Shimano FlightDeck SC-6500, FlightDeck SC-6500-M, FlightDeck SC-6500-MX, FlightDeck SC-6500-T Service Instructions Manual

Page 1

Page 2

One Holland Irvine CA 92618 U.S.A. Phone 949-951-5003

®

Industrieweg 24 NL-8071 CT Nunspeet Holland Phone 31-3412-72222

77

Oimatsu-cho 3-cho Sakai Osaka

590-8577

Japan Phone

0722-23-3243

Page 3

SI-7AB0D

SERVICE INSTRUCTIONS

MONTAGE-INSTRUCTIES

EINBAUANLEITUNG

I

NSTRUCTIONS DE MONTAGE

INSTRUCCIONES DE SERVICIO

取扱い説明書

ISTRUZIONI per l'ASSISTENZA

MANUAL DE INSTRUÇÕES

Cycle Computer

SC-6500/SC-6500-M

SC-6500-MX/SC-6500-T

®

Page 4

English

3–24

Dutch

25 – 46

German

47 – 68

French

69 – 90

Spanish

91 –

112

Japanese

113

–

13 4

Italian

13 5

–

15 6

Portuguese

15 7

–

17 8

Page 5

3

English

Cycle Computer

SC - 6500 / SC - 6500 - M

SC - 6500 - MX / SC - 6500 -T

INDEX

1. External appearance • • • • • • • • • • •

5

2. Display Contents • • • • • • • • • • • • • • •

6

3. Display Modes • • • • • • • • • • • • • • • • •

8

•

Current speed (VEL

)

• • • • • • • • • • • • • • • •

9

•

Gear indicator (bar)•

Time display (CLK

)

•

Trip distance group (TIM, DST, MAX, AVE

)

• • •

10

•

ODO meter (ODO

)

• • • • • • • • • • • • • • • • •

11

•

Stopwatch (STW)group

•

Cadence (rpm

)

• • • • • • • • • • • • • • • • • • •

12

•

Main display cadence (VEL)•

Lap counter (CNT

)

•

Digital gear number F- R

• • • • • • • • • • • • •

13

•

Gear ratio•Pace Arrow

•

Low battery display (LO BAT

)

•

Power saver function

• • • • • • • • • • • • • • •

14

4. Resetting • • • • • • • • • • • • • • • • • • • • •

14

5.

