SHIMPO 50XL User Manual

Motorized HorizontalMotorized Horizontal

Motorized Horizontal

Motorized HorizontalMotorized Horizontal

TT

est Standsest Stands

T

est Stands

TT

est Standsest Stands

Model FGSModel FGS

Model FGS

Model FGSModel FGS

-50XH & 50XL-50XH & 50XL

-50XH & 50XL

-50XH & 50XL-50XH & 50XL

Instruction ManualInstruction Manual

Instruction Manual

Instruction ManualInstruction Manual

Inspection

If any shipping damage is found, do not unpack test stand.

Notify your shipping carrier immediately for damage claim

instructions.

Check nameplate to confirm model number ordered and

record serial number for future reference. Items included with

test stand are:

1) Three M5 x 6 and four M4 x 8 screws

2) One 5mm Allen wrench

General Information

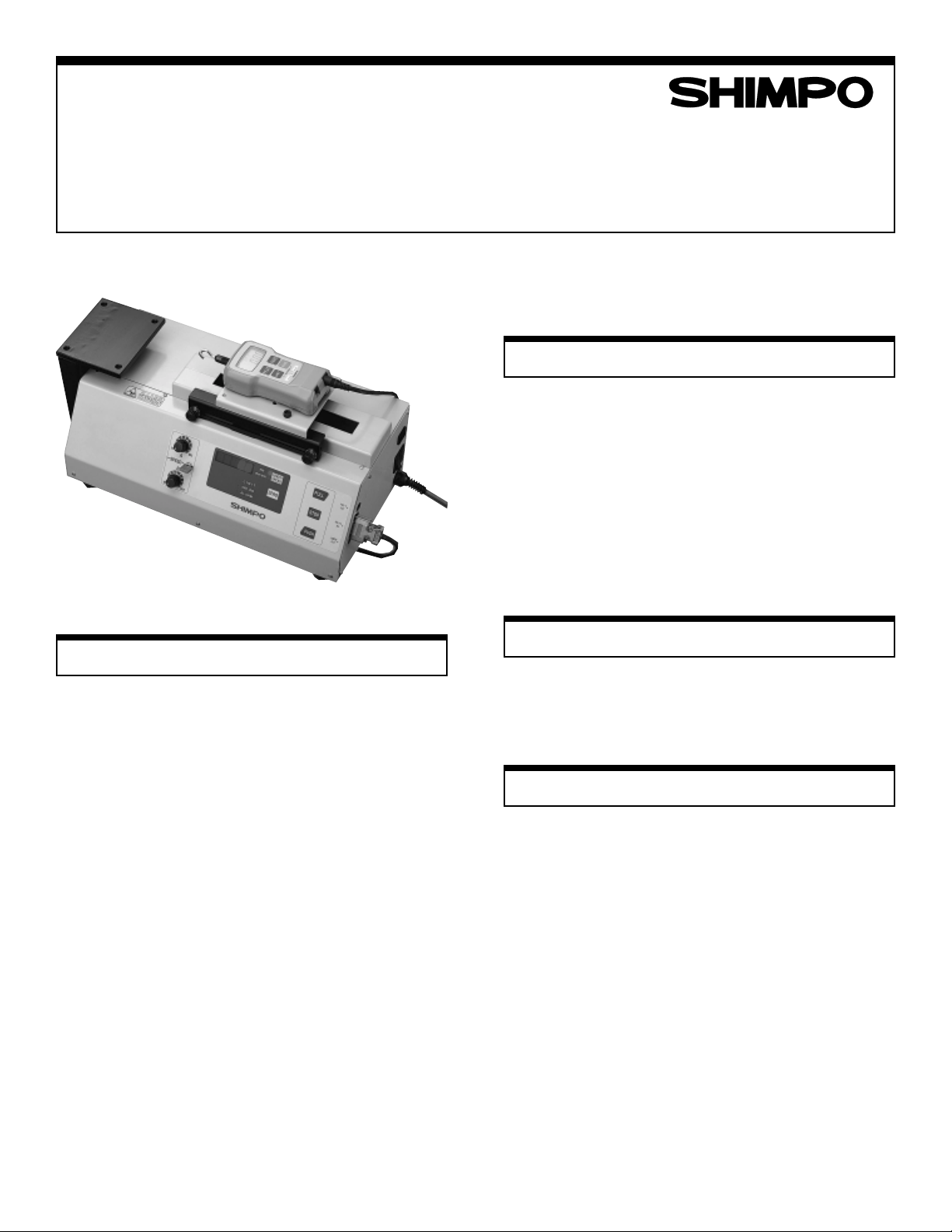

The Shimpo FGS motorized test stands are designed for a

wide variety of tensile and compression force testing up to

110 pounds. The all steel construction guarantees durability

and stability for production, laboratory and quality control

applications.

Dual speed controls are optimally positioned to adjust test

and return travel rates of the drive assembly. This assembly

accepts a universal mounting plate which enables the

interfacing of a lar ge selection of force gauge models. Consult

the compatibility table, found elseware in this manual, or

contact Shimpo for specific models.

1

A 4

/2 digit LED display indicates displacement or rate of

the drive assembly. An analog output, labeled “Length Out”

is convenient for data acquisition requirements.

Cables (sold separately)

FGV-CTRL CABLE FGV-RS232 CABLE

FGS-ANALOG CABLE DFS-CTRL CABLE

Important Safety Instructions

1) Position test stand on a heavy duty, vibration free, level

table.

2) Keep hands, hair and jewelry away from stand when

drive assembly is in motion.

3) Confirm that the test stand case is properly grounded to

the AC line.

4) Operate the membrane keypad with care. Do not use

sharp objects that may puncture the overlay.

5) Make sure AC power is removed from test stand before

making any adjustments.

Mounting Shimpo Force Gauges

Drive Assembly Control

With the 5mm Allen wrench, remove the mounting plate

from the test stand. For the FGE/FGV series use four M4 x 8

mounting screws, supplied with stand, when mounting force

