Page 1

● Please follow all 『Safety Precautions』

to avoid fire、 electric shock and other

related injuries.

● After reading the manual, please ensure

to store it in an accessible area.

● In case the unit is used by other persons,

give the unit together with this manual.

● This device is manufactured under Japan

laws so it is for domestic use only.

In case this device is used overseas,

please observe the safety laws implemented

by the country.

● Warranty coverage shall be based on

TOSOK's warranty policies.

・ Even if the device is under warranty ,

if the cause of the breakdown is due to

the negligence of the user, the repair

cost shall be charged to the customer.

・ In case the device becomes defective

due to modifications made by customer,

there shall be cases that TOSOK

can refuse to accept the repair.

・ The repair is based upon receipt of the

defective unit. Even if the device is

under warranty, in case the repair will

need on site visit, the cost of the trip

shall be charged to the customer.

. Safety Precautions ..

. Overview ..

・ Specifications ..

・ Model ..

・ Standard Accessories ..

. Names and Functions of ..

Controls and Parts

. Installation ..

. Power “ON”/“OFF” ..

. Operating Procedure ..

. Setting Procedure ..

・ Program Change ..

・ Setting values ..

. Adjustment ..

・ Standard Pressure ..

Thank you for your purchase of the ・ ZERO/MAG ..

CAG3000 ・ Calibration ..

. RS232C Output ..

. External Switch Input ..

●

In order to use this product safely and correctly,

. Appendix ..

please read through the manual thoroughly and ・ Setting Procedure ..

understand it very well. Summary

● After reading the manual, please have it readily

available for future use.

Please read before using the device

Column Type Air Micrometer

CAG3000

Instruction Manual

Table of Contents

1

2

2

3

3

4

4

3

5

4

7

5

7

6

8

7

10

10

10

8

13

13

14

15

9

16

10

17

11

18

18

98301A

1

Page 2

7 . Do not use damaged cables or plugs.

Damaged cables or plugs are possible

Before using this device, make sure you

causes of fire and electric shock.

read the safety precautions thoroughly.

8 . Power cable must be checked periodically.

Please comply with the directions and use Do not use damaged cables anymore.

the device properly. Damaged cables are possible causes

of fire and electric shock.

9 . Check extension cord periodically.

Do not use if it is damaged already.

Important notice for usage : Damaged extension cords are possible

causes of fire and electric shock..

! Warning

! Caution

10 . Before plugging in the power line to

the power source, check if the 「Power SW」

is classified by the above symbols. is turned "OFF". If the 「Power SW」 is

turned "ON" before plugging, it can cause

! Warning ● May cause death or severe injuries electric shock.

if used improperly. 11 . When unplugging the power cable, do not

pull the cable out from the power source.

! Caution ● May cause severe injuries Pulling the cable from the power source

if used improperly. can damage it and cause fire and electric

shock.

●

May result to damage to the device

12 . When power cables are placed near places

if used improperly. that are heated, oily or cornered, do not

let it be damaged. If the power cable is

damaged, it can cause fire and electric

For those items marked with ! Caution

shock.

depending on the conditions, it can still 13 . Clean dirt on power cable periodically.

result in serious siutations. All safety If the dirt piles up, it can cause fire.

related important details are written here 14 . During maintenance/repair of the device,

so please follow them by all means. disconnect the power cable.

If the power cable is left plugged in

! Warning

during maintenance, it can cause

1 . Do not modify or disassemble the device. electric shock.

Modification or disassembly of the device 15 . In case the device will not be used for

by unqualified personnel can cause

long period of time, unplug the power

malfunction and possible fire, electric cable from the source. Deterioration

shock and injuries. can cause fire and electric shock.

2 . Do not let an unqualified personnel 16 . Do not use the device in humid places

repair the device. Repair by an or wet environment.

unqualified personnel can cause

This can lead to electrical failure and

malfunction and possible fire, electric can cause fire and electric shock.

shock and injuries. 17 . Do not use the device in unstable places.

3 . Please supply the correct power rating The device can become defective if it is

as stated in the instruction manual. turned over, dropped with great impact.

Any power supply that is out of spec In case the device is turned over or

can cause fire and electric shock. dropped, please contact our company.

The main unit operates on 5 to 7 VDC. 18 . Do not put objects inside the device.