Viewing data after removing the

• • • • • • •

15

computer from the bracket mount

6. Setting tolerances

7. Installation to the bicycle

• • • • • • • •

16

8. Data input • • • • • • • • • • • • • • • • • • • •

17

Trouble Shooting • • • • • • • • • • • • • • • • •

24

Page 6

4

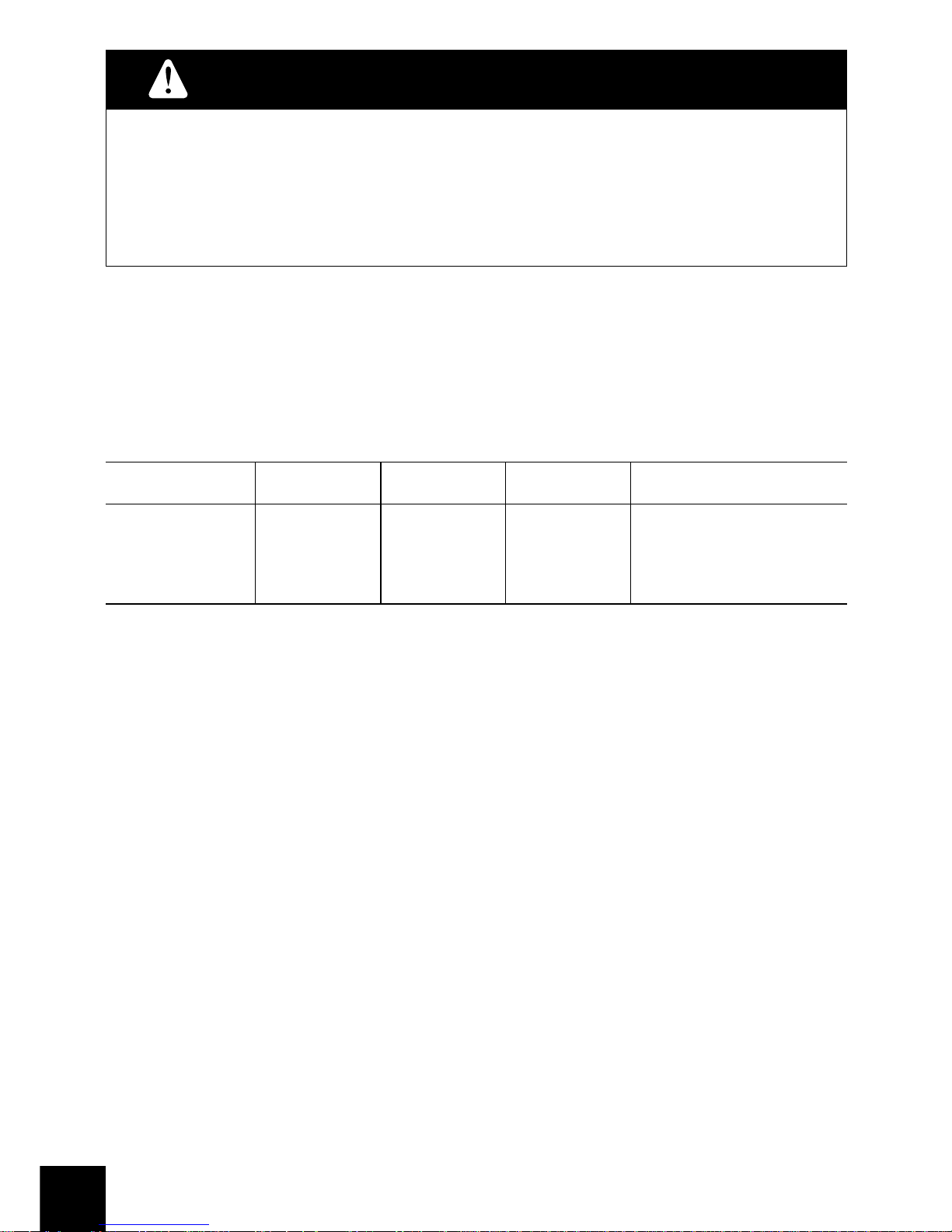

Warning

Be careful not to pay excessive attention to

the computer data while riding, otherwise you

might have an accident.

NOTE;

* The all clear (AC) button is used to clear the main unit memory.

*

Never disassemble the main unit, as it cannot be reassembled.

*

The main unit is fully waterproofed to withstand wet weather

conditions; however, do not deliberately place it into water.

*

Avoid leaving the main unit exposed to extremely hot weather

conditions.

*

Handle the main unit carefully, and avoid subjecting it to any

shocks.

*

Do not use thinner or other solvents to clean parts such as the

main unit and sensor, as they may dissolve the part casings.

*

To clean these parts, wipe them with a cloth soaked in a weak

mixture of neutral detergent and water.

Model No.

