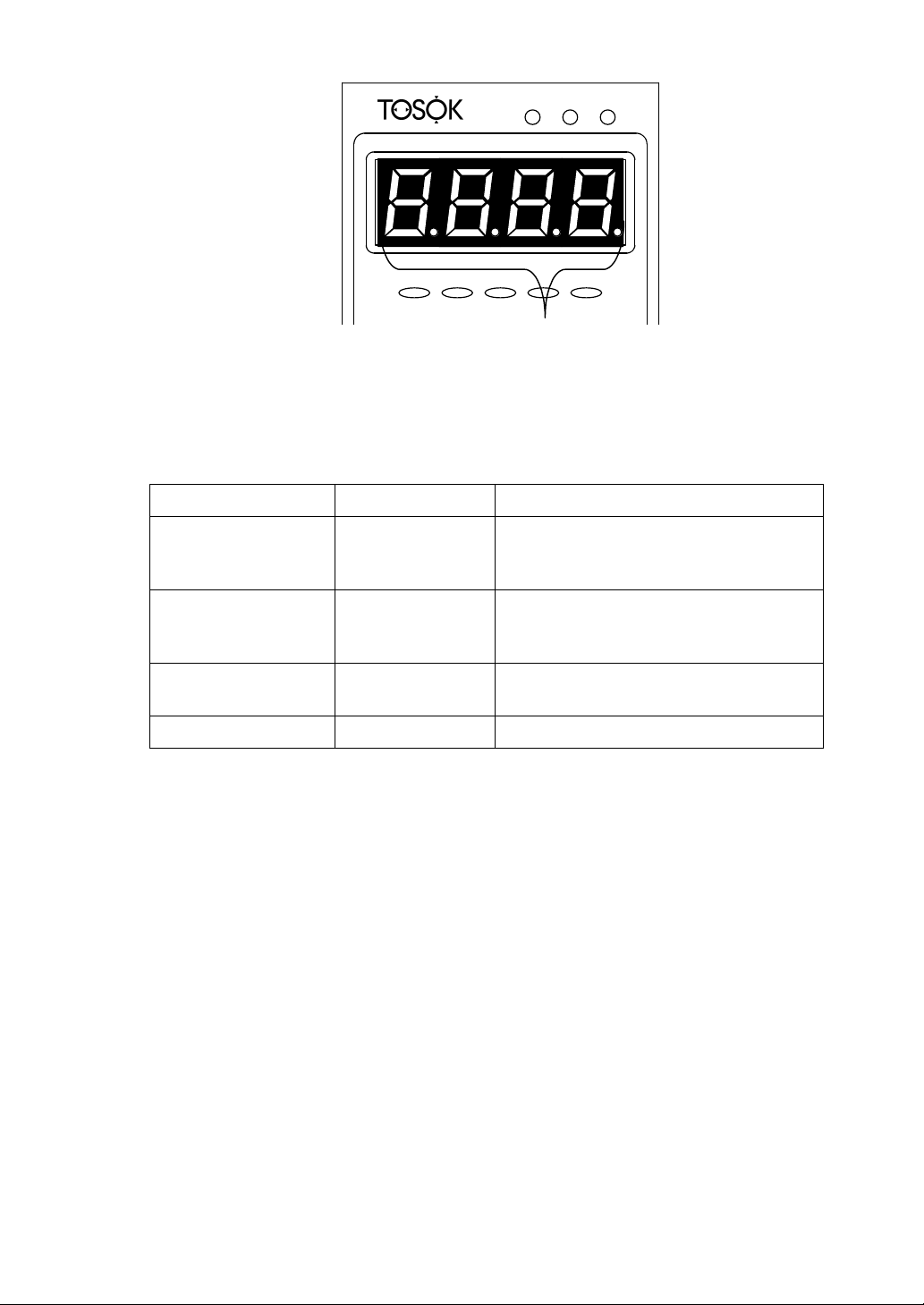

Page 5

-NG-

OK

OK +OK +NG

12

3

➁

2

◯

Main display

Shows a value or condition in one of three colors. The display colors in each mode are

as given in Table 2.

Table 2. Display colors and items in each mode.

Mode Color Item

Measure Green (light)

Red (light)

Orange (light)

Hold measured value Green (dark)

Red (dark)

Orange (dark)

Master Green (light)

Red (light)

Measured value (Judgment result OK)

Measured value (Judgment result ±NG)

Measured value (Judgment result ±OK)

Measured value (Judgment result OK)

Measured value (Judgment result ±NG)

Measured value (Judgment result ±OK)

Mastering enabled

Mastering disabled

Adjust detector Orange (light) Measured value

3

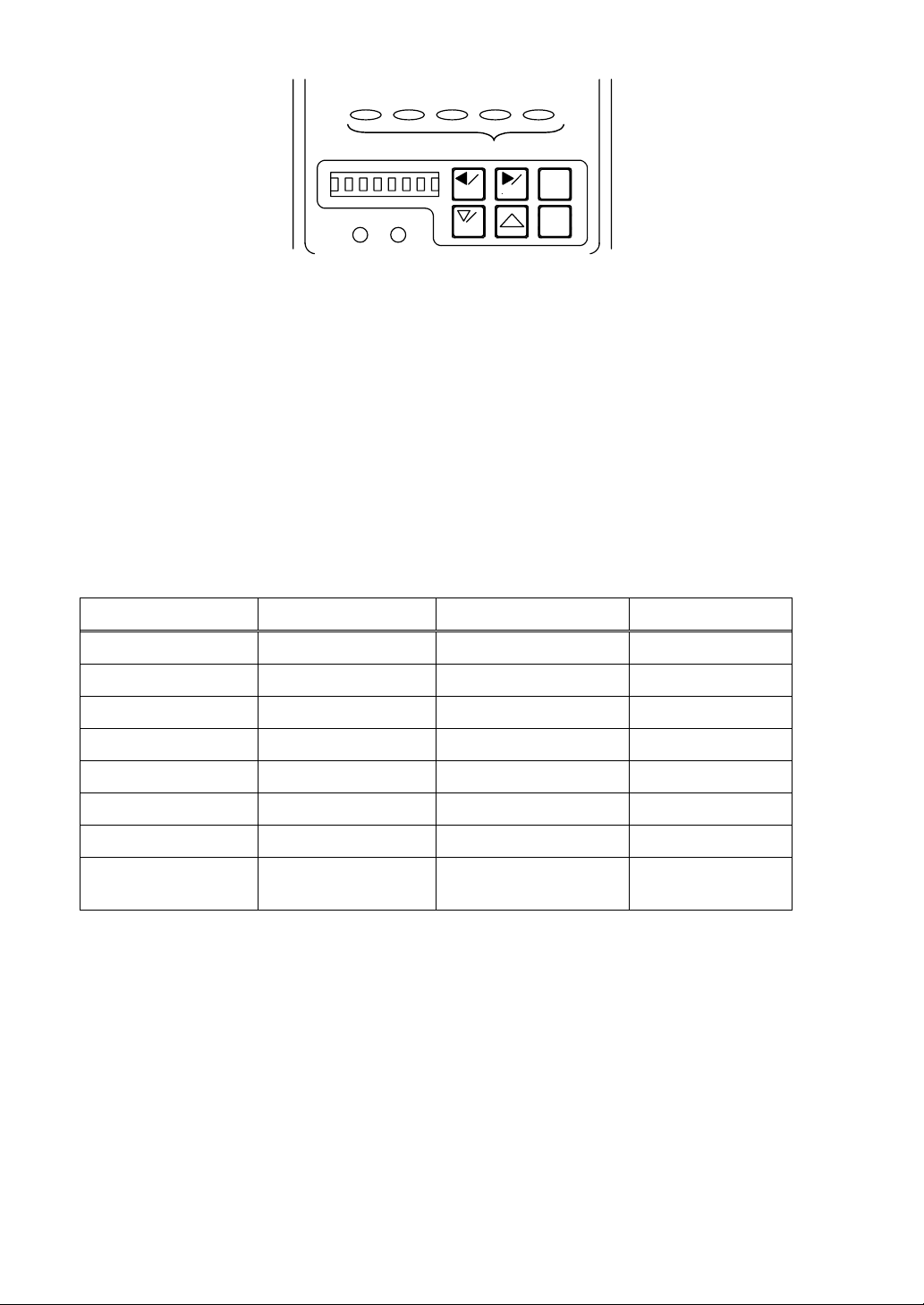

Page 6

OK OK +OK +NG

-NG-

➃

SET MAS

➂

SET MAS

PROG

RST

ENT

➄

3

◯

Display item judgment LEDs

Judge the data shown on the main display. OK is indicated by green, ±OK by orange,

and ±NG by red. ±OK is used only when the number of ranks is three.

4

◯

Alphanumeric display

The measured value, set value, set description, and other data are indicated by 8-digit 7

× 5 dot characters.

5

◯

Mode LEDs

Indicate the condition of the current mode and the mastering result. The LED lighting

colors, modes, and mastering results are as shown in Table 3.

Table 3. LED colors and conditions indicated.

