Page 1

SI-4G30A-002-00

General Safety Information

WARNING

● The WH-M988-F15 is not designed for downhill bicycle riding and freeriding. However,

depending on the riding condition, the hub axle could develop a crack, which may result in

failure of the hub axle. This can lead to an accident that could result in serious injury or even

death. Before riding, you should carefully check your hubs to make sure that there are no

cracks in the axles , and if you fi nd any sign of a crack or any other unusual condition, do

NOT use the bicycle.

● The WH-M988-F15 can be used in combination with a special front fork and the E-Thru. If

it is used in combination with any other front fork or fi xed axle, it may cause the wheel to

become detached from the bicycle while you are riding and result in serious bodily injury.

● The securing method and tightening torque for the front wheel both vary depending on

the type of front suspension fork being used. When installing the front wheel to the front

suspension fork, always be sure to follow the directions given in the Service Instructions for

the front suspension fork. If the directions are not followed, the front wheel may fall out of the

front suspension fork and serious injury may result.

● Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose

in any way, they may come off the bicycle and serious injury may result.

● Before use, check the wheels to make sure that there are no bent or loose spokes, dents,

scratches or cracks on the rim surface. Do not use the wheel if any of these problems are

found.

● The wheel is designed for trail riding. Do not use it for downhill riding, otherwise the wheel

may become bent or otherwise damaged, and accidents may occur as a result.

● If the axle release lever is not used correctly, the wheel may come off the bicycle and serious

injury could result.

● If the axle release lever is on the same side as the rotor, there is the

danger that it may interfere with the rotor, so check that it does not

interfere.

● These wheels are designed exclusively for use with disc brakes. Do

not use these wheels with rim brakes.

● Be sure to carefully read the Service Instructions for the disc brakes

also.

● Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or

damaged parts may cause the bicycle to fall over and serious injury may occur as a result.

We strongly recommend only using genuine Shimano replacement parts.

● Read these Technical Service Instructions carefully, and keep them in a safe place for later

reference.

Axle release

lever

Rotor

Replacing the spokes

1. Pass the washer and plug over the spoke.

2. After inserting the spoke into the hole in the hub

fl ange, tighten the nut. When installing, use the

spoke stopper to secure the spoke so that it does not

turn, and then insert a screwdriver or similar tool into

the groove in the nut to screw in the nut.

3. Turn the plug clockwise to screw it into the screw hole

in the rim.

At this time, use the spoke stopper to stop the spoke

from turning.

Note:

● If the washer is not installed, it will

not be possible to adjust the spoke

tension, so be sure to include the

washer.

● Tighten the nut as far as the edges

of the thread.

Spoke

2

Nut

Spoke lacing

Lace the spokes as shown in the illustration.

To assemble the wheels, use the assembly tool TL-HB16.

1

Washer

Plug

Spoke tension value

Right side Left side

600 - 1000 N

(135 - 225 lbf)

* These values should be used as a guide only.

3

Spoke stopper

900 - 1350 N

(202 - 304 lbf)

CAUTION

● Do not use rim tape. Rim tape may make it diffi cult to remove and install the tire, and the tire

or tube may become damaged or the tires may suddenly puncture and come off, and severe

injury may result.

■ Burn-in period

● Disc brakes have a burn-in period, and the braking force will gradually increase as the burnin period progresses. Make sure that you are aware of any such increases in braking force

when using the brakes during the burn-in period. The same thing will happen when the brake

pads or rotor are replaced.

NOTICE

● Use genuine Shimano spokes, nuts, plugs and washers, otherwise damage to the rim and

hub unit may result.

● The air pressure should be within the range of 200-400 kPa {29-58 psi}.

● Be careful not to overtighten the plugs when adjusting the spoke tensions. If the plugs are

overtightened, damage to the rim may result.

(We recommended that you ask authorized bicycle dealers to make the adjustments.)

● We do not recommend that you use general-purpose alkaline puncture repair agents, as they

may cause the rims to corrode and allow air leaks to occur.

● When using the special tool (TL-FC36) to remove and install the rotor mounting ring, be

careful not to touch the outside of the rotor with your hands. Wear gloves to protect your

hands from getting cut.

Note

● If the wheel becomes stiff and diffi cult to turn, you should lubricate it with grease.

● Do not apply any oil to the inside of the hub, otherwise the grease will come out.

● Special spoke wrenches are available as optional accessories.

● We recommend that you ask authorized bicycle dealers to adjust the spoke tensions if there

is any initial play in the spokes and after the fi rst 1,000 km of riding.

● Do not use detergents or chemical cleaners to wipe the wheel, otherwise they may cause the

air sealant that has been applied to the joints in the rim to peel off.

● Do not use detergent or other chemicals when wiping the wheel, otherwise it may cause the

sticker on the rim to peel off.

● Refl ectors are also sold separately. Please ask your bicycle dealer for details.

Model number Specifi cation Color

RR-550-WUW SW W/O BRACKET JIS / CPSC White

RR-550-WUA SW W/O BRACKET AS Amber

RR-317-WUA SW W/O BRACKET DIN Amber

● For maximum performance we highly recommend Shimano lubricants and maintenance

products.

● Parts are not guaranteed against natural wear or deterioration resulting from normal use.

● If the brake caliper mounting boss and the dropout are not parallel, the rotor and caliper may

touch.

● If the rotor is worn, cracked or warped, it should be replaced.

