SHIMPO 933 User Manual

TD-522 (06/01)

Model 933A

Life Cycle Test System

Software / Hardware Manual

NOTICE

Microsoft Windows, Windows 95, Windows 98, Windows ME, Windows 2000 and

Windows NT are registered trademarks of Microsoft Corporation.

The Model 933A application software operates in a graphical environment named

Microsoft Windows, created by Microsoft Corporation. Microsoft Windows gives a

standard look and feel to TRICOR’s application as well as all other Windows

applications.

In order to run the Model 933A application under Microsoft Windows, the user needs to

license and install a Microsoft Windows version listed in Section 2, Getting Started.

2

Contents

Section Page

1 Introduction......................................................................................................... 4

2 Getting Started .................................................................................................... 6

3 Testing ............................................................................................................... 11

4 Configuration .................................................................................................... 18

5 Test Results ...................................................................................................... 25

6 Force and Speed .............................................................................................. 27

3

Section 1

Introduction

Tester Description

The Model 933A Life Cycle Test System (LCTS) is a complete and ready to use piece of

test equipment for the endurance testing of materials and electrical switches. The LCTS

can be configured to continuously depress a test sample using a pneumatically

controlled cylinder. The Model 933A is designed to measure one electrical contact with

each up/down stroke according to ASTM Designation F1578 - 96. The LCTS can also

be used to mechanically stress a device without a contact measurement. In this case,

testing is performed at a fixed speed and there are no pass / fail results. The air pressure

to the cylinder can be adjusted to control the maximum force applied to the sample and

with the optional flow restrictors the rate at which this force is applied can also be

adjusted. The electrical contact can be tested for resistance and also bounce. Bounce is

measured using techniques described in the ASTM Designation F1661 - 96. These

measurements have tolerances assigned so that the LCTS can determine the pass / fail

status of each test cycle. A count is kept of all cycles, failures and sequential test

failures. These counts are compared against programmed limits to stop testing at user

defined events. For example, the testing can be stopped after 1,000,000 test cycles or

after 100 test failures.

The basic LCTS consists of:

Controller Unit - containing the pneumatic air valves, pressure regulator,

pressure gauge, air couplings, electronics module and computer data

connector.

Power Module - a wall mount power source.

Test Head - consisting of the air cylinder, flexible air hose and quick disconnect

air coupling (with an adjustable slide post) and mounting hardware.

Test Stand - an 8-inch base plate to which the Test Head slide post can be

mounted.

Data Cable - a 20 foot cable with modular connectors on each end and a 9-pin

adaptor to attach to the user’s PC.

Application Software - a single software application to communicate, control and

store data from the Controller Unit. This is provided on a CD.

4

The application software can configure all the programmable features of the LCTS

including test times, resistance and bounce tolerances and maximum event counts. It

has a “learn” mode for switches to automatically set test tolerances and a mode for

manual operation and contact measurement. The software can be set up to store the test

results to an open file. The file format is comma delimited text which is easily imported to

other programs such as Microsoft Excel and Access. The text file format is directly

readable by both of these programs. The configuration setup of the LCTS can also be

stored and recalled from files. All test data is viewable on the main application screen.

The software application will run on any of Microsoft’s 32-bit Windows Operating

Systems. It will not function on Windows 3.11 or earlier versions.

5

Section 2

Getting Started

General

This section is for new users and describes the installation and hookup of the Life Cycle

Test System. The user supplied resources are discussed and verification of proper setup

is provided.

User Supplied Resources

The LCTS uses shop air to drive the pneumatic air cylinder. There is a coupling on the

back of the Controller Unit which will accept a standard 1/4 inch NPT quick disconnect

hose coupling. The user must supply the air using a sleeve lock socket. The maximum

air pressure must be limited to 150 psi. Standard pressures of 85 to 125 psi are best.

The air must be clean and free of water and oil. The air exhausted from the air cylinder is

expelled into the Controller Unit. Excessive liquids will build up in the Controller Unit

and may cause failure. An air dryer is recommended. Only compressed air should be

used. No other gasses are approved.

