Page 1

㻥㻤㻞㻤㻝㻭

COLUMNAR ELECTRONIC MICROMETER

CEG2000 Instruction Manual

Page 2

Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Names and functions of the parts . . . . . . . . . . . . . . . . 2

5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1.1 What to do when the detector has been connected

and adjusted and the settings have already been

entered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1.2 What to do when the measurement head has been

replaced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2.1 Measurement mode. . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2.2 Hold measured value. . . . . . . . . . . . . . . . . . . . . . . . 9

6.3 Set-up mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3.1 Selecting the measurement range. . . . . . . . . . . . . 10

6.3.2 Setting the shift value . . . . . . . . . . . . . . . . . . . . . . 10

6.3.3 Selection for mask matching 10

6.3.4 Polarity selection for each measuring unit . . . . . . . 11

6.3.5 Item selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3.6 Input channel selection (In items 1 and 2) . . . . . . . 12

6.3.7 Setting the decision upper limit value

(Set for all items) . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3.8 Setting the decision lower limit value

(Set for all items) . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3.9 Setting the large master value

(Set in items 1 and 2). . . . . . . . . . . . . . . . . . . . . . . 13

6.3.10Setting the small master value

(Set in items 1 and 2). . . . . . . . . . . . . . . . . . . . . . . 13

6.3.11 Selecting the calculation method (in Item 3 only) . 14

6.3.12Saving setting values

(Saving the previous items 6.3.1-11) . . . . . . . . . . . 14

6.4 Master Matching Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4.1 Master matching . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4.2 Adjusting the detectors . . . . . . . . . . . . . . . . . . . . . 17

6.4.3 Clearing the master match. . . . . . . . . . . . . . . . . . . 19

6.5 Program Switching Mode. . . . . . . . . . . . . . . . . . . . . . . . . 20

-i-

Page 3

7 An explanation of input and output . . . . . . . . . . . . . . 21

7.1 Serial output (RS232C). . . . . . . . . . . . . . . . . . . . . . . . . . .21

7.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7.1.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7.1.3 Serial port settings . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.1.4 Composition of transmitted data . . . . . . . . . . . . . . .21

7.1.5 Method of data transmission to PCs. . . . . . . . . . . . 21

7.1.6 Requesting data from PCs . . . . . . . . . . . . . . . . . . . 22

7.1.7 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.2 Input from an external button . . . . . . . . . . . . . . . . . . . . . . 23

7.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.2.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.2.3 The port's pin layout . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2.4 Operation with external buttons . . . . . . . . . . . . . . .23

8 Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1 Main unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.2 Sold separately . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11 Breakdowns: Causes and Responses . . . . . . . . . . . 25

12 Points of Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

13 Structural diagrams of the main unit . . . . . . . . . . . . . 26

14 Operational floe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

15 Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

-ii-

Page 4

1 Overview

Our columnar electronic micrometer features color bars of three different colors, which makes

the display easy to see. The meter also features an automatic master matching function.

It can be used by itself or can easily be deployed in complex combinations with other

components. With the bar displays arrayed next to each other, the property of the object being

measured can be ascertained.

2 Features

(1) Displays measurement results clearly using a three-color color bar display.

(2) With an eight-digit display, it can display such information as measured values and setting

names.

(3) Master alignment for both large and small limits can be accomplished at the push of a

button.

(4) Because the instrument is only 50mm wide, it can be used in a series configuration.

(5) With the serial communications function (included standard), data can be output to a PC and

printer. The data can be saved and input into statistical and spreadsheet applications (such as

Microsoft Excel).

(6) In the Set-up Mode, all settings can be entered in order by pressing the ENT key.

(7) Up to 10 different sets of settings and master values can be saved and selected from.

3Operation

This instrument has the following four principal modes of operation:

(1) Measurement mode

• Measurement mode Measures

• Hold measurement Saves the measured values

However, if master matching was unsuccessful, the values are

not saved.

(2) Set-up Mode

• Set-up Mode Inputs or changes settings.

(3) Master matching mode

• Master matching Matches with a master.

This instrument conducts comparative measurements, so only

use it after having measured a master for comparison.

• Adjust detector (ADJ) This will adjust the detector.

• Clear master match This will clear master match data.

(4) Program switching mode

• Program switching mode Switches programs.

The instrument launches with the last program that was used

before it was last shut down.

-1-

Page 5

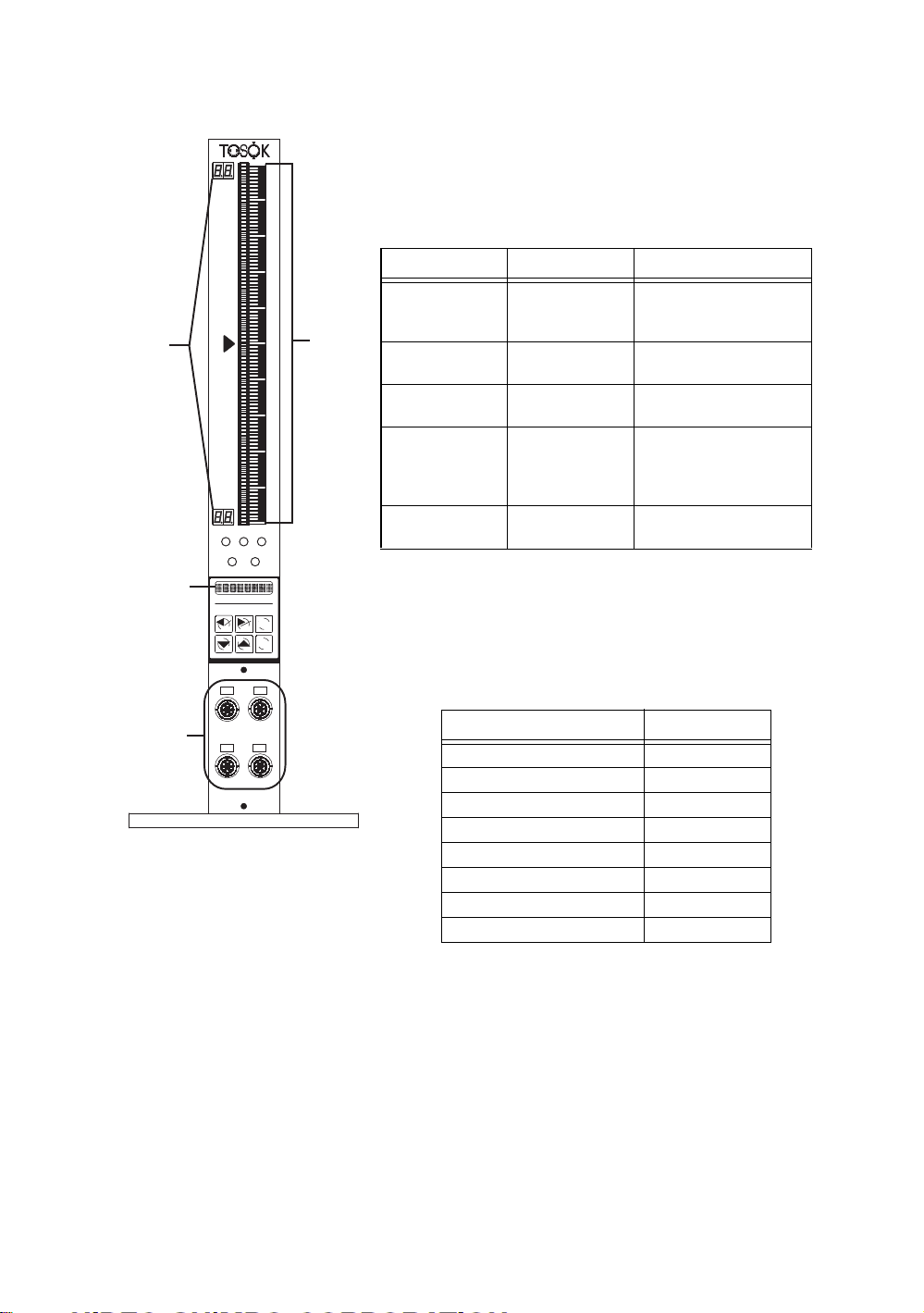

4 Names and functions of the parts

[1] Bar graph display

Displays a 101-dot, three-color bar graph.

