Page 1

Contents

1 INTRODUCTION ................................................................................. 1.1

2 SETUP AND INTERCONNECTION .................................................... 2.1

2.1 Hardware ..................................................................................... 2.1

2.2 PC Connection............................................................................. 2.1

2.3 Software....................................................................................... 2.1

2.4 Precision Drive Mechanism Setup/Connection ............................ 2.3

2.5 Electrical Resistance Connection (Optional)................................ 2.4

2.6 Generic Nest Assembly Connection (Optional) ........................... 2.4

2.7 User Nests ................................................................................... 2.4

2.8 Force Transducer Tips ................................................................. 2.4

2.8.1 Interchangeable Force Transducer Tips ......................... 2.4

2.8.2 75 g, 360 g and 750 g Transducer Tips .......................... 2.7

2.9 Changing Force Transducer Assemblies ..................................... 2.7

3 CONFIGURATION ............................................................................... 3.1

3.1 Turn-On ....................................................................................... 3.1

3.2 Self-Test ...................................................................................... 3.1

4 OPERATION........................................................................................ 4.1

4.1 Calibration Mode .......................................................................... 4.1

5 SERVICE & ADJUSTMENTS .............................................................. 5.1

5.1 Service Mode ............................................................................... 5.1

5.1.1 Force Calibration ............................................................. 5.1

5.1.2 Resistance Offset (Resistance Option Only)................... 5.2

5.1.3 Lamp Test ....................................................................... 5.2

5.1.4 Resistance CCA Code/Switch Installed

(Resistance Option Only) ................................................ 5.2

5.1.5 Pressure Code ................................................................ 5.2

5.1.6 Displacement Verification ............................................... 5.3

6 TROUBLESHOOTING ........................................................................ 6.1

Appendix A Restrictions and DF Warning / Problem / Failure Message

Descriptions

Appendix B Force Transducer CCA Calibration

Appendix C Resistance Adjustment / Verification

Appendix D Displacement Verification Procedure

ii

Page 2

SECTION 1

INTRODUCTION

The Model 921A Displacement - Force (DF) Test Station operation is similar

to the highly acclaimed Models 951A and 961A Test Stations. The high

accuracy and many of the features of the 951A and 961A have been

incorporated in the 921A. Testing on the 921A is performed using remote

test fixtures similar to the 961A. The remote operation permits testing a wide

variety of components/devices and also allows the 921A to operate as part of

a fully automated test line. Keyboards, springs, switches and other

components requiring measurement of displacement, force, or resistance

(one channel optional) can be tested manually, individually or with automatic

feed. The 921A is also ideally suited for engineering investigation and new

product development. Table 1-1 lists the specifications of the 921A.

When interfaced with a personal computer (PC), the resulting test data can

be viewed, analyzed, and printed. The 921A stores test criteria for one test

configuration. To assure simplicity of operation and efficient, effective, errorfree use by anyone, the test station displays operator prompts and provides a

minimum of operator controls: a MODE switch and a TEST switch.

Three operating modes are featured: 1) Local - a pass/fail indication is

provided during standalone operation, test results are not stored; 2) PC - a

PC interfaces with the test station and is used to configure device test criteria

and view stored test results; and 3) Engineering - test data is logged for

every 0.0001 inch of travel and is available for viewing at the PC.

The 921A features a precision lead-screw drive mechanism used to trip the

device under test which serves to guarantee repeatability of results.

Prior to testing, the operator must perform a calibration cycle (refer to section

4.1). Testing cannot be initiated until a calibration cycle has been performed.

1.1

Page 3

TABLE 1-1

MODEL 921A DISPLACEMENT - FORCE TEST STATION

SPECIFICATIONS

Power Requirements 115/220 V ac, 50/60 Hz, 230 VA

Test Cycle Time 6 to 10 seconds typ

Resistance Test Current 10 mA standard*

Resistance Measurement One (Optional)

Channels

Displacement*

Range: 6.25 to 62.51 mm (0.246 to 2.461 inches)

standard*

Resolution: 0.00254 mm (0.0001 inch)

programmable

Abs Accuracy†: ±0.00762 mm (±0.0003 inch) max

±0.00254 mm (±0.0001 inch) typ

±0.00762 mm (±0.0003 inch) max

±0.00254 mm (±0.0001 inch) typ

Force*

Range: 0 to 3.6 kg (0 to 8 lb)

Resolution: 1 g (0.035 oz)

Abs Accuracy: ±0.25% of fsc max, ±0.2% of fsc typ

Repeatability: ±0.1% of fsc max, ±0.05% of fsc typ

Resistance* (Optional)

Range: 0 to 4 5

Resolution: 1 m5

Abs Accuracy: ±0.25% of fsc max, ±0.1% of fsc typ

Repeatability: ±0.1% of fsc max, ±0.05% of fsc typ

* Other ranges available.

† Related to free position.

standard*

standard*

1.2

Page 4

The test sequence is initiated by pressing the TEST switch or externally by the

PC. During the test sequence, sensor data is logged in 921A memory. Test

data is then analyzed, parameters are calculated, and the results are

compared with the configuration criteria to determine a pass or fail status. The

PASS or FAIL indicator then illuminates. Upon completion of the test

sequence, the 921A is ready to test the next device.

The 921A stores test criteria for one device configuration and up to 32 test

results (PC operating mode) in non-volatile memory so that once loaded the

station will retain the test criteria even upon power-down. Device

configurations are identified by device part numbers. The operator's display

indicates which device is currently being tested by displaying the part number

of the device in the left-hand corner of the display.

For a complete description of operating modes, configuration parameters, test

results, test algorithms and the details for creating configurations and viewing

results, refer to the DFR Operations Software Manual.

1.3

Page 5

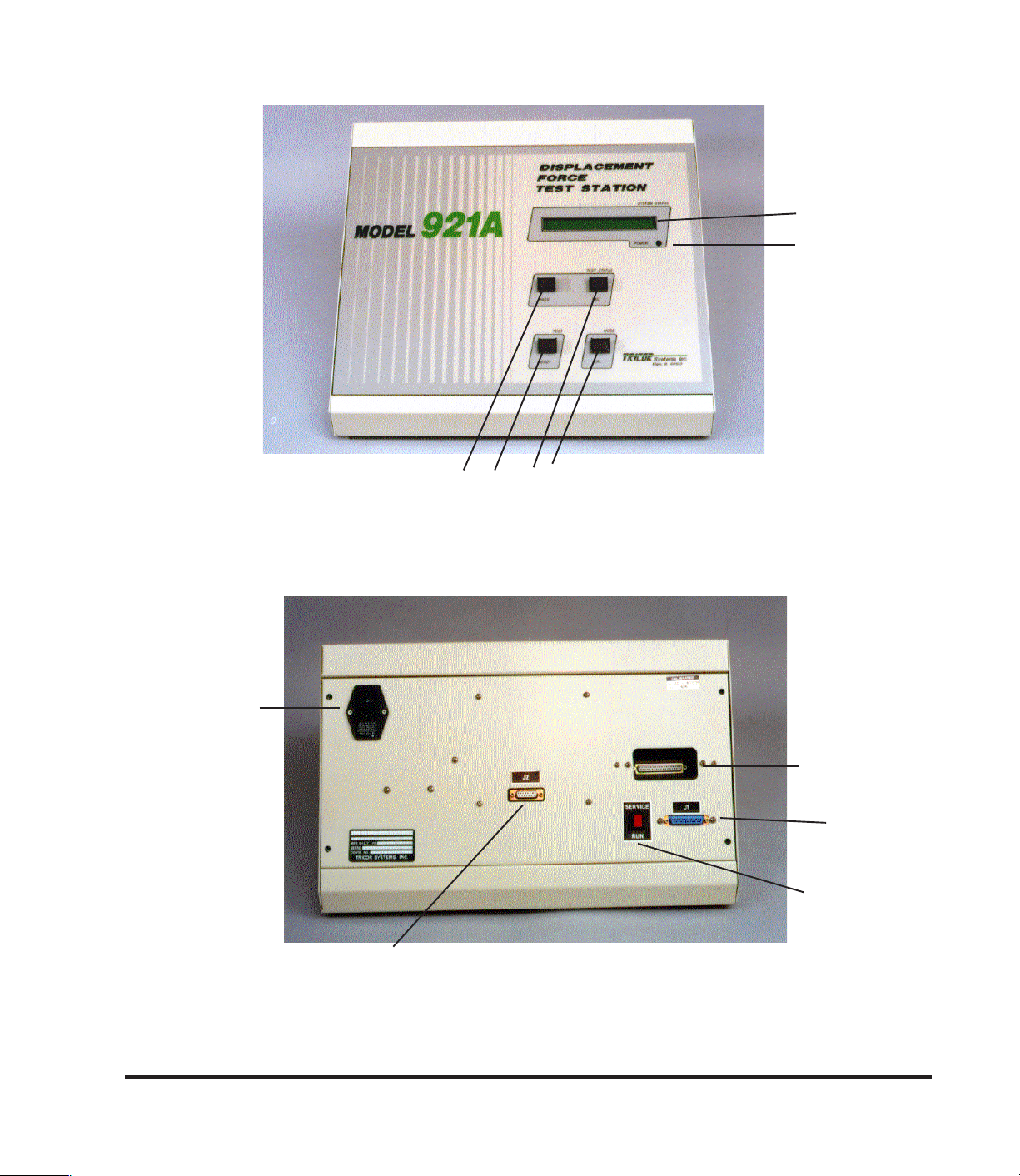

F G

HI

FRONT PANEL

K

J

2-204-3

C

E

BACK PANEL

Figure 1.1 921A Controls and Indicators

D

A

B

2-204-4

1.4

Page 6

TABLE 1-2

CONTROLS AND INDICATORS

(Refer to Figure 1.1)

A - Back Panel Connector J1 — the serial communication channel

connector used to connect the 921A to a PC using the supplied serial

cable (Figure 1.4 or 1.5).

B - SERVICE/RUN Select Switch — active only when power is first

applied to the 921A. This switch is placed in the RUN position for

normal operation. When the switch is placed in the SERVICE

position, the 921A is in the Service Mode where internal

instrumentation circuits can be adjusted

and various system functions checked.

C - Power Switch / Back Panel Input Power

Module

—

consists of the following:

1) Input power voltage selection permits selecting 110-120 V ac or

220-240 V ac operation by positioning

the slideout voltage selector as

Slideout Panel

indicated in section 2.1.