The device is provided with AC adaptor

Any objects like conductive materials

(standard accessory)that runs at 85~264VAC. inserted on the main body's small

4 . During air connection, installation openings can cause the unit to fail.

or movement of the device, please remove 19 .

Do not use benzene or thinner in

the electric cable from the main unit. cleaning the device.

Doing these with the electric cables still It can cause the unit to discolor.

plugged in can cause electric shock.

5 .

Connect the device to a ground line.

No proper grounding can cause electric

shock when device breakdown or short circuit.

6 . Check the power line is securely plugged in

the power source. Power lines that are

loosely plugged-in can cause fire and

electric shock.

1.Safety Precautions

Warning display

Important

Important

2

Page 3

Product name

Model

Basic Specifications

No. of channels

Measurement items

Measurement range[μm] Preset prior to shipment.

Display range [μm]

Depends on the prescribed range.

Display resolution[μm]

Depends on the measurement range

Error margin [μm]

Mastering

MASTER adjustment

Master Set function

Measurement

Measurement function * Option: Peak measurement

Display

Measured value

Judgement result OK = GREEN,NG = RED

* Option: Rank display

Setting

Display

MENU display language

Can be changed through settings.

No. of programs

Interface(I/F)

RS232C OUT Output meas.value/judgement result

Ext SW(DRY port) IN

Push button SW/Foot SW connector

Environment condition

Operating temp [℃]

Air supply [MPa]

Flowrate [L/min]

Power [V]

EXT cable adaptor is for AC85-264[V].

Current consumption

[A]

Weight [kg]

2.Overview

Specifications

Item

Specifications

Notes

Column type air micrometer

CAG300011

20501001640800.2

0.5

1.0

0.4

1.0

2.0

Electric type

The air type model will have no

ZERO/MAG knobs in the future.

Minimum・Maximum

Real time

101dot BAR LED

2" TFT LCD

BAR LED Color

TFT LCD Color

2" TFT LCD

Chinese, Japanese, English

10

1 port

4ports(measure,RESET,min,max)

5 - 40

0.4 - 0.6

50

DC 7 - 12

2

2.5

3

Page 4

- -

Option

: Peak measurement function

: Rank display function

Orifice diameter & Board

Depending on a connected probe spec,

orifice dia and board configuration

will change.

: μm (Standard)

: μm (Standard)