SET mode LED MAS mode LED Mode Mastering result

Orange Off Set OK

Orange Red flashing Set NG

Green Off Change program OK

Green Red flashing Change program NG

Off Orange Master OK

Off Orange and red Master NG

Off Red flashing Measure NG

Off Off Measure,

OK

Hold measured value

4

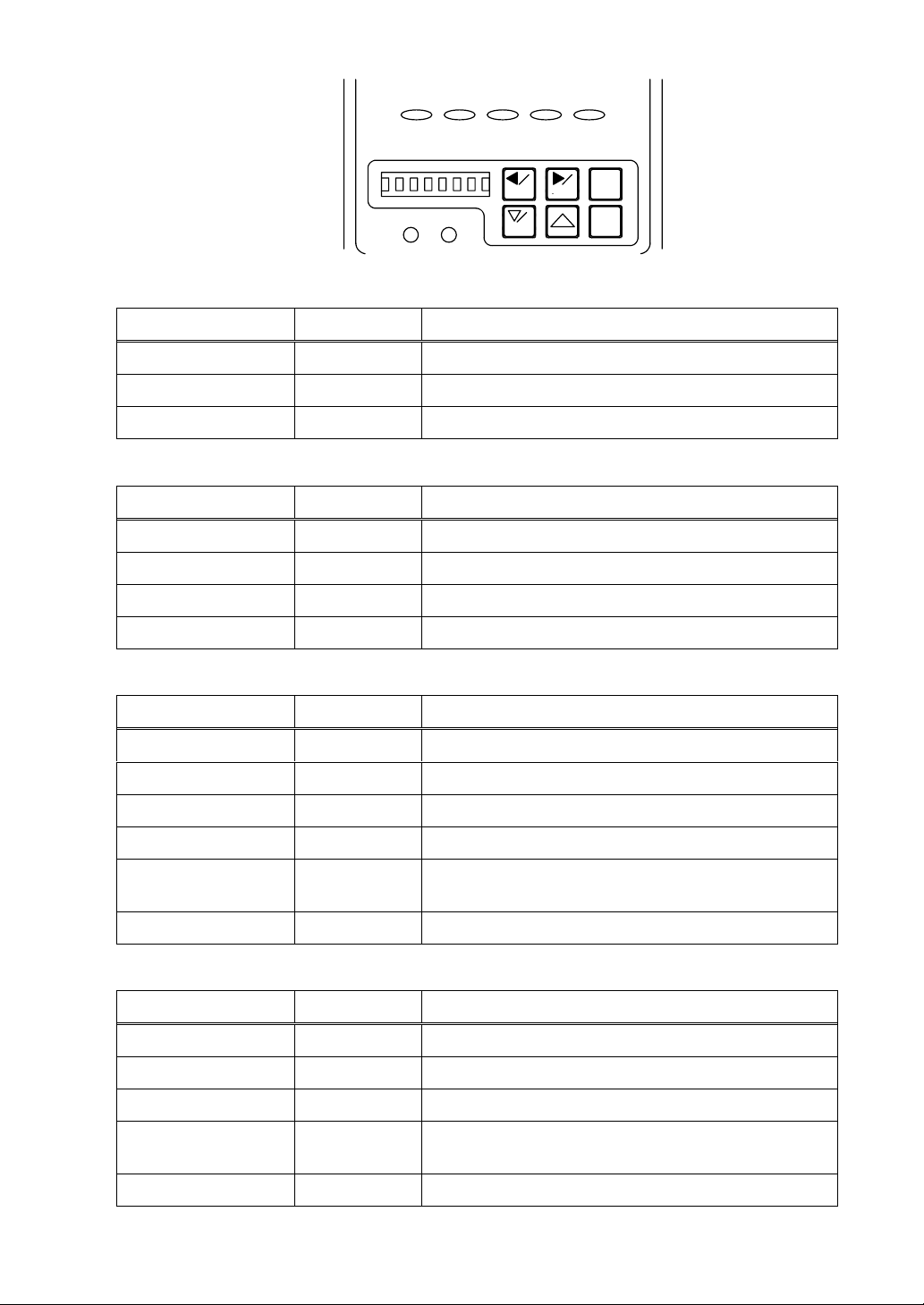

Page 7

OK OK +OK +NG

-NG-

➅➆

RST

ENT

SET MAS

SET MAS

PROG

➇ ➈

6

◯

Left arrow /SET key

Mode Keying Operation

Measure Press 2 sec. Mode is changed to set mode.

Set Press once. Set description is changed.

Adjust detector Press once. Measuring head is changed.

7

◯

Right arrow/MAS key

Mode Keying Operation

Measure Press 2 sec. Mode is changed to master mode.

Set Press once. Set description is changed.

Master Press once. Mode is changed to adjust detector mode.

Adjust detector Press once. Measuring head is changed.

8

◯

Down arrow/PROG key

Mode Keying Operation

Measure Press 2 sec. Mode is changed to change program mode.

Measure Press once. Item is changed from ITEM 3 to ITEM 1.

Set Press once. Set value is entered (or decremented).

Master Press once. Master is changed from MAS 2 to MAS 1.

Adjust detector Press once. Master is changed from MAS 2 to MAS 1, or set

value is entered (or decremented).

Change program Press once. Program is changed from PROG 4 to PROG 1.

9

◯

Up arrow key

Mode Keying Operation

Measure Press once. Item is changed from ITEM 1 to ITEM 3.

Set Press once. Set value is entered (or incremented).

Master Press once. Master is changed from MAS 1 to MAS 2.

Adjust detector Press once. Master is changed from MAS 1 to MAS 2, or set

value is entered (or incremented).

Change program Press once. Program is changed from PROG 1 to PROG 4.

5

Page 8

OK OK +OK +NG

-NG-

◯

10

RST

ENT

11

◯

10

◯

RST (reset) key

SET MAS

SET MAS

PROG

Mode Keying Operation

Hold measured

Press once. Measured value hold is cleared.

value

Set Press once. Set description is returned to previous condition.

Setting is finished (WRITE or CANCEL).

Master Press once. Reading of master measured value is canceled.

Adjust detector Press once. Set description is returned to previous condition.

11

◯

ENT (enter) key

Mode Keying Operation

Measure Press once. Mode is changed to hold measured value mode

(when mastering result is OK).

Set Press once. Set description is determined.

Master Press once. Master measured value is read.

Adjust detector Press once. Adjustment description is determined.

6

Page 9

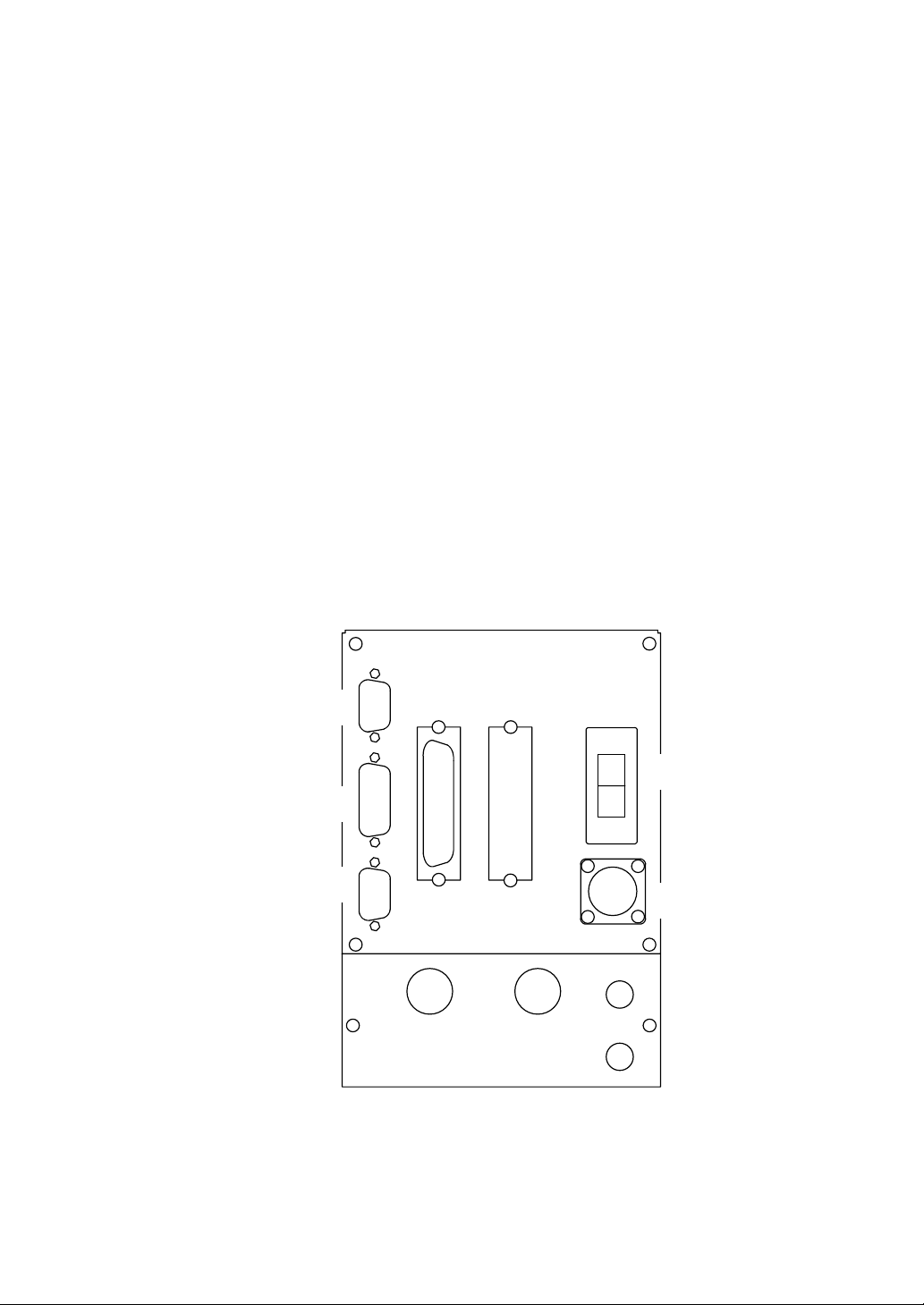

12

◯

RS232C connector

A serial communication connector for connecting a personal computer or printer.

13

◯

Switch input connector

A connector for entering a measure or mastering command with an external button. It is

also used for RS422 communication and Digimatic output.

14

◯

Analog input/output connector

A connector for external analog signal input and amplifier signal output.

15

◯

DC input/output connector

A judgment result input/output connector for connecting LEDs, sequencers, etc.

16

◯

DC input/output connector (option)

17

◯

Power switch

Used to turn on and off the power of the instrument.

18

◯

Power connector

Used to input AC power. It can be used in the range of 85 to 264 VAC, but the

accessory power cable must be used in the range of 85 to 125 VAC.