Table 1: Bar color and information displayed in each

mode

Mode Bar color Information displayed

[2]

[3]

123

SET

MAS

RST

MAS

SET

ENT

[1]

Measurement Green (bright)

Hold

measurement

Setting Orange (bright)

Master matching Green (bright)

ADJ Orange (bright)

[2] Range display

The upper and lower measurements of the bar are given

with a two-digit display. The display is the same for

items 1-3 as shown in Table 2 below.

Red (bright)

Orange (dotted)

Green (dark)

Red (dark)

Green (dotted)

Red (bright)

Orange (dotted)

Green (dotted)

Value measured was OK.

Value measured not OK.

Upper or lower limit value.

Value measured was OK.

Value measured not OK.

Current setting value

Previous setting value

Master matching possible

Master matching not

possible

Master setting value

Value measured

Master setting value

[4]

C

A

D

B

Table 2: Range display

Measured range (microns) Digital display

52.5

10 5.0

20 10.

50 25.

100 50.

200 10

500 25

1000 50

[3] Display

A 7 × 5 dot character, eight-digit display can show

measured values, set values, setting names, and other

information.

[4] Measurement device ports

Measurement devices can be connected as follows: A

and B for two-channel type devices, and A-D for fourchannel type devices.

-2-

Page 6

123

MAS

SET

SET MAS

RST

ENT

[5]

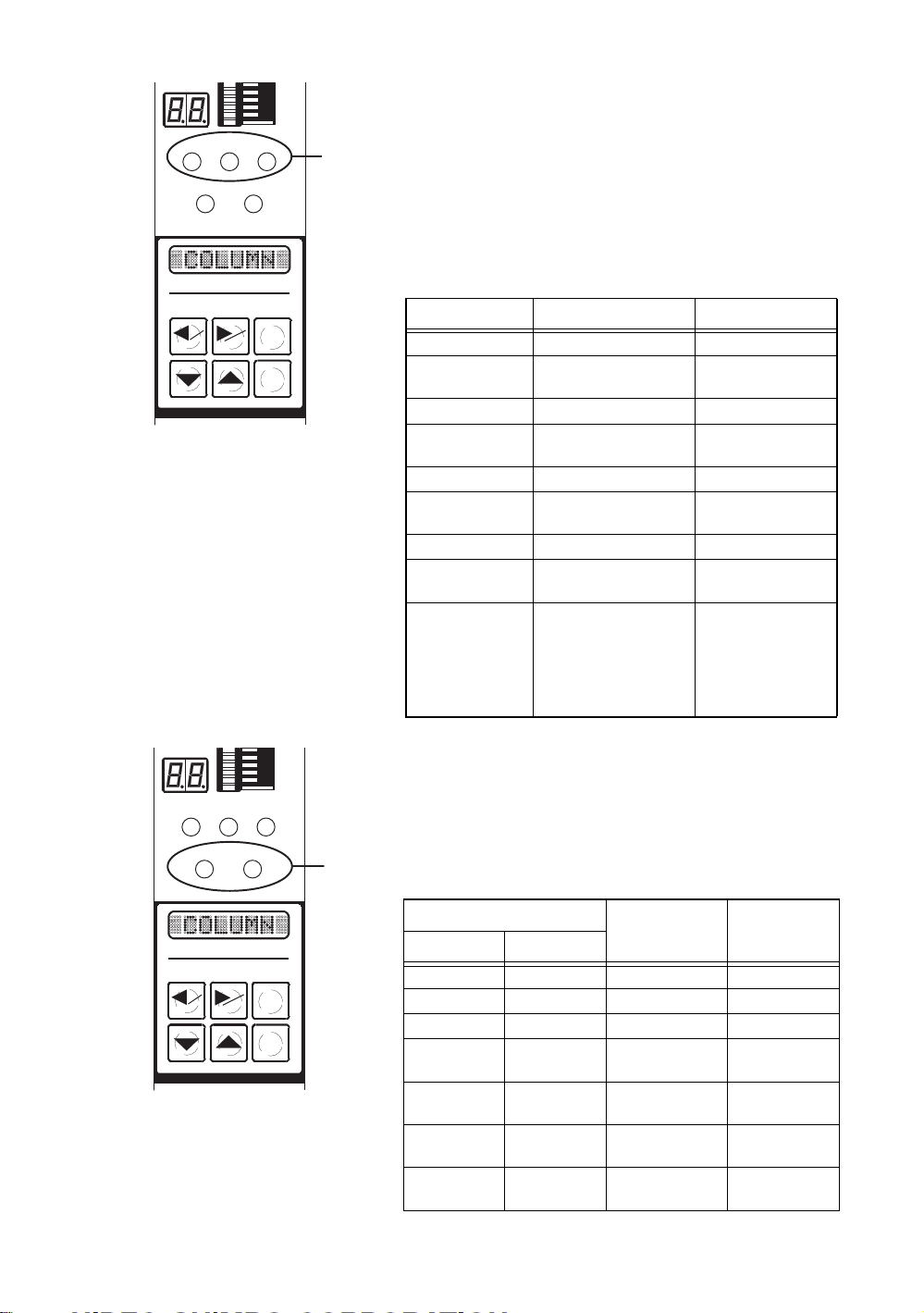

[5] Item/decision lamps

This shows information such as the decision made and

whether a measurement is currently being taken

(whether the bar is being displayed).

Each number, 1-3 shows the status for the corresponding

item (3 is for the calculated result).

Table 3 shows the relationship between lamp colors and

status.

Table 3: Lamp colors and status

Lamp color Status Mode

Green (bright) Decision: OK Measurement

Green

(bright and dark)

Green (dark) Decision: OK Hold measurement

Green (dark) and

black

Red (bright) Decision: NG Measurement

Red

(bright and dark)

Red (dark) Decision: NG Hold measurement

Red (dark) and

black

Orange (bright) Item-related settings

Decision: OK

(bar being displayed)

Decision: OK

(bar being displayed)

Decision: NG

(bar being displayed)

Decision: NG

(bar being displayed)

being input

Master matching

(Item 3 excluded)

Sensor being adjusted

(Item 3 excluded)

Measurement

Hold measurement

Measurement

Hold measurement

Setting

Master matching

ADJ

123

SET MAS

SET MAS

RST

ENT

[6]

[6] Mode lamps

These show the current mode and master matching

status.

Table 4 shows the relationship between lamp color,

mode and master matching status.