Measurement range

: μm

: μm

: μm

Model number

Standard model code

● AC adaptor

XXPR

Model

CAG30XXXX100

111

50/100

10

1032050

CAG0520

02

Standard Accessories

30

4

Page 5

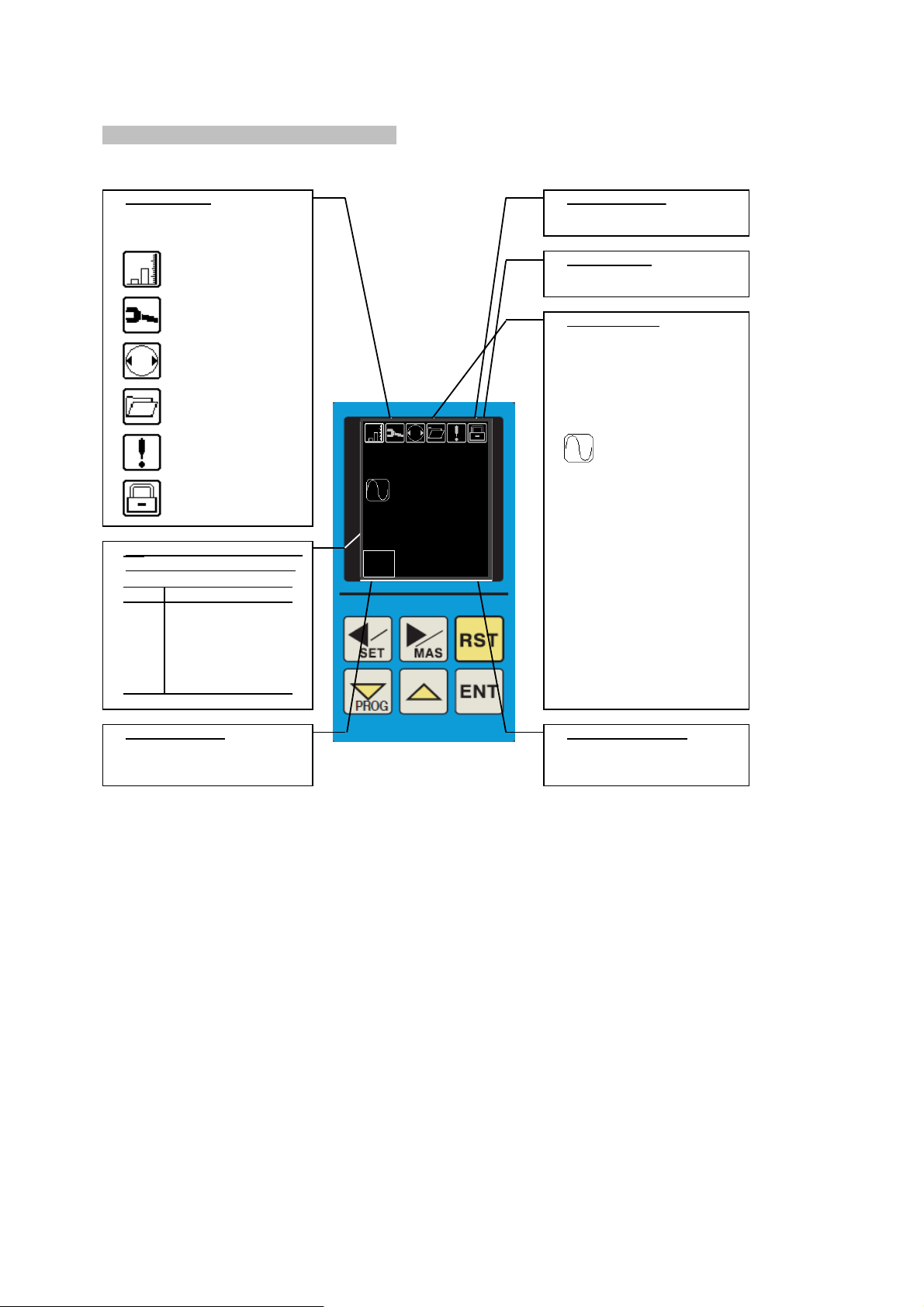

① BAR LED

Displays the meas. value

② LCD display

Displays the meas. value,

judgement result and

set values.

③ Panel switch for

mastering

Used to change mode and

set values for each type.

④ Pressure adjustment valve

Used when a mastering

error occurs during

measuring jig replacement.

⑤ ZERO/MAG Adjustment Knob

Used when a mastering

error occurs during

measuring jig replacement.

⑩ External switch input

⑥ GAGE port Used to connect

Connects the measuring jig push button or

like the measuring head foot switch.

and measuring block.

⑦ Power switch

Used to power ON/OFF ⑪

RS232C port

the device. Used to connect the

RS232C cable.

⑧ Power connector

Connects the AC adaptor.

⑨ Precision regulator

Supply pressure

0.4 - 0.6[MPa]

Please use clean air.

Used to adjust pressure.

Please do not operate

the handle.

3.Names/Functions of each part

5

Page 6

⑫ Mode display ⑮

Measured value

Displays the current mode

and condition.

Measurement mode ⑯ Unit display

Set mode

⑰ Value display

Displays the measured

Calibration mode value format.

When mastering is NG

※ Normally 「Raw data」

Program change mode is displayed only.

Error condition

Raw data

Measured value 最大値

hold condition

最小値

⑬ Displays judgement result

and mastering condition.

最大値-最小値

Disp

Detail

OK Result is “OK”

NG Result is “NG”

CAL Mastering request

condition.

Please perform

mastering.

⑭ Program number ⑱ Measurement range

Displays the current Displays the measurement

program number. range.

②.LCD display detail

最大値-最小値

2

最大値+最小値

2

20.0000

mm

1

50

μm

OK

6

Page 7

● Install the device on a stable Plug the AC adaptor to the power

and level surface with no source.

vibrations.

Set the device on the desired place. Turn "ON" the 「⑦.Power switch」.

! Warning ● Connect the air hose only when

power is turned OFF.

The opening demo will be shown.

Turn OFF the 「⑦.Power switch」.

