Page 1

NO.AIRーTE0306

CAG2000 Instruction Manual

Column Type Air Micrometer

Page 2

Contents

1. Introduction・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

2. Main Features ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1

3. Main Modes ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2

4. Names and Functions of Controls and Parts ・・・・・・・・・・・・・・・・・・・・・・・ 3

5. Specifications・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 8

6. Measurement ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・10

6.1 Preparation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・10

6.2 Measuring ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・10

7. Mastering ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・12

7.1 Automatic mastering ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・12

7.2 Clearing mastering data ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・15

8. Changing Programs ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・16

9. Setting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・18

10. Adjusting Zero Position and Sensitivity with Zero and

Sensitivity Adjustment Knobs・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・27

10.1 Adjusting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・27

10.2 Indication below mastering range ・・・・・・・・・・・・・・・・・・・・・・・・・・・・31

10.3 Indication above mastering range ・・・・・・・・・・・・・・・・・・・・・・・・・・・・32

11. I/O Description ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・34

11.1 Serial output (RS232C) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・34

11.2 External input ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・39

12. Model Identification・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・41

13. Options ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・42

14. Maintenance ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・43

15. Troubleshooting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・44

16. Cautions ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・45

17. Operation Flow ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 46

Page 3

1. Introduction

The column type air micrometer is a measuring instrument with an easy-to-see three-

color bargraph display. Combination with an air/electric (A/E) converter provides this

compact instrument with an automatic mastering function. It can also be easily

connected with another or more identical units to allow the trend of works to be read from

the bargraph displays arranged side by side.

2. Main Features

(1) A three-color bargraph display allows the measurement result to be more easily

seen.

(2) An eight-digit alphanumeric display indicates the measured value, set item, and other

types of information.

(3) Control keys are used to automatically calibrate the instrument with the maximum

and minimum masters.

(4) The instrument is only 50 mm wide, so that it is suited for measuring with another or

more identical units operating together.

(5) The standard serial communication function allows the output of data to the personal

computer and printer. The data can be stored, statistically processed, and input to a

spreadsheet program like Excel.

(6) In the set mode, the ENT key can be pressed to sequentially select all items.

(7) Programs can be selected to store ten types of set values and mastering data and

change from one type to another.

1

Page 4

3. Main Modes

The instrument operates in the following four main modes:

(1) Measure mode

Measure (in free run condition): Measures a work.

Hold measured value: Holds the measured value, except when the

mastering result is NG.

(2) Set mode

Enters and changes the set value.

(3) Master mode

Master: Calibrates the instrument with the masters. This

instrument is a comparative measuring instrument.

Be sure to use it upon completion of the mastering

operation.

Adjust detector: Adjusts the detector.

Clear mastering data: Clears the mastering data.

(4) Change program mode

Changes from one program to another. When the instrument is started, the

program used last is launched.

2

Page 5

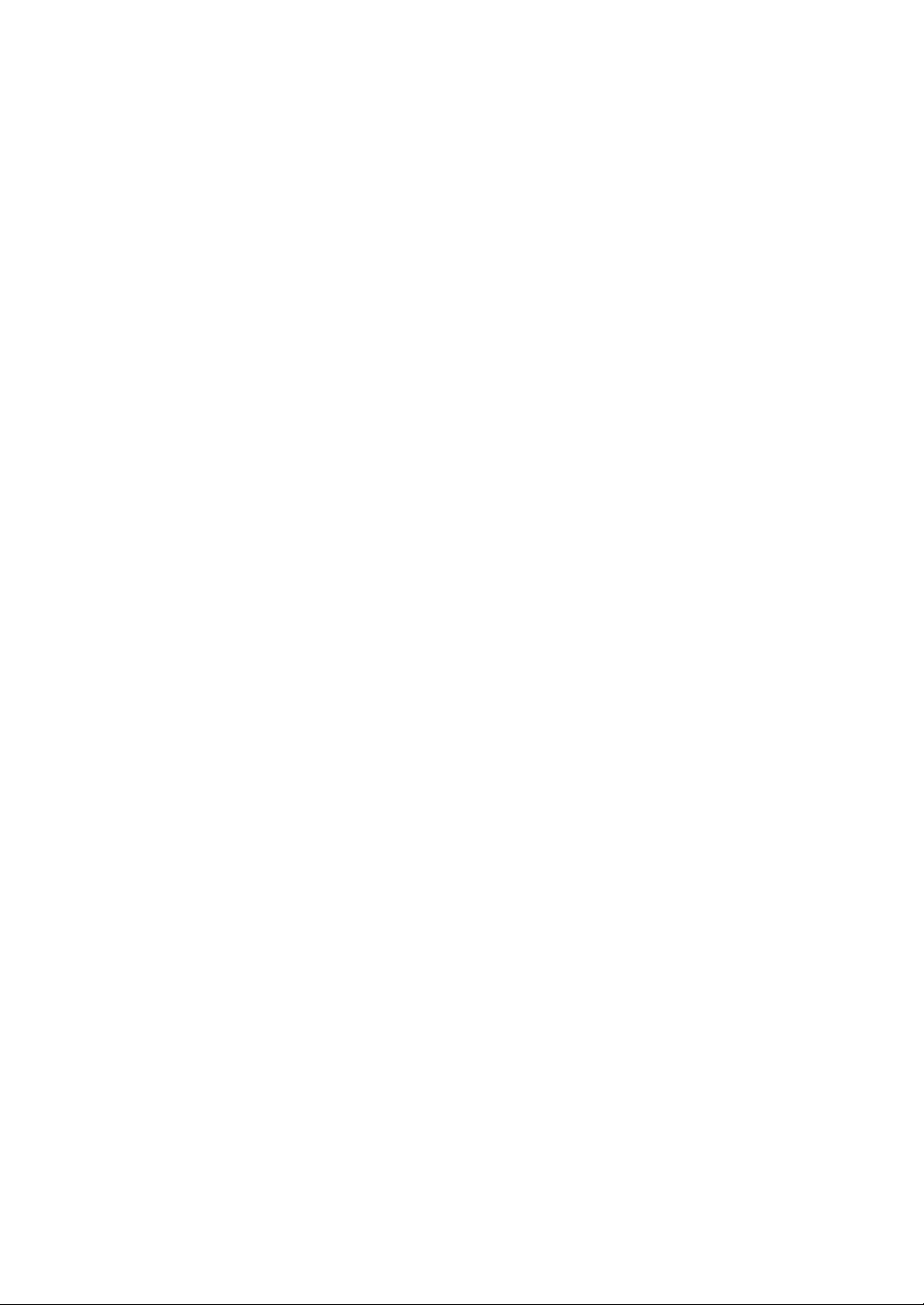

4. Names and Functions of Controls and Parts

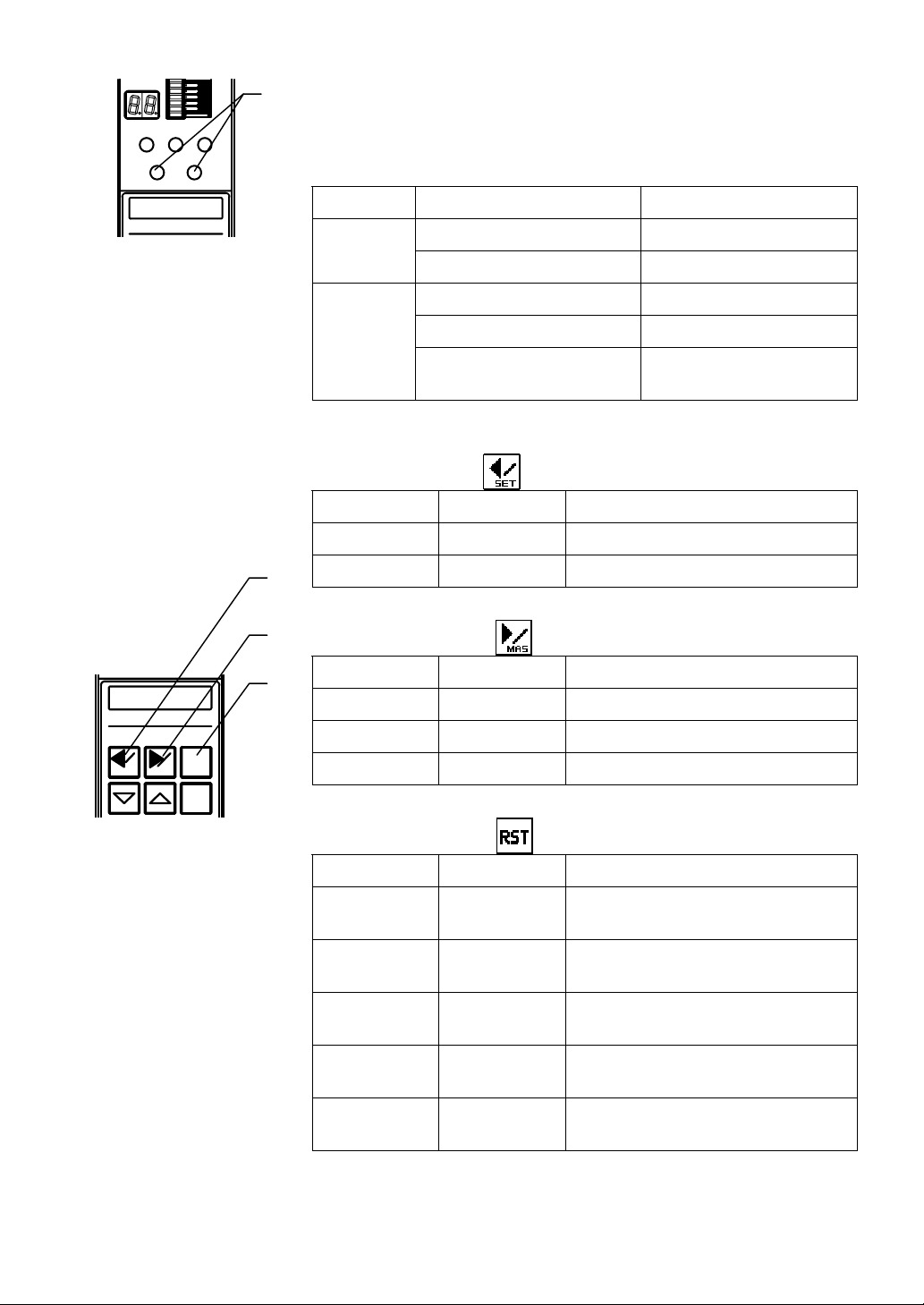

(1) Bargraph display

Indicates the measured value, judgment result, or other

types of information by a 101-dot, 3-color bar.