Table 4: Colors and status

Lamp name

SET MAS

Orange (bright) — Setting —

Green (bright) — Program switching —

— Orange (bright) Master matching —

Orange (bright) Red (bright) Setting Master matching

Green (bright) Red (bright) Program switching Master matching

— Orange (bright)

& Red (bright)

— Red (bright) Measurement

Mode

Master matching Master matching

Hold measurement

Master

matching status

unsuccessful

unsuccessful

unsuccessful

Master matching

unsuccessful

-3-

Page 7

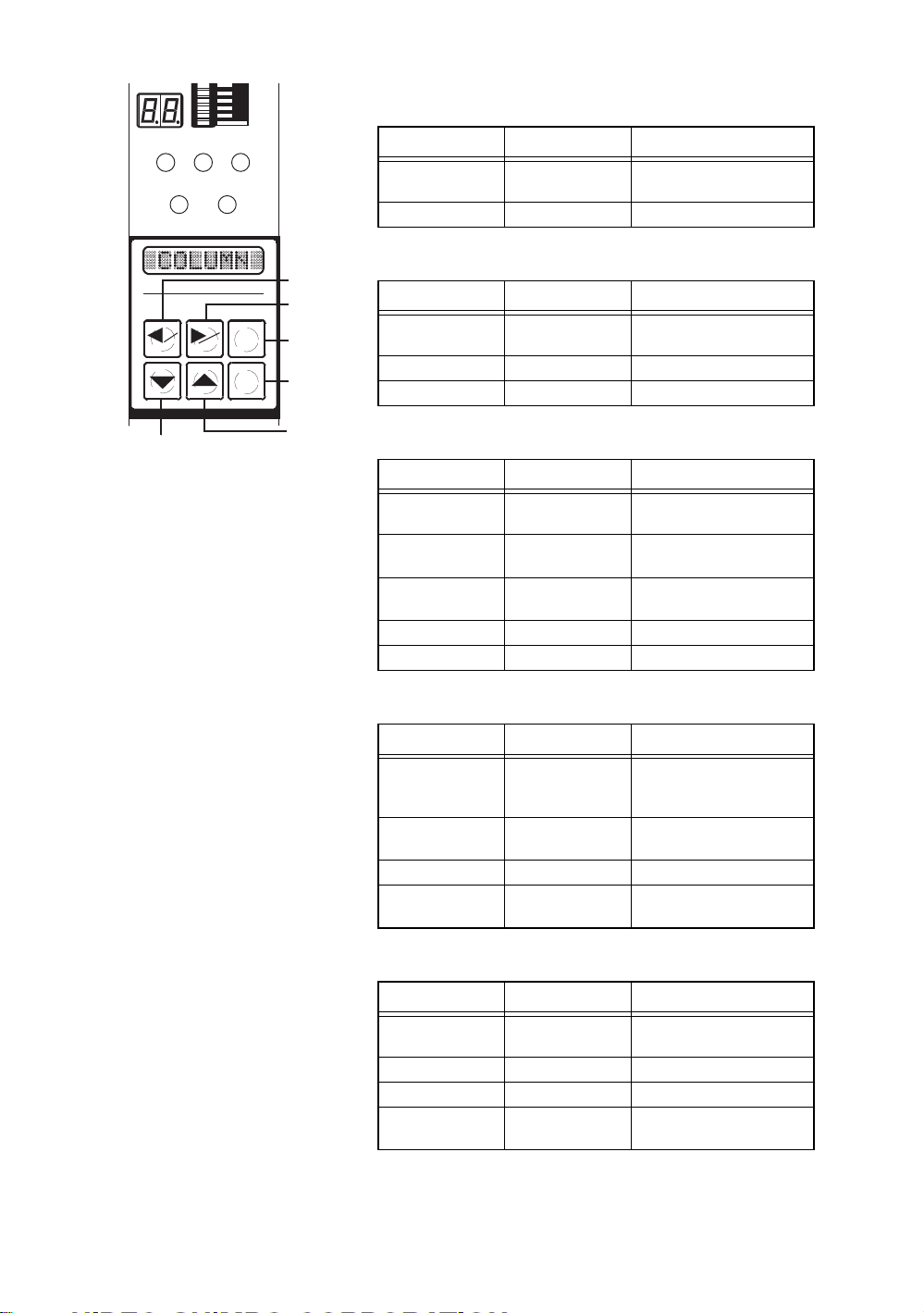

[7] Panel switches

(a) Left arrow key (SET key)

123

SET MAS

SET MAS

RST

ENT

(f)

(a)

(b)

(c)

(d)

(e)

Mode Key action Status

Measurement Hold down for two

seconds

Setting Press once Select setting parameter

Switches to master matching

(b) Right arrow key (MAS key)

Mode Key action Status

Measurement Hold down for two

seconds

Setting Press once Select setting parameter

Master matching Press once Switch displayed information

Switches to master matching

(c) Reset key

Mode Key action Status

Hold setting value Press once Switches to measurement

Setting (settings

being input)

Setting (item being

selected)

Master matching Press once Returns to previous display

ADJ Press once Returns to previous display

Press once Returns settings to their

Press once Cancel settings (Write/

mode

previous values

Cancel)

(d) ENTER key

Mode Key action Status

Measurement Press once Holds the measured values

Setting Press once Decide setting item and

Master matching Press once Read in master values

ADJ Press once Decide adjustment item and

(If master matching was

successful)

setting value

adjustment value

(e) Up arrow key

Mode Key action Status

Measurement Press once Switch which information is

Setting Press once Enter setting values

Master matching Press once Switch display masters

ADJ Press once Switch detector that is

displayed

displayed

-4-

Page 8

(f) Down arrow key

Mode Key action Status

Measurement Hold down for two

seconds

Measurement Press once Switch which information is

Setting Press once Enter setting values

Master matching Press once Switch display masters

ADJ Press once Switch detector that is

Switch to program switching

mode

displayed

displayed

[10]

Back

AC85 264V

FUSE

EXT I/O

RS232C

SW,ETC

ANALOG

[8] Input power connector/power switch

This turns on the AC power. Although the instrument

can be used within the 85-264V AC range, the included

power cable can only be used in the 85-125V AC range.

[8]

[9] Output power connector

When used in a series configuration, this connects to the

[9]

input power connector of the neighboring unit. It

connects to the input power connector internally.

3A

[10] Fuse holder

Glass tube fuses (5.2 × 20 3A) are used.

[11] DC input and output connectors (optional)

[11]

This is a connector for decision/ BCD output for

connection to lamps, sequences, etc.

[12] RS232C connectors

This is a serial connector for use in linking to PCs and

[12]

[13]

printers.

[13] Switch input connector

This connector enables measurement commands and

master commands to be given by means of an external

[14]

push button. This can also be used for RS422

communication and Digimatic output (optional).

[14] Analog input/output connector

This connector is for input of external analog signals and

output of amp output signals.

-5-

Page 9

5 Specifications

Item Specification Comments

Input Electrically, 2 (4) channels

Measurement item 3 (Calculation 1)

Calculation method 1–2, 1+2, 2–1, AVE (1–2), AVE (1+2), AVE (2–1) 1=ITEM 1 2=ITEM 2

Measurement range

(mm)

Resolution (mm) 0.00005 0.0001 0.0002 0.0005

Bar display 101-dot (red, green, orange, bright/dark)

Bar display type Bar (OK: Green, Not OK: Red), Dots (Max./Min.)

Scale display Two-digit (numbers), two locations

Multi-function display Eight-digit (Numbers/letters)

Shift range ±300% (Full scale)

Decision ± Not OK/OK

Display of decision Bar display (color), items, decision lamp, multi-

Automatic master

matching

Automatic master range Small: ±50% (full scale)

Program entry Push-button on panel

Number of set programs 10

Power voltage and

frequency

Power capacity 30VA

Dimensions/weight 50mm (width) × 480mm (height) ×

Operating temperature 0-45°C

Standard

External input buttons 4 (measurement, reset, large limit, small limit) Push-button, Foot SW

Serial output 1 (printer, PC) RS232C

Options

Printer output 1 (DP1) Digimatic

Decision output 8 (DC12/24V)

BCD output 1 set (DC12/24V)

Analog input 4 (connection to column)

Serial communication 1 RS422/RS485

0.00500 0.0100 0.0200 0.0500

0.100 0.200 0.500 1.00

0.001 0.002 0.005 0.01

Measured values, setting items, setting values,

error messages

function display

Small limit, large limit

Large: ±20% (full scale)

85-256V AC 50/60Hz Comes with 100V AC

200mm (depth), 4 kg

cable

-6-

Page 10

6Operation

6.1 Overview

• What to do when the detector has been connected and adjusted and the settings have

already been entered.