2) The slideout voltage selector panel contains two fuses. Remove

the slideout panel to access the fuses.

3) Contains the male connector for the power

cord.

4) Contains the power On/Off switch.

D - Precision Drive Mechanism — includes the

motor, lead screw, and precision guide and sensor

used to apply the force to the device under test.

The connector on the corrugated cable of this

assembly is connected to the rear (D) of the 921A

electronics unit.

Precision Drive Mechanism

(Cover Removed)

Force Sensor

1.5

Page 7

TABLE 1-2

CONTROLS AND INDICATORS (Cont.)

E - Back Panel Resistance Connector J2 (optional) — the electrical

resistance connector used with the resistance cable PN 921-112 to

connect 921A to generic or user nests.

F - TEST STATUS PASS Indicator — illuminates green after a test

cycle in which the device being tested passes all of the specified

parameters (within tolerance).

G - TEST Switch / READY Indicator — has two functions:

1) The READY indicator illuminates when the 921A is ready for

another device test sequence. The indicator extinguishes when a

test sequence is initiated or if the 921A is not ready to accept a

device for test.

2) The TEST switch is a pushbutton switch which, when illuminated,

is pressed to initiate a test sequence. This switch is also used to

initiate a calibration cycle when the 921A is in Calibration Mode.

NOTE: The READY indicator does not indicate when to press the TEST

switch. Its function is only to indicate that the 921A is ready for

another test cycle.

H - TEST STATUS FAIL Indicator — illuminates red after a test

sequence in which a device fails one or more of the specified test

parameters (out of tolerance).

I -MODE Switch / CAL Indicator — has two functions:

1) The MODE switch is used to initiate a calibration cycle.

2) The CAL indicator illuminates green when the 921A is in the

Calibration Mode.

1.6

Page 8

TABLE 1-6

CONTROLS AND INDICATORS (Cont.)

J - POWER Indicator — illuminates green when the 921A is turned on

with power applied.

K - SYSTEM STATUS Operator's Display — contains two 40-

character lines which supply information about 921A operation, such

as the part number and version of the device configuration being

tested. This display also prompts the operator concerning necessary

actions, such as "Install Device and Press Ready," etc.

1.7

Page 9

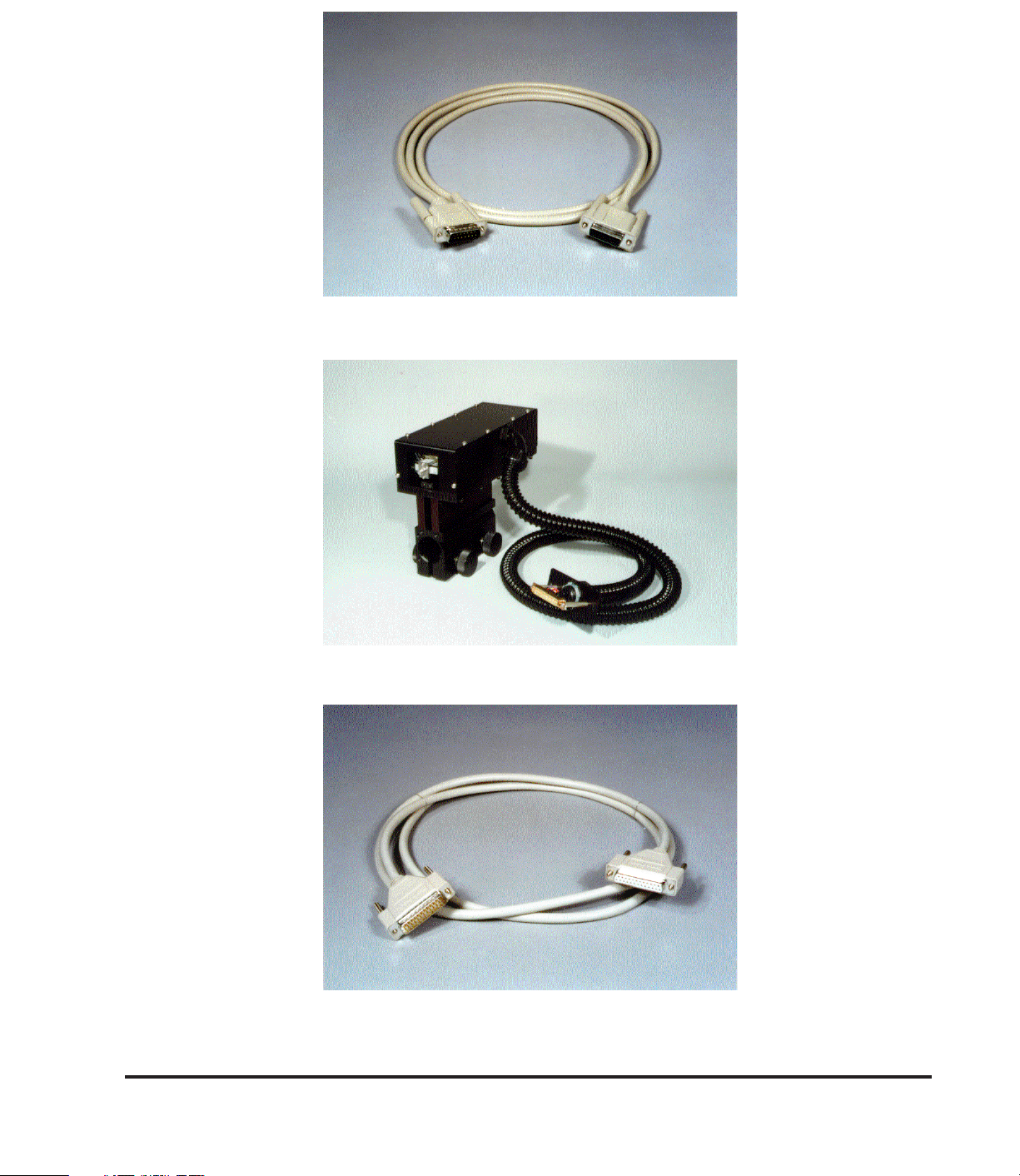

Figure 1.2 Resistance Cable 15-Pin M/F Sub D (Optional)