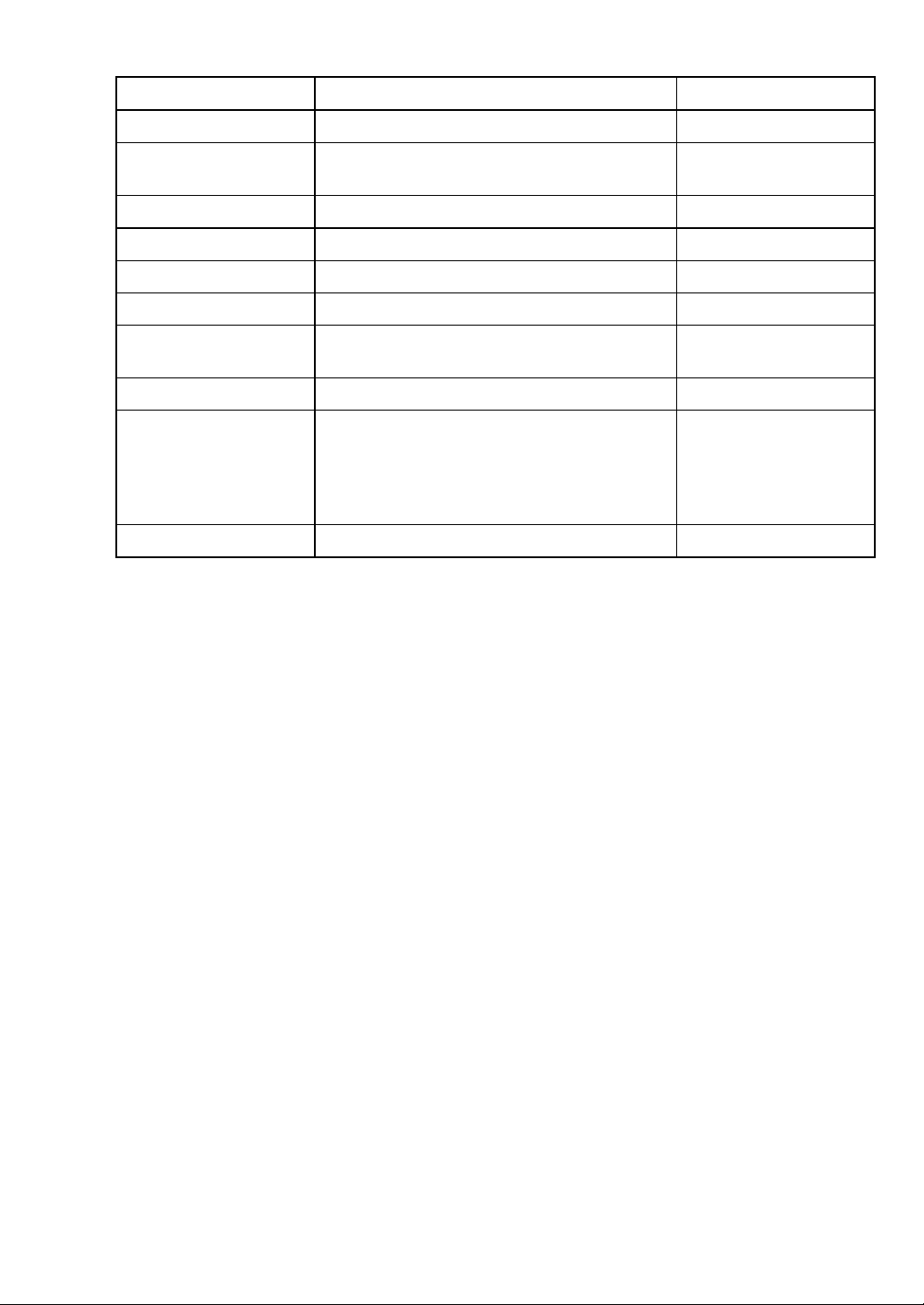

Table 4-1. Relationship between bar color and display description in

each mode.

Mode Bar color Display description

(1)

Measure

Hold measured value

Master

(2) Range displays

Indicate the bar top and bottom dimensions in two digits.

Green (light) Measured value (judgment

result OK)

Red (light) Measured value (judgment

result NG)

Orange (dot) Upper or lower limit value

Green (dark) Measured value (judgment

result OK)

Red (dark) Measured value (judgment

result NG)

Orange (light) Current set valueSet

Green (dot) Previous set value

Green (light) Mastering enabled condition

Red (light) Mastering disabled condition

Orange (dot) Mastering data

Orange (light) Measured valueAdjust detector

Green (dot) Mastering data

(2)

SET

213

MAS

Table 4-2. Range displays.

Measuring range (µm)

20 10.

50 25.

100 50.

200 10

Digital display

3

Page 6

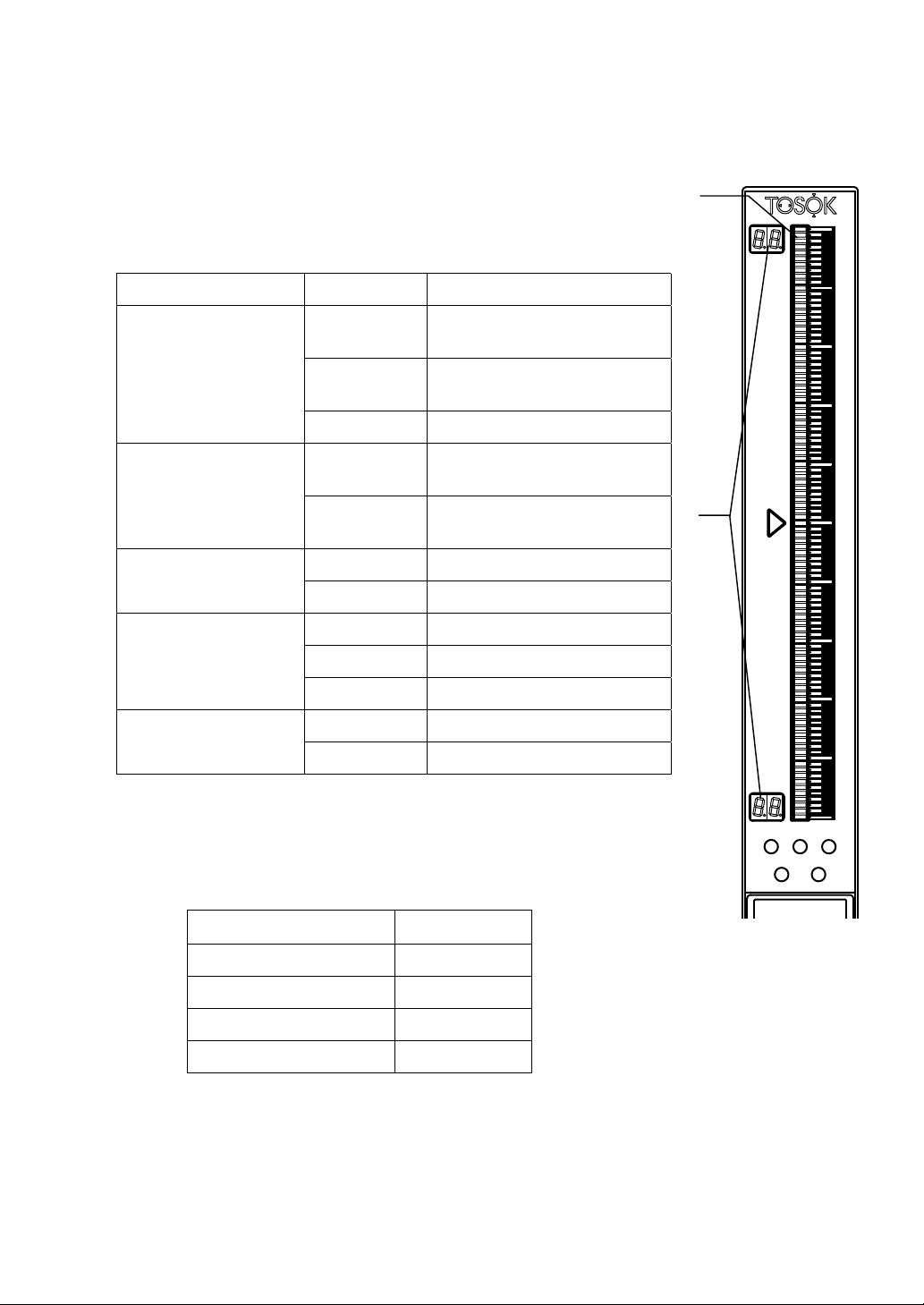

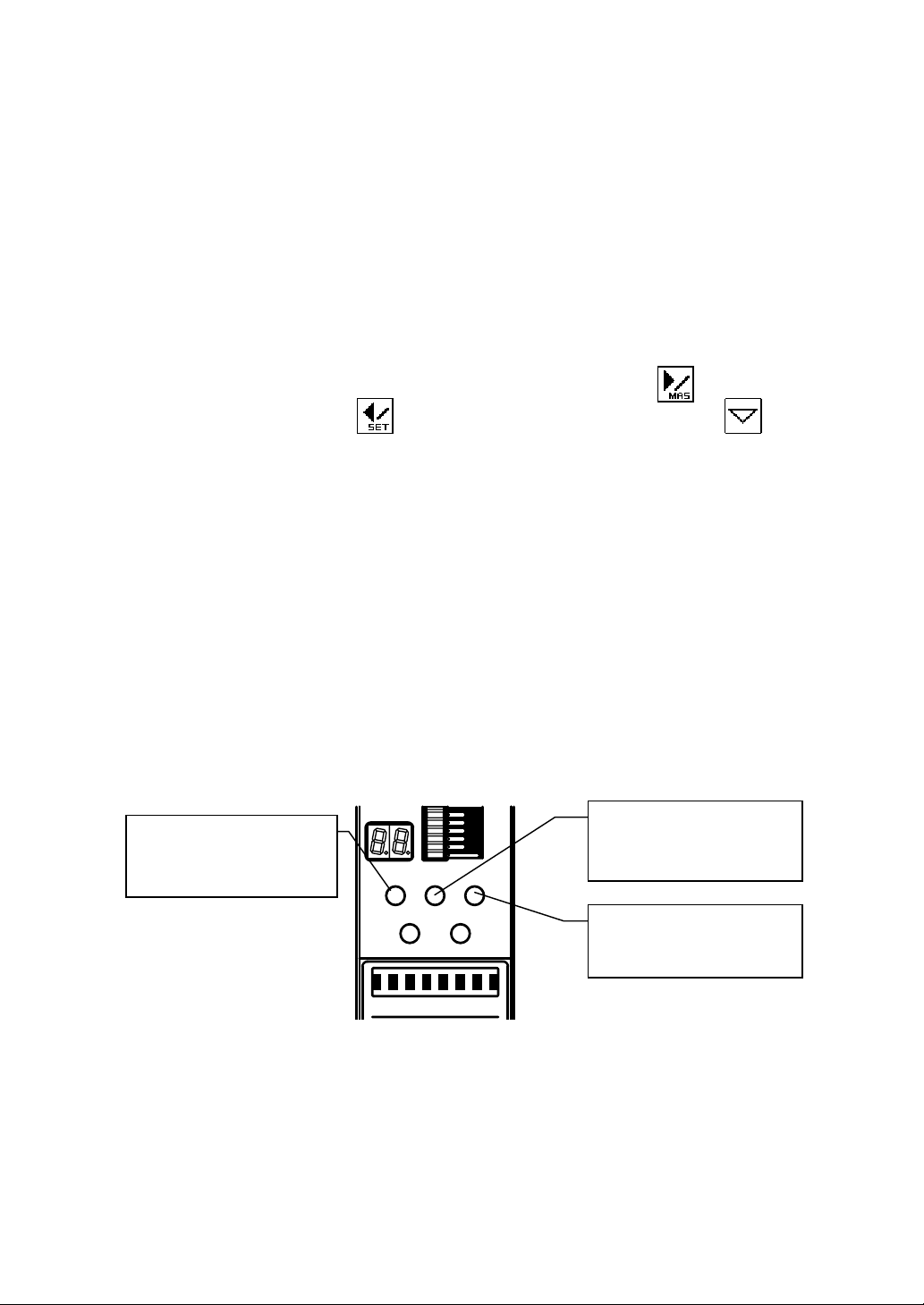

(3) Alphanumeric display

SETMA

S

Indicates the measured value, set value, set item, or other

types of information by 8-digit 7 × 5 dot characters.