Connect the air hose of the

measuring block to the

「⑥.GAGE port」. Software version shall be displayed.

Connect the air hose from the filter 起動プログラム番号

to the 「⑨.Precision regulator」. 測定レンジ

Please connect the 「AC Adaptor」 Turn "OFF" the 「⑦.Power switch」.

following the procedure below.

Turn "OFF" the 「⑥.Power switch」.

Unplug the AC adaptor from the

power source.

Connect the AC adaptor to the

「⑨.Power connector」. Unplug the AC adaptor from the

power source.

4.Installation

5.Power “ON”“OFF”

Installing the device

Supply the power

Important

1

2

Connect the air hose.

312

3

Connect the AC adaptor

Turn the power OFF

11232

6

9

7

7

CAG3000

Ver1.00

20.0000

mm

1

50

μm

OK

7

Page 8

Perform calibration by master.

● Mastering must be done on any of the

following conditions.

●

Air micrometer is a comparative

・ Every 2 to 4 hours

measuring device. ・ When power or air supply is turned "ON".

The precision cannot be guaranteed if ・ When indicated value looks abnormal.

there are dirt, scratch, dent or rust

on the master or measurement jig.

Press

for more than 2 secs.

● Precision is not guaranteed if measurement Mode display will change to .

jigs made by other companies is connected

to the device.

● Air micrometer is weak on water and oil.

In case water or oil gets in the device,

the following conditions may happen :

・ Precision becomes bad.

・ The displayed value becomes unstable.

・ Different values are displayed

for the same measured object.

By periodically replacing the filter

element, the above conditions can be

prevented from happening.

Set 「Min master」 the measurement jig.

We recommend the overhaul of the device Once the indicator stabilizes,

if water or oil gets inside the main press .

unit.

Set 「Max master」 on measurement jig.

Check the filter condition. Once the indicator stabilizes,

● Is water or oil clogged up? press .

Check the measure jigs and master.

● Any dirt, scratch, dent or rust? Perform 「Max mastering」.

With compressed air, turn the power

"ON". Check the display of 「TFT LCD」.

After the opening demo, 「MAS OK」 Mastering is successful.

「CAL」 shall be displayed. Proceed to measurement.

Please perform mastering.

「ERR ZERO」

「ERR MAG 」 There is error if any of

Chinese English 「ERR REV 」 these three appears.

Please deal with the cause

of the mastering error.

If error occurs, please confirm and correct

the condition.

・ Is the supply pressure correct?

・ Was the min master and max master

taken by mistake?

・ Is there any dirt, scratch, dent or rust

on the measure jig or master?

・ If none of the above, proceed to

8. Adjustments and perform the task.

6.Operating Procedure

Mastering

Preparations before measurement

Important

Important

567

12384

Mastering error processing

20.0000

mm

1

50

μm

OK

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

8

Page 9

Measure the work object. Hold the measured value and output

! Caution it to RS232C.

● During measurement mode, ! Caution

By pressing for more than 2 secs. ● If the mastering is NG, you cannot

hold and output the measured value.

the mode will change to Master mode.

With the mode display at ,

In order to maintain the measurement

press

.

accuracy, perform mastering about every

2 hours. The measured value shall be held

and hold condition is displayed.

Set the work object on the measurement

jig. The measured value and judegement

The measured value and judgement result shall output to RS232C.

result shall be displayed.

If the color of the「BAR LED」is …

“green”, value is OK and in range.

“red”, value is out of range.

O K N G

If is pressed,

the display shall disappear

and reset the measured value hold

condition.

Measurement

Hold/Output meas. value

112

2

20.0000

mm

1

50

μm

OK

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

9

Page 10

Input the new set value of the measurement jig.

It is possible to store up up to 10 types of

measurement conditions.

Input new set values to a program. ! Caution

● Changing the measurement range

The user cannot change the measurement

! Caution range.

● In case you will change the settings In case you need to change the setting,

of the current program, the device has to be pulled out for

do the following procedure modification.

「Input set value」. ● Changing the measure jig JET diameter

In case you need to change the measurement

Turn "ON" the power. jig JET diameter, the device maybe

After the opening demo, pulled out for modification.

「 CAL 」 shall be displayed.

Japanese

● The set mode has 2 component displays.