2-204-5

PN 921-112

2-204-8

Figure 1.3 Precision Drive Mechanism Showing Corrugated Cable

and 37-Pin Connector

2-204-7

Figure 1.4 25-Pin M/F Sub D Serial Cable

PN 905-390-101

1.8

Page 10

2-204-6

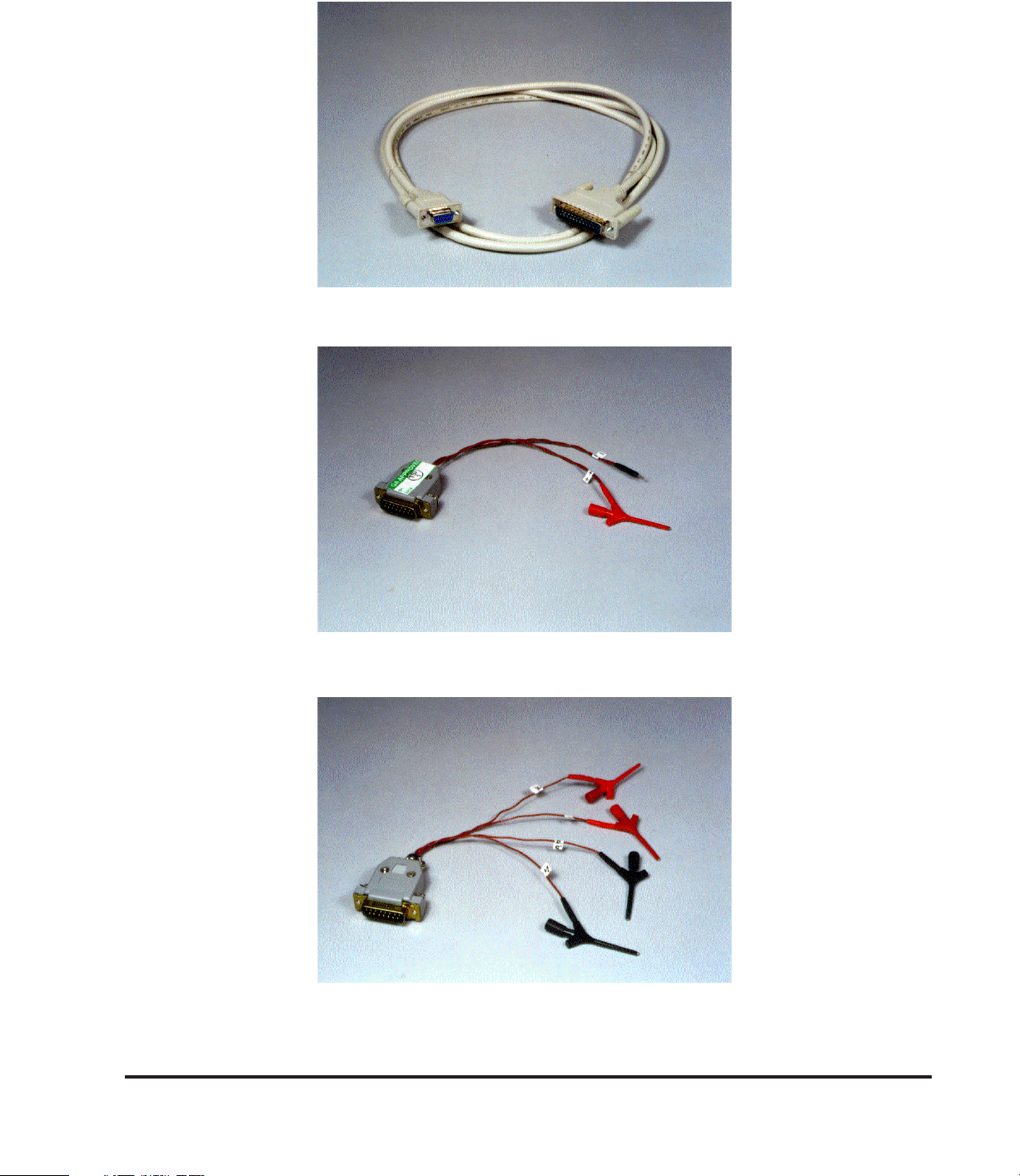

Figure 1.5 25 Pin M/ 9-Pin Female Serial Cable

PN 905-390-102

2-204-9

Figure 1.6 Two-Clip Generic Nest Assy

PN 921-140-101

2-204-10

Figure 1.7 Four-Clip Generic Nest Assy

PN 921-140-102

1.9

Page 11

SECTION 2

SETUP AND INTERCONNECTION

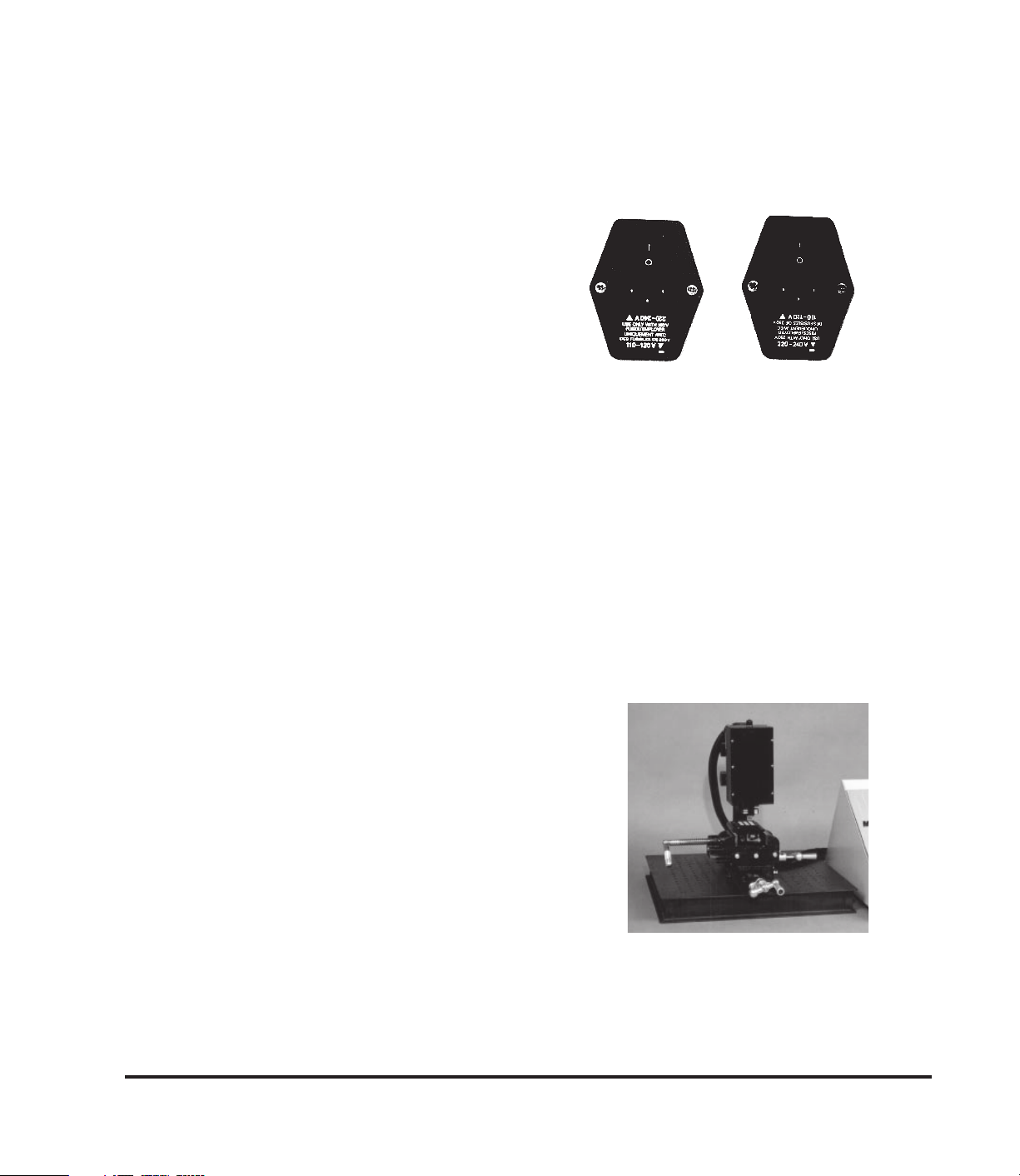

2.1 HARDWARE

The power entry module (C-Figure 1.1)

must be set for the user's facility power.

The 921A is normally supplied configured

for 110-120 V ac, 60 Hz. To reconfigure

the 921A for 220-240 V ac, 50-60 Hz

rotate the slideout voltage selector and

position it accordingly. Plug the power

cord into the 921A power entry module

and into a properly grounded outlet.

2.2 PC CONNECTION

The 921A must be connected to a PC to upload configuration data to the

station or download test data to the PC. Connect a PC with an open

communication channel to the 921A using the serial communication cable

supplied with the unit (see Figure 1.4 or 1.5) between the PC Serial COM port

connector and 921A connector J1 (A-Figure 1.1). Tighten the connector

securing screws to ensure a secure connection. If the cable supplied with the

921A is not long enough, a generic 1:1 25-pin

D-type extension cable can be used with the

cable supplied.

110-120V 220-240V

2.3 SOFTWARE

Refer to DFR Operations Software Manual.

Typical Test Fixture

Setup

2.1

Page 12

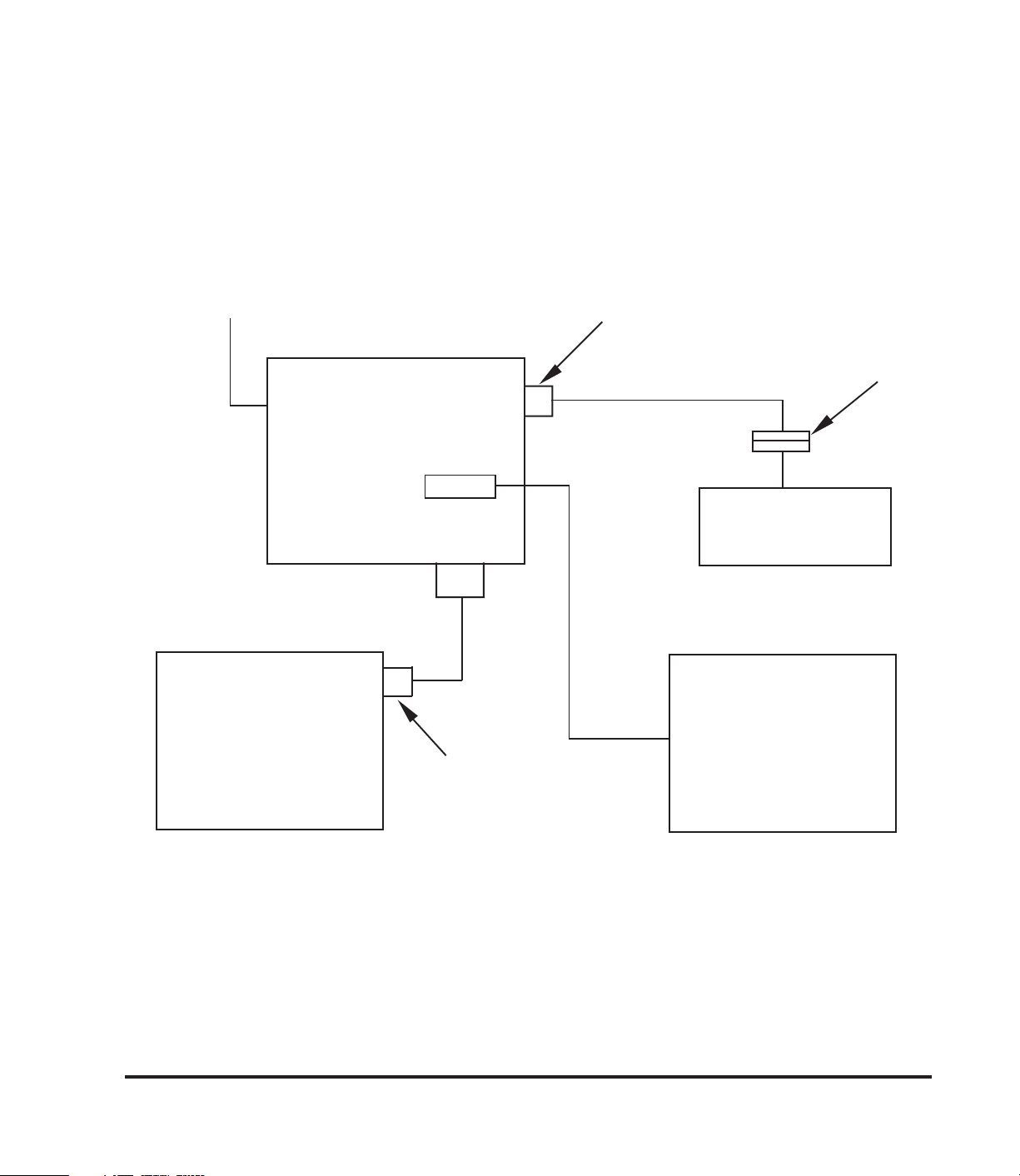

Set up unit for facility power (115 or 220 Vac) prior

to connecting to facility power (see paragraph 2.1).

110 - 120 VAC OR

220 - 240 VAC

WARNING

15-PIN MALE

DF TEST STATION

25-PIN MALE

SERIAL COM

CHANNEL

PC

MODEL 921A

SERIAL CABLE

25-PIN FEMALE

(9-PIN OPTIONAL)

J1

J2

RESISTANCE CABLE

15-PIN FEMALE

GENERIC NEST

PN 921-140-

(OR USER NEST)

PRECISION DRIVE

MECHANISM

Figure 2.1 921A DF Test Station Interconnect

2.2

Page 13

2.4 PRECISION DRIVE MECHANISM SETUP/CONNECTION

A suitable test fixture or vice should be used to hold the device for test. The

drive mechanism force sensor must be centered over the device button,

dome, etc., to which force is to be applied. The sensor must not be in contact

with the device for test (allow at least a 1/16-inch gap). If the optional

platform was purchased, the height of the force sensor above the device for

test can be easily adjusted by loosening the knobs and raising and lowering

the Precision Drive Mechanism to the desired position, and tightening the

knobs.

WARNING

Support the Precision Drive Mechanism when loosening

the knobs or the mechanism will slip on the post,

possibly damaging the force transducer and/or the

device under test.