SC-6500

SC-6500-

MX

STI lever

ST-6501

ST-5500-C

ST-M951

ST-M950

SL-M951

SC-6500-T

ST-T400

ST-T300

SC-6500-M

ST-M952

ST-M750

SL-M570

SL-M952

SL-M750

SL-M570

Specifications

Page 7

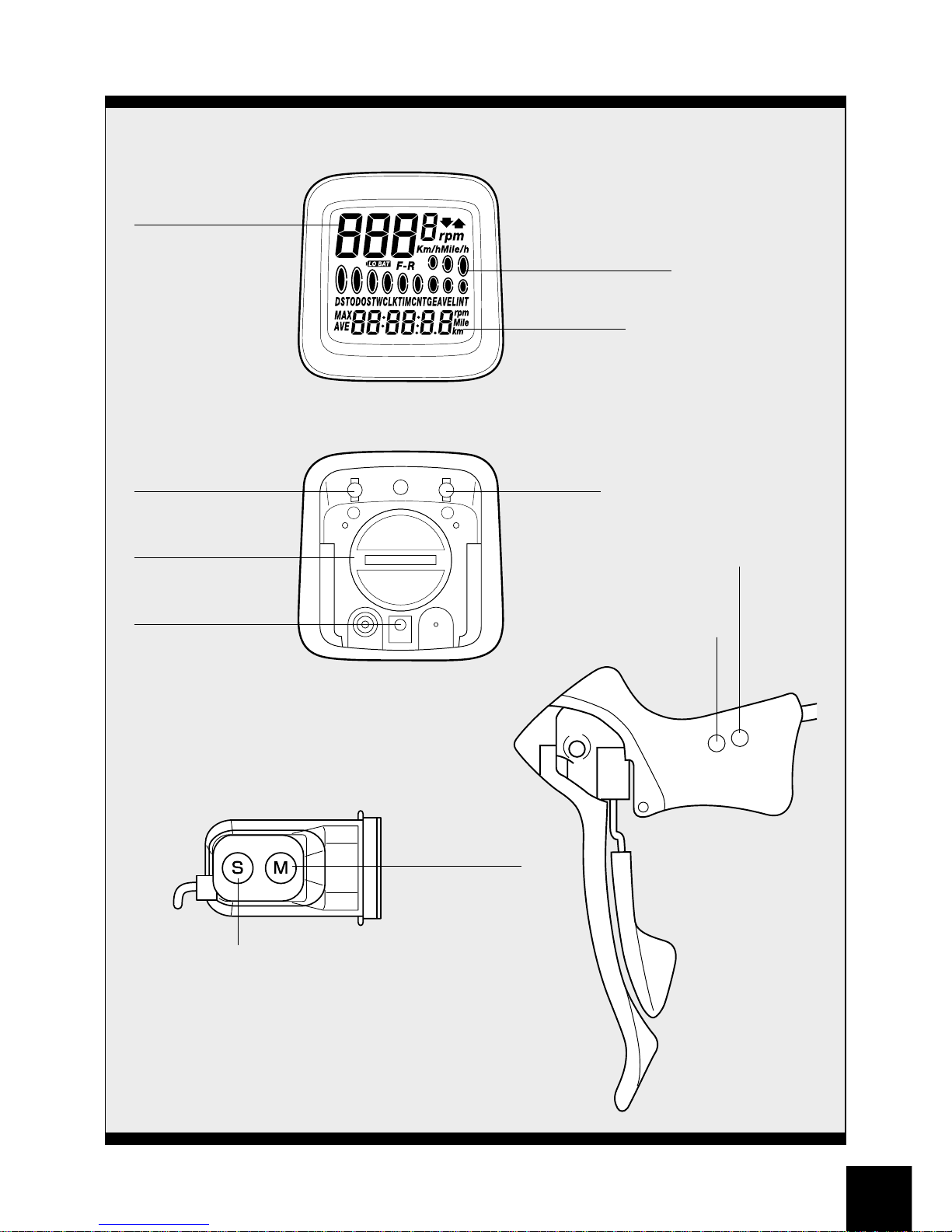

5

1. External appearance

Front

Main Display

Start stop button

1. Current speed

(VEL)

10. Cadence

15. Gear number

(digital)

Sub Display

2-14, 16

17. Gear indicator

(bar)

Rear

Switch B

AC All clear

Switch

Battery cap

Switch A

Mode button

<

SC-6500

>

Rear STI Brake Bracket

Start stop button

<

SC-6500-M /SC-6500-MX /SC-6500-T

>

Mode button

Page 8

6

2. Display Contents

mode 1

1. Current

speed

(VEL)

2. Clock

(CLK)

3. Trip time

(TIM)

4. Trip distance

(DST)

5. ODO meter

(ODO)

7. Stop watch–

trip distance

(DST STW)

8. Stop watch–

average speed

(AVE STW)

9. Stop watch–

maximum speed

(MAX STW)

6. Stop watch

Page 9

7

mode 2

10. Cadence

(rpm)

11.

Main display

cadence

12. Maximum

speed

13. Average

speed

15. Gear number

(digital)

16. Gear ratio

17. Gear indicator

(bar)