Chinese English 「Set items」 selection display and

「 Set values 」input display.

●

Selection of set items procedure

Press for more than 2 secs.

The mode display will change to .

There are multiple pages.

Press

. Under set item display

Upper box displays current program no.

Lower box displays the new program no.

Press to 「Select」

input.

then press to 「Set」

● Set values input procedure

Upper box displays

current value.

Lower box displays

changed value.

Press to move

input digit.

The program is selected by .

Press

to change

Press

and the mode display

the value.

will change to .

Press to set value.

7.Setting Procedure

Input set value

Program change

1

Important

2

4

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

10

Page 11

Press for more 2 seconds Setting the measured value display unit.

Select

「 Shift unit 」 then SET.

Display will change to as below

If in μm, select

「 1.μm 」

If in mm, select

「 2.mm 」

Chinese English Chinese English

Setting the polarity. Setting shift value of measurements.

Select

「

Polarity

」 then SET.

Select

「

Shift Value

」 then SET.

For Inner diameter, 「 1.+ 」 Input 「Work tolerance

For outer diameter, 「 2.- 」 target value(median)」.

Chinese English Chinese English

Setting the measurement range. Setting work upper tolerance limit value.

Select

「 Range 」 then SET.

Select

「 +NG/OK 」 then SET.

Select the measurement range as Input upper tolerance limit value.

stated on the nameplate of the

measurement jig.

Chinese English Chinese English

14253

6

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

11

Page 12

Setting work lower tolerance limit value.

Setting the language.

Select

「 OK/-NG 」 then SET.

Select

「

Language

」 then SET.

Input lower tolerance limit value. Select preferred display language.

Chinese English Chinese English

Setting the max master value.

Setting all the values changed.

Select

「 Max Master 」 then SET.

Select

「 End 」 then SET.

Input the engraved characters Select 「Cancel」 if you don’t

value on the max master. want to save the set values.

Select 「Write」 if you want

to save the set values.

Chinese English Chinese English

Setting the min master value.

This concludes the program setting.

Select

「 Min Master 」 then SET. Proceed to 「8.Adjustment」

Input the engraved characters

value on the min master.

Chinese English

7108911

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

12

Page 13

Turn the ZERO adj knob full to the

right then turn it to the left

2.5 times.

Adjust CAG measurement standard pressure.

ZERO adj. knob

Press for more than 2 secs.

The mode display will change to

Chinese English

When the min master and max master is

placed, adjust the standard pressure

valve so the position of the BAR LED

display is divided in the center.

Standard pressure

adjustment valve

Press .「ADJ」 will be displayed.

Chinese English

8.Adjustment

3

Adjust the standard pressure

142

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

1 .

-30

μm

0

100

μm

调整

2/3

調整

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

1 . Adjustment

100

μm

2/3

Adjustment

-30

μm

1

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

13

Page 14

Adjusts the ZERO and MAG Set min master on the measurement jig.

position of the measurement Adjust 「ZERO 」 so the indicator

jig and CAG. is close to the min master value.

The magnification

is adjusted with Set max master on the measurement jig.

「MAG 」 and zero is Adjust 「MAG 」 so the indicator

adjusted with 「ZERO」 is close to the max master value.

knob.

Set min master on the measurement jig.

When the indicator is close to the

min master value, the adjustment

is completed. Proceed to 11 .

● Adjustment procedure

For inner diameter measurement,

proceed to 5 .

For outer diameter measurement,

proceed to 8 .

Set max master on the measurement jig.

Adjust 「ZERO 」 so the indicator

is close to the max master value.

Set min master on the measurement jig.

Adjust 「MAG 」 so the indicator

is close to the min master value.

Set max master on the measurement jig.

When the indicator is close to the

max master value, the adjustment

is completed. Proceed to 11 .

Green bar dot display :

Upper part 「Max master」

Lower part 「Min master」

(set values)

ZERO・MAG Adjustment

Inner diameter measurement

567

Outer diameter measurement

8910

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

1 .

-30

μm

0

100

μm

调整

2/3

調整

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

1 . Adjustment

100

μm

2/3

Adjustment

-30

μm

1

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

14

Page 15

Set 「Max Master」 on measurement jig.