• What to do when the measurement head has been replaced

In this section, we will explain the procedures for the above two situations.

6.1.1 What to do when the detector has been connected and adjusted and

the settings have already been entered.

Please use the following procedure.

(1) Power on

Turn on the power switch in the rear of the unit (press the side marked with a circle)

to supply power (85-265V AC and 50/60Hz). The unit will start up in Measurement

Mode.

In Measurement Mode, hold down the right arrow (MAS) key for two seconds.

Holding the key down for an additional two seconds switches to Clear Master Match.

(2) Clearing the master matching data

Clear the master matching data as necessary. For details, refer to 6.4.3 “Clearing the

Master Match.”

(3) Master matching

Now match to a master. For details, refer to 6.4.1 “Master matching.”

(4) Measuring

In Measurement Mode, press the ENT key once, the unit will be set to Hold

Measurement Value. This can be cleared by pressing the RST key. However, if the

master match was unsuccessful, the measured value cannot be saved. For details,

please refer to 6.2 “Measuring.”

-7-

Page 11

6.1.2 What to do when the measurement head has been replaced

Please use the following procedure.

(1) Connection

Connect the detectors to the front of the column unit and the included power cord to

the back.

(2) Power on

Turn on the power switch in the rear of the unit (press the side marked with a circle)

to supply power (85-265V AC and 50/60Hz). The unit will start up in Measurement

Mode.

In Measurement Mode, hold down the left arrow (SET) key for two seconds, which

will switch to Set-up Mode.

(3) Inputting setting values

Please input the setting values. For details, please refer to 6.3 “Set-up mode.”

In Measurement Mode, hold down the right arrow (MAS) key for two seconds. After

that, pressing the key down once switches to Adjust Detector (ADJ).

(4) Adjust Detector

Please adjust the detector. For details, refer to 6.4.2 “Adjusting the detector.”

In “Adjust Detector” mode, holding down the ENT key for two seconds switches to

Master Matching.

(5) Master matching

Please match to a master. For details, refer to 6.4.1 “Master matching.”

(6) Measuring

In Measurement Mode, pushing the ENT key once switches to Hold Measured

Values. This can be cleared by pressing the RST key. However, if the master match

was unsuccessful, the measured values cannot be saved. For details, please refer to

6.2 “Measuring.”

-8-

Page 12

6.2 Measuring

123

SET MAS

6.2.1 Measurement mode

• Items currently being shown in the bar display are indicated by the blinking (light

and dark) of “Item/decision lamps 1, 2, and 3.” For details on the colors of the

lamps, refer to 4. [5] “Item/decision lamps.”

• The up and down arrow keys can be used to toggle between bar display items.

6.2.2 Hold measured value

• In Measurement Mode, pressing the ENT key will hold the measured value (will

enter a holding state). However, if master matching was unsuccessful, the

measurements will not be held.

• For the item shown in the bar display, the Item/decision lamps will blink (light and

blank). For details on the colors of the lamps, refer to 4.[5] “Item/decision lamps.”

• The up and down arrow keys can be used to toggle between bar display items.

• Pressing RST (reset) releases the hold.

SET MAS

RST

ENT

-9-

Page 13

6.3 Set-up mode

Set-up must be performed for each program used. After changing the program number,

please perform set-up.

6.3.1 Selecting the measurement range

1) In Set-up Mode, hold down the left arrow key for at least two seconds.

2) The orange “SET” LED will light up, “RANGE” will be displayed and the

system will be in Set-up Mode.

3) Push the ENT key once.

4) The current measurement range will be displayed.

5) Press the up and down arrow keys to select a measurement range (5, 10, 20, 50,

100, 200, 500, and 1000 microns).

6) After making a selection, press the ENT key.

7) After measurement range selection has been completed, next is the set-up of the

shift value. “SHIFT” will now be displayed.

6.3.2 Setting the shift value

For one-sided tolerances and such, the bar display will move to the center. Set this

function to 0 to make it inactive.

1) With “SHIFT” displayed, press the ENT key.

2) The current shift value will be diaplayed.

3) Use the up and down arrow keys to enter the new shift value.

4) After entering the shift value, press the ENT key.

5) After the shift value is set, next will come selection for mask matching. “MAS

SET” will be displayed.

6.3.3 Selection for mask matching

1) With “MAS SET” displayed, press the ENT key.

2) The current mask matching setting value will be displayed.

3) Use the up and down arrow keys to select either “ALL” or “EACH.”

4) When carrying out mask matching:

“ALL” . . . . . . Mask matching is performed all at once.

“EACH” . . . .Mask matches are performed one by one.

5) After selecting the mask match settings, press the ENT key.

6) After mask matching set-up is complete, next will come polarity selection for

each measuring unit. “XDUCER” will be displayed.

-10-

Page 14

6.3.4 Polarity selection for each measuring unit

1) With “XDUCER” displayed, press the ENT key, and perform the set-up of each

measuring unit.

2) Use the up and down arrow keys to toggle between measuring units A-D and

“FINISH” as shown on the display. Select the name of the measuring unit to

change the settings for and press the ENT key.

• Select a letter A-D . . . to change the settings for a particular measuring unit.

• Select “FINISH”. . . . . to quit the set-up process.

Go to selections in “6.3.5 Item selection.”

3) With “POL” displayed, press the ENT key. Set the polarities for each measuring

unit.

4) Use the up and down arrow keys to select “+” or “–”, and then press the ENT

key.

Internal diameter measurement

Direct Direct

Measuring methodSelection of POL

Using levers

5) Return to step 2) above.

6.3.5 Selection of items

1) With “ITEM” and the eight-digit display visible, press the ENT key. Then, enter

the settings for each item.

2) Use the up and down arrow keys to toggle between item numbers 1-3 and

“FINISH” as shown on the display. Select the name of the item to change the

settings for.

PG Type

External diameter measurement Height

OG Type

Using levers

measurement

+ ++

3) Select the name of the item to change the settings for and press the ENT key.

Select item 1 or 2 6.3.6 Input channel selection

Select item 3

Select finish 6.3.12 Save setting values

6.3.11 Selecting the calculation

method

-11-

Page 15

6.3.6 Input channel selection (In items 1 and 2)

1) With “INPUT” and the eight-digit display visible, press the ENT key. Next,

select an input channel.

2) The current input channel will be displayed. Use the up and down arrow keys to

select an input channel.

3) Select the input channel and press the ENT key.

None 6.3.5 Item selection

Other

6.3.7 Setting the decision upper

limit value

6.3.7 Setting the decision upper limit value (Set for all items)

1) With “MAX” displayed, press the ENT key.

2) “Current decision upper limit value” will be displayed.

3) Use the up and down arrow keys to input the new decision upper limit value.

4) After selecting the decision upper limit value, press the ENT key.

5) After decision upper limit value has been set, next will come selection of the

decision lower limit value. “MIN” will be displayed.

6.3.8 Setting the decision lower limit value (Set for all items)

1) With “MIN” displayed, press the ENT key.

2) The current decision lower limit value will be displayed.

3) Use the up and down arrow keys to input the new decision lower limit value.

4) After selecting the decision lower limit value, press the ENT key.

Item being set in

items 1 and 2

6.3.9 Setting the large master value

Item being set in

item 3

6.3.5 Item selection

2) To state in which FINISH is

selected.