Rear of DEG2000

12

◯

13

◯

14

◯

ANALOG SW.ETC RS232C

15

◯

EXT I/O

16

◯

AB

AC85~264V

C

D

17

◯

18

◯

7

Page 10

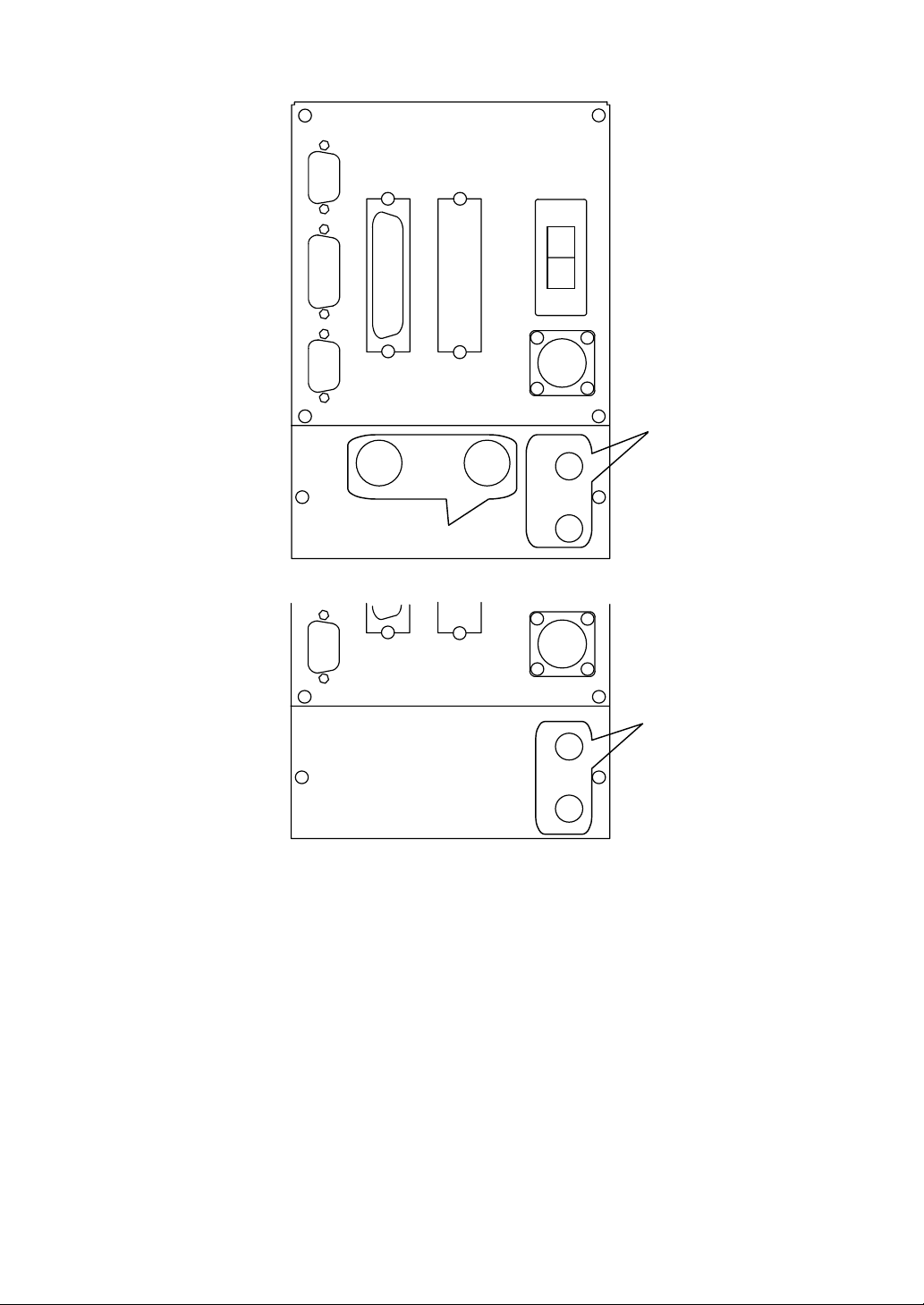

Rear of standard model DEG2000-N

ANALOG SW.ETC RS232C

EXT I/O

AB

AC85~264V

C

20

◯

19

◯

Rear of dedicated model DEG2000-A for air micrometer

19

◯

Electric micrometer connector

Two detectors can be connected.

20

◯

A/E converter (AE2000) connector

Two AE2000 converters can be connected.

D

20

◯

C

D

8

Page 11

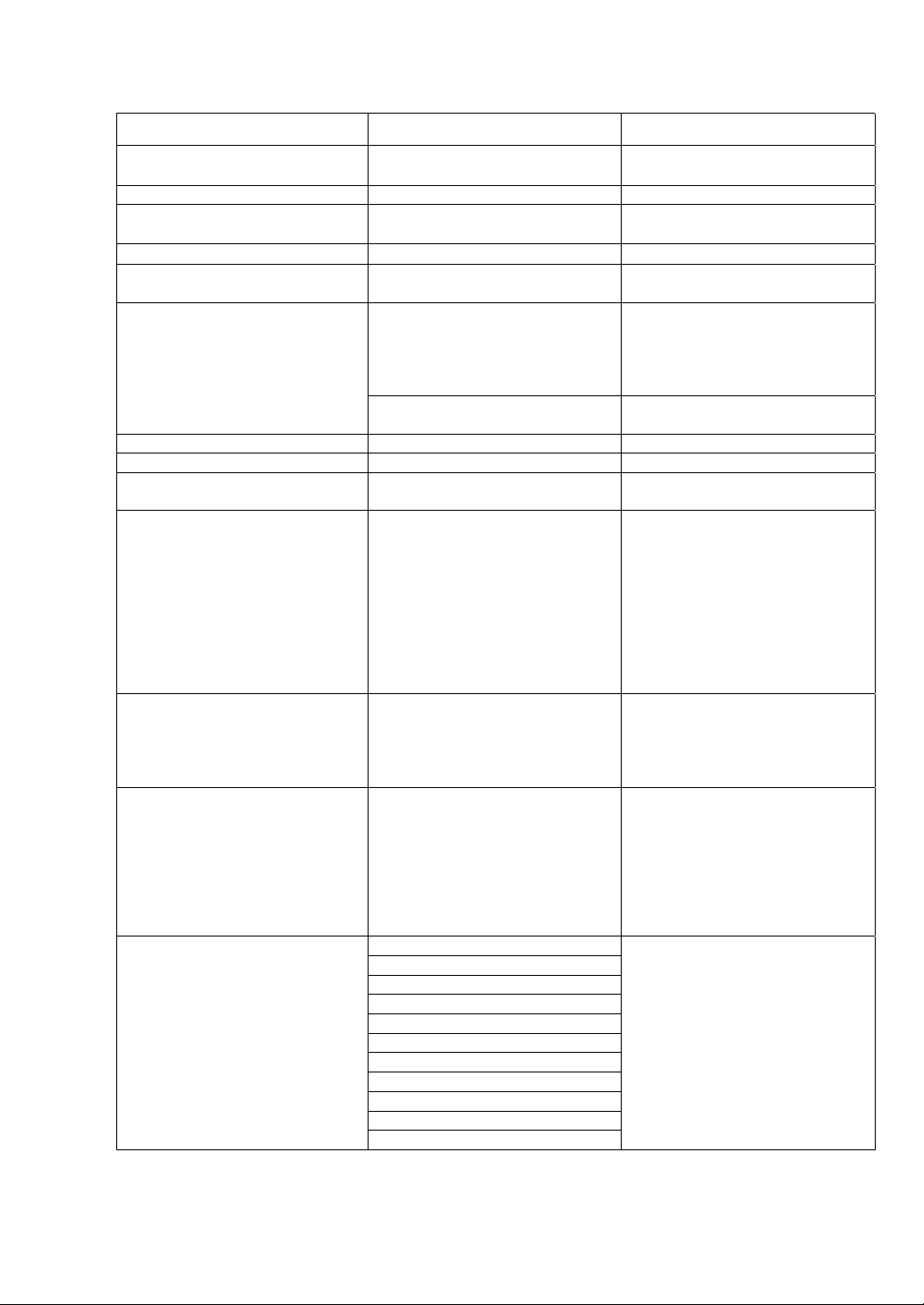

5. Specifications

Item Specification Remarks

Power supply voltage and

frequency

Power supply capacity 30 VA

Dimensions and mass

Operating temperature

Number of programs 4 (Programs 1 to 4) Programs 1 to 3 are changeable

Input module 1. Standard

Number of measurement items 3 (Items 1 to 3)

Number of masters 2 (MAS 1 and MAS 2)

Number of input channels

(XDUCER)

Indicating range (resolution)

Mastering data input Select from among four detectors

Operation functions Item 1 can select MAS 1 or MAS

Measuring functions

85 to 264 VAC, 50/60 Hz 100 VAC power cable supplied as

accessory

120 mm wide × 200 mm high ×

220 mm deep, 2.7 kg

0 to 45°C

from external input.

Changeable by software and

(1) Electric micrometer

(2) Air micrometer

2. Dedicated for air micrometer 2 channels for air micrometer

4

Air micrometer

1. FS±10 µm (0.05 to 2)

2. FS±20 µm (0.1 to 2)

3. FS±50 µm (0.1 to 2)

4. FS±100 µm (0.1 to 2)

Electric micrometer

1. FS±20 µm (0.1 to 2)

2. FS±100 µm (0.1 to 2)

3. FS±1000 µm (1 to 2)

A to D (multiple choice possible).

Symbols and coefficients (-9.999

to +9.999) can be freely

combined.

2, Item 2 can select MAS 1, MAS

2, or Item 1, and Item 3 can select

MAS 1, MAS 2, Item 1, or Item 2

(multiple choice possible).

Symbols and coefficients (-9.999

to +9.999) can be freely

combined.

1. BYPASS

2. +PEAK

3. -PEAK

4. TIR

5. TIR/2

6. MAX

7. min

8. MAX - min

9. (M - m)/2

10. (M + m)/2

11. ABS

unusable simultaneously:

2 channels for air micrometer

(external) and 2 channels for

electric micrometer (internal)

(external)

Set for each program.