18. Pace Arrow

19. Low battery

display

14. Lap counter

Page 10

8

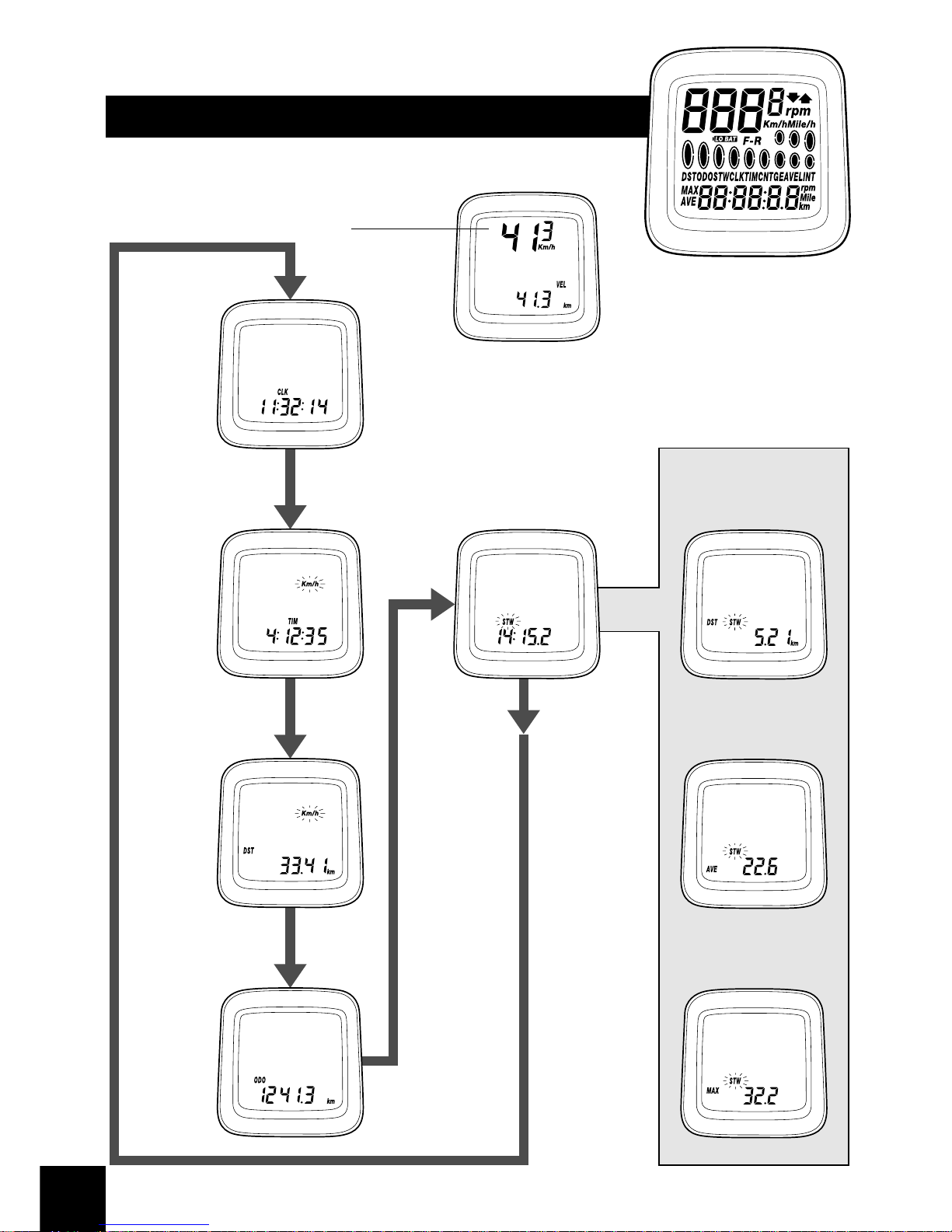

3. Display Modes

“Current speed” and “Gear indicator (bar)” are always displayed

mode 1 mode 2

TIM Trip time

DST Trip distance

ODO ODO meter

STW Stop watch

CLK Clock rpmCadence

VEL

Main display cadence

MAX

Maximum speed

AVEAverage speed

CNTLap counter

ST/SP Button

Mode Button

Press mode button

once

Press mode button

continuously for 2

seconds or more

SC-6500

SC-6500-M

SC-6500-MX

SC-6500-T

ST/SP Button

Mode Button

Page 11

9

(1)

Current speed (VEL

)

km/h, mph

When main

display cadence

appears on top

Current speed

will appear in

the sub - display

0.0 (2.0) - 130.0km/h

0.0 (1.2) - 80.0mph (Range)

The current speed will appear at

the top of the main display.