(3)

(4) Sensitivity adjustment knob

Adjusts the sensitivity of the air circuit. This adjustment is

necessary only for changing the measuring nozzle and

correcting a mastering error.

(5) Zero adjustment knob

Adjusts the zero position of the air circuit. This adjustment

is necessary only for changing the measuring nozzle and

correcting a mastering error.

(6) Measuring nozzle port

Accepts the vinyl hose of the measuring nozzle.

(7) Item and judgment LEDs

SET

(7)

21

3

MAS

Indicate the judgment result. LED 1 comes on red when the

measured value is –NG, LED 2 comes on green when the

measured value is OK, and LED 3 comes on red when the

measured value is +NG.

Table 4-3. LED colors and conditions indicated.

Color Condition Mode

(4)

(5)

(6)

SET MAS

CAG

RST

ENT

2000

MAG

ZERO

GAGE

LED 1: Red (light) Judgment result –NG Measure

LED 2: Green (light) Judgment result OK Measure

LED 3: Red (light) Judgment result +NG Measure

LED 1: Red (dark) Judgment result –NG Hold measured value

LED 2: Green (dark) Judgment result OK Hold measured value

LED 3: Red (dark) Judgment result +NG Hold measured value

LED 1: Orange (light) Mastering Master

4

Page 7

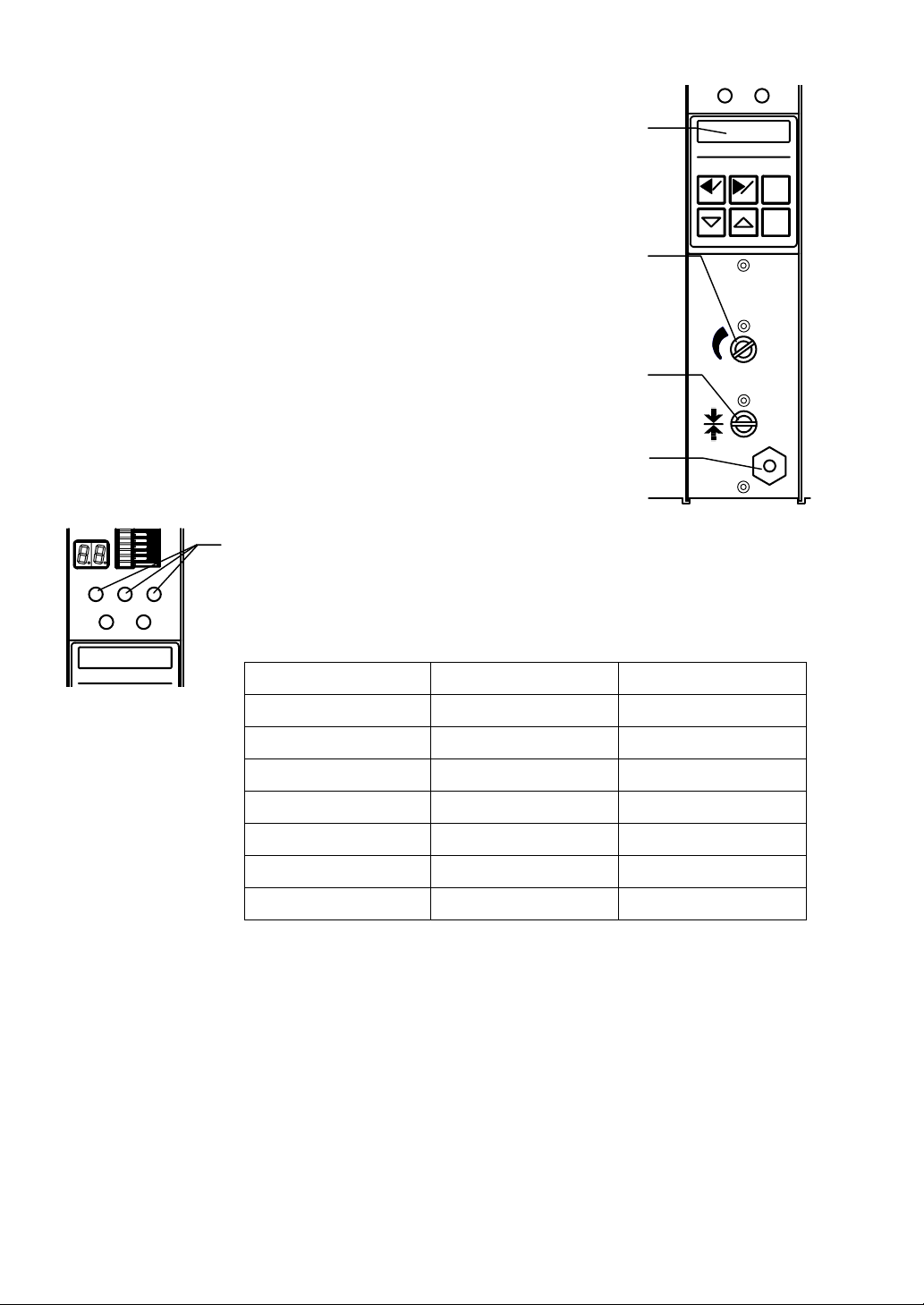

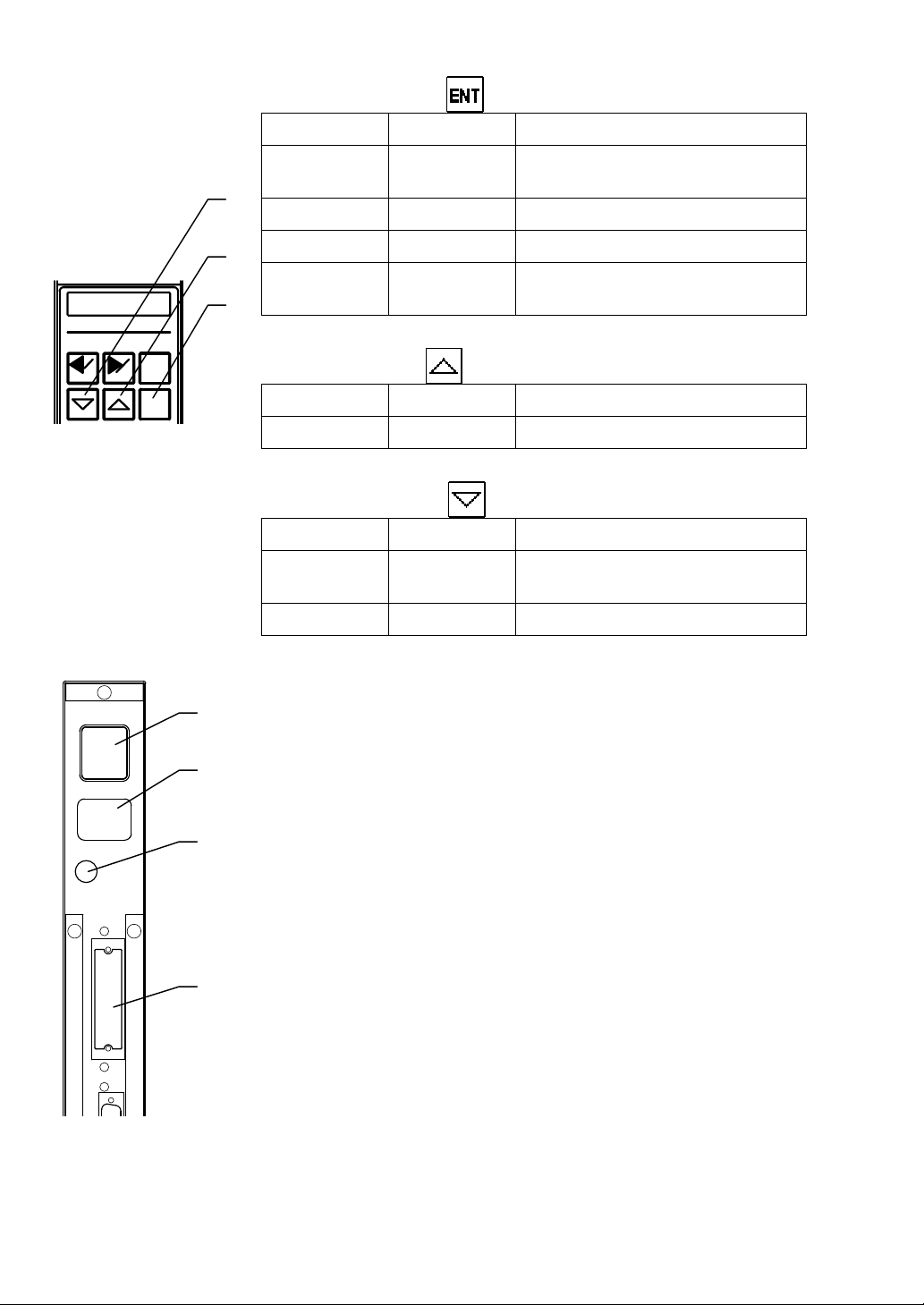

SET

(8) Mode LEDs

(8)

21

3

MAS

Indicate the current mode and the mastering result. The

relationship between the LED color and the mode or mastering

result is as shown in Table 4-4.

Table 4-4. LED colors and conditions indicated.

LED name LED color Mode or condition

Orange Set modeSET

Green Change program mode

SET MAS

RST

ENT

MAS

Orange Master mode

Flashing red Mastering result NG

Alternately red and orange Master mode,

Mastering result NG

(9) Control keys

Left arrow key

Mode Keying Condition

Measure Press 2 sec. Mode is changed to set mode.

Set Press once. Set item can be selected.

Right arrow key

Mode Keying Condition

Measure Press 2 sec. Mode is changed to master mode.

Set Press once. Set item can be selected.

Master Press once. Display description is changed.

RST (reset) key

Mode Keying Condition

Hold measured

Press once. Measured value hold is cleared.

value

Set (set value

being entered)

Set (set item

being selected)

Press once. Set value is returned to previous

condition.

Press once. Setting can be finished (WRITE or

CANCEL).

Master Press once. Display description is returned to

previous condition.

Adjust detector Press once. Display description is returned to

previous condition.