Resolution is available in six types

of 0.05, 0.1, 0.2, 0.5, 1, and 2.

Set for each master.

Example:

MAS 1 = A + B + C

MAS 2 = -A + B

Set for each item.

Example:

Item 1 = MAS 1 + MAS 2

Item 2 = -MAS 1 +MAS 2

Item 3 = Item 1 - Item 2

Set for each item.

9

Page 12

Item Specification Remarks

Judgment method ±NG and rank Set for each item.

1. EQUAL Equal ranking:

Maximum of 99 ranks

(Judgment result output:

Maximum of 99 ranks)

2. SELECT Arbitrary ranking:

Maximum of 39 ranks

(Judgment result output:

Maximum of 39 ranks)

1. All masters togetherNumber of masters with which

instrument is to be automatically

calibrated

Mastering range

Number of smoothing cycles 1 to 30 cycles Set for each program.

Communication functions

Judgment result output

Options

2. Each master separately

1. MIN M.Mastering method

2. MAX & MIN

Zero adjustment:

Indicating range ± 30%

Sensitivity adjustment:

Indicating range ± 20%

1. Measured value output to

personal computer

2. Measured value output to

printer

3. External input and foot switch External buttons and foot switch

1. ±NG, ±OK, and OK Output for 3 measurement items +

2. ±NG and 16 ranks Output for 1 measurement item

3. ±NG and 99 ranks (code

output)

1. Digimatic output Output to printer (DP-1)

2. BCD output (addition of output

board required)

3. Additional judgment result

output (addition of output board

required)

4. Serial communication RS422 output

Set for each program.

Automatic mastering is possible

from external signal.

Set for each program.

RS232C communication cable is

sold separately.

are sold separately.

All OK/NG

BCD data output

Individual output of ranks 17 to 39

10

Page 13

6. Operation

6.1 Description

Here is described a series of steps from connecting a measuring head to measuring with

the head.

1

Connecting

2

Turning on power

In the measure mode, press the

3

Entering set value

In the measure mode, press the

to change to the adjust detector mode.

4

Adjusting detector

Connect the measuring head or the AE2000 (A/E

converter), and the accessory power cable to the rear

of the instrument.

Turn on the power switch at the rear of the instrument

to supply the power of 85 to 264 VAC (50/60 Hz).

Immediately after the startup, the instrument falls in

the master request condition (“MAS REQ”

on the alphanumeric display). Press one of the

The instrument changes to the measure mode.

Enter the set value. Refer to “6.4 Setting” and “Set

mode” in “13. Operation flow”.

Adjust the detector or AE2000. Refer to “Adjust

detector mode” in “13. Operation flow”.

or AE2000

appears

key for 2 sec or more to change to the set mode.

key for 2 sec or more, and press the key once

keys to clear the master request.

In the adjust detector mode, press the

(showing “MIN M.” on the alphanumeric display).

5

Mastering

6

Measuring

Calibrate the instrument with a master. Refer to “6.3

Automatic mastering” and “Master mode” in “13.

Operation flow”.

In the measure mode, press the

change to the hold measured value condition.

Press the

The measured value cannot be held when the

mastering result is NG. Refer to “6.2 Measuring”.

key twice to change to the master mode

11

key once to

key to clear the measured value hold.

Page 14

6.2 Measuring

Measure mode

• The conditions indicated by the colors of the item and judgment LEDs in this mode are

as shown in Table 4.

Table 4. Conditions indicated by colors of item and

judgment LEDs in measure mode.

Color Condition

Green (light/dark) Judgment result OK; Main display item

Green (light) Judgment result OK; Other item

Red (light/dark) Judgment result NG; Main display item

Red (light) Judgment result NG; Other item

• Press the

measured value cannot be held when the mastering result is NG.

• Press the

another.

• Select the program to be used for the measurement in the change program mode.

Refer to “Measure mode and change program mode” in “13. Operation flow”.

Hold measured value mode

• Press the

• The conditions indicated by the colors of the item and judgment LEDs in this mode are

as shown in Table 5.

• Press the

another.

key once to change to the hold measured value condition. The

and keys to change from one main display item (ITEM 1 to 3) to

key to clear the measured value hold and return to the measure mode.

Table 5. Conditions indicated by colors of item and

judgment LEDs in hold measured value mode.

Color Condition

Green (dark/blank) Judgment result OK; Main display item

Green (dark) Judgment result OK; Other item

Red (dark/blank) Judgment result NG; Main display item

Red (dark) Judgment result NG; Other item

and keys to change from one main display item (ITEM 1 to 3) to

12

Page 15

6.3 Automatic mastering

Notes: 1. This instrument is a comparative measuring instrument. Be sure to use it

after calibrating it with a master.

2. During a program change, the instrument reads the previous mastering

data.

3. Clear the mastering data when changing the settings of [I-RANGE],

[RESOLUTION], [XDUCER] and [MASTER] and when turning on the

power of the instrument.

➀ Press the

➁ The MAS mode LED (orange) lights, “MIN M.” appears on the alphanumeric display,

and the instrument changes to the master mode.

When the

the last condition or to the measure mode when “MIN M.” is shown on the

alphanumeric display.

➂ Set the minimum master in the detector. When the main display is stabilized, press

the

When “EACH” is selected with [SYSTEM]–[MasSet] in the set mode beforehand…

The mastering operation is carried out according to the master (MAS 1 or MAS 2)

whose mastering data is shown on the main display. Press the

to select the master to be used. The master selection is indicated by one of the

item and judgment LEDs as follows:

LED 1 lights to indicate MAS 1.

➃ The alphanumeric display shows “MAX M.”.

➄ Set the maximum master in the detector. When the main display is stabilized, press

the

➅ “MAS OK” appears for 2 sec on the alphanumeric display to indicate the completion of

the mastering procedure. (The instrument automatically returns to the measure

mode.)

For other details, refer to “Master mode” in “13. Operation flow”.

key for 2 sec or more in the measure mode.

key is pressed during the mastering operation, the instrument returns to

key.

key.

and keys

Mastering errors

• The alphanumeric display shows the following errors:

ERR ZERO: Zero error (outside of mastering range)

ERR MAG: Sensitivity error (outside of mastering range)

ERR REV: Maximum and minimum master values reversed

ERR OFFR: Outside of measuring range

Press the

• When calibrating the instrument with individual masters separately, the mastering

channel changes to return to step ➁ above unless the mastering result is OK for both

maximum and minimum masters.

When a mastering error occurs despite re-mastering, adjust the detector. Refer to

“Adjust detector mode” in “13. Operation flow”.

key to return to step ➁ above. Re-master.

13

Page 16

6.4 Setting

The set value is entered and changed in the set mode.

6.4.1 Set mode

The set mode covers the following settings:

[XDUCER]

The sensitivity of the detector is set. Refer to “Set mode (2)” in “13. Operation flow”.

[MASTER]

The master input channel and the maximum and minimum master values are set. Refer

to “Set mode (3)” in “13. Operation flow”.

[ITEM]

The item constitutive data, measuring function, number of ranks, and boundary values

(upper/lower limits) are set. Refer to “6.4.2 Measuring functions”, “Set mode (4)” in “13.

Operation flow” and “Set mode (5)” in “13. Operation flow”.

[COMM]

Input/output data, like A/D external input and judgment result output data, are set.

Refer to “Set mode (6)” in “13. Operation flow”.

[SYSTEM]

The mastering and automatic measuring functions are set. Refer to “6.4.3 Automatic

measuring functions” and “Set mode (7)” in “13. Operation flow”.

6.4.2 Measuring functions

The measuring functions are set with [ITEM]–[FUNCTION] in the set mode. Here is

described [ITEM], centering on [FUNCTION].

[STRUCT]

The constitutive data of each item and the coefficient of each constitutive data are set.

[FUNCTION]

The measuring function of each item is selected.

Example

When “+PEAK”, “–PEAK”, “TIR”, and “TIR/2” are selected, the automatic measuring

functions are enabled. Refer to “6.4.3 Automatic measuring functions” and “Set

mode (7)” in “13. Operation flow”.

When the constitutive data of Item 1 are MAS 1 and MAS 2…

➀ Select “BYPASS”.

The measured value of Item 1 is (MAS 1 + MAS 2).

➁ Select “+PEAK”.

The measured value of Item 1 is the maximum value of (MAS 1 +

MAS 2).

➂ Select “MAX”.

The measured value of Item 1 is the larger measured value of

(MAS 1 and MAS 2).

14

Page 17

[RANK]

The OK ranking method of each item and the number of OK ranks are set.

[LIMIT]

The OK rank boundary of each item is set.

Example

Refer to “Set mode (5)” in “13. Operation flow”.

➀ When [RANK] = EQUAL, [RANK n] = 4, [R1/-NG] = -30, and

[+NG/Rn] = +30 are set…

-NG < -30 ≤ R1 < -15 ≤ R2 < 0 ≤ R3 ≤ +15 < R4 ≤ +30 < +NG

➁ When [RANK] = SELECT, [RANK n] = 3, [R1/-NG] = -15,

[R1/R2] = -5, [R2/R3] = 0, and [+NG/Rn] = +15 are set…

-NG < -15 ≤ R1 < -5 ≤ R2 ≤ 0 < R3 ≤ +15 < +NG

6.4.3 Automatic measuring functions

The automatic measuring functions are enabled when “+PEAK”, “-PEAK”, “TIR”, and

“TIR/2” are selected with [FUNCTION]. The following automatic measuring functions

are set with [SYSTEM] in the set mode.

[AutoMeas]

Sets the percentage of all master data in the indicating range at which to start the

automatic measurement start function. Disabled when the automatic measurement

start function is turned off.

[InToOut]

Sets whether to hold or reset the measured value when the mastering data change from

inside of the measuring range to outside of the measuring range. Disabled when the

automatic measurement start function is turned off.

[WaitTime]

Sets the stabilizing timer at the time for the automatic measurement to start. When the

stabilizing timer is set at 0.00 sec, the automatic measurement start function is turned off.