-12-

Page 16

6.3.9 Setting the large master value (Set in items 1 and 2)

1) With “MAX M.” displayed, press the ENT key.

2) The current large master value will be displayed.

3) Use the up and down arrow keys to input the new large master value.

4) After inputting the large master limit, press the ENT key.

5) The eight-digit display will be shown.

MIN M.

ERR MAS

6.3.10 Setting the small master

value

The value will return to what it was

before it was changed and the

display will be as in 2) above.

An error will be displayed if the

large master value is equal to or

less than the small master value.

6.3.10 Setting the small master value (Set in items 1 and 2)

1) With “MIN M.” displayed, press the ENT key.

2) The current small master value will be displayed.

3) Use the up and down arrow keys to input the new small master value.

4) After inputting the small master limit, press the ENT key.

5) The eight-digit display will be shown.

Item 1, Item 2

Item 3, Item 4

Switches to the same state as in

2) in 6.3.5 Item Selection

ERR MAS

The value will return to what it was

before it was changed and the

display will be as in 2) above.

An error will be displayed if the

small master value is equal to or

greater than the small master value.

-13-

Page 17

6.3.11 Selecting the calculation method (in Item 3 only)

1) With “CALC” displayed, press the ENT key.

2)

The current calculation expression will be displayed.

! NOTE In the calculation method display, “1” shows Item 1 and “2” shows

Item 2.

3) Use the up and down arrow keys to either select a calculation method, or select

“Use none.”

4) After selecting the calculation method, press the ENT key.

5) The eight-digit display will be shown.

FINISH

MAX

Switches to the same state as in

B in 6.3.5 Item Selection

Switches to 6.3.7 Setting the

decision upper limit value

6.3.12 Saving setting values (Saving the previous items 6.3.1-11)

If you quit while still inputting settings, “END” can be displayed by pressing both

reset and the left and right arrow keys.

1) With “END” displayed, press the ENT key.

2) “WRITE” will be displayed.

3) Use the up and down arrow keys to either select either “WRITE” or

“CANCEL.”

4) After making this selection, press the ENT key.

5) Quit Set-up Mode and return to Measurement Mode.

Selection items in

WRITE

Selection items in

CANCEL

Save the new settings.

Erase the new settings and revert

to the previous settings.

-14-

Page 18

6.4 Master Matching Mode

6.4.1 Master matching

23

1

SET MAS

SET

MAS

23

1

SET MAS

SET

MAS

RST

ENT

RST

ENT

1)

4)

2)

5)

1) In Set-up Mode, hold down the right arrow (MAS)

key for at least two seconds.

2) The “MAS” LED (orange) will light up and “MIN

M.” will be displayed, switching to “Master

Matching.”

3) When “ALL” is selected under “Master Match

Selection (MAS SET)” in Setting Mode, master

matching will be done all at once. If “EACH” is

selected, master matching will be performed one at

a time.

4) When master matching is performed one at a time,

master matching is performed for the item currently

shown in the bar display. Use the up and down

arrow keys to toggle between the items that master

matching will be performed on. The Item/Decision

Lamps show which item is currently shown in the

bar display.

When “1” is lit, it means that Item 1 is displayed.

When “2” is lit, it means that Item 2 is displayed.

5) Set the small master to a detector, and when the bar

display stabilizes, press the ENT key.

-15-

Page 19

1

23

6) Small master matching will be performed, and

“MAX M.” will be displayed.

SET MAS

SET

MAS

RST

ENT

6)

7)

7) Set the large master to a detector, and when the bar

display stabilizes, press the ENT key.

8) Large master matching will be performed.

If there are no errors....... To 9)

If there is an error........... To 10)

9) “MAS OK” will be shown in the eight-digit display

for two seconds, after which Master Matching will

be concluded and the unit will return to

Measurement Mode.

10) The following error messages may appear in the

eight-digit display.

“ERR ZERO”. . . A “zero” error (outside the

master matching range)

“ERR MAG” . . . A “sensitivity” error (outside the

master matching range)

“ERR REV” . . . . A MAX/MIN reversal

“ERR OFFR” . . . Out of measurable range

Press the ENT key to return to B above.

If the detector requires adjustment, press the right

arrow key and proceed to adjust the detector.

11) If master matching is being performed one at a

time, and master matching is OK for both items, the

unit will switch to a new master matching channel

and return to B above.

12) If the RST key is pressed during master matching,

the unit will return to its previous state. If “MIN

M.” was displayed, it will return to Measurement

Mode.

-16-

Page 20

6.4.2 Adjusting the detectors

No adjustment is required except after the measurement head is replaced.

1) ZERO ADJ (zero adjustment)

In the following procedure, the small master is used to match the small master

value and the bar display position.

(a) In Measurement Mode, hold down the right arrow (MAS) key for at least

two seconds.

(b) The “MAS” LED (orange) will light up, “MIN M.” will be displayed, and

the unit will switch to Master Matching Mode.

(c) Press the right arrow button.

(d) The unit will switch to Detector Adjustment Mode and “ADJ” will be

displayed.

(e) Use the up and down arrow keys to switch to the item to be adjusted (Item

1 or 2). The item currently shown in the bar display is indicated on the

Item/Decision Lamps. In addition, the Detector Name for the measuring

unit the item is using for measurement is shown in the eight-digit display.

(f) Press the ENT key.

(g) “ZERO ADJ” will be displayed.

(h) Press the ENT key.

(i) The name of the measurement unit that the item selected in (e) uses, as well

as its current ZERO ADJ setting will be displayed.

(j) If the ZERO ADJ setting is not displayed, it is because the item selected in

E has data for two measurement units. Use the left and right arrow keys to

toggle between the ZERO ADJ settings for the two units.

(k) Set to small master and use the up and down arrow keys to adjust each

measurement units ZERO ADJ setting so that the item’s data approaches

the small master setting.

(l) After setting is compete, press the ENT key.

(m) “GAIN ADJ” will be shown in the eight-digit display. Proceed to set the

GAIN ADJ setting.

-17-

Page 21

2) GAIN ADJ (sensitivity adjustment)

In the following procedure, both small and large masters are used to match the

small and large master values with the bar display range.

(a) With “GAIN ADJ” displayed, press the ENT key once.

(b) The measuring unit that the item selected in 6.4.2 1) (e) uses, as well as the

current GAIN ADJ setting value, will be shown in the eight-digit display.

(c) If the GAIN ADJ setting value is not shown, it means that the item selected

in 6.4.2 1) (e) has data for two measuring units. Use the right and left arrow

keys to toggle between the data for these two measuring units.

(d) Alternately set the small master and the large master, and use the up and

down arrow keys to adjust each item's measurement unit GAIN ADJ

setting so that it approaches the small master setting and the large master

setting.

(e) After these settings are complete, press the ENT key.

(f) “MAG ADJ” will be displayed. That concludes the GAIN ADJ setting

input procedure.

(g) Proceed to input settings for MAG ADJ.

3) MAG ADJ (fine sensitivity adjustment)

The following procedure is used to set the coefficient for each item when one

item has two measuring units. This should be set to 1,000 for most purposes.

(a) With “MAG ADJ” displayed, press the ENT key once.

(b) The name of the measuring unit that the item selected in 6.4.2 1) (e) uses

will be shown in the eight-digit display, along with its current MAG ADJ

setting.

(c) If the MAG ADJ setting is not displayed, it is because the item selected in

6.4.2 1) (e) has data for two measuring units. Use the left and right arrow

keys toggle between the data for each one.

(d) Use the up and down arrow keys set the GAIN ADJ for each measuring

unit.

(e) After these settings are complete, press ENT.

(f) “MIN M.” will be displayed and the unit will switch to 6.4.1 “Master

Matching.” This concludes the MAG ADJ setting procedure.