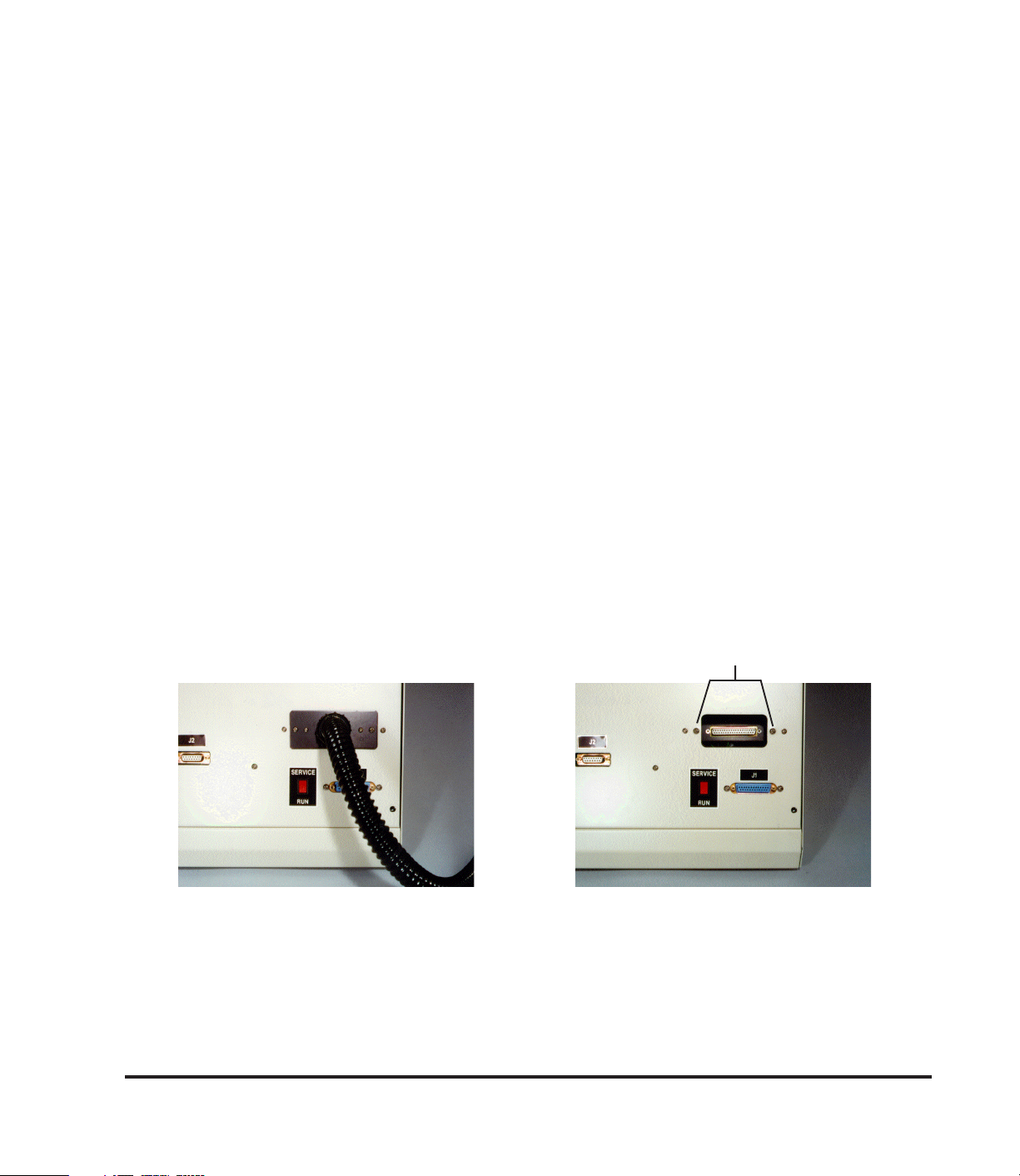

The Precision Drive Mechanism cable connector connects to the rear of the

921A electronic unit using the two screws provided. Refer to Figure 2.2.

Carefully remove the two screws, at the sides of the opening in the rear

panel. Carefully mate the cable connector with the connector recessed in the

rear panel opening. Secure with the two screws removed above.

2 Screws

2-204-12 2-204-11

Figure 2.2a Figure 2.2b

2.3

Page 14

2.5 ELECTRICAL RESISTANCE CONNECTION (OPTIONAL)

The 5-foot 15-pin Subminiature "D" Male/Female connector cable supplied

with the resistance option is used to connect either the supplied generic nest

assembly or the user's nest to the 921A (refer to Figure 1.2).

2.6 GENERIC NEST ASSEMBLY CONNECTION (OPTIONAL)

Two types of Generic Nest Assemblies are available: a two-clip version and a

four-clip version. The type must be specified when ordering.

PN 921-140-101 Two-Clip Version

Resistance channel source and sense plus (red clip) are connected

together and channel source and sense minus (black clip) are connected together. This nest does not allow 4-wire resistance measurement.

PN 921-140-102 Four-Clip Version

Resistance channel source (I+) and sense (S+) plus are separated and

supplied with red clips. Resistance channel source (I-) and sense (S-)

minus are separated and supplied with black clips. This nest allows

performing 4-wire (Kelvin) resistance measurements with the 4 5

resistance options.

2.7 USER NESTS

Table 2-1 shows the wiring of the 15-pin connector J2 on the rear of the unit.

This information is provided for users who wish to wire their own nests.

2.8 FORCE TRANSDUCER TIPS

2.8.1 Interchangeable Force Transducer Tips (2.0 kg, 3.6 kg and 50 lb

Transducers)

2.4

Page 15

Table 2-1

J2 Connector Wiring

PIN SIGNAL

1 INSTALL

2 CH1 SENSE +

3 CH1 SENSE 4

5

6

7

8 CH1 SRC+

9 CHASSIS GROUND

10

11

12

13

14 SIGNAL GND

15 CH1 SRC -

Notes: 1. Pin 9, chassis ground is provided for shield termination. If user-

designed nests have wire lengths in excess of 8 inches, those

wires should be shielded. If the user nest is to be used in an

electrically noisy environment, the wiring should be metal en-

closed with the metal enclosure chassis grounded.

2. Pin 1, INSTALL signal provides a device installed interlock for

testing. The test cycle will not initiate unless the Install signal is

grounded (connected to Pin 14). The user-designed nest can

incorporate a switch which is actuated when a device is in-

stalled in the nest, thereby grounding the Install signal. The

user's nest design can defeat the interlock by jumpering Pin 1 to

Pin 14 if the interlock function is not required.

3. Pin 3, CH1 SENSE - applies only to the 4 5resistance options.

2.5

Page 16

WARNING

Care must be taken whenever handling the force

transducer. These transducers are easily damaged. The 2.0 kg, 3.6 kg and 50 lb transducers

are supplied with protective stops for overload

under compression. However, tension or rotational forces applied in excess of 150% of fullscale rating will permanently damage the transducer.