(2)

Gear indicator (bar

)

Front display

Rear display

Displays;

Low position for double

front chainwheel Mid

position for triple front

chainwheel

Displays;

Top for smallest sprocket

Low for largest sprocket

(3)

Time display (CLK

)

24-hours clock

Gear indicator bar will not appear

if the sensor wire is not connected

or it has been turned off.

Clock will appear when changing

mode 2 to mode 1 and during

power saver function.

Page 12

10

(4)

Trip distance group

(

TIM, DST, MAX, AVE

)

The trip distance group includes trip time (TIM) , trip distance (DST)

maximum speed during trip (MAX) average speed during trip (AVE) .

To activate the trip distance group, press Mode button to (TIM) and press

ST/SP button to activate.

The km/mile symbol will blink. The computer will automatically record

data whenever the wheel sensor is activated by wheel rotation. The

computer will automatically stop recording data when the wheel stops

rotating.

To manually stop functions, press the ST/SP button once.

To reset trip distance group, press the Mode button and ST/SP button

simultaneously.

Whole group will reset to zero.

Additionally, while this group is operating the km/mph, rpm and F - R

displays will flash.

Average speed (AVE)

0.0 (2.0) - 130.0km/h

0.0 (1.2) - 80mph.

Trip time (TIM)

0 - 99:59:59 (h ; min; sec)

Trip distance (DST)

0 - 999.99 (km, mile)

Maximum speed (MAX)

0.0 (2.0) - 130.0km/h

Note;

To calculate the average speed,

You must travel for more than 10

seconds or more.

An arrow- up displayed indicates

that your current speed is faster

than your average speed and an

arrow- down if the speed is lower.

If the trip time exceeds 100hours or the trip distance exceeds

1,000kilometers (620miles), “ER” will be displayed and the pace arrow

comparison will disappear. However, TIM and DST measurements will start

again from zero and the MAX speed will be retained.

Page 13

11

(5)

ODO meter (ODO

)

0-9999.9 km, mile

(6)

Stopwatch (STW)group

Stopwatch

(STW)

0.0 - 90:00 (min,sec)

Stopwatch trip

distance (DST,STW)

km mile

Stopwatch average

speed (AVE,STW)

km/h mile/h

Stopwatch maximum

speed (MAX, STW)

km/h mile/h

This group includes stopwatch trip distance average

speed and maximum speed.

The stopwatch is activated by pressing ST/SP button.

While the stopwatch group is operating the stopwatch

(STW) display will flash.

Stopwatch trip distance (DST,STW) records total during

STW function.

Stopwatch average speed (AVE,STW) records the

average speed during STW function.

Maximum speed (MAX,STW) records the Maximum

speed during the stopwatch function.

STW

DST, STW

AVE, STW

MAX, STW

Stopwatch-Trip distance (DST, STW)

Stopwatch - Average speed (AVE, STW)

Stopwatch - Maximum speed (MAX, STW)

Stopwatch (STW

)

Press switch B to change mode

Note;

The functions of this group are

only available when stopwatch is

activated.

If the trip distance mode is also

activated simultaneously, it is not

possible to view at the distance.

However the trip distance,

average speed and maximum

speed will still be recorded during

this time.

Page 14

12

(7)

Cadence (rpm

)

Cadence is calculated from the F- R

gear tooth numbers and current

speed.

Note;

Cadence always appears during

bicycle movement regardless if the

crankarms are rotating.

(9)

Lap counter (CNT

)

This function is used to count laps,

etc. (range 0 - 99)

Lap counter is activated by

pressing the ST/SP button.

To reset the counter to zero, press

mode and ST/SP button

simultaneously.

To reset all of the TIM group, STW

group and lap counter values to

zero, press the Mode button and

ST/SP button simultaneously for 2

seconds or more.

This is possible regardless of what

is currently appearing on the

display.

(8)

Main display cadence (VEL

)

Cadence (rpm) can also be shown

in main display. Current speed

will move to sub- display.

Cadence on main display

Current speed on sub- display

Page 15

13

(

10

)

Digital gear number F - R

Gear combinations are displayed

when a shift has been made. This

will show for approx 4 seconds

then original screen will return.

The gear combinations are;

(

11

)

Gear ratio

(

12

)

Pace Arrow

Gear ratio is also displayed only when a

shift has been made.

This will show for approx 4 seconds.