-18-

Page 22

6.4.3 Clearing the master match

23

1

SET MAS

SET

MAS

2

1

SET MAS

SET

MAS

RST

ENT

3

RST

ENT

1)

2)

3)

1) In Measuring Mode, hold down the right arrow

(MAS) key for at least two seconds.

2) The “MAS” LED (orange) will light up, “MIN M.”

will be displayed, and the unit will switch to Master

Matching Mode.

3) Press the right arrow key once.

23

1

SET MAS

SET

MAS

23

1

SET MAS

SET

MAS

RST

ENT

RST

ENT

4)

5)

6)

7)

4) This will switch to Detector Adjustment, and

“ADJ” will be displayed.

5) Press the right arrow key once.

6) This will switch to Clear Master Match, and

“MAST CLS” will be displayed.

7) Pressing the ENT key will clear all master matching

data, “M.CLS OK” will be displayed and the unit

will return to 6.4.1 “Master Matching.”

-19-

Page 23

6.5 Program Switching Mode

23

1

SET MAS

SET

MAS

1)

2

1

SET MAS

SET

MAS

RST

ENT

3

RST

ENT

2)

3)

(1) In Measurement Mode, hold down the down arrow

key for at least two seconds.

(2) The “SET” LED (green) will light up, “PROG” will

be displayed, and the unit will enter Program

Switching Mode.

(3) Press the ENT key.

23

1

SET MAS

SET

MAS

5)

RST

ENT

4)

6)

(4) The program that is currently in use is indicated by

a number 0-9.

(5) Using the up and down arrow keys, select the

number of the program number to be used.

(6) After making a selection, press the ENT key.

(7) This will quit Program Switching Mode and return

to Measurement Mode.

(8) After a new program number has been selected, it

may be necessary to perform master matching. If a

measuring device has been replaced, it may be

necessary to adjust the detector.

(9) In order to perform set-up, first switch to the new

program number and then enter Set-up Mode.

(10) When power is turned on, the most recently

selected program is launched.

-20-

Page 24

7 An explanation of input and output

7.1 Serial output (RS232C)

7.1.1 Overview

Through the RS232C, this unit is capable of outputting measured values to a printer

or sending the data to a PC. The following information can be sent to a PC:

(1) Measurement items Items 1-3

(2) Measured values The data shown in the unit's eight-digit display, Use None

(3) Decision +Not OK, OK, –Not OK, NJG (only with “Use None”)

7.1.2 Preparation

This units RS232C port enables it to output data. Please connect the optional Dsub9C (male) communications cable to this unit’s RS232C port. Three different

optional communications cables are available for different applications. For details,

please refer to 9. “Options.”

7.1.3 Serial port settings

Baud rate 9,600

Bits/text 8

Stop bit 1

Start bit 1

Parity bit None

7.1.4 Composition of transmitted data

Item 1 (five digits), space (one digit), measured value (eight digits), space (one digit),

decision (three digits), space (one digit).

Item 2 (five digits), space (one digit), measured value (eight digits), space (one digit),

decision (three digits), space (one digit).

Item 3 (five digits), space (one digit), measured value (eight digits), space (one digit),

decision (three digits), CR, LF.

ITEM1

ITEM2

ITEM3 CRLF

7.1.5 Method of data transmission to PCs

In Measurement Mode, press the ENT key. This will switch to the Hold Measured

Value Mode described in 6.2.2, and will transmit the measured value. If the master

match was unsuccessful data will not be transmitted.

Measured value

Measured value

Measured value

Decision

Decision

Decision

-21-

Page 25

7.1.6 Requesting data from PCs

(1) Latch (data hold) command for the measured value

Send command byte “E” (45H). This micrometer will hold the measured value.

(2) Latch release command

Send command byte “R” (52H). This micrometer will release its hold on the

measured value.

(3) Request for measured value

Send command byte “D” (44H). This micrometer will send the data in 4 above

to the PC.

7.1.7 Examples

Text

ASCII cord

ITEM1

ITEM2

ITEM3 CRLF

49

54 45 4D 31

49 54 45 4D 32

49 54 45 4D 33 0D

N

202020

0.52

5.21

ESUO

G47N

K47O

G47J4AN

20

4E2D20302E35322D20

20

4F2020352E32312020202020

4E20455355204F4E202020

0A

-22-

Page 26

7.2 Input from an external button

7.2.1 Overview

With this unit, the following can be done from external buttons.

(1) Measuring

(2) Resetting

(3) Large master matching

(4) Small master matching

7.2.2 Preparation

SW, ETC port on the back of the unit is the port for external buttons. The D-sub 15P

(male) cable can be connected to this unit’s SW, ETC port.

7.2.3 The port’s pin layout

Description

GND

Measure button

Reset button

No.

1

2

3

4

5

6

7

8

The pin layout of the SW, ETC port on the back of this unit.

7.2.4 Operation with external buttons

(1) Measure button

(a) In Measurement Mode, press the Measure button.

(b) This will hold the measured value..

! NOTE If master matching was unsuccessful, this data cannot be held.

(2) Reset button

This releases the hold.

(3) Large Master Matching button

(a) In large master matching waiting status, set the large master to the detector.

(b) After the bar display stabilizes, press the Large Master Matching button.

(c) The unit will carry out large master matching and return to Measurement

Mode.

(d) If there is a master matching error (see 6.4.1 10)), please cope with it using

this unit’s panel switches.

(4) Small Master Matching button

(a) In Measurement Mode, set the small master to the detector.

(b) After the bar display stabilizes, press the Small Master Matching button.

(c) The unit will carry out small master matching and return to large master

matching status.

No.

Large master button

9

Small master button

10

11

12

13

14

15

Description

! NOTE In Set-up Mode, please choose ALL from the Selection for mask

matching (refer to 6.3.3).

-23-

Page 27

8 Models

CEG 20 00 -2 -DP

9 Options

9.1 Main unit

(1) Digimatic output Printer (DP1), etc.

(2) Decision output 24V DC

(3) BCD output 24V DC

9.2 Sold separately

(1) Communications cable (CAG2000-OP-CB-1)

(2) Communications cable (CAG2000-OP-CB-2)

(3) Communications cable (CAG2000-OP-CB-3)

External input

and output

Input

Model number

Basic model

number

D-sub 9-pin port for PCs (EIA-232))

D-sub 25-pin port for PCs (EIA-574))

D-sub 25-pin port for PCs (EIA-574))

None: Standard

DP: Digimatic output

DC: Decision output

BC: BCD output

2: Two-channel

4: Four-channel

20

CEG

10 Maintenance

(1) Use alcohol to clean dirt off of the main unit.

The use of thinner causes color loss and dullness.

-24-

Page 28

11 Breakdowns: Causes and Responses

Symptom

Repeat precision is

unstable

The bar graph

display does not

move

The bar graph and

digital display are

blinking.

Location of breakdown or

maladjustment

Movement of the part that secures the

measuring unit

1) The proper amount of power is not

being supplied.

2) The detector is maladjusted.

3) The unit is in Hold Measurement

Mode (the bar graph is green or dark

red).

4) The unit is in Set-up Mode (orange).

1) Power is not being supplied.

2) A fuse has blown.

3) The power supply or an internal

circuit has failed.

12 Points of Caution

(1) Electrical wiring

The power cable included standard with this unit is 100V. To use the unit with voltage that

exceeds 125V, please use the 250V power cable.

(2) Do not use a hard tool, something sharp, to press the operation keys.

(3) About exporting these units

Export of this product may fall under the Export Control Directive, and may therefor require

the permission of the Ministry of Trade and Industry. Please discuss this with a

representative at our nearest sales office.