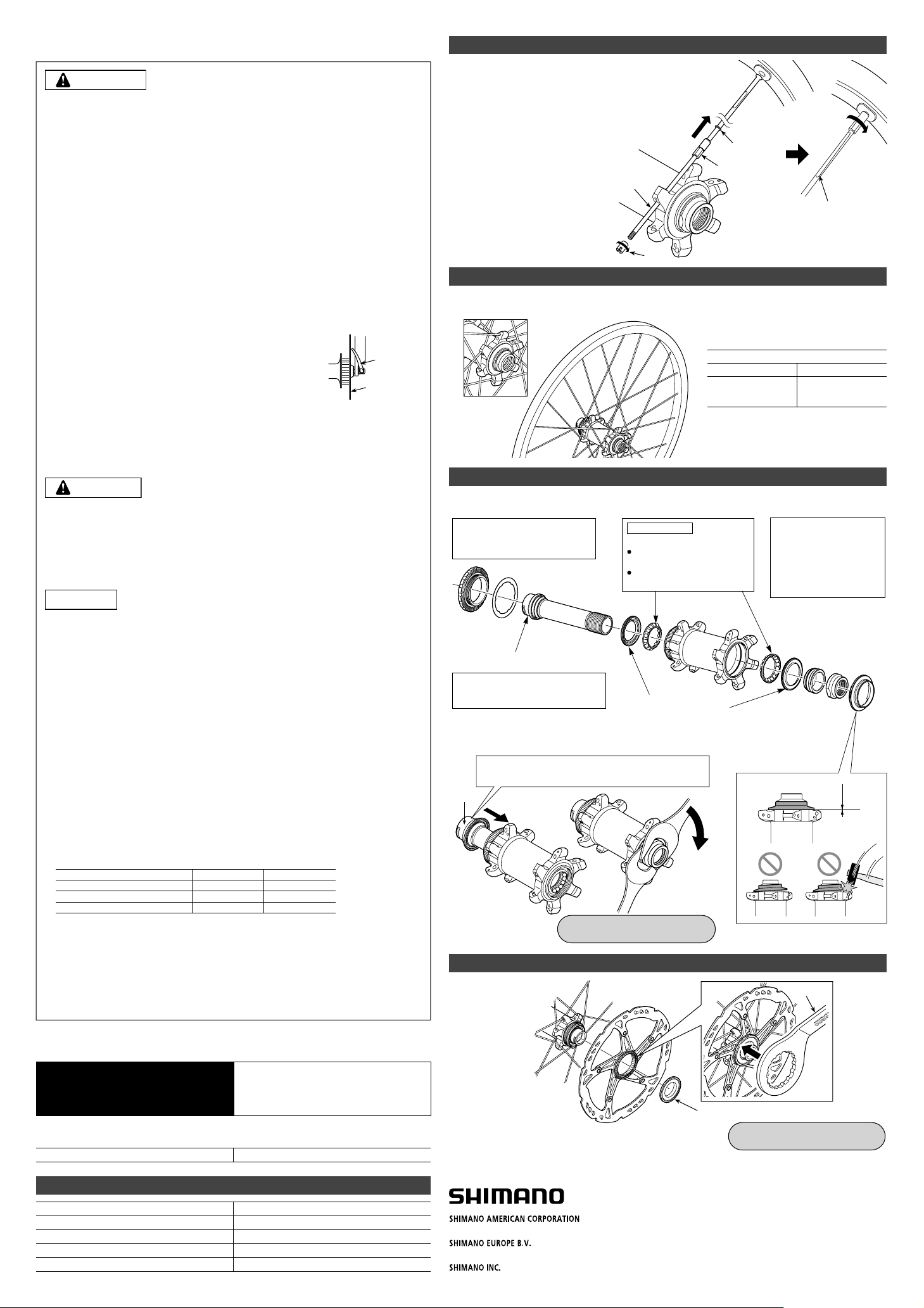

Maintenance

These units can be disassembled as shown in the illustrations. Grease should be applied to each part at

periodic intervals.

Note:

It cannot be disassembled from the

left side of the hub (the side with the

fixed rotor serrations).

Dust cover

Note:

Do not disassemble the dust cover

which is crimped onto the left axle cap.

<Assembly>

Install the axle pipe, and then use the special tools (TL-7S20 / 22 mm) to tighten the lock nut

so as to double-lock the mechanism as shown in the illustration.

If using a hub spanner on the beveled parts of the left-hand

axle cap, be careful not to apply excessive torque, otherwise

damage may occur.

Axle pipe

Applying grease

DURA-ACE grease (Y-04110000)

Left

No. of balls: 15 Ball size: 5/32"

Right

No. of balls: 17 Ball size: 5/32"

Seal

(Lip is on the Outside)

TL-7S20 / 22 mm

Note:

When removing and installing

the seal, do it very carefully so

that the seal does not become

bent. When reinstalling the

seal, make sure that it is facing

the right way, and insert it as

far as it will go.

0mm

Tighten

TL-7S20 / 22 mm

Tightening torque:

21 - 26 NὉm {183 - 226 in. lbs.}

Installation of the rotor

TL-FC36

Technical Service Instructions SI-4G30A-002

WH-M988-F15

In order to realize the best performance, we recommend that the following combination be used.

Rotor SM-RT98

Specifi cations

No. of spokes 24

Rim width 25.8 mm

Rim size 26”

Applicable tire size 26 x 1.95 ~ 2.5

Applicable brakes Disc brake

Front Wheel

Rotor fixing lock ring

* Service Instructions in further languages are available at :

http://techdocs.shimano.com

Please note: Specifi cations are subject to change for improvement without notice. (English)

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

3-77 Oimatsu-cho, Sakai, Osaka 590-8577, Japan

Tightening torque:

40 - 50 N·m {348 - 435 in. lbs.}

© Nov. 2010 by Shimano Inc. AWS. SZK. Printed in Japan

Loading...

Loading...