5

Page 8

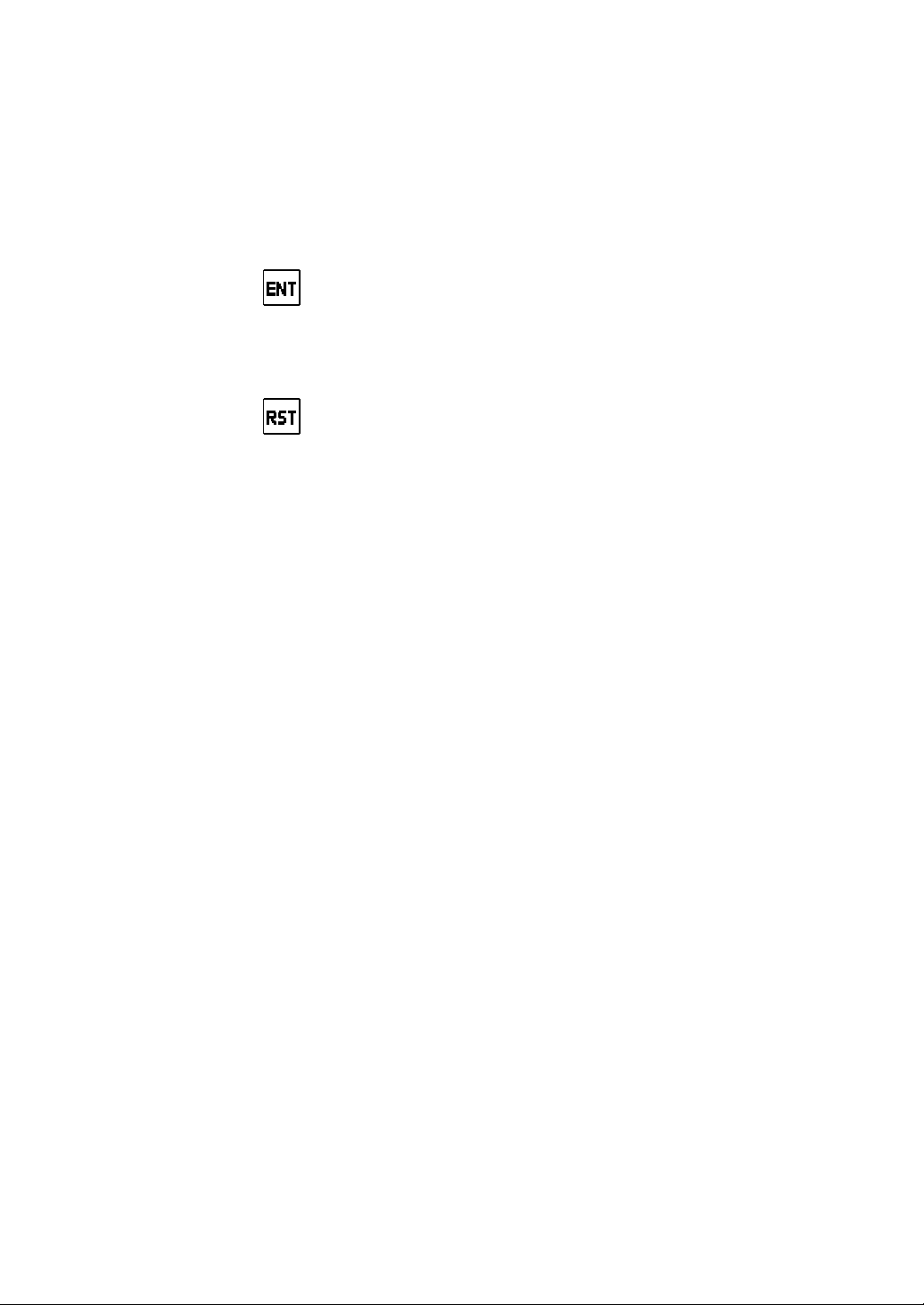

ENT (enter) key

Mode Keying Condition

Measure Press once. Measured value is held (when

mastering result is OK).

Set Press once. Set item and value are determined.

Master Press once. Master measured value is read.

Adjust

detector

Press once. Detector adjustment is finished.

SET MAS

AC85~264V

FUSE

3A

RST

ENT

(10)

(11)

(12)

Up arrow key

Mode Keying Condition

Set Press once. Set value is entered.

Down arrow key

Mode Keying Condition

Measure Press 2 sec. Mode is changed to change

program mode.

Set Press once. Set value is entered.

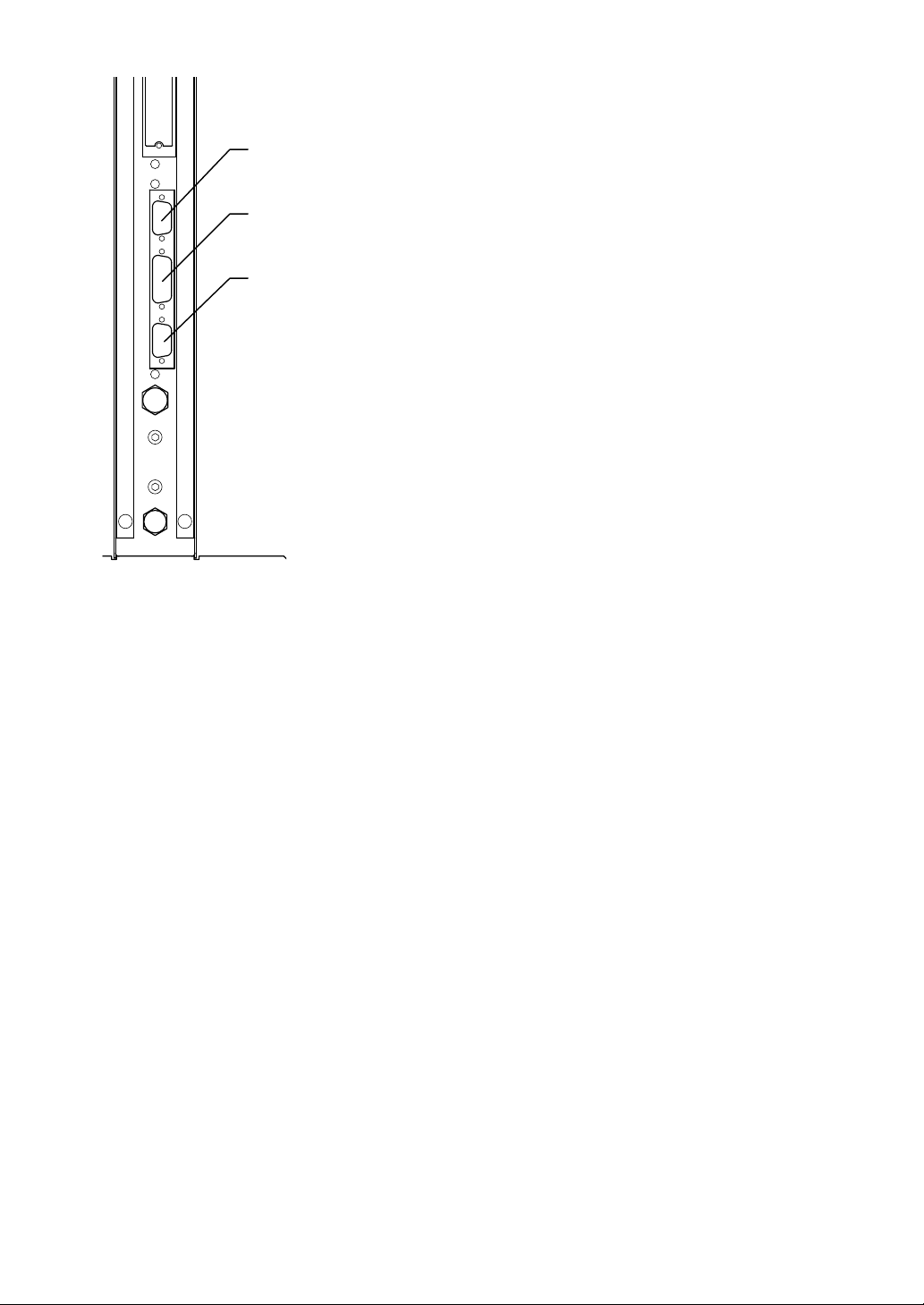

(10) Power connector (input) and power switch

Input AC power. Usable in the range of 85 to 264 VAC. Use

the accessory power cable in the range of 85 to 125 VAC.

(11) Power connector (output)

Accepts the power connector (input) of an adjacent instrument to

be used in combination, and is internally connected to the power

connector (input).

(12) Fuse holder

EXT I/O

(13)

A glass tube fuse (φ5.2 × 20, 3 A) is used.

(13) DC input/output connector (option)

Connector to be connected to an LED or sequencer, and used

2C

for input of measure, mastering and other commands and for

output of judgment result and BCD.

6

Page 9

EXT I/RS232CSW.ETCANALOG

(14) RS232C connector

A serial communication connector for connecting a personal

computer or printer.

(14)

(15) Switch input connector

(15)

A connector for input of a measure or mastering command with

an external button. It is also used for RS422 communication

and Digimatic output (options).

(16)

(16) Analog input/output connector

A connector for external analog signal input and amplifier signal

output.

7

Page 10

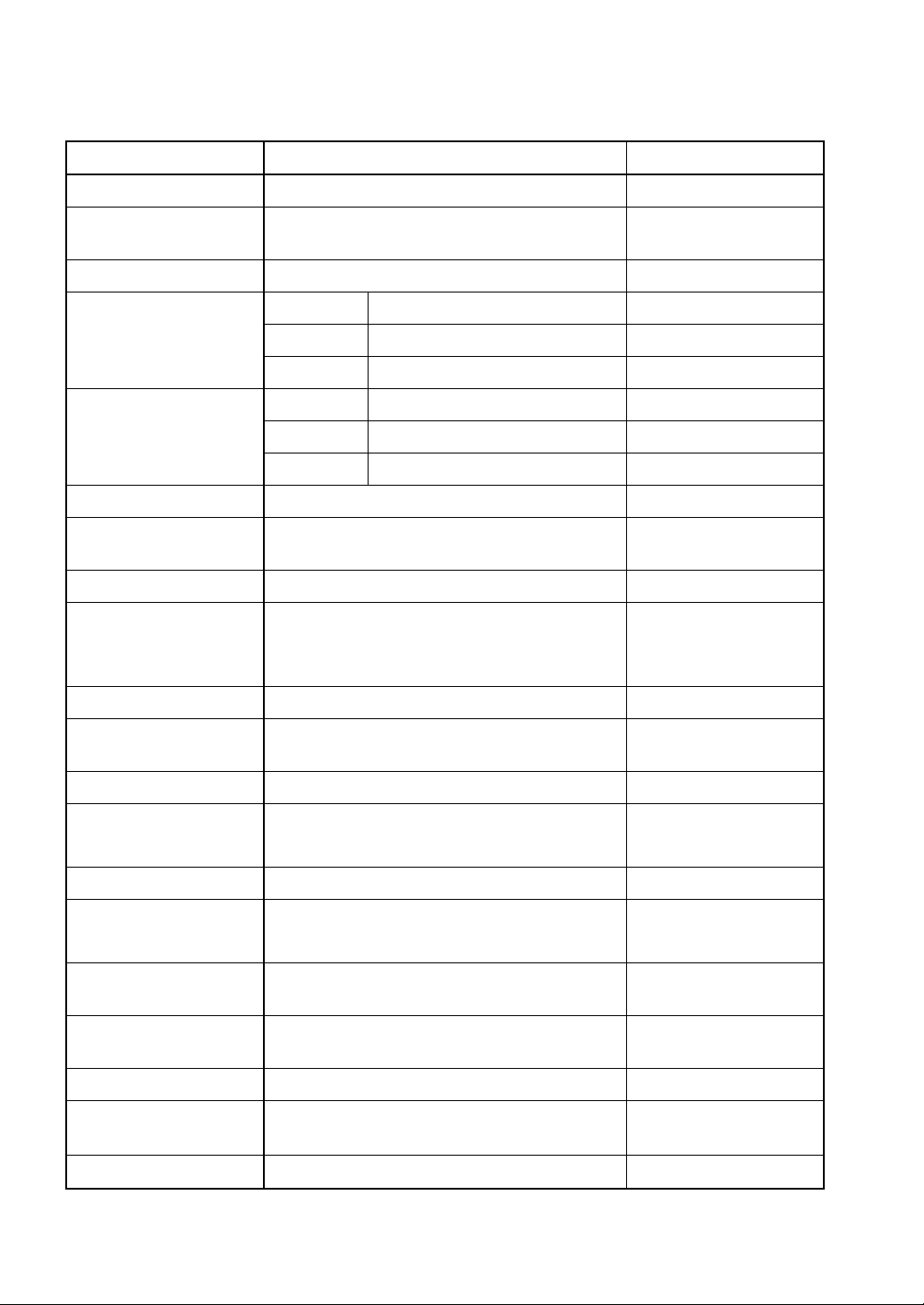

5. Specifications

Item Specification Remarks

Input 1 air channel

Air supply pressure 0.196 MPa Source pressure:

0.3 MPa or more

Measurement item 1

Measuring range (mm)

Resolution (mm)

Bargraph display 101 dots (red, green, orange, light/dark)

Bargraph display

method

Range display 2 digits (numbers), 2 places

Multifunctional display 8 digits (numbers/alphabet)

Shift range ±1000% (full scale) From Version 2.60

Actual dimension

display

Judgment result ±NG and OK

Judgment result

display

CAG2000 0.0200, 0.0500, 0.100, 0.200

CAG2000E 0.0250, 0.0500, 0.100, 0.200

CAG2000H 0.0100, 0.0200, 0.0500, 0.1000

CAG2000 0.0002, 0.0005, 0.001, 0.002

CAG2000E 0.00025, 0.0005, 0.001, 0.002

CAG2000H 0.0001, 0.0002, 0.0005, 0.0010

Bar (OK: Green, NG: Red), Dots (Max/Min)

Measured value, set item, set value, and

error display

000.0000 mm (7 digits + decimal point)

Bargraph display (color), judgment LEDs

Multifunctional display

Automatic mastering Minimum and maximum masters

Automatic mastering

range

Number of setting

programs

Power supply voltage

and frequency

Power supply capacity 30 VA

Dimensions and mass

Operating temperature

Zero position: ±50% (full scale)

Sensitivity: ±20% (full scale)

10

85 to 264 VAC, 50/60 Hz 100-VAC power cable

50 mm wide × 480 mm high × 200 mm deep,

4 kg

0 to 45°C

8

supplied as accessory

Page 11

Standard

Item Specification Remarks

External input 4 (measure, reset, maximum master, and

minimum master)

Serial output 1 (printer or personal computer) RS232C

Optional

Printer output 1 (DP1) Digimatic

Judgment result output –NG, OK, +NG (12/24 VDC)

Rank output –NG,OK1 to OK14, +NG (12/24 VDC) Rank function

BCD output 1 (12/24 VDC)

Peak measurement

function

Rank function 99 ranks maximum OK range

+PEAK, –PEAK,

TIR (= +PEAK – (–PEAK)),

TIR (= +PEAK – (–PEAK) /2)

External buttons or foot

switch

combined use

Based on

measurement value

change with auto

measurement start

function

9

Page 12

6. Measurement

6.1 Preparation

Attach the regulator to the rear of the instrument, and connect it with the air filter.

Connect the measuring nozzle hose to the front of the instrument, and connect the

accessory power cable to the rear of the instrument.

Turn on the power switch (or press the position marked I of the switch) at the rear of

the instrument, so that the power of 85 to 264 VAC (50/60 Hz) will be supplied to the

instrument. Supply air at 0.3 to 0.7 MPa to the air filter.

When the instrument is started, it is in the measure mode. Press for 2 sec to

change to the master mode, for 2 sec to change to the set mode, and for 2

sec to change to the change program mode.

6.2 Measuring

Bargraph display, and item and judgment LEDs

(1) The judgment upper and lower limit values are indicated by orange (dark) on the

bargraph display.

(2) The bargraph display is illuminated green (light) and red (light) when the judgment

result is OK and NG, respectively.

(3) The item and judgment LEDs 1, 2 and 3 come on red, green and red when the

measured value is –NG, OK and +NG, respectively.

Comes on red when

measured value is –NG

Fig. 6-1. Item and judgment LEDs during measurement.

SET

21

3

MAS

Comes on green when

measured value is OK

Comes on red when

measured value is +NG

10

Page 13

Hold measured value mode

The measured value is held, except when the mastering result is NG.

(1) The bargraph display is usually in the measure mode and shows the value being

measured (this is called the free run condition). In the free run condition, the

measured value is indicated by green (light) on the bargraph display when it is OK

and by red (light) on the bargraph display when it is NG.

(2) Press in the free run condition to hold the measured value (this is called the

hold condition). In the hold condition, the measured value is indicated by green

(dark) on the bargraph display when it is OK and by red (dark) on the bargraph

display when it is NG.

(3) Press to clear the measured value hold.

11

Page 14

7. Mastering

7.1 Automatic mastering

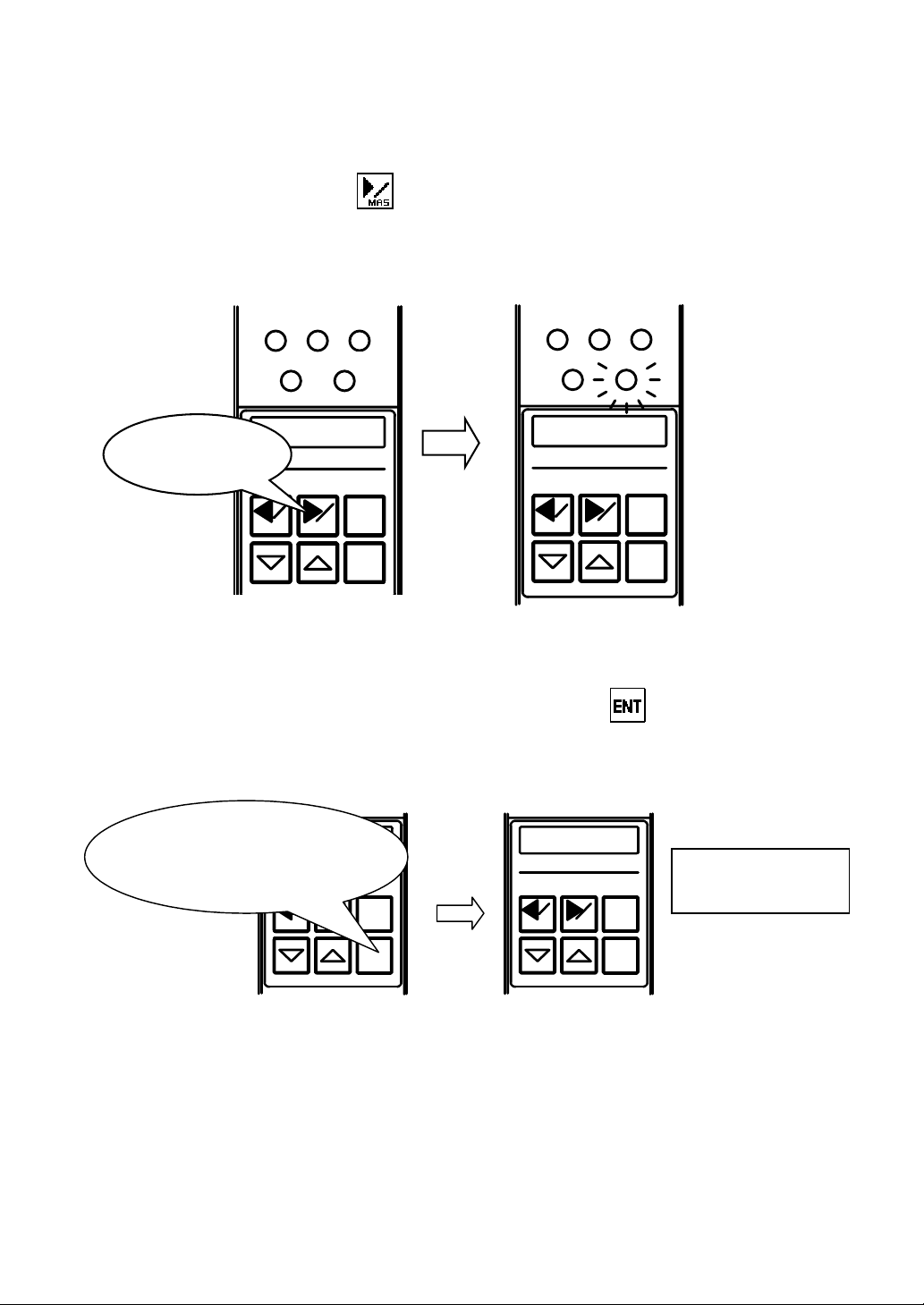

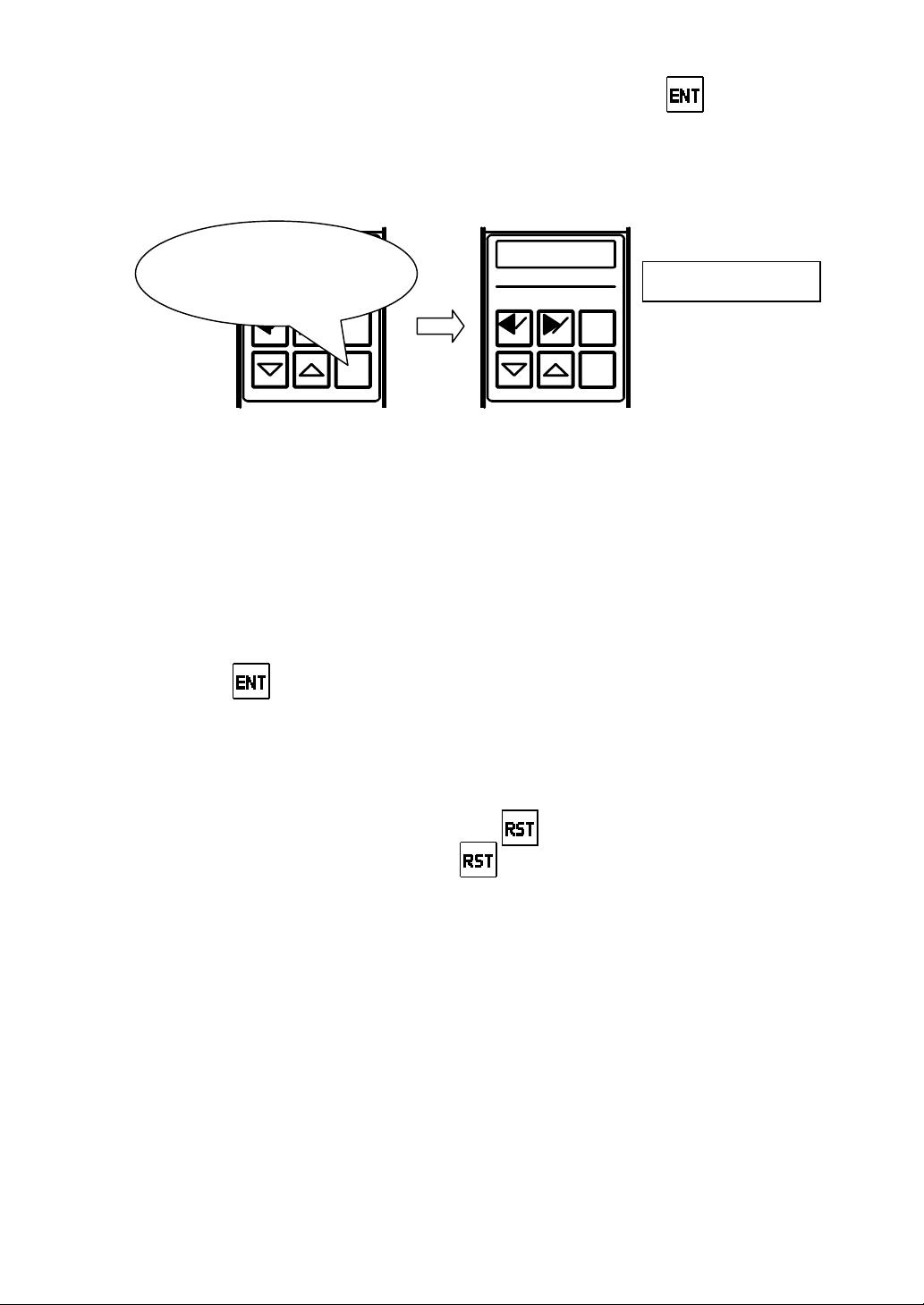

In the measure mode, press for 2 sec or more.