Controller Unit power is powered by a wall mount power source. The basic unit comes

complete with an American style, 115 vac, 60 Hz module. Other variations are available

from TRICOR Systems by special request. A suitable power receptacle must be located

near the LCTS so that the Power Module can be connected.

User Supplied Computer

A personal computer running any 32-bit version of Microsoft Windows is required to

configure the LCTS and to download test data. Any version of Windows 95, Windows

98, Windows Me, Windows 2000 or Windows NT version 4.0 can be used. The computer

does not need to be located at the same sight where testing will occur, but it is much

more convenient if it is. The LCTS can operate stand-alone, and can be configured at a

different location. It then can be moved to the sight of the testing. The LCTS is connected

to a serial port on the PC. The LCTS comes with a 20 foot cable with modular

connectors on each end. One end plugs into the back of the Controller Unit. The other

end of the cable plugs into the modular connector of a 9-pin D connector adaptor which

is also supplied. The adapter plugs into the serial communication port of the user’s PC.

A special order, 25-pin version of the adaptor can be obtained from TRICOR Systems.

The PC must have one active serial port available. The application software will

automatically search all available ports in an attempt to locate the LCTS. The

application software is delivered on CD-ROM. The PC must have a CD-ROM drive to

install this software. By special request when ordering the LCTS, TRICOR Systems can

provide the application on floppy disks.

6

Software Installation

Begin the setup process by installing the application software. This software is on the

CD provided with the basic unit. Since you are viewing the manual provided on this disk

it is assumed that the installation should be complete. If not, follow the instructions

below.

• Close all other windows applications before starting the installation.

• Insert the 933A Software installation CD in the CD disk drive of your computer.

On most systems, the installation program will begin running as soon as the

computer sees the disk inserted. If not, navigate to CD file folder using Windows

Explorer or My Computer. Double click the setup.exe file.

• The installer will ask you to shut down any other applications that may be running.

Press the OK button if you have already closed other programs.

• A dialog box will appear which will allow you to change the location on your harddrive where the 933 application will be stored. You may change this location if

necessary, but TRICOR recommends the default setting. Press the large button

(top left) on this dialog to begin the installation.

• A second dialog appears that allows the name of the program group on the start

button menu to be changed. Again, TRICOR recommends that the default setting

be used.

• The software installs quickly and a dialog indicating successful completion

should appear. Click OK. The Life Cycle application software is now ready to

use.

7

Test Contacts

Terminal Connection

Air Cylinder Coupling

Air Inlet Coupling

Expansion Connector

Serial Data Connector

Power Connector

Figure 1.

Back of Control Unit

Equipment Setup

Connect a supply of air to the air inlet coupling on the back of the Control Unit (Figure 1).

This fitting accepts a 1/4 NPT quick disconnect sleeve lock socket.

The Test Head is delivered mounted on the slide post. Attach the slide post to the base

plate using the 1/4 x 20 screws and washers found in the mounting hardware plastic

bag. See Figure 2 for details.

Connect the Test Head air hose connector to the air cylinder coupling on the back of the

Control Unit (Figure 1). This connector can be released by depressing the metal thumb

slide on the air cylinder coupling. This coupling/connector should be coupled together

whenever power is applied to the Control Unit to prevent air from escaping. Adjust the

pressure regulator on the front panel of the Control Unit for at least 40 psi on the gauge.