Moves when distance time is

operating

(

13

)

Low battery display (LO BAT

)

This flashes when the remaining

battery power is low. The battery

should be replaced with a new

one as soon as possible.

• Front double • Front triple

inner

• • • • 1 inner • • • • 1

outer

• • • 2mid • • • • • 2

outer

• • • • 3

Rear Numbers are displayed in

order starting from low end.

Low1

• • • • • • High • • • • • • 9.etc.

Gear ratio formula;

Gear ratio =

number of teeth front chain wheel

number of teeth rear sprocket

48

15

=

3.2

F

R

Gear ratio

Page 16

14

(

14

)

Power saver function

When the computer is left without

receiving any signal or any button

activation the unit will be in a

“sleep” state and only the clock will

appear on the display.

The normal display will return as

soon as a signal is received or a

button has been pressed.

Note;

During the stopwatch function the

stopwatch will continue to operate

even when the power saver

function has been activated. The

stopwatch will stop automatically

after 90minutes have passed.

4. Resetting

This function allows you to reset km/h- mph, tire circumference, gear

combination, type of rear derailleur, and time without losing any data (i.e.

total distance, trip distance etc)

To re- set go to any display other than CLK on the sub display. Press switch

“B” for 5 seconds or more. Then follow instruction section 8 data input.

Switch B 5sec.

Normal display

Tire circumference

F - R no.of chainring teeth, no.of sprocket teeth

Type of rear derailleur

Time

km/h mile/h

Switch B 5sec.

Sub - display (CLK

)

Page 17

15

6. Setting tolerances

5.

Viewing data after removing the

computer from the bracket mount

The data can still be viewed even when the computer has been removed

from the handlebar bracket.

CLK

rpm

VEL

MAX

AVE

STW

DST, STW

AVE, STW

MAX, STW

CNT

TIM

DST

ODO

STW

changes in order

when switch B is

pressed

changes in order when switch A is pressed

mode1 mode2

VEL

• • • • • • • • • • • • • • • • • • • • • • • 1%

DST, ODO • • • • • • • • • • • • 0.05%

CLK • • • • • • • • • • • • • • • • • • • 30ppm

STW, TIM • • • • • • • • • • • • • 50ppm

(5minutes or less per month)

Page 18

16

7. Installation to the bicycle

Install the levers to the handlebars. Then connect and adjust the brake and

shifting cables. Refer to the STI Lever Service Instructions for details on

these procedures.

* For the SC-6500-M, SC-6500-MX and SC-6500-T,

refer to the Service Instructions included.

(1)

Installing the signal cable (SC-6500)

Install the signal cable as shown

in Figure No1.

(2)

Installing the computer

Install the band and the bracket as

shown in Figure No2.

Tape the signal cable to the

handlebars.

(3)

Slide the computer onto the

bracket until it clicks into its

place.

as shown in Figure No3.

After this, wrap handlebar with

finishing tape around the

handlebars to secure both the

signal cable and the brake cable

Fig.1

Tightening torque:

0.3 - 0.5 Nm

{

2 - 4 in. lbs.

}

Fig.3

ComputerBracket

Fig.2

Bracket

Band

Tightening torque:

1 Nm

{

8 in. lbs.

}

Page 19

17

8. Data input

(4)

Installing the magnet and

sensors

Use a screwdriver to temporarily

secure the magnet to a spoke on the

right hand side of the front wheel as

shown in fig4.

Put a rubber shim between the fork

and the sensor as shown in fig5.

(Fork diameter range is 11- 35mm)

Place the magnet on one of the two

sensor lines.

Adjust the position of the magnet so

that the distance between the

magnet and the sensors is 1- 5mm.

Secure the magnet and the sensors

firmly in these positions.

(1)

Measuring the tire circumference

To measure the tire circumference,first ensure that the tire is inflated to the

standard tire pressure. Make a mark on the tire and the ground at the point where

the tire touches the ground, and move the bicycle forward one full revolution of

the front wheel while seated on the bicycle, Mark the point where the marking on

the tire touches the ground again. Measure the distance between the two points

in millimeters. Round the distance to the nearest multiple of 5mm.