[MeasTime]

Sets the measuring timer at the time for the automatic measurement to stop. When the

measuring timer is set at 0.0 sec, the automatic measurement stop function is turned off.

Example

➀ When [WaitTime] = 0.0 and [MeasTime] = 0.0 are set…

Press the ENT key to start the measurement and the RST key to

stop the measurement.

➁ When [I-RANGE (indicating range)] = ±100, [WaitTime] = 1.00,

[AutoMeas] = ±80%, and [MeasTime] = 5.0 are set…

The automatic measurement starts 1 sec after the mastering data

fall within the range of -80 to +80 and stops 5 sec after the start.

The instrument remains in the hold measured value mode until

the measured value falls outside the range of -80 to +80.

15

Page 18

7. I/O Description

g

7.1 Serial output

(1) Description

This instrument can output the measured values to a printer and communicate with a

personal computer (PC) through RS232C.

Data to be transmitted from instrument to PC

Measurement item: Items 1 to 3

Measured value: Data displayed on instrument, NO USE

Judgment result: R 1 to R99, NJG (stabilizing timer in operation), or NDT (only

when NO USE is displayed)

(2) Preparation

The RS232C connector at the rear of the instrument is provided for the PC or printer.

Connect the D-sub 9-pin (male) plug of the optional communication cable to the RS232C

connector.

(3) Connector pin arrangement

(4) Serial port settings

Baud rate: 9600

Bits/character: 8

Stop bit: 1

Start bit: 1

Parity bit: None

(5) Transmission data composition

Item 1 (5 characters), space (1 character), measured value (8 characters), space (1

character), rank (3 characters), space (1 character);

Item 2 (5 characters), space (1 character), measured value (8 characters), space (1

character), rank (3 characters), space (1 character);

Item 3 (5 characters), space (1 character), measured value (8 characters), space (1

character), rank (3 characters), CR, LF

Description No.

1

R × D 2

T × D 3

4

GND

5

Measured value

Jud

No. Description

6

7RTS

8CTS

9

ment result

ITEM1

ITEM2

ITEM3 CRLF

(6) Data transmission method to PC

In the measure mode, press the key. The instrument falls in the hold measured

value condition and transmits the measured value to the personal computer. The data

transmission is disabled when the mastering result is NG.

16

Page 19

(7) Data request command from PC

➀ Measured value latch (data hold) command

Transmit the command byte “E”<45H>. The instrument holds the measured value.

➁ Latch clear command

Transmit the command byte “R”<52H>. The instrument clears the measured value

hold.

➂ Measured value request

Transmit the command byte “D”<44H>. The instrument transmits the abovementioned data (5) to the PC.

Example

Example

Character string

ASCII code

ASCII code 49 54 45 4D 31 20 20 20 20 2D 32 35 2E 30 20 2D 4E 47 20

I TEM1 –25 . 0 –NGcharacter-string

ITEM2 12.5 +OK

ITEM3 NO USE NDTCRLF

49 54 45 4D 32 20 20 20 20 20 31 32 2E 35 20 2B 4F 47 20

49 54 45 4D 33 20 20 20 4E 4F 20 55 53 45 20 4E 44 54 0D 0A

17

Page 20

7. 2 External input

(1) Description

The instrument allows no-voltage contacts, such as those of an external button or foot

switch, to be connected to the SW. ETC connector at the rear. This external input can

be used to perform measurement, reset, maximum mastering, and minimum mastering.

Notes: • Use a cable of 2 m or less in length.

• Do not connect to a sequencer.

(2) Preparation

The SW. ETC connector at the rear of the instrument is provided for external buttons. It

accepts a D-sub15-pin (male) plug.

(3) Connector pin arrangement and connection diagram

(4) Operation with external buttons

a. MEASURE button

➀ In the measure mode, press the MEASURE button.

➁ The measured value is held. (This is called the hold measured value condition.)

Note: The measured value cannot be held when the mastering result is NG.

b. RESET button

➀ Clears the measured value hold.

c. MAX M. (maximum master) button

➀ In the measure mode, set the maximum master in the measuring head.

➁ When the measured value is stabilized, press the MAX M. button. When the

maximum mastering procedure is completed, the instrument returns to the measure

mode.

d. MIN M. (minimum master) button

➀ In the measure mode, set the minimum master in the measuring head.

➁ When the measured value is stabilized, press the MIN M. button. When the minimum

mastering procedure is completed, the instrument returns to the measure mode.

When a mastering error occurs, adjust the detector. Refer to “Adjust detector mode” in

“13. Operation flow”.

18

Page 21

7.3 Judgment result output

The result of three-item judgment, two-item judgment, or ranking is output to the DC

input/output connector. (refer to ◯

7.3.1 Specifications

Item Specification

Input type Photocoupler insulated input

15

on page 7).

Input resistance

Input on voltage 10 V or more

Input

section

Output

section

Current consumption 110 mA

Input off voltage 2 V or less

Number of input signals 8

Input protection circuit No

Response time 1 msec or less

External circuit power supply 12 to 24 VDC

Output type Open collector output

Output voltage 30 VDC

Rating

Output current Maximum of 50 mA per output signal

Number of output signals 24

Output protection circuit No

5 kΩ

19

Page 22

7.3.2 Input signal arrangement

Note: The input signals are enabled when “READY” is turned on. The following

table shows the input signal arrangement of the DC input/output connector

(refer to ◯

Pin No. Signal name Description

15

on page 7).

1 Measure command

Hold measured value and data output command

(Enabled when mastering result is OK.)

2 Minimum mastering Minimum mastering command

3 Maximum mastering Maximum mastering command

4 RESET Measured value hold clear command

5 Program change (lower)

6 Program change (higher)

7 Item bit (less significant)

8 Item bit (more significant)

Specifies program numbers 1 to 3 to be changed.

(Refer to Table 6.)

Specifies measurement items 1 to 3 to be output.

(Refer to Table 7.)

9+COM

Input common line: +12/24 V

10 +COM

Table 6. Program change and program numbers.

Program number

123

Program change (lower) On Off On

Program change (higher) Off On On

Table 7. Item bits and measurement items to be output.

Setting for this instrument*

Item bit (less

significant)

Item bit (more

significant)

Off On Off On

Off Off On On

*1 Item set with [JUDG OUT] is output.

Measurement item to be output

1

123

20

Page 23

7.3.3 Procedure for calibrating instrument with masters by external input

(1) Description

Set the minimum and maximum masters in that order.

(2) Mastering

➀ Check that “READY” is displayed.

➁ Set the minimum master in the measuring head.

➂ After about 2 sec of stabilization time, input the “Minimum mastering” signal.

➃ Set the maximum master in the measuring head.

➄ After about 2 sec of stabilization time, input the “Maximum mastering” signal.

➅ Check that “MAS OK” is displayed. If “MAS OK” is displayed, the mastering

procedure is completed. If “MAS OK” is not displayed, check the setting of each

master, and adjust the measuring head and A/E converter, among other things.

<I: Input to instrument, O: Output from instrument>

0.1 sec or more

I: Minimum mastering

0.1 sec or more

I: Maximum mastering

O: READY

O: Master OK

0.05 sec or less 0.05 sec or less

O: Check input signal

(3) Program change

When the program change on condition is held for 0.2 sec, the measuring program is

changed. Programs 1 to 3 can be freely changed from one to another.

*No change can be made to program 4.

<I: Input to instrument>

I: Program change (lower)

I: Program change (higher)

Condition of instrument

No

program

change

PROG1PROG2PROG

PROG

3

3

21

Page 24

7.3.4 Measuring procedure

(1) Description

In the measure mode, the instrument continues to produce the judgment result output.

In the case of static measurement, it holds the measured value display and judgment

result output when the measure command changes from off to on.

(2) Static measurement

➀ Check that “READY” is displayed.

➁ Check that “MAS OK” is displayed.

➂ Set the work in the measuring head.

➃ After about 2 sec of stabilization time, turn on the measure command. (The

measured value display and judgment result output are held, and “All OK/NG” is

output.)

➄ Read the data.

➅ Input the RESET signal. (The measured value display and judgment result output

hold is cleared.)

<I: Input to instrument, O: Output from instrument>

0.1 sec or more

I: Measure command

0.1 sec or more

I: RESET

O: READY

O: Master OK

O: All OK/NG

O: Hold measured value

0.05 sec or less

0.05 sec or less

O: Check input signal

(3) Dynamic measurement

When “+PEAK”, “–PEAK”, “TIR”, or “TIR/2” is selected at [FUNCTION], the instrument

makes dynamic measurement. When any other item is selected, the instrument makes

static measurement.

The dynamic measurement differs from the static measurement in that the instrument

starts the measurement at the first measure command and holds the measured value at

the second measure command. When making a measurement at an external input

signal, usually set WaitTime and MeasTime both at 0 sec. Before the start of the

measurement, input the RESET signal to clear the peak value accumulation.

22

Page 25

7.3.5 Selecting judgment result output and BCD output

Number 1 2 3 4 5 6

Parallel Parallel Parallel Parallel Code

Output type

OK 3 or

less

OK 7 or

less

OK 16 or

less

OK 39 or

less

OK 99 or less

BCD

All items

Output

items

External

input/output type

Setup of

number

of ranks

Output item

change by input

signal

Remarks Refer to

Each

item

Items 1

and 2

Setup

item

name

Setup

description

––

–

All All All DC DC

–

– Rank n Rank n Rank n Rank n Rank n –

–7 or less

No No Yes Ye s Yes Ye s Ye s

24 page

––––––

Item 1

Item 2

Refer to

25 page

–––––

Other

than

those

shown at

left

Item Item Item Item –

16 or

less

Refer to

26 page

39 or

less

Refer to

27 page

40 or

more

Refer to

28 page

17 or

more

Refer to

28 page

BC

Refer to

29 page

–

1. Output type selection

• The output types marked by are normally usable, and the other output types are

options.

• The output types marked by call for addition of a circuit board.

• Numbers 4 and 6 cannot be selected at the same time.

2. Output item change

• The settings of output items 1 to 5 can be changed with [JUDG OUT] in the set mode.