The MAS LED below the bargraph display comes on orange, “MIN M.” appears on the

alphanumeric display, and the instrument changes to the master mode.

Measure mode Master mode

2

1

3

213

MAS

SET

Press 2 sec or

more

12.3

SET MAS

RST

SET MAS

ENT

Fig. 7-1. Changing to master mode.

Set the minimum master in the measuring nozzle, and press . The instrument is

calibrated with the minimum master, and “MAX M.” is shown on the alphanumeric

display.

Set minimum master in

measuring nozzle, and

press this

SET MAS

RST

MAX M.

SET MAS

SET

MIN M.

MAS

RST

ENT

Completion of

minimum-mastering

RST

ENT

Fig. 7-2. Calibrating with minimum master.

ENT

12

Page 15

Set the maximum master in the measuring nozzle, and press . The instrument

is calibrated with the maximum master. If there is no mastering error, “MAS OK” is

shown for 2 sec on the alphanumeric display, and the instrument ends the master

mode and returns to the measure mode.

Set maximum master in

measuring nozzle, and

press this

SET MAS

RST

ENT

MAS OK

SET MAS

Mastering finished

RST

ENT

Fig. 7-3. Ending mastering.

If there is a mastering error, its description is shown on the alphanumeric display as

follows:

ERR ZERO: Zero position error (outside of automatic mastering range)

ERR MAG: Sensitivity error (outside of automatic mastering range)

ERR REV: Maximum and minimum master values reversed

ERR OFFR: Outside of measuring range

Press to return to step above. If it is necessary to adjust the zero position

and sensitivity of the air circuit with the zero and sensitivity adjustment knobs,

respectively, refer to “10. Adjusting Zero Position and Sensitivity with Zero and

Sensitivity Adjustment Knobs”.

In the middle of the master mode, press to return to the previous condition.

When “MIN M.” is displayed, press to return to the measure mode.

Mastering data storing function

The instrument is designed to read the last mastering data and fall in the master request

condition.

(1) Master request condition

When the power of the instrument is turned on or when a program change is made,

the instrument operates as follows:

13

Page 16

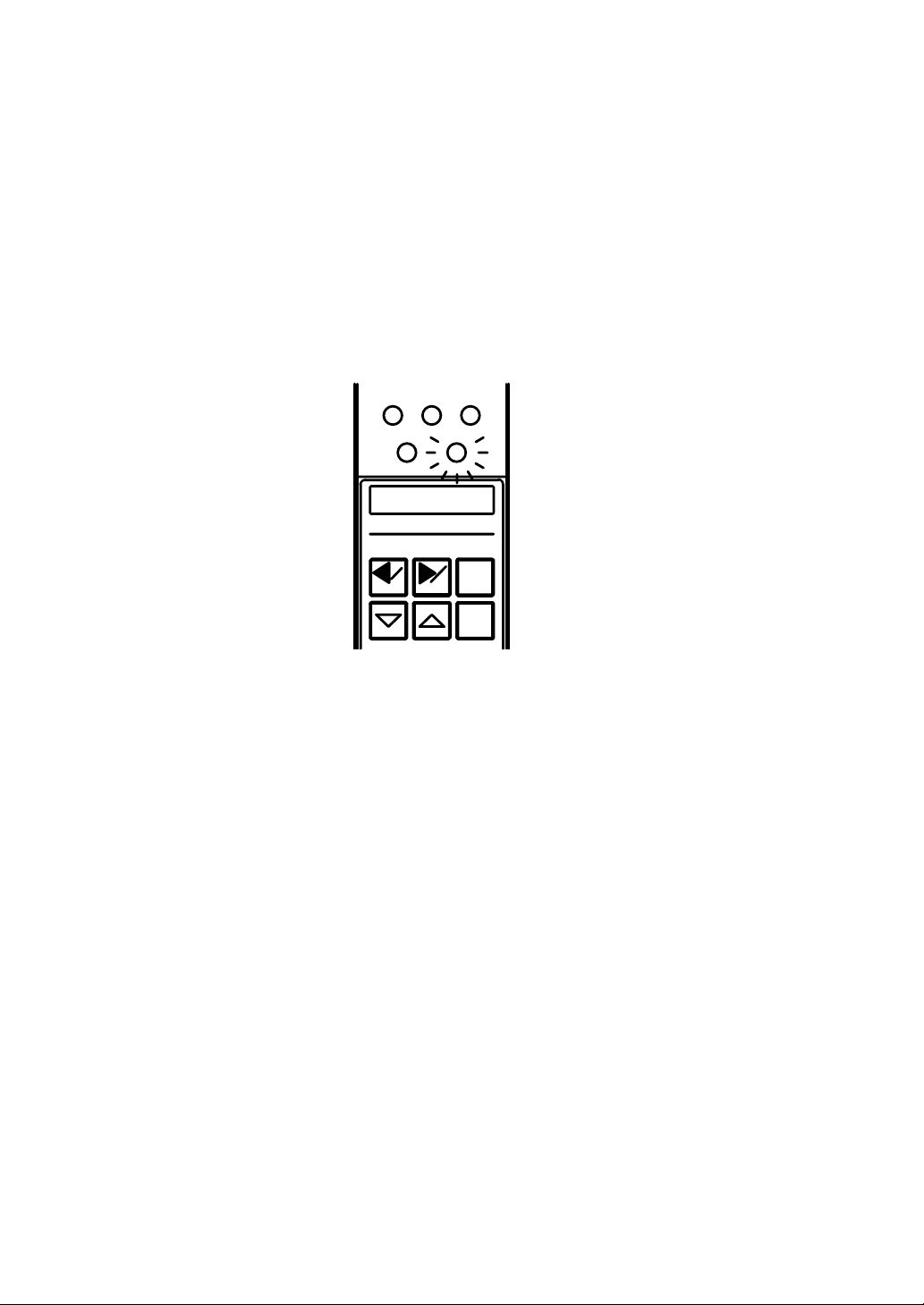

Flashing of MAS LED

The MAS LED flashes orange to indicate that the last mastering data is effective

for the currently selected program and flashes red to indicate that the last

mastering data is not effective for the currently selected program (or the mastering

data is cleared).

Indication on alphanumeric display

“MAS REQ” is shown on the alphanumeric display.

Judgment result output signal (when judgment result output option is added)

The judgment result output signal “MAS OK” is turned off.

213

MAS

SET

MAS REQ

SET MAS

RST

ENT

Fig. 7-4. Master request condition.

(2) Procedure for coping with master request condition

Calibrate the instrument with the masters.

When the MAS LED is flashing orange, the mastering operation can be omitted by

any of steps to below.

Press one of the control keys.

Input a reset command from an external signal or with an external button.

Input a clear master request command through the serial communication

(RS232C). (Refer to “11.1 Serial output”.)

These steps to clear the condition described in in (1) above when the MAS

LED is flashing red, and clear the conditions described in to in (1) above when

the MAS LED is flashing orange.

14

Page 17

7.2 Clearing mastering data

In the measure mode, press for 2 sec or more.

When the MAS LED below the bargraph display is turned on and “MAX M.” or

“MIN M.” is shown on the alphanumeric display (refer to Fig. 7-1), press to

change to the adjust detector mode and show “ADJ.” on the alphanumeric display.

Press to change to the clear mastering data mode and show “MAST CLS”

on the alphanumeric display.

Press to clear the mastering data, show “M. CLS OK” on the alphanumeric

display, and return to the master mode.

SET

SET MAS

Press

213

MAS

ADJ.

RST

ENT

213

MAS

SET

MAST CLS

Press

SET MAS

Fig. 7-5. Clearing mastering data.

RST

ENT

213

MAS

SET

M .CLS OK

SET MAS

RST

ENT

15

Page 18

8. Changing Programs

In the measure mode, press for 2 sec or more.

The SET LED below the bargraph display comes on green, “PROG” appears on

the alphanumeric display, and the instrument changes to the change program

mode.

Measure mode Change program mode

213

SET

PROG

MAS

Press 2 sec

SET

213

MAS

10.0

or more

SET MAS

RST

ENT

SET MAS

RST

ENT

Fig. 8-1. Changing to change program mode.

With “PROG” shown on the alphanumeric display, press . The current

program number is shown on the alphanumeric display.

SET

213

MAS

SET

213

MAS

PROG

2

Press

SET MAS

RST

ENT

SET MAS

Fig. 8-2. Display of current program number.

16

RST

ENT

Page 19

Press or to select the number of the program to be used, and press

r

to determine the selection. The instrument ends the change program mode

and returns to the measure mode.

SET

213

MAS

12.0

213

Decrements

program numbe

SET

2

MAS

SET

213

MAS

7

Increments

program number

Determines

selection

SET MAS

RST

ENT

SET MAS

RST

ENT

SET MAS

RST

ENT

Fig. 8-3. Selecting and determining program number.

X A program number change calls for mastering. A measuring nozzle change may

call for the zero position and sensitivity of the air circuit to be adjusted with the zero

and sensitivity adjustment knobs, respectively.

X When setting any item, select the number of the program to be used before

changing to the set mode.

X When its power is turned on, the instrument starts at the program number selected

last.

17

Page 20

9. Setting

–

Setting relevant items is required for each program to be used. After a program change,

set necessary items. (Refer to “8. Changing Programs”.)

(1) Setting polarity

In the measure mode, press

bargraph display comes on orange, “POL” appears on the alphanumeric display,

and the instrument changes to the set mode.

Measure mode Set mode

213

MAS

SET

10.0

Press 2 sec

or more

SET MAS

Press to show the current polarity on the alphanumeric display, and press

or to change between “+ (ID measurement)” and “– (OD measurement)”.

RST

ENT

Fig. 9-1. Changing to set mode.

for 2 sec or more. The SET LED below the

213

MAS

SET

POL

SET MAS

RST

ENT

213

SET

POL

Press

SET MAS

MAS

Changes

between + and

RST

ENT

Fig. 9-2. Changing polarity.