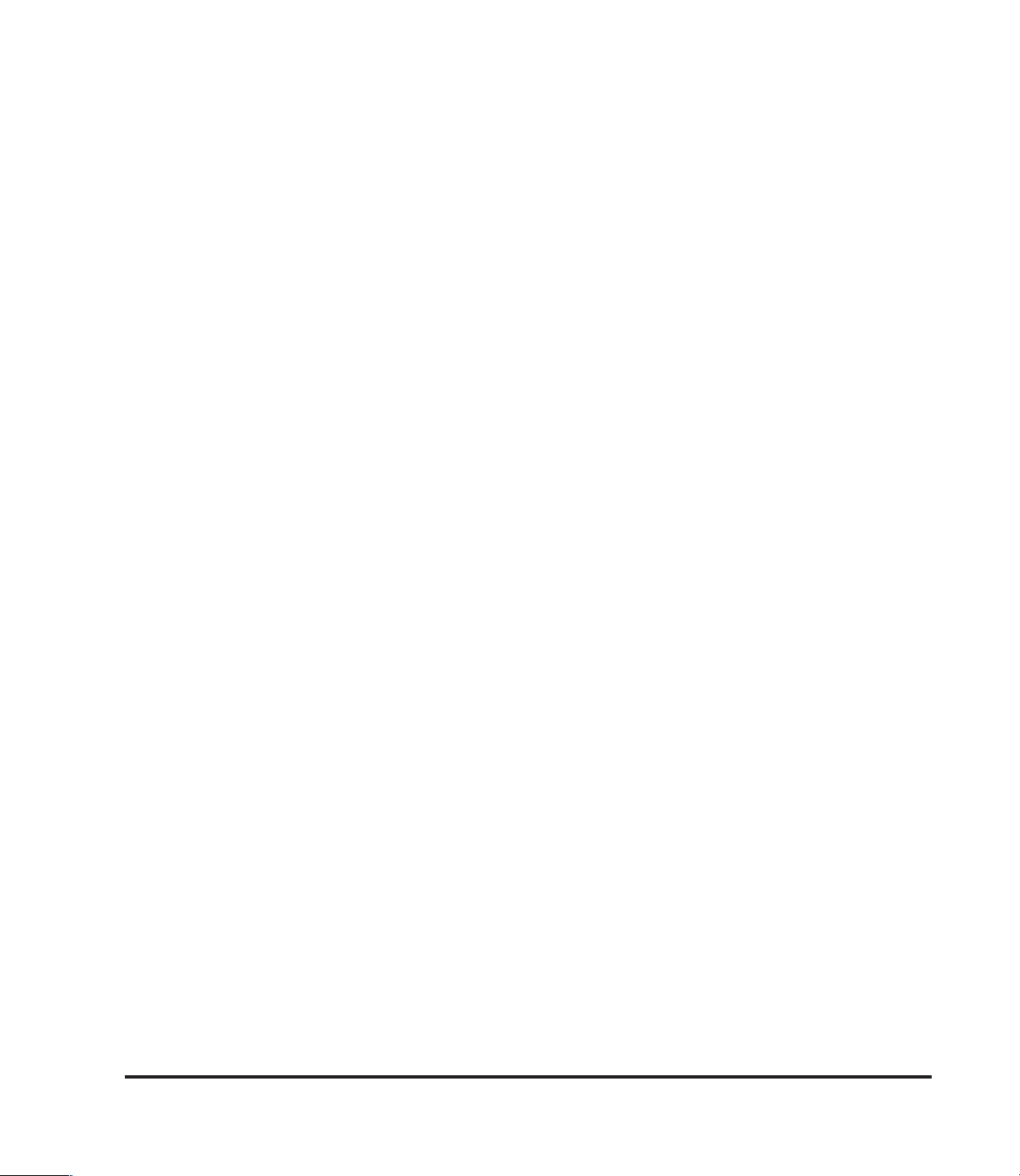

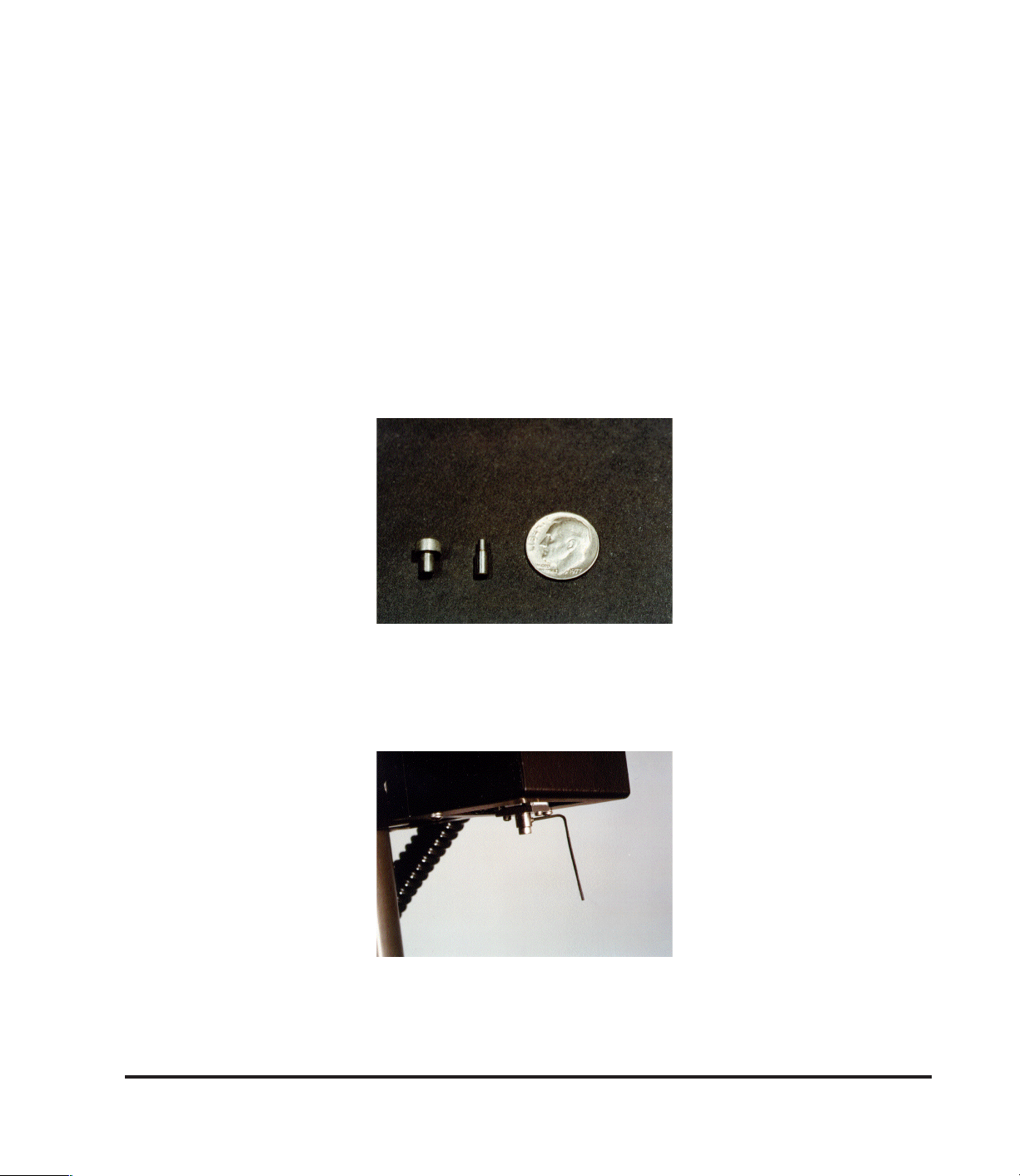

The 2.0 kg, 3.6 kg and 50 lb force transducers are supplied with two tips

(small and large, refer to Figure 2.3). To change tips on the force transducer,

use the allen wrench provided and carefully loosen the set screw holding the

tip (refer to Figure 2.4).

2-204-13

Figure 2.3 Typical Tips

Install the desired tip until it seats (bottoms out) in the transducer opening,

and carefully tighten the set screw with the allen wrench.

2-204-14

Figure 2.4 3.6 kg / 2.0 kg / 50 lb Tip Setscrew Location

2.6

Page 17

CAUTION

If users design their own tips, the mass and length

must be kept at a minimum (comparable to the

large tip supplied) or performance may be impaired.

2.8.2

The 75 g, 360 g and 750 g transducers are supplied with a 4-40 setscrew as

the transducer tip. This setscrew should not be removed. If the user requires

a different size tip, the user tip should be designed to thread onto the 4-40

setscrew.

75 g, 360 g and 750 g Transducer Tips

WARNING

Care must be taken whenever handling the force

transducer. These transducers are easily damaged. Compression, tension or rotational forces

applied in excess of 150% of full scale rating will

permanently damage the transducer.

CAUTION

If users design their own tips, the mass and length

must be kept at a minimum, since performance of

the system may be impaired by the additional

mass/length.

2.9 CHANGING FORCE TRANSDUCER ASSEMBLIES

The 921A allows changing force transducer assemblies (i.e., 3.6 kg, 2.0 kg,

400 g, 75 g, etc.). However each force transducer assembly must be specifically calibrated on the 921A unit on which it is used. Transducer assemblies

calibrated on the same unit can be interchanged without recalibration. Refer

to section 5.1 for transducer calibration information.

2.7

Page 18

WARNING

DO NOT TOUCH THE TRANSDUCER TIP DURING HANDLING OR INSTALLATION/REMOVAL

OR PERMANENT DAMAGE MAY RESULT.

Use proper ESD Handling procedures during

installation/removal and handling/packaging (antistatic) the force transducer assembly. Failure to

comply may result in damage to the equipment.

The transducer assembly consists of the force transducer, the force transducer circuit card assembly (CCA) and the CCA/transducer interconnect

cable.

To remove the transducer assembly from the precision drive mechanism,

remove the cover from this assembly as described in Appendix B, step 1.

Remove the five (5) screws holding the left side plate to the back plate of the

precision drive mechanism (Figure 2.5). Loosen the two (2) screws securing

the harness connector to the force transducer CCA, then disconnect this

connector (Figure 2.6). Remove the four (4) screws securing the force transducer CCA to the side plate (Figure 2.6). Carefully cut the tie wraps securing

the force transducer assembly interconnect cable to the platform tie downs

(Figure 2.7). Support the force transducer and remove the two (2) mounting

screws (Figure 2.8). Carefully remove the transducer assembly. Bubble

wrap and protect the force transducer/tip. Place the transducer assembly in

an antistatic bag for ESD protection.

Install the new transducer on the precision drive mechanism in the reverse

order of removal above. Be sure to secure the transducer interconnect cable

to the tie downs, with tie wraps, as shown in Figure 2.7. The critical tie down

area is the first tie down nearest the transducer. The cable must be secured

to this tie down using two (2) tie wraps, 90o to each other, and tightened

securely. The cable should not be able to be slide through this tie down if

pulled with moderate force. The cable from the transducer to this tie down

also cannot drag or come in contact with any surface during platform movement, or the system will not operate properly.

2.8

Page 19

The remaining two tie down areas are not critical for performance. The cable

should be tied down to these as shown in Figure 2.9 to provide the service

loop for operation. Be sure sufficient slack in the cable is provided so that the

precision drive mechanism limit switch (the furthest extended outward position) is actuated with some slack remaining. When the platform is in the

home position (furthest retracted inward position) there must also be some

slack remaining in the cable.

2.9

Page 20

Screws (5)

2-204-15

Figure 2.5 Figure 2.6

Screws (2)

2-204-18

Figure 2.7 Figure 2.8

Tie downs

Screws (4)

2-204-16

2-204-19

Screws (2)

Tie downs

2-204-17

Figure 2.9

2.10

Page 21

SECTION 3

CONFIGURATION

WARNING

Set up unit for facility power (115 or 220 Vac) prior

to connecting to facility power.

After the 921A has been set up as described in section 2, it is ready for

power.

3.1 TURN-ON

The power ON-OFF switch is located on the back panel as part of the power

module (C-Figure 1.1). Place this switch in the ON position. The green

POWER indicator should illuminate and all other indicators should remain off.

If the POWER indicator does not illuminate, see section 6 Troubleshooting.

3.2 SELF-TEST

Upon application of power, the 921A performs a series of self-tests to verify

that it is functioning properly. If any of the self-tests fail, see section 6

Troubleshooting. The message PERFORMING SYSTEM SELF TEST

TESTING CHECKSUM will appear on the operator's display.

Areas tested during self-test include: CHECKSUM, CPU RAM, RAM 1, RAM

2, and RAM 3. The name of each of these areas is displayed as it is tested.

During the self-test routine, either a message is briefly displayed stating that

an area has passed, or the self-test routine stops and a message is displayed

stating what area has failed. If a failure occurs, the 921A will not allow further

operation. The reason for failure must be corrected before continuing (See

Appendix A).

After a successful self-test, the CAL indicator will illuminate indicating that the

station has automatically entered the Calibration mode. When the 921A is

turned on, it has no reference for measurement and must perform a

calibration cycle as discussed in paragraph 4.1 to establish measurement

references.

If the display indicates a mismatch, the system setup and device are not

compatible with the stored configuration. (See Appendix A)

3.1

Page 22

SECTION 4

OPERATION

After the 921A has been configured, it is ready for operation. Turn on the

921A and allow it to perform its self-test routine and enter the Calibration

Mode.

The operator's display contains two lines of information. The first line

provides data about the device test configuration, i.e., the device part

number, the version of the device configuration, and the work order (if

applicable). This information is dependent upon the device test parameters

stored in memory for the configuration. The second line of the display

provides instructions for the operator.