Fig.4

Fig.5

Sensors

Magnet

1- 5 mm

Ø 2.1mm or less

Front Fork

Pull

Sensors

Front Fork

1. Km or Miles

2. Tire circumference

3. No.of chainring teeth

4. No.of sprocket teeth

5. Type of rear derailleur

6. Current time

[]

Example

2028 - 2032mm

• • • • • 2030mm

2033 - 2037mm

• • • • • 2035mm

2038 - 2042mm

• • • • • 2040mm

Roll forward

Wheel circumference

Speed sensor

Plastic tie

Page 20

18

(2)

Checking the number of chainring and sprocket teeth

Check whether the front chainwheel is a double or a triple chainwheel.

(3)

Selecting Km or Miles

When switch “AC” (All Clear) is

pressed, the display as shown in

fig6 appears and the k/h setting

starts flashing. Select your choice

for Km/h or Mile/h by pressing

switch “A”.

Once your choice is displayed,

press switch “B” continuously for 2

seconds or more to set.

Check whether the

cassette has 7,8, or 9

sprockets.

[]

Example

12,13,14,15,16,17,19,21,23

• • • • • • 9 sprocket

12,13,14,15,16,17,19,21

• • • • • • • • • 8 sprocket

Example

48x38x28 • • • • triple 53x39 • • • • • Double

Fig.6

(4)

Entering the tire circumference

The display will appear as shown in fig7, Enter the value which was

measured previously.

Fig.7

2050 • • • Tire circumference (mm)

26 1.75

• • • Indicates the tire size

for 26inch x 1.75

Page 21

19

The value will increase by 5mm each time switch “A” is pressed.

The value will change rapidly when switch “A” is pressed continuously.

Once the desired value is displayed, press switch “B” for 2 seconds or more

to set.

In the case of tires which have circumference of less than 2050mm, press

switch “A” continuously. After the value increases to 2395, it will change

to 1700.

Continue pressing switch “A” until the desired value is reached, and then

press switch “B” 2 seconds or more to set.

The tire size display can appear as any one of the following 11 displays, in

addition to 26 x 1.75 (2050mm)

Tires with sizes other that these are

not displayed

700 18

• • • • • • • • • • • 700 x 18C (2070)

700 19 • • • • • • • • • • • 700 x 19C (2090)

700 20

• • • • • • • • • • • 700 x 20C (2110)

700 25

• • • • • • • • • • • 700 x 25C (2115)

700 28 • • • • • • • • • • • 700 x 28C (2135)

26 13/8

• • • • • • • • • 26inch x 1 3/8(2075)

26 2.00

• • • • • • • • • 26inch x 2.00 (2085)

26 11/2

• • • • • • • • • 26inch x 1 1/2 (2100)

26 1.00 • • • • • • • • • 26inch x 1 (1970)

26 1.4

• • • • • • • • • • 26inch x 1.40 (2005)

26 1.5

• • • • • • • • • • 26inch x 1.50 (2050)

Page 22

20

(5)

Entering the number of chainring and sprocket teeth

The display will then change to that shown in fig8.

Enter the value starting from the outer chainring. “48” will flash on the

display. The value will increase by one tooth each time switch “A” is

pressed. The value is set by pressing switch “B”. If the value is correct,

press switch “B” once to accept the setting.

The “--” is displayed once for every five times the value is changed.

If this value is set for the outer chainring by switch “B”, all gear indicator

related screen display will be eliminated.

Fig.8

Inner

chainring

Outer

chainring

Front chainring

(3S)

Rear

sprocket (9S)

Low gear Top gear

The following tooth numbers are pre - set into the computer

Front chainrings 48 x 38 x 28 (3 chainrings)

Cassette 12,13,14,15,16,17,19,21,23 (9 sprockets)

No. of teeth for

largest chainring

When the switch “A” is pressed 2

seconds or more, the value will

change rapidly. Once the value

reaches 60, the value changes to

40 and then continues increasing

to 60 again.

After setting the largest chainring

the display will change to that

shown in fig9.

Fig.9

Page 23

21

Enter the number of teeth for the

inner chainring (for double front

chainwheel) or the middle

chainring (for triple front

chainwheel).

“38” will flash on the display. This

position can be set from 20 - 50 by

the same procedure of setting

outer chainring. After setting the

inner chainring or the middle

chainring, the display will change

to that shown in fig10.