213

SET

+

SET MAS

MAS

Changes

between + and –

RST

ENT

18

Page 21

Press to determine the selected polarity. The next step is setting the

measuring range, and “RANGE” is shown on the alphanumeric display.

SET

213

MAS

+

213

MAS

SET

RANGE

Determines polarity

SET MAS

RST

ENT

SET MAS

RST

ENT

Fig. 9-3. Determining polarity.

(2) Setting measuring range

Changing the measuring range may call for the A/E converter to be switched over.

When changing the measuring range between 50 and 100 µm, the A/E converter

need not be switched over, but the instrument must be adjusted as described in “10.

Adjusting Zero Position and Sensitivity with Zero and Sensitivity Adjustment Knobs”.

In other cases, contact NIDEC TOSOK.

With “RANGE” shown on the alphanumeric display, press . The current

measuring range is shown. Press or to change the measuring range

to 20, 50, 100, or 200 µm.

SET

RANGE

Press

SET MAS

213

MAS

Changes

measuring range

RST

ENT

213

SET

50

SET MAS

MAS

Changes

measuring range

RST

ENT

Fig. 9-4. Changing measuring range.

19

Page 22

Press to determine the selected measuring range. The next step is setting

the shift value, and “SHIFT” is shown on the alphanumeric display.

SET

213

MAS

100

SET

SHIFT

213

MAS

Determines

measuring range

SET MAS

RST

ENT

SET MAS

RST

ENT

Fig. 9-5. Determining measuring range.

(3) Setting shift value

In the case of a one-side tolerance, for example, the measured value is shown at the

center of the bargraph display. When not using this function, set the shift value at 0.

With “SHIFT” shown on the alphanumeric display, press . The current

notation unit is shown. Press or to change to the tolerance notation

in µm or the nominal notation in mm. Press to determine the selected

notation.

213

SET

SHIFT

Press

SET MAS

MAS

RST

ENT

213

MAS

SET

MM

Changes

notation unit

SET MAS

Changes

notation unit

RST

ENT

Fig. 9-6. Changing notation unit.

20

213

MAS

SET

MICRO

Determines

notation unit

SET MAS

RST

ENT

Page 23

When the tolerance notation is selected, press or to enter the shift

value. When the nominal notation is selected, press or to change

the digit to be set, and press or to enter the shift value. Usually,

enter the median value of the tolerances as the shift value.

SET

213

MAS

0.000

SET

213

MAS

0.000

SET

213

MAS

2.000

Enters shift

value

SET MAS

RST

SET MAS

RST

Enters shift

SET MAS

RST

value

Changes digit

ENT

ENT

ENT

Changes digit

Fig. 9-7. Entering shift value (for nominal notation).

Press to determine the entered shift value. The next step is setting the

judgment upper limit value, and “MAX” is shown on the alphanumeric display.

SET

213

MAS

SET

213

MAS

9.045

Determines

shift value

SET MAS

Fig. 9-8. Determining shift value.

RST

ENT

21

MAX

SET MAS

RST

ENT

Page 24

(4) Setting judgment upper limit value

With “MAX” shown on the alphanumeric display, press . The current

judgment upper limit value is shown. Press or to enter the new

judgment upper limit value.

SET

213

MAS

MAX

SET

213

MAS

9.085

Decrements

Press

SET MAS

RST

ENT

judgment upper

limit value

SET MAS

Increments

RST

judgment upper

limit value

ENT

Fig. 9-9. Entering judgment upper limit value.

Press to determine the new judgment upper limit value. The next step is

setting the judgment lower limit value, and “MIN” is shown on the alphanumeric

display.

SET

213

MAS

SET

213

MAS

9.065

MIN

Determines

SET MAS

RST

ENT

SET MAS

RST

ENT

Fig. 9-10. Determining judgment upper limit value.

22

Page 25

(5) Setting judgment lower limit value

With “MIN” shown on the alphanumeric display, press . The current

judgment lower limit value is shown. Press or to enter the new

judgment lower limit value.

SET

213

MAS

MIN

SET

213

MAS

9.005

Decrements

judgment lower

limit value

SET MAS

Press

RST

ENT

SET MAS

RST

Increments

ENT

judgment lower

Fig. 9-11. Entering judgment lower limit value.

Press to determine the new judgment lower limit value. The next step is

setting the maximum master value, and “MAX M.” is shown on the alphanumeric

display.

SET

213

MAS

SET

213

MAS

9.025

Determines

SET MAS

RST

MAX M.

SET MAS

ENT

Fig. 9-12. Determining judgment lower limit value.

23

RST

ENT

Page 26

(6) Setting maximum master value

With “MAX M.” shown on the alphanumeric display, press . The current

maximum master value is shown. Press or to enter the new

maximum master value.

213

SET

MAX M.

Press

SET MAS

MAS

Decrements

maximum

RST

ENT

213

SET

9.085

SET MAS

MAS

Increments

maximum

master value

RST

ENT

Fig. 9-13. Entering maximum master value.

Press to determine the new maximum master value. The next step is

setting the minimum master value, and “MIN M.” is shown on the alphanumeric

display.

SET

213

MAS

SET

213

MAS

9.065

Determines

SET MAS

RST

ENT

SET MAS

RST

ENT

Fig. 9-14. Determining maximum master value.

When the maximum master value is equal to or smaller than the minimum master

value, “ERR MAS” is shown on the alphanumeric display, the set value returns to

the previous value, and the instrument returns to the condition in step above.

Again enter the new maximum master value.

24

Page 27

(7) Setting minimum master value

With “MIN M.” shown on the alphanumeric display, press . The current

minimum master value is shown. Press or to enter the new minimum

master value.

213

SET

MIN M.

Press

SET MAS

MAS

RST

ENT

Decrements

minimum

master value

213

SET

9.005

SET MAS

MAS

Increments

minimum

RST

master value

ENT

Fig. 9-15. Entering minimum master value.

Press to determine the new minimum master value. The next step is

storing the set values, and “END” is shown on the alphanumeric display.

SET

213

MAS

SET

213

MAS

9.025

Determines

SET MAS

RST

ENT

END

SET MAS

RST

ENT

Fig. 9-16. Determining minimum master value.

When the minimum master value is equal to or greater than the maximum master

value, “ERR MAS” is shown on the alphanumeric display, the set value returns to

the previous value, and the instrument returns to the condition in step above.

Again enter the new minimum master value.

25

Page 28

(8) Storing set values (described in Items (1) to (7) above)

CANC

9.030

When the setting of the minimum master value is finished as the last step of the

setting procedure, “END” is shown on the alphanumeric display. When is

pressed in the middle of the set mode, “END” is also shown. Press to show

“WRITE” on the alphanumeric display.

SET

Press

SET MAS

213

MAS

END

RST

ENT

213

SET

WRITE

SET MAS

MAS

RST

ENT

Fig. 9-17. Ending setting.

Press or to select “WRITE” or “CANCEL”, and press to

determine the selection. When “WRITE” is selected, the current set values are

stored. When “CANCEL” is selected, the current set values are canceled, and

the previous set values are made effective. After this determination, the

instrument ends the set mode and returns to the measure mode.

SET

Changes

SET MAS

213

MAS

EL

Changes

RST

ENT

213

MAS

SET

WRITE

Determines

SET MAS

Fig. 9-18. Storing set values.

RST

ENT

26

Measure mode

213

MAS

SET

SET MAS

RST

ENT

Page 29

10. Adjusting Zero Position and Sensitivity with Zero

and Sensitivity Adjustment Knobs

The zero position and sensitivity of the air circuit need not be adjusted, except after a

measuring head change or after the output of the mastering result NG due to wear.

10.1 Adjusting

In the measure mode, press for 2 sec or more.

The MAS LED below the bargraph display comes on, and “MAX M.” or “MIN M.”

appears on the alphanumeric display. Press to change to the adjust

detector mode. The alphanumeric display shows “ADJ.” for 2 sec and then the

measured value.

213

MAS

SET

12.3

Press 2 sec or more

SET MAS

RST

ENT

213

MAS

SET

MIN M.

SET MAS

Press

Fig. 10-1. Changing to adjust detector mode.

RST

ENT

213

SET

ADJ.

SET MAS

MAS

RST

ENT

27

Page 30

Press to double the indicating range of the bargraph display and show the

measured value on the bargraph and alphanumeric displays.

Maximum

master value

(green)

Minimum

master value

(green)

Press

1

2

3

MAS

SET

10.0

Fig. 10-2. Doubling indicating range.

1

SET

2

10

Maximum

master value

Minimum

master value

3

MAS

28

Page 31

Set the minimum master in the measuring head, and turn the zero adjustment

knob to set the indication at the minimum master value.

SET MAS

RST

ENT

Set indication at

CAG

2000

minimum master

value

Set minimum master

in measuring head

MAG

and turn knob

1

2

ZERO

SET

GAGE

3

MAS

Fig. 10-3. Adjusting zero position.

Set the maximum master in the measuring head. If the indication is about the

maximum master value, the adjustment is finished.

Adjustment

finished

Fig. 10-4. Finishing adjustment with zero and sensitivity adjustment knobs.

When the indication is not in the automatic mastering range (or the bargraph

display is illuminated red), refer to “10.2 Indication below mastering range” on

page 31 or “10.3 Indication above mastering range” on page 32.

29

Page 32

After the adjustment is finished, press to change to the master mode and

show “MIN M.” on the alphanumeric display. For automatic mastering, refer to “7.

Mastering”.

213

SET

MAS

12.0

Press

SET MAS

When returning to the measure mode without automatic mastering, press .

Master mode Measure mode

SET

RST

ENT

Fig. 10-5. Changing to master mode.

213

MAS

213

SET

MAS

MIN M.

SET MAS

213

SET

MAS

RST

ENT

12.3

SET MAS

Fig. 10-6. Returning to measure mode.

RST

ENT

SET MAS

30

12.3

Press

RST

ENT

Page 33

10.2 Indication below mastering range

–

(1) When the indication does not reach the mastering range, the instrument is insufficient

in sensitivity. With the maximum master set in the measuring head, turn the

sensitivity adjustment knob clockwise so that the indication exceeds the maximum

master value by about 5 times the insufficiency from the maximum master value.

(2) Turn the zero adjustment knob clockwise to set the zero position at the maximum

master value.

Maximum

master value

Insufficiency

of 30 µm

Insufficiency × 5 + Maximum master value

= 30 × 5 + 20

= 170

However, alphanumeric display cannot

show more than 100

1

2

SET MAS

10

CAG

RST

ENT

2000

MAG

Z

ERO

GAGE

SET MAS

Turn to bring

indication to

SET MAS

3

Turn to bring

indication to 100

maximum master

CAG

RST

ENT

2000

MAG

ZERO

GAGE

value

Fig. 10-7. Adjusting for indication below mastering range.

(3) Set the minimum master in the measuring head. When the indication is about the

minimum master value, the adjustment is finished.

When the indication is not about the minimum master value, turn the zero adjustment

knob to bring the indication to the minimum master value. Set the maximum master

in the measuring head. If the indication does not come to about the maximum

master value, repeat steps (1) and (2) in 10.2 or 10.3.

31

Page 34

10.3 Indication above mastering range

(1) When the indication is above the mastering range, the instrument is excessive in

sensitivity. With the maximum master set in the measuring head, turn the sensitivity

adjustment knob counterclockwise so that the indication is returned from the

maximum master value by about 5 times the excess from the maximum master

value.