(4) Other

This product’s specifications may be changed without prior notice.

Response

Tighten the loose part.

1) Supply power in the 85-264V range.

2) Adjust the detector.

3) Release using the RST (reset) key.

4) Quit Set-up Mode.

1) Supply power in the 85-264V range.

2) Replace the fuse (3A).

3) Request service from the

manufacturer.

-25-

Page 29

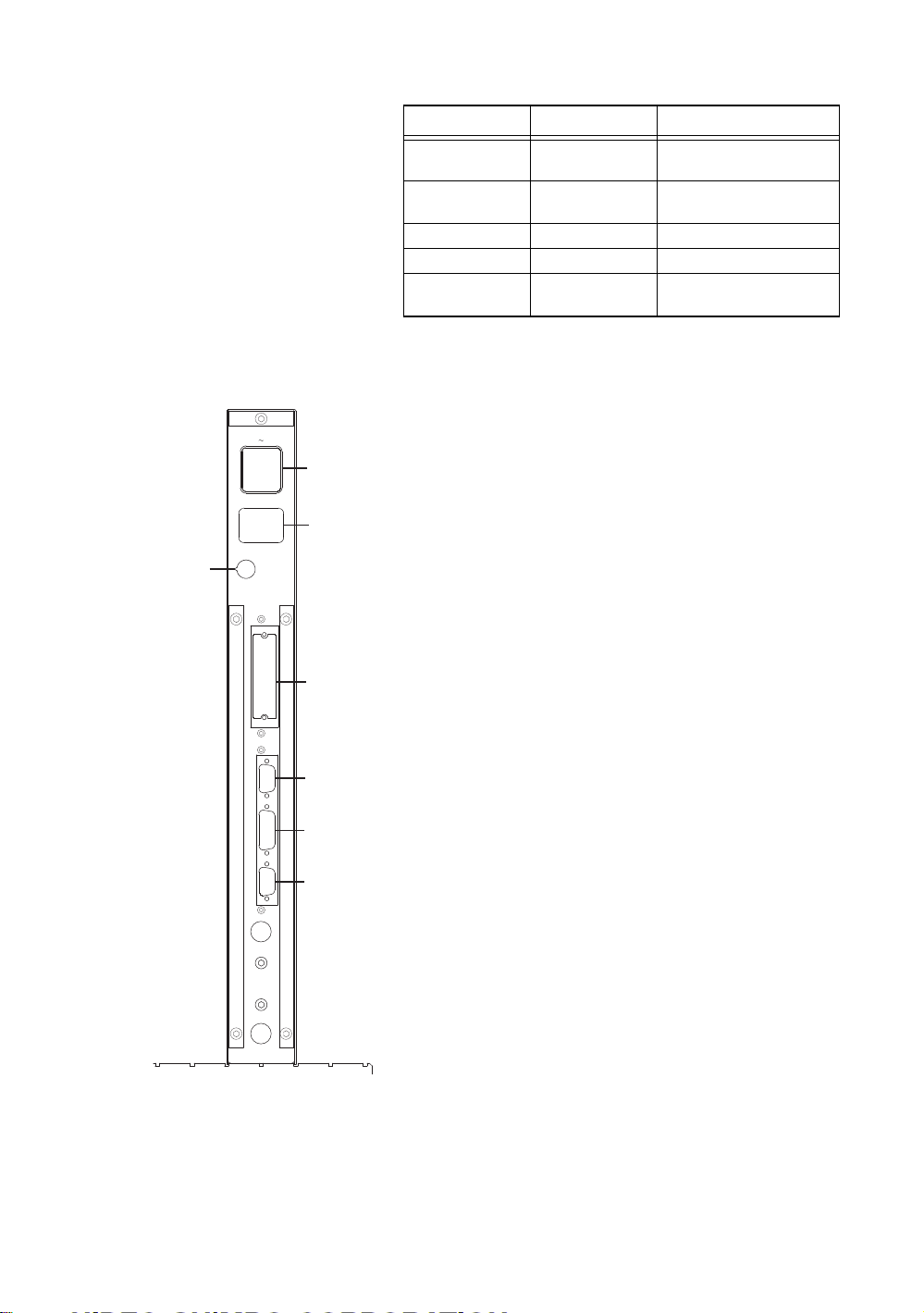

13 Structural diagrams of the main unit

Structural diagram of the (two-channel) Columnar Electronic Gage

! NOTE An asterisk indicates an option.

Front Back

LED digital range

display (two)

AC85~264V

Power switch

Power port (input)

Power port (output)

LED bar graph

display

Item/Decision lamp

(three)

Mode lamp (two)

Display

Panel switches (six)

Fuse holder

FUSE

3A

DC output port *

EXT I/O

RS232C port

1

32

SET

MAS

RST

MAS

SET

ENT

RS232CSW. EJCANALOG

Switch input port

Analog input and

output port

Detector port

[A]

[B]

-26-

Page 30

Structural diagram of the (four-channel) Columnar Electronic Gage

! NOTE An asterisk indicates an option.

Front Back

LED digital range

display (two)

AC85~264V

Power switch

Power port (input)

Power port (output)

LED bar graph

display

Item/Decision lamp

(three)

Mode lamp (two)

Display

Panel switches (six)

12

MAS

SET

MAS

SET

RST

ENT

Fuse holder

FUSE

3A

DC output port *

EXT I/ORS232CSW. ETCANALOG

RS232C port

3

Switch input port

Analog input and

output port

Detector port

[A] [C]

[B] [D]

-27-

Page 31

Clear master data

M. CLS OK

MAST CLS

See Master Matching Mode (Ref. 2).

R

(eight-digit and bar displays)

Raw data display

Detector Adjustment Master Data Clear

28

RUN

OK

MAS1 OK?

Error present

E

E

Error present

E

E E

detected

Error

M A X M.

R

M I N M.

R

RUN

OK

MAS2 OK?

detected

Error

M A X M.

R

MIN M. ADJ.

R

NO

MAS OK display

Error absent

to MAS1.

3.

3. Use the and keys to switch

MAS 2

NO

MAS OK display

Error absent

to MAS2.

*2 *2

2.

2. Use the and keys to switch

MAS 1

E

Error display

R

E

Error display

R

Error display

Error present

E

E

RUN

detected

Error

MAS OK display

Error absent

M A X M.

1.

R

*1 *1

M I N M.

1.

R

ALL

EACH

MAS SET

through the items in the display.

1. Use the and keys to toggle

See Master Matching Mode (Ref. 1).

becomes invalid.

changed, the master matching data

When the program number is

Select ten items.

RUN

E

0

9

R E

PROG

Switch programs

Clear master data

M. CLS OK

E

MAST CLS

See Master Matching Mode (Ref. 2).

R

R

ADJ.

(eight-digit and bar displays)

Raw data display

Detector Adjustment Master Data Clear

Error items are shown on the lamp display.

E

Set-up Mode

seconds.

cannot be held.

unsuccessful, the measured value

When master matching is

ITEM 1

ITEM 2

ITEM 3

Toggle displayed item

R

Hold measured value

E

for two seconds.

Press and hold key

ITEM 1

ITEM 2

ITEM 3

RUN

for two

hold key

Press and

Toggle displayed item

Measurement Mode

for two seconds.

Press and hold key

Standard software (for Electronic Micrometer) Ver2.11

14 Operational flow

Page 32

Standard software (for Electronic Micrometer) Ver2.11

Master Matching Mode (Ref. 2)

ADJ.

[A]

[B]

[C]

[D]

[A+B]

[C+D]

E

R

*2

ZERO ADJ

E

R

127

*1 *1 *1

-128

E

GAIN ADJ

R

[A] [D]

R

MAG ADJ

E

255

0

E

R

[A] [D][A] [D]

MIN M.