Note: A valid configuration must be previously installed using the PC DFR

Operations Software. If not, refer to the DFR Operations Software

Manual and create/install a configuration in the 921A prior to

proceeding.

4.1 CALIBRATION MODE

The Calibration Mode is used to obtain measurement references and is

automatically entered upon the successful completion of a self-test routine. It

can also be entered by pressing the MODE switch on the front panel

whenever the operator's display indicates READY. The 921A will also enter

the Calibration Mode if the Configuration is changed and the new device

configuration requires a different calibration. Whenever the 921A is in

Calibration Mode, only the CAL indicator is illuminated.

Press the Mode (CAL) switch to enter the Calibration Mode.

If the configuration parameters include a Reference Block Size (Ref Blk Size)

value other than zero (refer to the DFR Operations Software Manual for

details) the display will prompt for installation of the Distance Reference

Gauge at this point; then to press test. (See restrictions, Appendix A).

If the Ref Blk Size value is zero or not applicable in the configuration, then

the message Ensure Pedestal Setup for CAL is displayed. Press TEST

when ready.

4.1

Page 23

If the configuration uses resistance, then the Generic Nest Assembly (or

equivalent) must be connected to the DF for calibration. If the four-clip

version, PN 921-140-102 is used, the Red clips (I+ and S+) must be

connected together and the black clips (I - and S -) must be connected

together for the purpose of calibration. The red and black clips cannot be

shorting together or to a metal surface. Failure to properly setup the Generic

Nest (or equivalent) will result in a calibration failure message when

calibration is attempted. The calibration process corrects out all system

offsets and hardware deviations so that the device to be tested is the only

unknown.

Install the block or tighten the vice clamp together. Position the sensor

approximately 1/2-inch above the block or vice clamp and press READY.

The message CALIBRATION IN PROCESS will be displayed.

The sensor will move in to the block or vice clamp and back out twice. This

process provides the exact positioning, force, and resistance data required to

accurately test a device.

When the calibration cycle is complete, the READY indicator will illuminate,

the CAL indicator will extinguish, and the message INSTALL DEVICE, THEN

PRESS READY will be displayed. This message indicates that the

calibration cycle is complete. All references have been obtained, and the

921A is ready to test the selected device.

The calibration cycle can be run whenever desired by pressing the MODE

switch. This is useful if the operator suspects the original calibration has

changed. For example, if the sensor has been moved by more than 1 inch,

the original calibration will be invalid and a new calibration cycle will be

necessary to reestablish calibration.

After the MODE switch has been pressed, the message INSTALL

DISTANCE REFERENCE GAUGE (or ENSURE PEDESTAL SETUP for

CAL), PRESS READY WHEN INSTALLED. PRESS CAL TO ABORT will be

displayed.

4.2

Page 24

This message indicates that a calibration cycle has been initiated. If an

operator accidentally pressed the MODE switch, he/she now has the option to

abort the calibration cycle by pressing the CAL switch. The 921A will retain

the former calibration values and be prepared to test another device.

Whenever a different Configuration is installed, the display may instruct the

operator to recalibrate. The 921A will automatically prompt the operator if a

calibration is required due to a configuration change.

4.3

Page 25

SECTION 5

SERVICE & ADJUSTMENTS

5.1 SERVICE MODE

WARNING

The Service Mode operates the moving platform at

some service mode steps. Never operate the unit

without the platform properly setup with the drive

mechanism height adjusted to provide a suitable

stop for the platform force transducer.

The Service Mode provides a means to periodically test and adjust the 921A

internal measurement circuits. Adjustments should be performed on a

regular basis as determined by the user's requirements. The Service Mode

adjustments/calibration should be performed at least on an annual basis.

The SERVICE/RUN switch is located on the back panel (B-Figure 1.1). Turn

off the 921A and place the switch in the SERVICE position. Install a

Calibration Force Gauge under pressure transducer before turning on the

921A. Ensure that the serial communication cable is disconnected from the

921A. Turn on the 921A. It will perform its self-test routine and enter the

Service Mode automatically. The message FORCE CALIBRATION MODE,

PRESS READY TO CONTINUE will be displayed.

The Service Mode requires pressing the TEST/READY switch on the front

panel to increment or step through the various service mode display screens.

The TEST/READY switch must be depressed and held for at least 1 second

prior to release to ensure the unit will recognize that the switch is pressed.

5.1.1 Force Calibration

This step allows adjusting the force offset and gain electronics on the force

transducer assembly. Appendix B provides the detailed instructions for

adjustment/calibration of the force transducer assembly.

If the operator wants to proceed to a different service mode step, be sure the

platform is properly setup (see warning above) then press TEST/READY, as

required.

5.1

Page 26

5.1.2 Resistance Offset (Resistance Option Only)

This step allows adjusting the resistance offset electronics and verifying the

internal resistance gain calibration value, as well as, verifying the resistance

readings.

Appendix C provides the detailed instructions for adjustment/verification of

the resistance electronics.

If the operator wants to proceed to a different service mode step, press

TEST/READY, as required.

5.1.3 Lamp Test

This step allows verifying that the PASS, FAIL, READY, and CAL indicators

are operational. Pressing the CAL switch will alternately turn all these

indicators on and off.

If the operator wants to proceed to the next service mode step, press TEST/

READY, as required.

5.1.4 Resistance CCA Code/Switch Installed (Resistance Option Only)

This step displays the Resistance CCA code (RCCA) value and the switch

installed status. The RCCA code indentifies the specific optional Resistance

CCA type installed in the unit. If the Generic Nest Assembly is connected to

the unit, the SW Install Status should indicate TRUE; if it is disconnected, it

should indicate FALSE.

If the operator wants to proceed to the next service mode step, press TEST/

READY, as required.

5.1.5 Pressure Code

This step displays the Pressure (Force) Transducer Code value. The

Pressure Code identifies the specific transducer type installed on the unit.

5.2

Page 27

If the operator wants to proceed to the next service mode step, press TEST/

READY, as required.

5.1.6 Displacement Verification

This step allows verifying the system displacement accuracy.

Appendix D provides the detailed instructions for verification of the system

displacement.

If the operator wants to proceed to the next service mode step, be sure the

platform is properly setup (see warning above), then press TEST/READY, as

required. In this case the next step is again Force Calibration (para. 5.1.1).

The sequence can be repeated as often as desired.

5.3

Page 28

SECTION 6

TROUBLESHOOTING

User troubleshooting of the 921A is limited to replacing fuses. Before

returning the unit to TRICOR for service, check the following:

1) Verify that the power outlet has power. Plug in and turn on the

921A.

2) Does the POWER indicator illuminate?

Yes - Go to step 3.

No - Remove power plug from outlet.

Remove slideout panel from power entry module (C-Figure 1.1).

Check the two 2-A fuses. Replace defective fuse(s). Reapply

power. If fuse(s) blow, return unit to TRICOR for service.

Otherwise allow 921A to perform its self-test routine.

3) Does the operator's display indicate Self-Test?

Yes - Go to step 4.

No - Return unit to TRICOR for service.

4) Does Self-Test pass?

Yes - Go to step 5.

No - Return unit to TRICOR for service.

5) Does Calibration mode cycle complete?

No - Remove plug from power outlet.

Note:

If the unit is under warranty, contact TRICOR prior to

proceeding.

6.1

Page 29

4-A

Fuse

Remove the back panel (Refer to Appendix C Warnings and

Step 1) prior to removing panel. Check the 4-A fuse (see

Figure 5.1) on the power supply CCA (located on the right side

of the base beneath the operator's display) .

Replace defective fuse, if any, with proper type. Reapply

power. If fuse blows or unit still does not operate properly,

return it to TRICOR for service.

2-204-20

Figure 5.1 4A Fuse Location on Power Supply CCA

6.2

Page 30

APPENDIX A

RESTRICTIONS AND WARNING / PROBLEM / FAILURE

MESSAGE DESCRIPTIONS

Max Force Restriction

Max Force parameter will establish the end of inward travel (bottomout). Max

Force should be set to a reasonable value for the device under test. If the

Max Force is set to small, the inward test range may not reach the desired

bottomout point of the device under test. If the Max Force is set to large

excessive force may be applied to the device under test.

Test Range Travel Restriction

The system can store a maximum of 2,500 data (log) points inward and 2,500

data (log) points outward. With the .0001" lead screw this is approximately

.25" of travel in and out when operating in the 1 step/log mode. Note that this

travel is the test range travel (free position to bottomout) and not total

platform travel. If the test travel range exceeds the 2,500 data (log) points

(more than approx. .25") then invalid results will occur. The configuration

must be changed to increase the steps/log (i.e. 2 steps/log provides ~ .5" test

travel with the standard .0001" lead screw). The user must configure the

parameters properly for the device under test to ensure the test travel does

not exceed the logging capacity of the system, or the test results/data will be

invalid.

Ref Blk Size Restriction

Two restrictions apply to the Distance Reference Gauge and Ref Blk Size.

One is the combination of the platform travel and the Ref Blk size cannot

exceed 6.5535 inches. The other is the location or reference point

established during the calibration cycle using the Distance Reference Gauge

and Ref Blk Size must occur further inward than device bottomout during

device testing. In other words, the reference point must be further (more

travel) away from the platform home position than the device bottomout point

during testing. Failure to comply with these restrictions will cause invalid

results.

A.1

Page 31

Sheet 1 of 2

Nest, press and hold "TEST" to back up platform from Nest. If Force Transducer is not in contact with Nest, check

number of the Force Transducer currently installed.

request and receive the stored results and clear the test result buffer before testing can resume.

Either a device is not proper ly installed, or the Nest is improperly installed or defectiv e.

down unit several minutes, try again. If problem recurs - consult factory.

If problem recurs -- consult factory.

The 921A Force Transducer offset exceeds acceptable limits for testing. Refer to 921A User's Manual for

calibration requirements/procedures for Force Offset. If Force Offset cannot be adjusted to specification -- consult

factory.

Force Gain/Offset calibration. If problem persists -- consult factory.