After the indicators stabilizes,

press .Calibration of the min master 「Max Master」 is performed.

and max master.

Chinese English

! Caution

● Master

Use only those with no rust

or dirt on it.

● Frequency of calibration

In order to maintain the accuracy,

it is highly suggested to do the

calibration every 2 hours.

After the adjustment is completed,

press .「1. Min Master」 is displayed.

Check the display of 「TFT LCD」.

Chinese English 「MAS OK」 Mastering is successful.

Proceed to measurement.

Chinese English

Set 「Min Master」 on measurement jig.

After the indicators stabilizes,

press .After 「Min Master」 is performed,

「 2.Max Master 」 is displayed. 「ERR ZERO」

「ERR MAG 」 There is error if any of

「ERR REV 」 these three appears.

Chinese English

After pressing , proceed to

2

13

Calibration

111412

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

1 .

-30

μm

0

100

μm

调整

2/3

調整

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

2 .

0

100

μm

mm

20.000

Max Master

20.060

Calibration

1/3

2 .

μm

校准标准件

1/3

0

100

mm

20.000

上限标准件值

20.060

2 .

μm

校准标准件

1/3

0

100

mm

20.060

上限标准件值

20.060

2 .

0

100

μm

mm

20.060

Max Master

20.060

Calibration

1/3

3 .

μm

0

100

校准結果

校准完成

校准标准件

1/3

3 .

0

100

μm

Master SET OK

Calibration

1/3

Result Master

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

1 . Adjustment

100

μm

2/3

Adjustment

-30

μm

1

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

15

Page 16

It is possible to output the measured

data(value and judgement) to the RS232C.

! Caution While the mode display is ,

● If mastering is NG, it is not possible

to output the measured results. input “D” only.

● Use cable length of up to 15m only.

The data below is transmitted out.

Ex .

Measured value 「 20.0000」

● Connector cable

In case judgement is

「OK」

The 「RS232C connector」 at the rear

side is the connection port. SP CR LF

SP 2 0 . 0 0 0 0 SP SP O K CR LF

No No

1 6

2 7

3 8

4 9

5

● Serial port settings

Setting label

Bits / second

Data bits

Parity

Stop bits

● Output data composition

The output data is composed of the

14 characters found below.

・ Measured value 8 chars

・ Space(SP) 1 char

・ Judgement 3 chars

・ Control character(CR) 1 char

・ Control character(LF) 1 char

SP CR LF

2

Connect the RS232C cable

Signal label

Signal label

9.RS232C Output

RxD

RTS

TxD

CTS

GND

Set value

96008none1Measured value

Judgement

20.0000

OK

Measured results output

1

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

1 .

-30

μm

0

100

μm

调整

2/3

調整

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

2 .

0

100

μm

mm

20.000

Max Master

20.060

Calibration

1/3

2 .

μm

校准标准件

1/3

0

100

mm

20.000

上限标准件值

20.060

2 .

μm

校准标准件

1/3

0

100

mm

20.060

上限标准件值

20.060

2 .

0

100

μm

mm

20.060

Max Master

20.060

Calibration

1/3

3 .

μm

0

100

校准結果

校准完成

校准标准件

1/3

3 .

0

100

μm

Master SET OK

Calibration

1/3

Result Master

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

1 . Adjustment

100

μm

2/3

Adjustment

-30

μm

1

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

16

Page 17

Calibration of masters with the use of

external switch.

If the device is connected with external

push button or foot switch, the following

operations are possible.

・ Output and Hold of measured value.

・ Mastering

Set 「Min Master」 on measurement jig.

! Caution After the indicators stabilizes,

● Use cable length of up to 2m only. turn "ON" the External Switch Input

● It is possible to connect no voltage 「Min Master」.

contact point push button/foot switch.

「Min Master」is performed.

● Input connector

Connect to D-SUB15P(Male).

No No

1 9 Max Master

2 10 Min Master

3 11

4 12

5 13

GND 6 14 Set 「Max Master」 on measurement jig.

MEAS 7 15 After the indicators stabilizes,

RESET 8 turn "ON" the External Switch Input

「Max Master」.

「Max Master」is performed.

If this mark disappears,

mastering is successful.

Proceed to measurement.

The output to RS232C and hold of measured

value is done with the use of the

external switch. If this mark is blinking,

! Caution mastering is failed.