R

E

1. 300

0. 700

E

Note

* 1) Use the left and right arrow keys to select the measuring device to change the settings for,

and use the up and down arrow keys to change the settings.

*2

-29-

Page 33

Standard software (for Electronic Micrometer) Ver2.11

E

CANCEL

WRITE

Setup Mode (Ref. 1)

R

R

R

R

E

END

R R

E

ITEM

E

XDUCER

R

E

MAS SET

R

CANCEL

WRITE

OPTION

of options.

Used with purchase

[A]

[D]

FINISH

ALL

EACH

E

[A]

E

E

RUN

[B]

[C]

Select 2 item. Select 2 item. Select 2 item.

[D]

Setup Mode (Ref. 2)

R

E

POL

R

E

Select 2 item.

FINISH

Set-up is required for each program that is to be

used. After changing the program number,

please go through the set-up procedure.

Press and hold key for two seconds.

R R

RANGE SHIFT

Measurement Mode

*1 *1

E

R

E

1000

R

+ 0.0

500

200

100

E

502010

Driver set-up

5

E

Select 8 item.

-30-

Page 34

Standard software (for Electronic Micrometer) Ver2.11

Setup Mode (Ref. 2)

ITEM

E

R

FINISH

ITEM 3

ITEM 2

ITEM 1

E

ITEM 1

ITEM 2

ITEM 3

*1 *1

Select 7 item.

* In the drive bar settings, use the up and down arrow keys to adjust the selected RANGE 1/100th at a time.

*2 *2

Select 9 item.

R R

INPUT

E

R

NO USE

A

B

A + B

C

D

C + D

E

Select Other.

Select Use none.

R

CALC

E

R

NO USE

ITEM 1

ITEM 2

1 - 2

1 + 2

2 - 1

AVE(1 - 2)

+

2)

AVE(1

AVE(2 -

1)

E

Select Use none.

Select Other.

MAX

E

R

+ 12. 5

E

Driver set-up

Driver set-up Driver set-up

Driver set-up Driver set-up Driver set-up

R

MAX

E

R

+ 12. 5

E

R

R

MIN

- 12. 5

R

MAX M.

E

E

R

MIN

E

R

- 12. 5

E

R

E

+ 12. 5

E

OPTION ON

YES

OPTION

R

MIN M.

R

- 12. 5

NO

END

E

E

FINISH

Note

* 3) In the drive bar settings, use the up and down arrow keys to adjust the selected RANGE 1/100th at a time.

-31-

Page 35

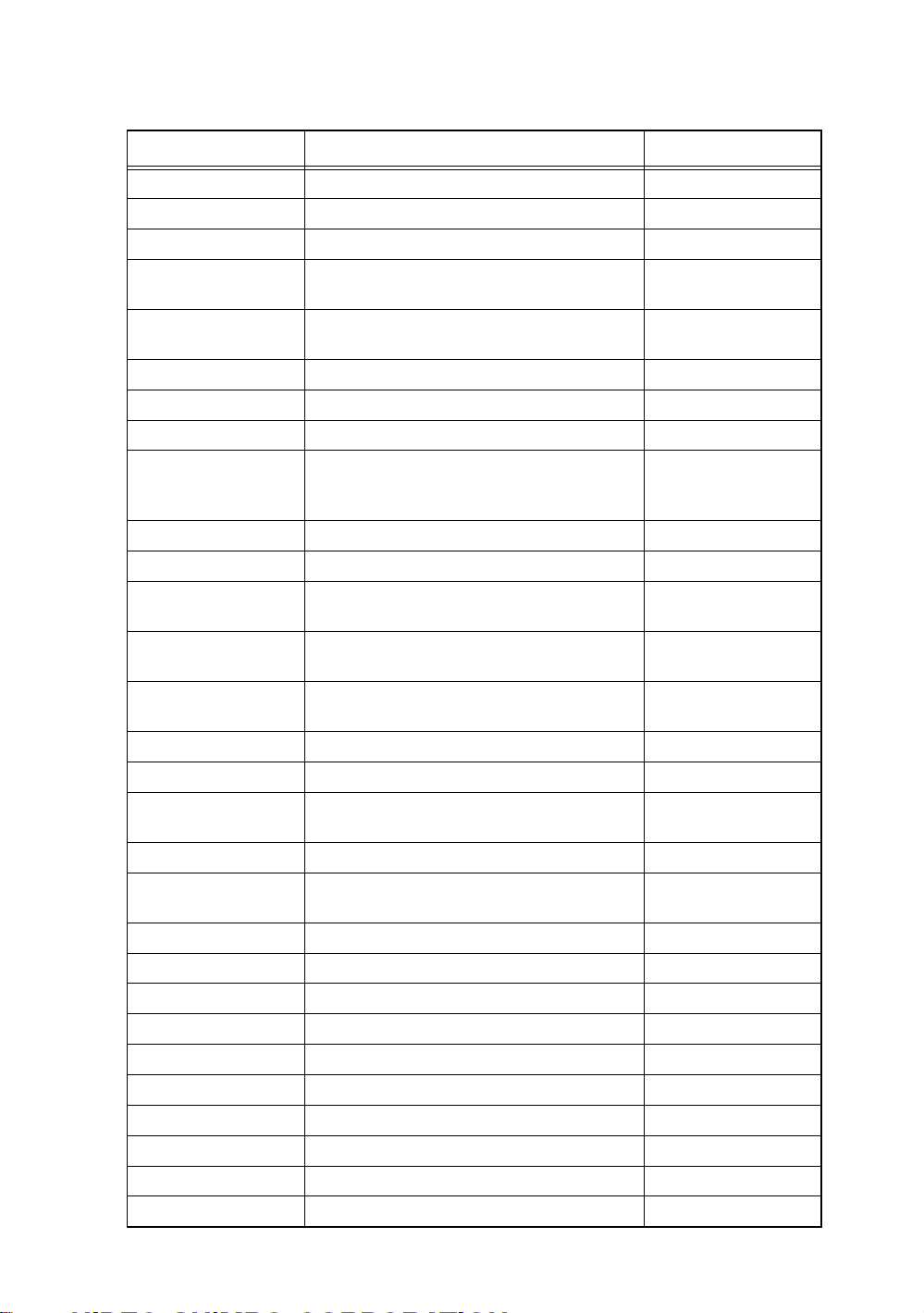

15 Worksheet

Standard software worksheet for the electronic gage

Program No.: PROG

Setting item

Range RANGE

Shift value SHIFT

Master matching method MAS SET

A/D polarity POL

DA ZERO ZERO ADJ

DA GAIN GAIN ADJ

A/D coefficient MAG ADJ

A/D polarity POL

DA ZERO ZERO ADJ

DA GAIN GAIN ADJ

A/D coefficient MAG ADJ

A/D polarity POL

DA ZERO ZERO ADJ

DA GAIN GAIN ADJ

A/D coefficient MAG ADJ

A/D polarity POL

DA ZERO ZERO ADJ

DA GAIN GAIN ADJ

A/D coefficient MAG ADJ

XDUCER being used INPUT

Upper limit value MAX

Lower limit value MIN

Large mask setting value MAX M.

Small mask setting value MIN M.

XDUCER being used INPUT

Upper limit value MAX

Lower limit value MIN

Large mask setting value MAX M.

Small mask setting value MIN M.

Calculation method CALC

Upper limit value MAX

Lower limit value MIN

Input channel: XDUCER

Items

Ch. A

Ch. B

Ch. C

Ch. D

Item 1

Item 2

Item 3

0123456789

-32-

Page 36

Loading...

Loading...