gauge to mounting plate. When mounting DFS series use

three M5 x 6 screws, supplied with stand, to mount force

gauge to mounting plate. Reinsert mounting plate to test stand.

Note : For gauges of other manufacturers see page 3

Uni-Plate option.

Display Operation

1) Plug in line cord and turn on power switch located on

rear of stand. All display segments and LEDs will

execute a power-up self test for two seconds. After the

self test, the 4-digit display defaults to length which is

displayed in millimeters.

2) To change the display from length(mm) to rate(mm/min)

press LENGTH/SPEED switch.

3) Press ZERO to reset display. The initial direction of the

drive assembly always shows a positive number on the

length meter.

The display ranges for length and rate are larger than what’s

listed in the specifications. This is due to a mechanical

backlash which may occur if the drive assembly is subjected

to excessive changes in direction.

Speed controls A & B can easily be adjusted and assigned

to control the test and return travel rates of the force gauge.

The position of the speed select switch determines which

control is active.

Adjustable Travel Limits

The travel limits can be adjusted by loosening the thumb

limit screws and sliding them to the desired position. Don’t

forget to hand tighten the limit screws when the desired

position is reached.

Coarse Control

1) Press PUSH to lower the force gauge. The gauge will

travel at the rate at which the active speed control is set.

The gauge will stop when the it reaches the lower limit

or when the STOP button is pushed.

2) To raise the force gauge, press PULL. The force gauge

will continue to move until the upper limit is reached or

until the STOP button is pushed.

Note: If PUSH or PULL is pressed while pressing ZERO,

the limit LED will flash and the length meter will

automatically reset to zero when a limit position is reached.

Fine Control

While pressing the STOP button, press PUSH or PULL.

The force gauge will travel a finite distance which is

determined by the active speed control setting.

Drive Assembly Overload

The alarm LED will light if the drive assembly is overloaded.

Turn off power switch and eliminate the overload condition.

Wait at least two minutes before reapplying power to the test

stand.

2

Loading...

Loading...