(2) Turn the zero adjustment knob counterclockwise to set the zero position at the

maximum master value.

Excess of

22 µm

1

2

SET MAS

Maximum master value – (Excess × 5)

= 20 – (22 × 5)

= –90

Maximum

master value

3

CAG

RST

ENT

2000

MAG

ZERO

GAGE

SET MAS

Turn to bring

indication to –90

CAG

RST

ENT

2000

MAG

ZERO

GAGE

SET MAS

Turn to bring indication

to maximum master

value

42

Fig. 10-8. Adjusting for indication above mastering range.

32

Page 35

(3) Set the minimum master in the measuring head. When the indication is about the

minimum master value, the adjustment is finished.

When the indication is not about the minimum master value, turn the zero adjustment

knob to bring the indication to the minimum master value. Set the maximum master

in the measuring head. If the indication does not come to about the maximum

master value, repeat steps (1) and (2) in 10.2 or 10.3.

33

Page 36

11. I/O Description

11.1 Serial output (RS232C)

(1) Description

This instrument can output the measured values to a printer and communicate with a

personal computer through RS232C.

Command Symbol

Hold measured value E

Clear measured value hold

Clear master request

Request measured value D

Minimum-mastering N

Maximum-mastering X

Change to Program 1 P01

Change to Program 4 P04

(2) Preparation

The RS232C connector at the rear of the instrument is provided for the personal

computer or printer. Connect the D-sub 9-pin (male) plug of an optional

communication cable to the RS232C connector. Three types of optional

communication cables are available for specific applications. For details, refer to

“13. Options”.

(3) Setting serial port

R

Baud rate: 9600

Bits/character: 8

Stop bit: 1

Start bit: 1

Parity bit: None

34

Page 37

(4) Transmitting measured values

Commands to instrument

Command Data type Symbol

Data transmitted to personal computer

Character string EHold measured value

ASCII 45H

Character string RClear measured value hold

ASCII 52H

Character string DRequest measured value

ASCII 44H

Measured value SP

*SP represents a space character.

In the measure mode, press . The measured value is held and transmitted

to the personal computer. The data transmission is disabled when the mastering

result is NG.

Judgment

result

20 0D 0A

CR LF

35

Page 38

(5) Automatic mastering

The master request condition can be cleared, and the instrument can be calibrated

with the minimum and maximum masters.

Commands to instrument

Command Data type Symbol

Character string RClear master request

ASCII 52H

Character string NMinimum-mastering

ASCII 4EH

Character string XMaximum-mastering

ASCII 58H

Calibrate the instrument with the minimum and maximum masters in that order.

Data transmitted to personal computer

When automatic mastering is performed through the serial communication, one of

the data shown in the table below is returned back.

Instrument condition Data type Externally returned data

Character string @ 0 O K SP SP SP M A S SP SP SP CR LFMastering result OK

ASCII (hex) 40304F4B2020204D41532020200D0A

Character string @ 0 E R R 0 1 Z E R O M 1 CR LFZero position

ASCII (hex) 403045525230315A45524F4D310D0A

Character string @ 0 E R R 0 4 G A I N M 1 CR LFSensitivity

ASCII (hex) 403045525230344741494E4D310D0A

Character string @ 0 E R R 0 7 R E V SP M 1 CR LFMasters reversed

Mastering error

Other than above

ASCII (hex) 40304552523037524556204D310D0A

Character string @ 0 E R R 1 0 O F F R M 1 CR LF

ASCII (hex) 403045525231304F4646524D310D0A

*SP represents a space character.

36

Page 39

(6) Changing programs

A change can be made to programs 0 to 9.

Commands to instrument

Command Data type Symbol

Character string P 0 1Change to program 1

ASCII 50H 30H 31H

Character string P 0 4Change to program 4

ASCII 50H 30H 34H

Data transmitted to personal computer

When a program change is made through the serial communication, one of the

data shown in the table below is returned back.

Instrument condition Data type Externally returned data

Change to program 1

finished

finished

Character string @ 0 P R O G 1 CR LF

ASCII 40H 30H 50H 52H 4FH 47H 31H 20H 20H 20H 20H 20H 20H 0DH 0AH

Character string @ 0 P R O G 2 CR LFChange to program 4

ASCII 40H 30H 50H 52H 4FH 47H 32H 20H 20H 20H 20H 20H 20H 0DH 0AH

37

Page 40

(7) Changing program and mastering timing charts

The commands cannot be executed in combination, but must be executed

individually.

(I: Transmission to CAG/CEG2000, O: Reception from CAG/CEG2000)

I: Change program

0.2 sec or less

O: Return 1

→←

I: Minimum-mastering

0.2 sec or less

O: Return 2

→←

I: Maximum-mastering

O: Return 3

0.2 sec or less

→←

I: Clear master request

O: Return 2

0.2 sec or less

→←

38

Page 41

11.2 External input

(1) Description

Using external buttons and a foot switch, the instrument can:

Measure a work.

Reset itself.

Be calibrated with the minimum master.

Be calibrated with the maximum master.

Note: Do not use the instrument through relay contact input.

(2) Preparation

The SW. ETC connector at the rear of the instrument is provided for external buttons.

It accepts a D-sub 15-pin (male) plug.

(3) Connector pin arrangement

Description No.

1

2

3

4

5

GND 6

Measure button 7

RESET button 8

Fig. 11-1. Pin arrangement diagram of SW. ETC connector at rear of instrument.

(4) Operation with external buttons

Measure button

(a) In the measure mode, press the measure button.

(b) The measured value is held. (This is called the hold measured value

condition.)

Note: The measured value cannot be held when the mastering result is NG.

RESET button

No. Description

9 Maximum master button

10 Minimum master button

11

12

13

14

15

Clears the measured value hold.

39

Page 42

Minimum master button

(a) In the measure mode, set the minimum master in the measuring nozzle.

(b) When the bargraph display is stabilized, press the minimum master button.

(c) The instrument is calibrated with the minimum master and readied for

calibrating itself with the maximum master (this is called the maximum-

mastering ready condition).

Maximum master button

(a) In the maximum-mastering ready condition, set the maximum master in the

measuring nozzle.

(b) When the bargraph display is stabilized, press the maximum master button.

(c) The instrument is calibrated with the maximum master and returns to the

measure mode.

(d) When a mastering error occurs (refer to step in “7.1 Automatic mastering”),

use the control keys on the instrument to clear the mastering error.

40

Page 43

12. Model Identification

CAG 20 00 –2 –DP

External input/output

None: Standard

DP: Digimatic output

DC: Judgment result output

DR: Rank output

BC: BCD output

A/E input

None: 1 channel

2: 2 channels

Measuring range

02: 20 µm

05: 50 µm

10: 100 µm

20: 200 µm (option)

Model number

20

Basic model designation

CAG

41

Page 44

13. Options

(1) Instrument

Measuring range : 200 µm

— Effective measuring range: 160 µm (with linear compensation)

Digimatic output: Output to printer (DP1), for example

Judgment result output : 12/24 VDC

Rank output : 12/24 VDC

BCD output : 12/24 VDC

(2) Separately sold parts

Filter (CAG2000-OP-AF): Air filter + Mist separator

Filter (CAG2000-OP-AFA): Air filter + Mist separator (with automatic drain)

Regulator (CAG2000-OP-AR): Precision regulator

Communication cable (CAG2000-OP-CB-1): D-sub 9-pin connector (EIA-232) for

Communication cable (CAG2000-OP-CB-2): D-sub 25-pin connector (EIA-574) for

personal computer

personal computer

Communication cable (CAG2000-OP-CB-3): D-sub 25-pin connector (EIA-574) for

printer

42

Page 45

14. Maintenance

(1) The air filter is clogged as it is used for a long period of time. Change the air filter

element after two years of use or when the pressure drop reaches 0.1 MPa.

(2) Cleaning A/E converter

When the A/E converter is used for a long period of time, oil and dust may

accumulate in the air circuit. Clean the A/E converter as described below.

Record the approximate installation position of the zero and sensitivity adjustment

knobs at the front of the instrument (or the distance of each knob from the edge).

This record facilitates mastering after cleaning.

Turn the zero and sensitivity adjustment knobs counterclockwise, and remove

them from the instrument.

Check the O-ring of each needle. If the O-ring is damaged, change it.

If the needle is dirty, clean it. Dampen a cotton swab with alcohol, and use it to

clean the φ3 mm hole into which the needle enters.

Replace the needle in each knob. If the split screw is loose, expand it with the tip

of a flat-end screwdriver. Take care not to overbend the split screw.

Turn the needle of each knob clockwise, and install the knobs in the original

position recorded at first. Adjust the zero position and sensitivity of the air circuit

with the zero and sensitivity adjustment knobs, respectively, and calibrate the

instrument with the minimum and maximum masters.

43

Page 46

15. Troubleshooting

Phenomenon Cause Remedy

Repeatability is not stable.

Zero adjustment knob is

ineffective.

Bargraph display does not

operate.

Air supply pressure is not

stable.

Regulator is

malfunctioning.

Measuring nozzle is worn. Change it.

Piping and joints are

leaking.

Entry of moisture or oil

causes trouble to

instrument.

Air supply pressure is too

low or high.

Piping and joints are

leaking.

Gap of measuring nozzle

is too small.

Gap of measuring nozzle

is too large.

Specified power is not

supplied.

Set regulator source

pressure at 300 kPa or

more.

Overhaul or change it.

Check for leakage, and

retighten.

Clean instrument.

Set regulator at 196 kPa.

Check for leakage, and

retighten.

Adjust to proper gap.

Adjust to proper gap.

Supply power of 85 to 264

VAC.

Bargraph and alphanumeric

displays are not illuminated.

Zero position of air circuit

is improperly adjusted.

Instrument is in hold

measured value mode.

Bargraph display is

illuminated green or red

(dark).

Instrument is in set mode. End set mode.

Power is not supplied. Supply power of 85 to 264

Fuse is blown. Change it.

Power supply or internal

circuit is faulty.

Calibrate instrument with

masters.

Press to clear this

condition.

VAC.

Ask NIDEC TOSOK for

repair.

44

Page 47

16. Cautions

(1) Air supply

Supply clean air free from dust, moisture, and oil. Drain the air filter once per day or

more frequently.

(2) Power cable

The power cable supplied as standard accessory is for 100 V. If you use supply

voltage in excess of 125 V, separately prepare a 250-V power cable.

(3) Control keys

Never operate the control keys with a sharp-pointed tool or the like.

(4) Export

When you try to export this instrument overseas, you may have to have the export

approved by the Ministry of Economy, Trade and Industry under the Export Trade

Control Ordinance. In such a case, contact your nearest NIDEC TOSOK sales

office.

(5) Specifications

The specifications are subject to change without notice.

45

Page 48

17. Operation Flow

46

Page 49

474849

Page 50

Page 51

Page 52

HEAD OFFICE 2-215 SOBU-DAI ZAMA CITY, KANAGAWA PREF. 228-8570 JAPAN

URL http://home.tosok.co.jp/

PRECISION MACHINERY SALES DEPT.

OVERSEAS SALES GROUP

TEL 81-46-252-3132〜3

FAX 81-46-252-3191

HOMEPAGE

This manual is printed on recycled paper.

Loading...

Loading...