Fig.10

Entering the number of rear

sprocket teeth

The display will then change to

that shown in fig11.

When using a double front chainwheel, press switch “A” once so that “--”

is displayed, and then press switch “B” once to set, the front chainwheel

will then be registered as a double front chainwheel and the display will

change to show the rear sprocket settings.

When using a triple front chainwheel, the value can be set from 15 to 34

by the same procedure of setting middle chainring.

Fig.11

Fig.12

Enter the number of teeth for each

sprocket by the same procedure as

that used for the chainrings.

Press switch “A” to set the desired

number of teeth, and then press

switch “B” to accept the setting.

The value can be set from 11 to

42. Once the setting for smallest

sprocket through to the 7th

sprocket have been made, the

display will change to that shown

in fig12.

No. of 7th sprocket

plus one teeth

No. of 7th sprocket

Page 24

22

If the cassette has seven sprockets, press switch “A” once to change the

flashing “21” to “--”, and then press switch B once. This will indicate that

there is no 8th sprocket, and the operation for entering the number of

sprocket teeth will be complete.

If the cassette has 8 sprockets, enter the number of teeth for this position

and follow the same procedure as above to enter “--” in the 9th position

otherwise enter the number of teeth for the 9th sprocket.

Checking the number of teeth entered

Once the setting of number of sprocket teeth is completed, the display will

return to the initial input display. Re check all values by repeatedly

pressing switch “B” to

confirm each number of teeth. Press switch “B” once each time and check

whether the entered number of teeth are matching with the sprocket

position on the display.

If all values entered are

correct, press switch “B” for

2 seconds or more to

continue the next entry

procedure.

Press switch “B” for 2 seconds or

more to continue the next entry

procedure.

Fig.13

111 • • • • • for Traditional rear

derailleur

222

• • • • • for Rapid Rise Rear

derailleur (reverse

spring type)

(6)

Entering the type of rear derailleur

The display will change to that shown in fig 13. The display will change

from “111” to “222” each time switch “A” is pressed.

This Value

Indicated

Section

Page 25

23

The hours will advance when switch

“A” is pressed. If switch “A” is

pressed continuously, the hours will

advance rapidly. Press switch “B”

once to set the hour.

The minutes section will then start

flashing as shown in Fig 15.

Set the minutes in the same

procedure as for setting the hours.

The clock will then start.

Note; To reset clock

Fig.14

Fig.15

[]

Example

If the time is 10:46:23

• • • • • 10:47: - -

If the time is 13:59:16

• • • • • 14:00: - -

Get a display where CLK appears on the sub - display. Press switch

“B” for 5 seconds or more to change the time setting.

(7)

Setting the time

(

24 hour format

)

The display will change to that

shown in fig 14.

Set the time to one minute later than

the current time.

This completes the data entry operations. The display will now return to

the normal display mode.

Insert the battery so that the “+”

side is visible as shown in Fig. 16,

and then tighten the battery cap.

The battery which is installed at the

time of purchase is for monitoring

purposes. If the low

battery indicator appears, replace

the battery as soon as possible.

Carry out the initialization

procedure after the battery has

been replaced.

Replacing the battery (CR-2032 battery)

Close

Open

Fig.16

CR-2032

Page 26

@@@@@@@@e?

@@@@@@@@e?

@@h?

@@h?

@@h?

@@h?

@@h?

@@h?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

?@@

?@@

?@@

?@@

?@@

?@@

?@@@@@@@@

?@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@

@@g

@@g

@@g

@@g

@@g

@@g

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

24

Trouble Shooting

* Speed is not displayed.

• Check that the positions of the speed sensor and

magnet are correct.

• Check that the main unit is fixed correctly to the

bracket.

* Display does not appear or is faint.

• Poor contact, or battery is depleted. Replace with a

new battery.

* Incorrect data is displayed.

• Press the A/C button to re - enter the data.

* Display is dark.

• This is because the main unit has become hot and has

been affected by long- term exposure to direct

sunlight, such as can occur during hot weather.

• Store the main unit in a cool, shady place so that it can

cool down and return to normal.

* Data display movement is slow.

• The computer operating temperature range is –10°C to

50°C. Check that the temperature is not lower than

–10°C.

* No. of gears and gear ratios are not displayed.

• Replace the gear number sensor.

Loading...

Loading...