WARNING / PROBLEM / FAILURE MESSAGE DESCRIPTION

DISPLAY MESSAGE DESCRIPTION

FORCE SENSOR/S ELECTION MISMATCH!!! The current configuration requires a Force Transducer on the 921A with a different part number than the part

TEST BUFFER FULL! WAITING FOR PC The 921A is operating in "PC" mode and the test buffer is full with 32 device test results stored. The PC must

WARNING! LOW BATTERY FOR MEMORY BACKUP. The 921A battery, used to retain configuration data in memory on power down, requires replacement.

THERE IS NO DEVICE INSTALLED TO TEST The 921A does not detect a device present in the Nest when the "TEST" switch is pressed to initia te a tes t cy cle.

A/D RESET, CALIBRATION FAILURE The 921A Analog-to-Digital Converter has failed to reset and calibrate properly. This is a hardware failure. Power

A/D CAL, CALIBRATION FAILURE The 921A Analog-to-Digital converter has failed to calibrate properly. Power down unit several minutes, try again.

A/D CONVERSION (EOC) FAILURE The 921A Analog-to-Digital Converter is not operating properly -- consult factory .

(Press Test to T ry Aga in . )

FORCE OFFSET CAL FAILURE

WARNING!!! FORCE LIMIT EXCEEDED. The Force measured by the Force Transducer exceeds the acceptable limit. If Force Transducer is in contact with

A.2

Page 32

Sheet 2 of 2

Resistance channel offset calibration failure. Check Nest, using correct calibration block or Generic Nest, to

ensure that Nest is pr operly installed. Be sure calibration block is properly seated and making contact with nest

socket. Be sure configuration resistance channel allocation is correct for Nest design. Check resistance channel

calibration and adjust if necessary. If problem persists -- consult factory.

Resistance channel gain calibration failure. Check Nest, using correct calibration block or Generic Nest, to ensure

that Nest is properly installed. Be sure calibration block is properly seated and making contact with Nest socket.

Be sure configuration resistance channel allocation is correct for Nest design. Check resis t ance channel

calibration and adjust if necessary. If problem persists -- consult factory.

Force limit exceeded or Limit switch contacted during platform travel. Typical cause is Maximum Force parameter

in configuration file set too high (near limit of transducer). Reduce Maximum Force parameter value. Other

causes are hardware failures -- consult factory.

and PC or PC being turned off during communication. If necessary, power down 921A and retry operating unit. If

problem persists -- consult factory.

The stored configuration does not contain a valid configuration. Refer to 921A User's Manual and install a

configuration.

If the 921A is operating in Engineering Mode, the test cycle is normally initiated by the remote PC and this

message is displayed if the 921A Test switch is pressed. If the 921A is operati ng in PC Mode, this message can

problem persists -- consult factory.

be displayed if the test switch is pressed while a PC serial data transfer is in process. This occurs infrequently and

WARNING / PROBLEM / FAILURE MESSAGE DESCRIPTION

No Nest/Cable

DISPLAY MESSAGE DESCRIPTION

SWITCH OFF SET CAL FAILURE.

Power Down or Press Test to Retry CAL.

SWITCH GAIN C AL FAILURE.

TESTING ABORTED - POWER DOWN.

Power Down or Press Test to Retry CAL.

FORCE OR LIMIT SWT SYSTEM FAILURE

WAITING -- SERIAL COMMUNICATION RS-232 serial communication with PC interrupted. Possible cause is loose or disconnected cable between 921A

SELF TEST FAILURE - POWER DOWN If self test fails, note failure indicted on second line of 921A display. Power down 921A and retry operation. If

POWER DOWN OR CHANGE SELECTION

NO VALID TEST CONFIGURATION STORED

PLEASE WAIT. . . .

951A HALTED BY EXTERNAL CONTROL!

SYSTEM FAILURE!! FORCE LIMIT EXCEE DED Force limit exceeded. Check force calibration per 921A User's Manual. If problem persists -- consult factory.

A.3

Page 33

APPENDIX B

Force Transducer CCA Calibration

Test Tool Required: Force Calibration Fixture PN 905-810

WARNING

Service is to be performed by qualified

personnel only. Use only plastic adjustment

tools. Failure to comply may result in damage

to the equipment.

Step 1 Power down the unit. Remove the cover from the drive

mechanism assembly (12 screws, Figure B.1). The force

transducer CCA is located on the left side of the drive

mechanism.

Step 2 Assemble the force calibration fixture PN 905-810 by attaching

the force gauge with 2 screws (provided) to the "L" bracket

(Figure B.2) Thread the force gauge tip (Figure B.3) onto the

force gauge. Install the assembled "L" bracket with force gauge

on the 921A baseplate (or equivalent) such that the force gauge

tip is centered under the 921A drive mechanism assembly force

transducer (refer to Figure B.4).

Step 3 Place the SERVICE/RUN switch on the unit rear panel in the

SERVICE position.

The Service Mode is used to perform the calibration/adjustment.

The Service Mode requires pressing the TEST/READY switch on

the front panel to increment or step through the various service

mode display screens. The TEST/READY switch must be

depressed and held for at least 1 second prior to release to

ensure the unit will recognize that the switch is pressed.

Step 4 Turn on the unit. After successful completion of the power-up

self-test, the unit displays the FORCE CALIBRATION MODE

message. Press the TEST/READY switch once. The message

to Adjust Force Pot and the Offset value is displayed. The force

transducer offset adjustment is performed using this display.

B.1

Page 34

Step 5 There are two types of force transducer CCAs which are

illustrated in Figures B.5a and B.5b. Examine your unit's force

transducer CCA to determine which type is on the unit.

Reference figure a or b accordingly to perform the adjustments

of steps 6, 7, and 8.

Step 6 Adjust the force transducer CCA potentiometer labeled "offset"

on Figure B.5 until the offset value displayed on the unit is as

close to the nominal value listed below for your transducer type.

The force offset adjustment must be within the range listed

below for your transducer type for proper calibration.

Type Nominal Acceptable Range

3.6 kg 0.075 kg 0.025 to 0.200 kg

360 g 7.5 g 2.5 to 20.0 g

75 g 1.6 g .5 to 4.2 g

2.0 kg 0.038 kg 0.012 to .100 kg

750 g 15 g 5 to 42 g

50 lb 1.04 lb .35 lb to 2.80 lb

20 lb 0.38 lb 0.12 to 1.00 lb

Step 7 Turn on the force gauge. Select the units (kg or g) and zero the

force gauge. Press the TEST/READY switch once. The unit

drive mechanism will operate until the unit force transducer is in

contact with the force gauge and reaches the calibration force

level. The unit displays the adjust force pot(s) message for

Force = Gauge value and displays

Force = "Measured Value"

Refer to Figure B.5 and adjust the GAIN 1 and/or the GAIN 2

potentiometer until the unit force "Measured Value" is equal to

the force gauge value within the tolerance listed below for your

transducer type.

Adjustment Specification

Type Tolerance Tolerance

3.6 kg ± .003 kg ± .010 kg

360 g ± 0.4 g ± 2.0 g

75 g ± 0.1 g ± 0.5 g

2.0 kg ± .002 kg ± .005 kg

750 g ± 0.8 g ± 3.8 g

50 lb ± 0.04 lb ± 0.25 lb

20 lb ± 0.02 lb ± 0.10 lb

B.2

Page 35

Step 8 Press the TEST/READY switch once. When the platform

mechanism stops moving power down the unit. Repeat steps 4

through 8 until the step 6 offset is within acceptable range and

the step 7 Measured Value is within adjustment tolerance

without requiring further potentiometer adjustment, at steps 6

and 7. It typically takes performing steps 4 through 8 at least

three times to achieve correct adjustment.

Step 9 Apply a small amount of Glytol to the potentiometer adjustment

screw being sure some Glytol is applied between the screw and

the body of the potentiometer. This completes the force

transducer calibration.

Step 10 Install the cover on the head assembly with the screws removed

in step 1. Remove the "L" bracket with force gauge from the

baseplate. Remove the force gauge from the "L" bracket. Store

force gauge and tip in original shipping case for protection.

B.3

Page 36

Screws (12)

2-204-21

Figure B.1 Drive Mechanism Assembly Cover Removal

B.4

Page 37

2-204-22

2-204-24

Figure B.2 L Bracket/Gauge

B.5

Page 38

Figure B.3 Force Gauge with Tip

2-204-23

B.6

Page 39

Figure B.4 Center Gauge to Transducer Tip

2-204-25

B.7

Page 40

GAIN 1GAIN 2

GAIN 1GAIN 2

Figure B.5a Resistance Pot Locations

Force Transducer CCA Type 1

2-201-43

OFFSET

OFFSET

GAIN 2 GAIN 1

OFFSET

Figure B.5b Resistance Pot Locations

Force Transducer CCA Type 2

2-204-26

B.8

Page 41

APPENDIX C

Resistance Adjustment/Verification

(Resistance Option Only)

Test Tool Required: Resistance Verification Fixture PN 921-811-XX

(See Table C-1 for the complete part number of the

fixture required based on the Resistance Option Type

installed in the Model 921A)

Table C-1

Resistance Option Type Resistance Fixture PN

4 5, 10mA 921-811-09

4 5, 25mA 921-811-09

16 k5, .25mA 921-811-01

1 k5, 1 mA 921-811-07

4 V, 4.99k Pullup 921-811-02

Each fixture consists of: The Resistance Test Box, a 37-pin to 15-pin

adapter cable and the Offset/Gain Jumpering

Connector.

Resistance Test Box Offset/Gain

Jumpering Connector

WARNING

DANGER

There is 115 V or 230 V ac voltages present

within the unit. Service is to be performed by

qualified personnel only. Use only plastic

adjustment tools. Do not touch or come in

physical contact with any wires, components or

assemblies within the unit or severe injury or

death can result.

C.1

Page 42

WARNING

The Service Mode operates the moving platform

at some service mode steps. Never operate the

unit without the platform properly set up with the

test fixture height adjusted to provide a suitable

stop for the platform force transducer.

Step 1 Power down the unit. Disconnect the ac power cord from the

primary power source. Remove the rear panel from the unit

(four screws - figure C.1) and lay down on a flat surface.

Step 2 Adjust the height of the Drive Mechanism to provide a suitable

stop for the platform force transducer.

Step 3 Connect the Drive Mechanism and Resistance Cable (PN 921-

112) to the rear panel connectors per section 2 of the 921A

User's Manual; however, do not connect P2 of the resistance

cable to a nest. Connect the ac power cord to the unit and to

the primary power source. Place the SERVICE/RUN switch on

the unit rear panel in the SERVICE position. Turn on the unit.