• The setting of output item 6 can be changed with [BCD OUT] in the set mode.

• When one of Items 1 to 3 is selected as output item, an item bit can be entered to

temporarily change the output item among Items 1 to 3. When the item bit is not

entered, the data of the set output item is output.

*In the case of BCD output, enter a BCD item bit instead of an item bit.

23

Page 26

7.3.6 Three-item judgment result output –– Output signal arrangement

The three-item judgment result output signal is output when “ALL ITEM” is selected with

[JUDG OUT] in the set mode (6).

Note: “Item” refers to “ITEM” of DEG2000. The following table shows the output

signal arrangement of the DC input/output connector (refer to ◯

7).

Pin No. Signal name Description

11 READY Turns on in measure mode during normal operation.

12 Error

Turns on when two signals are simultaneously input and

turns off when all signals are turned off.

13 Master OK Turns on when mastering result is OK.

14 Check input signal

15 All OK

16 All NG

Turns on when input signal is received and processing is

completed, and turns off when input signal is turned off.

Turns on at input of measure command when all items

are OK.

Turns on at input of measure command when any one

item is NG.

17 Item 1 -NG

18 -OK

19 OK

20 +OK

21 +NG

22 Item 2 -NG

23 -OK

24 OK

25 +OK

26 +NG

27 Item 3 -NG

28 -OK

29 OK

30 +OK

31 +NG

32

33

34

35 -COM

36 -COM

Output common line: 0 V

15

on page

24

Page 27

7.3.7 Two-item judgment result output –– Output signal arrangement

The two-item judgment result output signal is output when “ITEM 1&2” is selected with

[JUDG OUT] in the set mode (6).

Note: “Item” refers to “ITEM” of DEG2000. The following table shows the output

signal arrangement of the DC input/output connector (refer to ◯

7).

Pin No. Signal name Description

11 READY Turns on in measure mode during normal operation.

12 Error

Turns on when two signals are simultaneously input and

turns off when all signals are turned off.

13 Master OK Turns on when mastering result is OK.

14 Check input signal

15 All OK

16 All NG

Turns on when input signal is received and processing is

completed, and turns off when input signal is turned off.

Turns on at input of measure command when all items

are OK.

Turns on at input of measure command when any one

item is NG.

17 Item 1 -NG

18 +NG

19 OK1

20 OK2

21 OK3

22 OK4

23 OK5

24 OK6

25 OK7

26 Item 2 -NG

27 +NG

28 OK1

29 OK2

30 OK3

31 OK4

32 OK5

33 OK6

34 OK7

35 -COM

36 -COM

Output common line: 0 V

15

on page

25

Page 28

7.3.8 Ranking output (OK rank 16 or less) –– Output signal arrangement

The ranking output signal is output when “ITEM 1”, “ITEM 2” or “ITEM 3” is selected with

[JUDG OUT], or an item bit is entered in the set mode (6).

Note: “Item” refers to “ITEM” of DEG2000. The following table shows the output

signal arrangement of the DC input/output connector (refer to ◯

7).

Pin No. Signal name Description

11 READY Turns on in measure mode during normal operation.

12 Error

Turns on when two signals are simultaneously input and

turns off when all signals are turned off.

13 Master OK Turns on when mastering result is OK.

14 Check input signal

15 All OK

16 All NG

Turns on when input signal is received and processing is

completed, and turns off when input signal is turned off.

Turns on at input of measure command when all items

are OK.

Turns on at input of measure command when any one

item is NG.

17 Item -NG

18 +NG

19 OK1

20 OK2

21 OK3

22 OK4

23 OK5

24 OK6

25 OK7

26 OK8

27 OK9

28 OK10

29 OK11

30 OK12

31 OK13

32 OK14

33 OK15

34 OK16

35 -COM

36 -COM

Output common line: 0 V

15

on page

26

Page 29

7.3.9 Ranking output (OK rank 39 or less) –– Output signal arrangement (option)

The ranking output signal is output when “ITEM 1”, “ITEM 2” or “ITEM 3” is selected with

[JUDG OUT], or an item bit is entered in the set mode (6). For OK rank 16 or less, refer

to “7.3.8 Ranking output”.

Note: “Item” refers to “ITEM” of DEG2000. The following table shows the output

signal arrangement of the optional DC input/output connector (refer to ◯

page 7).

Pin No. Signal name Description

11 Item OK17

12 OK18

13 OK19

14 OK20

15 OK21

16 OK22

17 OK23

18 OK24

19 OK25

20 OK26

21 OK27

22 OK28

23 OK29

24 OK30

25 OK31

26 OK32

27 OK33

28 OK34

29 OK35

30 OK36

31 OK37

32 OK38

33 OK39

34

35 -COM

36 -COM

Output common line: 0 V

16

on

27

Page 30

7.3.10 Ranking code output (OK rank 99 or less) –– Output signal arrangement

The ranking code output signal is output when “ITEM 1”, “ITEM 2” or “ITEM 3” is selected

with [JUDG OUT] or an item bit is entered in the set mode (6).

Note: “Item” refers to “ITEM” of DEG2000. The following table shows the output

signal arrangement of the DC input/output connector (refer to ◯

7).

Pin No. Signal name Description

11 READY Turns on in measure mode during normal operation.

12 Error

Turns on when two signals are simultaneously input and

turns off when all signals are turned off.

13 Master OK Turns on when mastering result is OK.

14 Check input signal

15 All OK

16 All NG

Turns on when input signal is received and processing is

completed, and turns off when input signal is turned off.

Turns on at input of measure command when all items

are OK.

Turns on at input of measure command when any one

item is NG.

17 Item -NG

18 +NG

19 OK1

20 OK2

21 OK4

22 OK8

23 OK16

“OK1” to “OK64” shown at left are ranking codes.

Total of ranking codes is number of ranks.

Example: When “OK2” and “OK4” are turned on, OK6.

24 OK32

25 OK64

26

27

28

29

30

31

32

33

34

35 -COM

36 -COM

Output common line: 0 V

15

on page

28

Page 31

7.3.11 BCD output –– Input/output signal arrangement (option)

The BCD input/output signal is output when “ITEM 1”, “ITEM 2” or “ITEM 3” is selected

with [BCD OUT] or a BCD item bit is entered in the set mode (6).

Note: “Item” refers to “ITEM” of DEG2000. The following table shows the

input/output signal arrangement of the DC input/output connector

(refer to ◯

Pin No. Signal name Description

BCD item bit (less

7

significant)

BCD item bit (more

8

significant)

9+COM

10 +COM

11 BCD OUT 1

12 2

13 4

14 8

15 10

16 20

17 40

18 80

19 100

20 200

21 400

22 800

23 1000

Decimal place

24

25 (1)

26 POL +: Off, -: On

27

28

29

30

31

32

33

34

35 -COM

36 -COM

16

on page 7).

Specifies measurement item to be BCD output.

Specifies measurement item to be BCD output.

Input common line: +12/24 V

(0)

Output common line: 0 V

29

Page 32

7.3.12 Timing charts

(

)

)

Three-item judgment and two-item judgment (I: Input signal to instrument, O: Output

signal from instrument)

O: READY

O: Master OK

0.1 sec or more

I: Measure command

0.1 sec or more

I: RESET

0.05 sec or less

O: Check input signal

0.05 sec

or less

O: All OK/NG

O: Judgment result

of each item

Ranking (I: Input signal to instrument, O: Output signal from instrument)

O: READY

O: Master OK

I: Measure command

I: RESET

O: All OK/NG

O: Check input signal

I: Item bit

less significant

I: Item bit

(more significant

O: Setup item of

instrument

O: Item 1 ranking data

O: Item 2 ranking data

O: Item 3 ranking data

30

Page 33

7.3.13 Connector pin arrangement diagram

A cable connector (57-30360 and DDK make) is supplied as accessory. Usually, a

cable is not supplied as accessory.

1

19

EXT I/O

36

18

31

Page 34

7.3.14 Input circuit diagram

PC844

7.3.15 Output circuit diagram

4.7k

PC8Q52

17

~

10

9

8

~

1

DC12~24V

L

DC12~ 24V

27

35

36

Open collector output: Maximum of 50 mA per output signal

32

MAX 50mA

Page 35

8. Model Identification

DEG 20 00 –– N –– DP

External input/output

None: Standard

DP: Digimatic output

DC: Additional judgment result output

BC: BCD output

SI: Serial communication

Input

N: 2 channels for air micrometer + 2

channels for electric micrometer

A: 2 channels for air micrometer

Model number

20

Basic model designation

DEG

9. Options

9.1 Instrument

➀ Digimatic output: Output to DP-1 printer (cable supplied as accessory)

➁ Additional judgment result output:

➂ BCD output: Output of BCD data (addition of output board required)

➃ Serial communication: RS422 output

Output of individual ranks above rank 17 (addition of

output board required)

9.2 Separately sold parts

➀ Communication cable (DEG2000-OP-CB-1): D-sub 9-pin connector (EIA-232) for

personal computer

➁ Communication cable (DEG2000-OP-CB-2): D-sub 25-pin connector (EIA-574) for

personal computer

➂ Communication cable (DEG2000-OP-CB-3): D-sub 25-pin connector (EIA-574) for

printer

10. Maintenance

(1) Use alcohol for cleaning the instrument. Use of thinner may discolor or darken the

instrument.

33

Page 36

11. Troubleshooting

Phenomenon Cause Remedy

Repeatability is not stable.

Main display does not

operate.

Main display and

alphanumeric display do not

light.

➀ Measuring head is loosely

secured.

➀ Specified power is not

supplied.

➁ Detector is improperly

adjusted.

➂ Instrument falls in hold

measured value

condition. Main display

appears green (dark) or

red (dark).

➃ Instrument is in set mode. ➃ End set mode.

➀ Power is not supplied. ➀ Supply power of 85 to 264

➁ Power supply or internal

circuit is faulty.

➀ Retighten its fasteners.

➀ Supply power of 85 to 264

VAC.

➁ Adjust detector.

➂ Press RST key to clear

this condition.

VAC.

➁ Ask NIDEC TOSOK for

repair.