● If the mastering result is NG, Please deal with the cause

the output and hold of measured value

of the mastering error.

is not possible.

With the mode display at ,

turn "ON" the

External Switch Input「MEAS」.

The icon is displayed to

show the measure hold condition.

The measured value and judgement

result shall be output to the RS232C.

Turn "ON" the

External Switch Input「RESET」.

The icon will disappear to show

the measured value hold condition

is RESET.

10

.

External Switch Input

Mastering

External switch input

3

Signal label信号名

Signal label

4

5

Meas. Value Hold/Output

1

2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

1 .

-30

μm

0

100

μm

调整

2/3

調整

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

2 .

0

100

μm

mm

20.000

Max Master

20.060

Calibration

1/3

2 .

μm

校准标准件

1/3

0

100

mm

20.000

上限标准件值

20.060

2 .

μm

校准标准件

1/3

0

100

mm

20.060

上限标准件值

20.060

2 .

0

100

μm

mm

20.060

Max Master

20.060

Calibration

1/3

3 .

μm

0

100

校准結果

校准完成

校准标准件

1/3

3 .

0

100

μm

Master SET OK

Calibration

1/3

Result Master

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

1 . Adjustment

100

μm

2/3

Adjustment

-30

μm

1

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

17

Page 18

Page No 設定項目名 Label

1 極性

Polarity

极性 □ 1 . +

□ 2 . -

2 測定レンジ Range

□ 1 . μm

□ 2 . μm

□ 3 . μm

3 シフト単位 Shift Unit

公差中间单位

□ 1 . μm

□ 2 . mm

4 シフト値 Shift Value

5 上限判定限界値 +NG/ OK

上限超差值

6 下限判定限界値 OK/-NG

下限超差值

7 大範マスタ Max Master

8 小範マスタ Min Master

9 Language(言語)

Language

□ 1 . ENGLISH

□ 2 .

JAPANESE

□ 3 . CHINESE

10 終了 END

11

.

Appendix

General setting

100

2/2

Set Values

Japanese

English

Chinese

1/22050

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

20.0000

mm

1

50

μm

OK

切换程序

程序编号

0

0

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

1 .

-30

μm

0

100

μm

调整

2/3

調整

1 .

μm

1/3

下限标准件值

20.000

20.000

mm

校准标准件

0

100

1 .

0

100

μm

mm

1/3

20.000

20.000

Calibration

Min Master

2 .

0

100

μm

mm

20.000

Max Master

20.060

Calibration

1/3

2 .

μm

校准标准件

1/3

0

100

mm

20.000

上限标准件值

20.060

2 .

μm

校准标准件

1/3

0

100

mm

20.060

上限标准件值

20.060

2 .

0

100

μm

mm

20.060

Max Master

20.060

Calibration

1/3

3 .

μm

0

100

校准結果

校准完成

校准标准件

1/3

3 .

0

100

μm

Master SET OK

Calibration

1/3

Result Master

1 .

校准标准件

0

100

1/3

下限标准件值

20.000

20.000

mm

μm

1 .

mm

1/3

20.000

20.000

Calibration

Min Master

0

100

μm

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

下限标准件值

下限超差值

上限标准件值

上限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

OK/-NG

Max Master

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

选择量程

极性

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Max Master

Min Master

+NG/ OK

OK/-NG

Shift Value

Shift Unit

Range

Polarity

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

上限标准件值

下限标准件值

下限超差值

上限超差值

公差中间单位

公差中间值

选择量程

极性

1/2

设定 项 目名称

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

下限标准件值

上限标准件值

上限超差值

下限超差值

公差中间值

公差中间单位

极性

选择量程

1/2

Label

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

Min Master

Max Master

OK/-NG

+NG/ OK

Shift Value

Shift Unit

Range

Polarity

1/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

Label

9 .

10 .

END

Language

2/2

Label

9 .

10 .

END

Language

2/2

设定 项 目名称

9 .

10 .

结束

Language(语言)

2/2

1 . Adjustment

100

μm

2/3

Adjustment

-30

μm

1

Program Change

Program No.

0

0

LABEL

1 .

1.

1.

2.

1/2

Polarity

+

+

-

18

Page 19

Page 20

Loading...

Loading...