The Service Mode is used to perform the calibration/adjustment.

The Service Mode requires pressing the TEST/READY switch

on the front panel to increment or step through the various

service mode display screens. The TEST/READY switch must

be depressed and held for at least 1 second prior to release to

ensure the unit will recognize that the switch is pressed.

Step 4 After successful completion of the power-up self-test, the unit

displays the Force Calibration Mode message. The Force

Calibration will not be performed as part of this procedure.

However, the unit must be sequenced through the service mode

Force Calibration screens by pressing the TEST/READY switch

on the front panel.

Press TEST/READY once- Force Offset Value displayed

Press TEST/READY again - Platform moves until Force Cal

value is reached and stops.

C.2

Page 43

Rear Panel

Mounting

Screws (4)

Figure C.1 921A Rear Panel

2-204-4

Press TEST/READY again - The platform returns to the home

position. The resistance Offset

Adjustment Mode message is

displayed.

Install the Offset/Gain Jumpering Connector (part of PN 921811-XX) on the Resistance Cable (PN 921-112) P2 Connector.

Do not remove the jumpering connector until instructed to

do so by this procedure.

Step 5 Press the TEST/READY switch once. The unit displays the

offset values for the resistance current source channel. Figure

C.2 identifies the location of the offset potentiometer (pot) and

the corresponding pot designator which is displayed by the unit.

Step 6 The resistance offset value must be within the acceptable range

listed below. If necessary, adjust the offset pot until the offset

value displayed by the unit is within the acceptable range.

C.3

Page 44

OFFSET POT

R21

Figure C.2 Resistance CCA Offset Pot Location

2-204-27

C.4

Page 45

Resistance Type Acceptable Range

4 5, 10 mA Channel Offset 0.010 to 0.030

4 5, 25 mA Channel Offset 0.004 to 0.012

16 k5, .25 mA Channel Offset 0.001 to 0.030

1 k5, 1 mA Channel Offset 0.001 to 0.030

4 V, 4.99 k Pullup Channel Offset 0.001 to 0.030

Step 7 Press the TEST/READY switch once. The unit displays the

GAIN Calibration Resistance Value message. Press the TEST/

READY switch again. The unit displays the GAIN Calibration

Value (GV). The Gain Values displayed should be in the range

3.800 ± .100. These are not adjustable values. Consult the

factory if the GV value is not within this range.

Step 8 Press the TEST/READY switch once. The unit displays the

Contact Resistance Value Mode message. Press the TEST/

READY switch again. The unit displays the measured

resistance for the resistance channel. The value displayed

must be 4.095. This is the open circuit condition. Consult the

factory if the channel is not equal to this value.

Step 9 Remove the Offset/Gain jumpering connector from the

Resistance Cable P2 connector. Connect the Resistance Test

Box (Part of PN 921-811-XX) connector to the Resistance Cable

P2 Connector.

Tables C.2 through C.5 provide the switch settings and

verification criteria for the different Resistance Option types.

Use the appropriate table for the Resistance Option installed in

the 921A.

Set the Resistance Test Box Resistance switch to each position

listed in the appropriate table below and verify that the value

displayed by the unit (CH1) equals the corresponding value

listed in the table within the tolerance specified.

C.5

Page 46

Table C.2 4 5, 10 mA or 25 mA Resistance Option using Resistance

Fixture PN 921-811-09

Resistance Switch Position Displayed Value (5) Tolerance

1 (0 5) 0.000 ±.010

2 (1 5) 1.000 ±.010

3 (2 5) 2.000 ±.010

4 (3 5) 3.000 ±.010

5 (3.8 5) 3.800 ±.010

6 (.025 5) 0.025 ±.010

7 (.050 5) 0.050 ±.010

8 (.075 5) 0.075 ±.010

Table C.3 16 k5, .25 mA Resistance Option using Resistance Fixture

PN 921-811-01

Resistance Switch Position Displayed Value* Tolerance

0 (0 k5) 0.000 ± 0.010

1 (4 k5) 1.000 ± 0.010

2 (8 k5) 2.000 ± 0.010

3 (12 k5) 3.000 ± 0.010

4 (16 k5) 4.000 ± 0.010

* Resistance = Displayed Value x 4000 (5)

Table C.4 1 k5, 1 mA Resistance Option using Resistance Fixture

PN 921-811-07

Resistance Switch Position Displayed Value* Tolerance

0 (0 5) 0.000 ± 0.010

1 (250 5) 1.000 ± 0.010

2 (500 5) 2.000 ± 0.010

3 (750 5) 3.000 ± 0.010

4 (1000 5) 4.000 ± 0.010

* Resistance = Displayed Value x 250 (5)

C.6

Page 47

Table C.5 4 V, 4.99k Pullup Resistance Option using Resistance

Fixture PN 921-811-02

Resistance Switch Position Displayed Value (Volts) Tolerance

0 (0 V) 0.000 ± 0.040

1 (1 V) 1.000 ± 0.040

2 (2 V) 2.000 ± 0.040

3 (3 V) 3.000 ± 0.040

4 (4 V) 4.000 ± 0.040

Consult the factory if any of the resistance values fail to meet

the specified requirement. This completes the resistance

calibration/verification.

Step 10 Power down the unit. Disconnect the ac power cord from the

primary power source. Disconnect Test Tool PN 921-811-09

from the Resistance Cable P2 connector.

Step 11 If the potentiometer was adjusted, apply a small amount of

Glytol to the potentiometer adjustment screw being sure

some Glytol is applied between the screw and the body of

the potentiometer.

Step 12 If no further internal adjustments are to be made, install the

rear panel on the unit using the four screws removed in

step 1.

C.7

Page 48

APPENDIX D

Displacement Verification Procedure

Test Tool Required: Force/Displacement Gauge Fixture PN 905-378

Displacement Gauge: Mitutoyo PN 543-146 (or Equivalent)

Align Parallel

2-204-28

Figure D.1 Fixture with Gauge

WARNING

The Service Mode operates the moving platform

at some service mode steps. Never operate the

unit without the platform properly setup with the

test fixture height adjusted to provide a suitable

stop for the platform force transducer.

Step 1 Adjust the height of the Drive Mechanism to provide a suitable

stop for the drive mechanism force transducer.

D.1

Page 49

Step 2 Connect the Drive Mechanism to the rear panel connector per

section 2 of the 921A User's Manual. Connect the ac power

cord to the unit and to primary power source. Place the

SERVICE/RUN switch on the unit rear panel in the SERVICE

position. Turn on the unit.

The Service Mode is used to perform the calibration/adjustment.

The Service Mode requires pressing the TEST/READY switch

on the front panel to increment or step through the various

service mode display screens. The TEST/READY switch must

be depressed and held for at least 1 second prior to release to

ensure the unit will recognize that the switch is pressed.

Step 3 After successful completion of the power-up self-test, the unit

displays the Force Calibration Mode message. The Force

Calibration will not be performed as part of this procedure.

However, the unit must be sequenced through the Service Mode

Force Calibration screens by pressing the TEST/READY switch

on the front panel.

Press TEST/READY once - Force Offset Value displayed

Press TEST/READY again - Platform moves until Force Cal

Value is reached and stops.

Press TEST/READY again - The platform returns to the home

position.

If the unit is equipped with the Resistance Option, Resistance

Offset Mode is displayed. If not, the Lamp Test Mode message

is displayed. Press TEST/READY switch, as required, until the

Displacement Verification Mode message is displayed, then

proceed to step 4.

Step 4 Assemble the Displacement Gauge to Fixture PN 905-378, as

shown in Figure D.1, using the bolt provided. Be certain the

gauge is mounted with the plunger parallel to the side of the

fixture (see Figure D.1). Install the assembled fixture with

gauge on the 921A baseplate (optional) or equivalent, such that

the displacement gauge plunger is slightly depressed

D.2

Page 50

(approximately 1/16-inch) when contacting the Force Transducer

Assembly (adjust the height of the drive mechanism, as

necessary) as shown in Figure D.2.

Figure D.2

2-204-29

Step 5 Prior to proceeding with the displacement test, the operator

needs to become familiar with the test method. Table D.1

provides the approximate displacement locations to test. When

the TEST/READY switch is pressed and released, the drive

mechanism will begin incrementing (moving) into the

displacement gauge. The 921A displacement value is presented

on the unit display. The drive mechanism is incremented until

the displacement reaches 0.2000 inch (standard .0001 inch lead

screw) or until the TEST/READY switch is pressed and held in.

The drive mechanism will remain stationary as long as the

TEST/READY switch is held in (actuated). By monitoring the

displacement value on the unit display and pressing/holding the

TEST/READY switch, the operator can stop the platform at the

approximate displacement points listed in Table D.1 and

compare the unit displayed displacement to that of the fixture

gauge.

D.3

Page 51

Step 6 With the Displacement Verification Mode message displayed on

the unit, turn on and zero the fixture gauge. Be sure the fixture

gauge reads zero, or re-zero the gauge as necessary until the

gauge reads zero before proceeding. Press, then release, then

press and hold in the TEST/READY switch. This is the

approximate zero reading. If the unit display still reads zero,

then re-zero the fixture gauge (if necessary). If the unit reads

other than zero, any difference should be noted and subsequent

fixture gauge readings corrected for the initial zero difference.

Release the TEST/READY switch, monitor the unit displacement

until the next approximate displacement point, then press and

hold the TEST/READY switch. Compare the fixture gauge to the

unit displayed value. The unit value must be within ±0.0003

inch of the corrected gauge value for each displacement check

for acceptance. Repeat until all displacement points listed in

Table D-1, prior to the last displacement point, have been

checked. The unit will automatically stop at the last

displacement point (Do not press TEST/READY switch for this

point). Check the unit displacement to the gauge at this point as

well.

Step 7 Press TEST/READY switch again. The drive mechanism will

retract and go to the home position. This completes the

displacement verification.

Step 8 Power down unit. Remove fixture from baseplate. Remove and

store gauge in original shipping case for protection.

D.4

Page 52

Table D-1

Displacement Verification Table

Approximate Unit Measurement Mitutoyo

Displacement Measurement

0.0000

0.0125

0.0250

0.0500

0.0750

0.1000

0.1250

0.1500

0.1750

0.2000

D.5

Loading...

Loading...