12. Cautions

(1)Power cable

The power cable supplied as standard accessory is for 100 V. If you use supply voltage

in excess of 125 V, separately prepare a 250-V power cable.

(2)Control keys

Never operate the control keys with a sharp-pointed tool or the like.

(3)Export

When you try to export this instrument overseas, you may have to have the export

approved by the Ministry of Economy, Trade and Industry under the Export Trade Control

Ordinance. In such a case, contact your nearest NIDEC TOSOK sales office.

(4)Specifications

The specifications are subject to change without notice.

34

Page 37

13. Operation Flow

35

Page 38

363738394041424344

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

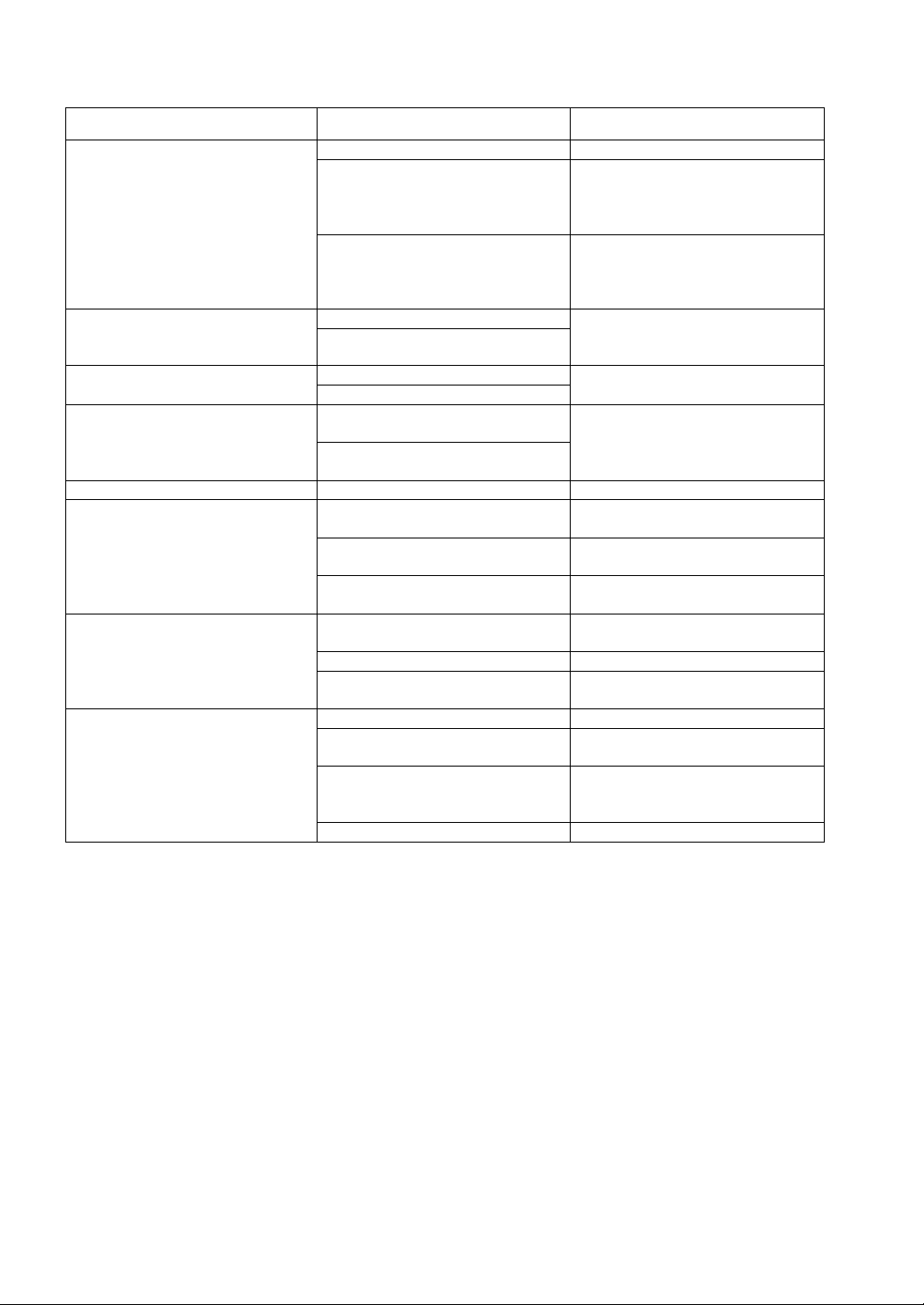

14. Work Sheet

DEG2000 Work Sheet No. 1

Manufacture No.:

Program

Setting description

Input module MODULE

Indicating range I-RANGE

Resolution RESOLUTION

PROG 1 PROG 2 PROG 3 PROG 4

XDUCER

MASTER

CH. A

CH. B

CH. C A/D polarity and coefficient

CH. D A/D polarity and coefficient

MAS 1

MAS 2

A/D polarity and coefficient

D/A ZERO ZERO ADJ

D/A GAIN GAIN ADJ

A/D polarity and coefficient

D/A ZERO ZERO ADJ

D/A GAIN GAIN ADJ

XDUCER used INPUT

Maximum master

value

Minimum master

value

XDUCER used INPUT

Maximum master

value

Minimum master

value

MAX M.

MIN M.

MAX M.

MIN M.

ITEM ITEM 1

STRUCT

(Sign and coefficient

input)

Measuring function FUNCTION

OK ranking method RANK

No. of OK ranks RANK n

LIMITS (3 OK ranks)

*For 4 or more OK

ranks, write on work

sheet No.2.

+NG/+OK

MAS 1Item constitutive data

MAS 2

+OK/OK

OK/-OK

-OK/-NG

45

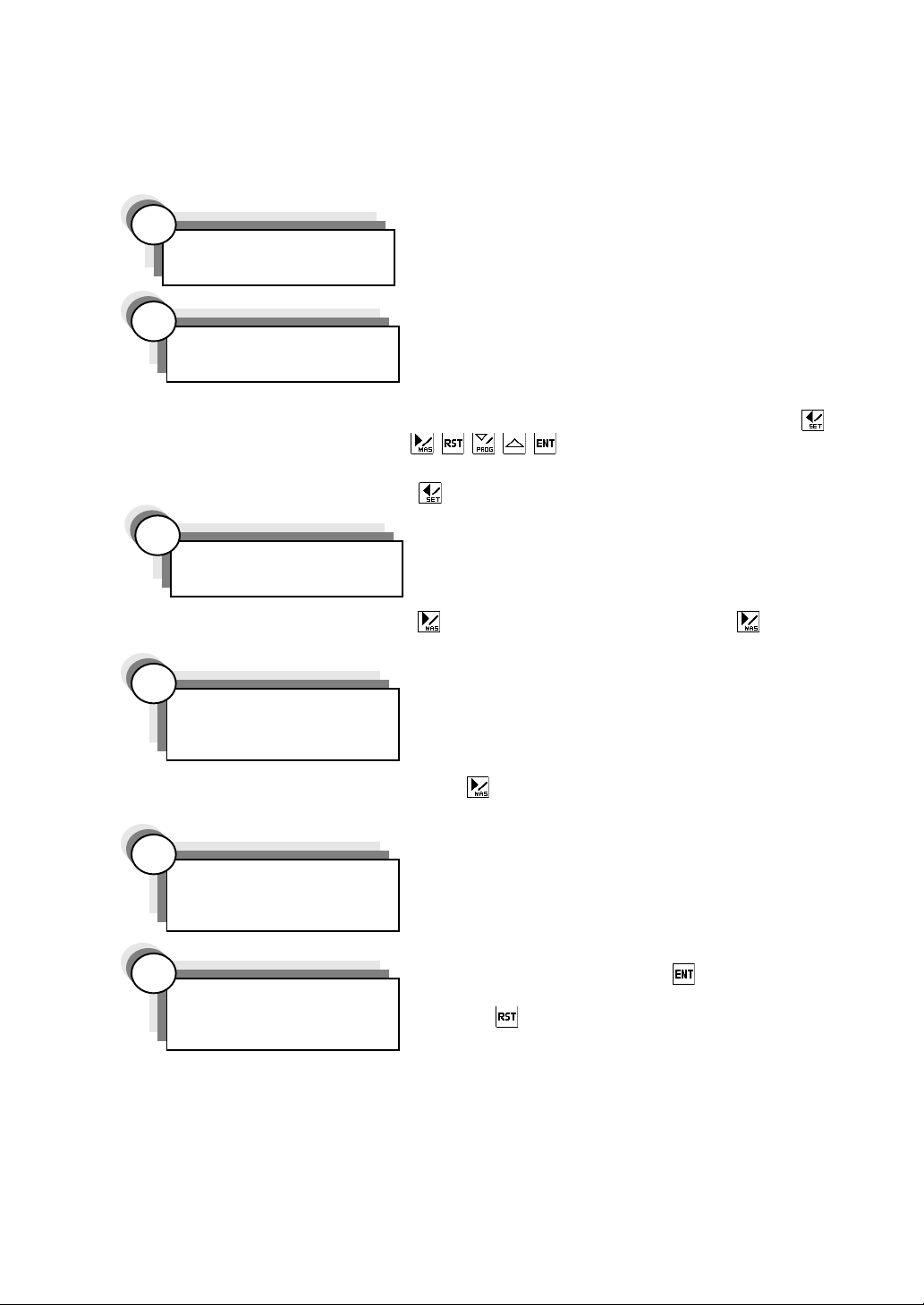

Page 48

Setting description

Program

PROG 1 PROG 2 PROG 3 PROG 4

ITEM ITEM 2 STRUCT MAS 1

ITEM 3 STRUCT MAS 1

Item constitutive data

(Sign and coefficient

input)

Measuring function FUNCTION

OK ranking method RANK

No. of OK ranks RANK n

LIMITS (3 OK ranks)

*For 4 or more OK

ranks, write on work

sheet No.2.