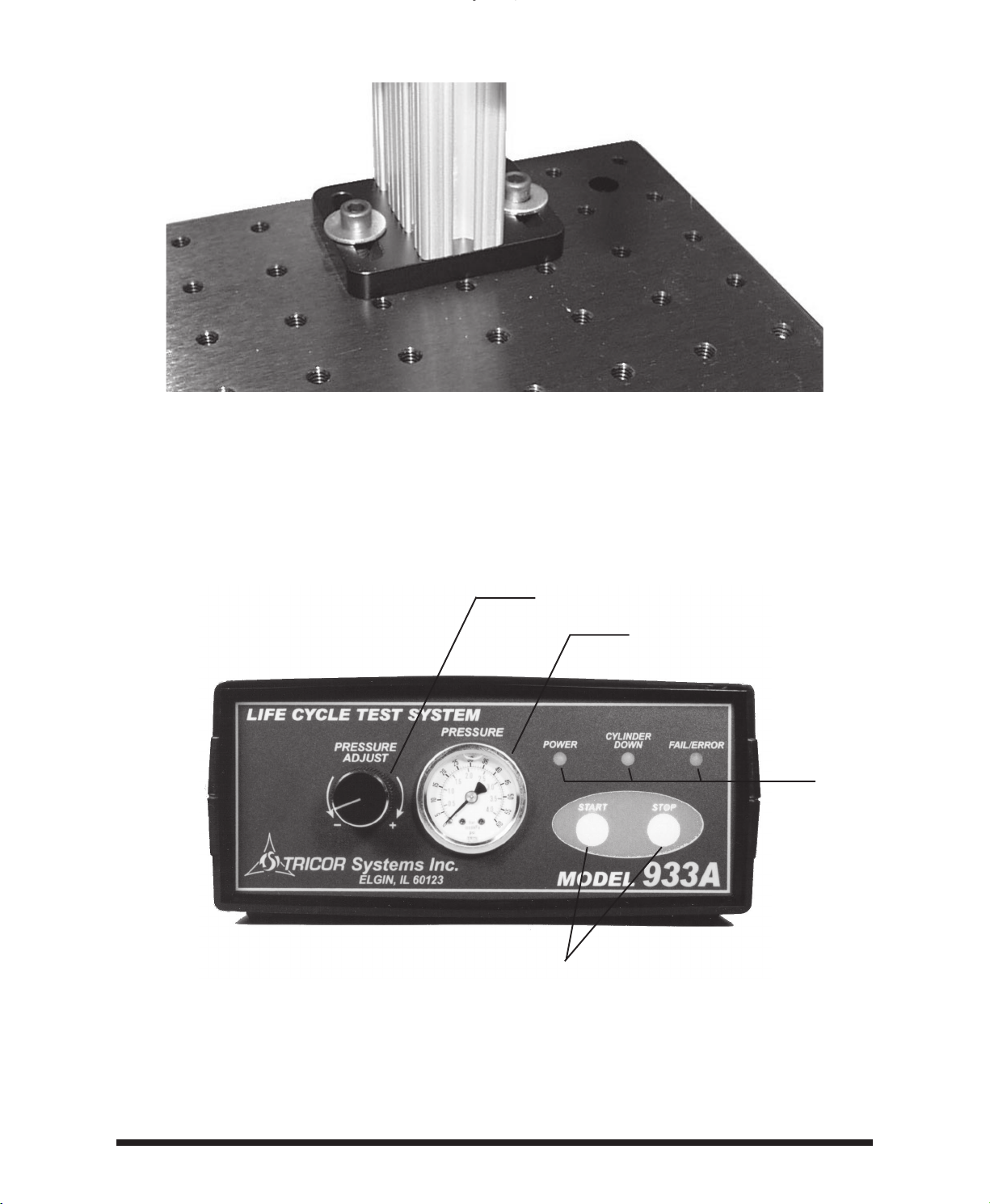

Connect the Power Module cable to the power connector on the back of the Control Unit

(Figure 1). Plug the Power Module into a suitable power source receptacle. The Control

Unit should now be powered with the power status indicator on the front of the Control

Unit illuminated. See figure 3. The air cylinder should be pulled to the retracted position.

The LCTS does not need a computer connected to operate. The Control Unit is shipped

8

Figure 2.

Slide Post Mounted to Base Plate

Force Adjustment

Pressure Gauge

Status Indicators

Control Switches

Figure 3.

Control Unit Front Panel

9

Loading...

Loading...