Item constitutive data

(Sign and coefficient

input)

Measuring function FUNCTION

OK ranking method RANK

No. of OK ranks RANK n

MAS 2

ITEM 1

+NG/+OK

+OK/OK

OK/-OK

-OK/-NG

MAS 2

ITEM 1

ITEM 2

LIMITS (3 OK ranks)

*For 4 or more OK

ranks, write on work

sheet No.2.

+NG/+OK

+OK/OK

OK/-OK

-OK/-NG

46

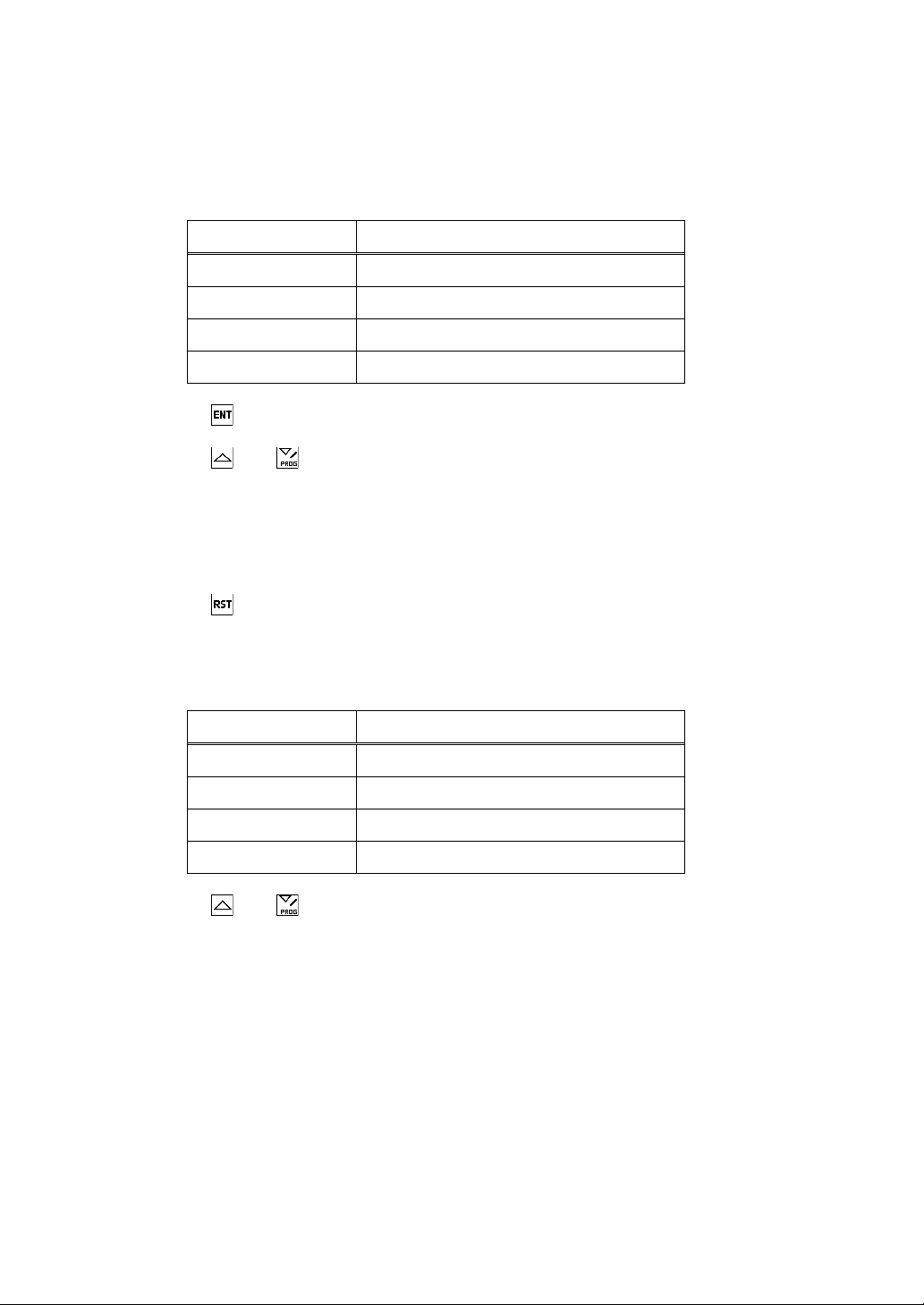

Page 49

DEG2000 Work Sheet No. 2

Setting description

ITEM Rank boundary value LIMITS

Manufacture No.

PROG 1 PROG 2 PROG 3 PROG 4Program item

ITEM1ITEM2ITEM3ITEM1ITEM2ITEM3ITEM1ITEM2ITEM3ITEM1ITEM2ITEM

3

R1/-NG

+NG/Rn

R2/R1

R3/R2

R4/R3

R5/R4

R6/R5

R7/R6

R8/R7

R9/R8

R10/R9

R11/R10

R12/R11

R13/R12

R14/R13

R15/R14

R16/R15

R17/R16

R18/R17

R19/R18

R20/R19

R21/R20

R22/R21

R23/R22

R24/R23

R25/R24

R26/R25

R27/R26

R28/R27

R29/R28

R30/R29

R31/R30

R32/R31

R33/R32

R34/R33

R35/R34

R36/R35

R37/R36

R38/R37

R39/R38

47

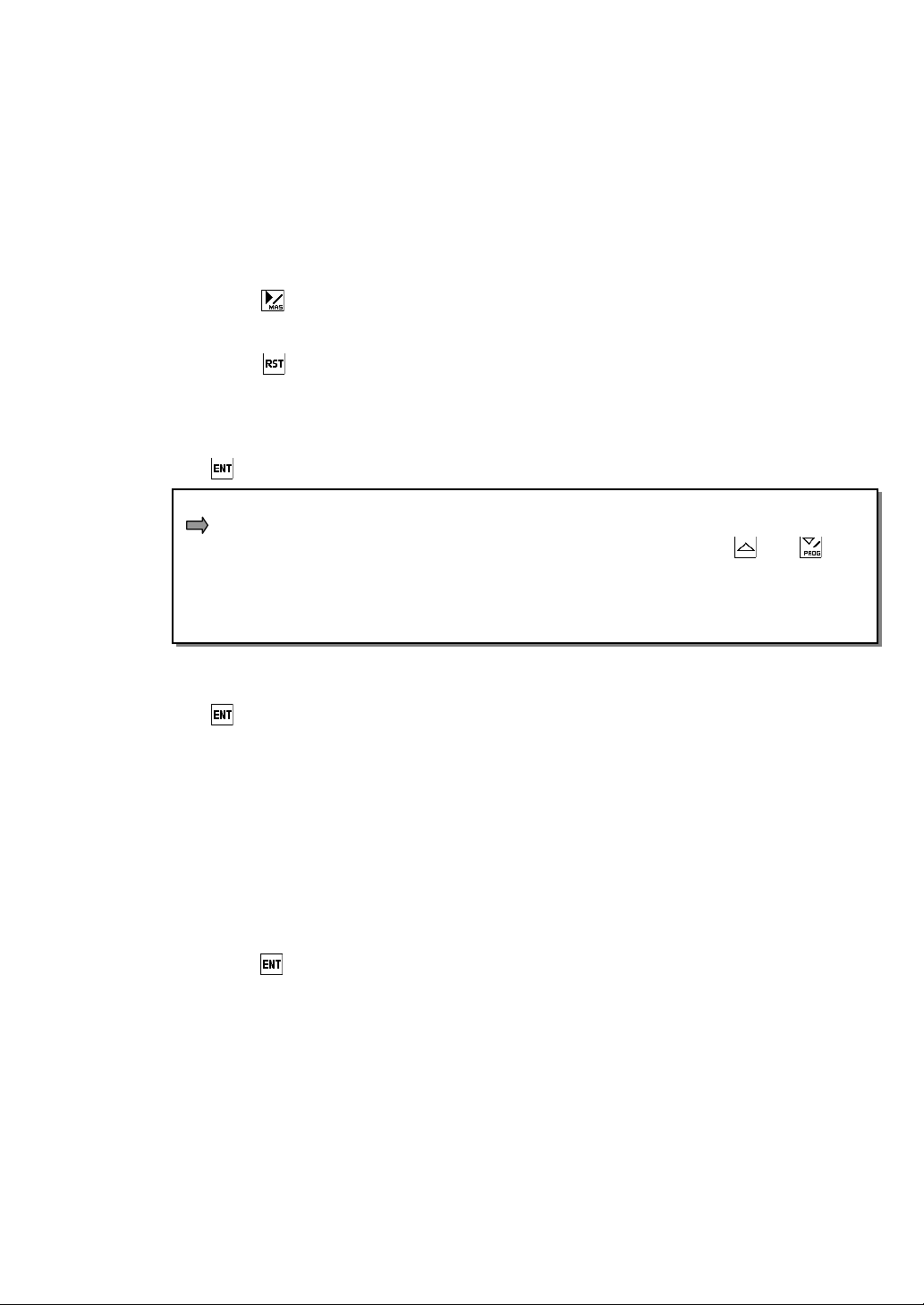

Page 50

Setting description

COMM

SYSTEM

A/D external input EXT CH

Judgment result output JUDG OUT

BCD output BCD OUT

Digimatic output DIGIMATI

No. of masters to be set MasSet

Mastering method SetRule

No. of smoothing cycles SMOOTH

Measuring range AutoMeas

Holding measured value

outside of measuring

range

Stabilizing timer WaitTime

Measuring timer MeasTime

PROG 1 PROG 2 PROG 3 PROG 4Program item

ITEM1ITEM2ITEM3ITEM1ITEM2ITEM3ITEM1ITEM2ITEM3ITEM1ITEM2ITEM

3

InToOut

48

Page 51

HEAD OFFICE 2-215 SOBU-DAI ZAMA CITY, KANAGAWA PREF. 228-8570 JAPAN

URL http://home.tosok.co.jp/

MEASURING MACHINERY SALES DEPT.

OVERSEAS SALES GROUP

TEL 81-46-252-3132〜3

FAX 81-46-253-4449

HOMEPAGE

This manual is printed on recycled paper.

Loading...

Loading...